Page 1

Resolver Option MCB 103

VLT® AutomationDrive FC 300

MCB 103 Resolver Option is used for interfacing resolver

motor feedback to FC 300 AutomationDrive. Resolvers

are used basically as motor feedback device for

Permanent Magnet brushless synchronous motors.

When the Resolver option is ordered separately the kitWhen the Resolver option is ordered separately the kit

When the Resolver option is ordered separately the kit

When the Resolver option is ordered separately the kitWhen the Resolver option is ordered separately the kit

includes:includes:

includes:

includes:includes:

••

• Resolver Option MCB 103

••

• Enlarged LCP fixture and enlarged terminal cover

Selection of parameters: 17-5x resolver Interface.

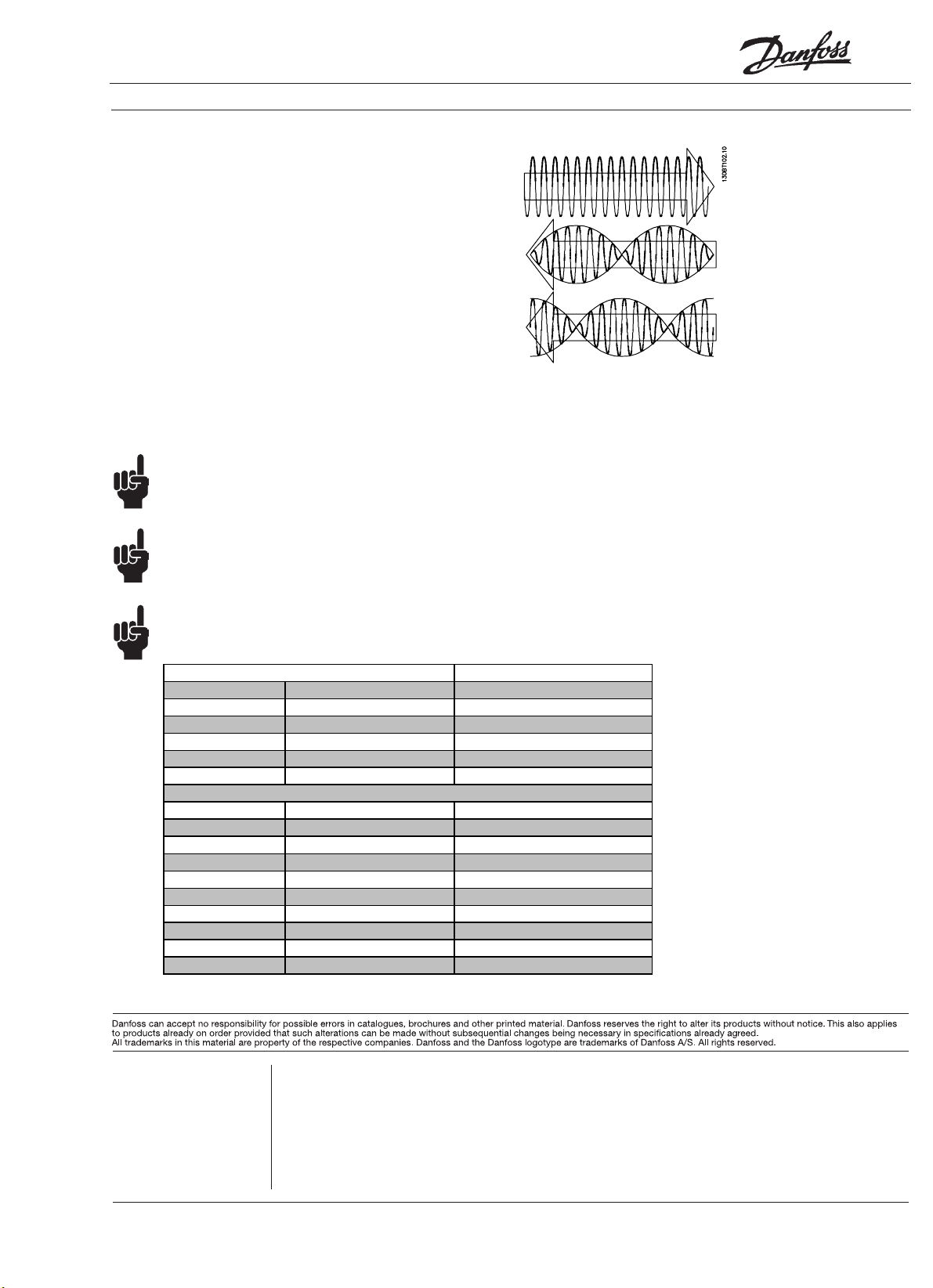

MCB 103 Resolver Option supports a various number of

resolver types.

Reso lver specifications:

Resolver poles

Resolver In put Voltage

Resolver Input Frequency

Transformation ratio

Secondary input voltage Max. 4 Vrms

Secondary load App. 10 k?

Par. 17-50: 2 *2

Par. 17-51: 2.0-8.0 Vrms *7.0 Vrms

Par. 17-52: 2-15 kHz *10.0 kHz

Par. 17-53: 0.1-1.1 *0.5

NB!NB!

NB!

NB!NB!

The resolver option MCB 103 can only be used with rotor-supplied resolver types.

Stator-supplied resolvers cannot be used.

MI.33.I1.02 - VLT is a registered Danfoss trademark

1

Page 2

VLT® AutomationDrive FC 300

A

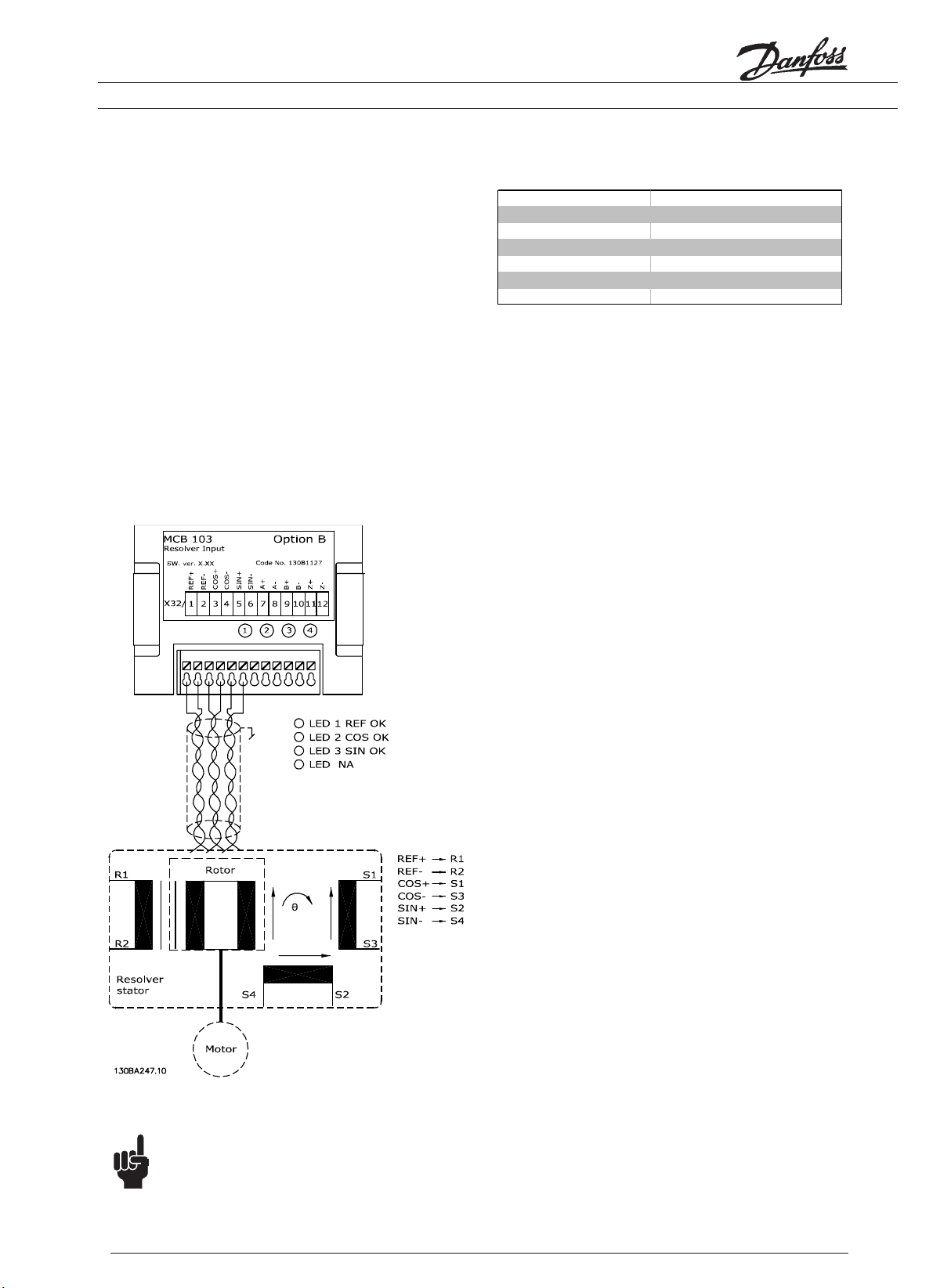

LED Indicators

LED 1 is on when the reference signal is OK to resolver

LED 2 is on when Cosinus signal is OK from resolver

LED 3 is on when Sinus signal is OK from resolver

The LEDs are active when par. 17-61 is set to Warning

or Trip.

Set-up example

In this example a Permanent Magnet (PM) Motor is used with the resolver as speed feedback. A PM motor

must usually operate in flux mode.

Wiring:Wiring:

Wiring:

Wiring:Wiring:

The max. cable length is 150 m when a twisted pair type of cable is used.

NB!NB!

NB!

NB!NB!

Resolver cables must be screened and separated from the motor cables.

NB!NB!

NB!

NB!NB!

The screen of the resolver cable must be correctly connected to the de-coupling

plate and connected to chassis (earth) on the motor side.

NB!NB!

NB!

NB!NB!

Always use screened motor cables and brake chopper cables.

Adjust following parameters:

Par. 1-00 Configuration Mode

Par. 1-01 Motor Control Principle Flux with feedback [3]

Par. 1-10 Motor Construction PM, non salient SPM [1]

Par. 1-24 Motor Current Nameplate

Par. 1-25 Motor Nominal Speed Nameplate

Par. 1-26 Motor Contr. Rated Torque Nameplate

MA is not possible on PM motors

Par. 1-30 Stator Resistance Motor data sheet

Par. 1-37 d-axis Inductance (Ld) Motor data shee t (mH)

Par. 1-39 Motor Poles Motor data sheet

Par. 1-40 Back EMF at 1000 RPM Motor data sheet

Par. 1-41 Motor Angle Offset Motor data sheet (Usually zero)

Par. 17-50 Poles Resolver data sheet

Par. 17-51 Input Voltage Resolver data sheet

Par. 17-52 Input Frequency Resolver data sheet

Par. 17-53 Transformation Ratio Resolver data sheet

Par. 17-59 Resolver Interface Enabled [1]

Speed closed loop [1]

130R0312

Rev. 2007-05-07

*MI33I102*

Loading...

Loading...