MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® PTC Thermistor Card MCB 112

VLT® HVAC Drive FC 102 • VLT® AQUA Drive FC 202

VLT® AutomationDrive FC 302

vlt-drives.danfoss.com

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Document and Software Version

1.4 Products Covered

1.5 Functional Overview

1.5.1 Intended Use 3

1.5.2 Foreseeable Misuse 4

1.5.3 Thermal Motor Protection 4

1.5.4 ATEX ETR Thermal Monitoring 4

1.5.5 Tripping Function 4

1.5.6 Safe Separation 4

1.5.7 Safe Disconnection Principle 4

1.6 Motor Requirements

1.6.1 Motor Limits and Rules 5

1.6.2 Additional Motor Requirements 5

1.7 Approvals and Certications

3

3

3

3

3

3

5

5

1.8 Symbols, Abbreviations, and Conventions

2 Safety

2.1 Safety Symbols

2.2 Qualied Personnel

2.3 Safety Precautions

3 Installation

3.1 Safety Instructions

3.2 Installation of Sensor Circuit Wires

3.3 Installation of the VLT® PTC Thermistor Card MCB 112

4 Commissioning

4.1 Operation and Maintenance

4.1.1 Monitoring Sensor Resistance 12

4.2 Parameter Set-up

4.2.1 Alarm Handling 13

4.3 Parameter Set-up for Ex-e and Ex-n Motors

6

7

7

7

7

9

9

9

10

12

12

13

14

4.3.1 Maximum Current 14

4.3.2 Maximum Current Limit 14

4.3.3 Minimum Motor Frequency 14

4.3.4 Maximum Motor Frequency 15

4.3.5 Minimum Switching Frequency 15

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 1

Contents

VLT® PTC Thermistor Card MCB 112

4.3.6 Disable Protection Mode 15

4.3.7 Safe Torque O Functionality 15

5 Application Examples

6 Maintenance and Troubleshooting

6.1 Maintenance

6.2 Troubleshooting

6.2.1 Alarm/Warning Code List 19

6.2.2 Description of Alarm Word, Warning Word, and Extended Status Word 19

7 Technical Specications

7.1 Mains Supply

7.2 Control Inputs and Outputs

7.3 Ambient Conditions

7.4 Other Specications

7.5 Safety Characteristics of the Built-in MCB 112

Index

17

19

19

19

21

21

21

21

22

22

23

2 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Introduction Operating Instructions

1 Introduction

1

1

1.1 Purpose of the Manual

This manual provides information for safe installation and

commissioning of VLT® PTC Thermistor Card MCB 112 used

with a Danfoss VLT® frequency converter with Safe Torque

O (STO). The manual is intended for use by qualied

personnel only.

VLT® PTC Thermistor Card MCB 112 is also referred to as

MS 220 DA.

The operating instructions are intended for use by

qualied personnel. Read and follow the operating

instructions to use the frequency converter safely and

professionally, and pay particular attention to the safety

instructions and general warnings. Keep these operating

instructions available with the frequency converter at all

times.

VLT® is a registered trademark.

1.2 Additional Resources

This manual is targeted at users already familiar with the

VLT® frequency converters. It is intended as a supplement

to the manuals and instructions available for download at

vlt-drives.danfoss.com/Support/Technical-Documentation/.

Read the instructions shipped with the frequency

converter and/or frequency converter option before

installing the unit, and observe the instructions for safe

installation.

1.3

Document and Software Version

1.4

Products Covered

The VLT® PTC Thermistor Card MCB 112 is available for the

following types of frequency converters:

VLT® HVAC Drive FC 102.

•

VLT® AQUA Drive FC 202.

•

VLT® AutomationDrive FC 302.

•

1.5 Functional Overview

1.5.1 Intended Use

The VLT® PTC Thermistor Card MCB 112 is intended to:

Protect electrical motors against inadmissible

•

heating due to overload.

Protect explosion-protected motors in explosive

•

atmospheres caused by gases, vapours, or mists,

Zone 1 and Zone 2, and/or in explosive

atmospheres caused by dust, Zone 21 and Zone

22. Refer to marking G for Zone 1 and Zone 2.

Refer to marking D for Zone 21 and Zone 22.

All functions in the MCB 112 serve to protect both nonexplosive-protected motors and explosive-protected

motors in regular operation and in case of failure.

The VLT® PTC Thermistor Card MCB 112 is designed in

accordance with EN 60947-8 (VDE 0660 part 0302). Only

connect PTC thermistor sensors according to DIN 44081

and 44082 (EN 60947-8).

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Please send

suggestions via email to

techcom_change_request@danfoss.com, including a

reference to the document version. Table 1.1 shows the

document version and the changes applied.

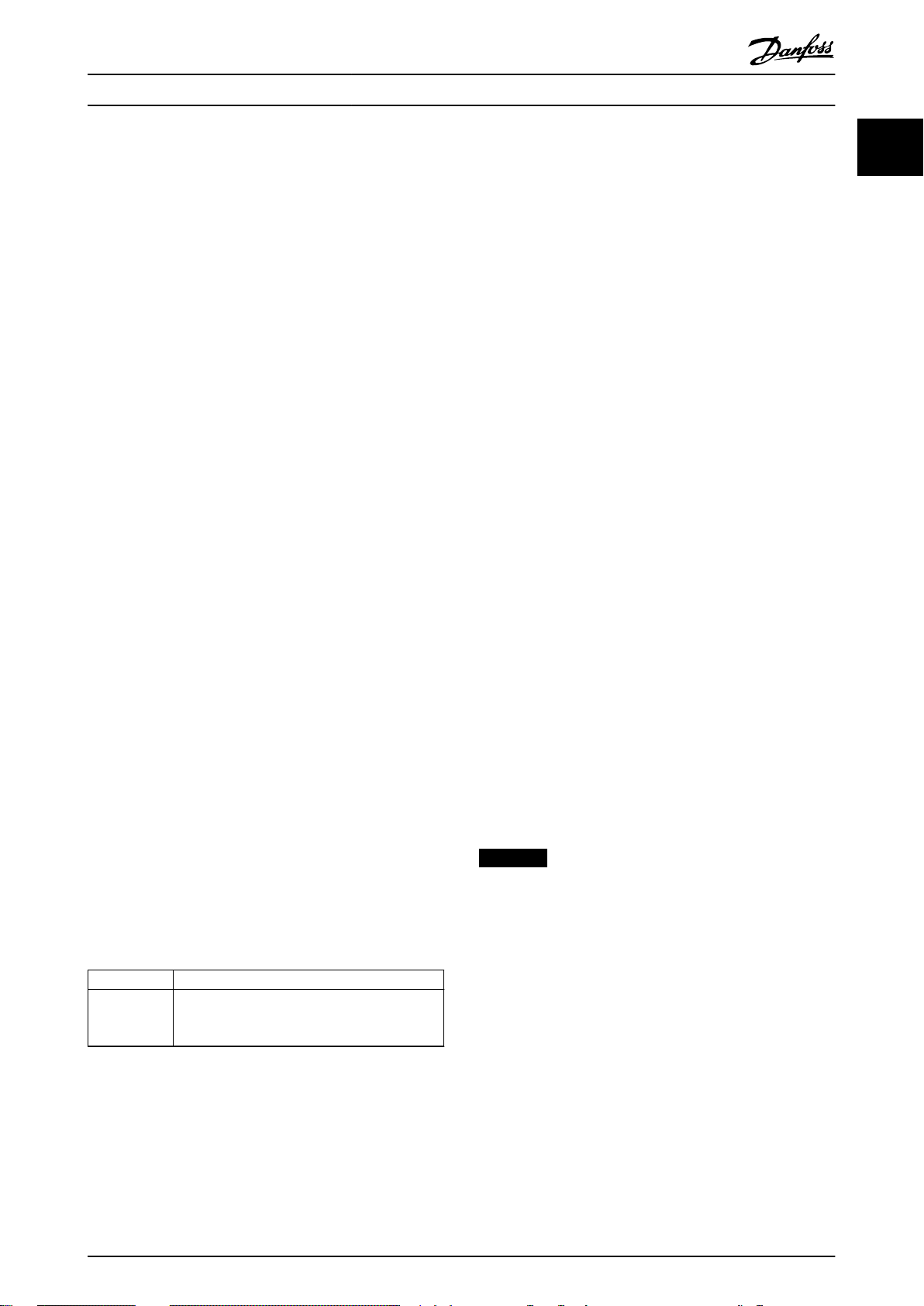

Edition Remarks

MG33V3xx Replaces MG33V2xx.

Editorial changes.

Now covering the complete system.

Table 1.1 Document Version

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 3

NOTICE

The VLT® PTC Thermistor Card MCB 112 is only functional

if it is built into the frequency converter. The option

cannot be used as a stand-alone.

MS 220 DA / MCB112

Code no.: 130B1137

Motor protection inside

See manual

for additional instruction

PTB 14 ATEX 3012U

CAUTION:

II (2) D [Ex tb][Ex tc]

II (2) G [Ex e] [Ex d] [Ex n]

ε

130BE103.10

Introduction

VLT® PTC Thermistor Card MCB 112

1

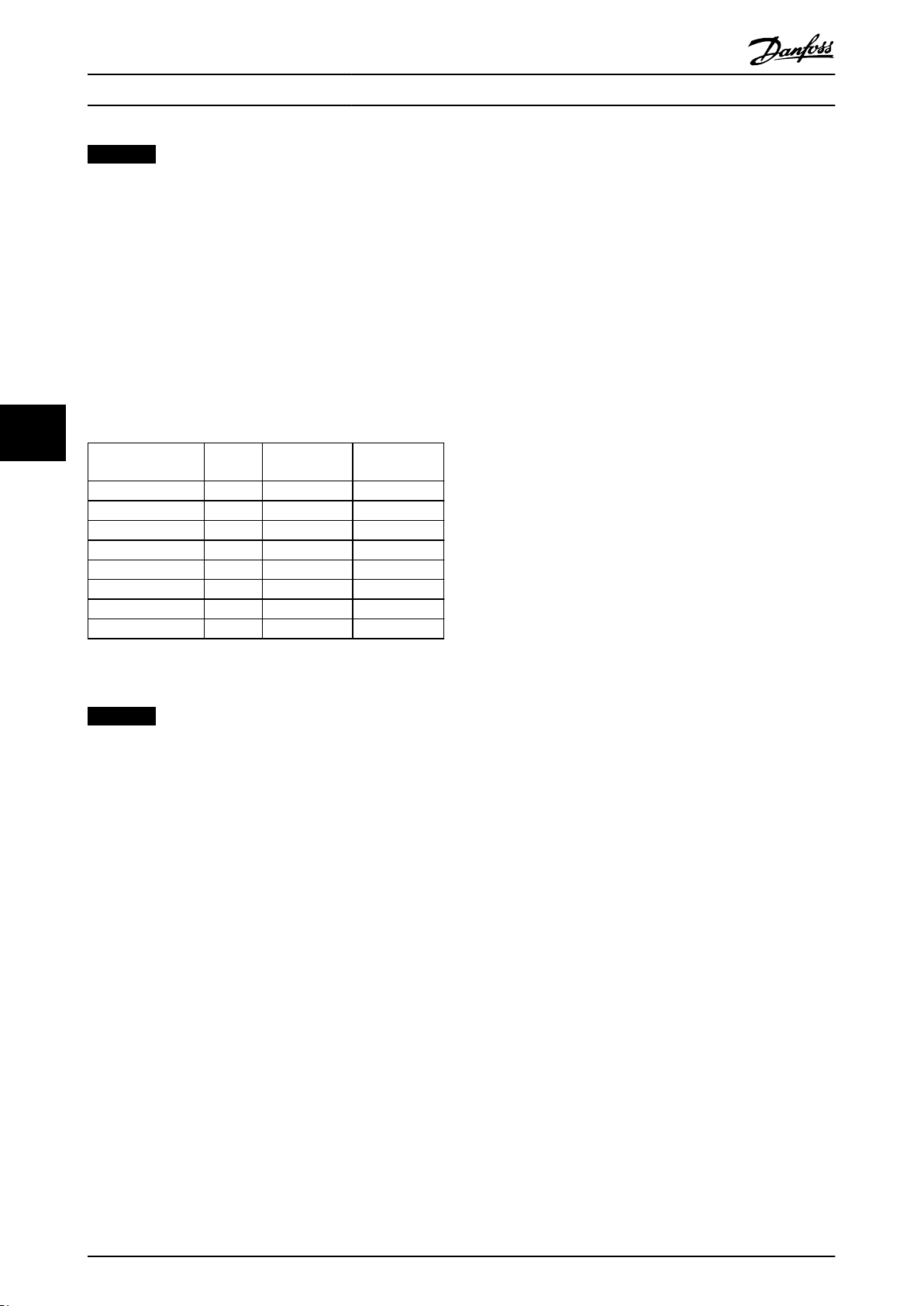

1.5.1.1 Markings of the Frequency

Converter

A sticker is delivered with the option as spare part or with

the frequency converter to signify ATEX certication. Apply

this sticker to the front of the frequency converter in

which the ATEX module is integrated. The sticker indicates

that the ATEX module is installed in the frequency

converter.

Illustration 1.1 Label to Apply to Frequency Converter

Foreseeable Misuse

1.5.2

Any use not expressly approved by Danfoss constitutes

misuse. This also applies to failure to comply with the

specied operating conditions and applications.

according to DIN 44081 or 44082, the MCB 112 oers

ATEX-approved monitoring of the motor temperature.

Alternatively, an external ATEX-approved PTC protection

device can be used.

1.5.4 ATEX ETR Thermal Monitoring

NOTICE

The ATEX ETR thermal monitoring function only applies

to Ex-e and Ex-n motors and is only available for VLT

AutomationDrive FC 302 frequency converters.

The FC 302 with

equipped with an ATEX ETR thermal monitoring function

for operation of Ex-e motors according to EN 60079-7 and

Ex-n motors according to EN 60079-15. Combined with an

ATEX-approved PTC monitoring device like MCB 112, the

installation does not need an individual approval from an

approbated organisation, that there is no need for

matched pairs.

The feature makes it easier to apply Ex-e and Ex-n motors

instead of the more expensive, larger, and heavier Ex-d

motors. The use of Ex-e and Ex-n motors is possible by

ensuring that the frequency converter limits the motor

current to prevent the motor from heating up.

Tripping Function

1.5.5

rmware version V6.3x or higher is

®

Danfoss assumes no liability of any sort for damage attributable to improper use.

Only operate with explosion-protected 3-phase motors

which are built, tested and labelled separately for

frequency converter use.

WARNING

EXPLOSION DANGER

Zone 0 and Zone 20 are not applicable to electric

motors.

To avoid explosion, only use motors in:

Zone 1/21.

•

Zone 2/22.

•

1.5.3 Thermal Motor Protection

According to ATEX Directive 94/9/EC and Standard EN

60079-14, motor overload protection is a requirement.

The MCB 112 monitors the temperature in the motor

windings with an ATEX-approved motor overload

protection device. If there is a critical temperature level or

a malfunction, switch o the motor. If the frequency

converter is equipped with 3–6 PTC thermistors in series

The MCB 112 includes a tripping stage for PTC thermistor

sensors with safe potential separation of supply voltage

from ground. The tripping function switches o the +24 V

DC directly at terminal 37 on the frequency converter.

The PNP logic output terminal X44/10 signals the status in

case of failure. The MCB 112 works according to the

closed-circuit principle. The device trips in case of short

circuit or line interruption.

Safe Separation

1.5.6

The PTC thermistor circuit (T1, T2) has a safe separation of

low-voltage electric circuits PELV, see chapter 3.2 Instal-

lation of Sensor Circuit Wires.

1.5.7

Safe Disconnection Principle

The Safe Torque O function disables the control voltage

of the power semiconductors or the frequency converter

output stage. Disabling the control voltage prevents the

inverter from generating the voltage required to rotate the

motor.

4 Danfoss A/S © 01/2015 All rights reserved. MG33V302

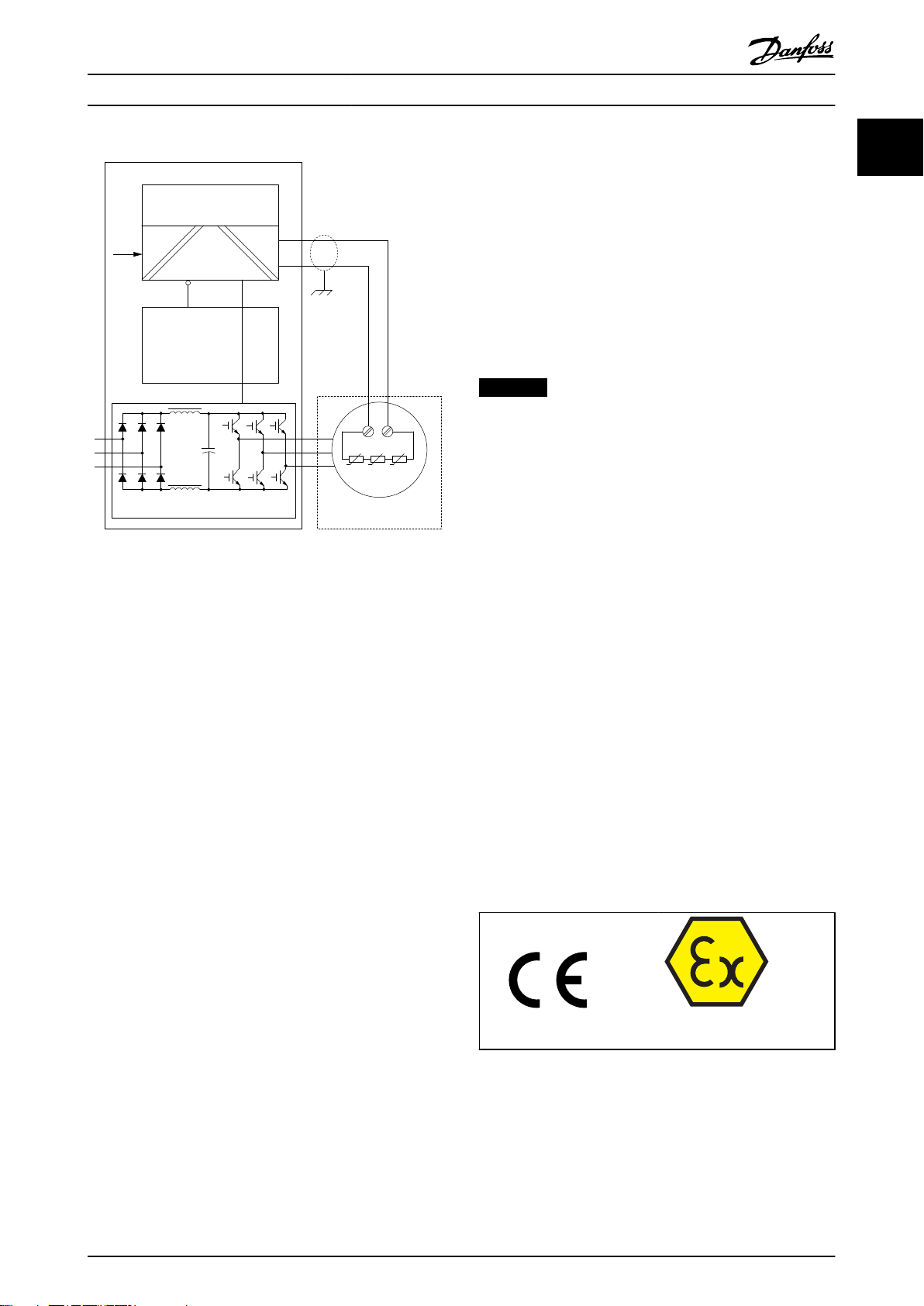

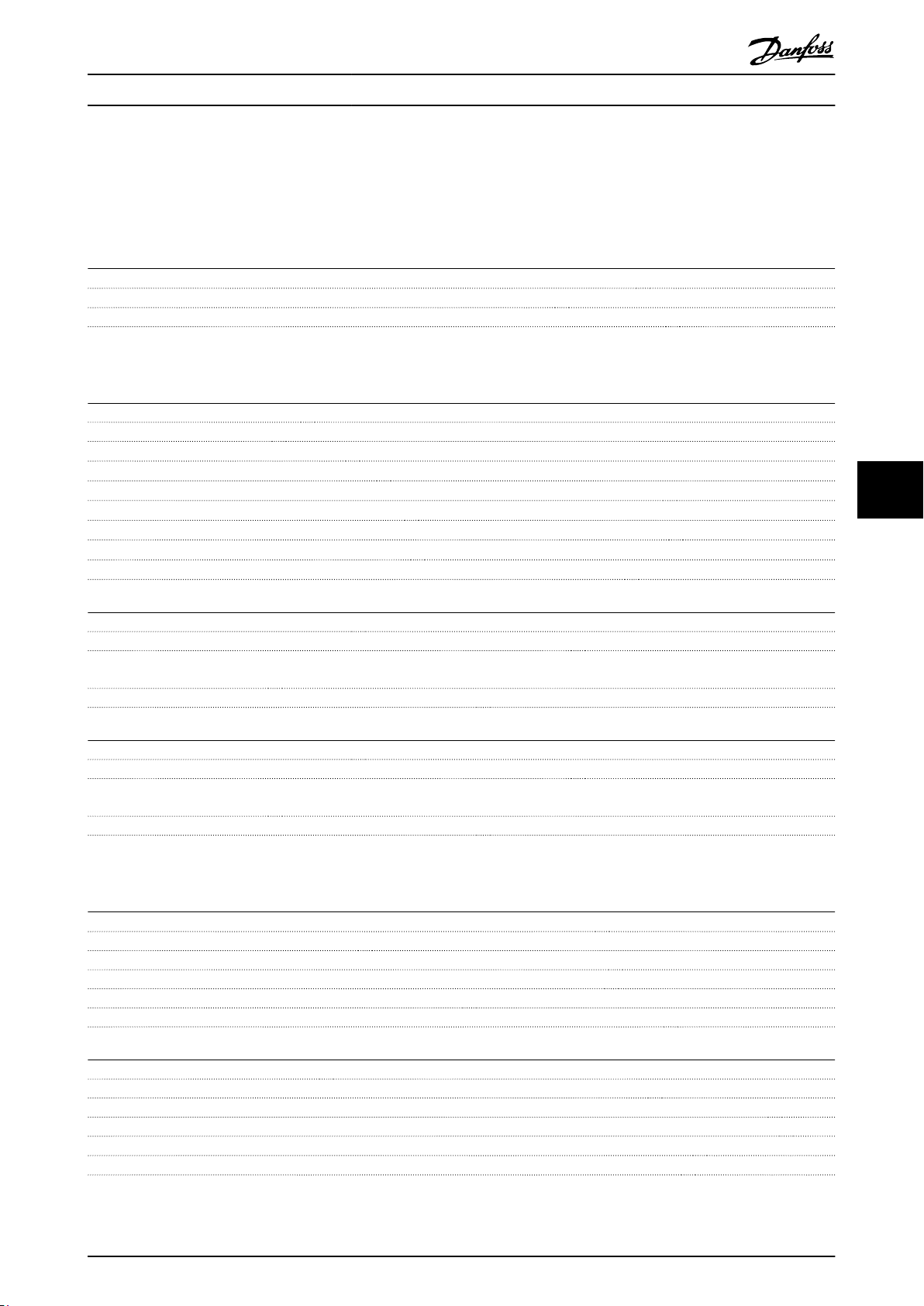

Frequency Converter

Logic

Out

Control Card

Potentially explosive

atmosphere

PTC-Sensors

3~ Ex-Motor

Safe Channel T37

Safe Stop

T37

T1

TP TP

T2

+24 V

PTC Thermistor Card

MCB 112

Non-explosive hazard zone

91

92

93

96

97

98

Converter module

130BE102.10

DI

Introduction

Illustration 1.2 Block Diagram of the System

Operating Instructions

1.6 Motor Requirements

1.6.1 Motor Limits and Rules

For every certied motor with increased safety, the

manufacturer supplies a data list including limits and rules.

During planning, installation, commissioning, operation,

and service, respect the limits for:

Minimum switching frequency.

•

Maximum current.

•

Minimum motor frequency.

•

Maximum motor frequency.

•

Furthermore, respect the following:

1.6.2

Additional Motor Requirements

The Ex-e motor must be approved for operation in

hazardous zones (ATEX Zone 1/21, ATEX Zone 2/22) in

combination with frequency converters. The motor must

be certied for the particular hazardous zone.

The Ex-n motor must be approved for operation in

hazardous zones (ATEX Zone 2/22) in combination with

frequency conveters. The motor must be certied for the

particular harzardous zone.

NOTICE

The motor can be placed in Zone 1/21 or 2/22 according

to motor approval. The frequency converter must always

be installed outside of the hazardous zone.

Only operate explosion-protected 3-phase motors

•

with frequency converters, if the motors are built,

tested, approved, and labelled separately for this

mode.

When the usage of the motor and its thermal

•

protective device are approved for frequency

converter operation, use the MCB 112 for each

ignition protection system for all motor types. For

motors of Ex-e and Ex-n-type ignition protection,

which are OEM-approved for frequency converter

operation in Ex-harzardous areas, consider and

use the requested limitations in the frequency

converter’s ATEX ETR thermal monitoring settings.

The necessary parameters and conditions can be

•

found on the nameplate or the documentation of

the motor. To prevent prohibited temperatures,

the motors are equipped as standard with

thermal winding protection, which has to be

evaluated by a suitable device like MCB 112. The

motors must not be operated as a group drive.

1.7

Approvals and Certications

1

1

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 5

Do not exceed the maximum allowable ratio

•

between frequency converter size and motor size.

The typical value is I

Consider all voltage drops from the frequency

•

converter to the motor. If the motor is running

with lower voltage than listed in the U/f characteristics, current might increase and cause an

alarm.

Multi-motor applications are not allowed. Only

•

connect 1 motor to the frequency converter.

≤2xI

VLT, n

m,n

.

Certication number:

PTB 14 ATEX 3012U

Certicates and declarations of conformity are available.

Contact a local Danfoss partner.

Introduction

VLT® PTC Thermistor Card MCB 112

1

1.8 Symbols, Abbreviations, and

Conventions

Abbreviation Description

ETR Electronic thermal relay.

LCP Local control panel.

NC Not connected.

PNP Positive negative positive (transistor).

TNF Nominal response temperature.

Table 1.2 Abbreviations

AbbreviationReference Description

ATEX ATEX Directive

94/9/EC

HFT EN IEC 61508 Hardware fault tolerance: HFT=n

PDS/SR EN IEC

61800-5-2

PFD EN IEC 61508 Average probability of failure on

SFF EN IEC 61508 Safe failure fraction [%]; percentage

SIL EN IEC 61508

EN IEC 62061

STO EN IEC

61800-5-2

SRECS EN IEC 62061 Safety-related electrical control

ATmosphere EXplosibles

means that n+1 faults could cause a

loss of the safety function.

Power drive system (safety-related).

demand, value used for lowdemand operation.

of safe failures and dangerous

detected failures of a safety function

or a subsystem related to all failures.

Safety integrity level.

Safe Torque O.

system.

Table 1.3 Abbreviations Related to Functional Safety

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of

illustrations.

Italicised text indicates:

Cross-reference.

•

Link.

•

Parameter name.

•

6 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Safety Operating Instructions

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualied Personnel

The products must only be assembled, installed,

programmed, commissioned, maintained, and decommissioned by persons with proven skills. Persons with proven

skills:

Are qualied electrical engineers, or persons who

•

have received training from qualied electrical

engineers and are suitably experienced to

operate devices, systems, plant, and machinery in

accordance with the general standards and

guidelines for safety technology.

Are familiar with the basic regulations concerning

•

health and safety/accident prevention.

Have read and understood the safety guidelines

•

given in this manual and also the instructions

given in the operating instructions of the

frequency converter.

Have a good knowledge of the generic and

•

specialist standards applicable to the specic

application.

Users of PDS(SR) are responsible for:

Hazard and risk analysis of the application. In EN

•

ISO 12100, risk assessment is dened as an

overall process comprising a risk analysis and a

risk evaluation.

Ensuring that the qualied personnel has

•

experience with working in ATEX areas according

to Directive 99/92/EC (also known as the ATEX

Workplace Directive).

Identifying safety functions required, and

•

allocating SIL to each of the functions.

Other subsystems and the validity of signals and

•

commands from those subsystems.

Designing appropriate safety-related control

•

systems (hardware, software, parameterisation,

and so on).

Protective measures

Safety engineering systems must only be installed

•

and commissioned by qualied and skilled

personnel.

Install the frequency converter in an IP54 cabinet

•

as per IEC 60529, or in an equivalent

environment. In special applications, a higher IP

degree may be necessary.

Ensure short-circuit protection of the cable

•

between terminal 37 and the external safety

device according to ISO 13849-2 table D.4.

When external forces inuence the motor axis (for

•

example suspended loads), additional measures

(for example a safety holding brake) are required

to eliminate hazards.

2.3

Safety Precautions

WARNING

EXPLOSION HAZARD

Using the VLT® PTC Thermistor Card MCB 112 in areas

with explosive gas and/or dust atmosphere may lead to

death, personal injury, or property damage. To avoid the

risk, adhere to the following:

Always provide the MCB 112 with a pressurised

•

enclosure according to EN 60079-1 (Explosive

atmospheres - Part 1: Equipment protection by

ameproof enclosures “d”).

Observe national safety rules and regulations

•

for prevention of accidents, as well as the

European Standard EN 60079-14 (Explosive

atmospheres - Part 14: Electrical installations

design, selection, and erection).

Only

•

•

qualied personnel (see

chapter 2.2 Qualied Personnel) is allowed to

install, connect, and commission the MCB 112.

Ensure that the motor thermal protection

switches o the motor directly, via the STO

function, or by using the ATEX ETR thermal

monitoring function.

2 2

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 7

Safety

VLT® PTC Thermistor Card MCB 112

WARNING

FIRE HAZARD

22

Using the VLT® PTC Thermistor Card MCB 112 in areas

with combustible dust may lead to death, personal

injury, or property damage. To avoid the risk, adhere to

the following:

Always provide the MCB 112 with a dust-proof

•

enclosure according to IEC 60529.

Observe national safety rules and regulations

•

for prevention of accidents, as well as the

European Standard EN 60079-14 (Explosive

atmospheres - Part 14: Electrical installations,

design, selection, and erection).

Only qualied personnel (see

•

chapter 2.2 Qualied Personnel) is allowed to

install, connect, and commission the MCB 112.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

the motor may start at any time, causing risk of death,

serious injury, equipment, or property damage. The

motor can start by means of an external switch, a serial

bus command, an input reference signal from the LCP,

after a cleared fault condition, or after the motor and

motor thermistors have cooled down.

Disconnect the frequency converter from mains

•

whenever personal safety considerations make

it necessary to avoid unintended motor start.

Press [O] on the LCP, before programming

•

parameters.

The frequency converter, motor, and any driven

•

equipment must be in operational readiness

when the frequency converter is connected to

AC mains.

CAUTION

RISK OF INJURY AND EQUIPMENT DAMAGE

Read and observe these operating instructions and

safety warnings before installing the VLT® PTC

Thermistor Card MCB 112. Not adhering to the

instructions and warnings in this manual may lead to

personal injury, and property and equipment damage.

8 Danfoss A/S © 01/2015 All rights reserved. MG33V302

130BT340.11

1

2

Installation Operating Instructions

3 Installation

3.1 Safety Instructions

CAUTION

The operator or electrical installer is responsible for

proper grounding and compliance with all applicable

national and local safety regulations.

See chapter 2 Safety and the relevant frequency converter

operating instructions. Also, always observe the

instructions provided by the motor manufacturer.

3 3

3.2 Installation of Sensor Circuit Wires

NOTICE

The connections are not pre-wired from the factory.

WARNING

NO SAFE FUNCTION

Using sensor wires with a resistance >20 Ω causes the

safe function not to work.

To ensure a properly working safe function, only use

sensor circuit wires with a resistance <20 Ω.

Sensor circuit wire connection

2

Wire cross-section [mm

1.5 2 x 800

1 2 x 500

0.75 2 x 300

0.5 2 x 250

Table 3.1 Maximum Permissible Length of Sensor Circuit Wires

]

Wire length [m]

NOTICE

Route the sensor circuit wires as separate control wires.

It is not allowed to use wires from the supply cable or

any other mains cables. Use screened control wires. See

Illustration 3.2 for correct wiring.

1. Select appropriate sensor wires.

2. Route the sensor wires.

3. Remove the screening in the area of the

screening clamps and press the wires into the

clamps.

1

Screening clamps

2 Removed screening

Illustration 3.1 Connecting Screened Wire

4. Measure the sensor resistance.

5. Connect the sensor circuit wires to X44/T1 and

T2. See Illustration 3.2.

NOTICE

Only check PTCs with measuring voltages of <2.5 V.

At commissioning and after modication of the plant,

check the sensor resistance with a suitable measuring

instrument. If the resistance between terminals 1 and 2 is

<50 Ω, examine the sensor circuit for a short circuit.

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 9

PTC

M 3~

TP TP

12 13 18 19 27 29 32 33 20 37

MS 220 DA

Code No. 130B1137

Motor protection

SEE MANUAL FOR

MCB 112 PTC Thermistor Option B

ADDITIONAL INSTRUCTIONS.

PTB 14 ATEX 3012U

CAUTION:

II (2) G [Ex e] [Ex d] [Ex n]

ε

10 10 mA

60 mA

12

20-28 VDC

20-28 VDC

II (2) D [Ex tb][Ex tc]

0102

12030-1201-03

.com

X44

1

T1 T2 NC NC NC

NC NC NC NC NC

LOGIC SAFE STOP

OUT T37

2 3 4 5 6 7 8 9 10 11 12

130BB161.11

130BE118.10

A

B

D

12/13

37

130BE099.10

Installation

VLT® PTC Thermistor Card MCB 112

Maximum current on MCB 112

Terminal 10: 10 mA.

•

Terminal 12: 60 mA.

•

CAUTION

Place the frequency converter with MCB 112 (including

the connection between output safe stop T37 output

(X44/12) on MCB 112 and terminal 37 input on the

control card) in an IP54 enclosure as per IEC 60529.

33

Installing the MCB 112

Illustration 3.2 Wiring Diagram

3.3

Installation of the VLT® PTC Thermistor

Card MCB 112

For motor connection, AC mains connection, and control

wiring, follow the instructions for safe installation in the

operating instructions of the frequency converter and the

VLT® Frequency Converter - Safe Torque O Operating

Instructions.

Terminal Description.

Terminal 12 24 V DC supply voltage.

Terminal 13 24 V DC supply voltage.

T37 (X44/12) Output terminal on the MCB 112 option.

Terminal 37 Input terminal on the control card.

X44/10 Logic output signals the status in case of

Table 3.2 Terminal Denitions

RISK OF OVERVOLTAGE

Long cables (voltage peaks) or increased mains voltage

CAUTION

may lead to overvoltage at the motor terminals and

damage the equipment.

Install a sine-wave lter.

•

failure.

Illustration 3.3 LCP Frame and Terminal Cover Removal

1. Disconnect power to the frequency converter.

2. Remove the LCP, the terminal cover, and the LCP

frame from the frequency converter.

3.

Fit the MCB 112 in slot B, see Illustration 3.3.

Wiring

1. Remove the jumper wire between control

terminals 37 and 12 or 13.

Cutting or breaking the jumper is not

•

sucient to avoid short circuiting.

2. Connect X44/12 on the option card to terminal

37 on the frequency converter.

10 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Installation Operating Instructions

3. Connect terminal X44/10 to a digital input of the

frequency converter. For reference when

programming, note the number of selected

digital input.

Assembly

1. Remove the knock-out in the extended LCP

frame, so that the option ts under the extended

LCP frame.

2. Fit the extended LCP frame and terminal cover.

3. Fit the LCP or blind cover in the extended LCP

frame.

4. To indicate that the ATEX module is integrated,

apply the delivered sticker to the front of the

frequency converter, see Illustration 1.1.

5. Connect power to the frequency converter.

6. Perform risk assessment and a commissioning

test according to EN ISO 12100.

3 3

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 11

Commissioning

4 Commissioning

VLT® PTC Thermistor Card MCB 112

Refer to the chapter Commissioning in the VLT® Frequency

Converters Safe Torque O Operating Instructions.

4.1 Operation and Maintenance

The safety function must be tested within regular intervals.

44

Test once per year, or within the maintenance cycle of the

plant. For recurring examinations of electrical systems in

hazardous areas, the inspection period must be kept within

3 years.

The safety test recognises 1 fault (1oo1 - 1 out of 1). One

fault between safety tests can cause loss of protection.

Commissioning test

Test the correct function of the MCB 112 by simulation of

the sensor resistance at terminals T1 and T2. This test must

also be done at maintenance services.

The tripping function is stated in the LCP and can be reset

manually when the failure is removed. Pay attention to the

ambient conditions in chapter 7 Technical Specications.

Short-circuit test: Resistance 20 Ω in parallel to

•

sensor terminals T1, T2.

Line interruption test: Disconnect sensor line at

•

terminal T1 or T2.

Temperature test: Increase resistance 50–1500 Ω

•

to 4000 Ω.

4.1.1 Monitoring Sensor Resistance

1) Short circuit

2) Tripping is not saved, and is not protected against 0 voltage

Illustration 4.1 Monitoring of Sensor Resistance

A current continuously monitors the resistance of the

sensors. In cold state, the resistance is <250 Ω per sensor

(sensor circuit <1.5 kΩ). The output to terminal X44/12 is

high=1. The resistance of the sensor rises rapidly at

nominal response temperature TNF. At a resistance of 3–4

kΩ, output to terminal X44/12 changes to low=0. The

devices also switch o if the sensor or wire short-circuits

(<20 Ω), or if the sensor or wire is interrupted. It switches

back on automatically when the temperature has

decreased by approximately 5 °C.

12 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Depending on the number of sensors, the following

tripping and release temperatures are achieved with

respect to TNF (nominal response temperature of the

sensors):

Trip temperature Release temperature

3 sensors in series TNF+5 K TNF-5 K

6 sensors in series TNF TNF-20 K

Table 4.1 Tripping and Release Temperatures

1 0 0 %

8 0 %

4 0 %

5 Hz 15 Hz 25 Hz 50 Hz

130BB909.10

130BD888.10

CONVERTER SUPPLY

VALID FOR 380 - 415V FWP 50Hz

3 ~ Motor

MIN. SWITCHING FREQ. FOR PWM CONV. 3kHz

l = 1.5XI

M,N

tOL = 10s tCOOL = 10min

MIN. FREQ. 5Hz MAX. FREQ. 85 Hz

PWM-CONTROL

f [Hz]

Ix/I

M,N

PTC °C DIN 44081/-82

Manufacture xx

EN 60079-0

EN 60079-7

СЄ 1180 Ex-e ll T3

5 15 25 50 85

0.4 0.8 1.0 1.0 0.95

1

2

3

4

xЗ

Commissioning

Operating Instructions

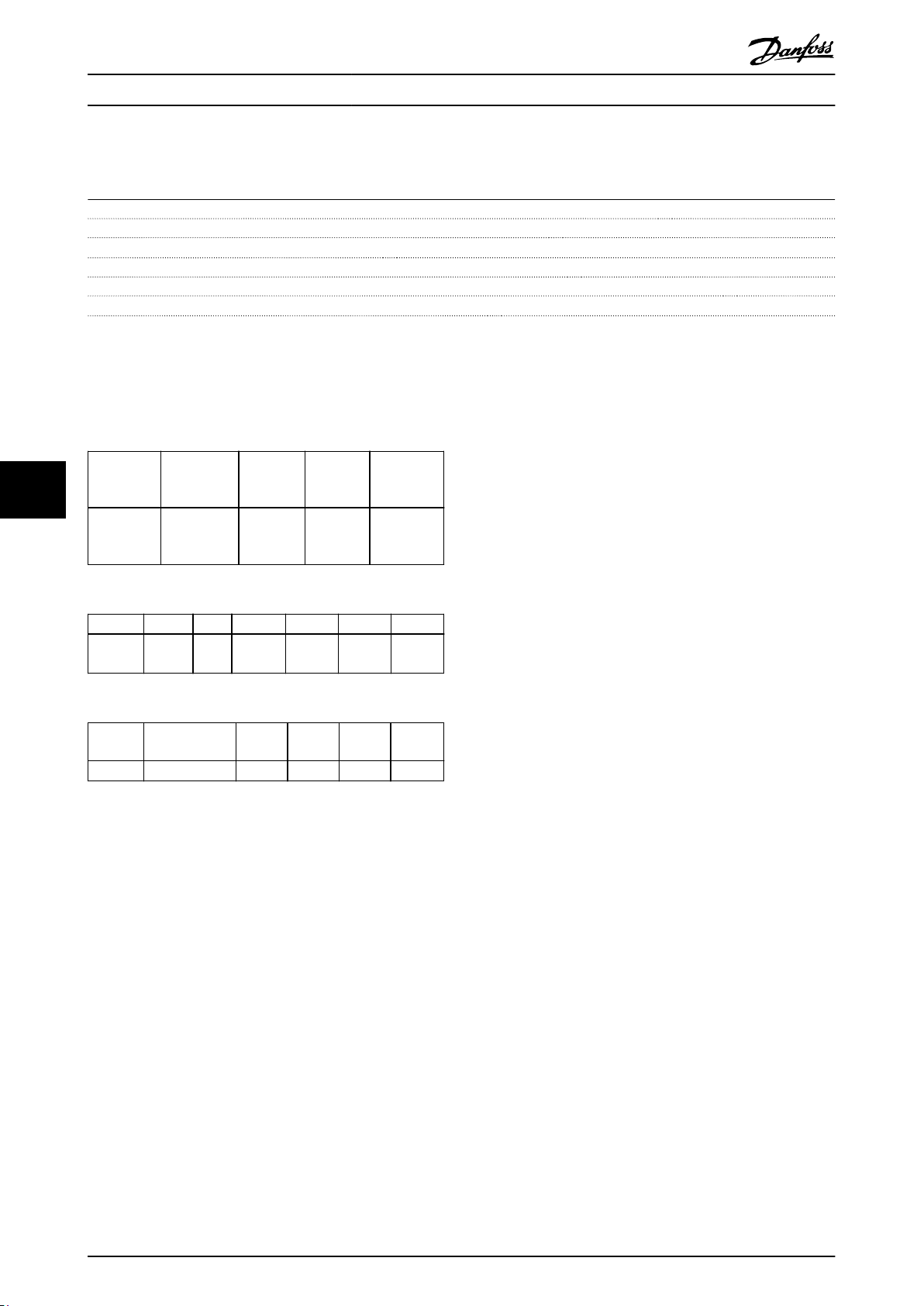

4.1.2 Thermal Limitation Curve

WARNING

EXPLOSION DANGER

Always use the thermal limitation curve in combination

with Ex-e and Ex-n motors. See Illustration 4.2.

The output current/motor speed is permanently monitored

and limited depending on the characteristic given by the

motor manufacturer on the motor nameplate and data

sheets.

1. Programme the characteristic values as

frequency/current pairs in parameters 1-98 ATEX

ETR interpol. points freq. and 1-99 ATEX ETR interpol

points current.

Minimum switching frequency

1

2 Maximum current

3 Minimum motor frequency

4 Maximum motor frequency

4 4

Illustration 4.2 Example of ATEX ETR Thermal Limitation Curve

1-98 ATEX ETR interpol. points freq. 1-99 ATEX ETR interpol

[0]=5 Hz [0]=40%

[1]=15 Hz [1]=80%

[2]=25 Hz [2]=100%

[3]=50 Hz [3]=100%

Table 4.2 Ratio between Motor Speed and Motor Current

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 13

points current

Illustration 4.3 Motor Nameplate Showing Frequency

Converter Requirements

2. Use the 4 current points [A] from the motor

nameplate.

3. Calculate the values as a percentage of nominal

motor current and enter it into the array.

Ix × 100

%

Im, n

4. Programme all frequency/current limit points

from the motor nameplate or motor data sheet.

5.

Enter frequency settings for 1-98 ATEX ETR

interpol. points freq. in Hz, not RPM.

4.2

Parameter Set-up

4.2.1 Alarm Handling

The digital input is congured in parameter group 5-1*

Digital Inputs.

Digital input function Select Terminal

No operation [0] All *terminals 32, 33

Reset [1] All

...

PTC Card 1 [80] All

...

Table 4.3 5-1* Digital Inputs

Commissioning

VLT® PTC Thermistor Card MCB 112

All digital inputs can be set to [80] PTC Card 1. However,

only 1 digital input can have this selection.

NOTICE

Ensure that the digital input set to [80] PTC Card 1 is not

also connected as a thermistor resource (motor overload

protection) in 1-93 Thermistor Resource.

44

For further description, refer to the relevant frequency

converter programming guide.

4.2.2 Parameter Settings

Ex-e and Ex-n-specic parameters

Function Setting

1-90 Motor Thermal Protection

1-94 ATEX ETR cur.lim. speed

reduction

1-98 ATEX ETR interpol. points freq.

1-99 ATEX ETR interpol points

current

1-23 Motor Frequency

4-19 Max Output Frequency

4-18 Current Limit

5-15 Terminal 33 Digital Input

Parameter 5-19 Terminal 37 Safe

Stop

14-01 Switching Frequency

14-26 Trip Delay at Inverter Fault

Table 4.4 Parameter Settings

[20] ATEX ETR

20%

Motor nameplate

Enter the same value as for

4-19 Max Output Frequency.

Motor nameplate, possibly

reduced for long motor

cables, sine-wave lter, or

reduced supply voltage.

Forced to 150% by 1-90 [20]

[80] PTC Card 1

[4] PTC 1 Alarm

Check that the default value

fulls the requirement from

the motor nameplate. If not,

use a sine-wave lter.

0

4.3.2

Maximum Current Limit

The operation above the thermal characteristic curve is

permitted for a limited period of 60 s.

The actual thermal overload is calculated based on the ETR

function selected in 1-90 Motor Thermal Protection and is

displayed in 16-18 Motor Thermal.

Running above the characteristic curve for more than 50 s

triggers Warning 163 ATEX ETR cur.lim. warning. Congure

the reaction for operating in Ex-e and Ex-n current limits in

1-94 ATEX ETR cur.lim. speed reduction.

0%: The frequency converter does not change

•

anything besides issuing Warning 163 ATEX ETR

cur.lim.warning.

>0%: The frequency converter issues Warning 163

•

ATEX ETR cur.lim.warning and reduces motor

speed following ramp 2 (parameter group 3–5*

Ramp 2).

Example:

Actual reference = 200 RPM

1-94 ATEX ETR cur.lim. speed reduction = 20%

Resulting reference = 160 RPM

Operating above the characteristic curve for more than

60 s within a period of 600 s triggers Alarm 164 ATEX ETR

cur.lim., and the frequency converter trips.

Operation above 150% nominal motor current trips the

frequency converter after 1 s with Alarm 164 ATEX ETR

cur.lim.

Operation above 180% nominal motor current immediately

trips the frequency converter with Alarm 164 ATEX ETR

cur.lim.

4.3

Parameter Set-up for Ex-e and Ex-n

Motors

4.3.1 Maximum Current

To activate the ATEX ETR monitor function, set 1-90 Motor

Thermal Protection to [20] ATEX ETR. This enables 1-94 ATEX

ETR cur.lim. speed reduction, 1-98 ATEX ETR interpol. points

freq., and 1-99 ATEX ETR interpol points current, and limits

4-18 Current Limit to 150%.

14 Danfoss A/S © 01/2015 All rights reserved. MG33V302

rst start-up (power-up), the overload counter starts

After

at a value that prevents resetting the thermal load value

by power cycling. After start-up, the overload warning is

suppressed until the motor current exceeds the rated

current limit for the rst time.

4.3.3

Minimum Motor Frequency

The operation below the minimum frequency in 1-98 ATEX

ETR interpol. points freq. is allowed for a limited time only.

Running below the minimum frequency for more than 50 s

triggers Warning 165 ATEX ETR freq.lim.warning.

Commissioning Operating Instructions

Operation below the minimum frequency for more than

60 s within a period of 600 s triggers Alarm 166 ATEX ETR

freq.lim.alarm. The frequency converter trips.

4.3.4 Maximum Motor Frequency

Do not exceed the maximum allowable output frequency.

The motor data sheet or nameplate shows the maximum

permissible value.

NOTICE

This value can be reduced for long motor cables, sinewave lter, or reduced supply voltage.

Un − Uloss

f

=

max

Example:

Use the result from the equation as the value set in

4-19 Max Output Frequency.

4.3.5

Thermal motor losses increase with lower switching

frequencies. Ensure that the frequency converter switching

frequency does not drop below the value stated by the

motor manufacturer.

x f n

Un

Nominal voltage = 480 V

Nominal frequency = 50 Hz

Voltage loss due to supply voltage of 450 V =

30 V

Resulting maximum frequency = 47 Hz

Minimum Switching Frequency

NOTICE

It is mandatory to compare the minimum switching

frequency requirement of the motor to the minimum

switching frequency of the frequency converter, which is

the default value in 14-01 Switching Frequency. If the

frequency converter does not meet this requirement, use

a sine-wave lter.

4.3.6 Disable Protection Mode

In protection mode, the frequency converter derates the

switching frequency below the default in 14-01 Switching

Frequency. For example, if the default value is 3 kHz, it can

derate down to 2.5 kHz, depending on EEPROM. Therefore,

disable protection mode in 14-26 Trip Delay at Inverter Fault.

More information about derating can be found in the

section Derating in the frequency converter design guide.

4.3.7

Safe Torque O Functionality

The desired Safe Torque O functionality is specied in

parameter 5-19 Terminal 37 Safe Stop. When a VLT® PTC

Thermistor Card MCB 112 is mounted, select 1 of the PTC

options to get the full benet from the alarm handling.

Options [4] PTC 1 Alarm and [5] PTC 1 Warning are relevant

when the MCB 112 is the only interrupt device using STO.

Options [6] PTC 1 & Relay A to [9] PTC 1 & Relay W/A are

relevant when other safety sensors are also connected to

STO.

Alarm: The frequency converter coasts. Reset the

•

alarm manually (via bus, digital I/O, or by pressing

[Reset]). Auto reset does not apply here. For more

details, see [4] PTC 1 Alarm in

parameter 5-19 Terminal 37 Safe Stop.

Warning: The frequency converter coasts, but

•

resumes operation when STO and the DI from

X44/10 are disabled. For more details, see [5] PTC

1 Warning in parameter 5-19 Terminal 37 Safe Stop.

Conguring a digital input in parameter group 5-1* Digital

Inputs makes it possible to give a warning/alarm that

species what triggered the Safe Torque O.

NOTICE

When selecting warning instead of alarm, automatic

restart is enabled. See Installation in Combination with

VLT® PTC Thermistor Card MCB 112 in the VLT® Frequency

Converters - Safe Torque O Operating Instructions.

Safe Torque O-related Parameter

5-19 Terminal 37 Safe Stop

To congure the Safe Torque O functionality, set this parameter.

A warning message makes the frequency converter coast the

motor and enables the automatic restart. An alarm message

makes the frequency converter coast the motor and requires a

manual restart (via a eldbus, digital I/O, or by pressing [Reset]

on the LCP). When the MCB 112 is mounted, congure the PTC

options to get the full benet from the alarm handling.

Option: Function:

[1] Safe Stop Alarm Coasts the frequency converter

when Safe Torque O is activated.

Manual reset from LCP, digital input,

or eldbus.

[3] Safe Stop

Warning

Coasts the frequency converter

when Safe Torque O is activated

(terminal 37 o). When Safe Torque

O circuit is re-established, the

frequency converter continues

without manual reset.

4 4

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 15

Commissioning

VLT® PTC Thermistor Card MCB 112

5-19 Terminal 37 Safe Stop

To congure the Safe Torque O functionality, set this parameter.

A warning message makes the frequency converter coast the

motor and enables the automatic restart. An alarm message

makes the frequency converter coast the motor and requires a

manual restart (via a eldbus, digital I/O, or by pressing [Reset]

on the LCP). When the MCB 112 is mounted, congure the PTC

options to get the full benet from the alarm handling.

44

Option: Function:

[4] PTC 1 Alarm Coasts the frequency converter

when Safe Torque O is activated.

Manual reset from LCP, digital input,

or eldbus.

[5] PTC 1 Warning Coasts the frequency converter

when Safe Torque O is activated

(terminal 37 o). When Safe Torque

O circuit is re-established, the

frequency converter continues

without manual reset, unless a

digital input set to [80] PTC Card 1 is

still enabled.

[6] PTC 1 & Relay A This option is used when the PTC

option gates with a stop button

through a safety relay to terminal

37. Coasts the frequency converter

when Safe Torque O is activated.

Manual reset from LCP, digital input,

or eldbus.

[7] PTC 1 & Relay W This option is used when the PTC

option gates with a stop button

through a safety relay to terminal

37. Coasts the frequency converter

when Safe Torque O is activated

(terminal 37 o). When Safe Torque

O circuit is re-established, the

frequency converter continues

without manual reset, unless a

digital input set to [80] PTC Card 1 is

still enabled.

[8] PTC 1 & Relay

A/W

[9] PTC 1 & Relay

W/A

This option makes it possible to use

a combination of alarm and warning.

This option makes it possible to use

a combination of alarm and warning.

Function Num-

ber

No Function [0] – –

Safe Stop Alarm [1]* – Safe Stop [A68]

Safe Stop

Warning

PTC 1 Alarm [4] PTC 1 Safe Stop

PTC 1 Warning [5] PTC 1 Safe Stop

PTC 1 & Relay A [6] PTC 1 Safe Stop

PTC 1 & Relay W [7] PTC 1 Safe Stop

PTC 1 & Relay

A/W

PTC 1 & Relay

W/A

Table 4.5 Overview of Functions, Alarms, and Warnings

W means warning and A means alarm. For further information, see

Alarms and Warnings in the Troubleshooting section in the design

guide or the operating instructions.

[3] – Safe Stop [W68]

[8] PTC 1 Safe Stop

[9] PTC 1 Safe Stop

PTC Relay

–

[A71]

–

[W71]

Safe Stop [A68]

[A71]

Safe Stop [W68]

[W71]

Safe Stop [W68]

[A71]

Safe Stop [A68]

[W71]

A dangerous failure related to Safe Torque O issues Alarm

72 Dangerous Failure.

Refer to Table 6.1.

NOTICE

Selecting Auto Reset/Warning enables automatic restart

of the frequency converter.

16 Danfoss A/S © 01/2015 All rights reserved. MG33V302

130BA966.13

Digital Input

PTC

Sensor

Non-Hazardous AreaHazardous

Area

X44/

PTC Thermistor Card

MCB 112

1 2 3 4 5 6 7 8 9 10 1112

DI DI

Safe Stop

12 13 18 19 27 29 32 33 20 37

e.g. Par 5-15

Par. 5-19

Terminal 37 Safe Stop

130BA967.12

Digital Input

PTC

Sensor

Non-Hazardous AreaHazardous

Area

X44/

PTC Thermistor Card

MCB 112

1 2 3 4 5 6 7 8 9 10 11 12

Safety Device

Manual Restart

SIL 2

Safe AND Input

Safe Output

Safe Input

DI DI

Safe Stop

Par. 5-19

Terminal 37 Safe Stop

12 13 18 19 27 29 32 33 20 37

e.g. Par 5-15

Application Examples Operating Instructions

5 Application Examples

The following 2 examples show the possibilities when

using the VLT® PTC Thermistor Card MCB 112.

Example 1: Standard use

Illustration 5.1 Standard Use of MCB 112

Parameter 5-19 Terminal 37 Safe Stop

[4] PTC 1

Alarm

5-15 Terminal 33 Digital Input

If the motor temperature is too high, or if a PTC

failure occurs, the MCB 112 activates the STO.

Terminal 37 goes LOW (active), and digital input

33 goes HIGH (active). This parameter decides the

consequence of the Safe Torque O (STO). With

this selection, the frequency converter coasts and

the LCP displays Alarm 71 PTC 1 Safe Stop. Reset

the frequency converter manually from the LCP,

digital input, or eldbus when the conditions of

the PTC are acceptable again (temperature of

motor has dropped).

Example 2: Combination with other components using

STO

5 5

Illustration 5.2 More Safety Devices in Combination with STO

and MCB 112

[80] PTC

Card 1

Connects the digital input of terminal 33 in the

FC 302 to the MCB 112, which enables MCB 112

to indicate when STO has been activated from

here.

Table 5.1 Programming Example 1

Alternatively, parameter 5-19 Terminal 37 Safe Stop could be

set to [5] PTC 1 Warning, which means an automatic restart

when the conditions of the PTC circuit have returned to

acceptable. The selection depends on customer demands.

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 17

Application Examples

Parameter 5-19 Terminal 37 Safe Stop

[6] PTC 1 &

Relay Alarm

55

5-15 Terminal 33 Digital Input

[80] PTC Card 1 Connects the digital input of terminal 33 to

If the motor temperature is too high, or if a

PTC failure occurs, the MCB 112 activates the

STO of the frequency converter. Terminal 37

goes LOW (active), and digital input 33 goes

HIGH (active). This parameter decides the

consequence of the Safe Torque O (STO).

With this selection, the frequency converter

coasts and the LCP displays Alarm 71 PTC 1

Safe Stop. Reset the frequency converter

manually from LCP, digital input, or

when the conditions of the PTC are

acceptable again (the motor temperature has

dropped). An emergency stop can also

activate STO. Terminal 37 goes LOW (active),

but MCB 112 X44/10 does not trigger digital

input 33 as the MCB 112 did not need to

activate the STO. Therefore, digital input 33

remains HIGH (inactive).

the MCB 112, which enables the MCB 112 to

indicate when STO has been activated from

here.

VLT® PTC Thermistor Card MCB 112

eldbus

Table 5.2 Programming Example 2

Alternatively, parameter 5-19 Terminal 37 Safe Stop could be

set to [7] PTC 1 & Relay Warning. Selecting this option

causes an automatic restart when the conditions of the

PTC circuit and/or emergency stop circuit have returned to

normal. The selection depends on customer demands. Also,

the setting of parameter 5-19 Terminal 37 Safe Stop could

be [8] PTC 1 & Relay A/W or [9] PTC 1 & Relay W/A, which is

a combination of alarms and warnings. The selection

depends on customer demands.

NOTICE

Selections [4] PTC 1 Alarm to [9] PTC 1 & Relay W/A in

parameter 5-19 Terminal 37 Safe Stop are only visible if

the MCB 112 is plugged into the B-option slot.

NOTICE

Take care that the digital input set to [80] PTC Card 1 is

not also congured as thermistor resource (motor

overload protection) in 1-93 Thermistor Resource.

18 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Maintenance and Troubleshoo... Operating Instructions

6 Maintenance and Troubleshooting

6.1 Maintenance

The devices are maintenance-free. Only the manufacturer

(www.ZIEHL.de) is allowed to perform repair work. Observe

EN 60079-17 Explosive atmospheres - Part 17: Electrical

installations, inspection, and maintenance.

6.2 Troubleshooting

The resistance in the sensor circuit must have a

•

value 50 Ω <R <1500 Ω. The terminal voltage

must be <2.5 V with the resistors attached.

If terminal T1-T2 is open, the relay must shut o.

•

The terminal voltage must be approximately 9 V.

Alarm/Warning Code List

6.2.1

Para-

Num-

Table 6.1 Alarms and Warnings Directly Related to STO

1) Cannot be auto reset via 14-20 Reset Mode.

ber

68

71

72

Descrip-

tion

Safe Stop

Activated

PTC 1 Safe

Stop

Dangerous

Failure

Warning

X

X

Alarm/

Trip

1)

X

1)

X

Alarm/

Trip lock

1)

X

meter

refe-

rence

Parameter

5-19 Termi

nal 37 Safe

Stop

Parameter

5-19 Termi

nal 37 Safe

Stop

Parameter

5-19 Termi

nal 37 Safe

Stop

NOTICE

Alarm 11, Motor Thermistor overtemp. relates to

1-93 Thermistor Resource and not to the MCB 112.

Alarm 68, Safe Stop

STO has been activated. To resume normal operation,

apply 24 V DC to terminal 37, then send a reset signal (via

bus, digital I/O, or by pressing [Reset]).

Warning 68, Safe Stop

STO has been activated. Normal operation is resumed

when STO is disabled.

Warning: Automatic Restart.

Alarm 71, PTC 1 Safe Stop

STO has been activated from the MCB 112 (motor too

warm). Normal operation can be resumed when:

The MCB 112 applies 24 V DC to terminal 37

•

again (when the motor temperature reaches an

acceptable level), and

The digital input from the MCB 112 is

•

deactivated.

When that happens, send a reset signal (via bus, digital I/O,

or by pressing [Reset]).

Warning 71, PTC 1 Safe Stop

STO has been activated from the MCB 112 (motor too

warm). Normal operation can be resumed when:

The MCB 112 applies 24 V DC to terminal 37

•

again (when the motor temperature reaches an

acceptable level), and

The digital input from the MCB 112 is

•

deactivated.

Warning: Automatic Restart.

Alarm 72, Dangerous Failure

STO with trip lock. If the combination of STO commands is

unexpected, the dangerous failure-alarm is issued. This

situation occurs if the MCB 112 enables X44/10 without

STO being enabled. Furthermore, if the MCB 112 is the

only device using STO (specied by [4] PTC 1 Alarm or [5]

PTC 1 Warning in parameter 5-19 Terminal 37 Safe Stop), an

unexpected combination activates the STO without

activating the X44/10. Table 6.2 summarises the

unexpected combinations that trigger this alarm.

6 6

6.2.2 Description of Alarm Word, Warning

Word, and Extended Status Word

Bit Hex Dec

4000

0000

8000

0000

10737

41824

21474

83648

30

31

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 19

Alarm

word

Safe

Stop

[A68]

Alarm

word2

PTC 1

Safe Stop

[A71]

Dangerous

Failure

[A72]

Warning

word

Safe Stop

[W68]

Warning

word2

PTC 1

Safe Stop

[W71]

Maintenance and Troubleshoo...

VLT® PTC Thermistor Card MCB 112

NOTICE

If X44/10 is activated in selection [2] Safe Stop Alarm or

[3] Safe Stop Warning, this signal is ignored. However, the

MCB 112 is still able to activate STO.

Example:

[5] PTC 1 Warning is selected in parameter 5-19 Terminal 37

Safe Stop, and X44/10 is not activated, but STO is. This is

an unexpected selection. [5] PTC 1 Warning in

parameter 5-19 Terminal 37 Safe Stop

only triggered from MCB 112.

+: Activated

-: Not activated

species that STO is

66

Function Number X44/10 (DI) STO terminal

37

PTC 1 Alarm [4] + -

- +

PTC 1 Warning [5] + -

- +

PTC 1 & Relay A [6] + PTC 1 & Relay W [7] + PTC 1 & Relay A/W [8] + PTC 1 & Relay W/A [9] + -

Table 6.2 Unexpected Combinations Triggering Alarm 72

Dangerous Failure

NOTICE

For correct and safe use of the STO function, follow the

related information and instructions in the VLT

Frequency Converters - Safe Torque O Operating

Instructions.

®

20 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Technical Specications Operating Instructions

7 Technical Specications

7.1 Mains Supply

Mains supply

Rated supply voltage U

Tolerance voltage U

Power consumption <1 W

S

S

7.2 Control Inputs and Outputs

PTC thermistor connection X44/1+X44/2

Standard DIN 44081/DIN 44082

Numbers Set with 3–6 PTCs in series

Cut-out point 3.3 kΩ...3.65 kΩ...3.85 kΩ

Reclosing point 1.7 kΩ...1.8 kΩ...1.95 kΩ

Collective resistance cold sensors ≤1.65 kΩ

Terminal voltage (sensors) ≤2.5 V at R ≤3.65 kΩ, ≤9 V at R=∞

Terminal current (sensors) ≤1 mA

Short circuit 20 Ω ≤R ≤40 Ω

Power consumption ≤2 mW

24 V DC

21–28 V DC

7 7

Safe stop terminal 37, X44/12

Output PNP transistor

Logical voltage level 0–24 V DC

Low=0, PNP <4 V DC

Voltage

Current 60 mA

Logic out, X44/10

Output PNP transistor

Logical voltage level 0–24 V DC

Voltage

Current 10 mA

High=1, PNP >20 V DC

Low=0, PNP <5 V DC

High=1, PNP >10 V DC

7.3 Ambient Conditions

Environment

Rated ambient temperature range, T

Relative humidity 5–95%, without condensation

EMC - Immunity industry standard EN 61000-6-2

EMC - Emission industry standard EN 61000-6-4

Vibration resistance 10–1000 Hz 1.14 g

Shock resistance 50 g

Testing conditions

Standards EN 60947-8, EN 50178

Rated impulse voltage 6000 V

Overvoltage category III

Contamination level 2

Rated insulation voltage U

Safe separation up to U

I

I

a

-20 °C to +55 °C

690 V

500 V

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 21

Technical Specications

VLT® PTC Thermistor Card MCB 112

7.4 Other Specications

Enclosure

Form 130B4065 PA 6

Dimensions (H x W x T) [mm] 82.5 x 69.5 x 29.5

Wire connection, solid wire 1 x 0.5–1.5 mm2 (AWG 20–16 solid wire)

Insulation strip length 8.5–9.5 mm

Protection rating IEC 60529 IP20

Weight ≈50 g

7.5 Safety Characteristics of the Built-in MCB 112

The safety characteristics include the connection between

output safe stop T37 (output X44/12 on MCB 112) and

terminal 37 input on the control card.

Operating

mode

77

Low

demand

mode

Table 7.1 Safety Integrity Level SIL (EN 61508)

MCB 112 MTBF SFF

Ta=40 °C

Table 7.2 Safety-related Parameters, Part 1

MCB 112 Proof test

Ta=40 °C

Table 7.3 Safety-related Parameters, Part 2

Hardware

architecture

1oo1 0 SIL 2 Type A

44

years

interval

PFD

avg

Fault

tolerance

HFT

λ

SD

96,5% 2103 x

10-9/h

1 year 3 years 5 years 10 years

3.37E-04 1.01E-03 1.68E-03 3.37E-03

λ

SU

41.8 x

10-9/h

Safety

integrity

level

λ

DD

1.23 x

10-9/h

Subsystem

device

λ

DU

81.4 x

10-9/h

Observe the proof test interval according to EN 60079-17

for electrical equipment ≤3 years.

The data of the functional safety stated in Table 7.1 to

Table 7.3 are valid for an ambient temperature of 40 °C.

Data for more ambient temperatures can be obtained by

request.

22 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Index Operating Instructions

Index

A

Abbreviations........................................................................................... 6

Alarm word............................................................................................. 19

Ambient conditions...................................................................... 12, 21

Ambient temperature......................................................................... 22

Approvals................................................................................................... 5

ATEX

ETR monitor function..................................................................... 14

Certication.......................................................................................... 4

Module............................................................................................ 4, 11

Thermal monitoring function.................................................... 4, 7

Zone 1................................................................................................ 3, 5

Zone 2................................................................................................ 3, 5

Zone 21.............................................................................................. 3, 5

Zone 22.............................................................................................. 3, 5

Auto reset................................................................................................ 15

B

Block diagram........................................................................................... 5

C

Cables/Wires

Control cable, mounting............................................................... 10

Mounting control cable................................................................. 10

Permissible length.............................................................................. 9

Screened control wire....................................................................... 9

Sensor circuit wire.............................................................................. 9

Separate control wire........................................................................ 9

Certications............................................................................................. 5

Combustible dust.................................................................................... 8

Commissioning test............................................................................. 12

Conventions.............................................................................................. 6

I

Intended use............................................................................................. 3

M

Maintenance.......................................................................................... 19

Manual reset........................................................................................... 15

Marking D.................................................................................................. 3

Marking G.................................................................................................. 3

Maximum current................................................................................... 5

Minimum frequency............................................................................ 14

Minimum switching frequency.......................................................... 5

Misuse of the product........................................................................... 4

Motor

Ex-d.......................................................................................................... 4

Ex-e........................................................................................ 4, 5, 13, 14

Ex-n....................................................................................... 4, 5, 13, 14

Maximum frequency......................................................................... 5

Minimum frequency.......................................................................... 5

Monitoring............................................................................................ 4

Nominal motor current.................................................................. 14

Protection.............................................................................................. 4

Requirement........................................................................................ 5

Multi-motor application....................................................................... 5

N

Nameplate.......................................................................................... 5, 13

O

Overvoltage............................................................................................ 10

P

Protection mode................................................................................... 15

D

Dangerous failure................................................................... 16, 19, 20

Derating................................................................................................... 15

Q

Qualied personnel....................................................................... 3, 7, 8

R

E

Environment........................................................................................... 21

Ex-e current limit.................................................................................. 14

Ex-n current limit.................................................................................. 14

Explosive dust atmosphere............................................................. 3, 7

Explosive gas atmosphere............................................................... 3, 7

Extended status word......................................................................... 19

F

Frequency converter

Requirement...................................................................................... 13

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 23

Release temperature........................................................................... 12

Repair work............................................................................................. 19

Resistance................................................................................................ 12

S

Safe separation........................................................................................ 4

Safe Torque O.................................................................................. 4, 16

Safe Torque O functionality........................................................... 15

Safety function...................................................................................... 12

Safety integrity level, SIL.................................................................... 22

Sensor resistance.................................................................................. 12

Index

Standards

ATEX Directive 94/9/EC..................................................................... 4

DIN 44081.................................................................................. 3, 4, 21

DIN 44082.................................................................................. 3, 4, 21

EN 50178............................................................................................. 21

EN 60079-1............................................................................................ 7

EN 60079-14................................................................................ 4, 7, 8

EN 60079-17....................................................................................... 22

EN 60079-17 Explosive atmospheres........................................ 19

EN 60079-7............................................................................................ 4

EN 60947-8..................................................................................... 3, 21

EN 61000-6-2..................................................................................... 21

EN 61000-6-4..................................................................................... 21

EN 61508............................................................................................. 22

EN ISO 12100................................................................................. 7, 11

IEC 60529................................................................................... 7, 8, 10

ISO 13849-2.......................................................................................... 7

Sticker.......................................................................................................... 4

Symbols...................................................................................................... 6

VLT® PTC Thermistor Card MCB 112

T

Terminals

Safe stop T37..................................................................................... 10

T1........................................................................................................... 12

T2........................................................................................................... 12

X44/1.................................................................................................... 21

X44/10................................................................. 4, 11, 15, 19, 20, 21

X44/12............................................................................... 4, 10, 12, 21

X44/2.................................................................................................... 21

Test............................................................................................................. 12

Testing conditions................................................................................ 21

Thermal limitation curve.................................................................... 13

Thermal overload................................................................................. 14

Thermal winding protection............................................................... 5

Tripping function............................................................................. 4, 12

Tripping temperature.......................................................................... 12

U

Unexpected combination................................................................. 20

V

Voltage drop............................................................................................. 5

W

Warning word........................................................................................ 19

24 Danfoss A/S © 01/2015 All rights reserved. MG33V302

Index Operating Instructions

MG33V302 Danfoss A/S © 01/2015 All rights reserved. 25

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

130R0104 MG33V302 01/2015

*MG33V302*

Loading...

Loading...