Page 1

Installation Guide

VLT® PROFINET MCA 120

VLT® AutomationDrive FC 361

1 Introduction

1.1 Purpose of this Installation Guide

This installation guide provides information for quick replacement of a VLT® PROFINET MCA 120 interface in the VLT® AutomationDrive

FC 361.

The installation guide is intended for use by qualified personnel. Users are assumed to be familiar with the VLT® drive, with PROFINET

technology, and with the PC or PLC used as a master in the system.

Read the instructions before installation and ensure that instructions for safe installation are observed.

1.2 Trademarks

VLT® is a registered trademark for Danfoss A/S.

Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856 | 1

Page 2

Installation Guide | VLT® PROFINET MCA 120

2 Safety

2.1 Safety Precautions

WARNING

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death

or serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The minimum waiting time is specified in table Discharge time and is also visible

-

on the nameplate on top of the drive.

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Safety

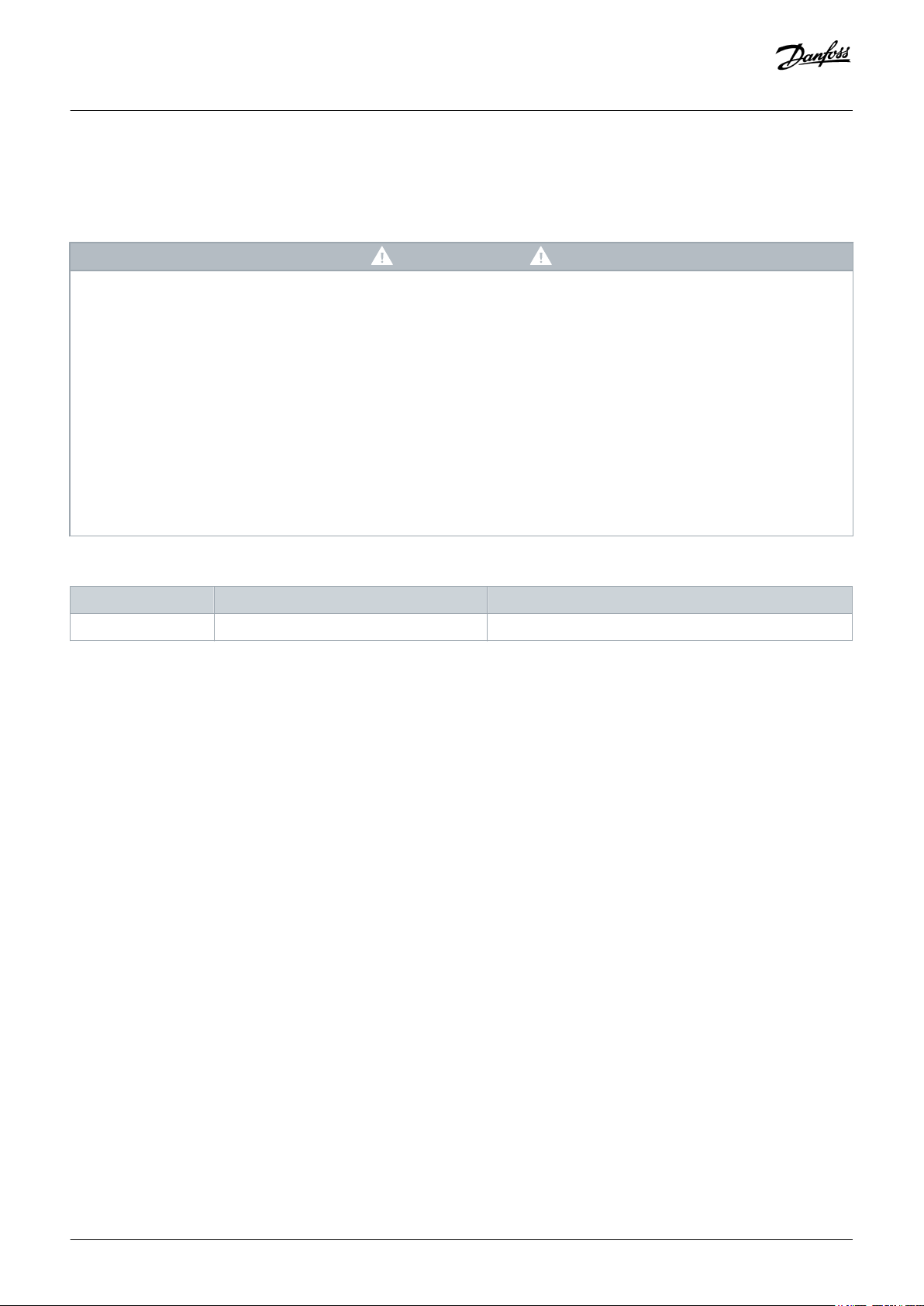

Table 1: Discharge Time

Voltage [V] Power range [kW (hp)] Minimum waiting time (minutes)

380–480 90–315 kW (125–450 hp) 20

2 | Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856

Page 3

Installation Guide | VLT® PROFINET MCA 120

Technical Data

3 Technical Data

3.1 Cabling Requirements

• Choose suitable media for Ethernet data transmission. CAT5e and CAT6 cables are recommended for industrial applications. Both

types are available as unshielded twisted pair and shielded twisted pair.

• Shielded cables are recommended for use in industrial environments and with drives.

• A maximum cable length of 100 m (328 ft) is allowed between the switches.

3.2 Cable Specifications

PROFINET cables used are based electrically on category 5 balanced LAN cables according to ISO/IEC 11801 Edition 2.0, Class D.

Type C cables can be used in special applications (for example, the use of trailing cables and frequently moved machine parts), even

though their design and mechanical parameters can deviate from the specifications of type A and type B cables. Still, most of the

electrical parameters (for example, impedance levels) are retained.

Highly flexible copper cables generally have the finest stranded conductors and a highly resistant polyurethane outer sheath. Various

outer sheath materials are permitted to meet the various demands regarding resistance of industrial environments and exterior/

underground laying (natural and synthetic oil, grease, coolants/lubricants, chemicals, high and low temperatures, UV radiation, and so

on).

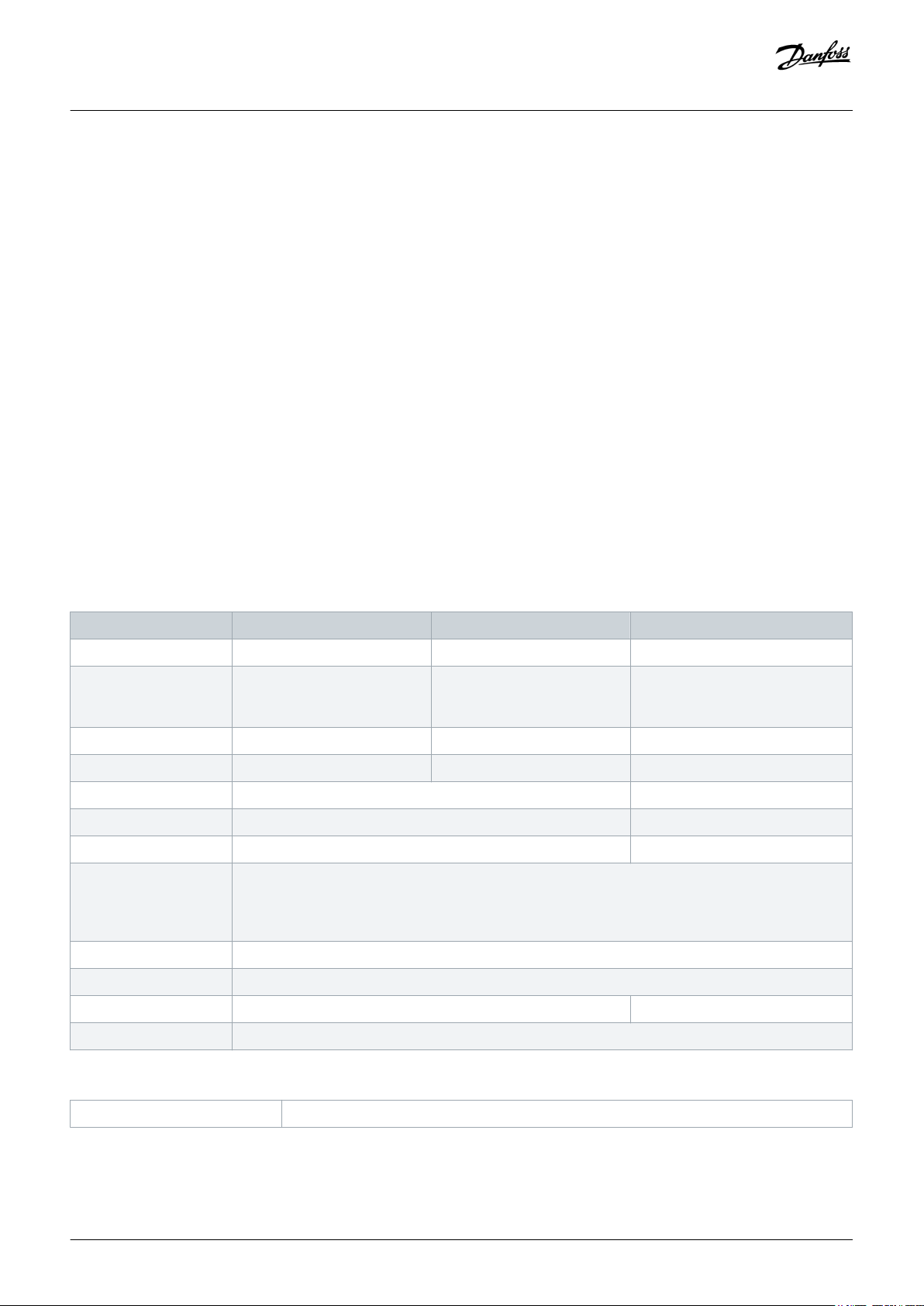

Table 2: Cable Specifications for Application Types A, B and C

Cable type Application type A Application type B Application type C

Design Data cable Data cable Data cable

Cable installation type Stationary, no movement after

installation.

Cable marking PROFINET type A PROFINET type B PROFINET type C

Core cross-section AWG 22/1 AWG 22/7 AWG 22/..

Outer diameter 5.5–8.0 mm (0.22–0.31 in) Application dependent

Core diameter 1.5 ± 0.1 mm (0.06 ± 0.004 in) Application dependent

Color (outer sheath) Green RAL6018 Application dependent

Core identification (colors)

star quad 2 pair

Number of cores 4

Cable design 2 pairs or 1 star quad

Shielding design type Aluminum foil + Cu braiding Application

Plug type RJ 45 (IP20 or IP65/67)/M12

White, yellow, blue, orange

Pair 1: white (RXD+), blue (RXD-) Pair 2: yellow (TXD+), orange (TXT-)

Flexible, occasional movement

or vibration.

Special applications (for example,

highly flexible, permanent movement, vibration, or torsion).

Table 3: Transmission Performance Requirements

Relevant standard ISO/IEC 11801 Edition 2.0, IEC 61156 (minimum Category 5)

Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856 | 3

Page 4

Installation Guide | VLT® PROFINET MCA 120

Delay skew ≤20 ns/100 m

Transfer impedance ≤50 m Ω/m at 10 MHz

Technical Data

4 | Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856

Page 5

e30bd910.10

2

4

3

M12 PIN#

RJ45

8

1

1

. . . . . .

Installation Guide | VLT® PROFINET MCA 120

Installation

4 Installation

4.1 Mounting

Procedure

1. Make sure that the power to the drive is disconnected.

2. Remove the front cover from the drive.

3. Remove the LCP (Local Control Panel) or blind cover, and then remove the LCP cradle from the drive.

4. Disconnect the communication cables from the existing MCA option card.

5. Remove the existing MCA option card from the drive.

6. Fit the new VLT® PROFINET MCA 120 option card into slot A. Mount the option with the Ethernet port facing up for top cable entry.

7. Connect the Ethernet cables. See

illustration 1 and table 4 for the definition of PROFINET connectors.

Illustration 1: PROFINET Connectors

Table 4: PROFINET Connectors

Signal M12 PIN# RJ 45

RX + 1 1

TX + 2 2

RX - 3 3

TX - 4 4

8. Set the address switches if needed.

9. Fit the LCP cradle.

10. Fit the LCP or blind cover in the LCP cradle.

11. Fit the front cover on the drive.

12. Connect power to the drive.

4.2 Setting Address Switches

The option has address switches that are used to set the station name (host name).

• When all switches are set to ON, or all are set to OFF, change the station name via 12-08 Host Name or via DCP command.

• In all other combinations, the address switches have priority over the parameter setting. The station name is set based on the value

in 15-40 FC Type, and a 3-digit number selected from the DIP settings.

Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856 | 5

Page 6

B:08:XX:XX:XX

Option A

134

B6779

Host Name

8 7 6 5 4 3 2 1

OFF

ON

Ethernet Port 2

e30bd786.11

Installation Guide | VLT® PROFINET MCA 120

Installation

Illustration 2: Address Switches

Use the address switches to set the 253 different station names according to table 5.

Table 5: Host Names Setting

Switch 8 7 6 5 4 3 2 1

12-08 Host Name +128 +64 +32 +16 +8 +4 +2 +1

005 OFF OFF OFF OFF OFF ON OFF ON

035 OFF OFF ON OFF OFF OFF ON ON

082 OFF ON OFF ON OFF OFF ON OFF

212 ON ON OFF ON OFF ON OFF OFF

The station name change comes into effect at the next power-up. Read the station name in 12-08 Host Name.

6 | Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856

Page 7

e30bg792.10

Installation Guide | VLT® PROFINET MCA 120

Installation

4.3 Wiring Procedures

Procedure

1. Mount the pre-configured cable wires with the connectors on the fieldbus option. For cable specifications, refer to 3.2 Cable

Specifications.

Illustration 3: Wiring

2. Fix the cable to the metal base plate using the springs.

3. Tie down the cable and route it with other control wires inside the unit.

NOTICE

Do not strip the Ethernet cable. Ground the shielded Ethernet cables through the RJ45 connector on the PROFINET

interface.

Danfoss A/S © 2019.03

AN274237376992en-000101 / 130R0856 | 7

Page 8

Installation Guide | VLT® PROFINET MCA 120

Installation

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

Danfoss A/S © 2019.03 MG06N102

AN274237376992en-000101/ 130R0856

*MG06N102*

Loading...

Loading...