Page 1

Installation Instructions

VLT® Sensor Input MCB 114

VLT

FC 202, VLT

The VLT® Sensor Input MCB 114 can be used in the following

cases:

FC series Software version

VLT

VLT

VLT

Table 1.1 Software Versions Supporting the VLT® Sensor Input

MCB 114

®

HVAC Drive FC 102, VLT® AQUA Drive

®

AutomationDrive FC 301/302

Sensor input for temperature transmitters PT100 and

•

PT1000 for monitoring bearing temperatures.

As general extension of analog inputs with 1 extra

•

input (0/4–20 mA) for multi-zone control or

ential pressure measurements.

Support extended PID controllers with I/Os for

•

setpoint, transmitter/sensor inputs.

®

HVAC Drive FC 102

®

AQUA Drive FC 202

®

Automation Drive FC 301/FC 302

1.00 and later

1.41 and later

6.02 and later

dier-

Items Supplied

Items supplied depend on ordered code number and

enclosure type of the frequency converter.

Code number Items supplied

130B1172 Uncoated version

130B1272 Coated version

Safety Information

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. High voltage can be present even when the

warning LED indicator lights are

specied time after power has been removed before

performing service or repair work can result in death or

serious injury.

Stop the motor.

•

Disconnect AC mains and remote DC-link power

•

supplies, including battery back-ups, UPS, and DClink connections to other frequency converters.

Disconnect or lock PM motor.

•

Wait for the capacitors to discharge fully. The

•

minimum duration of waiting time is specied in

Table 1 . 2 to Tab le 1 . 4 .

Before performing any service or repair work, use

•

an appropriate voltage measuring device to make

sure that the capacitors are fully discharged.

Failure to wait the

o.

Illustration 1.1 Parts for Coated/Non-coated Code Numbers

Danfoss A/S © 04/2017 All rights reserved.

MI38T202

Page 2

®

Sensor Input MCB 114

VLT

Installation Instructions

®

HVAC Drive FC 102, VLT® AQUA Drive

VLT

FC 202, VLT

®

AutomationDrive FC 301/302

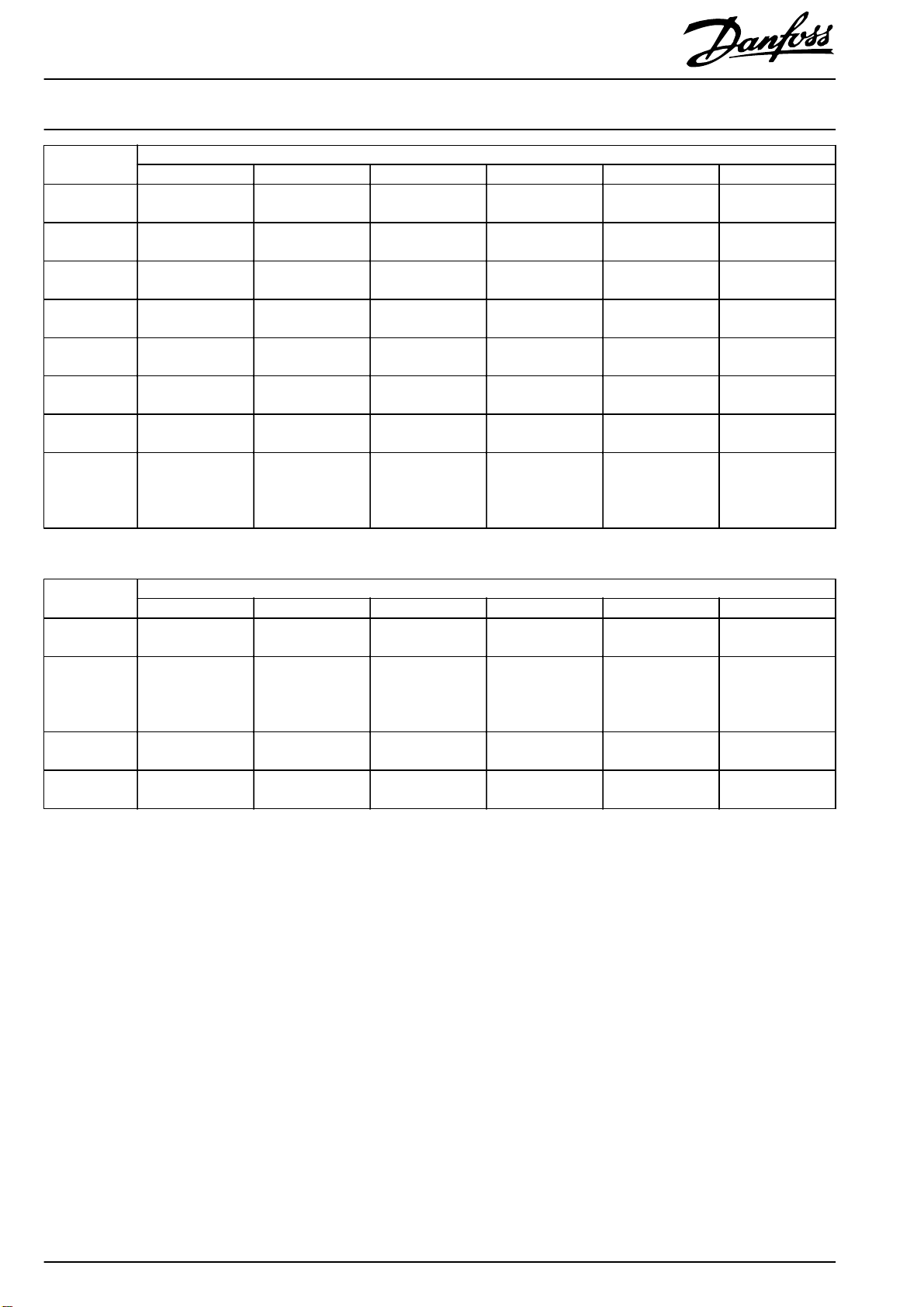

Voltage [V] Minimum waiting time (minutes)

4 7 15 20 30 40

200–240 1.1–3.7 kW

(1.50–5 hp)

380–480 1.1–7.5 kW

(1.50–10 hp)

–5.5–45 kW

(7.5–60 hp)

– 11–90 kW

(15–121 hp)

–––

– – 315–1000 kW

400 – – – 90–315 kW

(121–450 hp)

500 – – – 110–355 kW

(150–500 hp)

525 – – – 75–315 kW

(100–450 hp)

525–600 1.1–7.5 kW

(1.50–10 hp)

– 11–90 kW

(15–121 hp)

–––

690 – – – 90–315 kW

(100– 350 hp)

525–690 – 1.1–7.5 kW

(1.50–10 hp)

11–90 kW

(15–121 hp)

–400–1400 kW

(450–1350 hp)

––

––

––

––

–

(500–1550 hp)

450–1400 kW

(600–1550 hp)

Table 1.2 Discharge Time, VLT® HVAC Drive FC 102

Voltage [V]

200–240 0.25–3.7 kW

4 7 15 20 30 40

–5.5–45 kW

(0.34–5 hp)

380–480 0.37–7.5 kW

– 11–90 kW

(0.5–10 hp)

525–600 0.75–7.5 kW

– 11–90 kW

(1–10 hp)

525–690 – 1.1–7.5 kW

(1.5–10 hp)

Table 1.3 Discharge Time, VLT® AQUA Drive FC 202

Minimum waiting time (minutes)

–––

(7.5–60 hp)

110–315 kW

(15–121 hp)

(150–450 hp)

–400–1400 kW

(15–121 hp)

11–90 kW

(10–100 hp)

75–400 kW

(75–400 hp)

– 315–1000 kW

(450–1350 hp)

355–560 kW

(500–750 hp)

–

(400–1550 hp)

– 450–800 kW

(450–950 hp)

2

Danfoss A/S © 04/2017 All rights reserved.

MI38T202

Page 3

®

Sensor Input MCB 114

VLT

Installation Instructions

Voltage [V] Minimum waiting time (minutes)

4

200–240 0.25–3.7 kW

(0.34–5 hp)

380–500 0.25–7.5 kW

(0.34–10 hp)

400 – – – 90–315 kW

500 – – – 110–355 kW

525 – – – 55–315 kW

525–600 0.75–7.5 kW

(1–10 hp)

525–690 – 1.5–7.5 kW

(2–10 hp)

690 – – – 55–315 kW

®

HVAC Drive FC 102, VLT® AQUA Drive

VLT

FC 202, VLT

7 15 20 30 40

–5.5–37 kW

– 11–75 kW

– 11–75 kW

®

AutomationDrive FC 301/302

(7.5–50 hp)

90–200 kW

(15–100 hp)

(15–100 hp)

11–75 kW

(15–100 hp)

(150–350 hp)

(125–450 hp)

(150–450 hp)

(75–400 hp)

37–315 kW

(50–450 hp)

(75–400 hp)

–––

250–500 kW

(450–750 hp)

––

––

––

355–1200 kW

(450–1550 hp)

––

250–800 kW

(450–1350 hp)

315–500

(500–750 hp)

355–2000 kW

(450–2050 hp)

355–710 kW

(400–950 hp)

Tab l e 1 . 4 Di s char ge T ime, VLT® Automation Drive FC 301/FC 302

Mounting

The installation procedure depends on the enclosure size of

the frequency converter.

Enclosure sizes A2, A3, and B3

1. Remove the LCP (local control panel), the terminal

cover, and the LCP frame from the frequency

converter.

2. Fit the option into slot B.

3. Connect the control cables and relieve the cable. See

Illustration 1.4 and Illustration 1.5 for details about

wiring.

4. Remove the knockout in the extended LCP frame

(supplied).

5. Fit the extended LCP frame and terminal cover on

the frequency converter.

6. Fit the LCP or blind cover in the extended LCP frame.

7. Connect power to the frequency converter.

8. Set up the input/output functions in the

corresponding parameters.

1LCP

2Terminal cover

3Slot B

4Option

5LCP frame

MI38T202

Illustration 1.2 Installation in Enclosure Sizes A2, A3, and B3

Danfoss A/S © 2017 All rights reserved.

3

Page 4

Installation Instructions

®

Sensor Input MCB 114

VLT

®

HVAC Drive FC 102, VLT® AQUA Drive

VLT

FC 202, VLT

®

AutomationDrive FC 301/302

Enclosure sizes A5, B1, B2, B4, C1, C2, C3, C4, D, E, and F

1. Remove the LCP (local control panel) and the LCP

cradle.

2. Fit the option card into slot B.

3. Connect the control cables and relieve the cable. See

Illustration 1.4 and Illustration 1.5 for details about

wiring.

4. Fit the cradle on the frequency converter.

5. Fit the LCP in the cradle.

Wiring

Wiring of VLT® Sensor Input MCB 114.

Illustration 1.4 2-Wire Sensors

1LCP

2LCP cradle

3Option

4Slot B

Illustration 1.3 Installation in Other Enclosures Sizes (Example)

Galvanic Insulation

Galvanically isolate the sensors from the mains voltage level.

Safety demands: IEC 61800-5-1 and UL 508C.

Illustration 1.5 3-Wire Sensors

Te rm in a l Na m e Fu n ct i on

1 VDD 24 V DC to supply 0/4–20 mA sensor

2 I in 0/4–20 mA input

3GND Analog input GND

4, 7, 10 Temp 1, 2, 3 Temperature input

5, 8, 11 Wire 1, 2, 3

6, 9, 12 GND Temperature input GND

Table 1.5 Legend table for Illustration 1.4 and Illustration 1.5

rd

3

wire input if 3 wire sensors are used

Cabling

Maximum signal cable length is 500 m (1640 ft).

4

Danfoss A/S © 04/2017 All rights reserved.

MI38T202

Page 5

®

Sensor Input MCB 114

VLT

Installation Instructions

®

HVAC Drive FC 102, VLT® AQUA Drive

VLT

FC 202, VLT

®

Electrical and Mechanical Specications

The option is able to supply the analog sensor with 24 V DC

(terminal 1).

Number of analog inputs 1

Format 0–20 mA or 4–20 mA

Wires 2 wires

Input Impedance

Sample rate 1 kHz

rd

3

order

lter

Table 1.6 Analog Input

Ω

<200

100 Hz at 3 dB

AutomationDrive FC 301/302

Number of analog inputs supporting

PT100/1000

Signal type PT100/PT1000

Connection PT100 2 or 3 wire

Frequency PT100 and PT1000 input 1 Hz for each channel

Resolution 10 bit

Tem p erat u re r a nge

Table 1.7 Temperature Sensor Input

3

PT1000 2 or 3 wire

-50 to +204

-58 to +399

°

C

°

F

Conguration

The 3 sensor inputs support 2 and 3 wire sensors

•

and an auto detection of sensor type, PT100 or

PT1000 takes places at power-up.

The analog input is capable of handling 0/4–20 mA.

•

For programming of the parameters, see the

programming guide, parameter group 35-** Sensor Input Option

and parameter group 18-3* Analog Readouts with data readouts

in parameter 18-36 Analog Input X48/2 [mA] to

parameter 18-39 Temp. Input X48/10.

product-specic

MI38T202

Danfoss A/S © 04/2017 All rights reserved.

5

Page 6

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI38T202130R0483

04/2017

*MI38T202*

Loading...

Loading...