Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

MCA 123 POWERLINK

vlt-drives.danfoss.com

Page 2

Page 3

Safety Operating Instructions

Safety

This publication contains information proprietary to

Danfoss. By accepting and using this manual, the user

agrees that the information contained herein is used solely

for operating equipment from Danfoss or equipment from

other vendors if such equipment is intended for communication with Danfoss equipment over a serial

communication link. This publication is protected under

the Copyright laws of Denmark and most other countries.

Danfoss does not guarantee that a software program

produced according to the guidelines provided in this

manual functions properly in every physical, hardware, or

software environment.

Although Danfoss has tested and reviewed the documentation within this manual, Danfoss gives no warranty or

representation, either expressed or implied, with respect to

this documentation. This includes its quality, performance,

or rness for a particular purpose.

In no event shall Danfoss be liable for direct, indirect,

special, incidental, or consequential damages arising out of

the use, or the inability to use information contained in

this manual, even if advised of the possibility of such

damages. In particular, Danfoss is not responsible for any

costs including, but not limited to those incurred as a

result of lost prots or revenue, loss or damage of

equipment, loss of computer programs, loss of data, the

costs to substitute these, or any claims by third parties.

1. The frequency converter must be disconnected

from mains before carrying out repair work.

Check that the mains supply has been disconnected and that the necessary time has passed

before removing motor and mains plugs.

2. The o-command on the serial bus does not

disconnect the equipment from mains and should

not be used as a safety switch.

3. Correct protective earthing or grounding of the

equipment must be established. The user must

be protected against supply voltage, and the

motor must be protected against overload in

accordance with applicable national and local

regulations.

4. The earth leakage currents are higher than 3.5

mA.

5. Do not remove the plugs for the motor and

mains supply while the frequency converter is

connected to mains. Check that the mains supply

has been disconnected and that the necessary

time has passed before removing motor and

mains plugs.

Danfoss reserves the right to revise this publication at any

time and to change its contents without prior notice or

any obligation to notify previous users of such revisions or

changes.

It has been assumed that all devices are sitting behind a

rewall that does packet ltering and the environment has

implemented restrictions on the software that can run

inside the rewall. All nodes are assumed to be "trusted"

nodes.

WARNING

HIGH VOLTAGE

The voltage of the frequency converter is dangerous

whenever connected to mains. Incorrect installation of

the motor, frequency converter, or eldbus may damage

the equipment, cause serious personal injury, or death.

Consequently, the instructions in this manual, as well as

national and local rules and safety regulations, must be

complied with.

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved.

Page 4

Safety MCA 123 POWERLINK

1. The motor can be brought to a stop with bus

commands while the frequency converter is

connected to mains. These stop functions do NOT

provide protection against unintended starts.

2. While parameters are being changed, there is a

risk that motor starts.

3. Electronic faults in the frequency converter and

cease of

temporary overload

•

faults in supply mains, or

•

fault in the motor connection

•

can cause an unintended start.

WARNING

ELECTRICAL HAZARD

Touching the electrical parts may be fatal - even after

the equipment has been disconnected from mains.

Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 5

Contents Operating Instructions

Contents

1 Introduction

1.1 General Information

1.1.1 About this Manual 3

1.1.2 Assumptions 3

1.1.3 Hardware 3

1.1.4 Background Knowledge 3

1.1.5 Available Literature 3

1.1.6 Abbreviations 4

2 How to Install

2.1 Installation

2.1.1 How to Install Option in Frequency Converter 5

2.1.2 Network 5

2.1.3 POWERLINK Cables 6

2.1.4 LED Behaviour 6

2.1.5 Topology 7

2.1.6 EMC Precautions 8

3

3

5

5

3 How to Congure

3.1 Congure the Parameters

3.1.1 IP Settings 10

3.1.2 Ethernet Link Parameters 10

3.2 Congure the Frequency Converter

3.2.1 VLT Parameters 10

3.3 Congure the POWERLINK Network

4 Congure the Master

4.1 Importing the XDD File

4.2 Setting Up the Master

5 How to Control the Frequency Converter

5.1 PDO Communication

5.2 Process Data

5.2.1 Process Control Data 15

5.2.2 Process Status Data 15

5.2.3 Reference Handling 16

10

10

10

10

12

12

12

15

15

15

5.2.5 Inuence of the Digital Input Terminals upon FC Control Mode 17

5.3 Control Prole

5.4 DS 402 Control Prole

5.4.1 Control Word According to DSP 402 Prole

(Parameter 8-10=DSP 402 prole) 17

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 1

17

17

Page 6

Contents MCA 123 POWERLINK

5.4.2 Status Word According to DS 402 Prole 18

5.4.3 DSP 402 State Transitions 21

5.5 Danfoss FC Control Prole

6 Communication Prole Area

6.1 Description - Communication Prole Area

6.2 1000-1FFF Communication Object Area

6.3 2000-5FFF Danfoss Specic Object Area

6.4 6000-Device prole Object Area

7 Parameters

7.1 Parameter Group 8-** Communication and Option

7.2 Parameter Group 12-** Ethernet

7.3 POWERLINK - Specic Parameter List

8 Application Examples

8.1 Example: Process Data with PDO 23

8.2 Example: Simple Control Word, Reference, Status Word and Main Actual Value

9 Troubleshooting

9.1 LED Status

21

25

25

25

31

31

34

34

38

41

44

44

46

48

48

9.2 Communication Problems

9.2.1 No Communication with the Frequency Converter 49

9.2.2 Endless Power-down - Power-up Cycle 52

9.3 Warnings and Alarms

9.3.1 Alarm and Warning Words 52

Index

49

52

55

2 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 7

Introduction

Operating Instructions

1 Introduction

1.1 General Information

1.1.1 About this Manual

Chapters

chapter 1 Introduction

chapter 2 How to Install

chapter 3 How to

contain essential information for quick installation and setup.

For more detailed information, including the full range of

set-up options and diagnosis tools, refer to the chapters:

chapter 4

chapter 5 How to Control the Frequency Converter

chapter 7 Parameters

chapter 8 Application Examples

chapter 9 Troubleshooting

Terminology

In this manual the term Ethernet is used to describe the

physical layer of the network and does not relate to the

application protocol.

Assumptions

1.1.2

These Operating Instructions are under the conditions that

the Danfoss POWERLINK option is used with a Danfoss

VLT® AutomationDrive FC 301/FC 302 or FCD 302

frequency converter. The installed controller must support

the interfaces described in this manual. Strictly observe all

the requirements stipulated in the controller and the

frequency converter, along with all limitations herein.

Hardware

1.1.3

This manual relates to the POWERLINK option MCA 123,

ordering number 130B5546 (uncoated) and 130B5646

(conformal coated).

1.1.4

Background Knowledge

The Danfoss POWERLINK option card is designed to

communicate with any system complying with the

POWERLINK standard. Familiarity with this technology is

assumed. Issues regarding hardware or software produced

by other manufacturers, including commissioning tools, are

Congure

Congure the Master

beyond the scope of this manual, and not the responsibility of Danfoss.

For information regarding commissioning tools, or

communication to a non-Danfoss node, consult the

appropriate manuals.

1.1.5 Available Literature

-

The VLT® AutomationDrive Operating Instructions

provide the necessary information for getting the

frequency converter up and running.

-

-

-

-

-

-

-

-

-

-

-

-

Danfoss technical literature is also available online at

www.danfoss.com/BusinessAreas/DrivesSolutions/

®

The VLT

technical information about the frequency

converter design and applications including

encoder, resolver, and relay options.

The VLT® AutomationDrive Probus Operating

Instructions provide the information required for

controlling, monitoring, and programming the

frequency converter via a Probus eldbus.

The VLT

Instructions provide the information required for

controlling, monitoring, and programming the

frequency converter via a DeviceNet eldbus.

The MCT 10 Set-up Software Operating Instructions

provide information for installation and use of the

software on a PC.

The VLT

provides information for installing the IP21/Type 1

option.

The VLT

Instruction provides information for installing the

24 V DC Back-up option.

The VLT

Instructions.

The VLT

Instructions.

The MCA 121 Ethernet/IP Operating Instructions.

The MCA 120 PROFINET Operating Instructions.

The MCA 124 EtherCAT Operating Instructions.

The MCA 122 Modbus TCP Operating Instructions.

AutomationDrive Design Guide entails all

®

AutomationDrive DeviceNet Operating

®

AutomationDrive IP21/Type 1 Instruction

®

AutomationDrive 24 V DC Back-up

®

AutomationDrive CANOpen Operating

®

AutomationDrive Modbus TCP Operating

1

1

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 3

Page 8

Introduction MCA 123 POWERLINK

1.1.6 Abbreviations

1

Abbreviation

API Actual Packet Interval

ASnd AsynchronousSend

CC Control card

CTW Control word

DCP Discovery and Conguration Protocol

DHCP Dynamic Host Conguration Protocol Conguration

EMC Electromagnetic Compatibility

I/O Input/Output

IP Internet Protocol

PDO Process Data Object

LCP Local Control Panel

LED Light Emitting Diode

LSB Least Signicant Bit

MAV Main Actual Value (actual output)

MN Managing Node

MSB Most Signicant Bit

MRV Main Reference Value

N/A Not applicable

PC Personal Computer

PCD Process Control Data

PLC Programmable Logic Controller

PNU Parameter Number

REF Reference (=MRV)

SDO Service Data Object

SoC Start Of Cycle Frame

SoA Start Of Asynchronous

STW Status Word

Denition

Table 1.1 Overview of Abbreviations

4 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 9

EtherNet Port1

EtherNet Port2

MCA 121 Option A

EtherNet/IP 130B1119

MS

MS1 MAC-00-1B-08-00-00-22

MS2

SW.ver.

130BT797.10

How to Install

2 How to Install

2.1 Installation

Operating Instructions

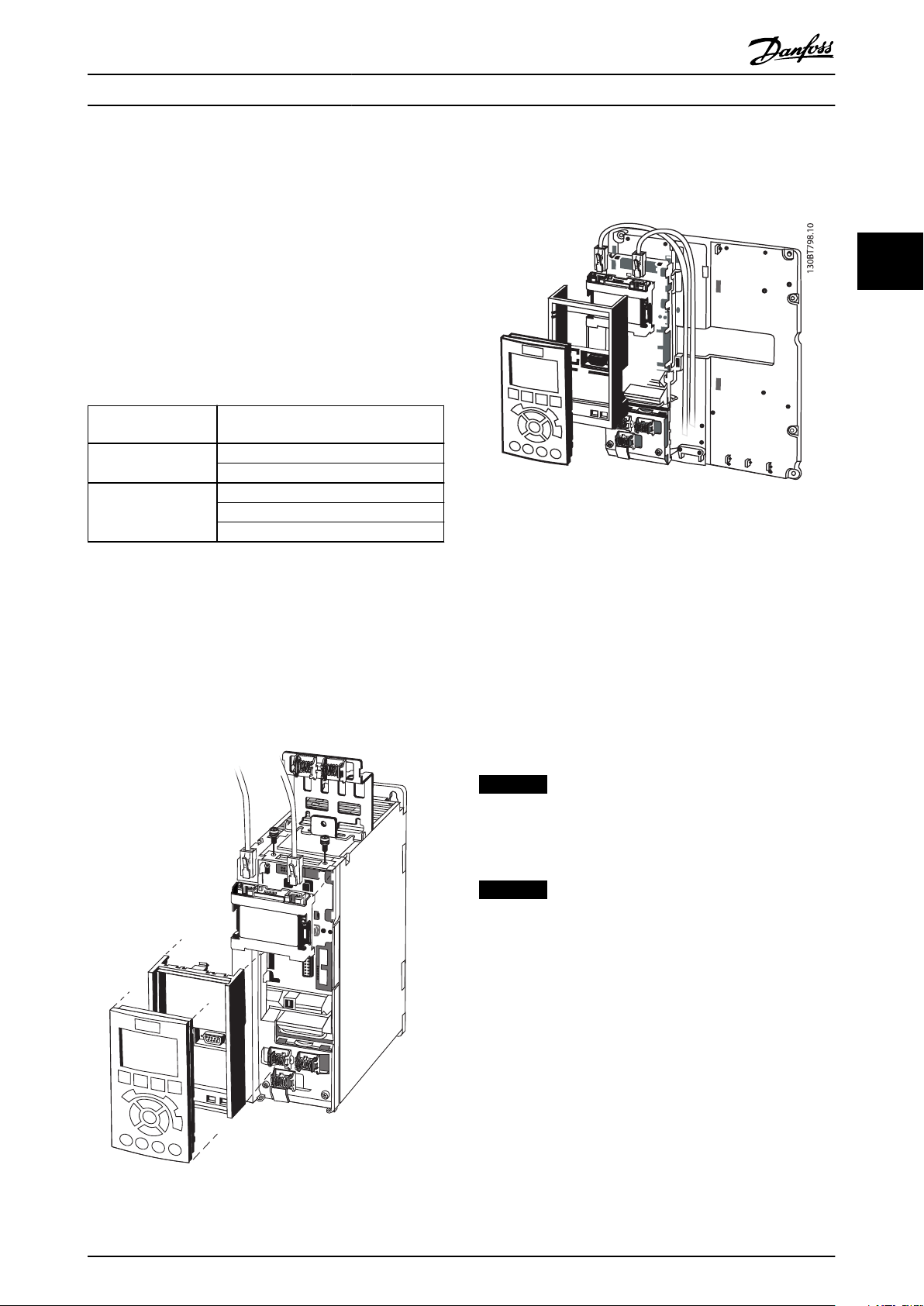

2.1.1 How to Install Option in Frequency

Converter

Before installing the option, make sure that the installed

rmware revision supports the POWERLINK option.

Following minimum versions of the frequency converter

rmware are required:

POWERLINK option

rmware version

1.01

1.12 FC 301 6.81

Table 2.1 Minimum Firmware Versions

Items required for installing the eldbus option in the

frequency converter

Fieldbus option

•

Fieldbus option adaptor frame for the FC Series.

•

This frame is deeper than the standard frame to

allow space for the eldbus option beneath.

Strain relief (only for A1 and A2 enclosures)

•

Frequency converter minimum

rmware version

FC 301 6.72

FC 302 6.72

FC 302 6.81

FCD 302 6.81

Illustration 2.2 Strain Relief for A1 and A2 Enclosures

Instructions

1. Remove LCP panel from the FC Series.

2. Remove the frame located beneath and discard it.

3. Push the option into place. The Ethernet

connectors must be facing upwards.

4. Remove knock-out on the

eldbus option adaptor

frame.

5. Push the eldbus option adaptor frame for the FC

Series into place.

6. Replace the LCP and attach cable.

2 2

Illustration 2.1 Fieldbus Option Adaption Frame

NOTICE

Do not strip and earth the Ethernet cable via the strain

relief-plate! The earthing of screened Ethernet cable is

done through the RJ-45 connector on the option.

NOTICE

After installing the MCA 123 POWERLINK option, set

parameter 8-01 Control Site to: [2] Control word only or [0]

Digital and ctrl. word.

parameter 8-02 Control Word Source to: [3] Option A

2.1.2 Network

It is important that the media selected for Ethernet data

transmission meets the required properties. Usually CAT 5e

and six cables are recommended for industrial applications.

Both types are available as unscreened twisted pair and

screened twisted pair. Generally, screened cables are

recommended for use in industrial environments and with

frequency converters.

A maximum cable-length of 100 m is allowed between

network devices.

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 5

Page 10

MCA123

POWERLINK

SW. ver. TM. ver.

S/E LED

L/C LED P1

L/C LED P2

Port 1 Port 2

Option A

130B1489

MAC 00-1B-08-00-00-00

Address

8 7 6 5 4 3 2 1

ON

OFF

130BD146.11

1

2

3

4

5

6

A

B

A

B

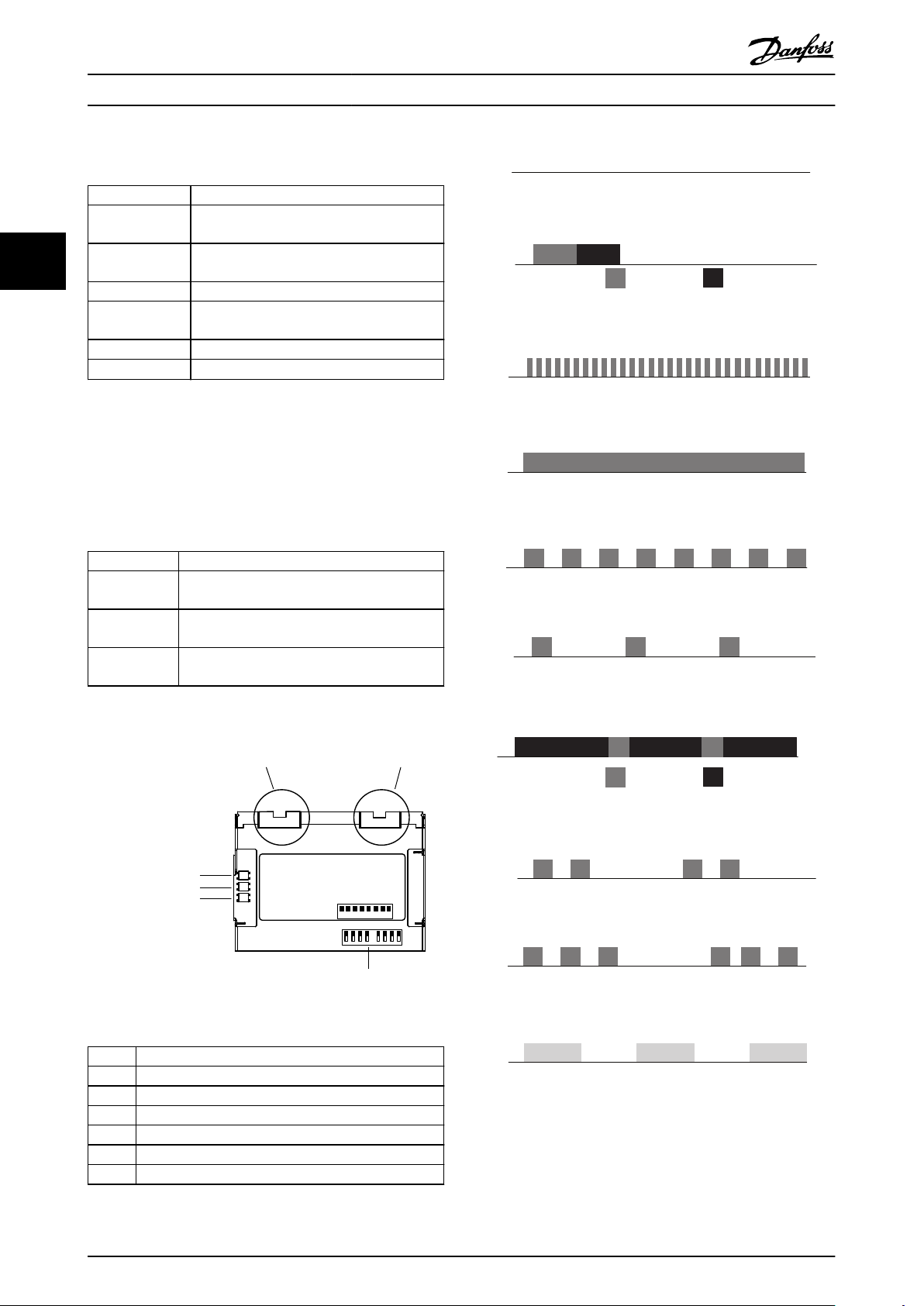

How to Install MCA 123 POWERLINK

2.1.3 POWERLINK Cables

Cable type Specication

S/E LED

Illustration 2.4 S/E LED Status - Power OFF or State

Ethernet standard Standard Ethernet (in accordance with IEEE

802.3), 100Base-TX (Fast Ethernet)

Cable Type S/FTP (screened foiled twisted pair, ISO (IEC

22

Damping 23.2 dB (at 100 MHz and 100 m each)

Crosstalk

11801 or EN 50173), CAT 5e

24 dB (at 100 MHz and 100 m each)

Illustration 2.5 S/E LED Status - Green (A)/Red (B) Flash

damping

Return loss 10 dB (100 m each)

Surge impedance

Table 2.2 Specication of POWERLINK Cables

LED Behaviour

2.1.4

The option has 3 bicolored LEDs that allow a fast and

detailed diagnosis. The three LEDs are each linked to its

100 Ω

Illustration 2.6 S/E LED Status - Flickering Green

Illustration 2.7 S/E LED Status - Solid Green

unique part of the POWERLINK option:

LED label Description

Status/Error Module Status, reects the activity on the

POWERLINK slave.

Link/Collision

Port 1

Link/Collision

Port 2

Link/Collision Port 1, reects the activity on the

POWERLINK port 1.

Link/Collision Port 2, reects the activity on the

POWERLINK port 2.

Illustration 2.8 S/E LED Status - Blinking Red

Illustration 2.9 S/E LED Status - Single Green Flash

Table 2.3 LEDs

Illustration 2.3 Overview of the Option

Item # Description

1 POWERLINK port 1

2 POWERLINK port 2

3 Status/error

4 Link/collision port 1

5 Link/collision port 2

6 Node ID dip switches

Table 2.4 Legend to Illustration 2.3

Illustration 2.10 S/E LED Status - Red (B)/Green (A) Flash

Illustration 2.11 S/E LED Status - Double Green Flash

Illustration 2.12 S/E LED Status - Tripple Green Flash

Illustration 2.13 S/E LED Status - Yellow Flash

6 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 11

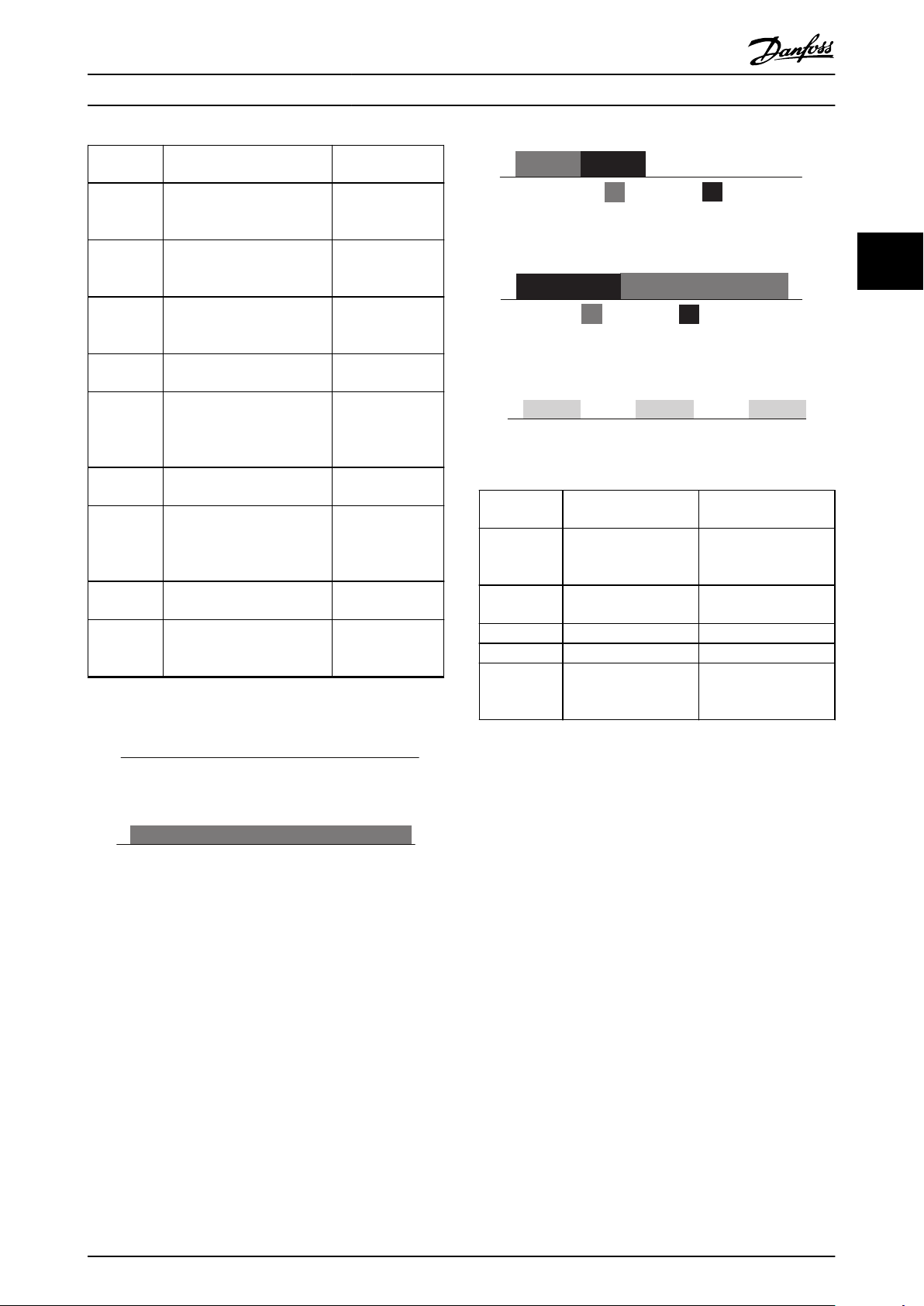

A

B

A

B

How to Install Operating Instructions

LED ash

pattern

Power OFF

or State

Flickering

Green

Solid green POWERLINK

Blinking

greed

Single green

ash

Red/green

ash

Double

green ash

Tripple

green ash

Yellow ash Wink command Node Identication

Table 2.5 S/E LED Pattern

Powerlink option state Description

NMT_GS,

NMT_GS_INITIALISATION

NMT_CS_NOT_ACTIVE,

Basic Ethernet mode POWERLINK

NMT_CS_Stopped PLC has stopped

NMT_CS_PRE_OPERATIONAL_1 POWERLINK

NMT_CS_PRE_OPERATIONAL_1 Communication to

NMT_CS_PRE_OPERATIONAL_2 POWERLINK

NMT_CS_READY_TO_OPERATE POWERLINK

No power supplied

to drive or

Initialising

interface is in basic

Ethernet mode

interface is on

operational state

the Network

interface is in Preoperation mode

state 1

PLC lost

interface is in Preoperation mode

state 2

interface is

activated from

MCT10

Illustration 2.16 L/C LED Status - Power-up Green (A)/Red (B)

Illustration 2.17 L/C LED Status - Collision Red (B)/Green (A)

Illustration 2.18 L/C LED Status - Yellow Flash

LED ash

pattern

Power OFF or

no link

Link NMT_GS_INITIALISATION Only shown once at

Power up Various states Link established

Collision

Yellow ash Wink command Node Identication

Powerlink option state Description

NMT_GS,

NMT_GS_INITIALISATION

NMT_CS_NOT_ACTIVE

No power supplied to

drive or Initialising

power up

activated from MCT 10

Set-up Software

2 2

L/C LED

Illustration 2.14 L/C LED Status - Power OFF or No Link

Illustration 2.15 L/C LED Status - Link

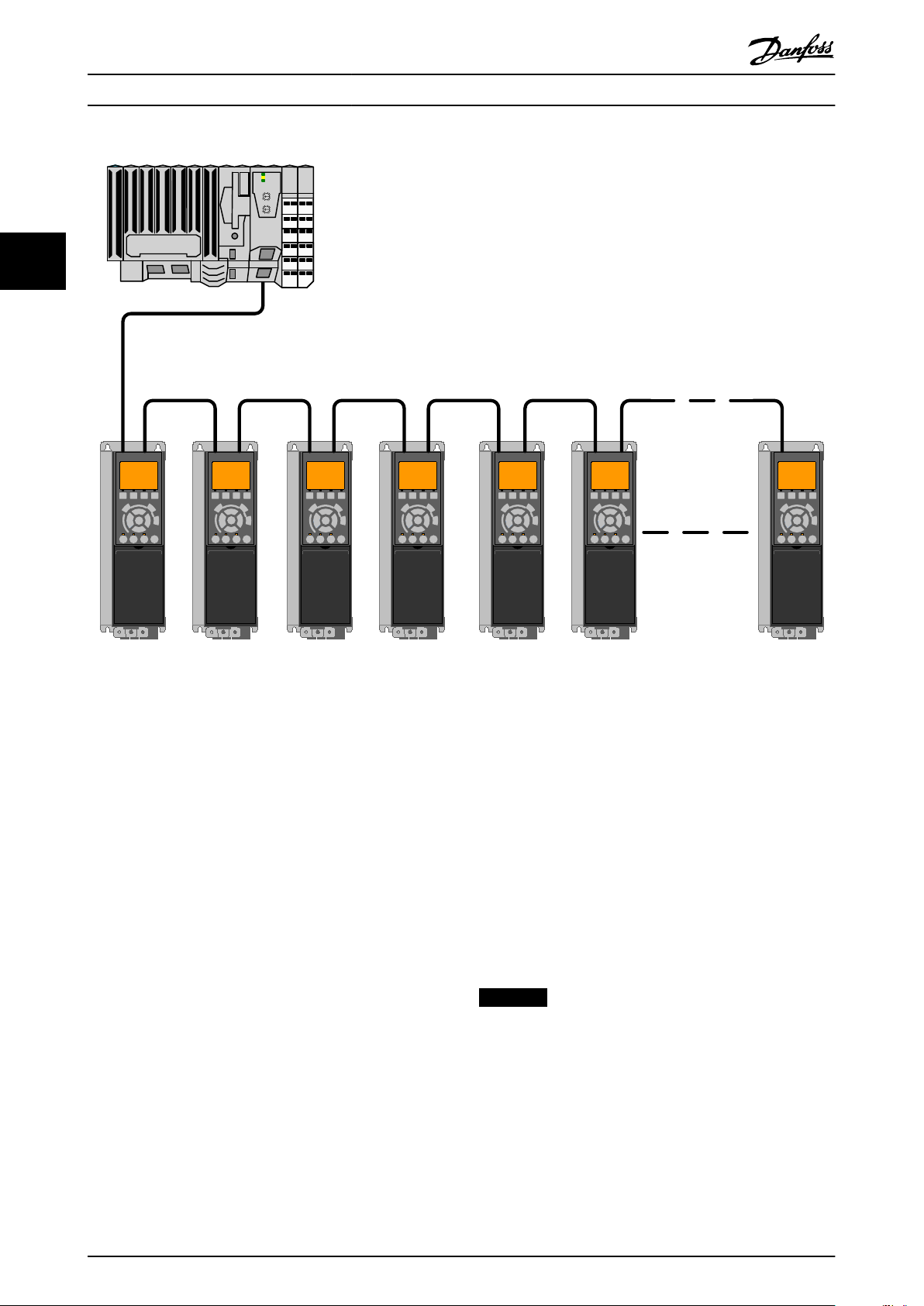

Topology

2.1.5

Table 2.6 L/C LED Pattern

The POWERLINK module features a built-in POWERLINK controlled node and a two-port hub. This module enables the

possibility for connecting several POWERLINK options in a line topology. If more than eight frequency converters are

connected in line, it requires special attention towards the timing in the network.

It is important in a POWERLINK system, that the connection is done correctly.

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 7

Page 12

130BD147.10

How to Install MCA 123 POWERLINK

22

Illustration 2.19 Line Topology

Take care that following design rules are followed

1. Do not connect any non-POWERLINK device (e.g.

a PC) to any free port as to avoid malfunction of

the complete POWERLINK network.

2. In a line topology, power all frequency converters

either by mains or by a 24 V DC option card, for

the built-in POWERLINK slave controller to work.

3. To achieve interference-free operation of the

Ethernet, observe the following EMC precautions.

The correct handling of the motor cable screen is

vital for the overall performance of the system. If

the rules are not followed, it leads to loss of the

control and malfunction of the system. The

Ethernet communication cable must be kept

away from motor and brake resistor cables to

avoid coupling of high frequency noise between

the cables. Normally, a minimum distance of 200

mm (8 inches) is sucient, but maintaining the

greatest possible distance between the cables is

recommended. Especially where cables run in

parallel, over long distances, or if frequency

converters with a bigger power size are installed.

More information can be found in the norm IEC

61000-5-2:1997.

4. When crossing of cables is unavoidable, the

Ethernet cable must cross motor and brake

resistor cables at an angle of 90°.

5. Always observe relevant national and local

regulations, for example regarding protective

earth connection.

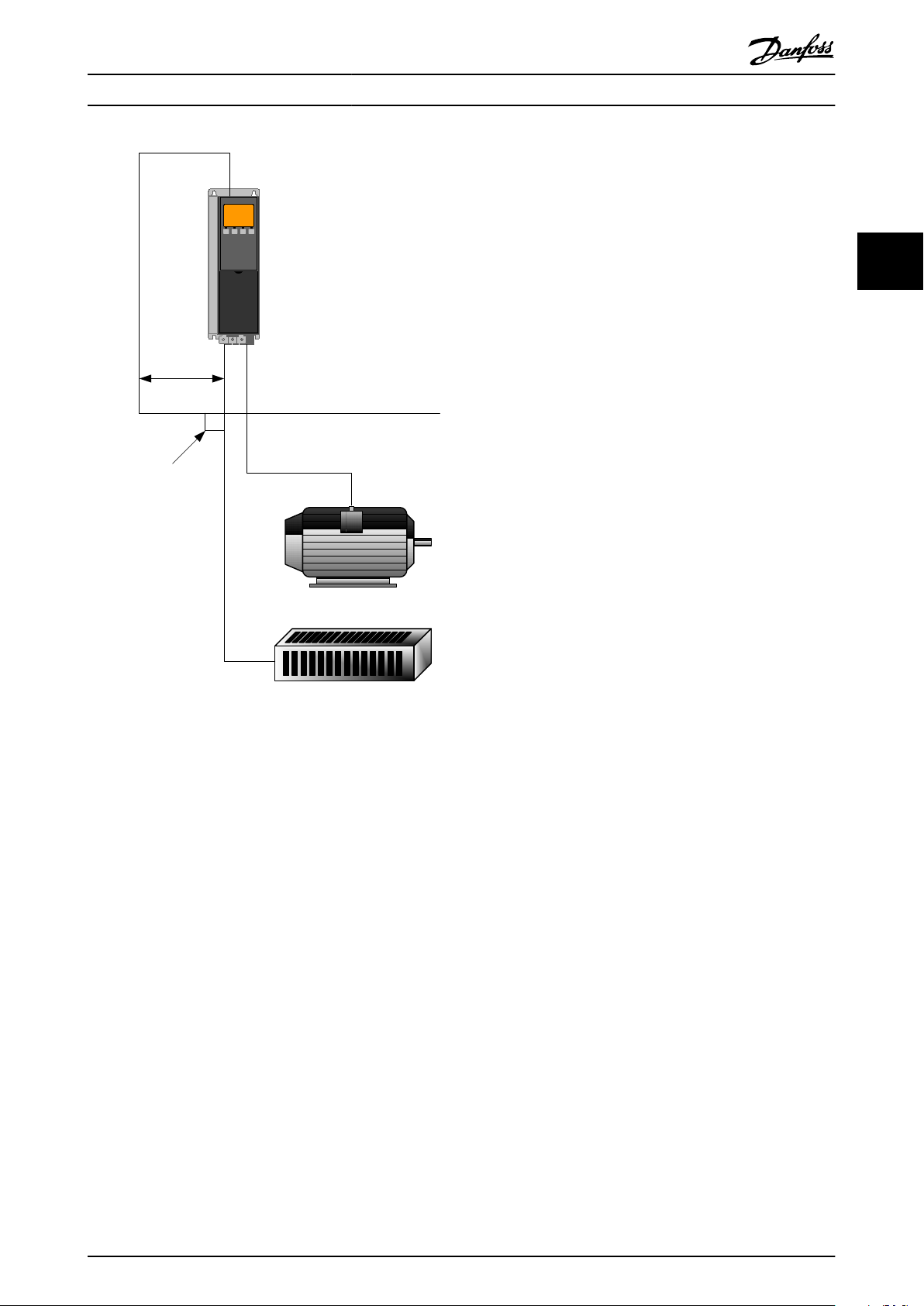

2.1.6 EMC Precautions

To achieve interference-free operation of the Ethernet,

observe the following EMC precautions. Additional EMC

information is available in the VLT® AutomationDrive Design

Guide.

NOTICE

The correct handling of the motor cable screen is vital

for the overall performance of the system. If the rules are

not followed, it can lead to loss of the control and

malfunction of the system.

8 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 13

min. 200 mm

90 ° crossing

Ethernet Cable

130BA908.11

How to Install Operating Instructions

2 2

Illustration 2.20 Correct Crossing of Ethernet Cable

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 9

Page 14

How to Congure MCA 123 POWERLINK

3 How to Congure

3.1 Congure the Parameters

3.1.1 IP Settings

All IP-related parameters are located in parameter group

33

12-0* IP Settings: The parameters are all set to POWERLINK

standard values, so no setting is needed. In POWERLINK,

the parameter 12-00 IP Address Assignment is xed to the

option "From node ID". The IP address follows the setting

in parameter 12-60 Node ID, so that the IP address is

192.168.100.xxx, where xxx is the node ID. For

parameter 12-02 Subnet Mask, the IP addres is

255.255.255.0 and cannot be changed.

The POWERLINK option oers two ways of node ID

assignment via parameter or DIP switch.

Ethernet Link Parameters

3.1.2

Parameter group 12-1* Ethernet Link Parameters holds

Ethernet Link information:

Parameter 12-10 Link Status

Parameter 12-11 Link Duration

Parameter 12-12 Auto Negotiation

Parameter 12-13 Link Speed

Parameter 12-14 Link Duplex

Each port has unique Ethernet link parameters.

Parameter 12-10 Link Status displays Link or No Link

according to the status of the present port.

Parameter 12-11 Link Duration displays the duration of the

link on the present port. If the link is broken, the counter

is reset.

Parameter 12-12 Auto Negotiation is a feature that enables

two connected Ethernet devices to select common

transmission parameters, such as speed and duplex mode.

In POWERLINK, this feature is

changed.

xed to OFF and cannot be

xed to

In POWERLINK, the Link Duplex is xed to Half Duplex, and

cannot be changed.

3.2 Congure the Frequency Converter

3.2.1 VLT Parameters

Pay particular attention to the following parameters when

conguring the frequency converter with a eldbus

interface.

Parameter 0-40 [Hand on] Key on LCP. If the [Hand

•

on] key on the frequency converter is activated,

control of the frequency converter via the

eldbus interface is disabled.

After an initial power-up, the frequency converter

•

automatically detects whether a eldbus option is

installed in slot A. It then sets

parameter 8-02 Control Word Source to [Option A].

Adding, changing, or removing an option from an

already commissioned frequency converter does

not change parameter 8-02 Control Word Source.

However, it causes a trip mode, and the

frequency converter displays an error.

Parameter 8-10 Control Word

•

between the Danfoss FC

prole. The change of parameter 8-10 Control

Word Prole is active at the next power-up.

Parameter 8-50 Coasting Select to

•

parameter 8-56 Preset Reference Select. Selection of

how to gate

digital input command of the control card.

eldbus control commands with

Prole. Select

Prole and the DS 402

NOTICE

When parameter 8-01 Control Site is set to [2] Control

word only, Bus-control overrules the settings in

parameter 8-50 Coasting Select to parameter 8-56 Preset

Reference Select.

Parameter 8-03 Control Word Timeout Time to

•

parameter 8-05 End-of-Timeout Function. The

reaction in the event of a bus time-out is set via

these parameters.

3.3

Congure the POWERLINK Network

Parameter 12-13 Link Speed - displays the link speed for

each port. If no link is present, “None” is displayed. In

POWERLINK, this feature is xed to 100 MBaud and cannot

be changed.

Parameter 12-14 Link Duplex - displays the duplex mode for

each port.

Using the hardware switches, it is possible to select an address range 0–239 (factory setting 1) according to

10 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

All POWERLINK stations that are connected to the same

bus network must have a unique node address. The node

address of the frequency converter can be selected via:

Hardware switches (from version 1.12)

•

parameter 12-60 Node ID

•

Setting the NODE Address using the Hardware Switches

Table 3.1:

Page 15

How to Congure Operating Instructions

Switch 8 7 6 5 4 3 2 1

Address value 128 +64 +32 +16 +8 +4 +2 +1

E.g. address 5 OFF OFF OFF OFF OFF ON OFF ON

E.g. address 35 OFF OFF ON OFF OFF OFF ON ON

E.g. address 82 OFF ON OFF ON OFF OFF ON OFF

E.g. address 157 ON OFF OFF ON ON ON OFF ON

Table 3.1

NOTICE

The switches are only read during power-up. Changes are active after the next power up, and can be read in

parameter 12-60 Node ID. Note the location and sequence of the hardware switches as illustrated in Illustration 2.3.

Setting the NODE Address via parameter 12-60 Node ID

Setting the address via parameter 12-60 Node ID, is only possible if the hardware switches are set to 0 or 255 (factory

setting). The address change becomes active at the next power-up. The node address has direct

in parameter 12-01 IP Address. If the hardware switch is set to an illegal number, the frequency converter immediately issues

Warning 34 in the display, and parameter 12-69 Ethernet PowerLink Status is set to 0 (zero).

inuence on the IP address

3 3

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 11

Page 16

130BD136.10

130BD139.10

130BD137.10

130BD140.10

Congure the Master MCA 123 POWERLINK

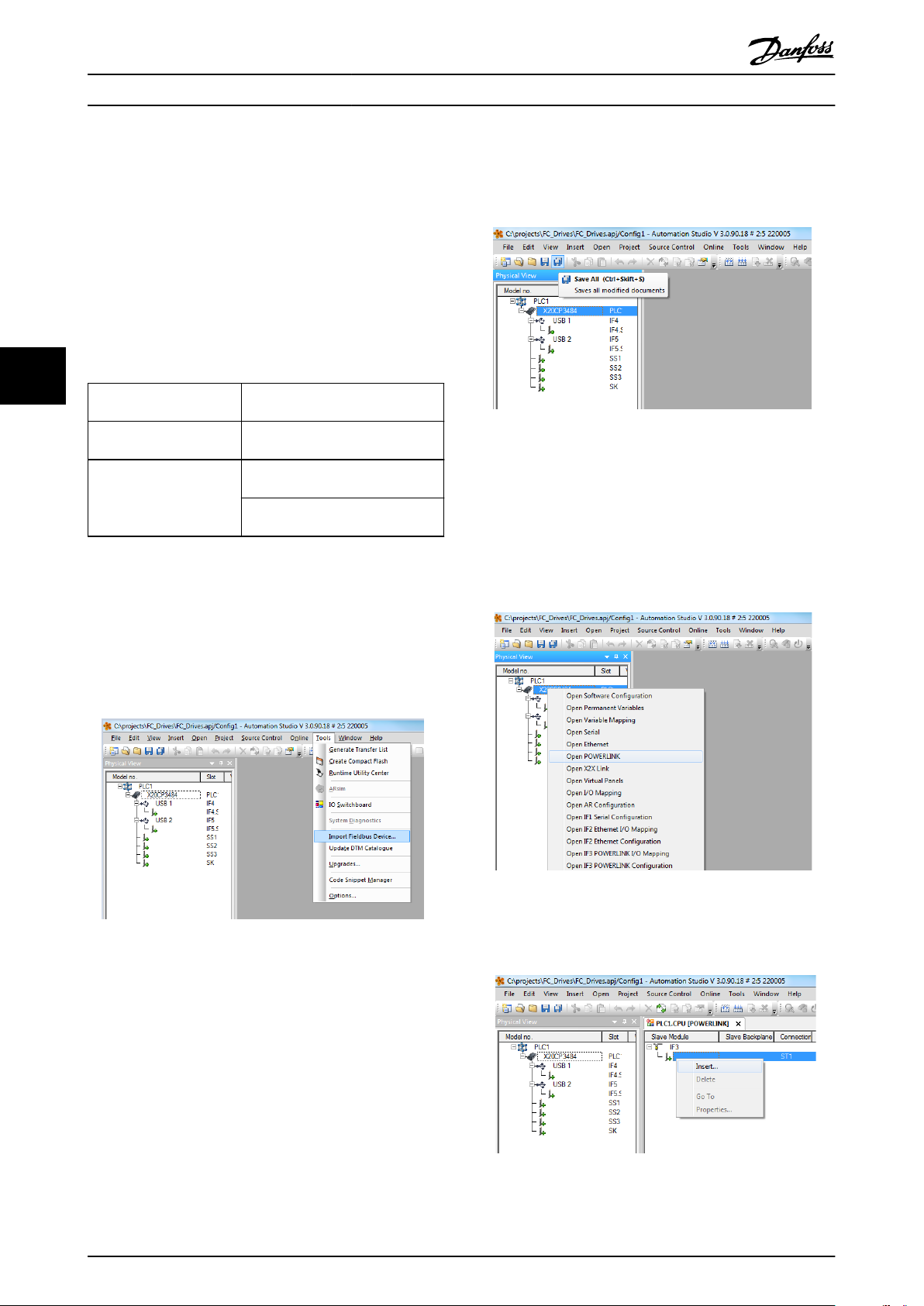

4 Congure the Master

4.1 Importing the XDD File

To congure a POWERLINK Master, the conguration tool

needs an XDD le for each type of slave on the network.

The XDD le is a text le containing the necessary

communications set-up data for a slave. Download the

le for the FC Series frequency converters at

XDD

www.danfoss.com/BusinessAreas/DrivesSolutions/.

44

parameter 15-61 Option

SW Version

1.02 FC 301: 0x0200008D_FC301_01.xdd

1.12 FC 301: 0x0200008D_FC301_08.xdd

Table 4.1 POWERLINK SW Version XDD File

The following steps show how to add a device to the

Automation Studio Tool. For tools from other vendors,

consult their relevant manuals.

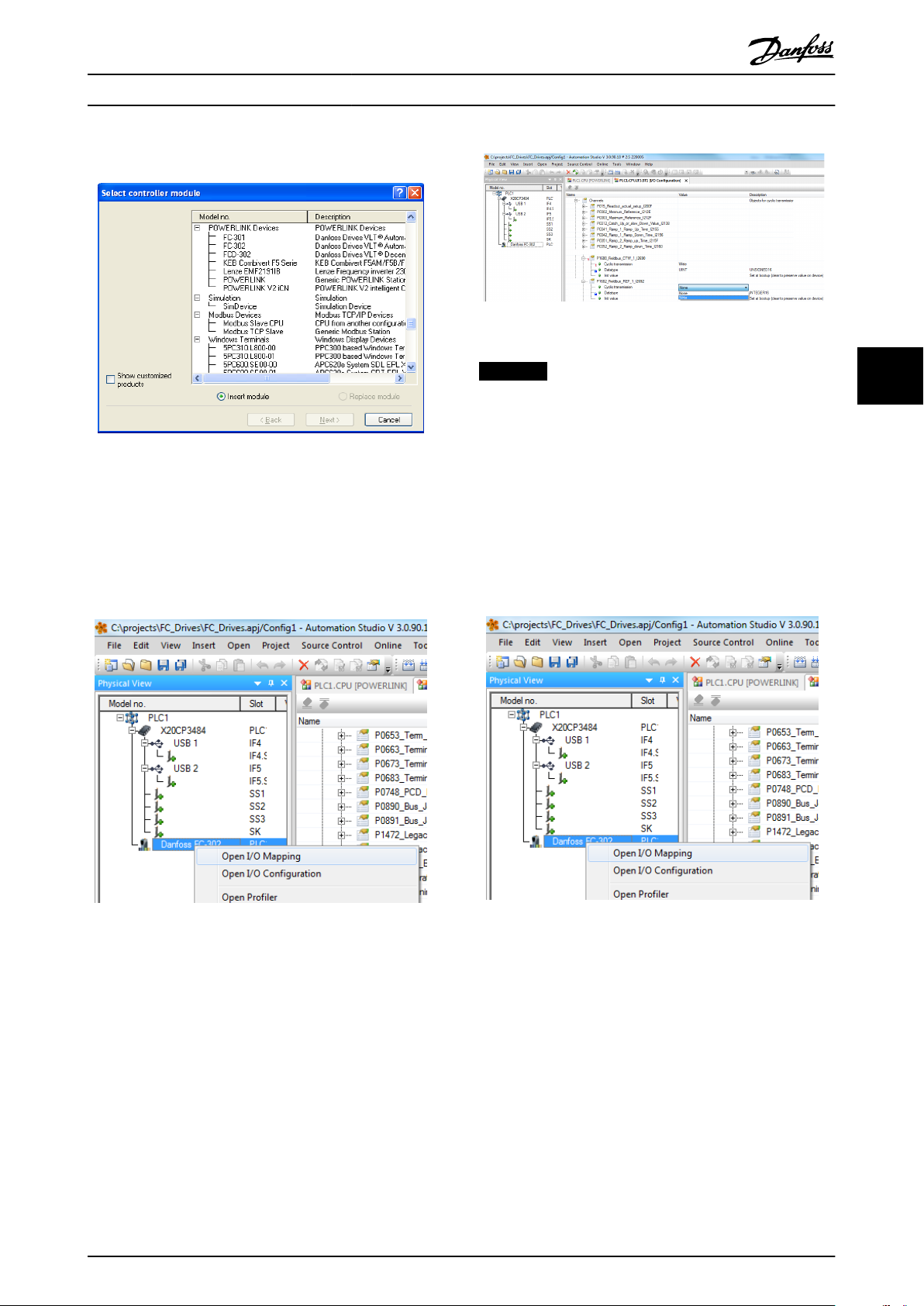

1. In the Automation Studio, select the menu [Tools]

and [Import Fieldbus Device].

File

FC 302: 0x0200008D_FC302_01.xdd

FC 302: 0x0200008D_FC302_08.xdd

FCD 302: FCD 302:

0x0200008D_FCD302_08.xdd

Illustration 4.2 Selecting the XDD File

4.2 Setting Up the Master

Select the POWERLINK I/O master to open the POWERLINK

interface in the Automation Studio Master.

1. Right click and select [Open POWERLINK].

Illustration 4.3 Open POWERLINK

Illustration 4.1 Automation Studio

2. Select the XDD le and the Automation studio,

imports it to its library. To save the new info,

select the [Save All] menu or the multiple oppy

disc icon.

12 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

2. Right click the network icon, and select [Insert].

Illustration 4.4 Physical View

Page 17

130BD145.11

130BD142.10

130BD141.10

130BD142.10

Congure

the Master Operating Instructions

3. Select [Danfoss FC 302].

Illustration 4.7 Select Parameters

Illustration 4.5 Select Controller Module

Danfoss FC Series is inserted in the POWERLINK master

system.

Congure the I/O conguration, right click the

4.

Danfoss Icon and select [Open I/O Conguration].

NOTICE

Make sure that maximum ten channels are selected in

each direction; or the PLC enters into an endless restart

of the network.

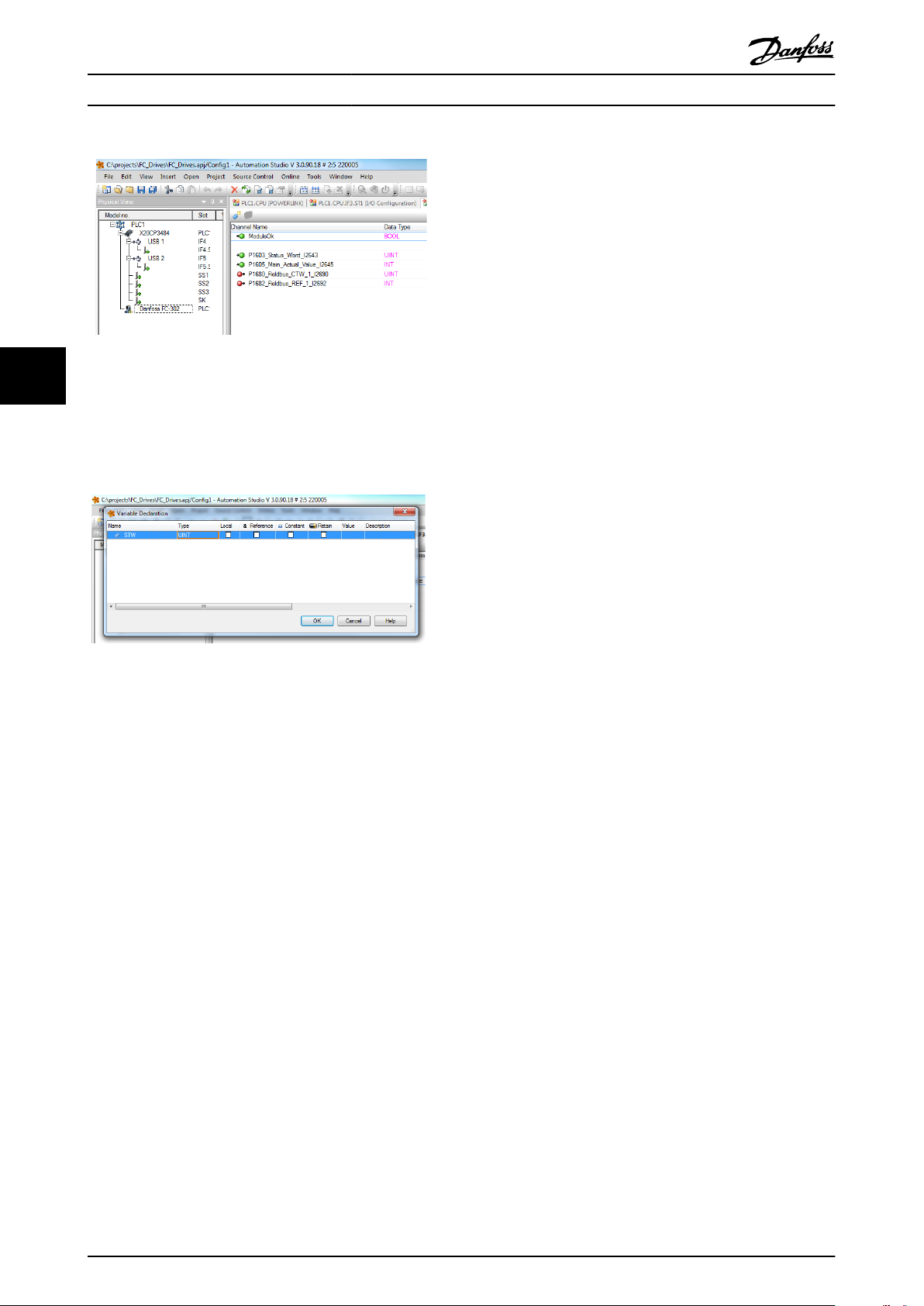

6. The POWERLINK

the Danfoss FC Series frequency converter as its

slave and communicates with the four words. The

nal step is to map the I/Os to PLC variables,

which is done in the I/O mapping. Select the I/O

Mappings by right-clicking the [Danfoss FC 302]

icon and selecting [Open I/O Mapping].

conguration does now contain

4 4

Illustration 4.6 I/O Conguration

5. By default the POWERLINK option does not have

any process data assigned to its I/O mapping.

Assign the process data by selecting the channels

(FC Parameter) as read or write. Selecting the [+]

sign in front of the channel menu expands the

list and the parameters can be selected. In this

example following has been selected:

Object 2690 eldbus control word 1

•

Object 2692 eldbus reference 1

•

Object 2643 status word

•

Object 2645 main actual value

•

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 13

Illustration 4.8 Mapping the I/Os ot the PLC Variables

Now, the mapping can be done directly to previous

dened variables.

Page 18

130BD143.10

130BD144.10

Congure the Master MCA 123 POWERLINK

Illustration 4.9 Previous Dened Variables

44

Variables can also be directly declared, via selecting the

Channel Name for each signal and enter the attributes

directly.

Illustration 4.10 Variables Directly Declared

This inserts the Danfoss FC 302 into the B&R system, and

the frequency converter can now be controlled and

supervised via the POWERLINK.

14 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 19

Receive PDOs (PLC

Drive)

Transmit PDOs (Drive PLC)

PCD 9

write

PDO 23

PCD 0

CTW

PCD 1

REF

PCD 9

read

PCD 0

STW

PCD 1

MAV

PDO 23

130BC177.10

How to Control the Frequenc...

Operating Instructions

5 How to Control the Frequency Converter

5.1 PDO Communication

The frequency converter uses the following proles:

Frequency converter proles

•

CANOpen DS 402 prole

•

For each of the two proles there is a set of SDO objects

that is only accessible if the prole is activated in

parameter 8-10 Control Word Prole. The change is active at

the next power-up. Congure the PDO communication,

where a subset of SDOs can be mapped into PDOs for

cyclic communication.

PDO communication is reserved for high-speed cyclic

access to parameters for control and status of the

frequency converter. The PLC sends out process control

data, and the frequency converter responds with a PDO

containing process status data. In the Danfoss POWERLINK

interface, both PDOs can be congured freely.

Select the signals for transmission from the master to the

frequency converter via the PLCs

PLC sets Parameter 12-21 Process Data

parameter 12-22EN-22 Process Data Cong Read and

parameter 12-23 Process Data Cong Write Size, which can

be used to control that the conguration has been sent

correctly from the PLC.

conguration tool. The

Cong Write,

5.2 Process Data

Use the process data part of the PDO for controlling and

monitoring the frequency converter via the POWERLINK.

5.2.1 Process Control Data

The example in Table 5.1 shows control and reference sent

from the PLC to the frequency converter, and status word

and Main Actual Value sent from the frequency converter

to the PLC.

Master to slave

0 1 2 ...... 9

PCD write

Table 5.1 Process Control Data (PCD)

CTW MRV PCD ...... PCD

PCD 0 contains a 16-bit control word where each bit

controls a specic function of the frequency converter, see

chapter 5.3 Control Prole. PCD 1 contains a 16-bit speed

setpoint in percentage format. See chapter 5.2.3 Reference

Handling.

The content of PCD 2 to PCD 9 is read only.

5 5

The POWERLINK option has only one PDO available: PDO

23. The PDO 23 is

exible in size and is adjustable to t all

needs (max. 10 PCDs). The selection is made in the master

conguration and is then automatically downloaded to the

frequency converter during the transition from Init to PreOp. No manual setting of PPO types in the frequency

converter is required.

Option [1] Standard telegram 1 is equivalent to PDO 23.

Illustration 5.1 Standard Telegram

Process Status Data

5.2.2

Process data sent from the frequency converter contain

information about the current state of the frequency

converter.

Slave to master

0 1 2 ...... 9

STW MAV PCD ...... PCD

PCD read

Table 5.2 Process Status Data

PCD 0 contains a 16-bit status word where each bit

contains information regarding a possible state of the

frequency converter.

PCD 1 contains per default the value of the current speed

of the frequency converter in percentage format (see

chapter 5.2.3 Reference Handling).

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 15

Page 20

How to Control the Frequenc...

MCA 123 POWERLINK

5.2.3 Reference Handling

The reference handling in FC Series is an advanced

mechanism that sums up references from dierent sources.

For more information on reference handling, refer to the

VLT® AutomationDrive Design Guide.

Limit [Hz]

limit the actual frequency converter output.

parameter 4-19 Max Output Frequency limits the maximum

output and can also inuence the maximum speed of the

motor.

For reference and MAV formats, see Table 5.3.

55

Illustration 5.2 Reference Handling

Table 5.3 Reference and MAV Formats

The reference, or speed setpoint (MRV, sent via

POWERLINK), is always transmitted to the frequency

converter in percentage format as integers represented in

hexadecimal (0-4000 hex).

NOTICE

Negative numbers are formed as a complement of two.

and parameter 4-14 Motor Speed High Limit [Hz]

MRV/MAV Integer in hex Integer in decimal

100% 4000 16.384

75% 3000 12.288

50% 2000 8.192

25% 1000 4.096

0% 0 0

-25% F000 -4.096

-50% E000 -8.192

-75% D000 -12.288

-100% C000 -16.384

NOTICE

Depending on the setting of parameter 3-00 Reference

Range the reference and MAV are scaled accordingly:

The data type for MRV and MAV is 16-bit standardise

value, which can express a range from -200% to +200%

(8001 to 7FFF).

Illustration 5.3 Scaling of MAV and Reference

NOTICE

If parameter 3-00 Reference Range is set to [0] Min - Max,

a negative reference is handled as 0%.

The speed limit settings depend on parameter 0-02 Motor

Speed Unit and can be set to RPM or Hz. If

parameter 0-02 Motor Speed Unit is set to RPM,

parameter 4-11 Motor Speed Low Limit [RPM] and

parameter 4-13 Motor Speed High Limit [RPM] limit the

actual frequency converter output. If parameter 0-02 Motor

Speed Unit is set to Hz, parameter 4-12 Motor Speed Low

Parameter 1-00 Conguration Mode set to [0] Speed open

loop.

Parameter 3-00 Reference Range set to [0] Min - Max.

Parameter 3-02 Minimum Reference set to 100 RPM.

Parameter 3-03 Maximum Reference set to 3000 RPM.

MRV/MAV Actual speed

0% 0 hex 100 RPM

25% 1000 hex 825 RPM

50% 2000 hex 1550 RPM

75% 3000 hex 2275 RPM

100% 4000 hex 3000 RPM

Table 5.4

5.2.4

Process Control Operation

In process control operation parameter 1-00 Conguration

Mode is set to [3] Process.

The reference range in parameter 3-00 Reference Range is

always [0] Min-Max.

- MRV represents the process setpoint.

- MAV expresses the actual process feedback (range

±200%).

16 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 21

Speed ref.CTW

Master-follower

130BA274.11

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit

no.:

How to Control the Frequenc...

Operating Instructions

5.2.5 Inuence of the Digital Input

Terminals upon FC Control Mode

The inuence of the digital input terminals upon control of

the frequency converter can be programmed in

parameter 8-50 Coasting Select to parameter 8-56 Preset

Reference Select.

NOTICE

The parameter 8-01 Control Site overrules the settings in

parameter 8-50 Coasting Select to parameter 8-56 Preset

Reference Select, and terminal 37 Coasting Stop (safe)

overrules any parameter.

Each digital input signal can be programmed to logic AND,

logic OR, or to have no relation to the corresponding bit in

the control word. This way, eldbus only, eldbus AND

Digital Input, or Ether Fieldbus OR Digital input terminal

can initiate a specic control command, that is stop/coast.

CAUTION

To control the frequency converter via POWERLINK, set

parameter 8-50 Coasting Select to either [1] Bus, or to [2]

Logic AND. Then set parameter 8-01 Control Site to [0]

Digital and ctrl.word or [2] control word only.

5.3 Control Prole

The frequency converter can be controlled according to

the DS 402 prole, or the Danfoss FC prole. Select the

desired control

Prole. The choice of prole aects the control and status

word only. The change of parameter 8-10 Control Word

Prole is activated at the next power-up.

Object 6060 Modes of operation can also control the

desired control prole which can be readout by object

6061 Modes of operation display. Value -1 indicates

frequency converter prole. Value 2 indicates DS 402

Velocity mode. If the frequency converter is run in DS 402

prole, the DS 402 prole must be selected (for example,

by parameter 8-10 Control Word Prole or object 6060). The

four process data Control Word, Reference, Status Word

and Main Actual Value will the information in according to

the specication. Make sure that the prole selected is also

the prole used in the PLC.

prole in parameter 8-10 Control Word

5.4

DS 402 Control Prole

5.4.1 Control Word According to DSP 402

Prole

(Parameter 8-10=DSP 402 prole)

Illustration 5.4 Control Word Prole

Bit Bit value=0 Bit value=1

00 Switch o Switch on

01 Disable voltage Enable voltage

02 Quick stop Run

03 Disable operation Enable operation

04 Disable ramp Enable ramp

05 Freeze Run enable

06 Ramp stop Start

07 No function Reset

08 Reserved

09 Reserved

10 Reserved

11 Jog 1 OFF Jog 1 ON

12 Reserved

13 Setup select (LSB)

14 Setup select (MSB)

15 Forward Reversing

Table 5.5 Denition of Control Bits

Explanation of the control bits

Bit 00, Switch OFF/ON

Bits 00, Switch OFF/ON

Bit 00=“0” - executes transition 2, 6 or 8.

Bit 00=“1” - executes transition 3.

Bit 01, Disable/Enable Voltage

Bit 01=“0” - executes transition 9, 10 or 12.

Bit 01=“1” - enables voltage.

Bit 02, Quick stop/Run

Bit 02="0" - executes transition 7, 10 or 11.

Bit 02="1" - quick stop not active.

5 5

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 17

Bit 03, Disable/enable Operation

Bit 03="0" - executes transition 5.

Bit 03="1" - enables operation.

Bit 04, Quick-stop/ramp

Page 22

Output freq.STW

Bit

no.:

Follower-master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

130BA273.11

How to Control the Frequenc...

MCA 123 POWERLINK

Bit 04="0" - executes transition 7 or 11, Quick stop.

Bit 04="1" - enables ramp.

5.4.2 Status Word According to DS 402

Prole

Bit 05, Freeze output frequency/run enable

Bit 05="0" - the given output frequency is maintained even

if the reference is changed.

Bit 05="1" - the frequency converter is again able to

regulate, and the given reference is followed.

Bit 06, Ramp stop/start

Illustration 5.5 Status Word Prole

Bit 06="0" - the frequency converter controls the motor

down to stop.

Bit 01="1" - gives a start command to the frequency

converter.

55

Bit 07, No function/reset

Reset of trip.

Bit 07="0" - there is no reset.

Bit 07="1" - a trip is reset.

Bit 08, 09 and 10

DSP402 reserved.

Bit 11, Jog 1 OFF/ON

Activation of pre-programmed speed in parameter 8-90 Bus

Jog 1 Speed

JOG 1 is only possible if Bit 04="0", and bit 00-03="1".

Bit 12

Danfoss reserved.

Bit Bit value=0 Bit value=1

00 Not ready to switch ON Ready to switch ON

01 Switched OFF Switched ON

02 Operation disabled Operation enabled

03 No malfunction Malfunction

04 Voltage disabled Voltage enabled

05 Quick stop Run

06 Switch on disable Switch on enable

07 No warning Warning

08 Not running Running

09 Remote disabled Remote enabled

10 Set point not reached Set point reached

11 Speed limit not active Speed limit active

12 Reserved

13 Reserved

14 Reserved

15 Reserved

Table 5.7 Denition of Status Bits

Bits 13/14, Selection of Setup

Bits 13 and 14 are used for selecting among the four menu

Explanation of the status bits

set-ups in accordance with Table 5.6:

Bit 00, Not ready to switch on/Ready to switch on

Set-up Bit 14 Bit 13

0 0 1

0 1 2

1 0 3

1 1 4

Bit 00="0" - state less than “Ready to switch on”.

Bit 00="1" - state at least = “Ready to Switch on”.

Bit 01, Switch o/Switch on

Bit 00="0" - state less than “Switched on”.

Bit 00="1" - state at least = “Switched on”.

Table 5.6 Set-up Selection Table

Bit 15, Forward/reversing

Bit 15="0" - no reversing.

Bit 15="1" - reversing.

Bit 02, Operation disable/Operation enable

Bit 00="0" - state less than “Operation enable”.

Bit 00="1" - state at least = “Operation enable”.

NOTICE

In factory setting reversing is set to [digital] in

parameter 8-54 Reversing Select.

18 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Bit 03, No fault/trip

Bit 03="0" - the frequency converter is not in a fault

condition.

Bit 03="1" - the frequency converter has tripped and needs

a reset signal to run.

Bit 04, Voltage disable/Voltage enable

Bit 04="0" - control word bit 01="1".

Bit 04="1" - control word bit 01="0".

Page 23

How to Control the Frequenc... Operating Instructions

Bit 05, Quick stop/Run

Bit 05="0" - control word bit 02="1".

Bit 05="1" - control word bit 02="0".

Bit 06, Start enable/Start disable

Bit 06="0" - state is not “Switch on disable”.

Bit 06="1" - state = “Switch on enable”.

Bit 07, No warning/Warning

Bit 07="0" - no warning situation.

Bit 07="1" - a warning has occurred.

Bit 08,

Danfoss reserved

Bit 09, Remote disable/Remote enable

Bit 09="0" - the frequency converter has been stopped

with the stop key on the LCP, or [Local] has been selected

in parameter 3-13 Reference Site.

Bit 09="1" - it is possible to control the frequency

converter via the serial port.

Bit 10, setpoint not reached/Set point reached

Bit 10="0" - the actual motor speed is dierent from the

speed reference set. This situation can occur while the

speed is ramped up/down during start/stop.

Bit 10="1" - the present motor speed equals the speed

reference set.

Bit 11, Speed limit not active/speed limit active

Bit 11="0" - the output frequency is out of the range set in

parameters 4-11/4-12 Motor Speed low Limit RPM/Hz or

parameters 4-13/4-14 Motor Speed high Limit RPM/Hz.

Bit 11="1" - the output frequency is within the mentioned

range.

Bit 12, DSP 402 reserved

Bit 13, DSP 402 reserved

Bit 14, Running/Not running

Bit 14="0" - the motor is not running.

Bit 14="1" - the frequency converter has a valid start signal

or that the output frequency is greater than 0 Hz.

Bit 15, Danfoss reserved

8-10 Control

Option: Function:

[0] * FC prole

[7] CANOpen DSP 402

FC Prole is the default control prole for the frequency

converter, whereas CANOpen DSP 402 is the CiA

standardized control

transition state machine.

Prole

prole, featuring the special DSP 402

5 5

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 19

Page 24

How to Control the Frequenc... MCA 123 POWERLINK

55

Illustration 5.6 DSP 402 State Machine

20 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 25

How to Control the Frequenc... Operating Instructions

5.4.3 DSP 402 State Transitions

Transition State Control

word

- Start condition 0000 0000 0

1

2

3

4

5

6

7

8

9

10

11

11

12

13

14

15

16

Start-up⇒Not ready to switch on

Switch On Disabled⇒Switch On Disabled

Not Ready to Switch On⇒Switched On

Ready to Switch On⇒Switched On

Switched On⇒Ready to Switch On

Operation Enabled⇒Switched On

Switched On⇒Ready to Switch On

Ready to Switch On⇒Switch On Disable

Operation Enable⇒Ready to Switch On

Operation Enable⇒Switch On Disable

Switched On⇒Switched On Disable

Operation Enabled⇒Quick Stop Active

Operation Enabled⇒Quick Stop Active

Quick Stop Active⇒Switch On Disabled

All states⇒Fault Reaction Active

Fault Reaction Active⇒Fault

Fault⇒Switch On Disabled

Quick Stop Active⇒Operation Enable (not

supported)

0000 0200 0000, 0001 0240 0006 0231 0007 0233 000F 0237 0007 0233 Motor ramps to 0 RPM with programmed ramp down

0006 0231 0001, 0000 0240 0006 0231 If the motor is not braked, and the power section is

0001, 0000 0240 If the motor is not braked, and the power section is

0001, 0000 0240 If the motor is not braked, and the power section is

0002 0207 Motor ramps to 0 RPM with programmed quick ramp

0003 0217 Motor ramps to 0 RPM with programmed quick ramp

0001, 0000 0240 If the motor is not braked, and the power section is

xxxx 023F xxxx 023F 0000 0240 -

- - -

Status

word

Action

parameter.

5 5

switched o immediately, the motor is free to rotate.

switched o immediately, the motor is free to rotate.

switched o immediately, the motor is free to rotate.

parameter.

parameter.

switched o immediately, the motor is free to rotate.

Table 5.8 DSP 402 State Transitions

5.5

Danfoss FC Control Prole

5.5.1 Control Word according to FC Prole

(CTW)

To select Danfoss FC protocol in the control word,

parameter 8-10 Control Word Prole must be set to [0]

frequency converter prole. The control word is used to

send commands from a master (PLC or PC) to a slave

(frequency converter).

Bit Bit value=0 Bit value=1

00 Reference value external selection lsb

01 Reference value external selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output frequency Use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 04 active

13 Parameter set-up selection lsb

14 Parameter set-up selection msb

15 No function Reverse

Table 5.9 Bit Values for FC Control Word

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 21

Page 26

How to Control the Frequenc...

MCA 123 POWERLINK

Explanation of the control bits

Bits 00/01 Reference value

Bits 00 and 01 are used to choose between the four

reference values, which are pre-programmed in

parameter 3-10 Preset Reference according to Table 5.10.

NOTICE

In parameter 8-56 Preset Reference Select a selection is

made to dene how Bit 00/01 gates with the

corresponding function on the digital inputs.

Bit 01 Bit 00 Programmed

ref. value

0 0 1 [0]

55

0 1 2 [1]

1 0 3 [2]

1 1 4 [3]

Table 5.10 Programmed Reference Values for Bits

Bit 02, DC brake

Bit 02=“0” - leads to DC braking and stop. Braking current

and duration are set in parameter 2-01 DC Brake Current

and parameter 2-02 DC Braking Time.

Bit 02=“1” - leads to ramping.

Bit 03, Coasting

Bit 03=“0” - causes the frequency converter to immediately

coast the motor to a standstill.

Bit 03=“1” - enables the frequency converter to start the

motor if the other starting conditions have been fullled.

Parameter

Parameter 3-10 Preset

Reference

Parameter 3-10 Preset

Reference

Parameter 3-10 Preset

Reference

Parameter 3-10 Preset

Reference

NOTICE

In parameter 8-50 Coasting Select a selection is made to

dene how Bit 03 gates with the corresponding function

on a digital input.

Bit 04, Quick stop

Bit 04=“0” - causes a quick stop, ramping the motor speed

down to stop via parameter 3-81 Quick Stop Ramp Time.

Bit 04=“1” - the frequency converter ramps the motor

speed down to stop via parameter 3-81 Quick Stop Ramp

Time.

Bit 05, Hold output frequency

Bit 05=“0” - causes the present output frequency (in Hz) to

freeze. The frozen output frequency can only be changed

with the digital inputs (parameter 5-10 Terminal 18 Digital

Input to parameter 5-15 Terminal 33 Digital Input)

programmed to Speed up and Speed down.

Bit 05=“1” - use ramp.

NOTICE

If Freeze output is active, stop the frequency converter

with

Bit 03 Coasting stop

•

Bit 02 DC braking

•

Digital input (parameter 5-10 Terminal 18 Digital

•

Input to parameter 5-15 Terminal 33 Digital

Input) programmed to DC braking, Coasting

stop, or Reset and coasting stop.

Bit 06, Ramp stop/start

Bit 06=“0” - causes a stop, in which the motor speed is

ramped down to stop via the selected ramp down

parameter.

Bit 06=“1" - permits the frequency converter to start the

motor, if the other starting conditions have been

fullled.

NOTICE

In parameter 8-53 Start Select a selection is made to

dene how Bit 06 Ramp stop/start gates with the

corresponding function on a digital input.

Bit 07, Reset

Bit 07="0" - does not cause a reset.

Bit 07="1" - causes the reset of a trip. Reset is activated on

the signals leading edge, that is, when changing from logic

"0" to logic "1".

Bit 08, Jog

Bit 08="0" - no function.

Bit 08="1" - parameter 3-19 Jog Speed [RPM] determines the

output frequency.

Bit 09, Selection of ramp 1/2

Bit 09="0" - ramp 1 is active (parameter 3-40 Ramp 1 Type

to parameter 3-47 Ramp 1 S-ramp Ratio at Decel. Start).

Bit 09="1" - ramp 2 (parameter 3-50 Ramp 2 Type to

parameter 3-57 Ramp 2 S-ramp Ratio at Decel. Start) is

active.

Bit 10, Data not valid/Data valid

Is used to tell the frequency converter whether it should

use or ignore the control word.

Bit 10="0" - the control word is ignored.

Bit 10="1" - the control word is used. This function is

relevant, because the control word is always contained in

the telegram, regardless of which type of telegram is used.

Thus, it is possible to turn

wished to use it when updating or reading parameters.

Bit 11, Relay 01

Bit 11="0" - relay 01 not activated.

Bit 11="1" - relay 01 activated, provided Control word bit

11 has been chosen in parameter 5-40 Function Relay.

Bit 12, Relay 04

Bit 12="0" - relay 04 has not been activated.

o the control word, if it is not

22 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 27

How to Control the Frequenc...

Operating Instructions

Bit 12="1" - relay 04 has been activated, provided Control

word bit 12 has been chosen in parameter 5-40 Function

Relay.

Bit 13/14, Selection of set-up

Bits 13 and 14 are used to choose from the four menu setups according to Table 5.11:

The function is only possible when [9] Multi-Set-up is

selected in parameter 0-10 Active Set-up.

Set-up Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

Table 5.11 Selection of Set-up

NOTICE

In parameter 8-55 Set-up Select a selection is made to

dene how Bit 13/14 gates with the corresponding

function on the digital inputs.

Bit 15 Reverse

Bit 15="0" - no reversing.

Bit 15="1" - reversing.

Status Word according to FC Prole

5.5.2

(STW)

The status word is used to inform the master (for example,

a PC) of the operation mode of the slave (frequency

converter).

Refer to chapter 8 Application Examples for an example of a

status word telegram using PPO type 3.

Bit Bit=0 Bit=1

00 Control not ready Control ready

01 Frequency converter not

ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved 06 No error Triplock

07 No warning Warning

08 Speed reference Speed=reference

09 Local operation Bus control

10 Out of frequency limit Frequency limit ok

11 No operation In operation

12 Frequency converter OK Stopped, autostart

13 Voltage OK Voltage exceeded

14 Torque OK Torque exceeded

15 Timer OK Timer exceeded

Table 5.12 Denition of Status Bits

Frequency converter ready

Explanation of the status bits

Bit 00, Control not ready/ready

Bit 00="0" - the frequency converter has tripped.

Bit 00="1" - the frequency converter controls are ready, but

the power component is not necessarily receiving any

power supply (in case of 24 V external supply to controls).

Bit 01, frequency converter ready

Bit 01="0" - the frequency converter is not ready for

operation.

Bit 01="1" - the frequency converter is ready for operation,

but there is an active coasting command via the digital

inputs or via serial communication.

Bit 02, Coasting stop

Bit 02="0" - the frequency converter has released the

motor.

Bit 02="1" - the frequency converter can start the motor

when a start command is given.

Bit 03, No error/trip

Bit 03="0" - the frequency converter is not in fault mode.

Bit 03="1" - the frequency converter is tripped, and that a

reset signal is required to re-establish operation.

Bit 04, No error/error (no trip)

Bit 04="0" - the frequency converter is not in fault mode.

Bit 04=“1” - there is a frequency converter error but no

trip.

Bit 05, Not used

Bit 05 is not used in the status word.

Bit 06, No error/triplock

Bit 06="0" - the frequency converter is not in fault mode.

Bit 06=“1” - the frequency converter is tripped, and locked.

Bit 07, No warning/warning

Bit 07="0" - there are no warnings.

Bit 07="1" - a warning has occurred.

5 5

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 23

Page 28

How to Control the Frequenc...

Bit 08, Speed reference/speed = reference

Bit 08="0" - the motor is running, but that the present

speed is dierent from the preset speed reference. It could,

for example, be the case while the speed is being ramped

up/down during start/stop.

Bit 08="1" - the present motor present speed matches the

preset speed reference.

Bit 09, Local operation/bus control

Bit 09="0" - [Stop/Reset] is activated on the control unit, or

that Local control in parameter 3-13 Reference Site is

selected. It is not possible to control the frequency

converter via serial communication.

Bit 09="1" - it is possible to control the frequency

converter via the eldbus/serial communication.

55

Bit 10, Out of frequency limit

Bit 10="0" - the output frequency has reached the value in

parameter 4-11 Motor Speed Low Limit [RPM] or

parameter 4-13 Motor Speed High Limit [RPM].

Bit 10="1" - the output frequency is within the dened

limits.

Bit 11, No operation/in operation

Bit 11="0" - the motor is not running.

Bit 11="1" - the frequency converter has a start signal or

the output frequency is greater than 0 Hz.

Bit 12, frequency converter OK/stopped, auto start

Bit 12="0" - there is no temporary over temperature on the

frequency converter.

Bit 12="1" - the frequency converter has stopped because

of over temperature, but the unit has not tripped and

resumes operation once the over temperature stops.

Bit 13, Voltage OK/limit exceeded

Bit 13="0" - there are no voltage warnings.

Bit 13="1" - the DC voltage in the frequency converters

intermediate circuit is too low or too high.

Bit 14, Torque OK/limit exceeded

Bit 14="0" - the motor current is lower than the torque

limit selected in parameter 4-16 Torque Limit Motor Mode or

parameter 4-17 Torque Limit Generator Mode.

Bit 14="1" - the torque limits in parameter 4-16 Torque Limit

Motor Mode and parameter 4-17 Torque Limit Generator

Mode have been exceeded.

Bit 15, Timer OK/limit exceeded

Bit 15="0" - the timers for motor thermal protection and

VLT thermal protection, respectively, have not exceeded

100%.

Bit 15="1" - one of the timers has exceeded 100%.

MCA 123 POWERLINK

24 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 29

Communication Prole Area Operating Instructions

6 Communication Prole Area

6.1 Description - Communication Prole Area

This chapter describes the general layout of the supported POWERLINK communication area. The process data objects are

dened in this area.

6.2 1000-1FFF Communication Object Area

Index [hex] Object (symbolic name) Name Type Read/write

1000 VAR Device type UNSIGNED32 ro

1001 VAR Error register UNSIGNED8 ro

1006 VAR Communication cycle period UNSIGNED32 rw

1008 VAR Manufacturer device name VISIBLE_STRING ro

1009 VAR Manufacturer hardware version VISIBLE_STRING ro

100A VAR Manufacturer software version VISIBLE_STRING ro

1010 ARRAY Store parameters UNSIGNED32 rw

1011 ARRAY Restore default parameters UNSIGNED32 rw

0x1C14 VAR DLL_CNLossOfSocTolerance_U32 UNSIGNED32 rw

0x1E40 RECORD NWL_IpAddrTable_1_REC NWL_IpAddrTable_TYPE ro/rw

0x1E4A RECORD RECORD NWL_IpGroup_REC NWL_IpGroup_TYPE ro/rw

1018 RECORD Identity object Identity (23h) ro

1020 RECORD CFM_VerifyConguration_REC CFM_VerifyConguration_TYPE ro

1030 RECORD NMT_InterfaceGroup_0h_REC NMT_InterfaceGroup_0h_TYPE ro

1031 RECORD NMT_InterfaceGroup_1h_REC NMT_InterfaceGroup_0h_TYPE ro

1300 VAR SDO_SequLayerTimeout_U32 UNSIGNED32 rw

1400 RECORD PDO_RxCommParam_16h_REC UNSIGNED8 ro

1600 ARRAY PDO_RxMappParam_00h_AU64 UNSIGNED64 rw

1800 ARRAY PDO_TxCommParam_16h_REC UNSIGNED8 ro

1A00 ARRAY PDO_TxMappParam_00h_AU64 UNSIGNED64 rw

1C0A RECORD DLL_CNCollision_REC UNSIGNED32 rw

1C0B RECORD DLL_CNLossSoC_REC UNSIGNED32 rw

1C0F RECORD DLL_CNCRCError_REC UNSIGNED32 rw

1C14 VAR DLL_CNLossOfSocTolerance_U32 UNSIGNED32 rw

1E40 RECORD NWL_IPAddrTable_1_REC NWL_IpAddrTable_TYPE ro/rw

1E4A RECORD RECORD NWL_IpGroup_REC NWL_IpGroup_TYPE ro/rw

1F81 VAR NMT_NodeAssignment_AU32

1F82 VAR NMT_FeatureFlags_U32 UNSIGNED32 ro

1F83 VAR NMT_EPLVersion_U8 UNSIGNED8 ro

1F8C VAR NMT_CurrNMTState_U8 UNSIGNED8 ro

1F93 RECORD NMT_EPLNodeID_REC UNSIGNED8 ro

1F98 VAR NMT_CycleTiming_REC UNSIGNED32 ro

1F99 VAR NMT_CNBasicEthernetTimeout_U32 UNSIGNED32 rw

1F9A VAR NMT_HostName_VSTR VISIBLE_STRING32 rw

1F9B VAR NMT_MultiplCycleAssign_AU8 UNSIGNED8 rw

1F9E VAR NMT_ResetCmd_U8 UNSIGNED8 rw

6 6

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 25

Page 30

Communication Prole Area MCA 123 POWERLINK

Index [hex] Object (symbolic name) Name Type Read/write

2000-5FFF Vendor specic area

603F VAR Error Code UNSIGNED16 ro

6040 VAR Control word UNSIGNED16 rw

6041 VAR Status word UNSIGNED16 ro

6042 VAR vl_target_velocity SIGNED16 rw

6043 VAR vl_velocity_demand SIGNED16 ro

6044 VAR vl_velocity_actual_value SIGNED16 ro

6046 ARRAY vl_velocity_min_max_amount UNSIGNED32 ro

6048 RECORD vl_velocity_acceleration See description ro

6049 RECORD vl_velocity_deceleration See description ro

6060 VAR Modes of operation SIGNED8 rw

6061 VAR Modes of operation display SIGNED8 ro

6502 VAR Supported drive mode UNSIGNED32 ro

6504 VAR Drive manufacture VISIBLE_STRING ro

See chapter 6.3 2000-5FFF Danfoss Specic Object

Area

66

Table 6.1 Communication Object Overview

1000h Device Type

6.2.1

This object describes the type of device and its

functionality. It is composed of a 16-bit eld describing the

device prole used, and a second 16-bit eld providing

additional information about optional functionality of the

device.

Additional information Device prole number

Mode bits Type bits Bits

31.. 24 23.. 16 15.. 0

0 1 (frequency converters) 0=FC Prole

402=DS 402

Table 6.2 1000h Device Type

1001h Error Register

6.2.2

1006h Communication Cycle Period

6.2.3

This object denes the communication cycle time interval

in μs. This object is reset to its default value by object

1011h. This object is set from the MN.

6.2.4 1008h Manufacturer Device Name

This object contains the device name as dened in

parameter 15-40 FC Type.

Index Meaning

1008h for example, FC 302

Table 6.4 1008h Manufacturer Device Name

1009h Manufacturer Hardware

6.2.5

Version

This object is the error register of the device. Only bit 0

and bit 5 is supported. The two bits are active (high) if an

alarm is active in alarm word 1 or alarm word 2.

This object contains the hardware version for the

POWERLINK interface.

Bit Meaning

0 Generic error

1 Current

2 Voltage

3 Temperature

4 Communications error (overrun, error state)

5 Device prole specic

6 Reserved (always zero)

7 Manufacturer specic

Table 6.3 1001h Error Register

26 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

100Ah Manufacturer Software Version

6.2.6

This object contains the Danfoss software version as

displayed in parameter 15-49 SW ID Control Card.

1010h Store Parameters

6.2.7

In the standard conguration, the contents of parameters

written via eldbus are stored in volatile memory. The

changed data will be lost after a power cycle. This index

permits non-volatile storage of all frequency converter

parameters which have been changed. Writing to one of

the indexes will set parameter 12-28 Store Data Values.

Page 31

Communication

Prole Area Operating Instructions

Index, sub-index Meaning

1010h 0 Number sub-index supported

1010h 1 Save option parameters

1010h 2 All

1010h 3 Not supported

Table 6.5 1010h Store Parameters

Writing the value “save” (0x65766173) to sub-index 1,

stores all frequency converter parameters of all set-ups into

non-volatile memory, all other values are rejected.

6.2.8 1011h Restore Default Parameters

To restore factory default settings:

1. Write the value “load” to sub-index 1.

2. Initiate the next power cycle manually.

The default value is restored.

Index, sub-index Meaning

1011h 0 Number of sub-index supported

1011h 1 Restore all default parameters and restart

Table 6.6 1011h Restore Default Parameters

Writing the value “load” (0x64616F6C) restores all

frequency converter parameters of all set-ups to factory

values, except the communications parameters. All other

values are rejected, and abort code 0x08000020 is

returned. The frequency converter has to be power cycled

before the changes get active and the motor must be in

the state coast or stopped.

1018h Identity Object

6.2.9

This object contains general information about the device.

The vendor ID (sub-index 1h) contains a unique value

allocated to each manufacturer.

The manufacturer-specic product code (sub-index 2h)

identies a specic device version.

The manufacturer-specic revision number (sub-index 3h)

consists of a major revision number and a minor revision

number.

Index, sub-index Meaning

1018h 0 Number of entries

1018h 1 Vendor ID

1018h 2 Product code

1018h 3 Revision number (major revision number and

minor revision number)

1018h 4 Serial number

Table 6.7 1018h Identity Object

6.2.10 1020h CFM_VerifyConguration_REC

This object contains the devices local conguration date

and time. The object values are set by managing node or

conguration tool.

Index, subindex

1020h 0 Number of entries

1020h 1 ConfDate_U32, Days since January 1, 1984

1020h 2 ConfTime_U32, milliseconds after midnight

1020h 3 ConfId_U32, assigned by the conguration tool

1020h 4 VerifyConfInvalid_BOOL, Value False indicates

Table 6.8 1020h

6.2.11

This object is used to congure and retrieve parameters of

the network interfaces (physical or virtual) via SDO.

Index, sub-index Meaning

1030h 0 Number of entries

1030h 1 InterfaceIndex_U16

1030h 2 InterfaceDescription_VSTR t

1030h 3 InterfaceType_U8

1030h 4 InterfaceMtu_U16

1030h 5 InterfacePhysAddress_OSTR

1030h 6 InterfaceName_VSTR

1030h 7 InterfaceOperStatus_U8

1030h 8 InterfaceAdminState_U8

1030h 9 Valid_BOOL

Table 6.9 1030h NMT_InterfaceGroup_0h_REC

6.2.12

Meaning

that conguration was not modied since last

storage of ConfId_U32

CFM_VerifyConguration_REC

1030h NMT_InterfaceGroup_0h_REC

1031h NMT_InterfaceGroup_1h_REC

6 6

This object is used to congure and retrieve parameters of

the network interfaces (physical or virtual) via SDO.

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 27

Page 32

Communication

Prole Area MCA 123 POWERLINK

Index, sub-index Meaning

1031h 0 Number of entries

1031h 1 InterfaceIndex_U16

1031h 2 InterfaceDescription_VSTR t

1031h 3 InterfaceType_U8

1031h 4 InterfaceMtu_U16

1031h 5 InterfacePhysAddress_OSTR

1031h 6 InterfaceName_VSTR

1031h 7 InterfaceOperStatus_U8

1031h 8 InterfaceAdminState_U8

1031h 9 Valid_BOOL

Table 6.10 1031h NMT_InterfaceGroup_1h_REC

6.2.13

1300h SDO_SequLayerTimeout_U32

This object provides a timeout value in [ms] for the

connection abort recognition of the SDO sequence Layer.

66

Default value is 30000. This object is linked to

parameter 12-62 SDO Timeout.

6.2.14

1400h

PDO_RxCommParam_16h_REC

Index, subindex

1600h 0 Number of sub-index supported

1600h 1 parameter 12-21 Process Data Cong Write, [0]

1600h 2 parameter 12-21 Process Data Cong Write, [1]

1600h 3 parameter 12-21 Process Data Cong Write, [2]

1600h 4 parameter 12-21 Process Data Cong Write, [3]

1600h 5 parameter 12-21 Process Data Cong Write, [4]

1600h 6 parameter 12-21 Process Data Cong Write, [5]

1600h 7 parameter 12-21 Process Data Cong Write, [6]

1600h 8 parameter 12-21 Process Data Cong Write, [7]

1600h 9 parameter 12-21 Process Data Cong Write, [8]

1600h 10 parameter 12-21 Process Data Cong Write, [9]

Table 6.13 1600h PDO_RxCommParam_00h _AU64

Meaning

Index

Index

Index

Index

Index

Index

Index

Index

Index

Index

This object describes attributes of PDO Communication for

RPDO. Object indices describe the Node ID and PDO

For every PDO channel up to ten objects can be mapped.

Mapping Version. Mapping Version must be set by congu-

ration tool depending on PDO mapping.

oset related to the start address of the PDO payload

The

and the length of data is provided for every mapped

High Nibble

Main version Sub version

Table 6.11 Mapping Version Structure

PDOs diering main version will be rejected. PDOs

diering sub version is accepted. Mapping version 0

indicates that no mapping version is available.

Index, sub-index Meaning

1400h 0 Number of sub-index supported

1400h 1 NodeID_U8

1400h 2 MappingVersion_U8

Table 6.12 1400h PDO_RxCommParam_16h_REC

6.2.15

1600h PDO_RxCommParam_00h

_AU64

This objects indices describe mapping of object contained

in RPDO payload to object dictionary entries.

Low Nibble

object.

Octet

oset

0-1 Index Index of the object to be mapped

2 Sub-index Sub-index of the object to be mapped

3 reserved

4-5 Oset Oset related to start of PDO payload (Bit

6-7 Length Length of the mapped object (Bit count)

Table 6.14 Description of Octet Oset

Bits 63 .. 48 47 .. 32 31 .. 24 23 .. 16

Name Length Oset Reserved Sub-index

Encoding UNSIGNED16 UNSIGNED16 - UNSIGNED8

Bits 15 .. 0

Name Index

Encoding UNSIGNED16

Name Description

count)

MSB

LSB

Table 6.15 Internal Mapping of PDO Mapping Entry

28 Danfoss A/S © Rev. 2013-02-11 All rights reserved. MG92C202

Page 33

Communication

Prole Area Operating Instructions

6.2.16 1800h

PDO_TxCommParam_16h_REC

This object describes attributes of PDO Communication for

RPDO. Object indices describe the Node ID and PDO

Mapping Version. Mapping Version must be set by congu-

ration tool depending on PDO mapping. Access is read/

write. Mapping version 0 indicates that no mapping

version is available.

Index, sub-index Meaning

1400h 0 Number of sub-index supported

1400h 1 NodeID_U8

1400h 2 MappingVersion_U8

Table 6.16 1800h PDO_TxCommParam_16h_REC

6.2.17

1A00h

PDO_TxMappParam_00h_AU64

This objects indices describe mapping of object contained

in RPDO payload to object dictionary entries.

Index, subindex

1A00h0 Number of sub-index supported

1A00h1 parameter 12-22EN-22 Process Data Cong Read, [0]

1A00h2 parameter 12-22EN-22 Process Data Cong Read, [1]

1A00h3 parameter 12-22EN-22 Process Data Cong Read, [2]

1A00h4 parameter 12-22EN-22 Process Data Cong Read, [3]

1A00h5 parameter 12-22EN-22 Process Data Cong Read, [4]

1A00h6 parameter 12-22EN-22 Process Data Cong Read, [5]

1A00h7 parameter 12-22EN-22 Process Data Cong Read, [6]

1A00h8 parameter 12-22EN-22 Process Data Cong Read, [7]

1A00h9 parameter 12-22EN-22 Process Data Cong Read, [8]

1A00h10 parameter 12-22EN-22 Process Data Cong Read, [9]

Table 6.17 1A00h PDO_TxMappParam_00h_AU64

Map up to ten objects for every PDO channel.

The oset related to the start address of the PDO payload

and the length of data is provided for every mapped

object.

Meaning

Index

Index

Index

Index

Index

Index

Index

Index

Index

Index

Octet

oset

0-1 Index Index of the object to be mapped

2 Sub-index Sub-index of the object to be mapped

3 Reserved

4-5 Oset Oset related to start of PDO payload (Bit

6-7 Length Length of the mapped object (Bit count)

Table 6.18 Description of Octet Oset

Bits 63 .. 48 47 .. 32 31 .. 24 23 .. 16

Name Length Oset Reserved Sub-index

Encoding UNSIGNED16 UNSIGNED16 - UNSIGNED8

15 .. 0

Index

UNSIGNED16

Table 6.19 Internal Mapping of PDO Mapping Entry

6.2.18

Name Description

count)

MSB

LSB

1C0Ah DLL_CNCollision_REC

This object contains information regarding collisions on the

network.

Index, sub-index Meaning

1C0Ah 0 Number of entries

1C0Ah 1 CumulativeCnt_U32

1C0Ah 2

1C0Ah 3

Table 6.20 1C0Ah DLL_CNCollision_REC

6.2.19

1C0Bh DLL_CNLossSoC_REC

parameter 12-68 Cumulative Counters

parameter 12-68 Cumulative Counters

This object contains information regarding loss of SoC on

the network.

Index, sub-index Meaning

1C0Bh 0 Number of entries

1C0Bh 1

1C0Bh 2

1C0Bh 3

Table 6.21 1C0Bh DLL_CNLossSoC_REC

6.2.20

1C0Fh DLL_CNCRCError_REC

CumulativeCnt_U32, [2]

parameter 12-68 Cumulative Counters

ThresholdCnt_U32, [2]

parameter 12-67 Threshold Counters

Threshold_U32, [2] parameter 12-66 Threshold

This object contains information regarding “CRC Errors” on

the network. CumulativeCnt_U32 increases with one each

time a CRC error occurs. CumulativeCnt_U32 decrements

6 6

MG92C202 Danfoss A/S © Rev. 2013-02-11 All rights reserved. 29

Page 34

Communication

Prole Area MCA 123 POWERLINK

with one for each cycle without an error. When CumulativeCnt_U32 is equal or larger than ThresholdCnt_U32, the

drive issues Warning 34 in the display.

Index, sub-index Meaning

1C0Fh 0 Number of entries

1C0Fh 1

1C0Fh 2

1C0Fh 3

CumulativeCnt_U32, [5]

parameter 12-68 Cumulative Counters

ThresholdCnt_U32, [5]

parameter 12-67 Threshold Counters

Threshold_U32, [5] parameter 12-66 Threshold

Binary value NMT state

0001 1100 NMT_CS_NOT_ACTIVE (Default)

0001 1101 NMT_CS_PRE_OPERATIONAL_1

0101 1101 NMT_CS_PRE_OPERATIONAL_2

0110 1101 NMT_CS_READY_TO_OPERATE

1111 1101 NMT_CS_OPERATIONAL

0100 1101 NMT_CS_STOPPED

0001 1110 NMT_CS_BASIC_ETHERNET

Table 6.25 NMS State

6.2.24 1F93h NMT_EPLNodeID_REC

Table 6.22 1C0Fh DLL_CNCRCError_REC

This object contains the POWERLINK NodeID.

6.2.21

Feature ags indicate communication prole specic

properties of the frequency converter.

66

Bit Name Remark

0 Isochronous

1 SDO by UDP/IP Not supported

2 SDO by ASnd

3 SDO by PDO Not supported

4 NMT Info Services Not supported

5 Extended NMT State Commands Not supported

6 Dynamic PDO Mapping

7 NMT Service by UDP/IP Not supported

8 Conguration Manager Not supported

9 Multiplexed Access

10 NodeID setup by SW Not supported

11 MN Basic Ethernet Mode Not supported

12 Routing Type 1 Support Not supported

13 Routing Type 2 Support Not supported

14 SDO Read/Write All by Index Not supported

15 SDO Read/Write Multiple Parameter by

16..31 Reserved

6.2.22

The object holds the POWERLINK communication prole

version that is implemented.