Page 1

Fac t Sheet

VLT® EtherNet/IP MCA 121

Ordering number

Unco ate d 13 0 B111 9

Coated 130B1219

High performance EtherNet/IPTM

eldbus option for

n VLT® HVAC Drive FC 102

n VLT® AQUA Drive FC 202

n VLT® AutomationDrive FC 302

n VLT® Lift Drive LD 302

The VLT® EtherNet/IP MCA 121 option

oers plug and play connectivity to

EtherNet/IP based networks, such as

Rockwell PLC systems, via the Common Industry Protocol (CIPTM) protocol.

The option can handle a single EtherNet/IP Class 1 connection with a

Requested Packet Interval (RPI) of 1 ms

in both directions. This makes it one of

the highest performing EtherNet/IP

devices in the market.

The option features a built-in 2-port

switch, facilitating traditional line

network or Device Level Ring (DLR)

topology. The DLR in the MCA 121 is

Beacon based, to achieve the fastest

fault detection with recovery time

down to 3 ms. These topologies

eliminate the need for the complex

cabling and expensive industrial

Ethernet switches, which are used in

star topology.

Other features

n Built-in web-server for remote

diagnosis and reading out basic drive

diagnosis.

n An E-mail notificator can be config-

ured for sending an e-mail message

to one or several receivers, if certain

warnings or alarms occur, or have

cleared again.

n Add On Instruction (AOI) that reduces

the time, effort and cost involved in

development of the PLC program.

The AOI contains a list of pre-defined

tags used to control the drive

n Swift integration into the PLC

configuration tool via an EDS file

Application protocols

n EtherNet/IP (Industrial Protocol) for

controlling and parameter settings

n

CIP (Common Industry Protocol) For

communication to the PLC

n

HTTP (Hypertext Transfer Protocol)

for diagnosis via build-in web server

n

SMTP (Simple Mail Transfer Protocol)

for e-mail notification

n

DHCP (Dynamic Host Configuration

Protocol) automatic IP address

configuration

n

Supports connection to

VLT® Motion Control Tool MCT 10

over TCP/IP

n

Supports read/write Scattered of

Drive parameters

DLR

Support for high

availability

Feature Benet

Connectivity to EtherNet/IP based networks

Requested Packet Interval (RPI) of 1 ms

Built-in web-server

E-mail noticator Noties if warnings or alarms occur

Two Ethernet ports with built-in switch

Based on CIP Protocol

Supports Device Level Ring (DLR) topology

Connects to Rockwell PLC-system via the

Common Industry Protocol (CIP

High performance

Remote diagnosis and reading out of

basic drive parameters

• Simple cabling

• No need for expensive switches or hubs

Reuse of PLC program when migrating from

DeviceNet to EtherNet/IP or supporting both

technologies.

A single fault in one of the Ethernet cables, or

one of the devices in the ring, will not lead to

loss of the communication to all devices.

TM

drives.danfoss.com

)

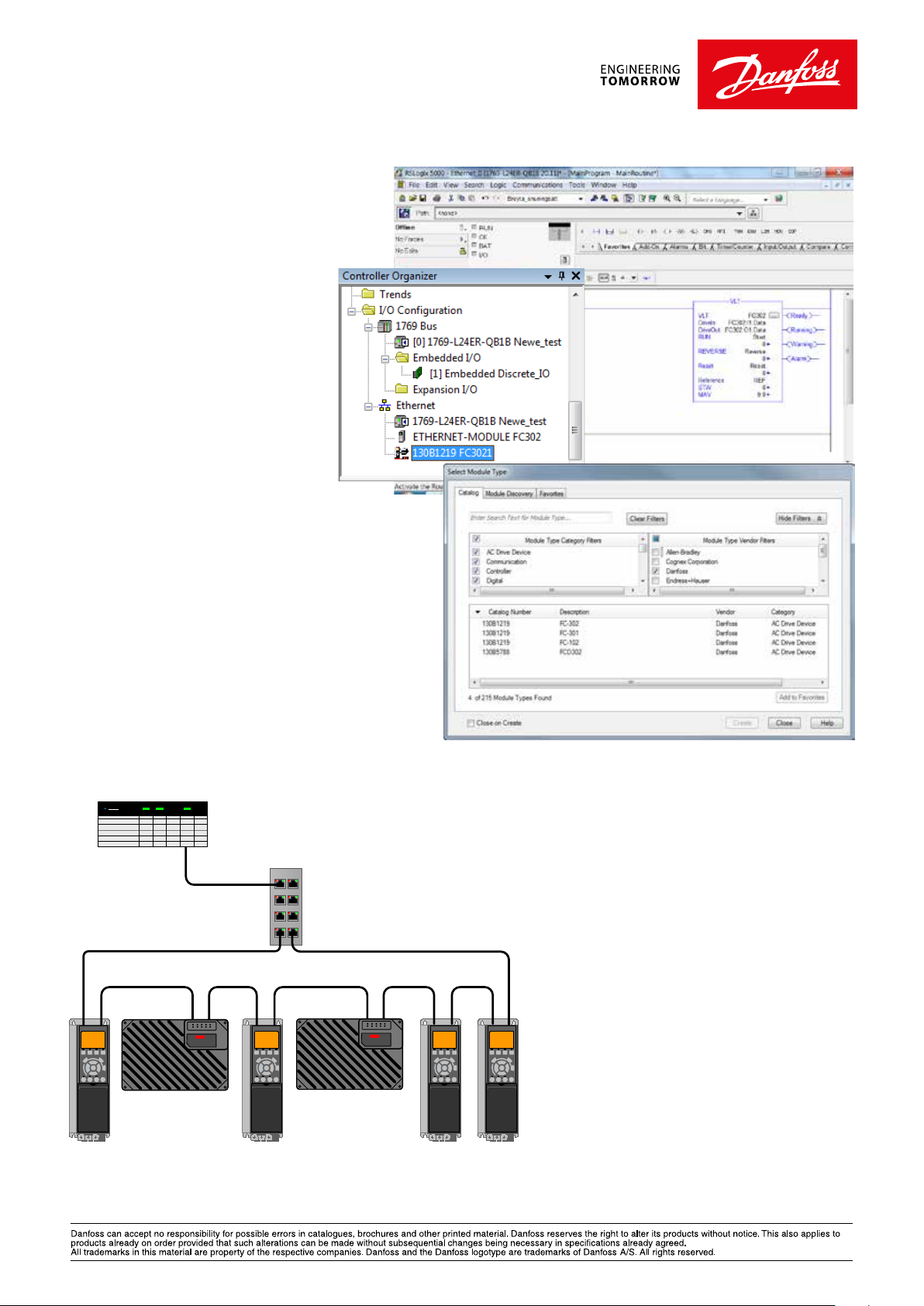

Page 2

The VLT® EtherNet/IP MCA 121 option

integrates swiftly into the PLC

conguration tool, via the EDS le.

VLT® drives support the ODVA and FC

proles for I/O Assembly objects.

Likewise, they also support:

n CIP objects, including I/O Assem-

blies for ve dierent assembly

objects (AO) to tailor the commutation for optimal performance

n AC Drive object

n Other objects to support easy

conguration and integration with

PLCs supporting EtherNet/IP

Downloads

These les are available free of charge

in the software download area at

drives.danfoss.com:

n Add-on Instruction (AOI)

n EDS le

Device Level Ring (DLR) topology

PLC

Ring

supervisor

AC drives

Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, drives.danfoss.com, E-mail: info@danfoss.com

DKDD.PFO.604.A4.02 © Copyright Danfoss Drives | 2016.04

EtherNet/IP™ is a trademarks of ODVA, Inc.

Loading...

Loading...