Page 1

Fact Sheet

VLT® PTC Thermistor Card MCB 112

VLT® PTC Thermistor Card MCB 112

improves the motor condition

surveillance in the Danfoss VLT®

AutomationDrive, VLT® HVAC Drive

and VLT® AQUA Drive frequency converters, compared to the standard

built-in ETR function with thermistor

terminal.

The MCB 112 option enables VLT® drives

to be used in systems that require

control of motors located in potentially

explosive environments. When MCB 112

is used with a VLT® drive with integrated

Safe Torque Off, the drive is certified to

coast the motor when motor temperature becomes too high. This helps to

eliminate the risk of explosion due to

an over-temperature condition in the

ATEX-certified motor (Ex d, Ex e, Ex n,

Ex tb and Ex tc).

ATEX Directive 94/9/EC is an EU directive that describes equipment permitted in an environment with a potentially explosive atmosphere.

The option is ATEX certified for

protection of certified Ex proof

motors, regardless of supplier, in zones

1 and 2 (gas) and zones 21 and 22

(dust), in accordance with the

dedicated additional measures of the

Ex protection system of the motor.

The frequency converter itself is not

ATEX rated and must be situated outside the hazardous area.

The Safe Torque Off function can be

used with external safety devices (with

integrated “&” function) and is compatible with simultaneous use of the

MCB 112.

Collaboration and approval

The MCB 112 is a standard plug-in

option for VLT® AutomationDrive, VLT®

HVAC Drive and VLT® AQUA Drive with

integrated Safe Torque Off.

Alarm handling

The MCB 112 surveillance function

detects motor overheating, possible

short circuits, or open circuit due to

breaks in the sensor circuit. It also

provides alarm logging, diagnosis and

intelligent evaluation, thus facilitating

troubleshooting.

Integrated Safe Torque Off

The MCB 112 uses the Safe Torque Off

function of the drive which is approved

in accordance with SIL2 EN 61508.

A mains disconnect contactor is not

necessary.

Feature Benefit

Independent of motor supplier Flexible choice of motor type

No binding between the different components Easy service

Temperature surveillance is performed

directly in the frequency converter

Can assume sole protection of an Ex d, Ex e,

Ex n, Ex tb and Ex tc certified motor within the

installation/facility

Current limiting feature

(only VLT® AutomationDrive)

Integrated safety technology Reduced cabling and commissioning cost

Plug-and-play

Isolated solution (PELV)

The MCB 112 has been developed in

collaboration with the company ZIEHL

industrie-elektronik, an experienced

specialist in thermal motor protection

in potentially explosive atmospheres,

approved by the PTB (PhysikalischTechnische Bundesanstalt).

Ex

Suitable for

operation of Ex d,

Ex e & Ex n and Ex

tb & Ex tc certi ed

motors

– No external components needed

– Less space required

– Reduced system cost

External components saved

Less costly Ex-e motors can be applied

– Swift and cost-efficient upgrade on-site

– The drive automatically identifies the option

Digital outputs are galvanically isolated from

supply and high-voltage

www.vlt-drives.danfoss.com

Page 2

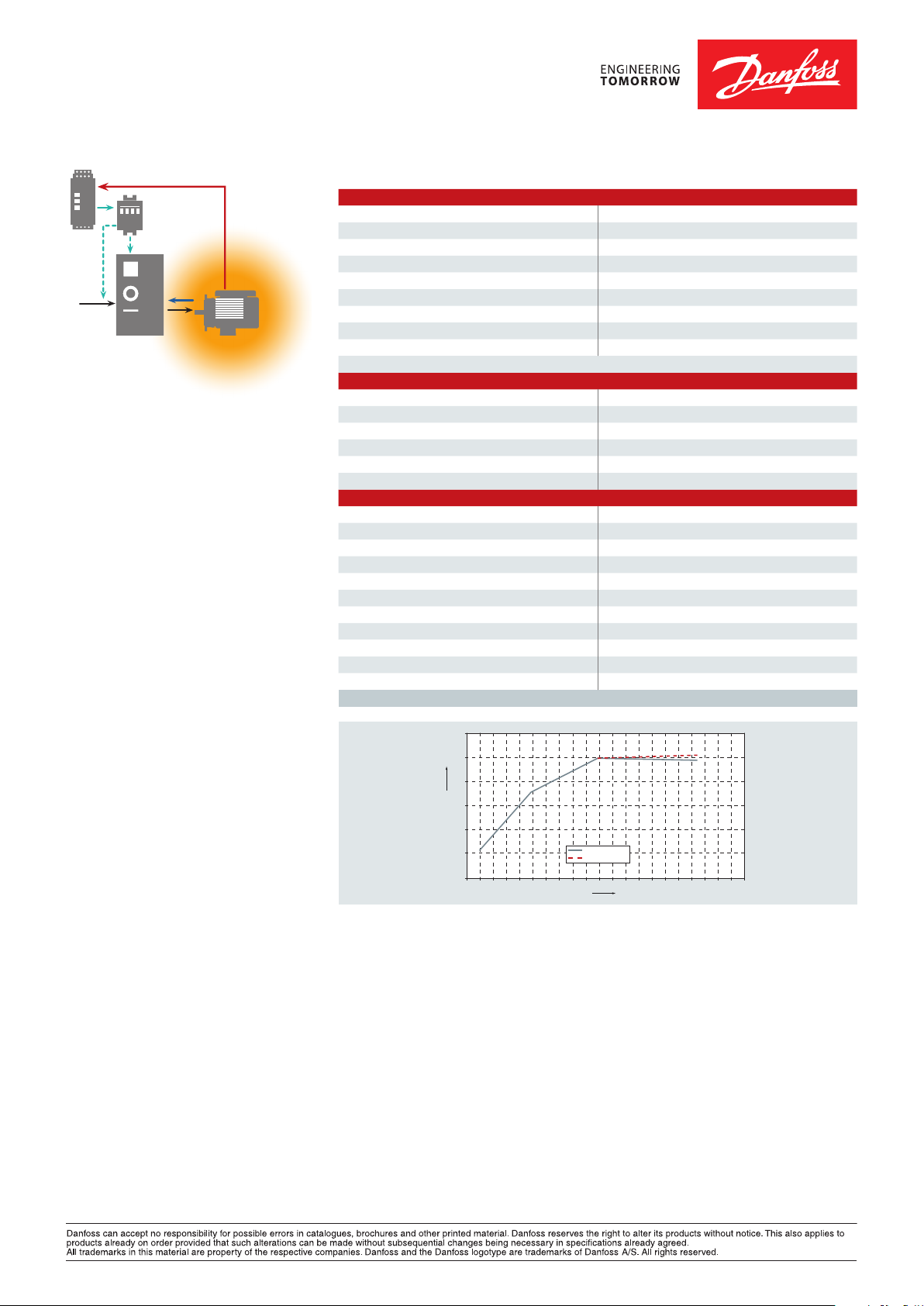

Thermistor relay

Contactor

Stop

Non-explosive hazard zone

ATEX

certified

motor

Explosive hazard zone

The integrated MCB 112 replaces external

components like thermistor relay, contactor and

wiring, since the drive communicates directly with

the motor.

Current limiting feature

VLT® AutomationDrive has a feature

that makes it possible to apply “Ex-e”

certified motors instead of the more

expensive “Ex-d” certified motors for

ignition protection. The combination of

the parameter setup and the MCB 112

ensures that the VLT® AutomationDrive

will never provide sufficient current to

cause the motor to overheat.

The feature is easy to use

Enter relevant data from the motor

name plate via variable speed current

limit parameters in the frequency

converter. From this data, the drive

creates an upper limit that limits the

current provided dependent upon the

motor speed.

Uncomplicated

Flexible use of speed control with

motors certified with increased safety

“e” ignition protection.

Compact

With increased safety “e” certification,

distinctly smaller frame size, lower

weight and lower costs compared

to speed control of motors with

flameproof enclosure “d” certification.

Flexible

Easy mix and match, resulting in

smaller stocks of motors and frequency

converters.

Specifications

PTC-thermistor connection

Monitoring function Temperature monitoring by means of PTC sensors

PTC compliant with DIN 44081, DIN 44082

Number of sensors in series Set with 3 -...6 resistors

Cut-out-point 3.3 kΩ .... 3.65 kΩ ... 3.85 kΩ

Reclosing point 1.7 kΩ .... 1.8 kΩ ... 1.95 kΩ

Collective resistance cold sensors < 1.65 kΩ

Terminal voltage (sensors) ≤ 2.5 V for R ≤ 3.65 kΩ, ≤ 9 V for R = ∞

Terminal current (sensors) ≤ 1 mA

Short circuit 20 Ω ≤ R ≤ 40 Ω

Max. sensor cable length for short-circuit detection 2 × 250 m with 0.5 mm

Testing conditions

EN 60 947-8

Rated impulse voltage 6000 V

Over voltage category III

Contamination level 2

EMC – Immunity industry standard EN61000-6-2

EMC – Emission industry standard EN61000-6-4

Safety-related parameters

EN 61508 for Ta = 40° C ongoing

SIL 2

HFT Type A

PFD (test interval one year) 3,37E-04

SFF 78%

λ

SD

λ

SU

λ

DU

2,35E-07

3,73E-08

7,69E-08

MTBF 179 years

Operating mode Low demand mode

Hardware architecture 1oo1

Ordering number: 130B1137

1.1

1

0.9

0.8

I/In

0.7

0.6

0.5

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105

Incorrect area

Correct area

Star connection

Delta connection

f/Hz

Variable speed current limitation, from the EC type-e xamination certifi cate of the Ex e motor. Enter the relevant

information from the motor nameplate into the control panel of the drive. Then the drive will calculate max.

current in relation to the motor speed. The curve represents the limit under which the current must be kept to

prevent overheating of the motor. The nodes for the curves are determined by measurement from the Ex

notifi ed body. With a second protective device like the MCB 112, direct temperature monitoring is possible via a

triple PTC thermistor circuit. Direct temperature monitoring also detects malfunctions such as blocked

ventilation or inadmissibly high ambient temperatures.

Economical

Lower investment costs enable faster

payback when speed control is used to

achieve energy savings.

No need for matched pairs

Suitable for operation of Ex d, Ex e, Ex n,

Ex tb and Ex tc certified motors without

the need for matched pair motor-drive.

Universal

Universal solution for the entire power

range of 0.25 to 630 kW.

2

, 2 × 800 m with 1.5 mm

2

Danfoss VLT Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.danfoss.com/drives, E-mail: info@danfoss.com

DKDD.PFO.614.A1.02 © Copyright Danfoss Power Electronics | Danfoss VLT Drives PE-MSMBM | October 2014

Loading...

Loading...