Installation Instructions

VLT® Analog I/O Option MCB 109

FC Series FC 102, FC 103, and FC 202

These installation instructions provide information about instal-

lation and use of the VLT

instructions are targeted at users already familiar with the

®

HVAC Drive FC 102, VLT® Refrigeration Drive FC 103, or

VLT

®

AQUA Drive FC 202. Read the instructions before instal-

VLT

lation and ensure that instructions for safe installation are

observed.

Additional resources

Further manuals and instructions are available for download at

www.vlt-drives.danfoss.com/Products/Detail/TechnicalDocuments---contextless/.

®

Analog I/O Option MCB 109. The

Items supplied

The VLT® Analog I/O Option MCB 109 is available in a standard

version (code number 130B1143) and in a coated version

(code number 130B1243)

Items supplied

VLT® Analog I/O Option MCB 109

•

Extended LCP (local control panel) frame (for use

•

with enclosure sizes A2, A3, B3, and B4)

Terminal covers (various sizes for use with enclosure

•

sizes A2, A3, and B4)

Product Overview

Safety

Qualied Personnel

Only

qualied

equipment. Qualied personnel is dened as trained sta, who

are authorised to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the personnel must be familiar with

the instructions and safety measures described in the product

specic

personnel are allowed to install or operate this

operating instructions.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors, which

can remain charged even when the frequency converter is

not powered. Failure to wait the specied time after power

has been removed before performing service or repair work,

could result in death or serious injury.

1. Stop the motor.

2. Disconnect the AC mains, permanent magnet type

motors, and remote DC-link power supplies,

including battery back-ups, UPS, and DC-link

connections to other frequency converters.

3. Wait for the capacitors to discharge fully before

performing any service or repair work. The duration

of waiting time is specied in Ta bl e 2 .1 to Tabl e 2 .3 .

The VLT® Analog I/O Option MCB 109 increases the number of

available inputs and outputs at the frequency converter.

Additionally, it provides a battery back-up for the built-in clock

function in the frequency converter.

Features

3 analog inputs, each

•

and temperature input.

Connection of 0–10 V analog signals as well as

•

PT1000 and NI1000 temperature inputs.

3 analog outputs each congurable as 0–10 V

•

outputs.

Battery back-up for the built-in clock function in the

•

frequency converter. The back-up battery typically

lasts for 10 years, depending on environment.

congurable

as both voltage

Danfoss A/S © 04/2015 All rights reserved. MI38B302

Volt age [V]

4715

200-240 1.1–3.7 kW – 5.5–45 kW

380-480 1.1–7.5 kW – 11–90 kW

525-600 1.1–7.5 kW – 11–90 kW

525-690 – 1.1–.5 kW 11–90 kW

High voltage may be present even when the warning LED indicator

lights are o.

Tab le 2.1 Dis ch ar ge Time, VLT® HVAC Drive FC 102

Minimum waiting time (minutes)

Installation Instructions

®

Analog I/O Option MCB 109

VLT

FC Series FC 102, FC 103, and FC 202

Voltage [V]

415

200–240 1.1–3.7 kW 5.5–45 kW

380–500 1.1–7.5 kW 11–90 kW

525–600 1.1–7.5 kW 11–90 kW

High voltage may be present even when the warning LED indicator

lights are o.

Table 2.2 Discharge Time, VLT® Refrigeration Drive FC 103

Voltage [V]

4715

200–240 0.25–3.7 kW – 5.5–45 kW

380–480 0.37–7.5 kW – 11–90 kW

525–600 0.75–7.5 kW – 11–90 kW

525–690 – 1.1–7.5 kW 11–90 kW

High voltage may be present even when the warning LED indicator

lights are o.

Table 2.3 Discharge Time, VLT® AQUA Drive FC 202

Installation

Minimum waiting time (minutes)

Minimum waiting time (minutes)

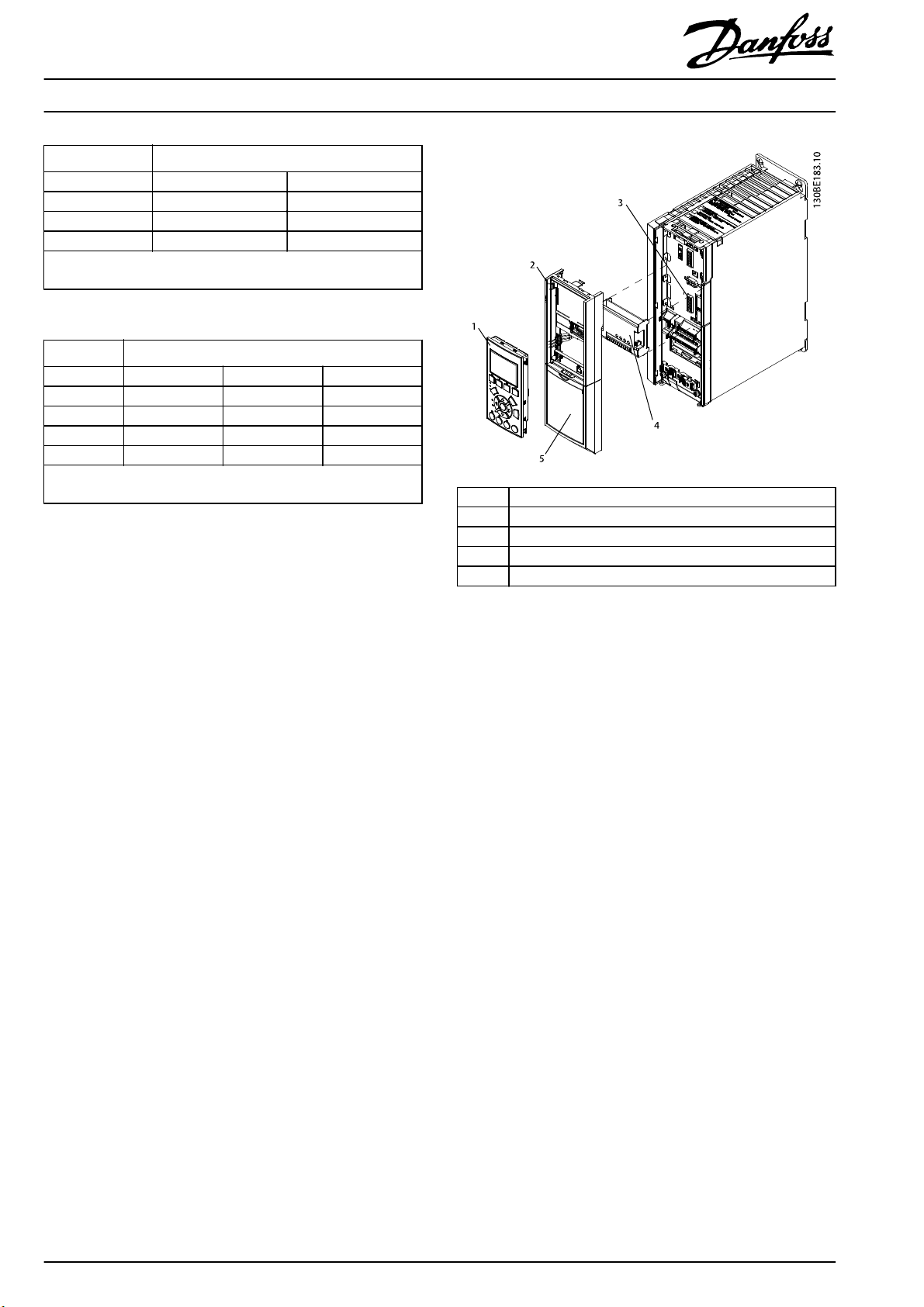

1LCP

2Terminal cover

3Slot B

4Option

5LCP frame

The installation procedure depends on the enclosure size of

the frequency converter.

Enclosure Sizes A2, A3, B3, and B4

1. Remove the LCP (local control panel), the terminal

cover, and the LCP frame from the frequency

converter.

2. Fit the option into slot B.

3. Connect the control cables and relieve the cable. See

Illustration 5.1 for details about wiring.

4. Remove the knock-out in the extended LCP frame

(supplied).

5. Fit the extended LCP frame and terminal cover on

the frequency converter.

6. Fit the LCP or blind cover in the extended LCP frame.

7. Connect power to the frequency converter.

Illustration 3.1 Installation in Enclosure Sizes A2, A3, B3, and B4

2

Danfoss A/S © 04/2015 All rights reserved. MI38B302

Installation Instructions

®

Analog I/O Option MCB 109

VLT

FC Series FC 102, FC 103, and FC 202

Enclosure Sizes A5, B1, B2, C, D, E, and F

1. Remove the LCP (local control panel) and the LCP

cradle.

2. Fit the option card into slot B.

3. Connect the control cables and relieve the cable. See

Illustration 5.1 for details about wiring.

4. Fit the cradle on the frequency converter.

5. Fit the LCP in the cradle.

Input X42/5. Refer to the programming guide, for

further details about programming of analog inputs.

To read the analog input values, go to parameter

•

group 18-3* Inputs & Outputs.

Analog Outputs

Analog outputs are used as voltage outputs.

Outputs are scalable by parameters for each output. VLT

Analog I/O Option MCB 109 analog output parameter options

are identical to the parameter options for the built-in analog

outputs of the frequency converter.

Conguring

To congure the analog outputs, go to parameter

•

groups for set-up: 26-4* Analog Out X42/7, 26-5*

Analog Out X42/9, and 26-6* Analog Out X42/11.

To read analog output values, go to parameter group

•

18-3* Inputs & Outputs.

®

Real-time Clock Back-up

1LCP

2LCP cradle

3Option

4Slot B

Illustration 3.2 Installation in Enclosure Sizes A5, B1, B2, C, D, E,

and F

Conguration

Analog Inputs

Analog inputs can be used as:

Voltage input.

•

Inputs are scalable by parameters for each input.

Temperature sensor input.

•

Input scaling is preset to necessary signal level for

specied

out value (°C or °F).

temperature span. Optional feedback read-

No further

I/O Option MCB 109 as a battery back-up.

The back-up battery typically lasts for 10 years, when the

frequency converter is operating at 40 °C ambient

temperature. If the battery pack back-up fails, replace the

analog I/O option.

conguration

is required to use the VLT® Analog

Conguring

To congure the analog inputs, go to parameter

•

groups 26-0* Analog I/O Mode, 26-1* Analog Input

X42/1, 26-2* Analog Input X42/3, and 26-3* Analog

MI38B302 Danfoss A/S © 04/2015 All rights reserved.

3

Specications

Block diagram

Specications

Used as

temperature sensor

input

Number of inputs 3 3

Terminal X42/1–6 X42/1–6

Voltage range – 0–10 V DC

Current range 0/4–20 mA (voltage

input 0–10 V)

Tem perat ur e senso r

Ω

at 0 °C)

(1000

– Pt1000 (according to

Accuracy

Tem perat ur e range

Resolution 11 bits 10 bits

Sampling 3 Hz 2.4 Hz

Maximum load –

Impedance –

Table 5.1 Analog Inputs

Ni1000 (according to

DIN 43760)

IEC 60751)

°C ±

1 Kelvin

-50

+150

°C ±

2 Kelvin

-50

°

C to +150 °C

Used as voltage input

–

–

–

0.2% of full scale at

calculated temperature

±

20 V continuously

5 k

Ω

Illustration 5.1 Block Diagram for VLT® Analog I/O Option MCB 109

Mounted in the Frequency Converter.

Number of outputs 3

Voltage level at analog output 0–10 V DC

Resolution 11 bits

Linearity 1% of full scale

Maximum load 1 mA

Table 5.2 An alog Outp ut s

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on

order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective companies. Danfoss

and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

MI38B302130R0322 04/2015

*MI38B302*

Loading...

Loading...