Page 1

Operating Guide

VLT® FCD 300 PROFIBUS Converter MCA 117

VLT® Decentral Drive FCD 300 and VLT® Decentral Drive FCM 300

Page 2

Page 3

ContentsOperating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Contents

1 Introduction 5

1.1 Purpose of this Operating Guide 5

1.2 Additional Resources 5

1.3 Document and Software Version 5

1.4 Product Overview 6

1.4.1 Intended Use 6

1.4.2 Hardware 6

1.4.3 Performance 7

2 Safety 8

2.1 Safety Symbols 8

2.2 Qualified Personnel 8

2.3 Safety Precautions 8

3 Installation 11

3.1 Introduction to Installation 11

3.2 Electrical Installation 11

3.2.1 Supply and Motor Terminals 11

3.2.2 Control Signal Connectors 13

3.2.3 EMC Precautions 16

4 Configuring the System 18

4.1 Preparing for Configuration 18

4.2 PROFIBUS Address Set via Hardware Switches 18

4.3 PROFIBUS Address Set via Parameter or SSA Command 20

4.4 Commissioning 20

4.5 LED Behavior 20

4.6 Factory Settings 22

5 Parameter Mapping Lists 25

5.1 FCD 300 Parameter Group 0 25

5.2 FCD 300 Parameter Group 1 31

5.3 FCD 300 Parameter Group 2 39

5.4 FCD 300 Parameter Group 3 48

5.5 FCD 300 Parameter Group 4 56

5.6 FCD 300 Parameter Group 5 65

5.7 FCD 300 Parameter Group 6 73

5.8 FCD 300 Parameter Group 8 78

5.9 FCD 300 Parameter Group 9 80

AQ289550754901en-000101 / | 3Danfoss A/S © 2019.11

Page 4

ContentsOperating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

6 Troubleshooting 86

6.1 Troubleshooting Hints 86

7 Appendix 87

7.1 Abbreviations 87

7.2 Conventions 87

AQ289550754901en-000101 /4 | Danfoss A/S © 2019.11

Page 5

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Introduction

1 Introduction

1.1 Purpose of this Operating Guide

This operating guide provides information for the installation, commissioning, and parameter mapping of a VLT® FCD 300 PROFIBUS

Converter MCA 117 when installed in a VLT® Decentral Drive FCD 302.

The operating guide is intended for use by qualified personnel. Users are assumed to be familiar with:

• VLT® decentral drives.

• PROFIBUS.

Read the instruction before installation and ensure that the instructions for safe installation are observed.

Essential information for quick installation and setup is found in:

1.4.1 Intended Use

•

•

1.4.2 Hardware

• 3.1 Introduction to Installation

•

3.2 Electrical Installation

Detailed information including the full range of setup options and diagnosis tools is found in:

• 5 Parameter Mapping Lists

VLT® is a registered trademark for Danfoss A/S.

1.2 Additional Resources

The following manuals may be helpful when installing the VLT® FCD 300 PROFIBUS Converter MCA 117:

• VLT® Decentral Drive FCD 302 Operating Guide.

• VLT® Decentral Drive FCD 302 Design Guide.

• VLT® AutomationDrive FC 301/FC 302 Programming Guide.

More manuals are available at www.danfoss.com.

1.3 Document and Software Version

This manual is regularly reviewed and updated. All suggestions for improvement are welcome.

The original language of this manual is English.

NOTICE

The converter is based on the latest firmware release of the VLT® Decentral Drive FCD300 and VLT® Decentral Drive FCM300.

The firmware versions are listed in table 1. If the FCD/FCM drive that has to be replaced has a older version (lower number) the

converter works, but may not convert parameters correctly.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 5

Page 6

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

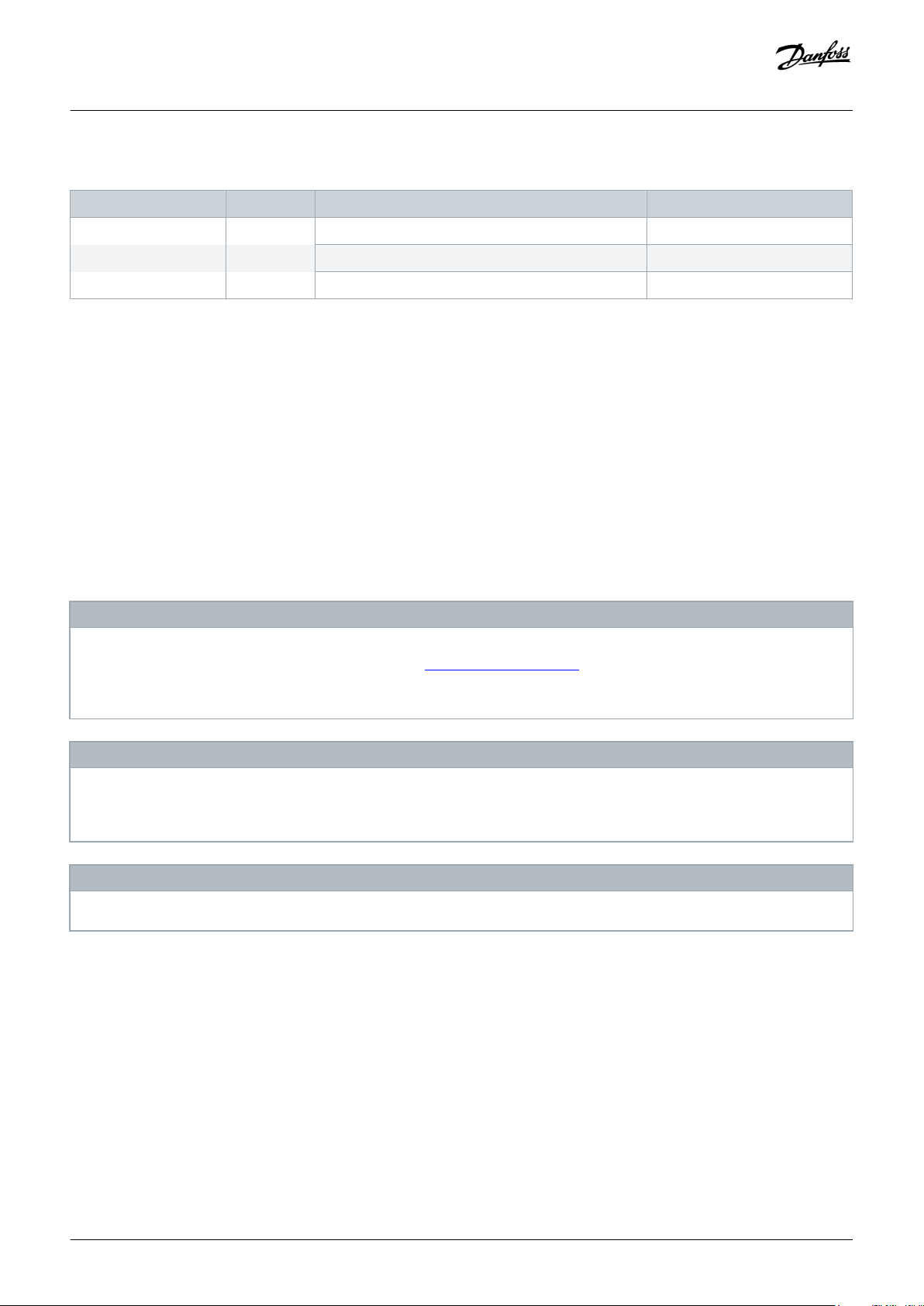

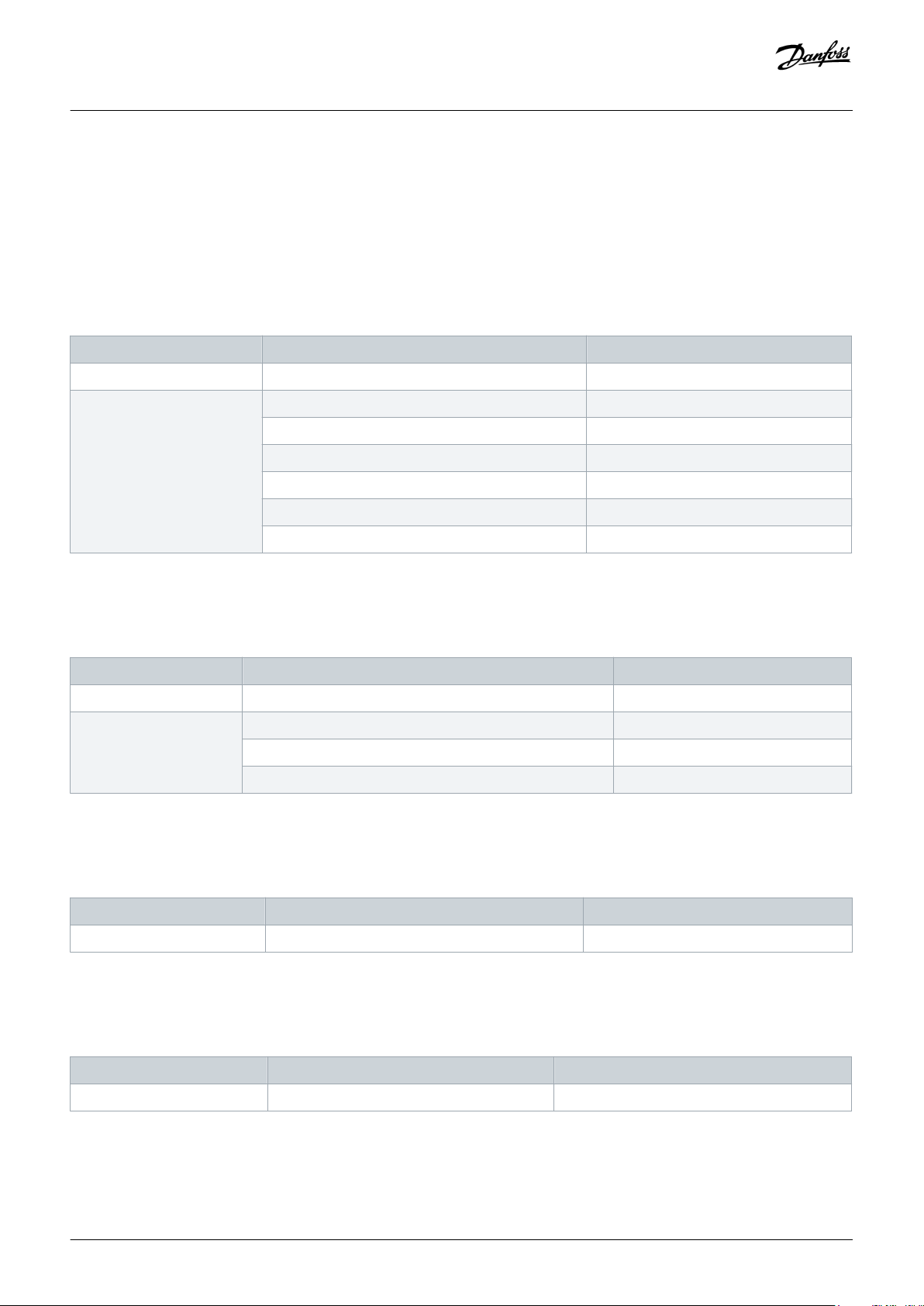

Table 1: Document, Firmware, and Software Versions

Edition Remarks Drive firmware version PROFIBUS firmware version

AQ2895507549010101 First release VLT® Decentral Drive FCD 302, version 7.67 or higher FCD300 Converter, version 2.0x

VLT® Decentral Drive FCD 300, version 1.6x PROFIBUS, version 3.x/4.x

VLT® Decentral Drive FCM 300, version 3.2x PROFIBUS, version 2.x/4.x

Introduction

1.4 Product Overview

1.4.1 Intended Use

This manual relates to the VLT® FCD 300 PROFIBUS Converter MCA 117.

The VLT® FCD 300 PROFIBUS Converter MCA 117 is intended for replacing a VLT® Decentral Drive FCD 300 or a VLT® Decentral Drive

FCM 300 with a VLT® Decentral Drive FCD 302 in a PROFIBUS network.

With this PROFIBUS converter option, the FCD 302 reacts as an FCD 300 or an FCM 300 on the PROFIBUS network. Changes to PLC

programming or configuration are normally not necessary.

The FCD 302 identifies itself either as an FCD 300 or an FCM 300 on the PROFIBUS network. A write command to, for example, ramp-up

time in FCD 300 is automatically linked to the corresponding ramp-up time parameter in the VLT® Decentral Drive FCD 302.

NOTICE

Some parameters in the FCD 300 and FCM 300 are not supported in the FCD 302, and some parameters cannot be accessed via

the VLT® FCD 300 PROFIBUS Converter MCA 117. Refer to 5 Parameter Mapping Lists for more information. If a write request is

attempted to a parameter selection which is not supported, the drive discards the value and issues a positive reply. Only

parameters and functions described in this manual are supported.

NOTICE

The replacement drive must match the power size or be bigger than the replaced FCD 300 or FCM 300. Make sure that the

brake chopper matches the new drive. Make sure that the new drive meets the local regulations concerning the Machinery

Directive, pre-fuses, and other appropriate regulations.

NOTICE

Observe local rules and regulations when replacing a drive in an existing installation.

1.4.2 Hardware

• The VLT® FCD 300 PROFIBUS Converter MCA 117 supports VLT® Decentral Drive FCD 302 only.

• There is no support for PROFIBUS FMS networks.

6 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 7

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Introduction

1.4.3 Performance

• The VLT® Decentral Drive FCD 302 reacts faster on most commands as the VLT® Decentral Drive FCD 300/FCM 300, which can

influence the applications. When replacing a VLT® Decentral Drive FCD 300/FCM 300 with the VLT® FCD 300 PROFIBUS Converter

MCA 117, the installer must ensure that the functionality is maintained. Due to the different timing, it may be necessary to

reprogram the controller, where signals from the drives react faster.

• The motor control algorithm of the VLT® Decentral Drive FCD 302 results in a better motor performance compared to FCD 300/FCM

300.

NOTICE

FACTORY SETTING OF PARAMETERS

After initialization of the FCD 302, most parameters are set to match the factory settings of the FCD 300/FCM 300 parameters.

NOTICE

LINKED SETUPS

To synchronize changes made with a running motor, ensure that setups are linked. Link the setups in parameter 0-12 This Setup

Linked to.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 7

Page 8

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

Safety

NOTICE

Indicates information considered important, but not hazard-related (for example, messages relating to property damage).

2.2 Qualified Personnel

Correct and reliable transport, storage, installation, operation, and maintenance are required for the trouble-free and safe operation of

the drive. Only qualified personnel are allowed to install and operate this equipment.

Qualified personnel are defined as trained staff, who are authorized to install, commission, and maintain equipment, systems, and

circuits in accordance with pertinent laws and regulations. Also, the qualified personnel must be familiar with the instructions and

safety measures described in this manual.

2.3 Safety Precautions

WARNING

HIGH VOLTAGE

AC drives contain high voltage when connected to AC mains input, DC supply, or load sharing. Failure to perform installation,

start-up, and maintenance by qualified personnel can result in death or serious injury.

Only qualified personnel must perform installation, start-up, and maintenance.

-

8 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 9

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

WARNING

UNINTENDED START

When the drive is connected to the AC mains, the motor may start at any time, causing risk of death, serious injury, and

equipment or property damage. The motor may start by activation of an external switch, a fieldbus command, an input

reference signal from the LCP or LOP, via remote operation using MCT 10 Set-up software, or after a cleared fault condition.

Press [Off] on the LCP before programming parameters.

-

Disconnect the drive from the mains whenever personal safety considerations make it necessary to avoid unintended

-

motor start.

Check that the drive, motor, and any driven equipment are in operational readiness.

-

WARNING

DISCHARGE TIME

The drive contains DC-link capacitors, which can remain charged even when the drive is not powered. High voltage can be

present even when the warning indicator lights are off.

Failure to wait the specified time after power has been removed before performing service or repair work could result in death

or serious injury.

Stop the motor.

-

Disconnect AC mains, permanent magnet type motors, and remote DC-link supplies, including battery back-ups, UPS, and

-

DC-link connections to other drives.

Wait for the capacitors to discharge fully. The time for full discharge of the capacitors is minimum 4 minutes for VLT®

-

Decentral Drive FCD 302, 400 V AC, 0.37–3.0 kW (0.5–4.0 hp).

Before performing any service or repair work, use an appropriate voltage measuring device to make sure that the capacitors

-

are fully discharged.

Safety

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the drive properly can result in death or serious injury.

Ensure the correct grounding of the equipment by a certified electrical installer.

-

WARNING

ROTATING SHAFTS

Contact with rotating shafts and electrical equipment can result in death or serious injury.

Ensure that only trained and qualified personnel perform installation, start-up, and maintenance.

-

Ensure that electrical work conforms to national and local electrical codes.

-

Follow the procedures in this guide.

-

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 9

Page 10

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

WARNING

UNINTENDED MOTOR ROTATION WINDMILLING

Unintended rotation of permanent magnet motors creates voltage and can charge the unit, resulting in death, serious injury, or

equipment damage.

Ensure that permanent magnet motors are blocked to prevent unintended rotation.

-

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the drive can result in serious injury when the drive is not properly closed.

Ensure that all safety covers are in place and securely fastened before applying power.

-

Safety

10 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 11

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

3 Installation

3.1 Introduction to Installation

The VLT® FCD 300 PROFIBUS Converter MCA 117 changes the functionality of a VLT® Decentral Drive FCD 302 so that it can be used as a

spare part for a VLT® Decentral Drive FCD 300 or a VLT® DriveMotor FCM 300.

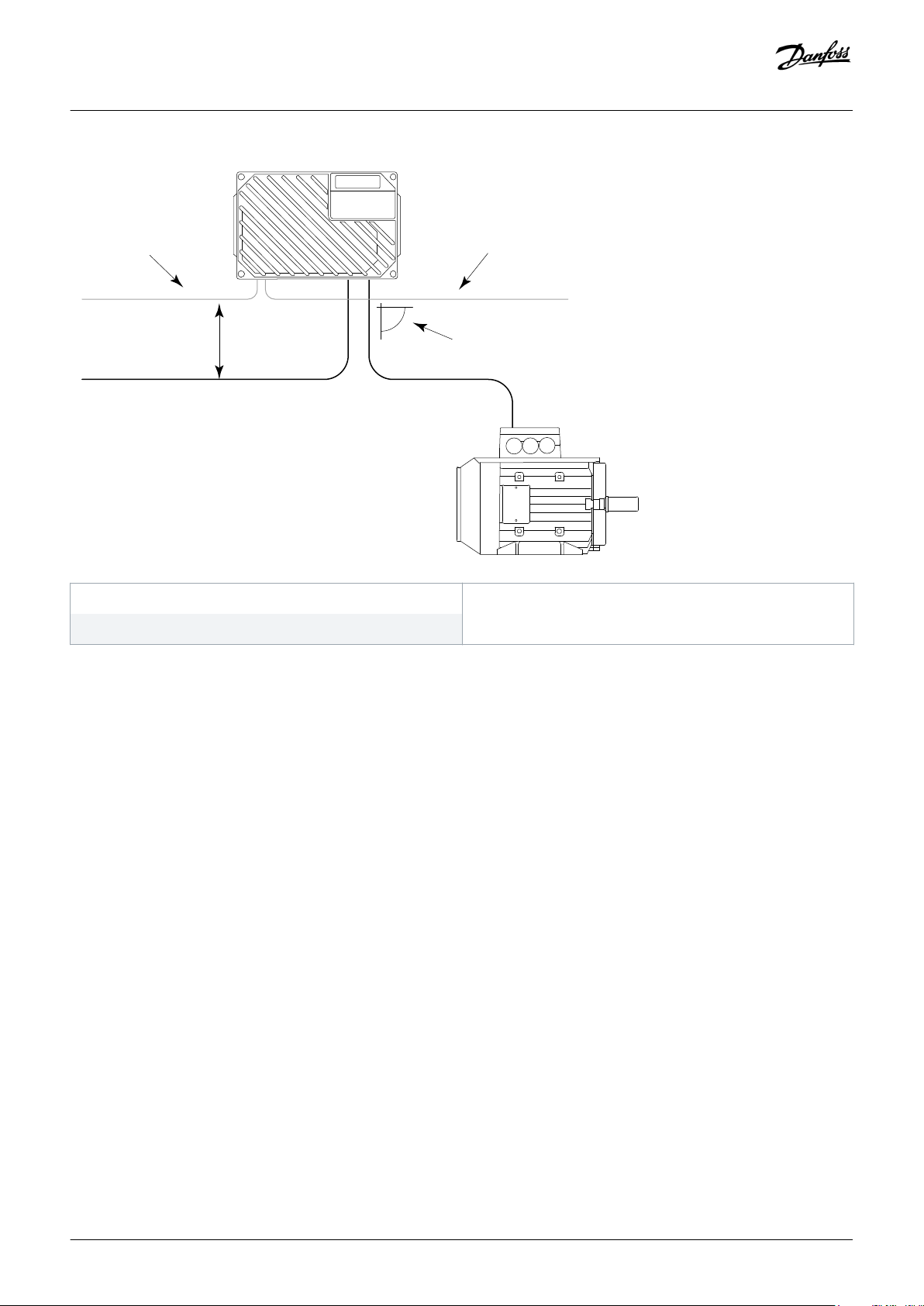

A VLT® Decentral Drive FCD 302 (0.37–2.2 kW (0.5–3.0 hp)) with flat bracket and adapter brackets (order number 134B6775) can be

mounted using the same drilling holes as for the FCD 300.

For a 3.0 kW (4.0 hp) FCD 302, mounting with adapter brackets is not possible. Thus, new holes must be drilled to mount the drive.

The FCD 302 cannot be used as a direct replacement of the VLT® Decentral Drive FCM 300 electronic part. For reuse of the existing

electric motor, a terminal box has to be fitted to the motor, and a motor cable has to be used as connection between the motor and

the FCD 302. Observe local regulations when changing the installation.

Initial power-up

The VLT® FCD 300 PROFIBUS Converter MCA 117sets the parameters of the VLT® Decentral Drive FCD 302 to FCD 300 defaults in 3

cases:

• At first time power up.

• When the drive has been set to initialize via parameter 14-22 Operation Mode.

• When a 3-finger reset is performed from the LCP at power-up.

This gives a short commissioning time and improves the backwards compatibility.

The MCA 117 also changes the default settings of the I/Os of the FCD 302 to match those of the FCD 300.

3.2 Electrical Installation

For electrical installation, local regulations might require further updates. This could be the case where the installation must be

updated to fulfill newer standards when machines are updated, or if local regulations have changed since the original decentral drives

were installed.

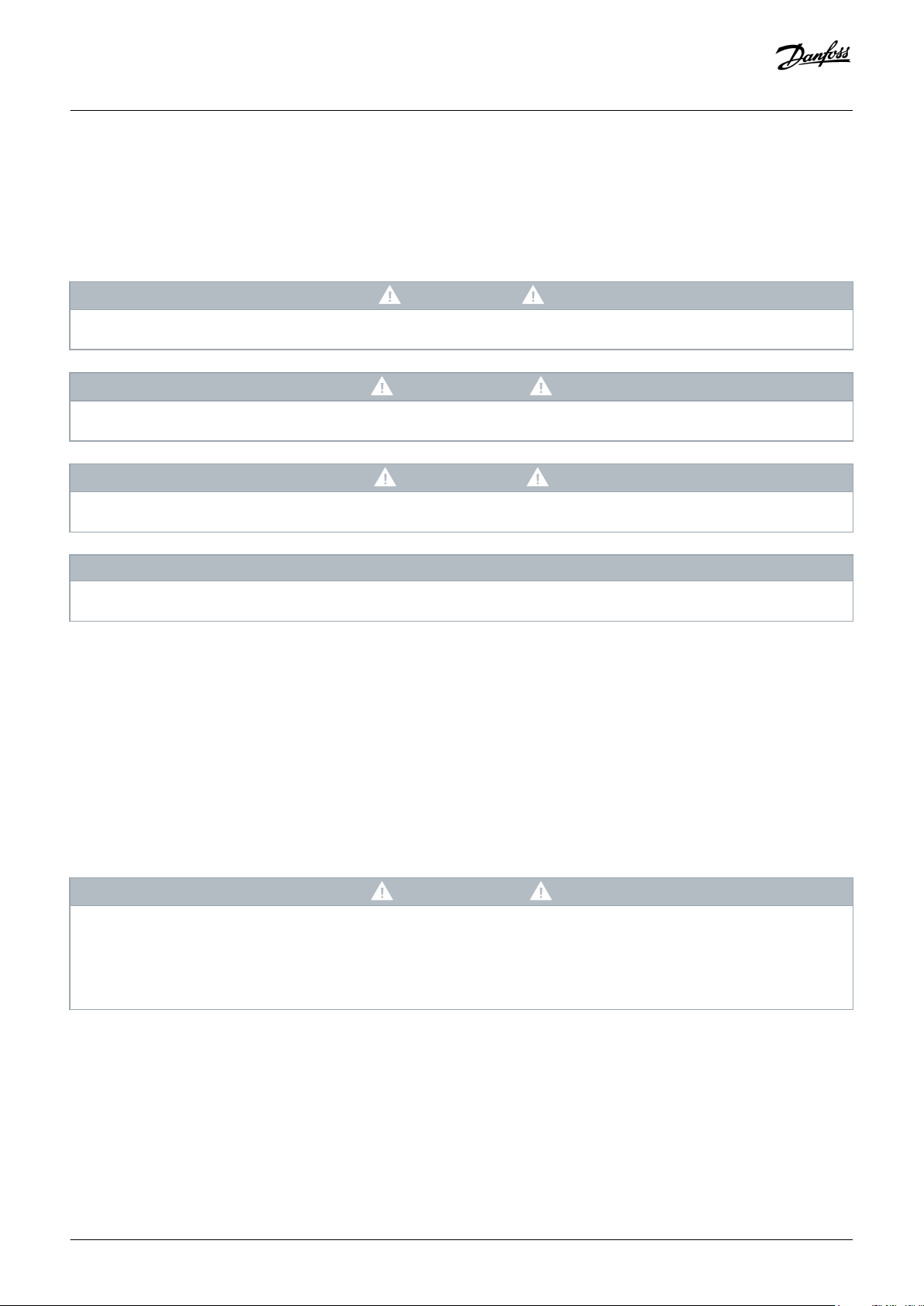

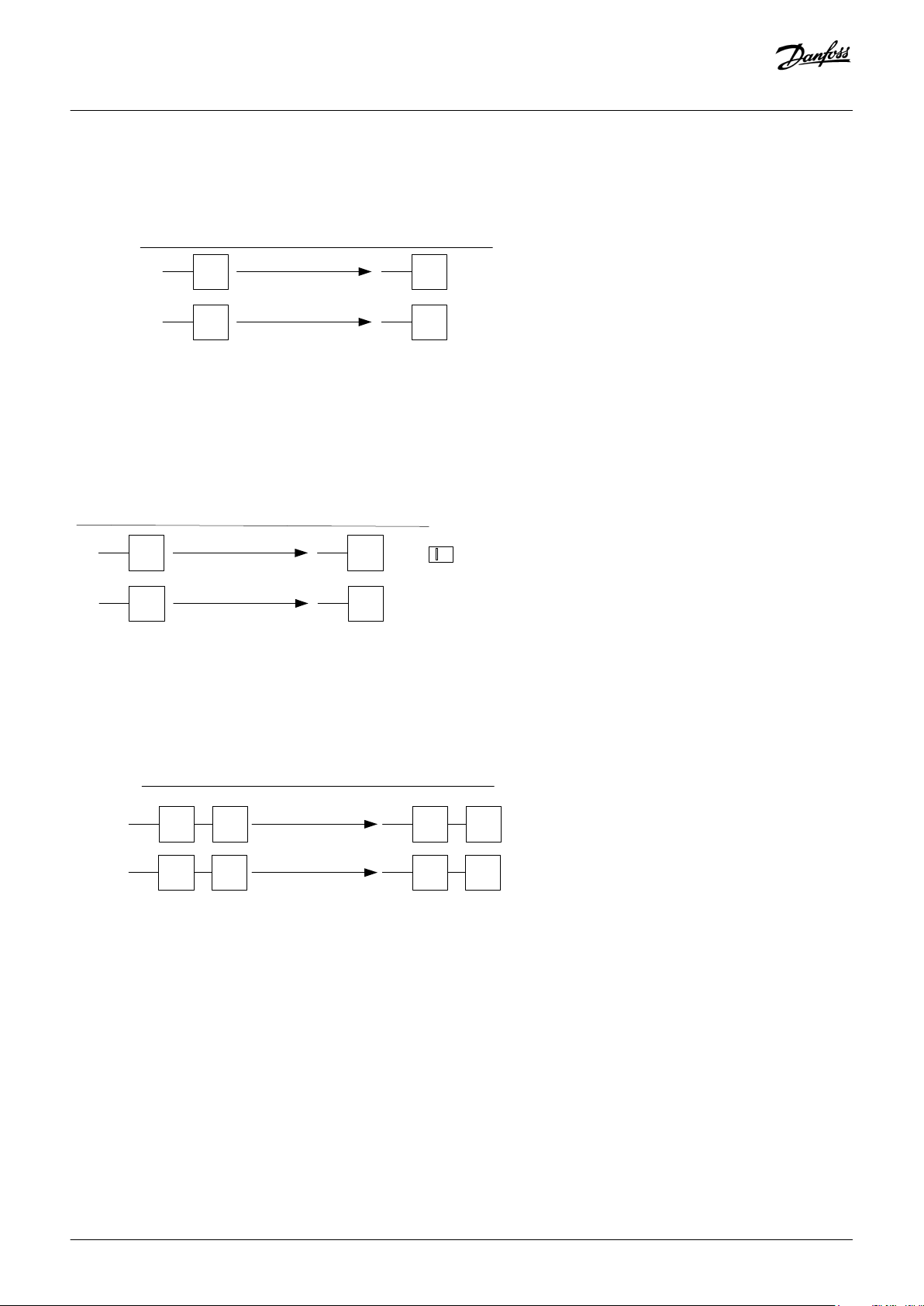

The following sections contain illustrations showing the old terminal number and their equivalents in the new drive. If a box in a

drawing is empty, there is no equivalent in the VLT® Decentral Drive FCD 302. In most cases, it is possible to program the FCD 302 to

deliver the same function on 1 of the terminals. If there are no boxes at all in an illustration, the drive has no terminal. For example, the

VLT® DriveMotor FCM 300 has a limited number of I/Os compared to the FCD 300.

3.2.1 Supply and Motor Terminals

Power cable terminals are 1:1 compatible between VLT® Decentral Drive FCD 300/VLT® DriveMotor FCM 300 and the VLT® Decentral

Drive FCD 302. If shielded cables are used, ensure that the shield is mounted as stated in the VLT® Decentral Drive FCD 302 Operating

Guide.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 11

Page 12

FCD 300

FCD 302

PE

L1

(91)

L2

(92)

L3

(93)

PE

(95)

L1

(91)

L2

(92)

L3

(93)

POWER

input

FCM 300

PE

L1

L2

L3

e30bh597.10

PE

PE

(99)

U

(96)

V

(97)

W

(98)

U

(96)

V

(97)

W

(98)

Motor

connector

FCD 300

FCD 302

FCM 300

e30bh604.10

122

123

122

123

Mechanical brake

FCD 300

FCD 302

FCM 300

e30bh603.10

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

Illustration 1: Power Cable Connections

Motor terminals are 1:1 compatible between FCD 300 and FCD 302. If shielded cables are used, ensure that the shield is mounted as

stated in the VLT® Decentral Drive FCD 302 Operating Guide.

Illustration 2: Motor Cable Connections

Mechanical brake cable terminals are 1:1 compatible between the FCD 300 EB versions and the FCD 302 with brake chopper and

mechanical brake supply. If shielded cables are used, ensure that the shield is mounted as stated in the VLT® Decentral Drive FCD 302

Operating Guide. To enable this functionality, the VLT® FCD 300 PROFIBUS Converter MCA 117 sets parameter 5-40 [1] Function Relay to

[32] Mech Brake Ctrl. In the FCD 302, it is not possible to enable mechanical brake control and use relay 2 for another purpose.

Illustration 3: Mechanical Brake Connection

12 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 13

81 -

82 +

81 -

82 +

Brake

Resistor

FCD 300

FCD 302

FCM 300

e30bh599.10

e30bh605.10

31A

31B

50

54

FCD300

FCD302FCM300

1 2

ON

S202

A54 OFF

36

(+)

36

(+)

35

(-)

35

(-)

36

(+)

36

(+)

35

(-)

35

(-)

External

24 V DC

back-up

FCD 300

FCD 302FCM 300

e30bh602.10

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

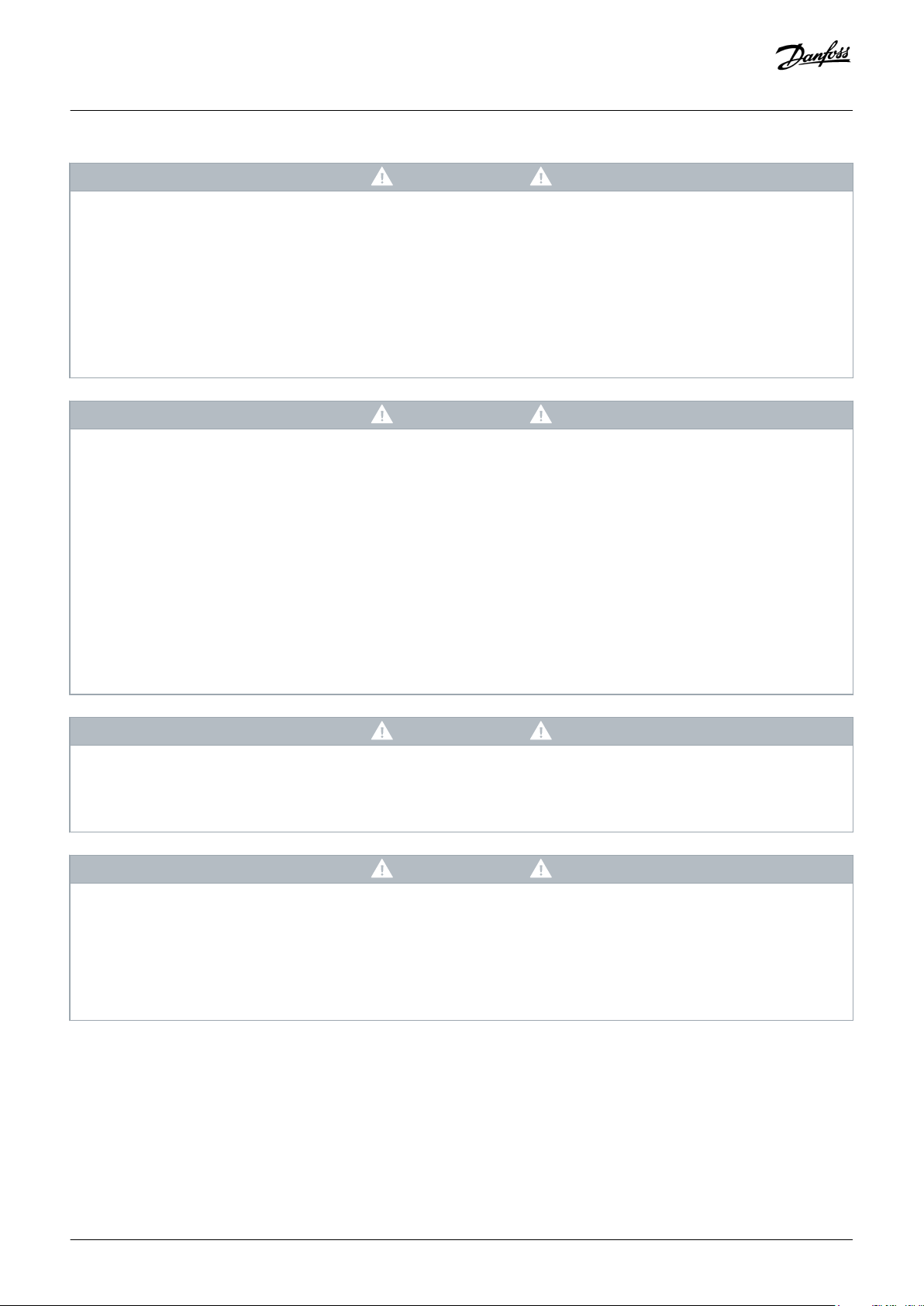

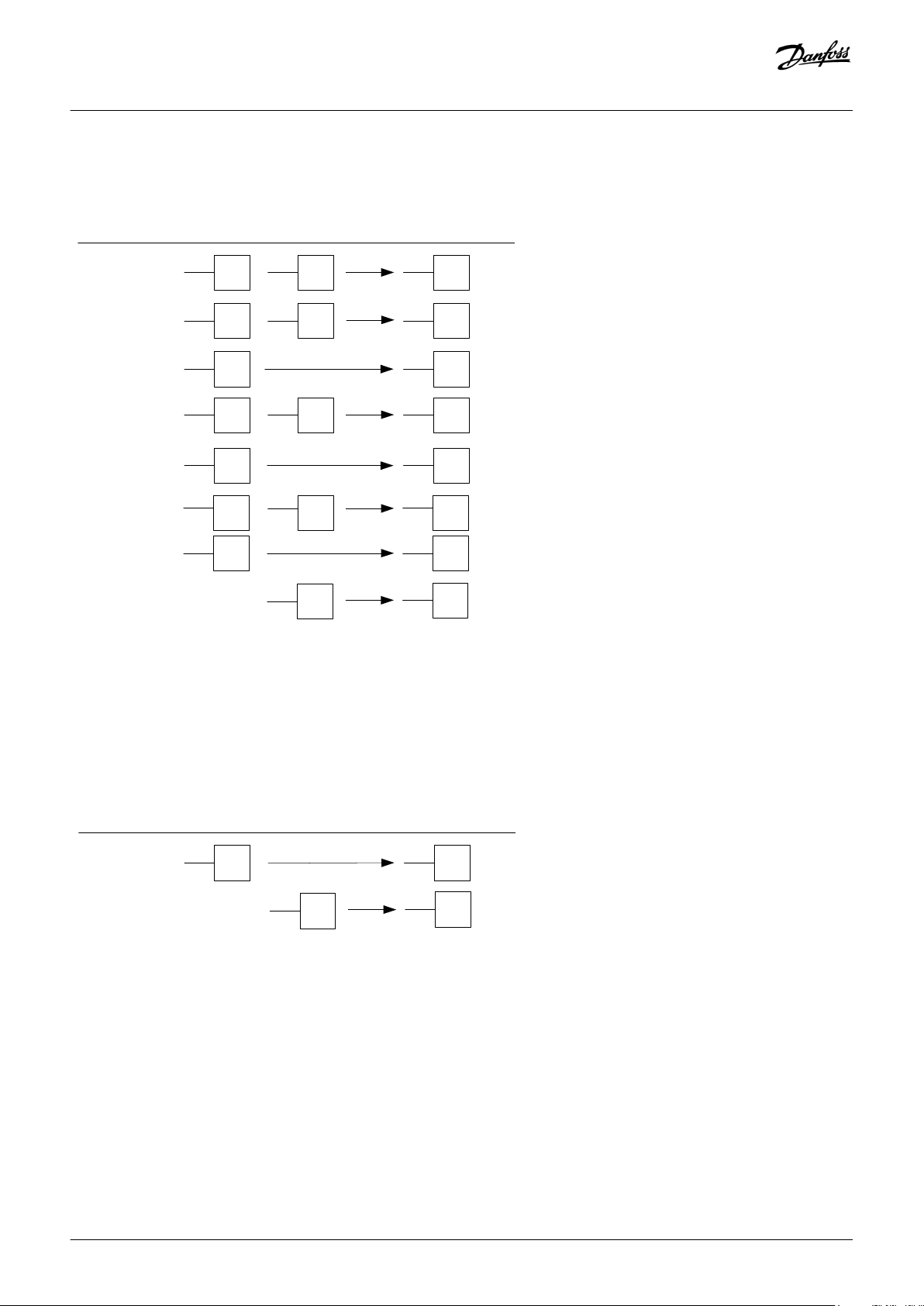

Brake resistor cable terminals are 1:1 compatible between the FCD 300 EB versions and the FCD 302. If shielded cables are used, ensure

that the shield is mounted as stated in the VLT® Decentral Drive FCD 302 Operating Guide.

Illustration 4: Brake Resistor Cable Connections

The FCD 300 has dedicated connectors 31A and 31B for connection of the motor thermistors. The FCD 302 with MCA 117 installed uses

AI54 as motor thermistor connector. The FCD 302 can also use 1 of the digital inputs as thermistor source, but if multiple sensors are

connected in series, it might cause false alarms/warnings. The motor thermistor configuration is done via parameter 1-90 Motor Thermal

Protection and parameter 1-93 Thermistor Resource.

Illustration 5: Motor Thermistor Cable Connection

The 24 V external supply cable terminals are 1:1 compatible between FCD 300 EB versions and the FCD 302. The FCD 302 may draw a

higher current from the 24 V supply. The FCD 300 has a power consumption of 12 W, where the FCD 302 consumes up to 50 W. The

consumption depends on the configuration of the I/O modules and the sensors connected to the drive.

Illustration 6: External 24 V Cable Connection

3.2.2 Control Signal Connectors

Digital input cable connection

Digital input terminals are 1:1 compatible between the VLT® Decentral Drive FCD 300 and the VLT® Decentral Drive FCD 302. If shielded

cable is used, ensure that the shield is mounted as stated in the VLT® Decentral Drive FCD 302 Operating Guide.

The FCD 300 reads the digital inputs every 12 ms whereas the FCD 302 reads the digital inputs every 1 ms.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 13

Page 14

20

27

12

18

19

29

33

20

27

12-

13

18

19

29

33

FCD 300

FCD 302

Digital in

FCM 300

6

4

5

8

3

e30bh600.11

46

Digital out

FCD 300

FCD 302

FCM 300

9

e30bh601.10

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

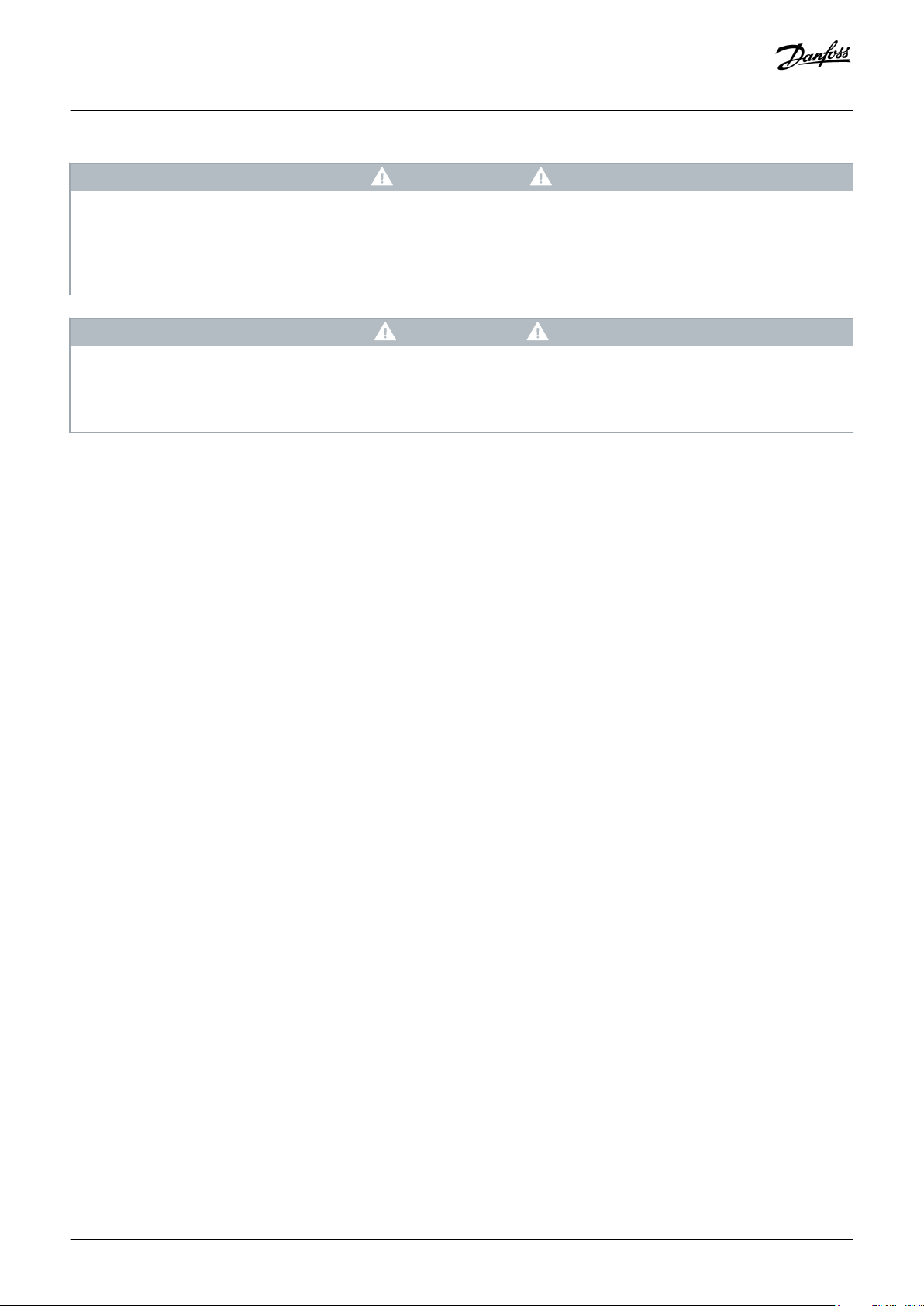

The digital inputs of the FCD 300 are converted fully to the I/Os of the FCD 302. Terminal 3 of the VLT® DriveMotor FCM 300 is not

converted to a corresponding terminal in FCD 302. To support terminal 3 in FCM 300, configure the FCD 302 manually.

Illustration 7: Digital Input Cable Connections

Digital output cable connections

The FCD 300 has 1 dedicated digital output, which is terminal 46. This terminal is not converted to an existing FCD 302 output.

In FCM 300, terminal 9 could be used as either analog or digital output. To obtain the same functionality in FCD 302, configure an

analog or digital output manually.

Illustration 8: Digital Output Cable Connections

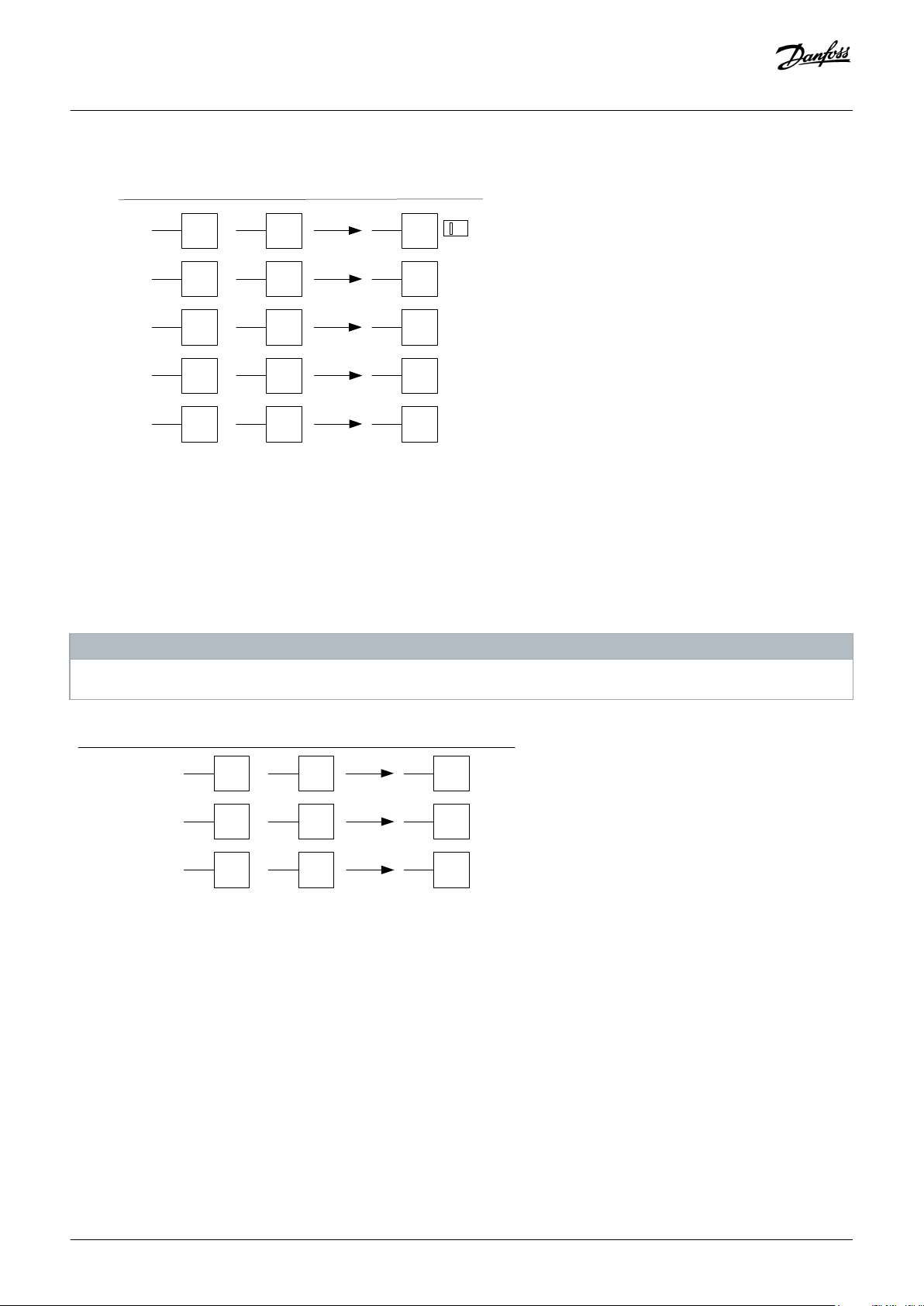

Analog I/O cable connections

The analog I/Os of the FCD 302 can be configured to cover most use cases. The default conversion from FCD 300 has a limitation as

there is no input 60 in the FCD 302. If analog input 54 in the FCD 302 is not used for motor thermistor, this input can be configured to

provide the functionality of output 60 in the FCD 300.

14 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 15

e30bh598.10

53

50

10 V

42

42

53

60

50

10 V

55

Gnd

55

Gnd

FCD300

FCD302

Analog

I/O

2

9

7

8

1

FCM300

1 2

ON

S202

A53 switch

OFF = 0‐10V

01

C

02

NO

03

NC

01

C

02

NO

03

NC

FCD 300

FCD 302

Relay

1

x102

2

x102

3

x102

FCM 300

e30bh607.10

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

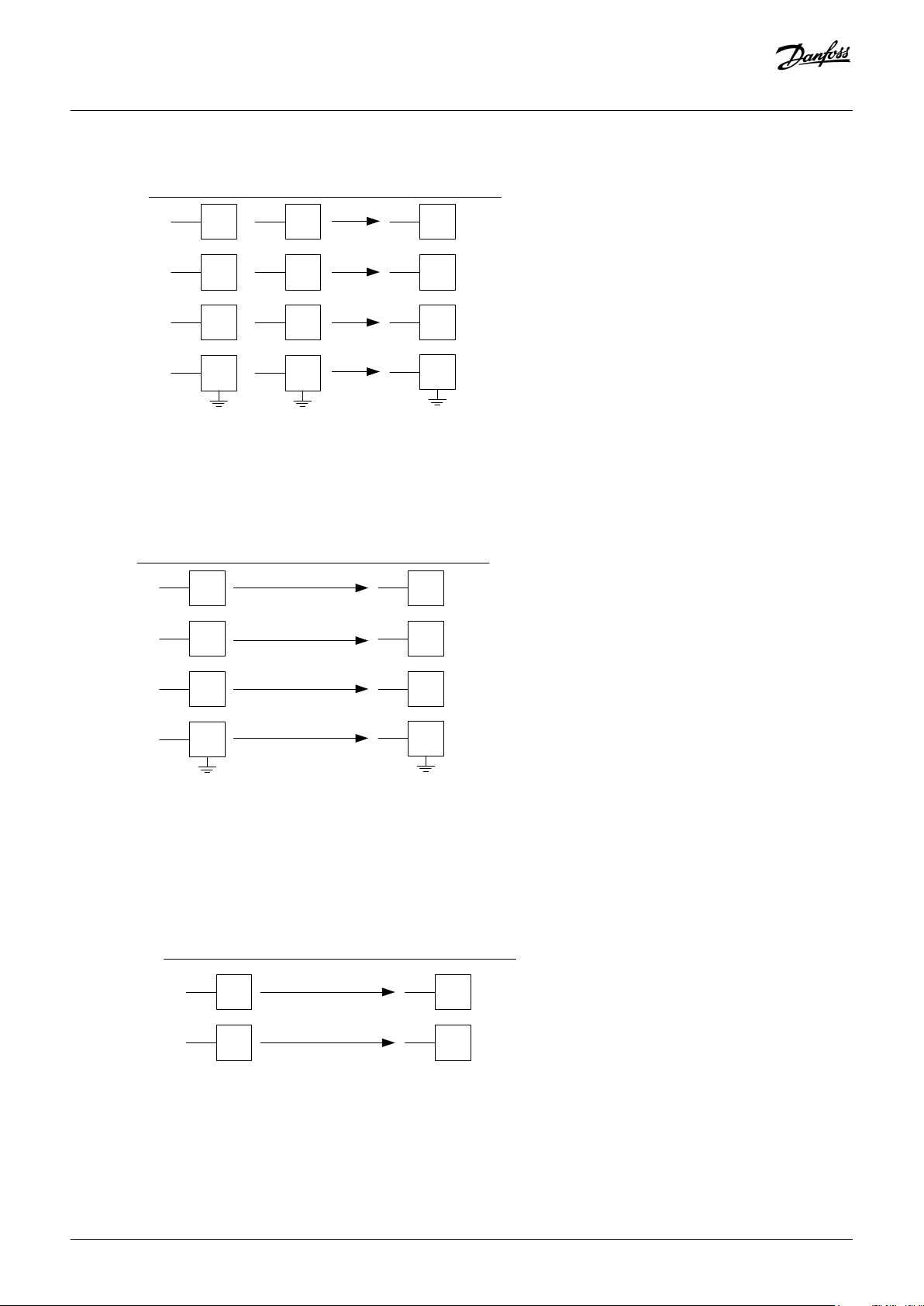

Illustration 9: Analog I/O Cable Connections

The 0–10 V analog input 53 of the FCD 300 is converted into the FCD 302 analog input 53. The analog input 53 of the FCD 302 can be

set to 0–10 V or 0–20 mA via switch S201. From factory, the switch is set in OFF position, which sets the analog input to 0–10 V.

Relay cable connections

The relays of the FCD 302 are compatible to the relays in FCD 300.

NOTICE

The relay in FCM 300 is rated to a resistive load of 5 A, 250 V AC, whereas the relay in FCD 302 is rated to a load of 2 A, 240 V AC.

Illustration 10: Relay Cable Connections

PROFIBUS cable connections

The PROFIBUS terminals of the FCD 300/FCM 300 are all converted to the PROFIBUS terminals of the FCD 302. The compensation coils

activated by the switches S101 to S104 of the FCD 300 are not needed in the FCD 302 PROFIBUS interface. The Termination of the

PROFIBUS line is done via the PROFIBUS termination switch.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 15

Page 16

e30bh606.10

67

68

68

69 69

70

67

68

68

69 69

66

FCD300

FCD302

PROFIBUS

3

x100

1

x100

2

x100

4

x100

FCM300

1 2 3

ON

PROFIBUS

TERM.

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

Illustration 11: PROFIBUS Cable Connections

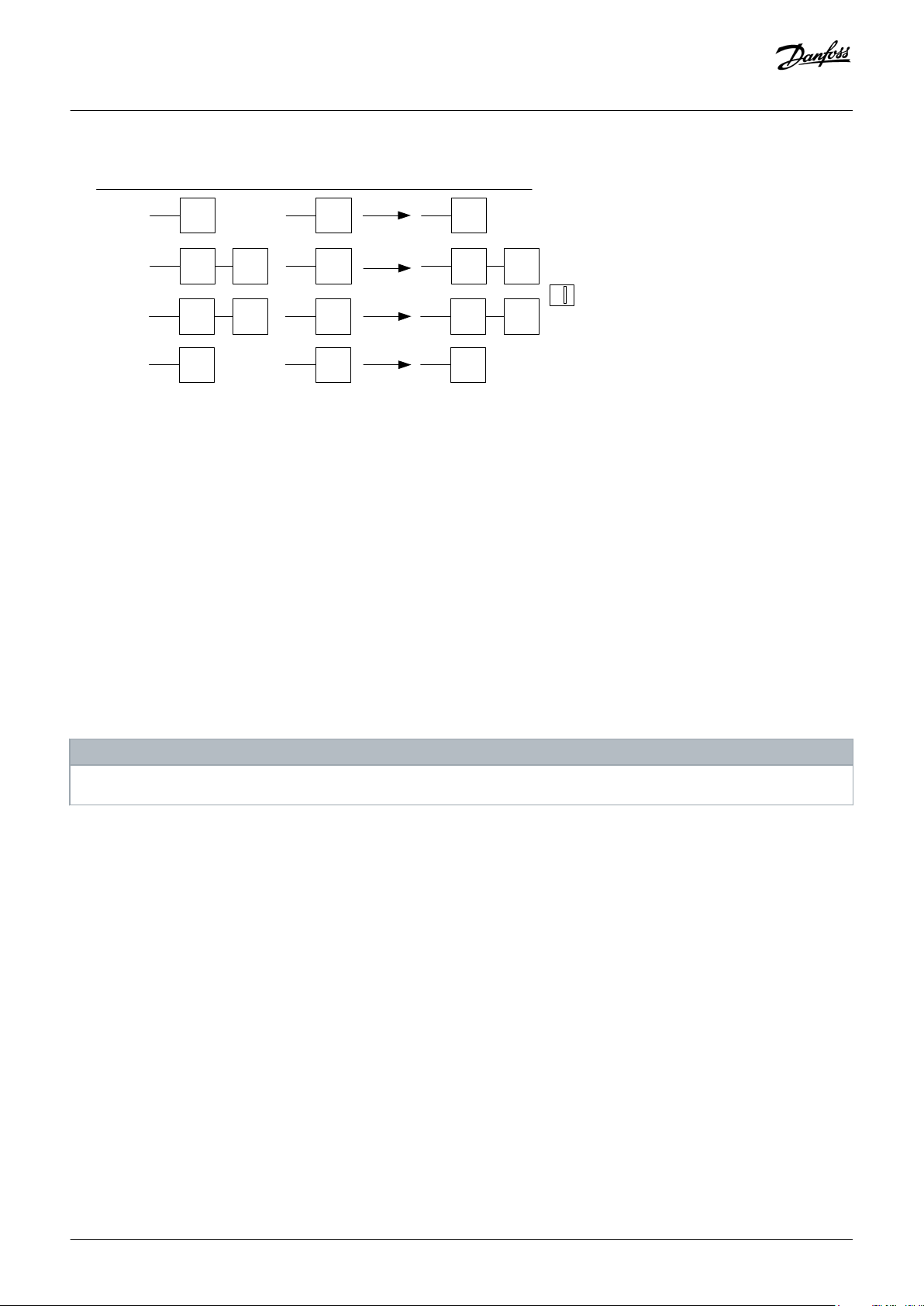

3.2.3 EMC Precautions

To achieve interference-free operation of the PROFIBUS, install the VLT® Decentral Drive FCD 302 and the cables as described in the

VLT® Decentral Drive FCD 302 Design Guide: When routing the PROFIBUS cable:

• maintain high distance (minimum 200 mm (8 in)) between the PROFIBUS communication cable and the motor and brake resistor

cables to avoid coupling of high-frequency noise from one cable to another.

• ensure that, when crossing is unavoidable, the PROFIBUS cable crosses the motor and brake resistor cables at an angle of 90° .

For installation on machines where the FCD 302 has poor electrical contact to the machine due to paint or high ohmic surface, a special

stainless steel plug and bracket exist. The order number is 175N2598.

This plug can be mounted in 1 of the unused cable entry holes and the supplied bracket has to be mounted to the plug and to the

metal construction of the machine. This ensures a low ohmic path for high-frequency noise that otherwise would have been added to

the shield of the PROFIBUS cable, causing disturbance of the communication.

NOTICE

Observe relevant national and local regulations, for example, regarding protective-earth connection.

16 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 17

2

1

3

90°

e30bh659.10

1

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Installation

1 PROFIBUS cable

3 ≥200 mm (≥7.9 in)

Illustration 12: EMC-correct Installation

2 90° intersection

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 17

Page 18

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Configuring the System

4 Configuring the System

4.1 Preparing for Configuration

Context:

All PROFIBUS stations connected to the same bus network must have a unique station address.

Prerequisites:

Before replacing an FCD 300 or FCM 300 by a VLT® Decentral Drive FCD 302 with VLT® FCD 300 PROFIBUS Converter MCA 117,

configure the station address in the FCD 302. Also, check that the FCD 302 detects which type of drive it has to replace.

Procedure

1. Set the PROFIBUS address of the VLT® Decentral Drive FCD 302 to the same address as the drive that has to be replaced.

2. Set parameter 8-02 Control Word Source to [3] Option A.

3. Cycle power (400 V AC and 24 V DC back-up if applied) to the FCD 302.

The MCA 117 probes for the different FCD300/FCM300 Ident numbers. While probing, the drive flashes the ST/MS LED (see

4.5 LED Behavior). When the matching Ident number used by the master is detected, the VLT® Decentral Drive FCD 302

locks the ident number to the option, and sets the parameters of the FCD 302 to match the functionality of the old drive.

The master/PLC now recognizes the FCD 302 as an FCD 300 or FCM 300.

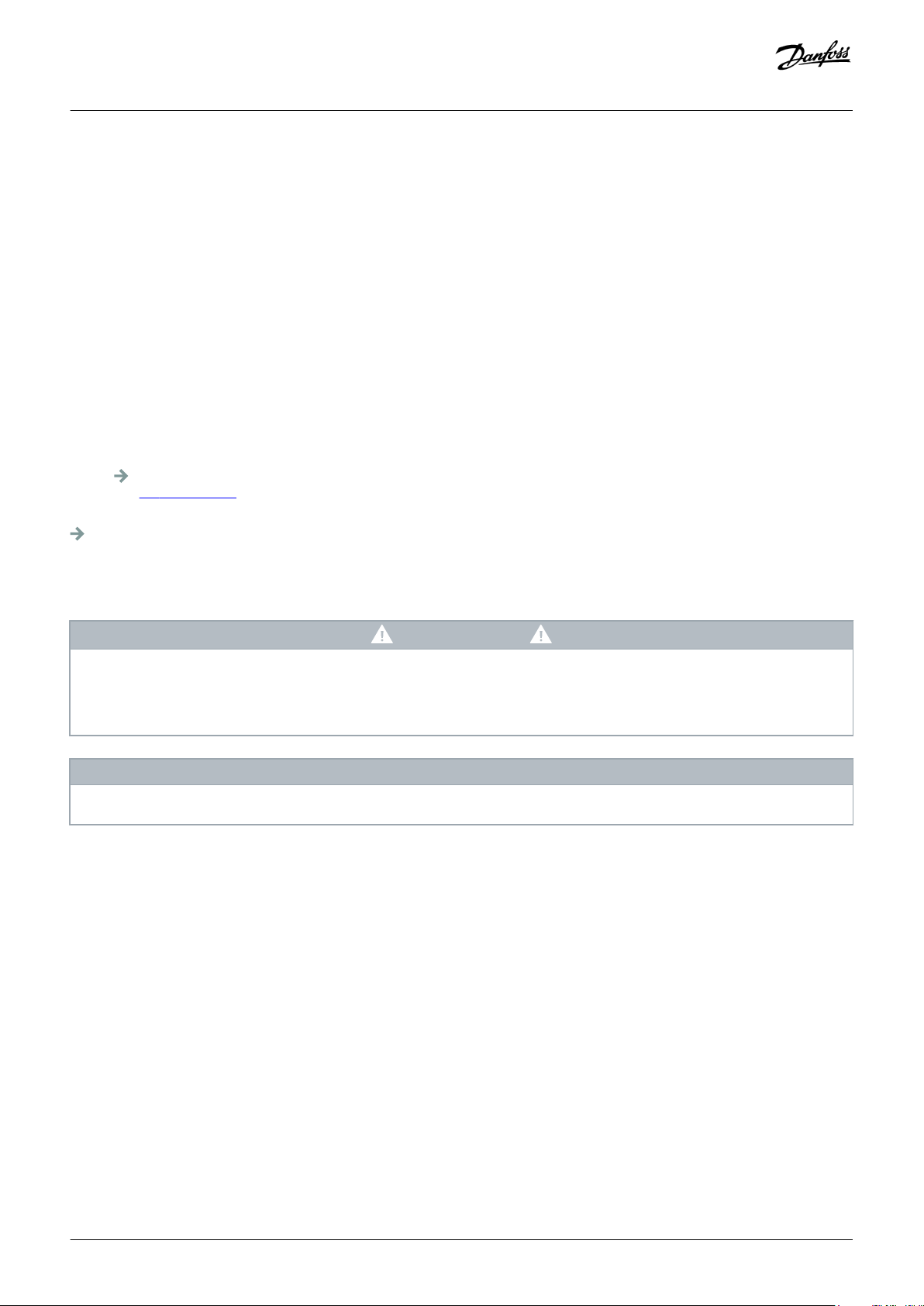

4.2 PROFIBUS Address Set via Hardware Switches

WARNING

SHOCK HAZARD

Working with the hardware switches while the power supply is still on may cause personal injuries.

Switch off the power supply before changing the hardware switches.

-

NOTICE

The address change comes into effect at the next power-up and can be read in parameter 9-18 Node Address.

18 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 19

e30bh608.10

1

2 3 4 5 6 7 8

8 7 6 5 4 3 2 1

ON

OFF

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Configuring the System

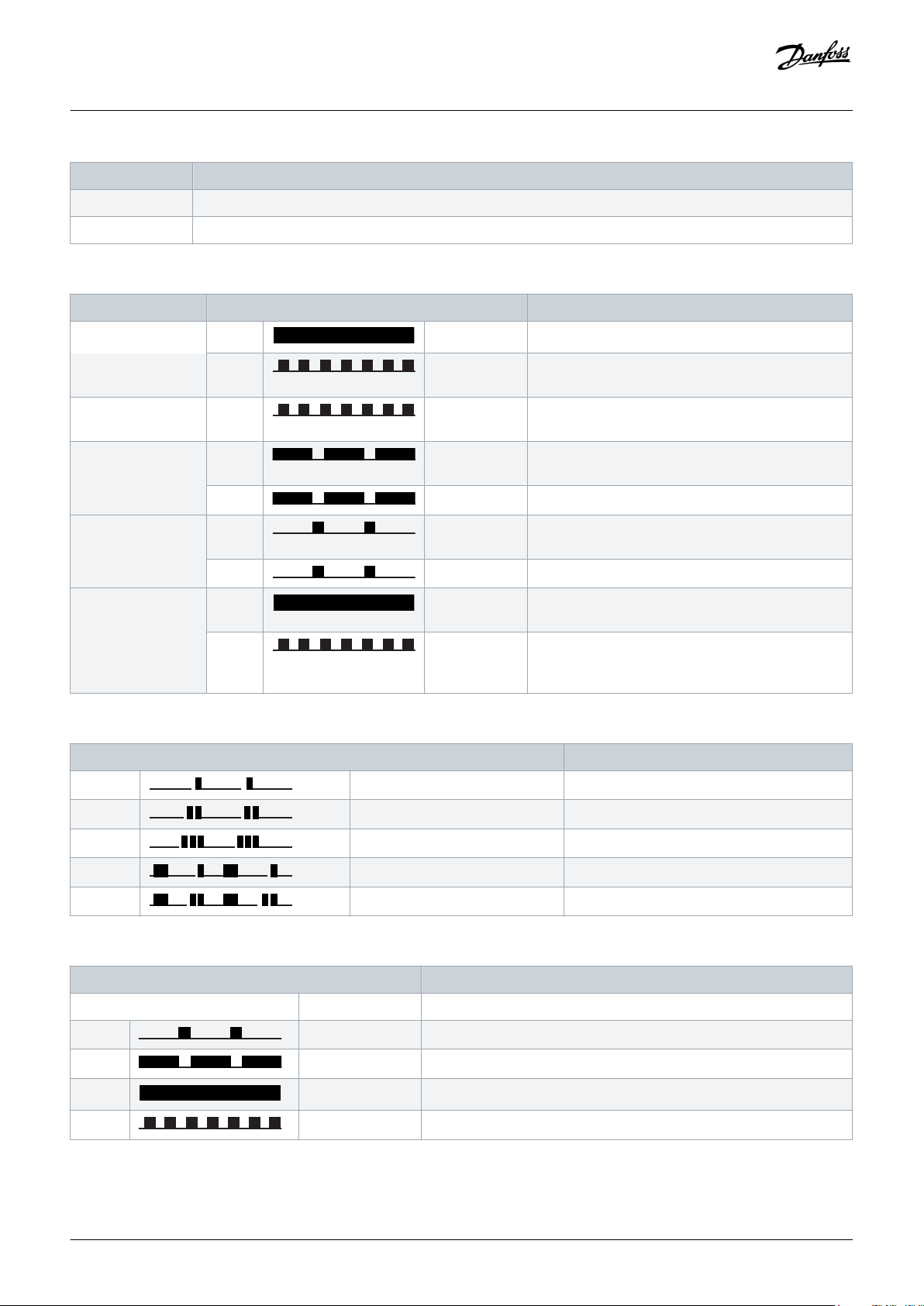

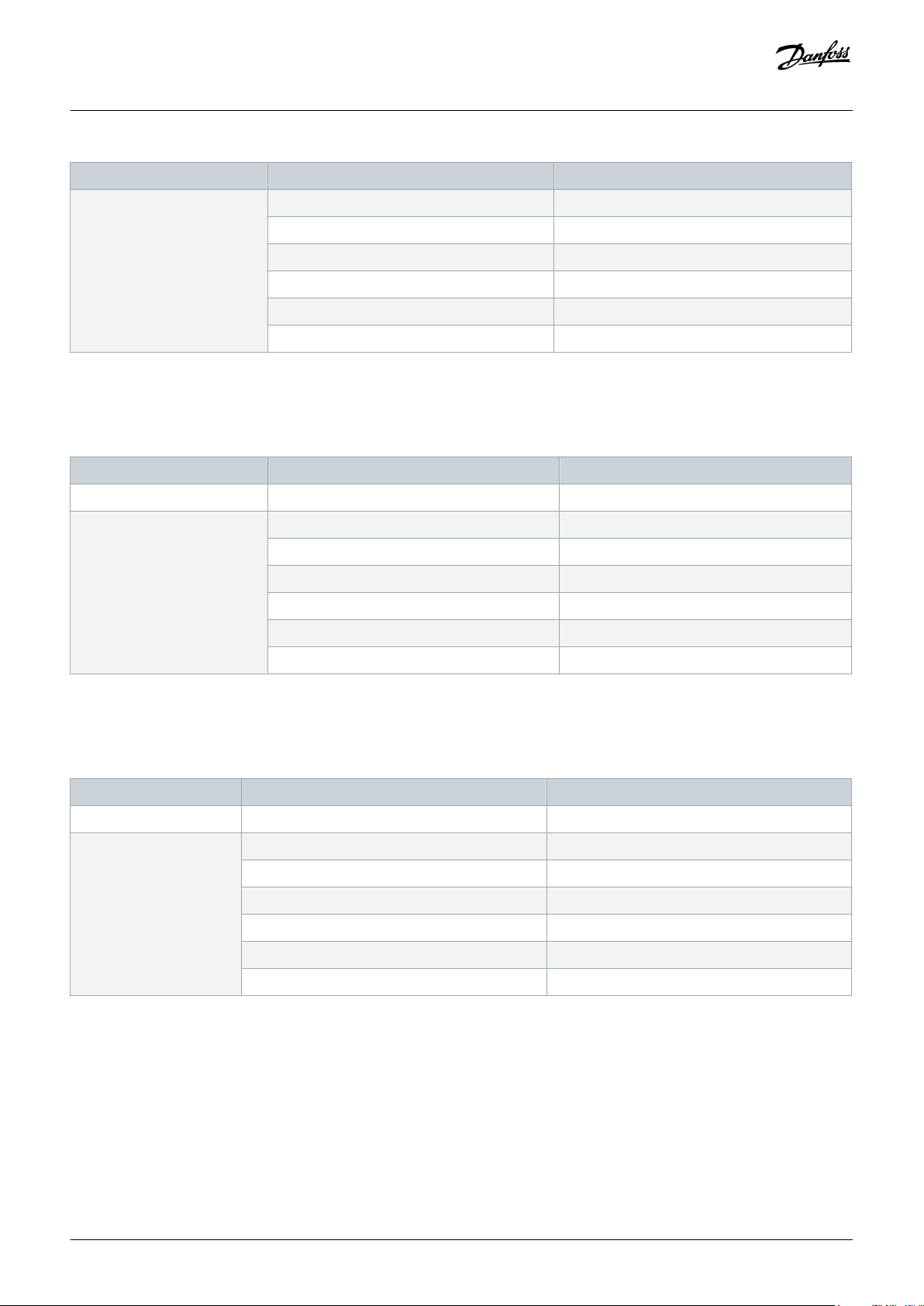

Illustration 13: Setting the PROFIBUS Address via Hardware Switches

Table 2: Hardware Switch Settings

VLT® Decentral Drive FCD 300 VLT® Decentral Drive FCD 302

Switch 1 2 3 4 5 6 7 8 8 7 6 5 4 3 2 1

Address +1 +2 +4 +8 +16 +32 +64 – – +64 +32 +16 +8 +4 +2 +1

Example:

1 1 0 0 0 0 0 0 – – 0 0 0 0 0 0 1

35 1 1 0 0 0 1 0 – – 0 1 0 0 0 1 1

82 0 1 0 0 1 0 1 – – 1 0 1 0 0 1 0

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 19

Page 20

BUS

ON

ALARM

ST/MS LA2/NS2

WARNING

LA1/NS1

e30bh741.10

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Configuring the System

4.3 PROFIBUS Address Set via Parameter or SSA Command

If all hardware switches are set to ON or OFF (factory switch setting), the PROFIBUS address can be set via parameter 9-18 Node Address

or the PROFIBUS SSA command. The address becomes valid after the next power cycle.

4.4 Commissioning

Prerequisites:

The station address of the VLT® Decentral Drive FCD 302 must be the same as for VLT® Decentral Drive FCD 300.

Procedure

1. Cycle power to the FCD 302.

The master/PLC now recognizes FCD 302 as an FCD 300.

Example:

A solid green NS LED on the VLT® FCD 300 PROFIBUS Converter MCA 117 indicates that communication between master and slave is

established.

If the NS LED flashes, the master/PLC has not recognized the FCD 302.

For more information, refer to 6.1 Troubleshooting Hints.

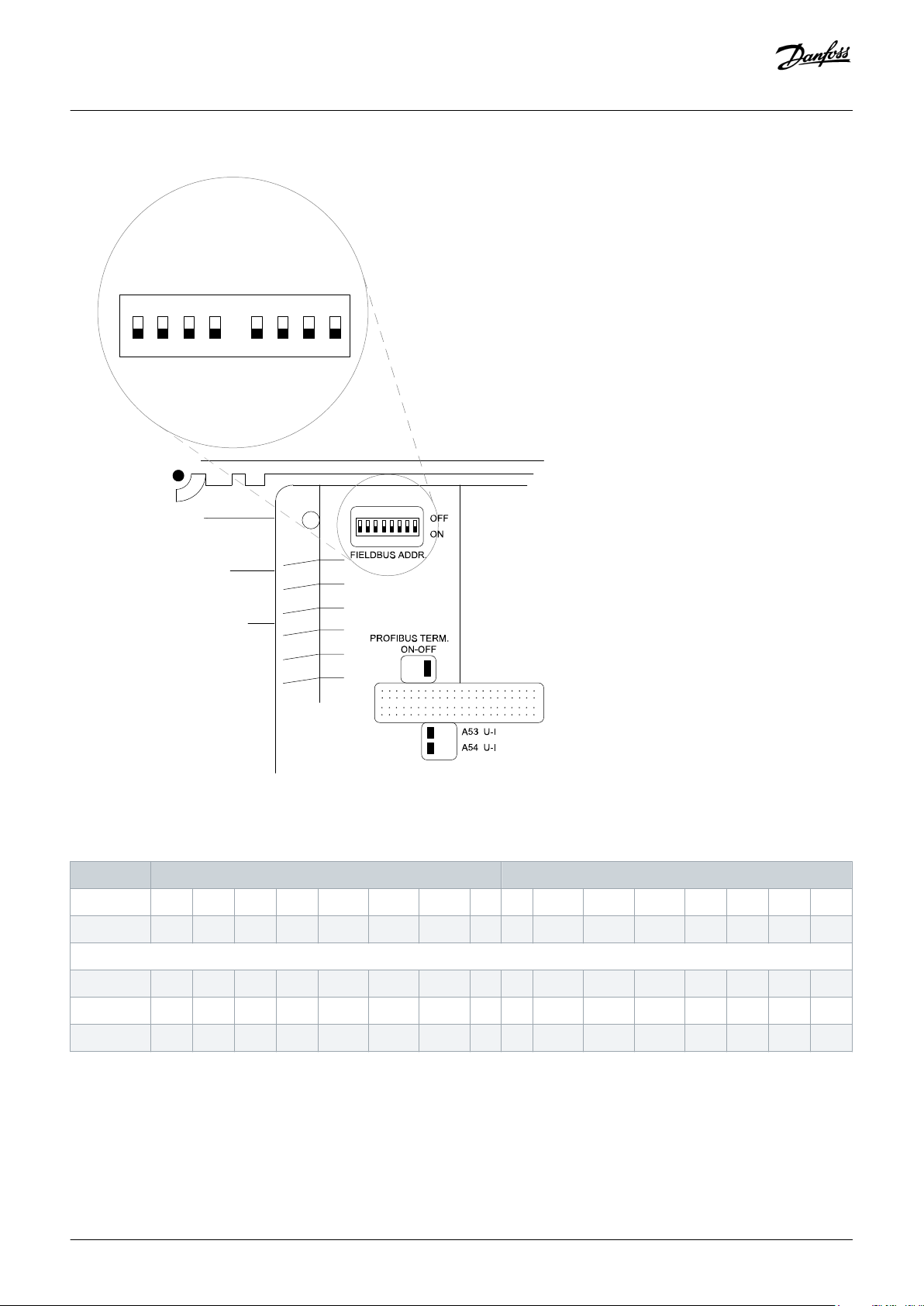

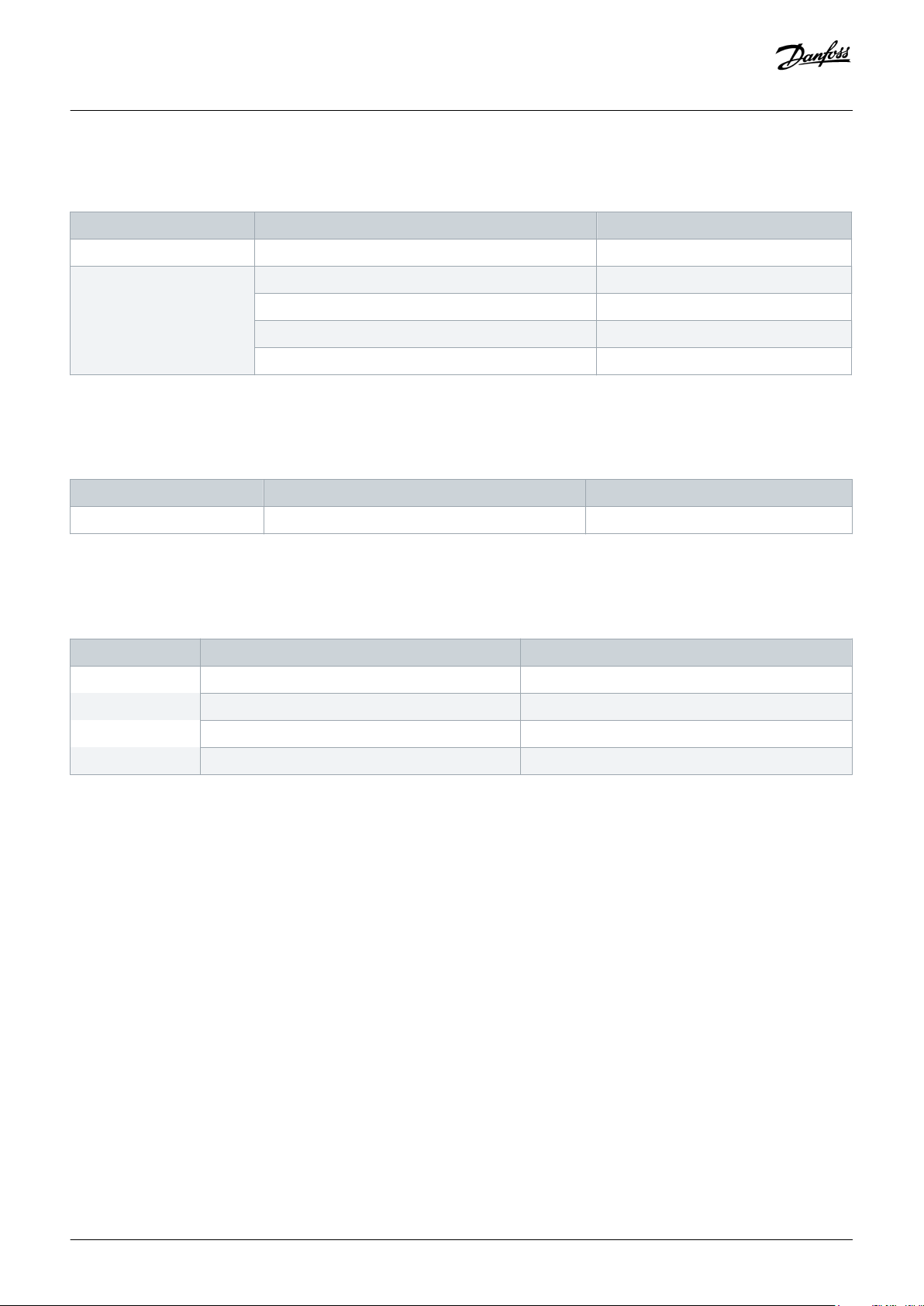

4.5 LED Behavior

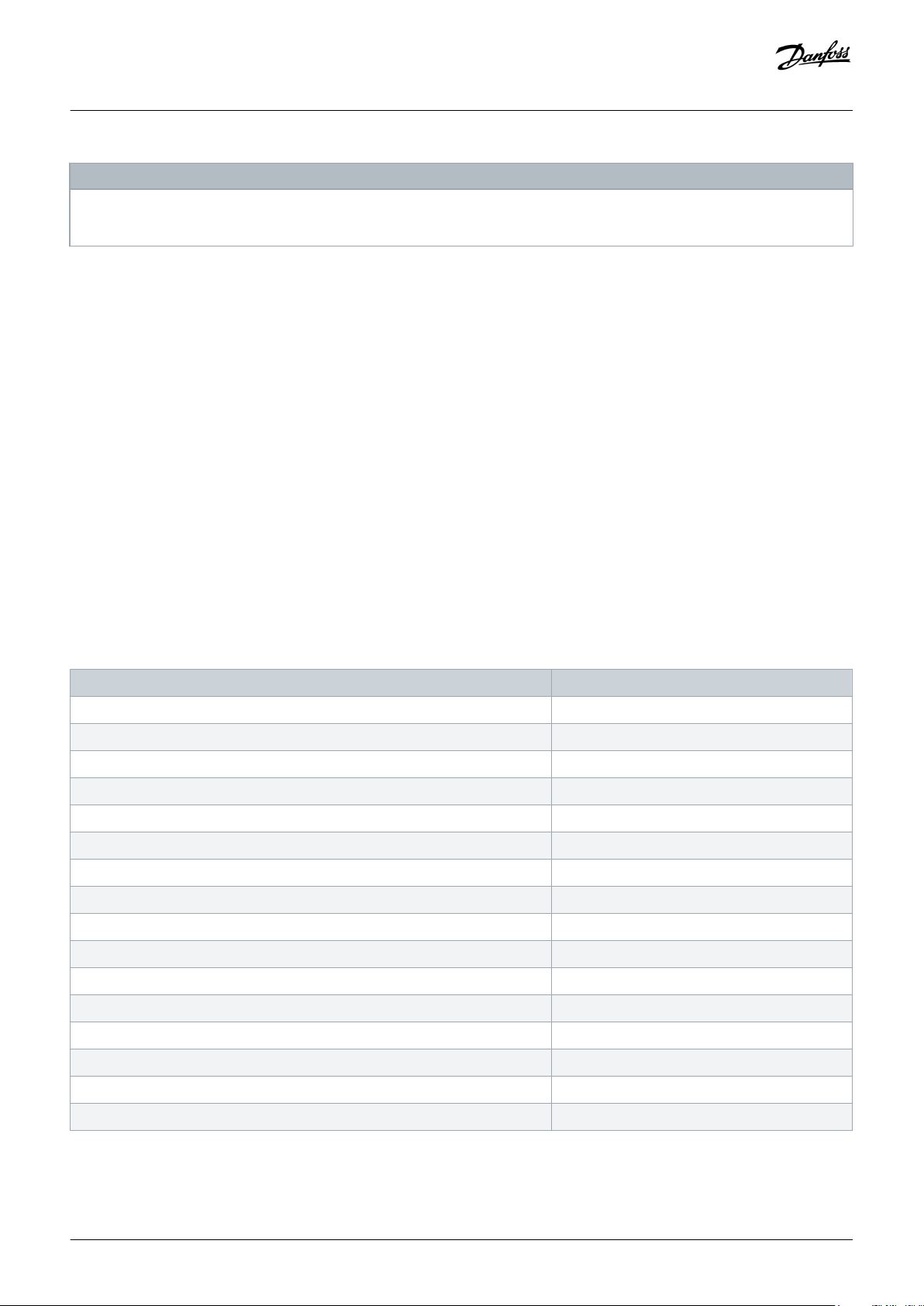

Illustration 14: Overview of LEDs

Table 3: Bicolored LEDs

LED label Description

LA1/NS1 Network status

20 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 21

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Configuring the System

LED label Description

ST/MS Module status (DP-V1 communication and Ident number detection)

LA2/NS2 Not used

Table 4: Net Status, ST/MS

State LED Description

Power on Red: Solid red The option is defect. Contact Danfoss.

Green: Flashing

The option is OK.

green

Baud rate search Green: Flashing

green

Wait parameterizing Green: Long green

flash

Searching for the baud rate. Check the connection

to the master if the option stays in this state.

Baud rate found - waiting for parameters from the

master.

Red: Long red flash Wrong parameters from the master.

Wait configuration Green: Short green

flash

Parameters from master OK - waiting for configuration data.

Red: Short red flash Wrong configuration data from the master.

Data exchange Green: Solid green Data exchange between the master and the FCD 302

is active.

Red: Flashing red Clear state. Warning 34, Fieldbus Fault is active and a

bus reaction in parameter 8-04 Control Word Timeout

Function is executed.

Table 5: Module Status (ST/MS LED while Detecting Ident Number)

LED description Description

Green One short flash Testing for FCD 300, 12 MB version

Green Two short flashes Testing for FCD 300, 3 MB version

Green Three short flashes Testing for FCD 302

Green One long, one short flash Testing for FCM 300, 3 MB version

Green One long, 2 short flashes Testing for FCM 300, 12 MB version

Table 6: Module Status (DP-V1 Communication)

Description

No light Off No PROFIBUS DP-V1 communication is active.

Green: Short green flash DP-V1 communication from a Master Class 1 (PLC) is active.

Green: Long green flash DP-V1 communication from a Master Class 2 (MCT 10, FDT) is active.

Green: Solid green DP-V1 communication from a Master Class 1 and 2 is active.

Red: Flashing red Internal error.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 21

Page 22

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Configuring the System

NOTICE

The LED flash patterns of the VLT® FCD 300 PROFIBUS Converter MCA 117 are not compatible with the patterns of the FCD

300/FCM 300 PROFIBUS LEDs.

4.6 Factory Settings

The VLT® FCD 300 PROFIBUS Converter MCA 117 is delivered from factory with the optimal settings to replace a VLT® Decentral Drive

FCD 300. If the VLT® FCD 300 PROFIBUS Converter MCA 117 is moved from one application to another, it is recommend to initialize the

drive. This initialization activates the factory settings and re-invoke of the Ident number detection. If the drive has been delivered from

factory with the option installed, initialization can be skipped.

Do the initialization via:

• Parameter 14-22 Operation Mode, or

• Three-finger reset by removing power to the drive, pressing [Status], [Main Menu], and [OK], and applying 400 V AC or 24 V DC

back-up power to the drive.

The MCA 117 sets the parameters of the FCD 302 so that the FCD 302/MCA 117 emulate the FCD 300 in the best way.

The parameters of the VLT® Decentral Drive FCD 302 are set to factory values and some FCD 302 parameters are set to values that

match the initial values of VLT® Decentral Drive FCD 300.

Factory copy via the FCD 300 parameter 006 Setup Copy is supported and initializes the FCD 302 and sets it to the FCD 300 default

settings.

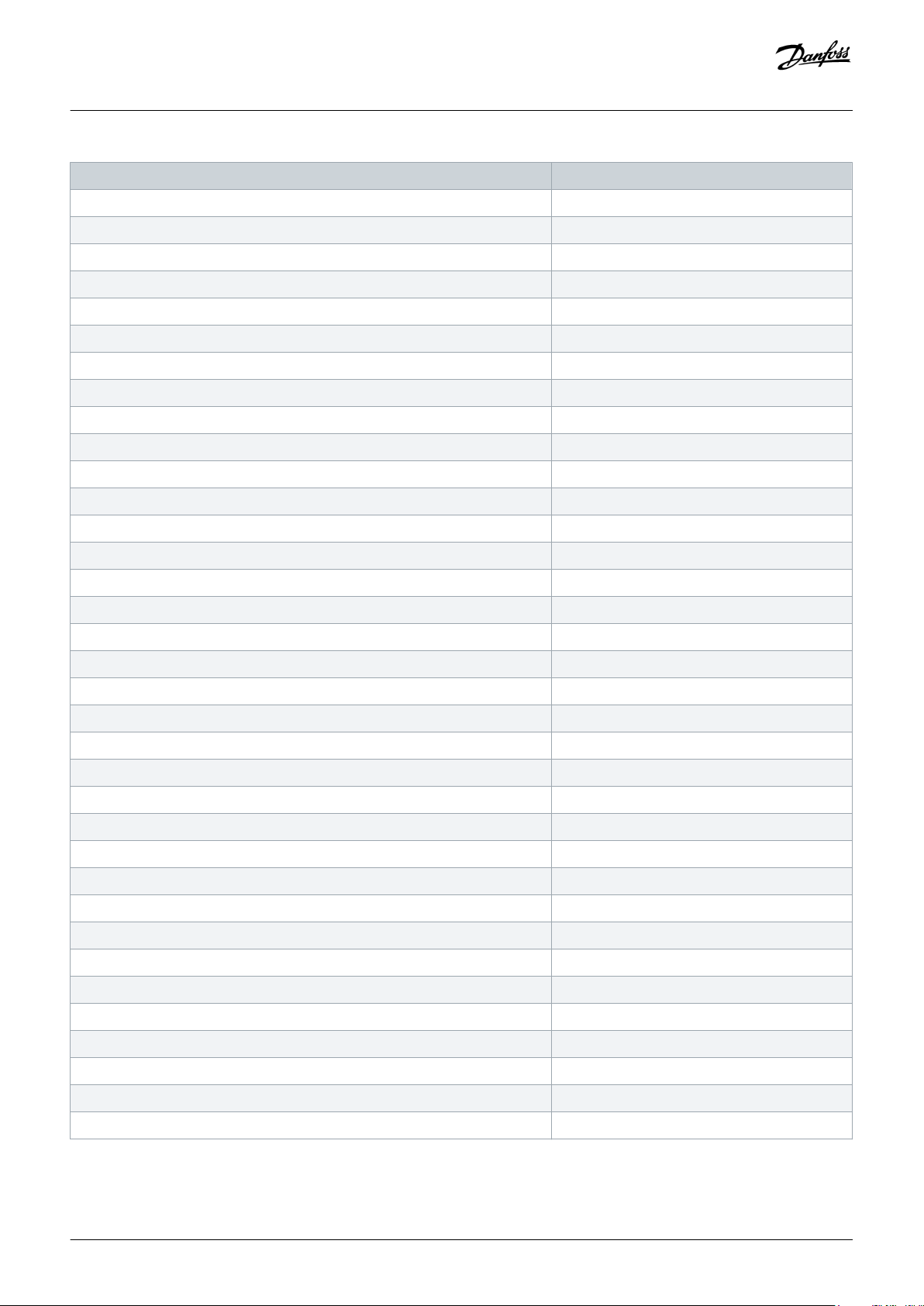

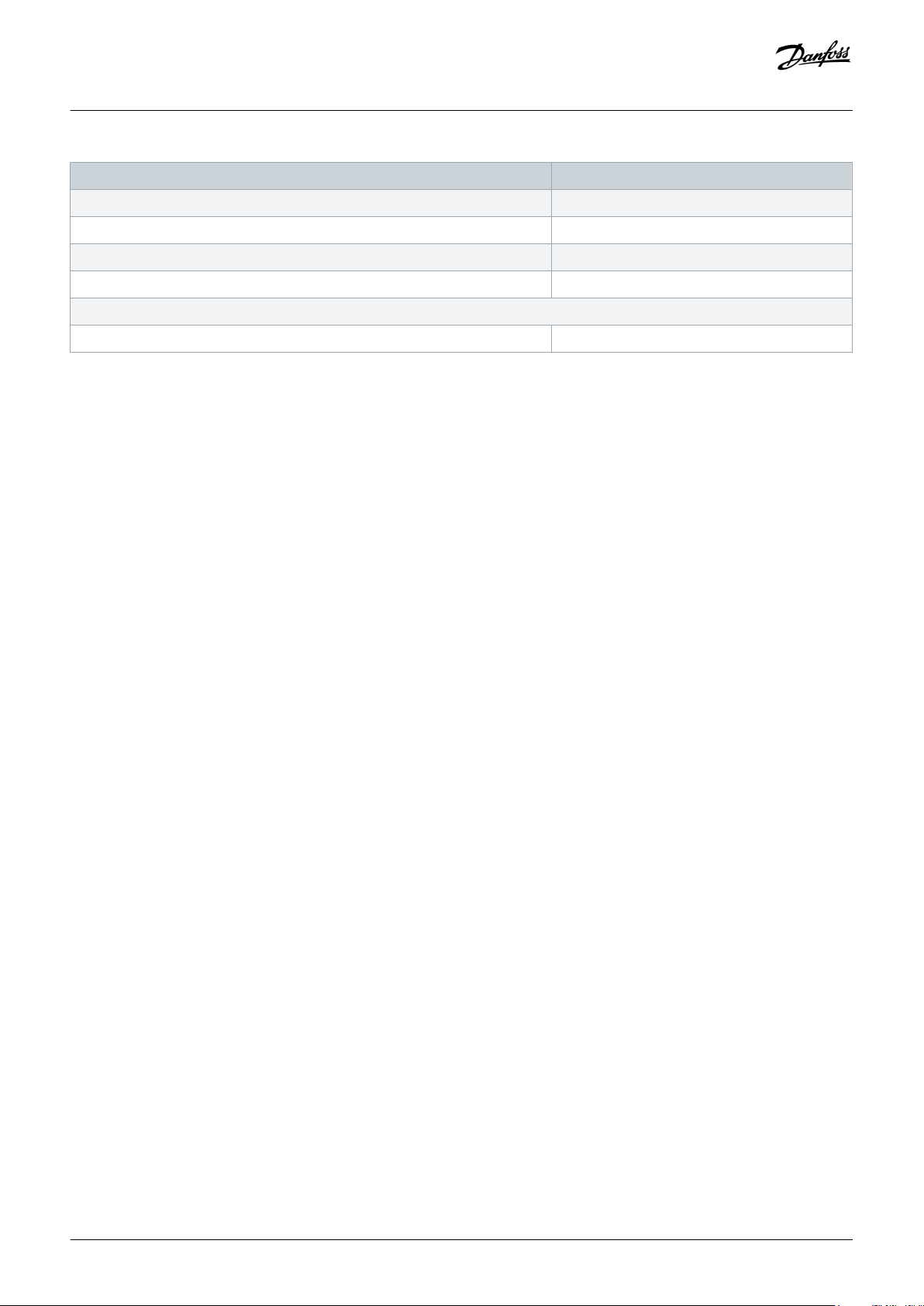

Table 7: Parameters Set During Initialization

Parameter Initialization setting

Parameter 0-02 Motor Speed Unit [Hz]

Parameter 1-51 Min Speed Normal Magnetizing [RPM] 30 RPM

Parameter 1-52 Min Speed Normal magnetising [Hz] 1.0 Hz

Parameter 1-64 Resonance Damping 0

Paramter 1-81 Min Speed for Function at Stop [RPM] 3 RPM

Parameter 1-82 Min Speed for Function at Stop [Hz] 0.1 Hz

Parameter 1-93 Thermistor Resource Analog input 54

Parameter 2-10 Brake Function [0] Off

Parameter 2-17 Overvoltage Control [0] Off

Parameter 3-00 Reference Range min – max

Parameter 3-01 Reference/Feedback Unit [1]%

Parameter 3-03 Maximum Reference 50.000

Parameter 3-11 Jog Speed [Hz] 10.0 Hz

Parameter 3-16 Reference Resource 2 [0] No function

Parameter 3-19 Jog Speed [RPM] 300 RPM

Parameter 4-13 Motor Speed High Limit [RPM] 3960 RPM

22 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 23

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Initialization setting

Parameter 4-14 Motor Speed Low Limit [Hz] 132.0 Hz

Parameter 4-16 Torque Limit Motor Mode 355.6

Parameter 4-17 Torque Limit Generator Mode 355.6

Parameter 4-30 Motor Feedback Loss Function [0] Disabled

Parameter 4-32 Motor Feedback Loss Timeout 1.00 s

Parameter 4-53 Warning Speed High 3960

Parameter 4-56 Warning Feedback Low -4000000

Parameter 4-57 Warning Feedback High 4000000

Parameter 5-02 Terminal 29 Mode [1] Output

Parameter 5-10 Terminal 18 Digital Input [8] Start

Parameter 5-11 Terminal 19 Digital Input [10] Reversing

Parameter 5-12 Terminal 27 Digital Input [3] Coast and reset inv

Parameter 5-14 Terminal 32 Digital Input [14] Jog

Configuring the System

Parameter 5-40.0 Function Relay [22] Ready, No Thermal Warning

Parameter 5-40.1 Function Relay [32] Mech Brake Ctrl

Parameter 5-41 On Delay, Relay [23] Remote, Ready, No TW

Parameter 5-51 Term. 29 High Frequency 5000 Hz

Parameter 5-53 Term. 29 High Ref./Feedb. Value 50.000

Parameter 5-56 Term. 33 High Frequency 25000 Hz

Parameter 5-58 Term. 33 High Ref./Feedb. Value 50.000

Parameter 6-10 Terminal 53 Low Voltage 0.00 V

Parameter 6-15 Term. 53 High Ref./Feedb. Value 50.000

Parameter 6-20 Terminal 54 Low Voltage 0.00 V

Parameter 6-22 Terminal 54 Low Current 0.00 V

Parameter 6-25 Terminal 54 High Ref./Feedb. Value 50.000

Parameter 6-50 Terminal 42 Output [103] Motor current

Parameter 7-04 Speed PID Differention Time 0.0

Parameter 7-08 Speed PID Feed Forward Factor 100

Parameter 7-09 Speed PID Error Correction w/Ramp 100000 (max)

Parameter 7-33 Process PID Proportional Gain 0.01

Parameter 8-54 Reversing Select [0] Digital input

Parameter 8-90 Bus Jog 1 Speed 300 RPM

Parameter 8-91 Bus Jog 2 Speed 300 RPM

Parameter 14-03 Overmodulation [0] Off

Parameter 14-11 Mains Voltage at Mains Fault 327

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 23

Page 24

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Initialization setting

Parameter 14-15 Kin. Back-up Trip Recovery Level 1,000.000

Parameter 14-21 Automatic Restart Time 5 s

Parameter 14-32 Current Lim Ctrl, Filter Time 27

Parameter 30-84 Process PID Proportional Gain 0.010

PROFIBUS-specific parameters

Parameter 9-71 PROFIBUS Save Data Values [1] Store All Setups

Configuring the System

24 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 25

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5 Parameter Mapping Lists

5.1 FCD 300 Parameter Group 0

5.1.1 Conversion of Parameter 001 Language Select

Table 8: Parameter 001

FCD 300 series FCD 302 series

Parameter 001 Language Select 0-01 Language

Options [0] English [0] English

[1] Deutsch [1] Deutsch

[2] French [2] French

[3] Dansk [3] Dansk

[4] Spanish [4] Spanish

[5] Italian [5] Italian

Parameter Mapping Lists

5.1.2 Conversion of Parameter 002 Operation Site

Table 9: Parameter 002

FCD 300 series FCD 302 series

Parameter 002 Operation Site Not converted

Options [0] Remote –

[1] Local with External Stop –

[2] Local –

5.1.3 Conversion of Parameter 003 Local Reference

Table 10: Parameter 003

FCD 300 series FCD 302 series

Parameter 003 Local Reference Not converted

5.1.4 Conversion of Parameter 004 Active Set-up

Table 11: Parameter 004

FCD 300 series FCD 302 series

Parameter 004 Active Set-up 0-10 Active Set-up

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 25

Page 26

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [0] Factory Setup [0] Factory Setup

[1] Setup 1 [1] Setup 1

[2] Setup 2 [2] Setup 2

[3] Setup 3 [3] Setup 3

[4] Setup 4 [4] Setup 4

[5] Multi Setup [9] Multi Setup

5.1.5 Conversion of Parameter 005 Edit Setup

Table 12: Parameter 005

FCD 300 series FCD 302 series

Parameter 005 Edit Setup 9-70 Set-up Copy

Options [0] Factory Set-up [0] Factory Set-up

Parameter Mapping Lists

[1] Setup 1 [1] Setup 1

[2] Setup 2 [2] Setup 2

[3] Setup 3 [3] Setup 3

[4] Setup 4 [4] Setup 4

[5] Active Setup [9] Active Setup

5.1.6 Conversion of Parameter 006 Setup Copy

Table 13: Parameter 006

FCD 300 series FCD 302 series

Parameter 006 Setup Copy 0-51 Set-up Copy

Options [0] No Copy [0] No Copy

[1] Copy to 1 from # [9] Copy to ALL from #

[2] Copy to 2 from # [9] Copy to ALL from #

[3] Copy to 3 from # [9] Copy to ALL from #

[4] Copy to 4 from # [9] Copy to ALL from #

[5] Copy to ALL from # [9] Copy to ALL from #

26 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 27

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.1.7 Conversion of Parameter 007 LCP Copy

Table 14: Parameter 007

FCD 300 series FCD 302 series

Parameter 007 LCP Copy 0-50 LCP Copy

Options [0] No copy Not converted

[1] Upload all Param Not converted

[2] Download All Not converted

[3] Download Size Inde Not converted

5.1.8 Conversion of Parameter 008 Frequency Scale

Table 15: Parameter 008

FCD 300 series FCD 302 series

Parameter 008 Frequency Scale Not converted

Parameter Mapping Lists

5.1.9 Conversions of Parameters 009 to 012 Display Line

Table 16: Parameters 009 to 012

FCD 300 series FCD 302 series

Parameter 009 Display Line 0-23 Display Line 2

010 Display Line 0-20 Display Line 1.1

011 Display Line 0-21 Display Line 1.2

012 Display Line 0-22 Display Line 1.3

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 27

Page 28

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [0] None [0] None

[1] Reference % [1602] Reference %

[2] Reference [Unit] [1601] Reference [Unit]

[3] Feedback [Unit] [1652] Feedback [Unit]

[4] Frequency [Hz] [1613] Frequency [Hz]

[5] Frequency x scale [1609] Custom readout

[6] Motor Current [A] [1614] Motor Current [A]

[7] Torque [1622] Torque [%]

[8] Power [kW] [1610] Power [kW]

[9] Power [HP] [1611] Power [HP]

[10] Output energy [kWh] [1502] kWh counter [kWh]

[11] Motor voltage [V] [1612] Motor voltage [V]

[12] DC link voltage [V] [1630] DC link voltage [V]

Parameter Mapping Lists

[13] Thermal load, motor [%] [1618] Thermal load, motor [%]

[14] Thermal load, VLT® [%] [1635] Inverter thermal [%]

[15] Running hours [hours] [1501] Running hours [hours]

[16] Digital input [1660] Digital input

[17] Analog input 53 [V] [1662] Analog input 53 [V]

[19] Analog input 60 [mA] [1662] Analog input 53 [mA]

[20] Pulse reference [Hz] [1651] Pulse reference [Hz]

[21] Ext. reference [%] [1650] Ext. reference [%]

[22] Status word [hex] [1603] Status word [hex]

[24] Brake effect/sec [kW] [1632] Brake effect/sec [kW]

[25] Heat sink temp. [1634] Heat sink temp.

[26] Alarm word [hex] –

[27] Control word [hex] [1600] Control word [hex]

[28] Warning word 1 [hex] –

[29] Warning word 2 [hex] –

[30] Com. Option warning [hex] [953] Com. Option warning [hex]

[31] RPM [min] [1617] Speed RPM [min]

28 | Danfoss A/S © 2019.11

[32] RPM x scaling [min] [1609] Custom readout

AQ289550754901en-000101 / 130R0890

Page 29

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.1.10 Conversion of Parameter 013 Local Ctrl./config

Table 17: Parameter 013

FCD 300 series FCD 302 series

Parameter 013 Local Ctrl./config Not converted

5.1.11 Conversion of Parameter 014 Local Stop Key

Table 18: Parameter 014

FCD 300 series FCD 302 series

Parameter 014 Local Stop Key 0-41 [Off] Key on LCP

Options [0] Disable [0] Disable

[1] Enable [1] Enable

– [2] Password

Parameter Mapping Lists

5.1.12 Conversion of Parameter 015 Local Jogging

Table 19: Parameter 015

FCD 300 series FCD 302 series

Parameter 015 Local Jogging Not converted

Options [0] Disable –

[1] Enable –

5.1.13 Conversion of Parameter 016 Local Reversing

Table 20: Parameter 016

FCD 300 series FCD 302 series

Parameter 016 Local Reversing Not converted

Options [0] Disable –

[1] Enable –

5.1.14 Conversion of Parameter 017 Local Reset of Trip

Table 21: Parameter 017

FCD 300 series FCD 302 series

Parameter 017 Local Reset of Trip 0-43 [Reset] Key on LCP

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 29

Page 30

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [0] Not Active [1] Disable

[1] Active [1] Enable

– [2] Password

5.1.15 Conversion of Parameter 018 Lock for Data Change

Table 22: Parameter 018

FCD 300 series FCD 302 series

Parameter 018 Lock for Data Change 0-61 Access to Main Menu w/o Password

Options [0] Not Locked [0] Full Access

[1] Lock [1] LCP: Read Only

5.1.16 Conversion of Parameter 019 Operating Mode at Power-up

Parameter Mapping Lists

Table 23: Parameter 019

FCD 300 series FCD 302 series

Parameter 019 Operating Mode at Power-up 0-04 Operating State at Power-up (Hand)

[0] Auto Restart, Use Saved Ref. [0] Resume

[1] Forced Stop, Use Saved Ref. [1] Forced Stop, Use Saved Ref.

[2] Forced Stop, Set Ref = 0 [2] Forced Stop, Set Ref = 0

5.1.17 Conversion of Parameter 020 Hand Operation

Table 24: Parameter 020

FCD 300 series FCD 302 series

Parameter 020 Hand Operation Not converted

5.1.18 Conversion of Parameter 024 User Quick Menu

Table 25: Parameter 024

FCD 300 series FCD 302 series

Parameter 024 User Quick Menu Not converted

30 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 31

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.1.19 Conversion of Parameter 025 Quick Menu Setup

Table 26: Parameter 025

FCD 300 series FCD 302 series

Parameter 025 Quick Menu Setup Not converted

5.1.20 Conversion of Parameter 026 LED Status

Table 27: Parameter 026

FCD 300 series FCD 302 series

Parameter 026 LED Status Not converted

5.2 FCD 300 Parameter Group 1

5.2.1 Conversion of Parameter 100 Configuration

Table 28: Parameter 100

Parameter Mapping Lists

FCD 300 series FCD 302 series

Parameter 100 Configuration 1-00 Configuration Mode

1-01 Motor Control Principle

Options [0] Speed Control, Open Loop Parameter 1-00: [0] Speed Open Loop

Parameter 1-01: [1] VVC

[1] Speed Control, Closed Loop Parameter 1-00: [1] Speed Closed Loop

Parameter 1-01: [1] VVC

[3] Process Control, Closed Loop Parameter 1-00: [3] Process

Parameter 1-01: [1] VVC

+

+

+

5.2.2 Conversion of Parameter 101 Torque Characteristic

Table 29: Parameter 101

FCD 300 series FCD 302 series

Parameter 101 Torque Characteristic 1-03 Torque Characteristics

Overload Mode

Danfoss A/S © 2019.11

VT Level

AQ289550754901en-000101 / 130R0890| 31

Page 32

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

[1] High Constant Parameter 1-03: [0] Constant Torque

[2] High Variable Torque Low Parameter 1-03: [1] Variable Torque

[3] High Variable Torque Medium Parameter 1-03: [1] Variable Torque

[4] High Variable Torque High Parameter 1-03: [1] Variable Torque

Parameter Mapping Lists

Parameter 1-04: [0] High

Parameter 14-40: 45%

Parameter 1-04: [0] High

Parameter 14-40: 66%

Parameter 1-04: [0] High

Parameter 14-40: 85%

Parameter 1-04: [0] High

[5] High Speial Motor Characteristic Parameter 1-01: [0] U/f

Parameter 1-04: [0] High

[6] High Variable Torque with Low Starting Torque Parameter 1-03: [1] Variable Torque

Parameter 14-40: 45%

Parameter 1-04: [0] High

[7] Variable Torque with CT Start Parameter 1-01: [1] Variable Torque

Parameter 14-40: 85%

Parameter 1-04: [0] High

[8] Special Motor Mode Parameter 1-01: [1] U/f

Parameter 1-04: [0] High

5.2.3 Conversion of Parameter 102 Motor Power

Table 30: Parameter 102

FCD 300 series FCD 302 series

Parameter 102 Motor Power 1-20 Motor Power [kW]

Range 0.18–4.0 kW 0.09–5.5 kW

32 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 33

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.2.4 Conversion of Parameter 103 Motor Voltage

Table 31: Parameter 103

FCD 300 series FCD 302 series

Parameter 103 Motor Voltage 1-22 Motor Voltage

Range 55–999 V 50–1000 V

5.2.5 Conversion of Parameter 104 Motor Frequency

Table 32: Parameter 104

FCD 300 series FCD 302 series

Parameter 104 Motor Frequency 1-23 Motor Frequency

Range 24–1000 Hz 20–1000 Hz

5.2.6 Conversion of Parameter 105 Motor Current

Parameter Mapping Lists

Table 33: Parameter 105

FCD 300 series FCD 302 series

Parameter 105 Motor Current 1-24 Motor Current

Range Depending on power size Depending on power size

5.2.7 Conversion of Parameter 106 Rated Motor Speed

Table 34: Parameter 106

FCD 300 series FCD 302 series

Parameter 106 Rated Motor Speed 1-25 Motor Nominal Speed

Range 100–60000 10–60000

5.2.8 Conversion of Parameter 107 Automatic Motor Tuning (AMT)

Table 35: Parameter 107

FCD 302 series FCD 302 series

Parameter 107 Automatic Motor Tuning (AMT) 1-29 Automatic Motor Adaptation (AMA)

Options [0] Adaptation Off [0] Off

[1] Adaptation On, Rs and Xs [1] Enable Complete AMA

[2] Adaptarion On, Rs [2] Enable Reduced AMA

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 33

Page 34

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.2.9 Conversion of Parameter 108 Stator Resistor

Table 36: Parameter 108

FCD 300 series FCD 302 series

Parameter 108 Stator Resistor 1-30 Stator Resistance (Rs)

Range Depending on power unit Depending on power unit

5.2.10 Conversion of Parameter 109 Stator Reactance

Table 37: Parameter 109

FCD 300 series FCD 302 series

Parameter 109 Stator Reactance 1-35 Main Reactance (Xh)

Range Depending on power unit 1.0000–10000.0000

5.2.11 Conversion of Parameter 117 Resonance Dampening

Parameter Mapping Lists

Table 38: Parameter 117

FCD 300 series FCD 302 series

Parameter 117 Resonance Dampening 1-64 Resonance Dampening

Range 0–500% 0–500%

5.2.12 Conversion of Parameter 119 High Starting Torque

Table 39: Parameter 119

FCD 300 series FCD 302 series

Parameter 119 High Starting Torque Not converted

5.2.13 Conversion of Parameter 120 Start Delay

Table 40: Parameter 120

FCD 300 series FCD 302 series

Parameter 120 Start Delay 1-71 Start Delay

Range 0.0–10.0 s 0.0–10.0 s

34 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 35

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

5.2.14 Conversion of Parameter 121 Start Function

Table 41: Parameter 121

FCD 300 series FCD 302 series

Parameter 121 Start Function 1-72 Start Function

Options [0] DC Hold in Start Delay Time [0] DC Hold/Delay Time

[1] DC Brake in Start Delay Time [1] DC Brake/Delay Time

[2] Coasting in Start Delay Time [2] Coast/Delay Time

[3] Start Frequency/Voltage Clockwise [3] Start Speed CW

[4] Start Frequency/Voltage in Reference Direction [4] Horizontal Operation

5.2.15 Conversion of Parameter 122 Function at Stop

Table 42: Parameter 122

FCD 300 series FCD 302 series

Parameter 122 Function at Stop 1-80 Function at Stop

Options [0] Coasting [0] Coast

[1] DC Hold [1] DC Hold

– [2] Motor Check

– [3] Pre-magnetizing

5.2.16 Conversion of Parameter 123 Min Frequency for Function at Stop

Table 43: Parameter 123

FCD 300 series

Parameter 123 Min Frequency for Function at Stop 1-82 Min Speed for Function at Stop [Hz]

Range 0.0–10.0 Hz 0.0–20.0 Hz

FCD 302 series

5.2.17 Conversion of Parameter 126 DC Braking Time

Table 44: Parameter 126

FCD 300 series FCD 302 series

Parameter 126 DC Braking Time 2-02 DC Braking Time

Range 0.0–60.0 s 0.0–60.0 s

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 35

Page 36

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.2.18 Conversion of Parameter 127 DC Brake Cut-in Frequency

Table 45: Parameter 127

FCD 300 series FCD 302 series

Parameter 127 DC Brake Cut-in Frequency 2-04 DC Brake Cut-in Speed [Hz]

Parameter Mapping Lists

Range 0.0 (Off) to f

(parameter 202) 0.0 (Off) to f

max

(parameter 4-14)

max

5.2.19 Conversion of Parameter 128 Motor Thermal Protection

Table 46: Parameter 128

FCD 300 series FCD 302 series

Parameter 128 Motor Thermal Protection 1-90 Motor Thermal Protection

Options [0] No Protection [0] No Protection

[1] Thermistor Warning [1] Thermistor Warning

[2] Thermistor Trip [2] Thermistor Trip

[3] ETR Warning 1 [3] ETR Warning 1

[4] ETR Trip 1 [4] ETR Trip 1

[5] ETR Warning 2 [5] ETR Warning 2

[6] ETR Trip 2 [6] ETR Trip 2

[7] ETR Warning 3 [7] ETR Warning 3

[8] ETR Trip 3 [8] ETR Trip 3

[9] ETR Warning 4 [9] ETR Warning 4

[10] ETR Trip 4 [10] ETR Trip 4

5.2.20 Conversion of Parameter 130 Start Frequency

Table 47: Parameter 130

FCD 300 series FCD 302 series

Parameter 130 Start Frequency 1-75 Start Speed [Hz]

Range 0.0–10.0 Hz 0.0–500 Hz, depending on unit

5.2.21 Conversion of Parameter 131 Initial Voltage

Table 48: Parameter 131

FCD 300 series FCD 302 series

Parameter 131 Initial Voltage Not converted.

36 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 37

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.2.22 Conversion of Parameter 132 DC Brake Voltage

Table 49: Parameter 132

FCD 300 parameter FCD 302 parameter

Parameter 132 DC Brake Voltage Not converted

5.2.23 Conversion of Parameter 133 Start Voltage

Table 50: Parameter 133

FCD 300 series FCD 302 series

Parameter 133 Start Voltage Not converted

5.2.24 Conversion of Parameter 134 Load Compensation

Table 51: Parameter 134

FCD 300 series FCD 302 series

Parameter Mapping Lists

Parameter 134 Load Compensation Not converted

5.2.25 Conversion of Parameter 135 U/f-Ratio

Table 52: Parameter 135

FCD 300 series FCD 302 series

Parameter 135 U/f-ratio Not converted

5.2.26 Conversion of Parameter 136 Slip Compensation

Table 53: Parameter 136

FCD 300 series FCD 302 series

Parameter 136 Slip Compensation 1-62 Slip Compensation

Range -500 to +500% -500 to +500%

5.2.27 Conversion of Parameter 137 DC Hold Voltage

Table 54: Parameter 137

FCD 300 series FCD 302 series

Parameter 137 DC Hold Voltage 2-00 DC Hold Current

Range 0–100% 0–160%

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 37

Page 38

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.2.28 Conversion of Parameter 138 Brake Cut Out Value

Table 55: Parameter 138

FCD 300 series FCD 302 series

Parameter 138 Brake Cut Out Value Not converted

5.2.29 Conversion of Parameter 139 Brake Cut In Frequency

Table 56: Parameter 139

FCD 300 series FCD 302 series

Parameter 139 Brake Cut In Frequency 2-04 Brake Cut In Speed [Hz]

Range 0.5–132/1000 Hz 0 to parameter 4-14

5.2.30 Conversion of Parameter 140 Current, Minimum Value

Table 57: Parameter 140

Parameter Mapping Lists

FCD 300 series FCD 302 series

Parameter 140 Current, Minimum Value 2-20 Release Brake Current

Range 0–100% 0 to parameter 16-37

5.2.31 Conversion of Parameter 142 Leakage Reactance XL

Table 58: Parameter 142

FCD 300 series FCD 302 series

Parameter 142 Leakage Reactance XL 1-33 Stator Leakage Reactance

1-34 Rotor Leakage Reactance

Range 0.000–xxx.xxx Ω 0.04–400.00 Ω

5.2.32 Conversion of Parameter 144 Gain AC Brake

Table 59: Parameter 144

FCD 300 series FCD 302 series

Parameter 144 Gain AC Brake 2-16 AC Brake Max. Current

Range 1.00–1.50

38 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 39

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.2.33 Conversion of Parameter 146 Reset Voltage Vector

Table 60: Parameter 146

FCD 300 series FCD 302 series

Parameter 146 Reset Voltage Vector Not converted

5.2.34 Conversion of Parameter 147 Motor Type

Table 61: Parameter 147

FCD 300 series FCD 302 series

Parameter 147 Motor Type Not converted

5.3 FCD 300 Parameter Group 2

5.3.1 Conversion of Parameter 200 Output Frequency Range/Direction

Table 62: Parameter 200

Parameter Mapping Lists

FCD 300 series FCD 302 series

Parameter 200 Output Frequency Range/Direction 4-10 Motor Speed Direction

Options [0] Only Clockwise, 0–132 Hz [0] Clockwise

[1] Both Directions, 0–132 Hz [2] Both Direction

[2] Only Clockwise, 0–1000 Hz [0] Clockwise

[4] Only Counterclockwise, 0–132 Hz [1] Counterclockwise

[5] Only Counterclockwise, 0–1000 Hz [1] Counterclockwise

5.3.2 Conversion of Parameter 201 Output Frequency Low Limit

Table 63: Parameter 201

FCD 300 series FCD 302 series

Parameter 201 Output Frequency Low Limit 4-12 Motor Speed Low Limit [Hz]

Range 0.0 to parameter 202, f

max

0 to parameter 4-14, f

max

[Hz]

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 39

Page 40

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

5.3.3 Conversion of Parameter 202 Output Frequency High Limit

Table 64: Parameter 202

FCD 300 series FCD 302 series

Parameter 202 Output Frequency High Limit 4-14 Motor Speed High Limit [Hz]

4-19 Max Output Frequency

Range 0.0–132/1000 Hz 0–1000 Hz

5.3.4 Conversion of Parameter 203 Reference/Feedback Area

Table 65: Parameter 203

FCD 300 series FCD 302 series

Parameter 203 Reference/Feedback Area 3-00 Reference Range

Options [0] Min–Max [0] Min–Max

[1] -Max to +Max [1] -Max to +Max

5.3.5 Conversion of Parameter 204 Minimum Reference

Table 66: Parameter 204

FCD 300 series FCD 302 series

Parameter 204 Minimum Reference 3-02 Minimum Reference

Range -100,000.000 to parameter 205, Ref

max

-100,000.000 to parameter 3-03, Ref

5.3.6 Conversion of Parameter 205 Maximum Reference

Table 67: Parameter 205

FCD 300 series FCD 302 series

Parameter 205 Maximum Reference 3-03 Maximum Reference

6-15 Terminal 53 High Ref./Feedb. Value

6-25 Terminal 54 High Ref./Feedb. Value

5-53 Term. 29 High Ref./Feedb. Value

5-58 Term. 33 High Ref./Feedb. Value

max

Range Parameter 204, Ref

40 | Danfoss A/S © 2019.11

to 100,000.000 Parameter 3-02 Ref

min

to 100,000.000

min

AQ289550754901en-000101 / 130R0890

Page 41

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.3.7 Conversion of Parameter 206 Ramp Type

Table 68: Parameter 206

FCD 300 series FCD 302 series

Parameter 206 Ramp Type 3-40 Ramp 1 Type

3-50 Ramp 2 Type

3-82 Quick Stop Ramp Type

Options [0] Linear Parameter 3-40: [0] Linear

Parameter 3-50: [0] Linear

Parameter 3-82: [0] Linear

[1] Sine Shape (S1) Parameter 3-40: [2] S-ramp Const Time

Parameter 3-45: 1%

Parameter 3-46: 25%

Parameter Mapping Lists

Parameter 3-47: 1%

Parameter 3-48: 25%

Parameter 3-50: [2] S-ramp Const Time

Parameter 3-55: 1%

Parameter 3-56: 25%

Parameter 3-57: 1%

Parameter 3-58: 25%

Parameter 3-82: [2] S-ramp Const Time

Parameter 3-83: 1%

Parameter 3-84: 25%

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 41

Page 42

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [2] Sin2 Shape (S2) Parameter 3-40: [2] S-ramp Constant Time

Parameter 3-45: 25%

Parameter 3-46: 25%

Parameter 3-47: 25%

Parameter 3-48: 25%

Parameter 50: [2] S-ramp Const Time

Parameter 3-55: 25%

Parameter 3-56: 25%

Parameter 3-57: 25%

Parameter 3-58: 25%

Parameter 3-82: [2] S-ramp Const Time

Parameter Mapping Lists

Parameter 3-83: 25%

Parameter 3-84: 25%

[3] Sin3 Shape (S3) Parameter 3-40: [2] S-ramp Const Time

Parameter 3-45: 50%

Parameter 3-46: 50%

Parameter 3-48: 50%

Parameter 3-50: [2] S-ramp Const Time

Parameter 3-55: 50%

Parameter 3-56: 50%

Parameter 3-57: 50%

Parameter 3-58: 50%

Parameter 3-82: [2] S-ramp Const Time

Parameter 3-83: 50%

Parameter 3-84: 50%

42 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 43

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [4] Sin2 Filter Parameter 3-40: [2] S-ramp Const Time

Parameter 3-45: 25%

Parameter 3-46: 25%

Parameter 3-47: 25%

Parameter 3-48: 25%

Parameter 3-50: [2] S-ramp Const Time

Parameter 3-55: 25%

Parameter 3-56: 25%

Parameter 3-57: 25%

Parameter 3-58: 25%

Parameter 3-82: [2] S-ramp Const Time

Parameter Mapping Lists

Parameter 3-83: 25%

Parameter 3-84: 25%

5.3.8 Conversion of Parameter 207 Ramp Up Time 1

Table 69: Parameter 207

FCD 300 series FCD 302 series

Parameter 207 Ramp Up Time 1 3-41 Ramp 1 Ramp Up Time

Range 0.05–3600.00 s 0.01–3600.00 s

5.3.9 Conversion of Parameter 208 Ramp Down Time 1

Table 70: Parameter 208

FCD 300 series FCD 302 series

Parameter 208 Ramp Down Time 1 3-42 Ramp 1 Ramp Down Time

Range 0.05–3600.00 s 0.01–3600.00 s

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 43

Page 44

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.3.10 Conversion of Parameter 209 Ramp Up Time 2

Table 71: Parameter 209

FCD 300 series FCD 302 series

Parameter 209 Ramp Up Time 2 3-51 Ramp 2 Ramp Up Time

Range 0.05 3600.00 s 0.01–3600.00 s

5.3.11 Conversion of Parameter 210 Ramp Down Time 2

Table 72: Parameter 210

FCD 300 series FCD 302 series

Parameter 210 Ramp Down Time 2 3-52 Ramp 2 Ramp Down Time

Range 0.05–3600.00 s 0.01–3600.00 s

5.3.12 Conversion of Parameter 211 Jog Ramp Time

Parameter Mapping Lists

Table 73: Parameter 211

FCD 300 series FCD 302 series

Parameter 211 Jog Ramp Time 3-80 Jog Ramp Time

Range 0.05–3600.00 s 0.01–3600.00 s

5.3.13 Conversion of Parameter 212 Quick Stop Ramp Time

Table 74: Parameter 212

FCD 300 series FCD 302 series

Parameter 212 Quick Stop Ramp Time 3-81 Quick Stop Ramp Time

Range 0.05–3600.00 s 0.01–3600.00 s

5.3.14 Conversion of Parameter 213 Jog Frequency

Table 75: Parameter 213

FCD 300 series FCD 302 series

Parameter 213 Jog Frequency 3-11 Jog Speed [Hz]

Range 0.0 to parameter 202 0.0 to parameter 4-14

44 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 45

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

5.3.15 Conversion of Parameter 214 Reference Function

Table 76: Parameter 214

FCD 300 series FCD 302 series

Parameter 214 Reference Function 3-04 Reference Function

Option [0] Sum [0] Sum

[1] Relative

[2] External/Preset [2] External/Preset

1

Relative reference is added to MRV from PROFIBUS.

(1)

5.3.16 Conversion of Parameter 215 Preset Reference 1

Table 77: Parameter 215

FCD 300 series FCD 302 series

Parameter Parameter 215 Preset Reference 1 3-10 Preset Reference

Range -100.00 to +100.00% -100.00 to +100.00%

5.3.17 Conversion of Parameter 216 Preset Reference 2

Table 78: Parameter 216

FCD 300 series FCD 302 series

Parameter 216 Preset Reference 2 3-10 Preset Reference

Range -100.00 to +100.00% -100.00 to +100.00%

5.3.18 Conversion of Parameter 217 Preset Reference 3

Table 79: Parameter 217

FCD 300 series FCD 302 series

Parameter 217 Preset Reference 3 3-10 Preset Reference

Range -100.00 to +100.00% -100.00 to +100.00%

5.3.19 Conversion of Parameter 218 Preset Reference 4

Table 80: Parameter 218

FCD 300 series FCD 302 series

Parameter 218 Preset Reference 4 3-10 Preset Reference

Range -100.00 to +100.00% -100.00 to +100.00%

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 45

Page 46

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

5.3.20 Conversion of Parameter 219 Catch Up/Slow Down Value

Table 81: Parameter 219

FCD 300 series FCD 302 series

Parameter 219 Catch Up/Slow Down Value 3-12 Catch Up/Slow Down Value

Range 0.00–100% 0.00–100%

5.3.21 Conversion of Parameter 221 Torque Limit for Motor Mode

Table 82: Parameter 221

FCD 300 series FCD 302 series

Parameter 221 Current Limit 4-18 Curret Limit

Range 0.0 to maximum torque % 0.0 to maximum torque %

5.3.22 Conversion of Parameter 223 Warning: Current Low

Table 83: Parameter 223

FCD 300 series FC 302 series

Parameter 223 Warning: Current Low 4-50 Warning Current Low

2-20 Release Brake Current

Range 0.0 to parameter 224 Warning: Current High 0.00 to parameter 4-51 Warning Current High

5.3.23 Conversion of Parameter 224 Warning: Current High

Table 84: Parameter 224

FCD 300 series FCD 302 series

Parameter 224 Warning: Current High 4-51 Warning Current High

Range Depending on power unit Depending on power unit

5.3.24 Conversion of Parameter 225 Warning Low Frequency

Table 85: Parameter 225

FCD 300 series FCD 302 series

Parameter 225 Warning Low Frequency 4-52 Warning Speed Low

2-22 Activate Brake Speed [Hz]

Range 0.0 to parameter 226 0.0 to parameter 4-53

46 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 47

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

5.3.25 Conversion of Parameter 226 Warning High Frequency

Table 86: Parameter 226

FCD 300 series FCD 302 series

Parameter 226 Warning High Frequency 4-53 Warning Speed High

Range Parameter 225 to parameter 202 Parameter 4-52 to parameter 4-13

5.3.26 Conversion of Parameter 227 Warning Low Feedback

Table 87: Parameter 227

FCD 300 series FCD 302 series

Parameter 227 Warning Low Feedback 4-56 Warning Feedback Low

Range -100000.000 to parameter 228 -999999.999 to parameter 4-57

5.3.27 Conversion of Parameter 228 Warning High Feedback

Table 88: Parameter 228

FCD 300 series FCD 302 series

Parameter 228 Warning High Feedback 4-57 Warning Feedback High

Range Parameter 227 to 1000000.000 Parameter 4-57 to 999999.999

5.3.28 Conversion of Parameter 229 Frequency Bypass, Bandwidth

Table 89: Parameter 229

FCD 300 series FCD 302 series

Parameter 229 Frequency Bypass, Bandwidth Stored in EEPROM only

Range 0–100% –

5.3.29 Conversion of Parameter 230 Frequency Bypass 1

Table 90: Parameter 230

FCD 300 series FCD 302 series

Parameter 230 Frequency Bypass 1 4-61 Bypass Speed From [Hz]

4-63 Bypass Speed To [Hz]

Range 0 to parameter 200 0 to parameter 4-14

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 47

Page 48

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.3.30 Conversion of Parameter 231 Frequency Bypass 2

Table 91: Parameter 231

FCD 300 series FCD 302 series

Parameter 231 Frequency Bypass 2 4-61 Bypass Speed From [Hz]

4-63 Bypass Speed To [Hz]

Range 0 to parameter 200 0 to parameter 4-14

5.4 FCD 300 Parameter Group 3

5.4.1 Conversion of Parameters 302 to 307 Terminal Input 18 to 33

Table 92: Parameters 302 to 307

FCD 300 series FCD 302 series

Parameter Mapping Lists

Parameter 302 Terminal 18 Input

303 Terminal 19 Input

304 Terminal 27 Input

305 Terminal 29 Input

307 Terminal 33 Input

5-10 Terminal 18 Input

5-11 Terminal 19 Input

5-12 Terminal 27 Input

5-13 Terminal 29 Input

5-15 Terminal 33 Input

48 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 49

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [0] No Function [0] No Operation

[1] Reset [1] Reset

[2] Stop Inverse [6] Stop Inverse

[3] Only Start Clockwise, On [12] Enable Start Forward

[4] Only Start Counterclockwise, On [13] Enable Start Reverse

[5] Jog [14] Jog

[6] Preset Reference, On [15] Preset Reference, On

[7] Preset Reference, LSB [16] Preset Reference Bit 0

[8] Preset Reference, MSB [17] Preset Reference Bit 1

[9] Freeze Reference [19] Freeze Reference

[10] Freeze Output [20] Freeze Output

[11] Speed Up [21] Speed Up

[12] Speed Down [22] Speed Down

Parameter Mapping Lists

[13] Choice of Setup, LSB [23] Setup Select Bit 0

[14] Choice of Setup, MSB [24] Setup Select Bit 1

[15] Catch Up [28] Catch Up

[16] Slow Down [29] Slow Down

[17] Ramp 2 [34] Ramp Bit 0

[18] Mains Failure Inverted Not supported

[28] Pulse Reference [32] Pulse Input

[29] Data Change Lock Not supported

5.4.2 Conversion of Parameter 308 Terminal 53, Analog Input Voltage

Table 93: Parameter 308

FCD 300 series FCD 302 series

Parameter Terminal 53, Analog Input Voltage 3-15 Reference Resource 1

7-00 Speed PID Feedback Source

1-93 Thermistor Resource

4-20 Torque Limit Factor Source

Options [0] No Operation Parameter 3-15 Reference Resource 1 set to [0] No Function

[1] Reference Parameter 3-15 Reference Resource 1 set to [1] Analog Input 53

[2] Feedback Parameter 3-15 Reference Resource 1 set to [1] Analog Input 53

Parameter 7-00 Speed PID Feedback Source set to [6] Analog Input 53.

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 49

Page 50

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

5.4.3 Conversion of Parameter 309 Terminal 53, Min. Scaling

Table 94: Parameter 309

FCD 300 series FCD 302 series

Parameter 309 Terminal 53, Min. Scaling 6-10 Terminal 53 Low Voltage

Range 0–10.0 V -10.00 to parameter 6-11

5.4.4 Conversion of Parameter 310 Terminal 53, Max Scaling

Table 95: Parameter 310

FCD 300 series FCD 302 series

Parameter 310 Terminal 53, Max Scaling 6-11 Terminal 53 High Voltage

Range 0–10.0 V Parameter 6-10 to 10.00 V

5.4.5 Conversion of Parameter 314 Terminal 60, Analog Input Current

Parameter Mapping Lists

Table 96: Parameter 314

FCD 300 series

FCD 302 series

(1)

Parameter 314 Terminal 60, Analog Input Current 3-17 Reference Resource 3

7-00 Speed PID Feedback Source

1-93 Thermistor Resource

4-20 Torque Limit Factor Source

Options [0] No Operation Parameter 3-17 Reference Resource 3 set to [0] No Function

[1] Reference Parameter 3-17 Reference Resource 3 set to [2] Analog Input 54

Parameter 7-00 Speed PID Source set to [7] Analog Input 54

[2] Feedback Signal Parameter 7-00 Speed PID Feedback Source set to [7] Analog Input 54

[3] Torque Limit Parameter 3-17 Reference Resource 3 set to [2] Analog Input 54

Parameter 4-20 Torque Limit Factor Source set to [6] Analog Input 54

[10] Wobble Not supported

1

The HW switch S202 for analog input 54 must be set to current (ON).

5.4.6 Conversion of Parameter 315 Terminal 60, Min. Scaling

Table 97: Parameter 315

FCD 300 series FCD 302 series

Parameter 315 Terminal 60, Min. Scaling 6-22 Terminal 54 Low Current

50 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 51

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Range 0.0–20.0 mA 0.00 to parameter 6-23

5.4.7 Conversion of Parameter 316 Terminal 60, Max. Scaling

Table 98: Parameter 316

FCD 300 series FCD 302 series

Parameter 316 Terminal 60, Max. Scaling 6-23 Terminal 54 High Current

Range 0.0–20.0 mA Parameter 6-23 to 20.00 mA

5.4.8 Conversion of Parameter 317 Time Out

Table 99: Parameter 317

FCD 300 series FCD 302 series

Parameter Mapping Lists

Parameter 317 Time Out 6-00 Live Zero Timeout Time

Range 0–99 s 0–99 s

5.4.9 Conversion of Parameter 318 Function After Time Out

Table 100: Parameter 318

FCD 300 series FCD 302 series

Parameter 318 Function After Time Out 6-01 Live Zero Timeout Funciton

Options [0] Off [0] Off

[1] Freeze Output Frequency [1] Freeze Output Frequency

[2] Stop [2] Stop

[3] Jogging [3] Jog

[4] Max Speed [4] Max Speed

[5] Stop and Trip [5] Stop and Trip

5.4.10 Conversion of Parameter 319 Terminal 42, Output

Table 101: Parameter 319

FCD 300 series FCD 302 series

Parameter 319 Terminal 42, Output 650 Terminal 42 Output

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 51

Page 52

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 series FCD 302 series

Options [0] No Function [0] No Function

[1] Ref min-max = 0–20 mA [101] Reference

[2] Ref min-max = 4–20 mA [131] Ref. 4–20 mA

[3] FB min-max = 0–20 mA [102] Feedback

[4] FB min-max = 4–20 mA [132] Feedback 4–20 mA

[5] 0–fmax = 0–20 mA [100] Output Frequency

[6] 0–fmax = 4–20 mA [130] Output Freq. 4–20 mA

[7] 0–imax = 0–20 mA [103] Motor Current

[8] 0–imax = 4–20 mA [133] Motor Current 4–20 mA

[9] 0–Pnom = 0–20ámA [106] Power

[10] 0–Pnom = 4–20 mA [136] Power 4–20 mA

[11] Temp 20–100 C = 0–20 mA Not supported

[12] Temp 20–100 C = 4–20 mA Not supported

Parameter Mapping Lists

5.4.11 Conversion of Parameter 323 Relay Output

Table 102: Parameter 323

FCD 300 series FCD 302 series

Parameter 323 Relay Function 5-40 Function Relay (Index 0)

01 Relay Relay 1

Options [0] No Function Parameter 5-40 = [0] No Operation

[1] Control Ready Parameter 5-40 = [1] Control Ready

[2] Ready Signal Parameter 5-40 = [2] Drive Ready

[3] Ready - Remote Control Parameter 5-40 = [3] Drive Rdy/Rem Ctrl

[4] Enabled, No Warning Parameter 5-40 = [4] Enable/No Warning

[5] Running Parameter 5-40 = [5] VLT Running

[6] Running, No Warning Parameter 5-40 = [6] Running/No Warning

[7] Running Within Range, No Warning Parameter 5-40 = [7] Run In Range/No Warn

[8] Run At Reference, Nor Warning Parameter 5-40 = [8] Run On Ref/No Warn

[9] Alarm Parameter 5-40 = [9] Alarm

[10] Alarm Or Warning Parameter 5-40 = [10] Alarm Or Warning

52 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 53

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

FCD 300 series FCD 302 series

Options [11] Torque Limit Parameter 5-40 = [11] At Torque Limit

[12] Out Of Current Range Parameter 5-40 = [12] Out Of Current Range

[13] Above I

[14] Under I

low

high

Parameter 5-40 = [13] Below Current, Low

Parameter 5-40 = [14] Above Current, High

[15] Out Of Frequency Range Parameter 5-40 = [15] Out Of Speed Range

[16] Over f

[17] Under f

low

high

Parameter 5-40 = [16] Below Speed Low

Parameter 5-40 = [17] Above Speed High

[18] Out Of Feedback Range Parameter 5-40 = [18] Out Of Feedb. Range

[19] Over Feedback Low Parameter 5-40 = [19] Below Feedback Low

[20] Under Feedback Low Parameter 5-40 = [20] Above Feedback High

[21] Thermal Warning Parameter 5-40 = [21] Thermal Warning

[22] Ready, No Thermal Warning Parameter 5-40 = [22] Ready. No Thermal W

[23] Ready - Remote Control - No Thermal Warning Parameter 5-40 = [23] Remote, Ready, No TW

[24] Ready - Mains Voltage Within Range Parameter 5-40 = [24] Ready, Voltage OK

[25] Reversing Parameter 5-40 = [25] Reverse

[26] Bus OK Parameter 5-40 = [26] Bus OK

[27] Torque Limit and Stop Parameter 5-40 = [27] Torque Limit & Stop

[28] Brake, No Brake Warning Parameter 5-40 = [28] Brake, No Brake Warning

[29] Brake Ready, No Fault Parameter 5-40 = [29] Brake Ready, No Fault

[30] Brake Fault Parameter 5-40 = [30] Brake Fault (IGBT)

[31] Relay 123 Parameter 5-40 = [31] Relay 123

[32] Mechanical Brake Control Parameter 5-40.0 = [32] Mech Brake Ctrl

Parameter 1-72 = [5] VVC+/Flux

[33] Control Word Bit 11/12 Parameter 5-40 = [36] Control Word Bit 11

Parameter 5-40.1 = [37] Control Word Bit 12

[34] Extended Mechanical Brake Control Parameter 5-40.0 = [32] Mech Brake Ctrl

Parameter 1-72 = [5] VVC+/Flux

[35] Safety Interlock Not supported

5.4.12 Conversion of Parameter 327 Pulse Reference, Max. Freq

Table 103: Parameter 327

FCD 300 FCD 302

Parameter 327 Pulse Reference, Max. Freq 5-51 Term. 29 High Frequency

Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890| 53

Page 54

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

FCD 300 FCD 302

Range 150–110000 Hz 0–110000 Hz

Parameter Mapping Lists

5.4.13 Conversion of Parameter 328 Pulse Feedback, Max. Freq

Table 104: Parameter 328

FCD 300 series FD 302 series

Parameter 328 Pulse Feedback, Max. Freq Parameter 5-56 Term. 33 High Frequency

Parameter 5-50 Term. 29 Low Frequency

Parameter 5-55 Term. 33 Low Frequency

Range 100–110000 Hz 0–110000 Hz

5.4.14 Conversion of Parameter 341 DO46 Max Pulse

Table 105: Parameter 341

FCD 300 series FCD 302 series

Parameter 341 DO46 Max Pulse 5-31 Terminal 29 Digital Output

Options [0] No Function [0] No Function

[21] Pulse Reference [55] Pulse Output

Parameter 5-63 = Reference

[26] Pulse Feedback [55] Pulse Output

Parameter 5-63 = Reference

[27] Output Frequency [55] Pulse Output

Parameter 5-63 = Output Frequency

[28] Pulse Current [55] Pulse Output

Parameter 5-63 = Motor Current

[29] Pulse Power [55] Pulse Output

Parameter 5-63 = 5-63 = Power

[30] Pulse Temperature Not supported

[31] Control Word Bit 12 Not supported

54 | Danfoss A/S © 2019.11

AQ289550754901en-000101 / 130R0890

Page 55

Operating Guide | VLT® FCD 300 PROFIBUS Converter MCA 117

Parameter Mapping Lists

5.4.15 Conversion of Parameter 342 Term. 46, Max. Pulse Scaling

Table 106: Parameter 342

FCD 300 series FCD 302 series

Parameter 342 Term. 46, Max. Pulse Scaling 5-65 Pulse Output Max Freq. #29

Range 150–10000 Hz 0–32000 Hz

5.4.16 Conversion of Parameter 343 Precise Stop Function

Table 107: Parameter 343

FCD 300 series FCD 302 series

Parameter 343 Precise Stop Function 1-83 Precise Stop Function

Options [0] Normal [0] Precise Ramp Stop

[1] Count Stop Reset [1] Cnt Stop With Reset

[2] Count Stop No Reset [2] Cnt Stop W/O Reset

[3] Spd Cmp Cstop [3] Speed Comp Stop

[4] Spd Cmp Cstop W. Reset [4] Cnt Stop W/Rst

[5] Spd Cmp Cstop No Reset [5] Comp Cnt Stop W/O Reset

5.4.17 Conversion of Parameter 344 Counter Value

Table 108: Parameter 344

FCD 300 series FCD 302 series

Parameter 344 Counter Value 1-84 Precise Stop Counter Value

Range 0–999999 0–999999999

5.4.18 Conversion of Parameter 349 Speed Compensated Delay

Table 109: Parameter 349

FCD 300 series FCD 302 series

Parameter 349 Speed Compensated Delay 1-85 Precise Stop Speed Compensation Delay

Range 0–100 ms 0–100 ms