Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® DeviceNet Converter MCA 194

VLT® AutomationDrive FC 302 • VLT® 5000

www.danfoss.com/drives

Page 2

Page 3

Contents Operating Instructions

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Product Overview

1.4 Constraints

1.4.1 Software Versions 3

1.4.2 Relations 3

1.4.3 Hardware 4

1.4.4 Performance 5

1.5 Abbreviations

2 Safety

2.1 Safety Symbols

2.2 Qualified Personnel

2.3 Safety Precautions

3 Installation

3.1 Connecting the Bus Line

3

3

3

3

3

5

6

6

6

6

8

8

3.2 Mechanical Installation

3.3 EMC Precautions

4 Commissioning

4.1 Configure the DeviceNet Network

4.1.1 Setting the DeviceNet Address using the Hardware Switches 11

4.1.2 Setting the DeviceNet Address via 10-02 MAC ID 11

4.1.3 Start-up 12

4.2 LED Behaviour

4.3 Initialisation

5 Parameter Mapping Lists

5.1 VLT® 5000 Parameter Group 0

5.2 VLT® 5000 Parameter Group 1

5.3 VLT® 5000 Parameter Group 2

5.4 VLT® 5000 Parameter Group 3

5.5 VLT® 5000 Parameter Group 4

5.6 VLT® 5000 Parameter Group 5

8

10

11

11

12

13

14

14

16

19

22

30

35

5.7 VLT® 5000 Parameter Group 6

5.8 VLT® 5000 Parameter Group 7

5.9 VLT® 5000 Parameter Group 8

5.10 VLT® 5000 Parameter Group 9

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 1

37

39

40

41

Page 4

Contents Operating Instructions

6 Troubleshooting

6.1 Step-by-step Troubleshooting

Index

43

43

44

2 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 5

Introduction

1 Introduction

Operating Instructions

1

1

1.1 Purpose of the Manual

These Operating Instructions provide information for

installing and configuring the DeviceNet Converter option

MCA 194. The Operating Instructions also contain the

parameter mapping lists and troubleshooting information.

First-time users can find the most essential information for

quick installation and set-up in:

Chapter 1.3 Product Overview

•

Chapter 1.4 Constraints

•

Chapter 3 Installation

•

For more detailed information including the full range of

set-up options and diagnosis tools, refer to:

Chapter 4 Commissioning

•

Chapter 5 Parameter Mapping Lists

•

VLT® is a registered trademark.

1.2 Additional Resources

The following literature is available for the FC 300 series:

VLT® AutomationDrive Operating Instructions

•

VLT® AutomationDrive Design Guide

•

VLT® AutomationDrive Programming Guide

•

Supplementary publications and manuals are available for

download. See www.danfoss.com/BusinessAreas/DrivesSo-

lutions/Documentations/VLT+Technical+Documentation.htm

for listings.

1.3

Product Overview

The MCA 194 DeviceNet Converter is a DeviceNet option

when installed in VLT® AutomationDrive FC 302. It

emulates the DeviceNet commands of a VLT® 5000 in a

DeviceNet network.

NOTICE

Some parameters in the VLT® 5000 are not supported in

the FC 302 and some FC 302 parameters cannot be

accessed via the DeviceNet converter option MCA 194.

Refer to chapter 5 Parameter Mapping Lists for more

information. If a write request is attempted to a

parameter selection not supported, the frequency

converter discards the value and issues a positive reply.

Only parameters and functions described in this manual

are supported.

NOTICE

The replacement frequency converter must match the

power size of the motor for optimal performance. In

some cases a bigger frequency converter may be needed

to replace the VLT® 5000. Make sure that the brake

resistor matches the new frequency converter.

Make sure that the new frequency converter meets the

local regulations concerning the machinery directive,

prefuses, and other appropriate regulations.

NOTICE

Observe local rules and regulations when replacing

frequency converter in existing installations.

1.4 Constraints

1.4.1 Software Versions

VLT® AutomationDrive FC 302 with firmware

•

version 6.54 or higher.

The MCA 194 DeviceNet Converter firmware is

•

based on a VLT® 5000 software version 3.9x and

DeviceNet software version 2.x.

Relations

1.4.2

This manual relates to the following hardware:

VLT® DeviceNet Converter option MCA 194, type

With this DeviceNet converter option the FC 302 reacts as

a VLT® 5000 on the DeviceNet network. Changes to PLC

programming or re-configuration are normally not

necessary.

The FC 302 identifies itself as a VLT® 5000 on the

DeviceNet network. For example, a write command to

ramp-up time in VLT® 5000 is automatically linked to the

corresponding ramp-up time parameter in VLT

AutomationDrive FC 302.

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 3

®

•

no. 130B5601

VLT® General I/O option MCB 101, type no.

•

130B1125 (uncoated), 130B1212 (coated)

VLT® External 24 Volt DC Supply MCB 107, type

•

no. 130B1108 (uncoated), 130B1208 (coated)

Page 6

130BT310.11

Introduction Operating Instructions

1

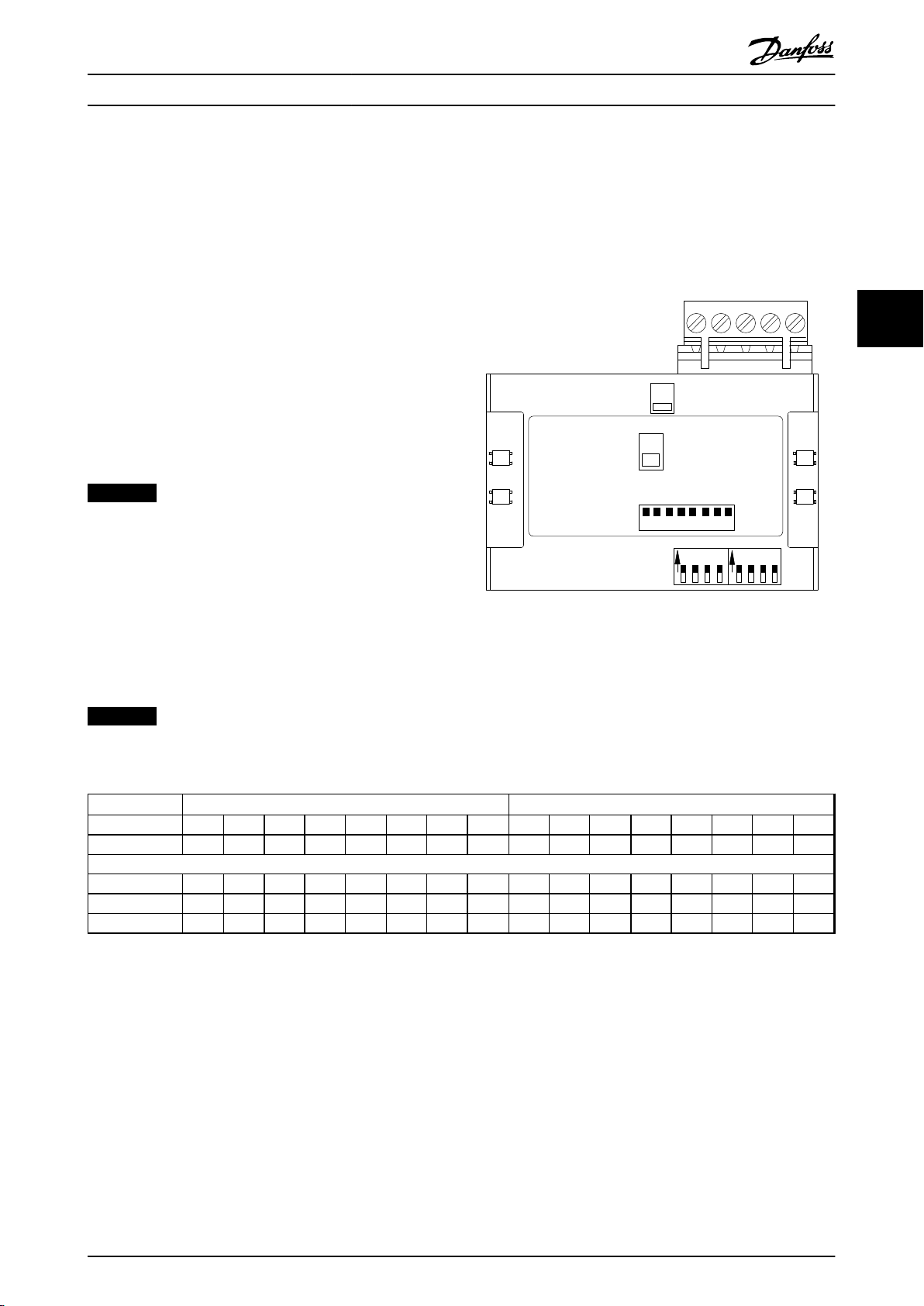

1.4.3 Hardware

The VLT® DeviceNet Converter MCA 194 supports

•

VLT® AutomationDrive FC 302 only.

The FC 302 has fewer digital I/Os and analog

•

output signals than VLT® 5000. The General I/O

Option MCB 101 must be mounted in the FC 302

to map these signals and utilise all I/Os.

VLT® 5000

Terminal Function Terminal Function

16 Digital input

17 Digital input

18 Digital input 18 Digital input

19 Digital input 19 Digital input

27 Digital input 27 Digital input

29 Digital input 29 Digital input

32 Digital input 32 Digital input

33 Digital input 33 Digital input

20 GND Digital

input

53 Analog input

voltage

54 Analog input

voltage

60 Analog input

current

55 GND analog/

digital input

voltage

42

39 GND analog/

04-05 Relay 04-06 Relay

01-03 Relay 01-03 Relay

68 RS-485-P 68 RS-485-P

69 RS-485-N 69 RS-485-N

61 GND RS-485 61 GND RS-485

12 24 V out 12 24 V out

13 24 V out 13 24 V out

50 10 V out 50 10 V out

Analog/digital

output

digital output

X30/2

X3/3

20 GND Digital input

53

X30/11

54

55 GND analog/digital

42 Analog output 0/4-20

X30/6

X30/7

39 GND analog /digital

FC 302

1)

1)

3)

1)

1)

Digital input

Digital input

Analog input voltage

Analog input voltage

Analog input current

input voltage

Digital output

Pulse output

mA

output

2)

Illustration 1.1 Location of Switches S801, S201, and S202 (Left

to Right)

3)

Table 1.1 Terminal Mapping

1) General I/O option MCB 101

2) Switch “S201” must be OFF

3) Switch “S202” must be ON

4 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 7

Introduction

Operating Instructions

1.4.4 Performance

The dynamic performance on the motor shaft in

•

the closed loop operation compared with VLT

5000 can be different in certain applications. If

necessary, adjust the PID controller manually.

The motor control algorithm of the VLT

•

AutomationDrive results in a better motor

performance compared to VLT® 5000.

®

®

NOTICE

Factory values:

After initialisation, most parameters are set to match the

factory settings of the VLT® 5000 parameters. For more

information about the initialisation, see the VLT

AutomationDrive FC 301/FC 302 Programming Guide.

®

NOTICE

Linked Set-ups:

To synchronise set-up changes made with running

motor, ensure that FC 302 set-ups are linked. This is

done in 0-12 This Set-up Linked to.

1

1

1.5 Abbreviations

AOC Application Oriented Control

CTW Control Word

EMC Electromagnetic Compatibility

I/O Input/Output

LED Light Emitting Diode

LSB Least Significant Bit

MAV Main Actual Value (actual output)

MOC Motor Oriented Control

MSB Most Significant Bit

MRV Main Reference Value (Setpoint)

N/A Not Applicable

PCD Peripherals Communication Data (process data)

PCV Parameter Characteristics Value (Parameter

channel)

PLC Programmable Logic Controller

PNU Parameter Number

PU Power Unit

REF Reference (= MRV)

STW Status Word

Table 1.2 Abbreviations

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 5

Page 8

Safety

2 Safety

Operating Instructions

22

2.1 Safety Symbols

The following symbols are used in this document:

WARNING

Indicates a potentially hazardous situation which could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which could

result in minor or moderate injury. It may also be used

to alert against unsafe practices.

NOTICE

Indicates important information, including situations that

may result in damage to equipment or property.

2.2 Qualified Personnel

Correct and reliable transport, storage, installation,

operation and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualified personnel is allowed to install or operate this

equipment.

Qualified personnel is defined as trained staff, who are

authorised to install, commission, and maintain equipment,

systems and circuits in accordance with pertinent laws and

regulations. Additionally, the personnel must be familiar

with the instructions and safety measures described in this

document.

2.3

Safety Precautions

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input power. Failure to perform

installation, start-up, and maintenance by qualified

personnel could result in death or serious injury.

Installation, start-up, and maintenance must be

•

performed by qualified personnel only.

Safety regulations

1. The frequency converter must be disconnected

from mains, if repair work is to be carried out.

Check that the mains supply has been disconnected and that the necessary time has passed

NOTICE

The function is initialised at 1.16 x rated motor current

and rated motor frequency. For the North American

market, the ETR functions provide class 20 motor

overload protection in accordance with NEC.

Warning against unintended start

before removing motor and mains plugs, see

Table 2.1.

2. The [Off] key does not disconnect the equipment

from mains and is thus not to be used as a safety

switch.

3. Establish correct protective earthing of the

equipment, protect the user against supply

voltage, and protect the motor against overload

in accordance with applicable national and local

regulations.

4. The earth leakage currents are higher than 3.5

mA.

5. Protection against motor overload is not included

in the factory setting. If this function is desired,

set 1-90 Motor Thermal Protection [4] ETR trip or

[3] ETR warning.

6. Do not remove the plugs for the motor and

mains supply while the frequency converter is

connected to mains. Check that the mains supply

has been disconnected and that the necessary

time has passed before removing motor and

mains plugs, see Table 2.1.

7. The frequency converter has more voltage inputs

than L1, L2 and L3, when load sharing (linking of

DC intermediate circuit) and external 24 V DC

have been installed. Check that all voltage inputs

have been disconnected and that the necessary

time has passed before commencing repair work,

see Table 2.1.

1. The motor can be brought to a stop with digital

commands, bus commands, references or a local

stop, while the frequency converter is connected

to mains. These stop functions are not sufficient

to prevent unintended starts.

2. While parameters are being changed, the motor

may start. Consequently, always press [Off].

3. A motor that has been stopped may start if faults

occur in the electronics of the frequency

converter, or if a temporary overload or a fault in

the supply mains or the motor connection ceases.

6 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 9

Safety Operating Instructions

WARNING

Touching the electrical parts may be fatal - even after

the equipment has been disconnected from mains.

2 2

Voltage [V]

200-240 0.25-3.7 kW 5.5-37 kW

380-480 0.25-7.5 kW 11-75 kW

525-600 0.75-7.5 kW 11-75 kW

525-690 11-75 kW

High voltage may be present even when the warning LED

indicator lights are off.

Table 2.1 Discharge Time

Also make sure that other voltage inputs have been

disconnected, such as external 24 V DC, load sharing

(linkage of DC intermediate circuit), as well as the motor

connection for kinetic back-up.

Minimum waiting time (minutes)

4 15

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 7

Page 10

130BD826.10

5 4 23 1

+24V

GND

Drain

CAN_LCAN_H

130BT318.11

Installation Operating Instructions

3 Installation

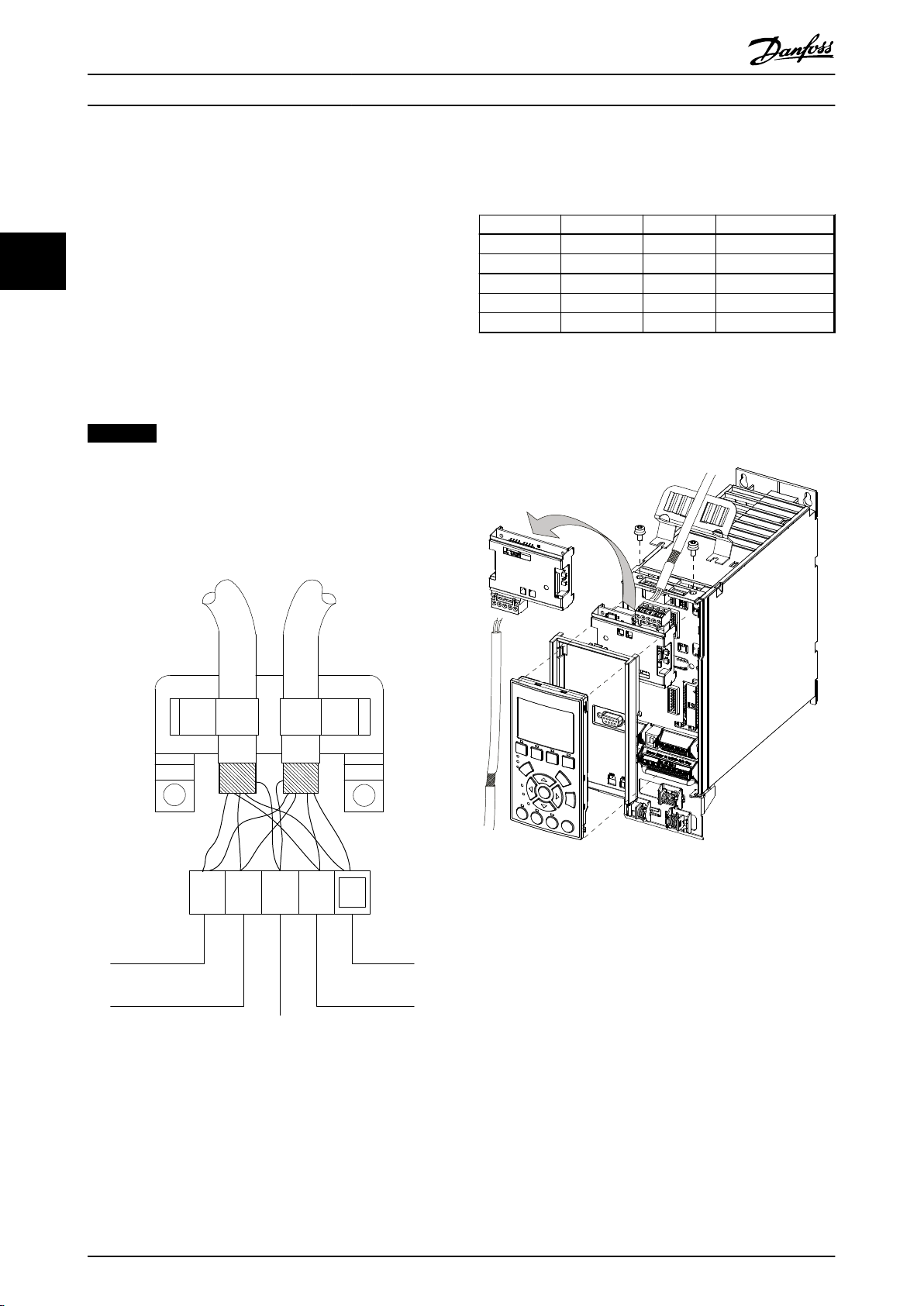

3.1 Connecting the Bus Line

33

Terminate the bus line at both ends of each segment. A

mismatch of impedance may result in reflections on the

line resulting in corrupt data transmission.

The DeviceNet Option Card contains a suitable termination.

To activate the termination, turn on Switch 1 on the

DeviceNet converter option. By default, the switch is

turned off.

NOTICE

Notice that pin numbers are colour-coded on the

DeviceNet connector.

Unlike the VLT

are colour-coded to avoid swapping the bus wires.

®

5000, the FC 302 DeviceNet connectors

Pin no. Terminal Colour Name

1 V- Black GND

2 CAN_L Blue CAN LOW

3 Drain (bare) Screen

4 CAN_H White CAN HIGH

5 V+ Red +24 V

Table 3.1 Correct Colour-Coding

3.2 Mechanical Installation

3.2.1 Mount the Option

Illustration 3.2 Installing Fieldbus Option

Illustration 3.1 Connecting Wires to VLT DeviceNet Converter

MCA 194

8 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 11

Installation Operating Instructions

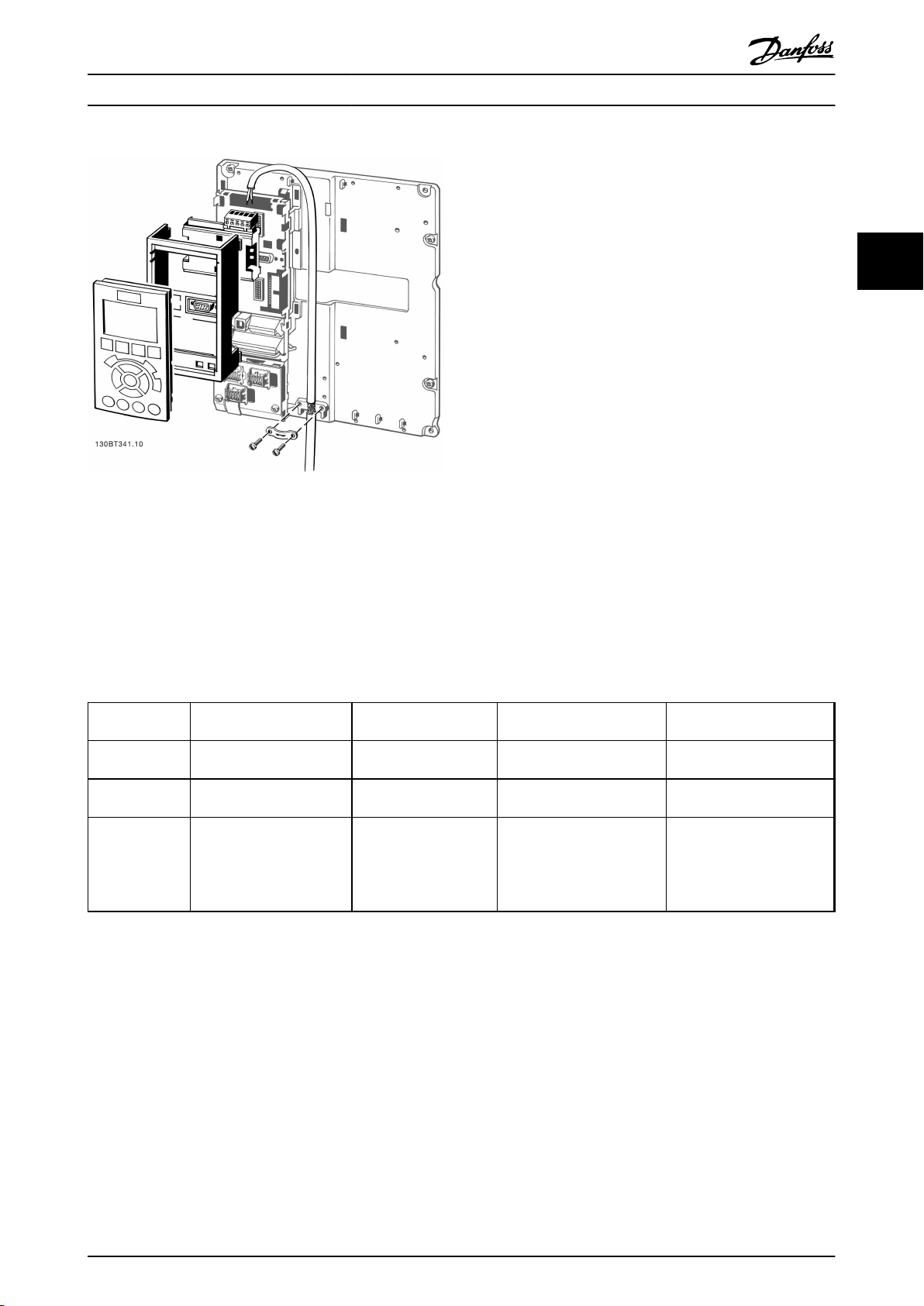

Illustration 3.3 Cable Holders

1. Remove the LCP from the FC 302.

2. Remove the frame below the LCP.

3. Push the option into place. 2 positions are

possible, with cable terminal facing either up or

down. The cable up position is often most

suitable when several frequency converters are

installed side-by-side in a rack, as this position

permits shorter cable lengths.

4. Push the fieldbus option adaptor frame for the FC

302 into place.

5. Remount the LCP.

6. Attach the cable.

7. Fasten the cable using cable holders.

3 3

Adapter Plate

3.2.2

To ease the replacement of VLT 5000 with VLT® AutomationDrive, there is a number of adapter plates available. The adapter

plates have the same footprints as VLT 5000 and have threaded holes for VLT® AutomationDrive. The adapter plate prevents

damage that can occur from drilling new threaded holes in the backboard of the enclosure. The adapter plate also

decreases the time required to exchange a broken frequency converter.

The following mechanical adapter plates are available:

Ordering

number

130B0183 Bookstyle, IP20 395 90

130B0184 Bookstyle, IP20 395 130

130B0185 Compact, IP20 395 220

Table 3.2 Ordering Numbers for Adapter Plates

Style Height [mm] Width [mm] Type

5001-5003 200-240 V

5001-5005 380-500 V

5004-5006 200-240 V

5006-5011 380-500 V

5001-5003 200-240 V

5001-5005 380-500 V

5004-5006 200-240 V

5006-5011 380-500 V

5001-5011 550-600 V

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 9

Page 12

Fieldbus cable

Min.200mm

90° crossing

130BA080.11

Installation Operating Instructions

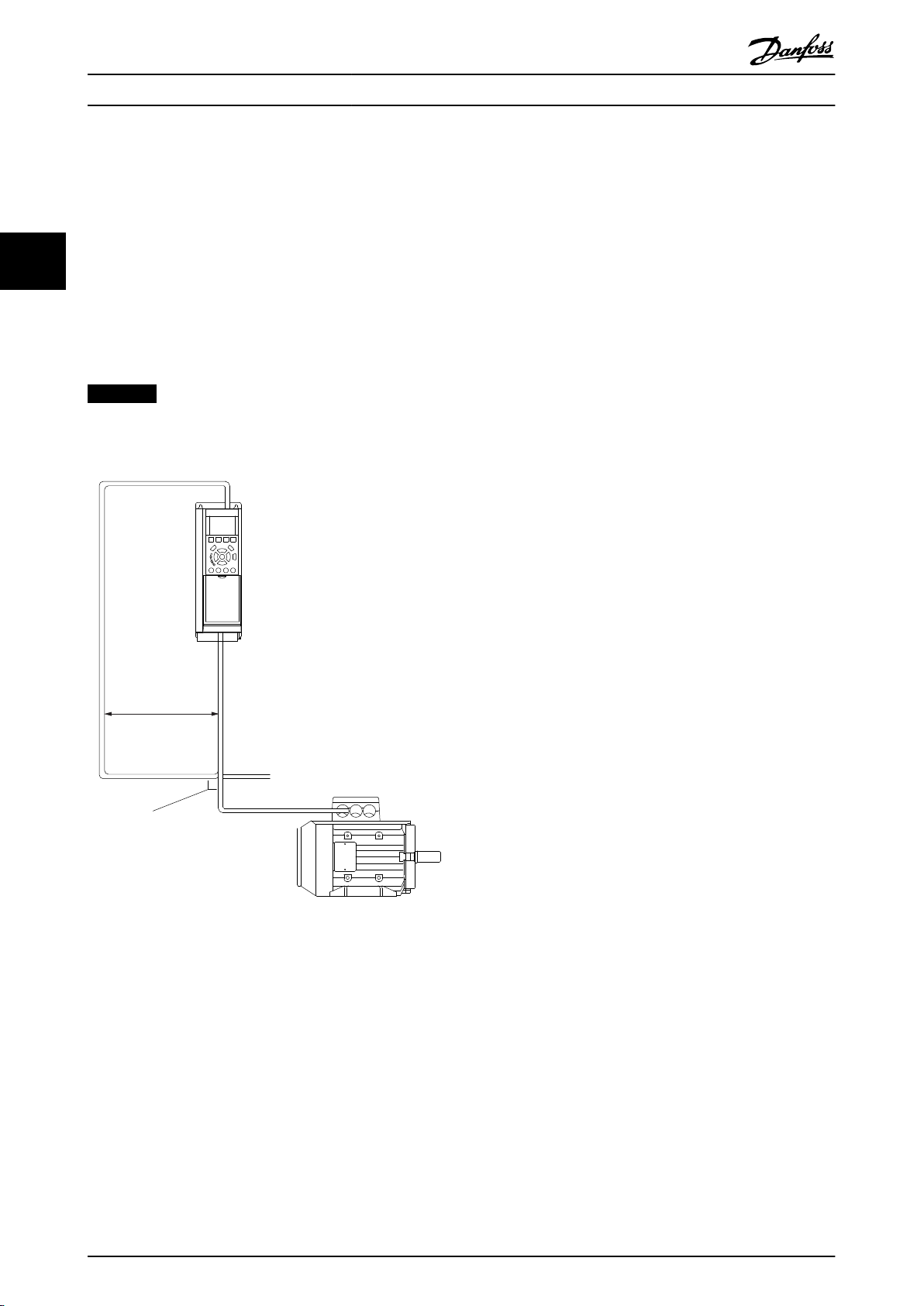

3.3 EMC Precautions

To achieve interference-free operation of the DeviceNet:

Maintain high distance (min. 200 mm [8"])

•

between the DeviceNet communication cable and

33

the motor and brake resistor cables to avoid

coupling of high frequency noise from one cable

to the other.

When crossing is unavoidable, ensure that the

•

DeviceNet cable crosses motor and brake resistor

cables at an angle of 90°.

NOTICE

Observe relevant national and local regulations, for

example regarding protective earth connection.

Illustration 3.4 Correct EMC Installation

10 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 13

130BD825.10

MCA 194

DeviceNet

Converter

MS

NS

Option A

130B5601

NS

MS

ON

OFF

S600

ON

OFF

ON

S300

ON ON

12345678

Commissioning Operating Instructions

4 Commissioning

4.1 Configure the DeviceNet Network

All DeviceNet stations connected to the same bus network

must have a unique station address.

Before a VLT® 5000 can be replaced with an FC 302 with

MCA 194, only the station address and baud rate needs to

be configured in the FC 302.

The DeviceNet address of the FC 302 can be selected via:

Hardware switches

•

Parameter 10-02 MAC ID (default 63)

•

Class code 0X03, Instance 1, Attribute 1

•

NOTICE

After installing DeviceNet Converter MCA 194, check that

8-02 Control Source is set to [3] Option A.

4.1.1 Setting the DeviceNet Address using

the Hardware Switches

Read the hardware switches during power-up. When

switches are changed, perform a power down-up

immediately to activate the changes.

Using the hardware switches, select an address range from

0 to 63 (factory setting 63) according to Illustration 4.1: ON

= 1, OFF = 0

4 4

Illustration 4.1 DeviceNet Converter Option A

NOTICE

The address change comes into effect at the next powerup, and can be read in 10-02 MAC ID.

Switch 1 2 3 4 5 6 7 8 8 7 6 5 4 3 2 1

Address +32 +16 +8 +4 +2 +1 - - - - +32 +16 +8 +4 +2 +1

Example:

1 0 0 0 0 0 1 - - - - 0 0 0 0 0 1

35 1 0 0 0 1 1 - - - - 1 0 0 0 1 1

52 1 1 0 1 0 0 - - - - 1 1 0 1 0 0

Table 4.1 Hardware Switches

VLT® 5000

4.1.2 Setting the DeviceNet Address via

10-02 MAC ID

Setting the address via parameter 10-02 MAC ID or the

DeviceNet Class code 0X03, Instance 1, Attribute 1, is

possible, if the hardware switches are all set in the "On"

position. The new address becomes active at the next

power-up.

FC 302

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 11

Page 14

Commissioning Operating Instructions

4.1.3 Start-up

communication between the master and the frequency

converter is established. If the NS LED flashes, the

After setting the station address from VLT® 5000 to VLT

®

master/PLC has not recognised the frequency converter.

AutomationDrive, cycle power on the frequency converter

to activate the new address. The master/PLC now

recognises the frequency converter as VLT® 5000. A solid

For more information, refer to chapter 6.1 Step-by-step

Troubleshooting.

green NS LED on the MCA 194 option indicates that

44

4.2 LED Behaviour

The option has 2 bi-coloured LEDs, as shown in Table 4.2. The status of the LEDs is shown in Table 4.3 and Table 4.4.

LED label Description

NS Network Status

MS Module Status ( DP-V1 communication)

Table 4.2 Bi Coloured LEDs

State Bi-colour LED Status

No Power Off There is no power applied to the option

Device

operational

Standby Green The DeviceNet option needs commis-

Minor fault Red Recoverable fault.

Green The DeviceNet option is operating in

normal condition.

sioning due to configuration missing,

incomplete or incorrect.

Unrecoverable

fault

Self test Green The DeviceNet option is in Self-test

Table 4.3 LED: Module Status (MS)

State Bi-colour LED Status

No Power/Not online

On-line, not

connected

On-line and

connected

Connection timeout

Critical link failure Red

Table 4.4 LED: Network Status (NS)

Red Unrecoverable fault, may need

replacing.

mode.

Red

Off The option has not completed

“Duplicate MAC ID” test yet or may not

be powered.

Green The option is on-line, but not allocated

to a master.

Green The DeviceNet option is on-line and

connected to a master.

Red One or more I/O connections are in

time-out state.

NOTICE

The LED status patterns of the MCA 194 are not compatible with the patterns of the VLT® 5000 DeviceNet LEDs.

12 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 15

Commissioning

Operating Instructions

4.3 Initialisation

To achieve the best performance, initialise the frequency converter after the option is mounted. If the frequency converter is

delivered from factory with the option installed, skip this step. The initialisation is done via 14-22 Operation Mode or a 3finger reset. The parameters of the FC 302 are set to factory values, and a number of FC 302 parameters are set to values

that match the VLT® 5000 initial values.

Factory copy via VLT® 5000 parameter 006 is supported and initialises the FC 302 and also set it to the VLT® 5000 default

settings.

Table 4.5 lists the parameter settings created during initialisation.

Parameter Initialisation setting

0-02 Motor Speed Unit [Hz]

1-52 Min Speed Normal Magnetising [Hz] 1.0 Hz

3-16 Reference 2 Source [0] No function

4-12 Motor Speed Low Limit [Hz] 132.0 Hz

3-00 Reference Range min – max

3-01 Reference/Feedback Unit [1] %

3-11 Jog Speed [Hz] 10.0 Hz

4-30 Motor Feedback Loss Function [0] Disabled

4-56 Warning Feedback Low -4000000

4-57 Warning Feedback High 4000000

6-10 Terminal 53 Low Voltage 0.00 Volt

6-20 Terminal 54 Low Voltage 0.00 Volt

6-22 Terminal 54 Low Current 0.00 Volt

5-51 Term. 29 High Frequency 5000 Hz

5-56 Term. 33 High Frequency 25000 Hz

4-32 Motor Feedback Loss Timeout 1.00 s

14-21 Automatic Restart Time 5 s

14-03 Overmodulation [0] Off

20-93 PID Proportional Gain 0.01

8-54 Reversing Select [0] Digital input

8-90 Bus Jog 1 Speed 300 RPM

8-91 Bus Jog 2 Speed 300 RPM

7-04 Speed PID Differentiation Time OFF

2-10 Brake Function [0] Off

2-17 Over-voltage Control [0] Off

5-40 Function Relay [22] Ready, no thermal Warning

5-41 On Delay, Relay [23] Remote, ready, no TW

7-09 Speed PID Error Correction w/ Ramp 100000 (max)

14-11 Mains Voltage at Mains Fault calculated value: VLT5000 level = FC 302 level

* 1,35 / sqrt(2)

MCB 101 option specific parameters

5-16 Terminal X30/2 Digital Input [1] Reset

5-17 Terminal X30/3 Digital Input [19] Freeze reference

PROFIBUS specific parameters

9-71 Profibus Save Data Values [1] Store all setups

4 4

Table 4.5 Parameter Set-up at Initialisation

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 13

Page 16

Parameter Mapping Lists

5 Parameter Mapping Lists

Operating Instructions

5.1

VLT® 5000 Parameter Group 0

Parameter 001 Language select 0-01 Language

Options [0] English [0] English

55

Table 5.1 Conversion of Parameter 001

Parameter 002 Local/remote control Not converted

Options [0] Remote

Table 5.2 Conversion of Parameter 002

Parameter 003 Local reference Not converted

Table 5.3 Conversion of Parameter 003

Parameter 004 Active Set-up 0-10 Active Set-up

Options [0] Factory Setup [0] Factory Setup

Table 5.4 Conversion of Parameter 004

Parameter 005 Setup Copy 0-51 Set-up Copy

Options [0] Factory Set-up [0] Factory Set-up

Table 5.5 Conversion of Parameter 005

VLT 5000 series FC 302 series

[1] Deutsch [1] Deutsch

[2] French [2] French

[3] Dansk [3] Dansk

[4] Spanish [4] Spanish

[5] Italian [5] Italian

VLT 5000 series FC 302 series

[1] Local with External Stop

[2] Local

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

[1] Setup 1 [1] Setup 1

[2] Setup 2 [2] Setup 2

[3] Setup 3 [3] Setup 3

[4] Setup 4 [4] Setup 4

[5] Multi Setup [9] Multi Setup

VLT 5000 series FC 302 series

[1] Setup 1 [1] Setup 1

[2] Setup 2 [2] Setup 2

[3] Setup 3 [3] Setup 3

[4] Setup 4 [4] Setup 4

[5] Active Setup [9] Active Setup

Parameter 006 Setup Copy 0-51 Set-up Copy

Options [0] No Copy [0] No Copy

Table 5.6 Conversion of Parameter 006

Parameter 007 LCP Copy Not converted

Table 5.7 Conversion of Parameter 007

Parameter 008 Display scaling of motor

Table 5.8 Conversion of Parameter 008

Parameter

number

Parameter

number

Parameter

number

Parameter

number

Options [0] None [0] None

VLT 5000 series FC 302 series

[1] [1]

[2] [2]

[3] [3]

[4] [4]

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Not converted

frequency

VLT 5000 series FC 302 series

009 Display line 0-23

010 Display line 0-20

011 Display line 0-21

012 Display line 0-22

[1] Reference % [1602] Reference %

[2] Reference [Unit] [1601] Reference

[Unit]

[3] Feedback [Unit] [1652] Feedback [Unit]

[4] Frequency [Hz] [1613] Frequency [Hz]

[5] Frequency x scale [1609] Custom

readout

[6] Motor current [A] [1614] Motor current

[A]

[7] Torque [%] [1622] Torque [%]

[8] Power [kW] [1610] Power [kW]

[9] Power [HP] [1611] Power [HP]

[10] Output energy [kWh] [1502] kWh counter

[kWh]

[11] Motor voltage [V] [1612] Motor voltage

[V]

Table 5.9 Conversion of Parameters 009 to 012

14 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 17

Parameter Mapping Lists

Operating Instructions

Parameter

number

Parameter

number

Parameter

number

Parameter

number

Options [12] DC link voltage

VLT 5000 series FC 302 series

009 0-09 Performance Monitor

010 0-10 Active Set-up

011 0-11 Programming Set-up

012 0-12 This Set-up Linked to

[V]

[13] Thermal load,

motor [%]

[14] Thermal load,

VLT® [%]

[15] Running hours

[hours]

[16] Digital input [1660] Digital input

[17] Analogue input

53 [V]

[18] Analogue input

54 [V]

[19] Analogue input

60 [mA]

[20] Pulse reference

[Hz]

[21] Ext. reference

[%]

[22] Status word

[hex]

[23] Brake effect/2

min [kW]

[24] Brake effect/sec

[kW]

[25] Heat sink temp. [1634] Heat sink temp.

[26] Alarm word

[hex]

[27] Control word

[hex]

[28] Warning word 1

[hex]

[29] Warning word 2

[hex]

[30] Com. Option

warning [hex]

[31] RPM [min] [1617] Speed RPM [min]

[32] RPM x scaling

[min]

[33] LCP display text Not possible

[1630] DC link voltage [V]

[1618] Thermal load, motor

[%]

[1635] Inverter thermal [%]

[1501] Running hours [hours]

[1662] Analogue input 53 [V]

[1664] Analogue input 54 [V]

[1662] Analogue input 53

[mA]

[1651] Pulse reference [Hz]

[1650] Ext. reference [%]

[1603] Status word [hex]

[1633] Brake effect/2 min

[kW]

[1632] Brake effect/sec [kW]

[1600] Control word [hex]

[953] Com. Option warning

[hex]

[1609] Custom readout

Parameter 013 Local Ctrl./config Not converted

Table 5.11 Conversion of Parameter 013

Parameter 014 Local Stop key 0-41 [Off] Key on LCP

Options [0] Disable [0] Disable

Table 5.12 Conversion of Parameter 014

Parameter 015 Local Jogging Not converted

Options [0] Disable

Table 5.13 Conversion of Parameter 015

Parameter 016 Local Reversing Not converted

Options [0] Disable

Table 5.14 Conversion of Parameter 016

Parameter 017 Local Stop key 0-43 [Reset] Key on LCP

Options [0] Disable [0] Disable

Table 5.15 Conversion of Parameter 017

Parameter 018 Lock for data

Options [0] Not locked [0] Full access

Table 5.16 Conversion of Parameter 018

Parameter 019 Power-Up Mode 0-04 Operating State at

Options [0] Auto Restart, use

Table 5.17 Conversion of Parameter 019

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

[1] Enable [1] Enable

[2] Password

VLT 5000 series FC 302 series

[1] Enable

VLT 5000 series FC 302 series

[1] Enable

VLT 5000 series FC 302 series

[1] Enable [1] Enable

[2] Password

VLT 5000 series FC 302 series

0-61 Access to Main Menu

change

[1] Lock [1] LCP: Read only

VLT 5000 series FC 302 series

saved ref.

[1] Forced stop, use

saved ref.

[2] Forced stop, set ref

= 0.

w/o Password

Power-up

[0] Resume

[1] Forced stop, use saved

ref.

[2] Forced stop, set ref = 0

5 5

Table 5.10 Conversion of Parameters 009 to 012

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 15

Page 18

Parameter Mapping Lists Operating Instructions

Parameter 027 Warning readout line Not converted

Options [0] Warning in line 1/2

Table 5.18 Conversion of Parameter 027

55

VLT 5000 series FC 302 series

[1] Warning in line 3/4

5.2

VLT® 5000 Parameter Group 1

Parameter 100 Configuration 0-02

Options [0] Speed control,

Table 5.19 Conversion of Parameter 100

Parameter 101 Torque charac-

Options [1] High constant

VLT 5000 series FC 302 series

1-01 Motor Control Principle

Par. 1-00 = [0] Speed open loop

open loop

[1] Speed control,

closed loop

[3] Process

control, closed

loop

[4] Torque control,

open loop

[5] Torque control,

speed feedback

VLT 5000 series FC 302 series

teristic

torque

[2] High variable

torque low

[3] High variable

torque medium

[4] High variable

torque high

[5] High special

motor characteristic

[6] High variable

torque with low

starting torque

Par. 1-01 = [1] VVC

Par. 0-02 = [0] RPM

Par. 1-00 = [1] Speed closed loop

Par. 1-00 = [3] Process

Par. 1-01 = [1] VVC

Par. 1-00 = [4] Torque open loop

Par.1-01 = [1] VVC

Par. 1-00 = [2] Torque close loop

Par. 1-01 = [3] Flux with motor fb

Par. 5-71 = [1] Counter clockwise

1-03 Torque Characteristics

1-04 Overload Mode

14-40 VT Level

Par. 1-03 = [0] Constant torque

Par. 1-04 Over load = [0] High

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 45%

Par. 1-04 Over load = [0] High

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 66%

Par. 1-04 Over load = [0] High

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 85%

Par. 1-04 Over load = [0] High

Par. 1-01 = [0] U/f

Par. 1-04 Over load = [0] High

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 45%

Par. 1-04 Over load = [0] High

+

+

+

Table 5.20 Conversion of Parameter 101

16 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 19

Parameter Mapping Lists

Operating Instructions

Parameter 101 Torque charac-

Options [7] High variable

VLT 5000 series FC 302 series

teristic

torque with

medium starting

torque

[8] High variable

torque with high

starting torque

[11] Normal

constant torque

[12] Normal

variable torque low

[13] Normal

variable torque

medium

[14] Normal

variable torque

high

[15] Normal special

motor characteristic

[16] Normal

variable torque

with low constant

starting torque

[17] Normal

variable torque

with medium

constant starting

torque

[18] Normal

variable torque

with high constant

starting torque

1-03 Torque Characteristics

1-04 Overload Mode

14-40 VT Level

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 66%

Par. 1-04 Over load = [0] High

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 85%

Par. 1-04 Over load = [0] High

Par. 1-03 = [0] Constant torque

Par. 1-04 Over load = [1] Normal

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 45%

Par. 1-04 Over load = [1] Normal

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 66%

Par. 1-04 Over load = [1] Normal

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 85%

Par. 1-04 Over load = [1] Normal

Par. 1-01 = [0] U/f

Par. 1-04 Over load = [1] Normal

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 45%

Par. 1-04 Over load = [1] Normal

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 66%

Par. 1-04 Over load = [1] Normal

Par. 1-03 = [1] Variable torque

Par. 14-40 VT level = 85%

Par. 1-04 Over load = [1] Normal

Parameter 105 Motor Current 1-24 Motor Current

Range Power Unit dependable Power Unit dependable

Table 5.25 Conversion of Parameter 105

Parameter 106 Rated motor speed 1-25 Motor Nominal Speed

Range 100 – 60000 10 – 60000

Table 5.26 Conversion of Parameter 106

Parameter 107 Automatic motor

Options [0] Adaptation off [0] Off

Table 5.27 Conversion of Parameter 107

Parameter 108 Stator resistor 1-30 Stator Resistance (Rs)

Range Power Unit dependable 0.0140 – 140.0000

Table 5.28 Conversion of Parameter 108

Parameter 109 Stator reactance 1-35 Main Reactance (Xh)

Range Power Unit dependable 1.0000 – 10000.0000

Table 5.29 Conversion of Parameter 109

Parameter 110 Motor magnetizing at

Range 0 – 300% 0 – 300%

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

1-29 Automatic Motor

adaptation

[1] Adaptation on, Rs

and Xs

[2] Adaptation on, RS [2] Enable reduce AMA

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

0 RPM

Adaptation (AMA)

[1] Enable complete AMA

1-50 Motor Magnetisation at Zero Speed

5 5

Table 5.21 Conversion of Parameter 101

Parameter 102 Motor Power 1-20 Motor Power [kW]

Range 0.18 – 600 kW 0.09 – 3000 kW

Table 5.22 Conversion of Parameter 102

Parameter 103 Motor Voltage 1-22 Motor Voltage

Range 200 – 600 Volt 50 – 1000 V

Table 5.23 Conversion of Parameter 103

Parameter 104 Motor frequency 1-23 Motor Frequency

Range 20 -1000 Hz 20-1000 Hz

Table 5.24 Conversion of Parameter 104

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 17

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Table 5.30 Conversion of Parameter 110

Parameter 111 Min. frequency

Range 0.1 – 10.0 Hz 0.3 – 10.0 Hz

Table 5.31 Conversion of Parameter 111

Parameter 113 Load compensation at

Range 0 – 300% 0 – 300%

Table 5.32 Conversion of Parameter 113

VLT 5000 series FC 302 series

low speed

VLT 5000 series FC 302 series

1-52 Min Speed

normal magnetizing

Normal Magnetising

[Hz]

1-60 Low Speed Load

Compensation

Page 20

Parameter Mapping Lists

Operating Instructions

Parameter 114 Load compensation at

Range 0 – 300% 0 – 300%

Table 5.33 Conversion of Parameter 114

Parameter 115 Slip Compensation 1-62 Slip Compensation

Range -500 - 500% -500 - 500%

Table 5.34 Conversion of Parameter 115

55

Parameter 116 Slip Compensation

Range 0.05 – 1.00 s 0.05 – 5.00 s

Table 5.35 Conversion of Parameter 116

Parameter 117 Resonance

Range 0 - 500% 0 - 500%

VLT 5000 series FC 302 series

1-61 High Speed Load

high speed

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Time constant

VLT 5000 series FC 302 series

dampening

Compensation

1-63 Slip Compensation

Time Constant

1-64 Resonance

Dampening

Parameter 121 Start function 1-72 Start Function

Options [0] DC hold in start delay

Table 5.40 Conversion of Parameter 121

Parameter 122 Function at stop 1-80 Function at Stop

Options [0] Coasting [0] Coast

VLT 5000 series FC 302 series

[0] DC hold/delay time

time

[1] DC brake in start delay

time

[2] Coasting in start delay

time

[3] Start frequency/voltage

clockwise

[4] Start frequency/voltage in

reference direction

[5] VVC+ clockwise [5] VVC+/Flux

VLT 5000 series FC 302 series

[1] DC hold [1] DC hold

[2] Motor check [2] Motor check

[3] Pre-magnetizing [3] Pre-magnetizing

[1] DC Brake/delay

time

[2] Coast/delay time

[3] Start speed cw

[4] Horizontal

operation

clockwise

Table 5.36 Conversion of Parameter 117

Parameter 118 Resonance

Range 5 – 50 ms 5 – 50 ms

Table 5.37 Conversion of Parameter 118

Parameter 119 High starting torque Not converted

Table 5.38 Conversion of Parameters 119

Parameter 120 Start delay

Option 0.0 – 10.0 s 0.0 – 10.0 s

Table 5.39 Conversion of Parameter 120

VLT 5000 series FC 302 series

1-65 Resonance

dampening time

constant

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Dampening Time Constant

1-71 Start Delay

Table 5.41 Conversion of Parameter 122

Parameter 123 Min frequency for

Range 0.0 – 10.0 Hz 0.0 – 20.0 Hz

Table 5.42 Conversion of Parameter 123

Parameter 124 DC holding

Range 0 - 100% 0 - 160% (motor depending)

Table 5.43 Conversion of Parameter 124

Parameter 125 DC braking current 2-01 DC Brake Current

Range 0 - 100% 0 – 160% P.U depending

Table 5.44 Conversion of Parameter 125

Parameter 126 DC braking time 2-02 DC Braking Time

Range 0.0 – 60.0 s 0.0 – 60.0 s

VLT 5000 series FC 302 series

1-82 Min Speed for

function at stop

VLT 5000 series FC 302 series

current

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Function at Stop [Hz]

2-00 DC Hold/Preheat

Current

Table 5.45 Conversion of Parameter 126

18 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 21

Parameter Mapping Lists

Operating Instructions

Parameter 127 DC brake cut-in

Range 0.0 (Off) – f

Table 5.46 Conversion of Parameter 127

Parameter 128 Motor thermal

Options [0] No protection [0] No protection

[1] Thermistor warning [1] Thermistor warning

[2] Thermistor trip [2] Thermistor trip

[3] ETR warning 1 [3] ETR warning 1

[4] ETR trip 1 [4] ETR trip 1

[5] ETR warning 2 [5] ETR warning 2

[6] ETR trip 2 [6] ETR trip 2

[7] ETR warning 3 [7] ETR warning 3

[8] ETR trip 3 [8] ETR trip 3

[9] ETR warning 4 [9] ETR warning 4

[10] ETR trip 4 [10] ETR trip 4

Table 5.47 Conversion of Parameter 128

VLT 5000 series FC 302 series

2-04 DC Brake Cut In

frequency

(par. 202) 0.0 (Off) – f

max

VLT 5000 series FC 302 series

protection

Speed [Hz]

1-90 Motor Thermal

Protection

max

(par. 414)

5.3

VLT® 5000 Parameter Group 2

Parameter 200 Output Frequency Range/

Options [0] Only clockwise, 0 – 132 Hz [0] Clockwise

[1] Both directions, 0 – 132 Hz [2] Both directions

[2] Only clockwise, 0 – 1000 Hz [0] Clockwise

[3] Both directions, 0 – 1000 Hz [2] Both directions

[4] Only counter clockwise, 0 –

[5] Only counter clockwise, 0 –

Table 5.52 Conversion of Parameter 200

Parameter 201 Output frequency

Range 0.0 – par. 202 F

Table 5.53 Conversion of Parameter 201

VLT 5000 series FC 302 series

4-10 Motor Speed

Direction

132 Hz

1000 Hz

VLT 5000 series FC 302 series

low limit

max

Direction

[1] Counter

clockwise

[1] Counter

clockwise

4-12 Motor Speed Low

Limit [Hz]

0 – par. 414 F

max

[Hz]

5 5

Parameter 129 External motor fan 1-91 Motor External Fan

Options [0] No [0] No

[1] Yes [1] Yes

Table 5.48 Conversion of Parameter 129

Parameter 130 Start frequency 1-75 Start Speed [Hz]

Range 0.0 – 10.0 Hz 0.0 – 500 Hz P.U depending

Table 5.49 Conversion of Parameter 130

Parameter 131 Initial voltage Not converted

Table 5.50 Conversion of Parameter 131

Parameter 145 Minimum DC brake time Not converted

Table 5.51 Conversion of Parameter 132

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Parameter 202 Output frequency

Range 0.0 – 132/1000 Hz 0 – 1000 Hz

Table 5.54 Conversion of Parameter 202

Parameter 203 Reference/feedback area 3-00 Reference Range

Options [0] Min – Max [0] Min – Max

Table 5.55 Conversion of Parameter 203

Parameter 204 Minimum

Range -100,000.000 – par.

Table 5.56 Conversion of Parameter 204

VLT 5000 series FC 302 series

4-14 Motor Speed High

high limit

VLT 5000 series FC 302 series

[1] - Max - +Max [1] - Max - +Max

VLT 5000 series FC 302 series

reference

205 Ref

Limit [Hz]

4-19 Max Output Frequency

3-02 Minimum

Reference

-100,000.000 – par.

max

3-03 Ref

max

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 19

Page 22

Parameter Mapping Lists

Operating Instructions

Parameter 205 Maximum

Range Par. 204 Ref

VLT 5000 series FC 302 series

3-03 Maximum Reference

reference

100,000.000

6-15 Terminal 53 High Ref./Feedb.

Value

6-25 Terminal 54 High Ref./Feedb.

Value

5-53 Term. 29 High Ref./Feedb.

Value

5-58 Term. 33 High Ref./Feedb.

Value

–

Par. 3-02 Ref

min

– 100,000.000

min

55

Table 5.57 Conversion of Parameter 205

Parameter 206 Ramp Type 3-40 Ramp 1 Type

Options [0] Linear Par. 3-40 = [0] Linear

Table 5.58 Conversion of Parameter 206

VLT 5000 series FC 302 series

3-50 Ramp 2 Type

3-82 Quick Stop Ramp Type

Par. 3-50 = [0] Linear

Par. 3-82 = [0] Linear

[1] Sine shape (S1) Par. 3-40 = [2] S-ramp Const Time

Par. 3-45 = 1%

Par. 3-46 = 25%

Par. 3-47 = 1%

Par. 3-48 = 25%

Par. 3-50 = [2] S-ramp Const Time

Par. 3-55 = 1%

Par. 3-56 = 25%

Par. 3-57 = 1%

Par. 3-58 = 25%

Par. 3-82 = [2] S-ramp Const Time

Par. 3-83 = 1%

Par. 3-84 = 25%

[2] Sin2 Shape

(S2)

Par. 3-40 = [2] S-ramp Const Time

Par. 3-45 = 25%

Par. 3-46 = 25%

Par. 3-47 = 25%

Par. 3-48 = 25%

Par. 3-50 = [2] S-ramp Const Time

Par. 3-55 = 25%

Par. 3-56 = 25%

Par. 3-57 = 25%

Par. 3-58 = 25%

Par. 3-82 = [2] S-ramp Const Time

Par. 3-83 = 25%

Par. 3-84 = 25%

Parameter 206

Options [0]

Table 5.59 Conversion of Parameter 206

Parameter 207 Ramp up Time 1 3-41 Ramp 1 Ramp Up Time

Range 0.05 – 3600.00 s 0.01 – 3600.00 s

Table 5.60 Conversion of Parameter 207

Parameter 208 Ramp down Time 1 3-42 Ramp 1 Ramp Down

Range 0.05 – 3600.00 s 0.01 – 3600.00 s

Table 5.61 Conversion of Parameter 208

Parameter 209 Ramp up Time 2 3-51 Ramp 2 Ramp Up Time

Range 0.05 – 3600.00 s 0.01 – 3600.00 s

VLT

5000

series

Ramp

Type

Linear

[3] Sin3

Shape

(S3)

[4] Sin2

filter

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

FC 302 series

3-40 Ramp 1 Type3-50 Ramp 2

Type3-82 Quick Stop Ramp Type

[0] Linear. Write to p.340, 350 and 382

Par. 3-40 = [2] S-ramp Const Time

Par. 3-45 = 50%

Par. 3-46 = 50%

Par. 3-47 = 50%

Par. 3-48 = 50%

Par. 3-50 = [2] S-ramp Const Time

Par. 3-55 = 50%

Par. 3-56 = 50%

Par. 3-57 = 50%

Par. 3-58 = 50%

Par. 3-82 = [2] S-ramp Const Time

Par. 3-83 = 50%

Par. 3-84 = 50%

Par. 3-40 = [2] S-ramp Const Time

Par. 3-45 = 25%

Par. 3-46 = 25%

Par. 3-47 = 25%

Par. 3-48 = 25%

Par. 3-50 = [2] S-ramp Const Time

Par. 3-55 = 25%

Par. 3-56 = 25%

Par. 3-57 = 25%

Par. 3-48 = 25%

Par. 3-82 = [2] S-ramp Const Time

Par. 3-83 = 25%

Par. 3-84 = 25%

Time

Table 5.62 Conversion of Parameter 209

Parameter 210 Ramp down Time 2 3-52 Ramp 2 Ramp Down

Range 0.05 – 3600.00 s 0.01 – 3600.00 s

Table 5.63 Conversion of Parameter 210

20 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

VLT 5000 series FC 302 series

Time

Page 23

Parameter Mapping Lists

Operating Instructions

Parameter 211 Jog ramp time 3-80 Jog Ramp Time

Range 0.05 – 3600.00 s 0.01 – 3600.00 s

Table 5.64 Conversion of Parameter 211

Parameter 212 Quick stop ramp

Range 0.05 – 3600.00 s 0.01 – 3600.00 s

Table 5.65 Conversion of Parameter 212

Parameter 213 Jog Frequency 3-11 Jog Speed [Hz]

Range 0.0 – par. 202 0.0 – par. 4-14

Table 5.66 Conversion of Parameter 213

Parameter 214 Reference function 3-04 Reference Function

Options [0] Sum [0] Sum

Table 5.67 Conversion of Parameter 214

*= Relative reference is added to the MRV from PROFIBUS.

Parameter 215 Preset Reference 1 3-10 Preset Reference

Range -100.00 – 100.00% -100.00 – 100.00%

Table 5.68 Conversion of Parameter 215

Parameter 216 Preset Reference 2 3-10 Preset Reference

Range -100.00 – 100.00% -100.00 – 100.00%

Table 5.69 Conversion of Parameter 216

Parameter 217 Preset Reference 3 3-10 Preset Reference

Range -100.00 – 100.00% -100.00 – 100.00%

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

3-81 Quick Stop Ramp

time

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

[1] Relative See comment below*

[2] External/Preset [2] External/Preset

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

Time

Parameter 221 Torque limit for

Range 0.0 – Max. torque % 0.0 – Max. torque %

Table 5.73 Conversion of Parameter 221

Parameter 222 Torque limit for

Range 0.0 – Max. torque % 0.0 – Max. torque %

Table 5.74 Conversion of Parameter 222

Parameter 223 Warning: Current

Range 0.0 – par. 2-24 Current

Table 5.75 Conversion of Parameter 223

Parameter 224 Warning: Current

Range Power Unit dependable Power Unit dependable

Table 5.76 Conversion of Parameter 224

Parameter 225 Warning Low

Range 0,0 – par. 226 0,0 – Par. 4-53

Table 5.77 Conversion of Parameter 225

Parameter 226 Warning High

Range par. 2-25 – par. 202 Par. 4-52 – par. 4-13

Table 5.78 Conversion of Parameter 226

VLT 5000 series FC 302 series

4-16 Torque Limit Motor

motor mode

VLT 5000 series FC 302 series

generating mode

VLT 5000 series FC 302 series

Low

High

VLT 5000 series FC 302 series

High

VLT 5000 series FC 302 series

Frequency

VLT 5000 series FC 302 series

Frequency

Mode

4-17 Torque Limit

Generator Mode

4-50 Warning Current Low

2-20 Release Brake Current

0.00 – par. 4-51

4-51 Warning Current

High

4-52 Warning Speed Low

2-22 Activate Brake Speed

[Hz]

4-53 Warning Speed High

5 5

Table 5.70 Conversion of Parameter 217

Parameter 218 Preset Reference 4 3-10 Preset Reference

Range -100,00 - 100,00% -100,00 - 100,00%

Table 5.71 Conversion of Parameter 218

Parameter 219 Catch up/slow

Range 0.00 – 100% 0.00 – 100%

Table 5.72 Conversion of Parameter 219

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 21

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

3-12 Catch up/slow Down

down value

Value

Parameter 227 Warning Low

Range -100,000.000 – par. 228 -999,999.999 – par. 4-57

Table 5.79 Conversion of Parameter 227

Parameter 228 Warning High

Range par. 227 – 100,000.000 Par. 4-56 – 999,999.999

Table 5.80 Conversion of Parameter 228

VLT 5000 series FC 302 series

4-56 Warning Feedback

Feedback

VLT 5000 series FC 302 series

Feedback

Low

4-57 Warning Feedback

High

Page 24

Parameter Mapping Lists

Operating Instructions

Parameter 229 Frequency bypass,

Range 0 - 100%

Table 5.81 Conversion of Parameter 229

Parameter 230 Frequency Bypass14-61 Bypass Speed From [Hz]

Range 0 – par. 200 0 – par. 4-14

55

Table 5.82 Conversion of Parameter 230

Parameter 2-31 Frequency Bypass24-61 Bypass Speed From [Hz]

Range 0 – par. 200 0 – par. 4-14

Table 5.83 Conversion of Parameter 231

Parameter 232 Frequency Bypass34-61 Bypass Speed From [Hz]

Range 0 – par. 200 0 – par. 4-14

Table 5.84 Conversion of Parameter 232

Parameter 233 Frequency Bypass44-61 Bypass Speed From [Hz]

Range 0 – par. 200 0 – par. 4-14

Table 5.85 Conversion of Parameter 233

Parameter 234 Motor phase

Range [0] Enable [2] Trip 1000 ms

Table 5.86 Conversion of Parameter 234

VLT 5000 series FC 302 series

Stored in EEprom only

bandwidth

VLT 5000 series FC 302 series

4-63 Bypass Speed To [Hz]

VLT 5000 series FC 302 series

4-63 Bypass Speed To [Hz]

VLT 5000 series FC 302 series

4-63 Bypass Speed To [Hz]

VLT 5000 series FC 302 series

4-63 Bypass Speed To [Hz]

VLT 5000 series FC 302 series

4-58 Missing Motor Phase

monitor

[1] Disable [0] Disable

Function

5.4

VLT® 5000 Parameter Group 3

Parameter 300 Terminal 16, input 5-16 Terminal X30/2 Digital

Options [0] No function [0] No function

Comments FC 302 does not have a digital input 16, so this is

Table 5.87 Conversion of Parameter 300

Parameter 301 Terminal 17, input 5-17 Terminal X30/3

Options [0] No function [0] No operation

Comments FC 302 does not have a digital input 17, so this is

VLT 5000 series FC 302 series

Input

[1] Reset [1] Reset

[2] Stop inverse [6] Stop inverse

[3] Only start clockwise,on[12] Enable start forward

[4] Jog [14] Jog

[5] Preset reference, on [15] Preset reference, on

[6] Preset reference, lsb [16] Preset reference bit 0

[7] Freeze reference [17] Freeze reference

[8] Freeze output [20] Freeze output

[9] Speed up [21] Speed up

[10] Choice of setup, lsb [23] Setup select bit 0

[11] Catch-up [28] Catch-up

[12] Ramp 2 [34] Ramp bit 0

[13] Mains failure

inverted

[29] Data change lock Not supported

linked to 5-16 Terminal X30/2 Digital Input

VLT 5000 series FC 302 series

[1] Reset [1] Reset

[2] Stop inverse [6] Stop inverse

[3] Only start

anticlockwise, on

[4] Jog [14] Jog

[5] Preset reference, on [15] Preset reference, on

[6] Preset reference, msb [17] Preset reference bit

[7] Freeze reference [19] Freeze reference

[8] Freeze output [20] Freeze output

[9] Speed down [22] Speed down

[10] Choice of setup, msb [24] Setup select bit 1

[11] Slow down [29] Slow down

[12] Ramp 2 [34] Ramp bit 0

[13] Mains failure inverted Not supported

[23] Pulse reference [32] Pulse input

[24] Safety interlock Not supported

[29] Data change lock Not supported

linked to 5-16 Terminal X30/2 Digital Input

Not supported

Digital Input

[13] Enable start reverse

1

Table 5.88 Conversion of Parameter 301

22 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 25

Parameter Mapping Lists

Operating Instructions

Parameter 302 Terminal 18, input 5-10 Terminal 18 Digital

Options [0] No function [0] No operation

Table 5.89 Conversion of Parameter 302

Parameter 303 Terminal 19, input 5-11 Terminal 19 Digital

Options [0] No function [0] No operation

Table 5.90 Conversion of Parameter 303

Parameter 304 Terminal 27, input 5-12 Terminal 27 Digital

Options [0] Coasting stop,

Table 5.91 Conversion of Parameter 304

VLT 5000 series FC 302 series

Input

[1] Start [8] Start

[2] Latched start [9] Latched start

[3] Only start clockwise,on[12] Enable start forward

VLT 5000 series FC 302 series

Input

[1] Reversing [10] Reversing

[2] Start reversing [11] Start reversing

[3] Only start

anticlockwise, on

VLT 5000 series FC 302 series

inverse

[1] Reset and Coasting

stop, inv.

[2] Quick-stop, inverse [4] Quick-stop, inverse

[3] DC-braking, inverse [5] DC-brake inverse

[4] Stop inverse [6] Stop inverse

[13] Enable start reverse

Input

[2] Coast inverse

[3] Coast and reset inv

Parameter 305 Terminal 29, input 5-13 Terminal 29 Digital

Options [0] No function [0] No operation

Table 5.92 Conversion of Parameter 305

Parameter 306 Terminal 32, input 5-14 Terminal 32 Digital

Options [0] No function [0] No operation

VLT 5000 series FC 302 series

Input

[1] Reset [1] Reset

[2] Stop inverse [6] Stop inverse

[3] Only start clockwise,on[12] Enable start forward

[4] Only start

anticlockwise, on

[5] Jog [14] Jog

[6] Preset reference, on [15] Preset reference, on

[7] Preset reference, lsb [16] Preset reference bit 0

[8] Preset reference, msb [17] Preset reference bit 1

[9] Freeze reference [19] Freeze reference

[10] Freeze output [20] Freeze output

[11] Speed up [21] Speed up

[12] Speed down [22] Speed down

[13] Choice of Setup, lsb [23] Setup select bit 0

[14] Choice of Setup, msb [24] Setup select bit 1

[15] Catch up [28] Catch up

[16] Slow down [29] Slow down

[17] Ramp 2 [34] Ramp bit 0

[18] Mains failure inverted Not supported

[28] Pulse reference [32] Pulse input

[29] Data change lock Not supported

VLT 5000 series FC 302 series

[1] Reset [1] Reset

[2] Stop inverse [6] Stop inverse

[3] Only start clockwise,on[12] Enable start forward

[13] Enable start reverse

Input

5 5

[4] Jog [14] Jog

[5] Preset reference, on [15] Preset reference, on

[6] Preset reference, lsb [16] Preset reference bit 0

[7] Freeze reference [19] Freeze reference

[8] Freeze output [20] Freeze output

[9] Speed up [21] Speed up

[10] Choice of Setup, lsb [23] Setup select bit 0

[11] Choice of Setup,

msb / Speed up

[12] Catch up [28] Catch up

[13] Ramp 2 [34] Ramp bit 0

[14] Mains failure

inverted

[24] Encoder input 2A [0] No operation

[29] Data change lock Not supported

Table 5.93 Conversion of Parameter 306

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 23

Not supported

Not supported

Page 26

Parameter Mapping Lists Operating Instructions

Parameter 307 Terminal 33, input 5-15 Terminal 33 Digital

Options [0] No function [0] No operation

55

Table 5.94 Conversion of Parameter 307

VLT 5000 series FC 302 series

Input

7-00 Speed PID Feedback

Source

[1] Reset [1] Reset

[2] Stop inverse [6] Stop inverse

[3] Only start

anticlockwise, on

[4] Jog [14] Jog

[5] Preset reference, on [15] Preset reference, on

[6] Preset reference, msb [17] Preset reference bit 1

[7] Freeze reference [19] Freeze reference

[8] Freeze output [20] Freeze output

[9] Speed down [22] Speed down

[10] Choice of Setup,

msb

[11] Choice of Setup,

msb / Speed down

[12] Slow down [29] Slow down

[13] Ramp 2 [34] Ramp bit 0

[14] Mains failure

inverted

[24] Pulse feedback [32] Pulse input,

[25] Encoder input 2B [0] No operation

[29] Data change lock Not supported

[13] Enable start reverse

[24] Setup select bit 1

Not supported

Not supported

Parameter 700 = [9]

Frequency input 33

Parameter 700 = [1] 24 V

encoder

Parameter 308 Terminal

Options [0] No

Table 5.95 Conversion of Parameter 308

Parameter 309 Terminal 53, min.

Range 0 – 10.0 Volt -10.00 – Par. 6-11

Table 5.96 Conversion of Parameter 309

Parameter 310 Terminal 53, max.

Range 0 – 10.0 Volt Par. 6-10 - 10.00 Volt

VLT 5000

series

53, Analogue

Input Voltage

Operation

[1] Reference Par. 3-15 Reference resource 1 set to

[2] Feedback

signal

[3] Torque

limit

[4] Thermistor Par. 3-15 Reference resource 1 set to

VLT 5000 series FC 302 series

scaling

VLT 5000 series FC 302 series

scaling

FC 302 series

3-15 Reference 1 Source

7-00 Speed PID Feedback Source

1-93 Thermistor Source

4-20 Torque Limit Factor Source

Par. 3-15 Reference resource 1 set to

[0] No function

[1] Analog input 53

Par. 3-15 Reference resource 1 set to

[1] Analog input 53

Par. 7-00 Speed PID Feedback Source

set to [6] Analog input 53

Par. 3-15 Reference resource 1 set to

[1] Analog input 53

Par. 4-20 Torque Limit Factor Source

set to [2] Analog in 53

[0] No function

Par. 1-93 Thermistor Ressource set to

[1] Analog input 53

6-10 Terminal 53 Low

Voltage

6-11 Terminal 53 High

Voltage

Table 5.97 Conversion of Parameter 310

24 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 27

Parameter Mapping Lists

Operating Instructions

Parameter 311 Terminal 54,

Options [0] No Operation Par. 3-16 Reference

VLT 5000 series FC 302 series

3-16 Reference 2

Analogue Input

Voltage

[1] Reference Par. 3-16 Reference

[2] Torque limit Par. 4-20 Torque

[3] Thermistor Par. 1-93 Thermistor

[4] Relative

reference

[5] Max. torque

frequency

Source

7-00 Speed PID

Feedback Source

4-20 Torque Limit

Factor Source

1-93 Thermistor

Source

4-21 Speed Limit

Factor Source

resource 2 set to [0]

No function

resource 1 set to [2]

Analog input 53

Limit Factor Source

set to [6] Analog in

54

Ressource set to [2]

Analog input 54

Not supported

Par. 4-21 Speed

Limit Factor Source

set to [6] Analog in

54

Parameter 314 Terminal 60,

Options [0] No

Comments The HW switch S202 for analogue input 54 must be

Table 5.101 Conversion of Parameter 314

Parameter 315 Terminal 60, min.

Range 0.0 – 20.0 mA 0.00 – Par. 6-23

VLT 5000 series FC 302 series

3-17 Reference 3 Source

Analogue Input

current

Operation

[1] Reference Par. 3-17 Reference resource 3 set

[2] Feedback

signal

[3] Torque limit Par. 3-17 Reference resource 3 set

[4] Relative

reference

set to current (ON).

VLT 5000 series FC 302 series

scaling

7-00 Speed PID Feedback Source

1-93 Thermistor Source

4-20 Torque Limit Factor Source

Par. 3-17 Reference resource 3 set

to [0] No function

to [2] Analog input 54 Par. 7-00

Speed PID

Feedback Source set to [7] Analog

input 54

Par. 7-00 Speed PID Feedback

Source set to [7] Analog input 54

to [2] Analog input 54 Par. 4-20

Torque Limit

Factor Source set to [6] Analog in

54

Not supported

6-22 Terminal 54 Low

Current

5 5

Table 5.98 Conversion of Parameter 311

Parameter 312 Terminal 54, min.

Range 0 – 10.0 Volt -10.00 – Par. 6-21

Table 5.99 Conversion of Parameter 312

Parameter 313 Terminal 54, max.

Range 0 – 10.0 Volt Par. 6-20 - 10.00 Volt

Table 5.100 Conversion of Parameter 313

VLT 5000 series FC 302 series

6-20 Terminal 54 Low

scaling

VLT 5000 series FC 302 series

scaling

Voltage

6-21 Terminal 54 High

Voltage

Table 5.102 Conversion of Parameter 315

Parameter 316 Terminal 60, max.

Range 0.0 – 20.0 mA Par. 6-22 - 20.00 mA

Table 5.103 Conversion of Parameter 316

Parameter 317 Time Out 6-00 Live Zero Timeout Time

Range 0 – 99 sec 0 – 99 sec

Table 5.104 Conversion of Parameter 317

VLT 5000 series FC 302 series

6-23 Teminal 54 High

scaling

VLT 5000 series FC 302 series

Current

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 25

Page 28

Parameter Mapping Lists Operating Instructions

Parameter 318 Function after time

VLT 5000 series FC 302 series

6-01 Live Zero Timeout

out

Function

Options [0] Off [0] Off

[1] Freeze output

frequency

[1] Freeze output

frequency

[2] Stop [2] Stop

[3] Jogging [3] Jog

[4] Max Speed, p202 [4] Max Speed

[5] Stop and trip [5] Stop and trip

VLT 5000 series FC 302 series

Parameter 319 Terminal 42,

Output

Parameter 321 Terminal 45,

Output

Digital = Par. 5-32 DO X30/7

(MCB 101)

Analogue values= Par. 6-50 AO

42

Pulse = Par. 5-66 DO X30/6

Digital = Par. 5-33 DO X30/7

(MCB 101)

Analogue values= Par. 6-60 AO

X30/8

Pulse = Par. 5-66 DO X30/6

Table 5.105 Conversion of Parameter 318

55

Parameter 319 Terminal 42,

VLT 5000 series FC 302 series

Digital = Par. 5-32 DO X30/7

Output

(MCB 101)

Options [15] Out of

frequency range

[16] Over f low Par. 5-32 = [16] Below speed

[17] Under f high Par. 5-32 = [17] Above speed

Analogue values = Par. 6-50 AO

42

Pulse = Par. 5-66 DO X30/6

Parameter 321 Terminal 45,

Output

Digital = Par. 5-33 DO X30/7

(MCB 101)

Analogue values= Par. 6-60 AO

X30/8

Pulse = Par. 5-66 DO X30/6

Options [0] No function Par. 5-32 = [0] No operation

[1] Control Ready Par. 5-32 = [1] Control Ready

[2] Ready signal Par. 5-32 = [2] Drive ready

[3] Ready - Remote

Par. 5-32 = [3] Drive rdy/rem ctrl

Control

[4] Enabled, no

warning

[5] Running

[6] Running, no

Warning

[7] Running within

range, no Warning

[8] Run at

reference, no

Par. 5-32 = [4] Enable / no

warning

Par. 5-32 = [5] VLT® running

Par. 5-32 = [6] Running /no

warning

Par. 5-32 = [7] Run in range/no

warning

Par. 5-32 = [8] Run on ref/no

warning

Warning

Table 5.107 Conversion of Parameters 319 to 321

[18] Out of feedback

range

[19] Over feedback

low

[20] Under feedback

high

[21] Thermal

warning

[22] Ready, no

thermal warning

[23] Ready - remote

control - no thermal

warning

[24] Ready – mains

voltage within range

[25] Reversing Par. 5-32 = [25] Reverse

[26] Bus OK Par. 5-32 = [26] Bus OK

[27] Torque limit

and stop

Par. 5-32 = [15] Out of speed

range

1)

low

1)

high

Par. 5-32 = [18] Out of feedb.

Range

Par. 5-32 = [19] Below

feedback low

1)

Par. 5-32 = [20] Above

feedback high

1)

Par. 5-32 = [21] Thermal

warning

Par. 5-32 = [12] Ready,no

thermal W

Par. 5-32 = [23] Remote, ready,

no TW

Par. 5-32 = [24] Ready, Voltage

OK

Par. 5-32 = [27] Torque limit &

stop

[9] Alarm Par. 5-32 = [9] Alarm

[10] Alarm or

Warning

Par. 5-32 = [10] Alarm or

Warning

[11] Torque limit Par. 5-32 = [11] At torque limit

[12] Out of current

range

Par. 5-32 = [12] Out of current

range

[13] Above I low Par. 5-32 = [13] Below current,

1)

low

[14] Under I high Par. 5-32 = [14] Above current,

1)

high

Table 5.106 Conversion of Parameters 319 to 321

26 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 29

Parameter Mapping Lists

Operating Instructions

Parameter 319 Terminal 42, Output Digital = Par. 5-32 DO

Parameter 321 Terminal 45, Output Digital = Par. 5-33 DO

Options [28] Brake, no brake

Table 5.108 Conversion of Parameters 319 to 321

VLT 5000 series FC 302 series

X30/7 (MCB 101)

Analogue values= Par. 6-50

AO 42

Pulse = Par. 5-66 DO X30/6

X30/7 (MCB 101)

Analogue values= Par. 6-60

AO X30/8

Pulse = Par. 5-66 DO X30/6

Par. 5-32 = [28] Brake, no

warning

[29] Brake ready, no

fault

[30] Brake fault Par. 5-32 = [30] Brake fault

[31] Relay 123 Par. 5-32 = [31] Relay 123

[32] Mechanical brake

control

[34] Extended

mechanical brake

control

[35] Safety Interlock Not supported

[36] 0 – 100 Hz ⇒ 0 – 20

mA

[37] 0 – 100 Hz ⇒ 4 – 20

mA

[38] 0 – 100 Hz ⇒ 0 –

32000 p

[39] 0 – f max ⇒ 0 – 20

mA

[40] 0 – f max ⇒ 4 – 20

mA

[41] 0 – f max ⇒ 0 –

32000 p

[42] Ref min – Ref max

⇒ 0 – 20 mA

brake warning

Par. 5-32 = [29] Brake

ready, no fault

(IGBT)

Par. 5-32 = [32] Mech

brake ctrl

Par. 5-32 = [32] Mech

brake ctrl

Not supported

Not supported

Not supported

Par. 6-50 = [109] Max Out

freq. 0 – 20 mA

Par. 6-50 = [130] Max Out

freq. 4 – 20 mA

Par. 5-66 = [109] Max Out

freq. 0 – 32000p Par. 568 =

32000

Par. 6-50 = [101] Reference

0 -20 mA

Parameter 319 Terminal 42,

Parameter 321 Terminal 45,

Options [43] Ref min – Ref max

VLT 5000 series FC 302 series

Output

Output

⇒ 4 – 20 mA

[44] Ref min – Ref max

⇒ 0 - 32000 p

[45] FB min – FB max

⇒ 0 – 20 mA

[46] FB min – FB max

⇒ 4 – 20 mA

[47] FB min – FB max

⇒ 0 - 32000 p

[48] 0 – I max ⇒ 0 – 20

mA

[49] 0 – I max ⇒ 4 – 20

mA

[50] 0 – I max ⇒ 0 –

32000 p

[51] 0 – T lim ⇒ 0 – 20

mA

[52] 0 – T lim ⇒ 4 – 20

mA

[53] 0 – T lim ⇒ 0 –

32000 p

[54] 0 – T nom ⇒ 0 –

20 mA

[55] 0 – T nom ⇒ 4 –

20 mA

[56] 0 – T nom ⇒ 0 –

32000 p

[57] 0 – P nom ⇒ 0 –

20 mA

[58] 0 – P nom ⇒ 4 –

20 mA

[59] 0 – P nom ⇒ 0 –

32000 p

Digital = Par. 5-32 DO X30/7

(MCB 101)

Analogue values= Par. 6-50

AO 42

Pulse = Par. 5-66 DO X30/6

Digital = Par. 5-33 DO X30/7

(MCB 101)

Analogue values= Par. 6-60

AO X30/8

Pulse = Par. 5-66 DO X30/6

Par. 6-50 = [131] Reference 4

-20 mA

Par. 5-66 = [101] Reference 0

– 32000p Par. 5-68 = 32000

Par. 6-50 = [102] Feedback 0

-20 mA

Par. 6-50 = [132] Feedback 4

-20 mA

Par. 5-66 = [102] Feedback 0

– 32000p Par. 5-68 = 32000

Par. 6-50 = [103] Motor

current 0 -20 mA

Par. 6-50 = [133] Motor

current 4 -20 mA

Par. 5-66 = [103] Motor

current 0 - 32000p Par. 5-68

= 32000

Par. 6-50 = [104] Torque

related to limit 0 - 20 mA

Par. 6-50 = [134] Torque

related to limit 4 - 20 mA

Par. 5-66 = [104] Torque

related to limit 0 – 32000p

Par. 5-68 = 32000

Par. 6-50 = [105] Torque

related to norm 0 - 20 mA

Par. 6-50 = [135] Torque

related to norm 4 - 20 mA

Par. 5-66 = [105] Torque

related to norm 0 – 32000p

Par. 5-68 = 32000

Par. 6-50 = [106] Power

related to norm 0 - 20 mA

Par. 6-50 = [136] Power

related to norm 4 - 20 mA

Par. 5-66 = [106] Power

related to norm 0 – 32000p

Par. 5-68 = 32000

5 5

Table 5.109 Conversion of Parameters 319 to 321

MG37E102 Danfoss A/S © Rev. 2014-03-06 All rights reserved. 27

Page 30

Parameter Mapping Lists

Operating Instructions

Parameter 319 Terminal 42,

VLT 5000 series FC 302 series

Digital = Par. 5-32 DO X30/7

Output

(MCB 101)

Analogue values= Par. 6-50

AO 42

Pulse = Par. 5-66 DO X30/6

Parameter 321 Terminal 45,

Output

Digital = Par. 5-33 DO X30/7

(MCB 101)

Analogue values= Par. 6-60

AO X30/8

Pulse = Par. 5-66 DO X30/6

Options

55

[60] 0 – SyncRPM ⇒ 0

– 20 mA

[61] 0 – SyncRPM ⇒ 4

Not supported

Not supported

– 20 mA

[62] 0 – SyncRPM ⇒ 0

Not supported

– 32000 p

[63] RPM at F max ⇒ 0

– 20 mA

[64] RPM at F max ⇒ 4

– 20 mA

[65] RPM at F max ⇒ 0

– 32000 p

Par. 6-50 = [107] Speed

related to norm 0 - 20 mA

Par. 6-50 = [137] Speed

related to norm 4 - 20 mA

Par. 5-66 = [107] Speed

related to norm 0 – 32000p

Par. 5-68 = 32000

Table 5.110 Conversion of Parameters 319 to 321

Parameter 320 Terminal 42 Output,

VLT 5000 series FC 302 series

5-68 Pulse Output Max

pulse scaling

Freq #X30/6

Range 1 – 32000 Hz 0 – 32000 Hz

Table 5.111 Conversion of Parameter 320

Parameter 322 Terminal 45 Output,

VLT 5000 series FC 302 series

5-68 Pulse Output Max

pulse scaling

Freq #X30/6

Range 1 – 32000 Hz 0– 32000 Hz

Table 5.112 Conversion of Parameter 322

VLT 5000 series FC 302 series

Parameter 323, 326 5-40 Function Relay

Range 01 Relay

04 Relay

Relay 1

Relay 2

[0] No function Par. 5-40 = [0] No operation

[1] Control Ready Par. 5-40 = [1] Control Ready

[2] Ready signal Par. 5-40 = [2] Drive ready

[3] Ready - Remote

Par. 5-40 = [3] Drive rdy/rem ctrl

Control

[4] Enabled, no

warning

Par. 5-40 = [4] Enable / no

warning

[5] Running Par. 5-40 = [5] VLT running

[6] Running, no

Warning

[7] Running within

range, no warning

[8] Run at

reference, no

Par. 5-40 = [6] Running / no

warning

Par. 5-40 = [7] Run in range/no

warn

Par. 5-40 = [8] Run on ref/no

warn

Warning

[9] Alarm Par. 5-40 = [9] Alarm

[10] Alarm or

Warning

Par. 5-40 = [10] Alarm or

Warning

[11] Torque limit Par. 5-40 = [11] At torque limit

[12] Out of current

range

Par. 5-40 = [12] Out of current

range

[13] Above I low Par. 5-40 = [13] Below current,

1)

low

[14] Under I high Par. 5-40 = [14] Above current,

1)

high

[15] Out of

frequency range

Par. 5-40 = [15] Out of speed

range

[16] Over f low Par. 5-40 = [16] Below speed

1)

low

[17] Under f high Par.5-40 = [17] Above speed

1)

high

[18] Out of

feedback range

[19] Over feedback

low

[20] Under

feedback high

[21] Thermal

warning

Par. 5-40 = [18] Out of feedb.

Range

Par. 5-40 = [16] Below feedback

1)

low

Par. 5-40 = [17] Above feedback

1)

high

Par. 5-40 = [21] Thermal

warning

Table 5.113 Conversion of Parameters 323 to 326

28 Danfoss A/S © Rev. 2014-03-06 All rights reserved. MG37E102

Page 31

Parameter Mapping Lists

Operating Instructions

Parameter 323, 326 5-40 Function Relay

Range [22] Ready, no

Table 5.114 Conversion of Parameters 323 to 326

Parameter 324 Relay 01, ON delay 5-41 On Delay, Relay

Range 0.00 – 600.00 sec 0.01 – 600.00 sec

Table 5.115 Conversion of Parameter 324

Parameter 325 Relay 01, OFF delay 5-42 Off Delay, Relay

Range 0.00 – 600.00 s 0.01 – 600.00 s

VLT 5000 series FC 302 series

Par. 5-40 = [22] Ready,no

thermal warning

[23] Ready - remote

control - no thermal

warning

[24] Ready – mains

voltage within range

[25] Reversing Par. 5-40 = [25] Reverse

[26] Bus OK Par. 5-40 = [26] Bus OK

[27] Torque limit

and stop

[28] Brake, no brake

warning

[29] Brake ready, no

fault

[30] Brake fault Par. 5-40 = [30] Brake fault

[31] Relay 123 Par. 5-40 = [31] Relay 123

[32] Mechanical

brake control

[33] Control word

bit 11/12

[34] Extended

mechanical brake

control

[35] Safety Interlock Not supported

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

thermal W

Par. 5-40 = [23] Remote, ready,

no TW

Par. 5-40 = [24] Ready, Voltage

OK

Par. 5-40 = [27] Torque limit &

stop

Par. 5-40 = [28] Brake, no

brake warning

Par. 5-40 = [29] Brake ready,

no fault

(IGBT)

Par. 5-40.0 = [32] Mech brake

ctrl

Par. 1-72 = [5] VVC+/Flux

Par. 5-40 = [36] Control word

bit 11

Par. 5-40.1 = [37] Control word

bit 12

Par. 5-40.0 = [32] Mech brake

ctrl

Par. 1-72 = [5] VVC+/Flux

Parameter 328 Pulse feedback, max. freq 5-56, 5-50, 5-55

Range 100 – 65000 Hz 0 – 110000 Hz

Table 5.118 Conversion of Parameter 328

Parameter 329 Encoder feedback

Range 1 – 4096 pulses 1 – 4096 pulses

Table 5.119 Conversion of Parameter 329

Parameter 330 Freeze ref. /output function Not converted

Table 5.120 Conversion of Parameter 330

Parameter 345 Encoder loss

Range 0.0 – 60.0 s 0.00 – 60.00 s

Table 5.121 Conversion of Parameter 345

Parameter 346 Encoder loss

Range [0] Off [0] Disable

Table 5.122 Conversion of Parameter 346

Parameter 357 Term. 42, Output

Range 0 – 100% 0 – 200%

Table 5.123 Conversion of Parameter 357

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

5-70 Term 32/33 Pulses Per

pulse/rev.

VLT 5000 series FC 302 series

VLT 5000 series FC 302 series

timeout

VLT 5000 series FC 302 series

function

[1] Freeze output

frequency

[3] Jog [3] Jog

[4] Max speed [5] Max speed

[5] Stop and trip [11] Stop and trip

[7] Select setup 4 [10] Select setup 4