Page 1

MAKING MODERN LIVING POSSIBLE

Installation Guide

VLT® CANopen MCA 105

VLT® AutomationDrive FC 301/302

vlt-drives.danfoss.com

Page 2

Page 3

Contents Installation Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Product Overview

1.4 Approvals and Certications

1.5 Disposal

1.6 Symbols, Abbreviations, and Conventions

2 Safety

2.1 Safety Symbols

2.2 Qualied Personnel

2.3 Safety Precautions

3 Installation

3.1 Safety Instructions

3.2 EMC-compliant Installation

3.3 Grounding

3.4 Cable Routing

2

2

2

2

2

3

3

4

4

4

4

6

6

6

6

6

3.5 Mounting

3.6 Setting Address Switches

3.7 Electrical Installation

3.8 Reassembling Cover

3.9 Applying Power

3.10 Checking Network Cabling

4 Troubleshooting

4.1 Warnings and Alarms

4.2 Troubleshooting

4.2.1 LED Status 11

4.2.2 No Communication with the Frequency Converter 11

Index

7

8

8

10

10

10

11

11

11

12

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 1

Page 4

Introduction

VLT® CANopen MCA 105

11

1 Introduction

1.1 Purpose of the Manual

This installation guide provides information for quick instal-

lation of a VLT® CANopen MCA 105 interface in the VLT

frequency converter.

The installation guide is intended for use by qualied

personnel. Users are assumed to be familiar with the VLT

frequency converter, with CANopen technology, and with

the PC or PLC that is used as a master in the system.

Read the instructions before installation and ensure that

instructions for safe installation are observed.

VLT® is a registered trademark.

1.2 Additional Resources

Resources available for the frequency converters and

optional equipment:

The VLT® AutomationDrive FC 301/FC 302

•

Operating Instructions provide the necessary

information for getting the frequency converter

up and running.

®

®

Product Overview

1.3

1.3.1 Intended Use

This installation guide relates to the CANopen interface.

Ordering numbers:

130B1103 (uncoated)

•

130B1205 (coated)

•

CANopen is a low-level network that standardises only

communications between industrial devices (sensors, limit

switches, motor controls) and high-level devices

(controllers). Congure CANopen systems to operate in a

master-slave or in a distributed control architecture using

peer-to-peer communication.

The CANopen interface is designed to communicate with

any master abiding by the CANopen standard.

VLT® CANopen MCA 105 is intended for use with VLT

AutomationDrive FC 301/FC 302.

®

The VLT® AutomationDrive FC 301/FC 302 Design

•

Guide provides detailed information about

capabilities and functionality to design motor

control systems.

The VLT® AutomationDrive FC 301/FC 302

•

Programming Guide provides greater detail on

working with parameters and many application

examples.

The VLT® CANopen MCA 105 Installation Guide

•

provides information about installing the

CANopen and troubleshooting.

The VLT® CANopen MCA 105 Programming Guide

•

provides information about conguring the

system, controlling the frequency converter,

parameter access, programming, troubleshooting,

as well as some typical application examples.

Supplementary publications and manuals are available

from Danfoss. See vlt-drives.danfoss.com/Support/Technical-

Documentation/ for listings.

1.3.2 Items Supplied

When the eldbus option is not factory mounted, the

following items are supplied:

Fieldbus option and connector.

•

LCP cradle.

•

Front covers (in various sizes).

•

Stickers.

•

Accessories bag (including EMC bracket).

•

Installation guide.

•

Approvals and Certications

1.4

More approvals and certications are available. For more

information, contact a Danfoss local partner.

2 Danfoss A/S © 05/2015 All rights reserved. MG33J402

Page 5

Introduction Installation Guide

1.5 Disposal

Do not dispose of equipment containing

electrical components together with

domestic waste.

Collect it separately in accordance with

local and currently valid legislation.

1.6 Symbols, Abbreviations, and

Conventions

Abbreviation Denition

CAN Controller area network

CiA CAN in automation

COB Communication object

COB-ID Communication object identier

CTW Control word

EDS Electronic data sheet

EMC Electromagnetic compatibility

EMCY Emergency message

I/O Input/output

LCP Local control panel

LED Light emitting diode

LSB Least signicant bit

MAV Main actual value (actual output)

MRV Main reference value

MSB Most signicant bit

NMT Network management

N/A Not applicable

OD Object directory

PCD Process data

PDO Process data object

PLC Programmable logic controller

PNU Parameter number

RPDO Receive process data object

RPM Revolutions per minute; unit for the speed of a

revolving motor

RTR Remote transmission request frame

RX Receive data

STW Status word

SDO Service data object

SYNC Object for synchronisation of process data

TPDO Transmit process data object

TX Transmit data

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and descriptions of

illustrations.

Italicised text indicates:

Cross-reference.

•

Link.

•

Parameter name.

•

Footnote.

•

Parameter group.

•

Parameter option.

•

Alarms/warnings.

•

1 1

Table 1.1 Symbols and Abbreviations

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 3

Page 6

Safety

VLT® CANopen MCA 105

2 Safety

22

2.1 Safety Symbols

WARNING

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualied Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualied personnel are allowed to install and operate this

equipment.

Qualied personnel are dened as trained sta, who are

authorised to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the qualied personnel must be

familiar with the instructions and safety measures

described in these operating instructions.

Safety Precautions

2.3

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input, DC supply, or load sharing.

Failure to perform installation, start-up, and maintenance

by qualied personnel can result in death or serious

injury.

Only qualied personnel must perform instal-

•

lation, start-up, and maintenance.

UNINTENDED START

When the frequency converter is connected to AC mains,

DC supply, or load sharing, the motor may start at any

time. Unintended start during programming, service, or

repair work can result in death, serious injury, or

property damage. The motor can start with an external

switch, a eldbus command, an input reference signal

from the LCP or LOP, via remote operation using MCT 10

Set-up Software, or after a cleared fault condition.

To prevent unintended motor start:

Disconnect the frequency converter from the

•

mains.

Press [O/Reset] on the LCP before

•

programming parameters.

Completely wire and assemble the frequency

•

converter, motor, and any driven equipment

before connecting the frequency converter to

AC mains, DC supply, or load sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors that

can remain charged even when the frequency converter

is not powered. Failure to wait the specied time after

power has been removed before performing service or

repair work, can result in death or serious injury.

Stop the motor.

•

Disconnect the AC mains and remote DC-link

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock the PM motor.

•

Wait for the capacitors to discharge fully before

•

performing any service or repair work. The

duration of waiting time is specied in the

relevant frequency converter operating

instructions, Chapter 2 Safety.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

frequency converter properly can result in death or

serious injury.

Ensure the correct grounding of the equipment

•

by a certied electrical installer.

4 Danfoss A/S © 05/2015 All rights reserved. MG33J402

Page 7

Safety Installation Guide

WARNING

EQUIPMENT HAZARD

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

perform installation, start-up, and maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this manual.

•

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the frequency converter can result

in serious injury, when the frequency converter is not

properly closed.

Ensure that all safety covers are in place and

•

securely fastened before applying power.

2 2

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 5

Page 8

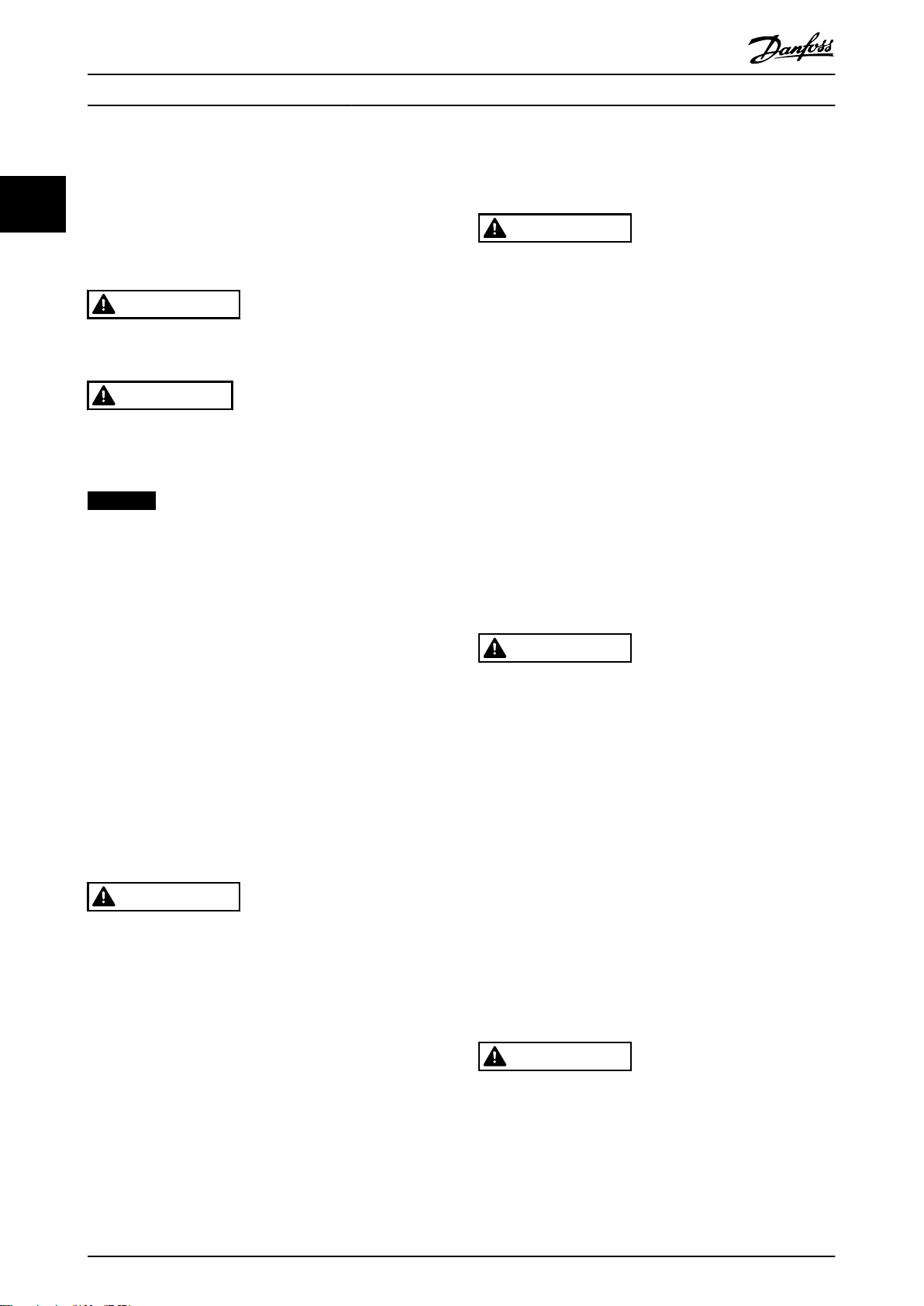

130BD866.10

≥ 200mm

2

1

Installation

3 Installation

VLT® CANopen MCA 105

3.1 Safety Instructions

33

See chapter 2 Safety for general safety instructions.

3.2 EMC-compliant Installation

To obtain an EMC-compliant installation, follow the

instructions provided in the relevant frequency converter

operating instructions and design guide. Refer to the

eldbus master manual from the PLC supplier for further

installation guidelines.

3.3 Grounding

Ensure that all stations connected to the eldbus

•

network are connected to the same ground

potential. When there are long distances between

the stations in a eldbus network, connect the

individual station to the same ground potential.

Install equalising cables between the system

components.

Establish a grounding connection with low HF

•

impedance, for example by mounting the

frequency converter on a conductive back plate.

Keep the ground wire connections as short as

•

possible.

Establish electrical contact between the cable

•

screen and the frequency converter enclosure by

using metal cable glands or by using the clamps

provided on the equipment.

Use high-strand wire to reduce electrical

•

interference.

Cable Routing

3.4

NOTICE

EMC INTERFERENCE

Use screened cables for motor and control wiring, and

separate cables for eldbus communication, motor

wiring, and brake resistor. Failure to isolate eldbus

communication from motor and brake resistor cables can

result in unintended behaviour or reduced performance.

Minimum 200 mm (7.9 in) clearance between power,

motor, and control cables is required. For power sizes

above 315 kW, it is recommended to increase the

minimum distance to 500 mm (20 in).

NOTICE

When the eldbus cable crosses a motor cable or a brake

resistor cable, ensure that the cables cross at an angle of

90°.

1 Fieldbus cable

2 90° crossing

6 Danfoss A/S © 05/2015 All rights reserved. MG33J402

Illustration 3.1 Cable Routing

Page 9

130BD876.10

1

2

4

3

130BD862.10

130BD863.10

Installation Installation Guide

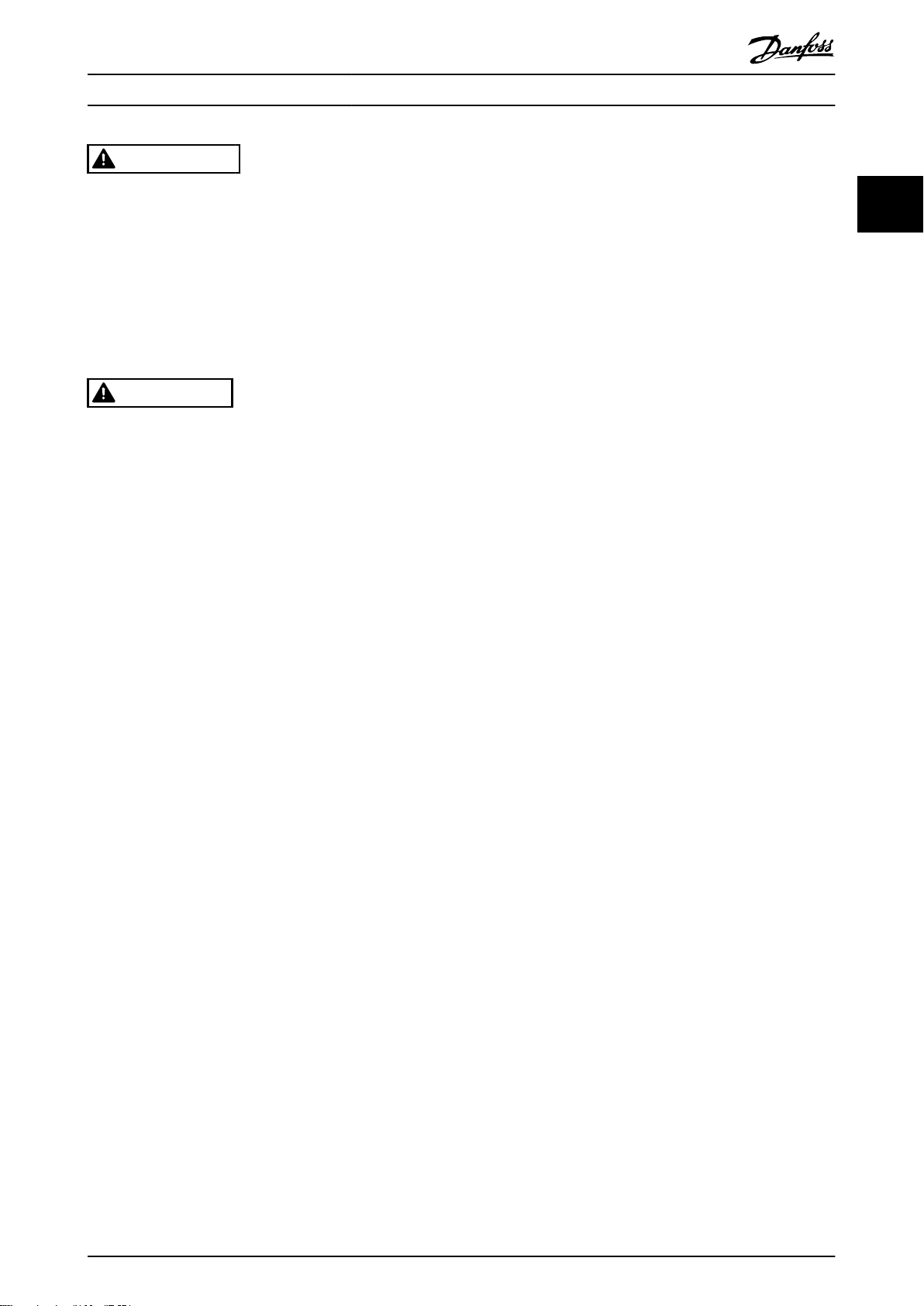

3.5 Mounting

1. Check whether the eldbus option is already

mounted in the frequency converter. If already

mounted, go to step 6. If not mounted, go to

step 2.

2. Remove the LCP or blind cover from the

frequency converter.

3. Use a screwdriver to remove the front cover and

the LCP cradle.

4. Mount the eldbus option. Mount the option

with the connector facing up for top cable entry

(see Illustration 3.3), or with the connector facing

down for bottom cable entry (see Illustration 3.4).

If an MCB option is installed, only top cable entry

is possible.

5. Remove the knock-out plate from the new LCP

cradle.

6. Mount the new LCP cradle.

3 3

1 LCP

2 LCP cradle

3 Fieldbus option

4 Connector

Illustration 3.2 Exploded View

Illustration 3.3 Top Cable Entry: Option Mounted with

Connector Facing Up

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 7

Illustration 3.4 Bottom Cable Entry: Option Mounted with

Connector Facing Down

Page 10

130BD877.10

1

2

Installation

VLT® CANopen MCA 105

3.6 Setting Address Switches

NOTICE

Switch o the power supply before changing the address

switches. The address change comes into eect at the

33

next power-up.

The address switches enable setting of baudrate and node

ID:

Switches 8 and 7 arefor setting the baudrate for

•

either: 125, 250, or 500 Kbps.

Switches 6–1 are for setting the node address in

•

the range 1–62.

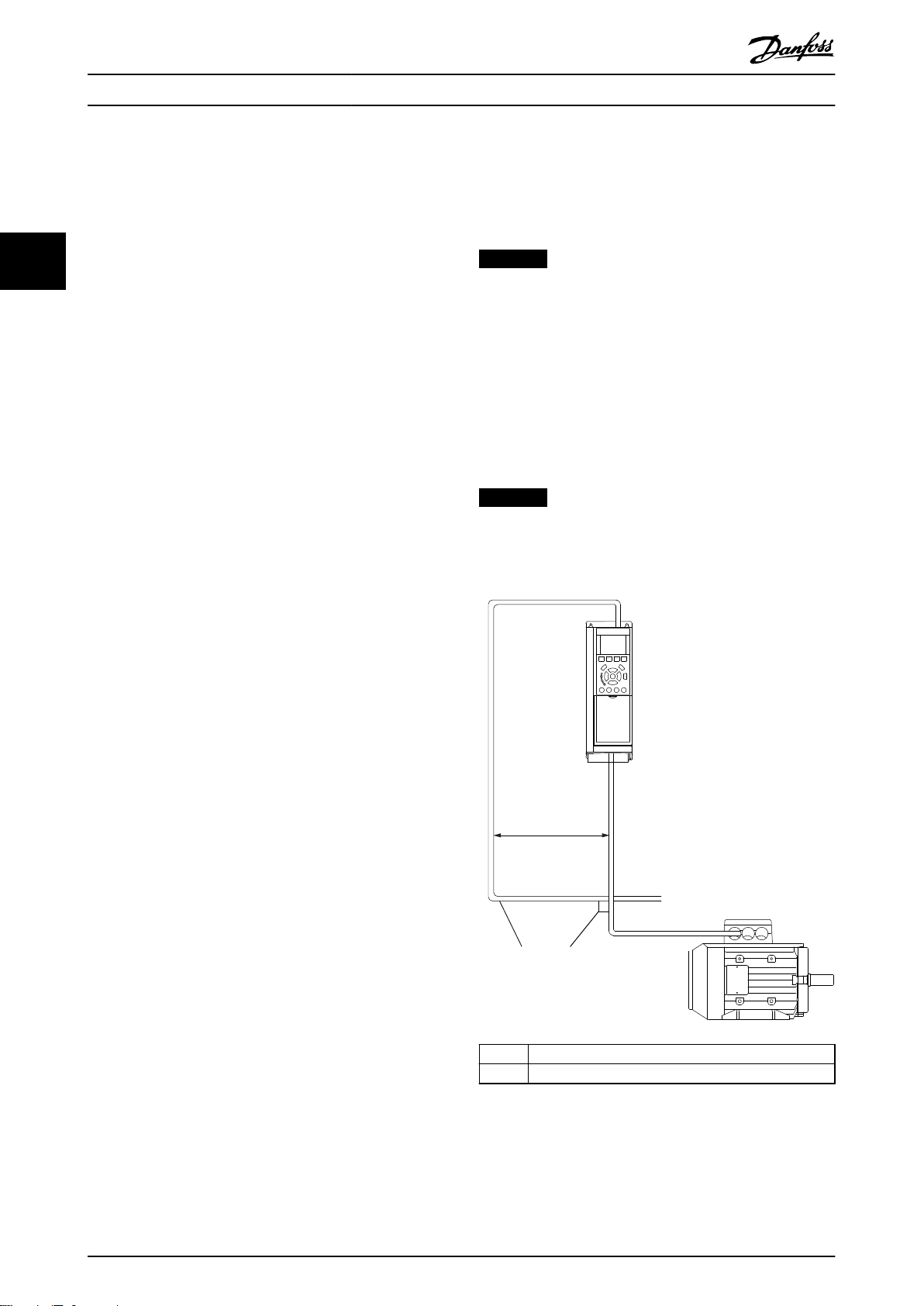

3.7.2 Wiring Procedures

Wiring procedure for enclosure sizes A1–A3

1. Mount the eldbus connector on the eldbus

option (CAN_L, Drain, CAN_H). For top cable

entry, mount the supplied EMC bracket on top of

the frequency converter with 2 screws.

2. Prepare the eldbus cable by stripping a section

of the cable insulation, so that the cable screen

contacts the EMC bracket. Keep the unshielded

wire as short as possible. For cable specications,

refer to chapter 3.7.1 Cable Specications.

3. Connect the eldbus cable wires to the terminals

according to the colour code of the wires, see

Switch Baudrate

8 7

On On Parameter 10-01 Bau

d Rate Select

On O 500 kbps

On On 250 kbps

On O 125 kbps

Table 3.1 Switches 8 and 7

Illustration 3.6.

4. To establish mechanical xation and electrical

contact between cable screen and ground,

position the stripped cable between the spring

loaded metal clamps.

Switch Node ID

6 5 4 3 2 1

On On On On On On Parameter

10-02 MAC

ID

On On On On On O 62

O O O O O On 1

Table 3.2 Switches 6–1

When both switch 8 and 7are set to ON, select baudrates

via parameter 10-01 Baud Rate Select: 10, 20, 50, 100, 125,

250, or 500 kbps.

When switches 6–1 are set to ON, select node ID via

parameter 10-02 MAC ID in the range: 1–127

Electrical Installation

3.7

3.7.1 Cable Specications

Baudrate

[kbps]

500 100 <60 0.34–0.6

250 250

125 500

50 1000

10 5000

Maximum

cable

length [m]

Resistance

[mΩ/m]

<40 0.5–0.6

<26 0.75–0.820 2500

Cable cross-

section

[mm2]

Termination

resistor [Ω]

120

1 Cable screen

2 EMC bracket (used for top cable entry only)

Illustration 3.5 Wiring for Enclosure Sizes A1–A3

Table 3.3 Cable Specications

8 Danfoss A/S © 05/2015 All rights reserved. MG33J402

Page 11

130BD864.10

Installation Installation Guide

Pin no. Terminal Colour Name

1 – – Not used

2 CAN_L Blue CAN LOW

3 Drain (bare) Screen

4 CAN_H White CAN HIGH

5 – – Not used

Wiring procedure for enclosure sizes A4–A5, B1–B4, and

C1–C4

1. Push the cable through cable glands.

2. Mount the eldbus connector on the eldbus

option ( CAN_L, Drain, CAN_H).

3. Prepare the eldbus cable by stripping a section

of the cable insulation. Keep the unshielded wire

as short as possible. For cable specications, refer

to chapter 3.7.1 Cable Specications.

4. Connect the eldbus cable wires to the terminals

according to the colour code of the wires, see

Illustration 3.6.

5. Fix the cable screen to the metal base plate using

cable clamp or cable tie, see Illustration 3.8.

6. Tighten cable glands securely.

3 3

Illustration 3.6 Fieldbus Cable Terminal Connections

CANopen termination

Install the termination resistors at each end of the bus line.

Mount the resistor between terminal 2 (CAN_L) and

terminal 4 (CAN_H).

The resistors have the following specication:

121 Ω

•

1% Metal

•

1/4 W

•

Illustration 3.7 Termination Resistor Mounted

lm

Illustration 3.8 Wiring for Enclosure Sizes A4–A5, B1–B4, and

C1–C4

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 9

Page 12

130BC527.10

Installation

VLT® CANopen MCA 105

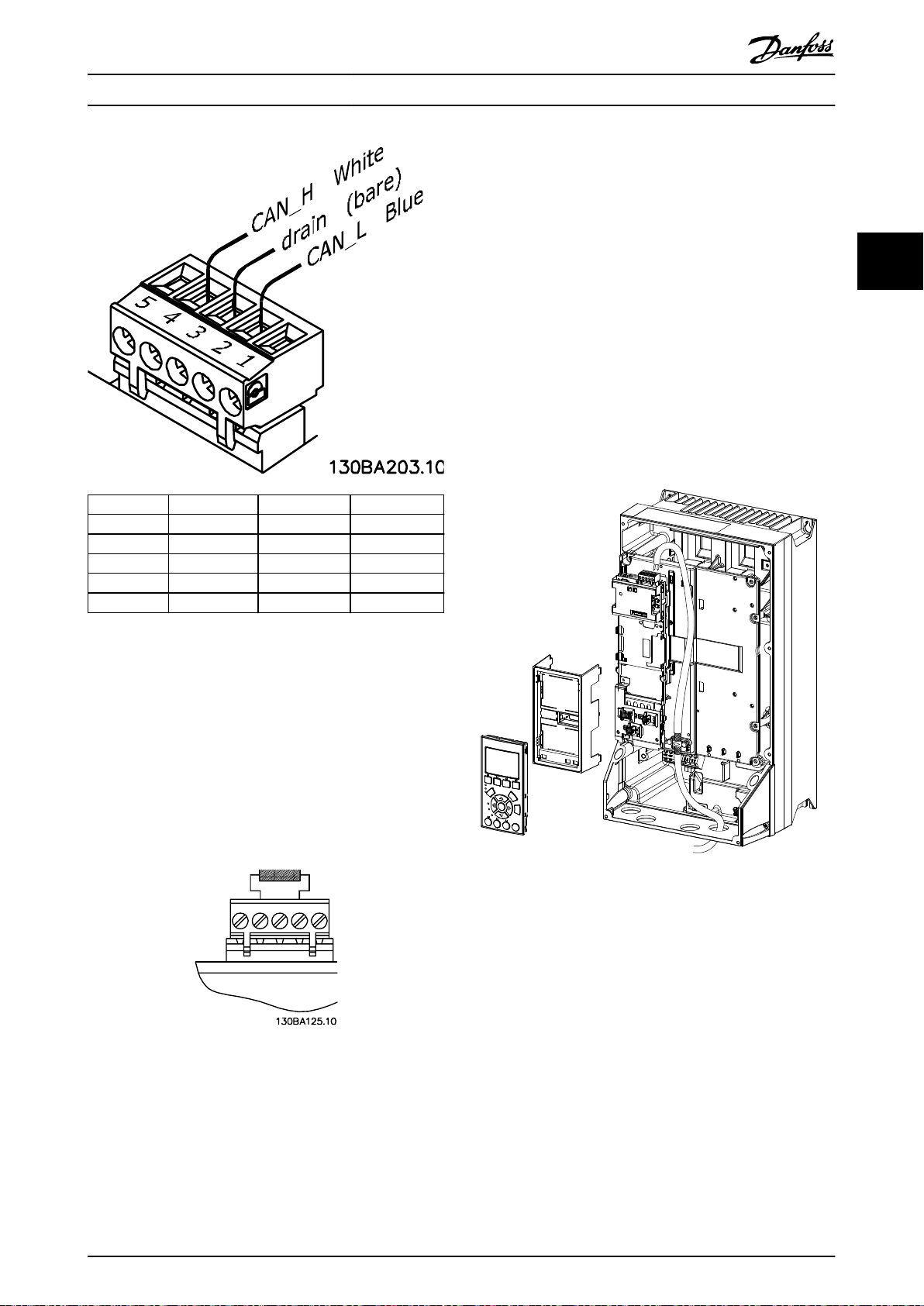

Wiring procedure for enclosure sizes D, E, and F

1. Mount the eldbus connector on the eldbus

option (CAN_L, Drain, CAN_H).

2. Prepare the eldbus cable by stripping a section

of the cable insulation. Keep unshielded wire as

33

short as possible. For cable specications, refer to

chapter 3.7.1 Cable Specications.

3. Connect the eldbus cable wires to the terminals

according to the colour code of the wires, see

Illustration 3.6.

4. Fix the cable screen to the metal base plate using

cable clamp or cable tie, see Illustration 3.9.

5. Tie down the cable and route it with other

control wires inside the unit, see Illustration 3.9.

Reassembling Cover

3.8

1. Mount the new front cover and the LCP.

2. Attach the sticker with the correct product name

to the front cover.

3.9 Applying Power

Follow the instructions in the frequency converter

operating instructions to commission the frequency

converter. The frequency converter automatically detects

the CANopen interface. A new parameter group (Group 10)

appears.

3.10 Checking Network Cabling

1. If the address has not been set via the address

switches, go to parameter 10-02 MAC ID to set the

address.

2. Connect to a running CANopen master.

3. Check that network cabling is correct or not.

Illustration 3.9 Wiring for Enclosure Sizes D, E, and F

10 Danfoss A/S © 05/2015 All rights reserved. MG33J402

Page 13

Troubleshooting Installation Guide

4 Troubleshooting

4.1 Warnings and Alarms

NOTICE

Refer to the relevant operating instructions for an

overview of warning and alarm types and for the full list

of warnings and alarms.

Alarm word, warning word, and CANopen warning word

are shown on the frequency converter display in hex

format. When there is more than 1 warning or alarm, the

sum of all warnings or alarms is shown. Alarm word,

warning word, and CANopen warning word can also be

displayed using the serial bus in:

Parameter 16-90 Alarm Word.

•

Parameter 16-91 Alarm Word 2.

•

Parameter 16-92 Warning Word.

•

Parameter 16-93 Warning Word 2.

•

4.2 Troubleshooting

4.2.1 LED Status

The 2 bi-colour LEDs on the CANopen card indicate the

status of CANopen communication:

The lower LED (NS) indicates the net status.

•

The upper LED (MS) indicates the module status.

•

Illustration 4.1 LED Panel VLT® CANopen MCA 105

State Red LED Description

No error O No error.

Warning limit

reached

Error control

event

Sync error Triple ash Sync message has not been

Bus o On Device in bus o-state.

Table 4.1 LED: Module Status (MS)

State Red LED Description

Stopped Single ash Device in stopped state.

Pre-operational Triple ash Device in pre-operational state.

Operational On Device in operational state.

Table 4.2 LED: Network Status (NS)

Single ash CAN error counter has reached/

exceeded warning level.

Double ash Node guard event has occurred.

received within the congured

timeout (object 0x1006).

4.2.2 No Communication with the

Frequency Converter

When there is no communication with the frequency

converter, proceed with the following checks:

1. Check that cabling is correct.

Check that the cables are connected to the

correct terminals as shown in Illustration 3.6.

2. Check that the bus connection is terminated at

both ends.

If not, terminate the bus connection with

termination resistors at the initial and

3. Check that each node connected to the CANopen

network has a unique node ID (address). If 2

devices have the same node ID, it leads to

malfunction in the network.

4. Communication drops out after some time. Check

the installation for correct routing of the

CANopen cables. Check if the screen of the motor

cable is mounted correctly.

5. Communication is unstable. Check

parameter 10-05 Readout Transmit Error Counter

and parameter 10-06 Readout Receive Error

Counter. These 2 parameters have to be close to 0

most of the time. If they show higher values,

check the CANopen cable for interference, wrong

termination, and so on.

nal nodes.

4 4

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 11

Page 14

Index

VLT® CANopen MCA 105

Index

A

Abbreviations........................................................................................... 3

Additional resources.............................................................................. 2

Address switch.................................................................................. 8, 10

Alarm......................................................................................................... 11

Alarm word............................................................................................. 11

Applying power.................................................................................... 10

Approvals................................................................................................... 2

C

Cable specications............................................................................... 8

Cable terminal connections................................................................ 9

CANopen termination........................................................................... 9

Certications............................................................................................. 2

Conventions.............................................................................................. 3

N

Network cabling.................................................................................... 10

P

Power, applying..................................................................................... 10

Q

Qualied personnel................................................................................ 4

S

Safety........................................................................................................... 5

Screened cable......................................................................................... 6

Symbols...................................................................................................... 3

U

Unintended start..................................................................................... 4

D

Discharge time......................................................................................... 4

E

Electrical interference............................................................................ 6

EMC interference..................................................................................... 6

EMC-compliant installation................................................................. 6

Exploded view.......................................................................................... 7

G

Grounding................................................................................................. 6

H

High voltage............................................................................................. 4

I

Intended use............................................................................................. 2

Items supplied.......................................................................................... 2

L

Leakage current....................................................................................... 4

LED panel................................................................................................. 11

LED status................................................................................................ 11

Load sharing............................................................................................. 4

W

Warning.................................................................................................... 11

Warning word........................................................................................ 11

Wiring procedure.................................................................................... 8

M

Motor wiring............................................................................................. 6

Mounting................................................................................................... 7

12 Danfoss A/S © 05/2015 All rights reserved. MG33J402

Page 15

Index Installation Guide

MG33J402 Danfoss A/S © 05/2015 All rights reserved. 13

Page 16

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specications already agreed. All trademarks in this material are property

of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Danfoss A/S

Ulsnaes 1

DK-6300 Graasten

vlt-drives.danfoss.com

130R0067 MG33J402 05/2015

*MG33J402*

Loading...

Loading...