Page 1

MAKING MODERN LIVING POSSIBLE

Programming Guide

VLT® CANopen MCA 105

VLT® AutomationDrive FC 301/302

vlt-drives.danfoss.com

Page 2

Page 3

Contents Programming Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Document and Software Version

1.4 Product Overview

1.5 Approvals and Certications

1.6 Symbols, Abbreviations, and Conventions

2 Safety

2.1 Safety Symbols

2.2 Qualied Personnel

2.3 Safety Precautions

3 Conguration

3.1 Congure the CANopen Network

3.2 Congure the Master

3.3 Congure the Frequency Converter

3

3

3

3

3

4

4

5

5

5

5

7

7

10

13

4 Control

4.1 PDO Communication

4.1.1 PDO Conguration 15

4.1.2 PDO Mapping Syntax 17

4.1.3 PDO Transmission Modes 17

4.1.4 PDO Triggering Modes 17

4.1.5 Inhibit Time 17

4.1.6 Event Timer 17

4.2 Control Prole

4.3 DSP 402 Control Prole

4.4 Danfoss FC control prole

4.4.1 Control Word according to FC Prole

(parameter 8-10 = FC prole) 22

4.4.2 Status Word according to FC Prole

(parameter 8-10 = FC prole) 23

4.5 Reference Handling

5 Parameter Access

14

14

18

20

22

25

26

5.1 Danfoss Specic Objects (2000h-5FFFh)

6 Parameters

6.1 Parameter List

7 Object Directory

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 1

26

27

35

37

Page 4

Contents

VLT® CANopen MCA 105

7.1 Communication Prole Area (1000h-1FFFh)

7.1.1 Communication Object Overview 37

7.1.2 1000h Device Type 38

7.1.3 1001h Error Register 38

7.1.4 1002h Manufacturer Status Register 38

7.1.5 1003h Predened Error Field 38

7.1.6 1005h COB-ID Sync Message Object 38

7.1.7 1008h Manufacturer Device Name 38

7.1.8 1009h Manufacturer Hardware Version 38

7.1.9 100Ah Manufacturer Software Version 39

7.1.10 100Ch Guard Time 39

7.1.11 100Dh Life Time Factor 39

7.1.12 1010h Store Parameters 39

7.1.13 1011h Restore Default Parameters 39

7.1.14 1014h COB ID Emergency Object 39

7.1.15 1017h Producer Heartbeat Time 39

7.1.16 1018h Identity Object 39

37

8 Troubleshooting

8.1 Warnings and Alarms

8.2 Troubleshooting

Index

40

40

43

46

2 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 5

Introduction Programming Guide

1 Introduction

1.1 Purpose of the Manual

The VLT® CANopen MCA 105 Programming Guide provides

information about conguring the system, controlling the

frequency converter, parameter access, programming, as

well as troubleshooting.

The programming guide is intended for use by qualied

personnel who are familiar with the VLT® frequency

converter, with CANopen technology, and with the PC or

PLC that is used as a master in the system.

Read the instructions before programming and follow the

procedures in this manual.

VLT® is a registered trademark.

1.2 Additional Resources

Resources available for the frequency converters and

optional equipment:

The VLT® AutomationDrive FC 301/FC 302

•

Operating Instructions provide the necessary

information for getting the frequency converter

up and running.

The VLT® AutomationDrive FC 301/FC 302 Design

•

Guide provides detailed information about

capabilities and functionality to design motor

control systems.

The VLT® AutomationDrive FC 301/FC 302

•

Programming Guide provides greater detail on

working with parameters and many application

examples.

The VLT® CANopen MCA 105 Installation Guide

•

provides information about installing the

CANopen and troubleshooting.

The VLT® CANopen MCA 105 Programming Guide

•

provides information about conguring the

system, controlling the frequency converter,

parameter access, programming, troubleshooting,

as well as some typical application examples.

Supplementary publications and manuals are available

from Danfoss. See vlt-drives.danfoss.com/Support/Technical-

Documentation/ for listings.

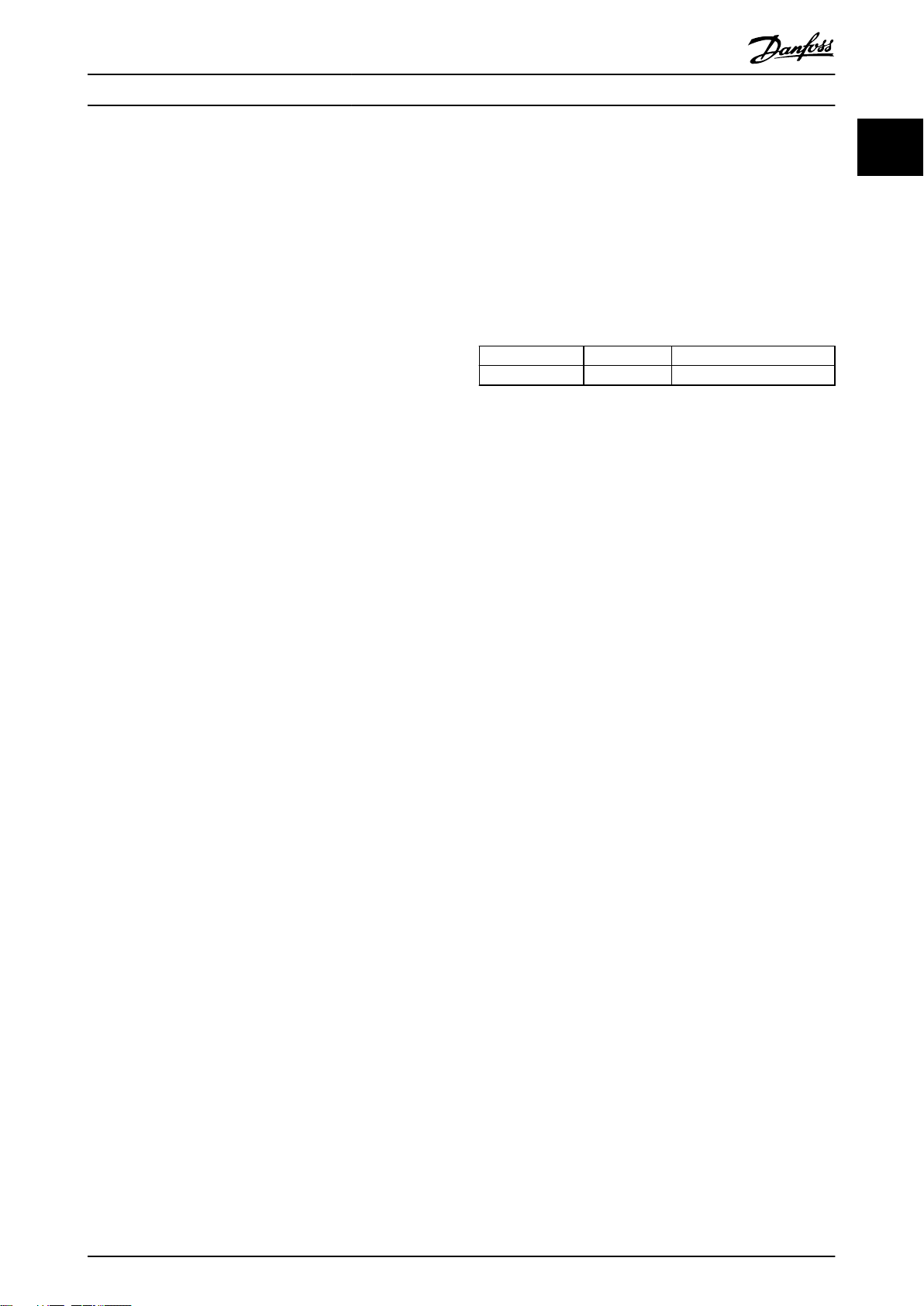

Document and Software Version

1.3

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

Edition Remarks Software version

MG92G1xx – –

Table 1.1 Document and Software Version

1.4 Product Overview

This programming guide relates to the CANopen interface.

Ordering number:

130B1103 (uncoated)

•

130B1205 (coated)

•

CANopen is a low-level network that standardises

communications between industrial devices (sensors, limit

switches, motor controls) and high-level devices

(controllers). CANopen follows the open systems interconnection (OSI) model and is based on CAN technology for

media access control and physical signalling.

Congure CANopen systems to operate in a master-slave

or a distributed control architecture using peer-to-peer

communication. Up to 127 nodes in a multi-drop network

topology are supported. By using the same cable for

communication, the bus can power the communication

options directly. Nodes can be removed or inserted

without powering down the network.

Each node on the network has its own unique communication object identier (COB-ID) to distinguish it on the

network. The access control is based on the CSMA/CA

(carrier sense multiple access/collision avoidance) principle,

meaning that all nodes may have access to the network at

the same time. When 2 nodes attempt to get control of

the network bus simultaneously, the CAN protocol resolves

the issue by arbitration. In this way, collisions on the

network are avoided.

CANopen denes device proles for devices belonging to

specic classes. For other devices, dene a custom class to

make it CANopen compatible. All of the above enhances

the interchangeability and interoperability of the network.

1 1

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 3

Page 6

Introduction

VLT® CANopen MCA 105

11

Symbols, Abbreviations, and

1.6

Conventions

Abbreviation Denition

CAN Controller area network

CiA CAN in automation

COB Communication object

COB-ID Communication object identier

CTW Control word

EDS Electronic data sheet

EMC Electromagnetic compatibility

EMCY Emergency message

I/O Input/output

LCP Local control panel

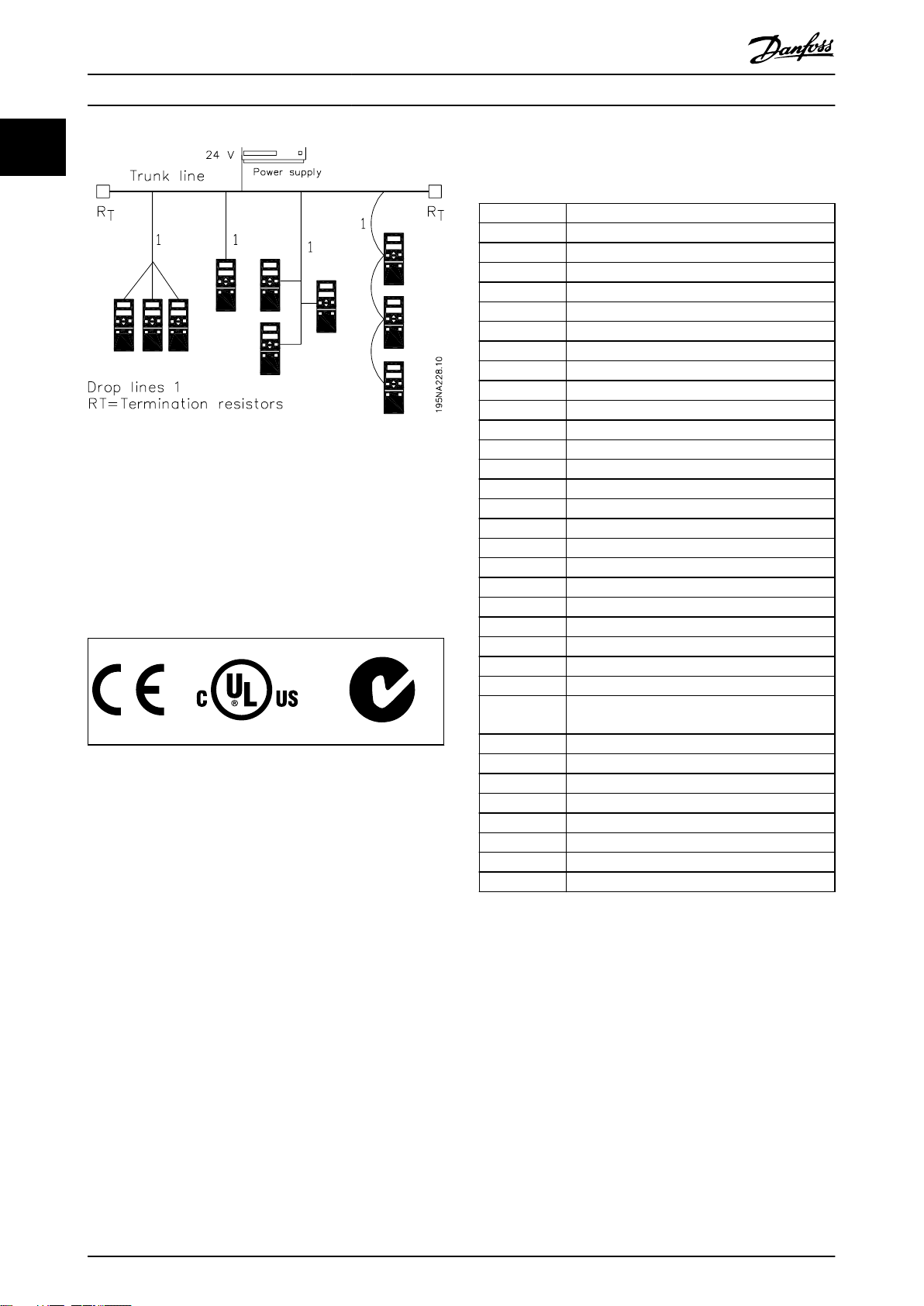

Illustration 1.1 Topology

VLT® CANopen MCA 105 is designed to communicate with

any master abiding by the DeviceNet standard. And it is

intended for use with:

VLT® AutomationDrive FC 301.

•

VLT® AutomationDrive FC 302.

•

Approvals and Certications

1.5

More approvals and certications are available. For more

information, contact a Danfoss local partner.

LED Light emitting diode

LSB Least signicant bit

MAV Main actual value (actual output)

MRV Main reference value

MSB Most signicant bit

NMT Network management

N/A Not applicable

OD Object directory

PCD Process data

PDO Process data object

PLC Programmable logic controller

PNU Parameter number

REC Receive error counter

RPDO Receive process data object

RPM Revolutions per minute; unit for the speed of a

revolving motor

RTR Remote transmission request frame

RX Receive data

STW Status word

SDO Service data object

SYNC Object for synchronisation of process data

TEC Transmit error counter

TPDO Transmit process data object

TX Transmit data

Table 1.2 Symbols and Abbreviations

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information and description of

illustrations.

Italicised text indicates:

Cross-reference.

•

Link.

•

Parameter name.

•

Footnote.

•

Parameter group.

•

Parameter option.

•

Alarms/warnings.

•

4 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 7

Safety Programming Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualied Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualied personnel are allowed to install and operate this

equipment.

Qualied personnel are dened as trained sta, who are

authorised to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the qualied personnel must be

familiar with the instructions and safety measures

described in these operating instructions.

Safety Precautions

2.3

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input, DC supply, or load sharing.

Failure to perform installation, start-up, and maintenance

by qualied personnel can result in death or serious

injury.

Only qualied personnel must perform instal-

•

lation, start-up, and maintenance.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC supply, or load sharing, the motor may start at any

time. Unintended start during programming, service, or

repair work can result in death, serious injury, or

property damage. The motor can start with an external

switch, a eldbus command, an input reference signal

from the LCP or LOP, via remote operation using MCT 10

Set-up Software, or after a cleared fault condition.

To prevent unintended motor start:

Disconnect the frequency converter from the

•

mains.

Press [O/Reset] on the LCP before

•

programming parameters.

Completely wire and assemble the frequency

•

converter, motor, and any driven equipment

before connecting the frequency converter to

AC mains, DC supply, or load sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors that

can remain charged even when the frequency converter

is not powered. Failure to wait the specied time after

power has been removed before performing service or

repair work, can result in death or serious injury.

Stop the motor.

•

Disconnect the AC mains and remote DC-link

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock the PM motor.

•

Wait for the capacitors to discharge fully before

•

performing any service or repair work. The

duration of waiting time is specied in the

relevant frequency converter operating

instructions, Chapter 2 Safety.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

frequency converter properly can result in death or

serious injury.

Ensure the correct grounding of the equipment

•

by a certied electrical installer.

2 2

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 5

Page 8

Safety

VLT® CANopen MCA 105

WARNING

EQUIPMENT HAZARD

22

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

perform installation, start-up, and maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this manual.

•

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the frequency converter can result

in serious injury, when the frequency converter is not

properly closed.

Ensure that all safety covers are in place and

•

securely fastened before applying power.

6 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 9

Conguration Programming Guide

3 Conguration

3.1 Congure the CANopen Network

3.1.1 Object Model

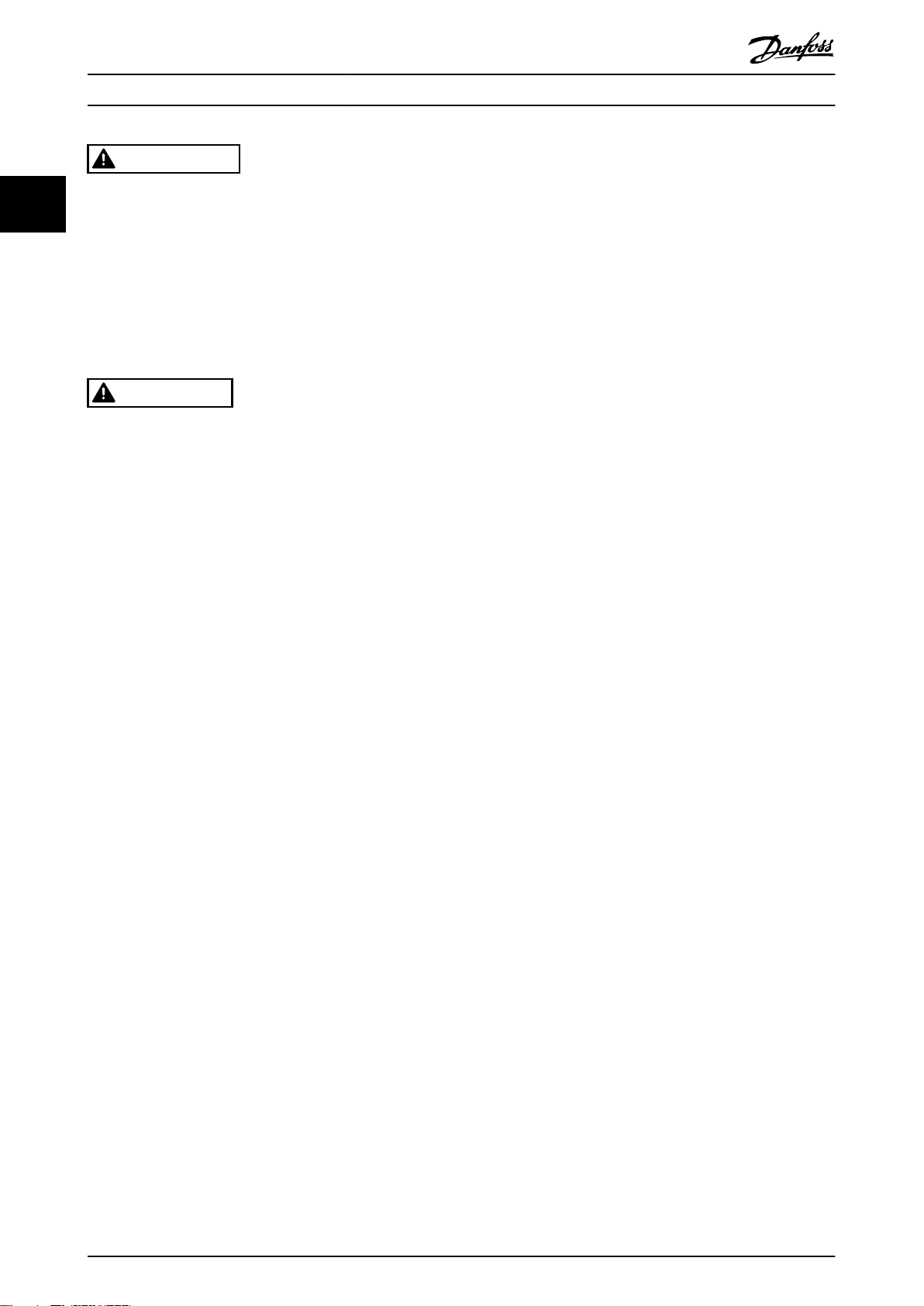

Illustration 3.1 Functional Principle of CANopen Nodes

All information accessible via the CAN-bus is stored in the

object directory (OD).

The contents of the OD are organised in Table 3.1.

Object directory

index range

0000h Not used

0001h–025Fh Data types

0260h–0FFFh Reserved

1000h–1FFFh Communication object area

2000h–5FFFh Manufacturer-specic area

6000h–9FFFh Standardised device prole area

A000h–FFFFh Reserved

Table 3.1 Contents of the OD

For a complete overview of the supported objects in the

OD, refer to chapter 7 Object Directory.

Object type

3 3

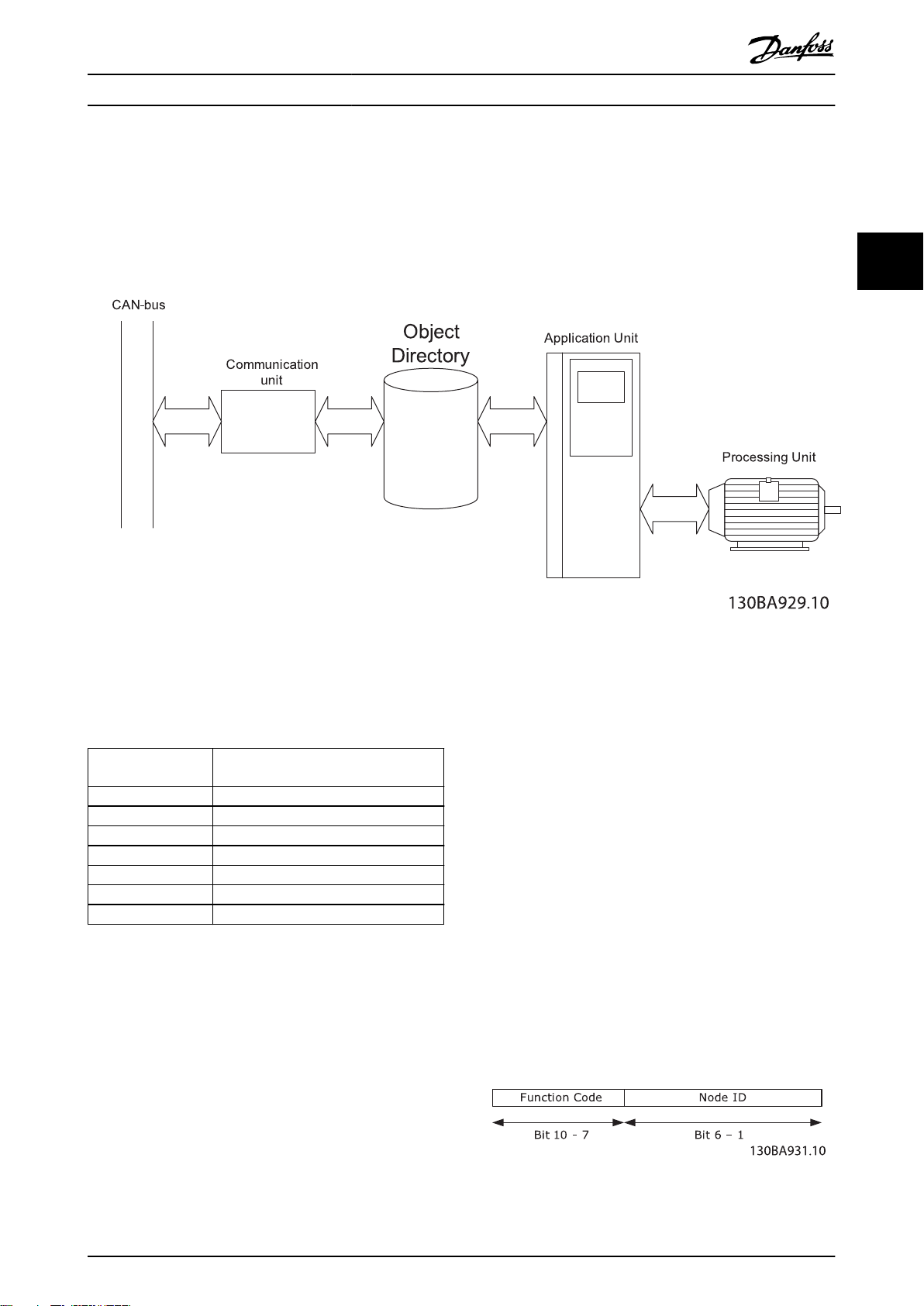

3.1.2 Communication in CANopen

Communication with the frequency converter in CANopen

is achieved via service data objects (SDOs), process data

objects (PDOs), and network management (NMT).

PDOs represent real-time process data with high priority.

PDOs are only available if the node is in operational state.

SDOs represent non-time-critical data and are used to

congure the frequency converter. SDOs are only available

if node is in both operational and pre-operational state.

NMT functions monitor the network stability and include

synchronisation, detection of faults, and emergency

message transmission.

COB-Identiers (ID)

Each communication object has a unique identity (COB-ID)

comprising the function code and the node ID (node

address), see Illustration 3.2.

Illustration 3.2 COB-ID

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 7

Page 10

Conguration

VLT® CANopen MCA 105

Object Function

code

(binary)

NMT 0000 0 –

SYNC 0001 125 (1005h)

33

Time stamp 0010 256 –

EMERGENCY 0001 129 (81h)–255

PDO1 (tx) 0011 385 (181h)–511

PDO1 (rx) 0100 513 (201h)–

PDO2 (tx) 0101 641 (281h)–

PDO2 (rx) 0110 769 (301h)–895

PDO3 (tx) 0111 897 (381h)–1023

PDO3 (rx) 1000 1025 (401h)–1151

PDO4 (tx) 1001 1153 (481h)–1279

PDO4 (rx) 1010 1281 (501h)–1407

SDO (tx) 1011 1409 (581h)–1535

SDO (rx) 1100 1537 (601h)–1663

NMT error control

(Nodeguarding)

1110 1793 (701h)–1919

Resulting COB-ID Communi-

cation

parameter in

OD

1014h

(FFh)

1800h

(1FFh)

1400h

639(27Fh)

1801h

767(2FFh)

1401h

(37Fh)

1802h

(3FFh)

1402h

(47Fh)

1803h

(4FFh)

1403h

(57Fh)

1200h – ...

(5FFh)

1200h – ...

(67Fh)

1016h, 1017h

(77Fh)

(100Eh)

The node must have a start network-command from an

NMT-master to enter the operational state.

In operational state, both SDO and PDO communication

are possible.

The NMT-state of the node is displayed with the green NS

LED:

Flashing = Pre-operational.

•

Solid on = Operational.

•

Single ash = Stopped.

•

A reset node or reset communication-command from the

NMT-master makes the node jump to initialisation state

and directly on to pre-operational state.

Table 3.2 Communication Object

Transmit and receive is always seen from the node’s point

of view:

RX = Nodes receiving data (Controller -> node)

•

TX = Nodes transmitting data (node -> controller)

•

Example:

COB-ID 383 = PDO3 transmit, from node address

•

3.

COB-ID 185 = PDO1 transmit, from node address

•

5.

COB-ID 604 = SDO receive, to node address 4.

•

3.1.3 Controlling the Network

In each CANopen node, a state machine controls the

dierent states of the node.

After power-up, the node transmits a boot-up message

with the COB-ID: 700h + Node ID, and goes from initialisation to pre-operational state.

In this state, SDO communication is possible, but not PDO

communication.

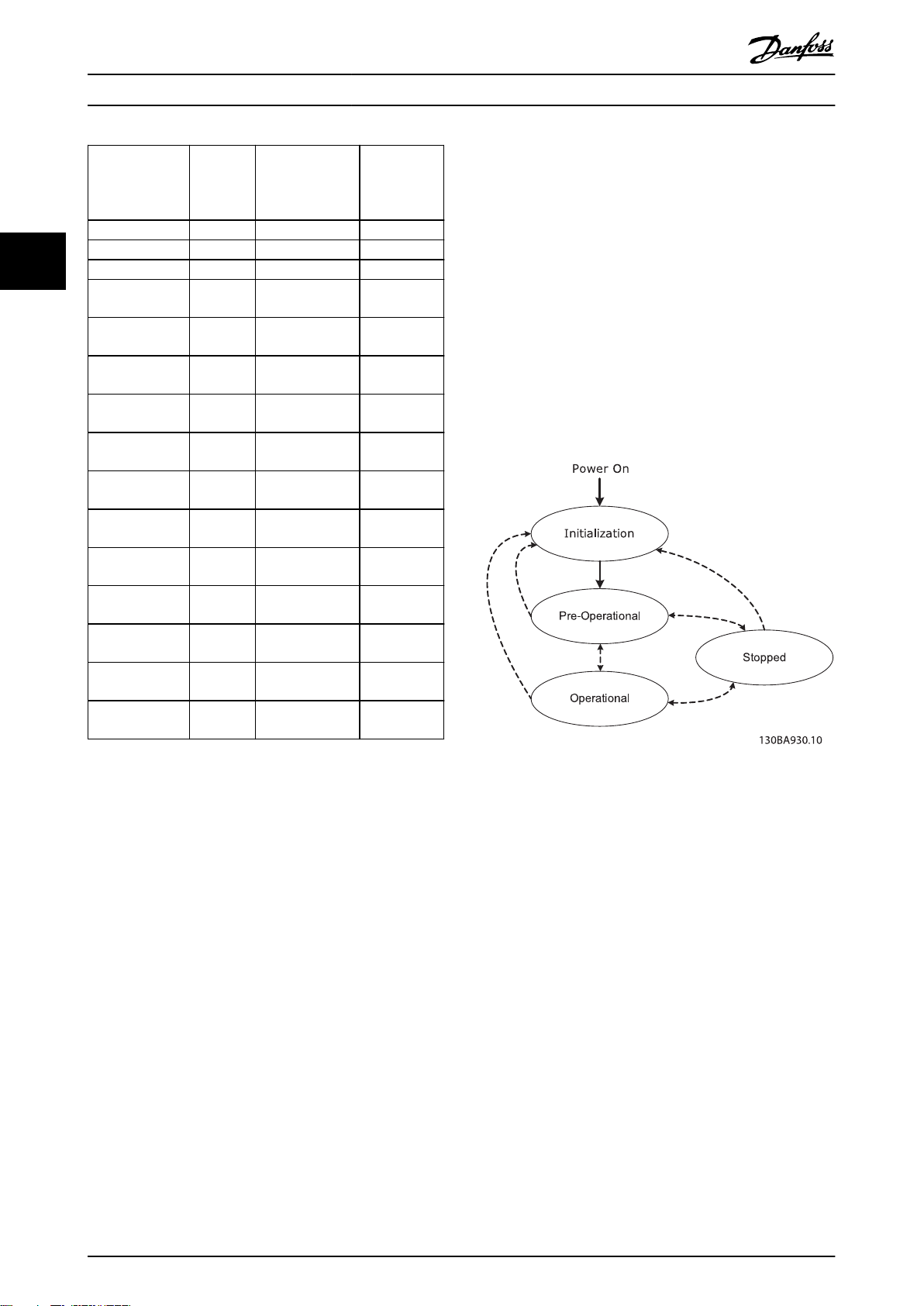

Illustration 3.3 Controlling the Network

3.1.4 Error Control

CANopen oers 2 ways of error-control: Node guarding

and Heartbeat.

In node guarding, the NMT-master sends a remote-frame

(RTR) cyclically: 700 + node ID.

The node replies with its actual status.

The node (frequency converter) monitors the reception of

the RTR-frames, and thereby monitors the presence of the

NMT-master.

Congure the monitoring of the NMT-master via:

OD: 100C Guard time in [ms].

•

OD: 100D Life time factor.

•

If Guard Time x Life Time Factor has expired, the action

programmed in the parameter 8-04 Control Word Timeout

Function is executed.

8 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 11

Conguration Programming Guide

The option can also be congured as heartbeat producer

via:

OD: 1017 Producer Heartbeat time [ms].

•

The MCA 105 option continuously transmits heartbeats

(RTRs with the frequency converters actual status) that can

be monitored by, for example, an NMT-master.

NOTICE

The MCA105 option does not support the heartbeat

consumer function.

Emergency object (EMCY)

The emergency object is used to signal error states, and is

sent automatically if an alarm in the frequency converter

occurs containing the data described in the following. If

the alarm is removed, another emergency telegram is sent

out with the contents 0, signalling the end of the

frequency converter’s alarm state.

Congure the behaviour of the EMCY object via

parameter 8-07 Diagnosis Trigger.

If parameter 8-07 Diagnosis Trigger is set to [0] Disable, the

EMCY is not sent at all. If it is set to Trigger alarms, it is

sent if an alarm occurs. If it is set to Trigger alarms and

warnings, it is sent if an alarm or a warning occurs.

OD 1014h contains the COB-ID of the node’s EMCY

message. This is xed to 80h + node ID.

The EMCY always consists of 8 bytes with the full data as

described in Table 3.3.

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Byte 6 Byte 7

EMCY code*

(OD: 1003 [1])

Table 3.3 EMCY Consists of 8 Bytes with the Full Data

*= For more information on EMCY codes, refer to

chapter 8 Troubleshooting.

Bit 0 1, alarm word 1 has an active alarm (parameter 16-90)

Bit 1 1, alarm word 2 has an active alarm (parameter 16-91)

Bit 2 0, Reserved

Bit 3 1, warning word 1 has an active warning (parameter

Bit 4 1, warning word 2 has an active warning (parameter

Bit 5–7 0, reserved

16-92)

16-93)

OD:

1001h

Vendor-specic information

Bus error counters

The frequency converter contains 2 CAN-bus error

counters:

Parameter 10-05 Readout Transmit Error Counter

•

(TEC).

Parameter 10-06 Readout Receive Error Counter

•

(REC).

These counters determine the error-state of the CANopen

node.

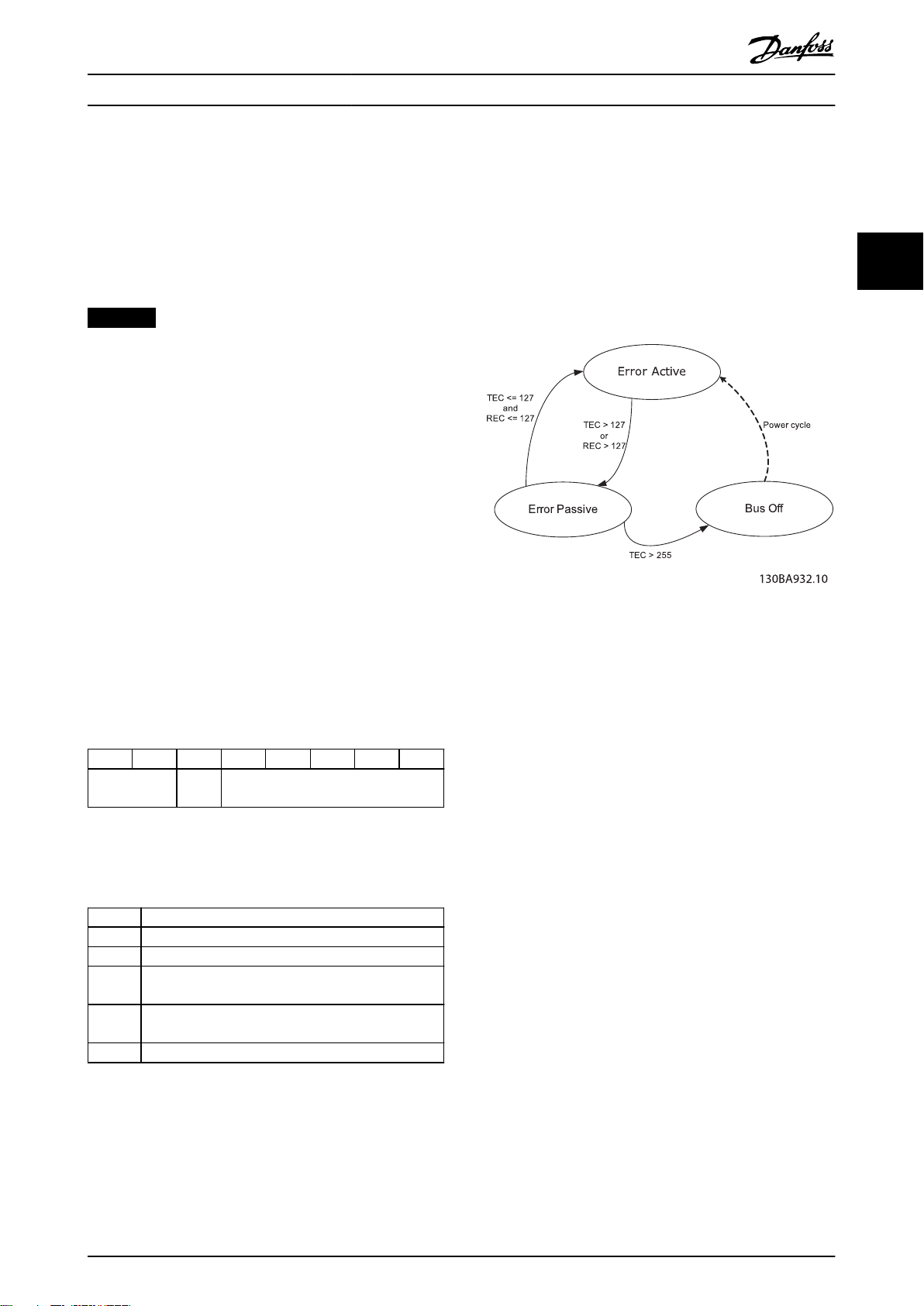

Illustration 3.4 Bus Error Counters

TEC is incremented with 8 if a transmit-error occurs and

decremented with 1 if a transmission is successful.

REC is incremented with 1 if a receive error is detected (8

if the transmitting node is in error active-mode) and

decremented with 1 if a reception is successful.

In normal operation the node is in error active state.

If the TEC or REC exceeds the value: 127, the node enters

error passive state.

In Error passive state, the error-ag is not transmitted

dominantly but recessively.

This means that an error passive node, as receiver, cannot

block communication from other nodes.

A node in error passive state has a lower prioritised access

to the bus.

If the TEC exceeds 255 (248 + 8), the node enters bus o

state.

In bus o state, the MS LED turns solid red, and a warning

34 is issued.

Power-cycle the frequency converter to leave the bus o

state.

3 3

Table 3.4 Byte 3 Description

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 9

Page 12

Conguration

VLT® CANopen MCA 105

3.1.5 SDO Communication

Restoring OD entries

To restore factory defaults, use OD index 1011h.

All CANopen objects and frequency converter parameters

can be accessed via SDOs (service data objects).

For a description of supported SDO abort codes, refer to

chapter 8 Troubleshooting.

33

COB-ID

Transmit SDO 1409 (581h)–1535 (5FFh) 580h + Node ID

Receive SDO 1537 (601h)–1663 (67Fh) 600h + Node ID

Table 3.5 COB-ID’s for SDO Communication

COB-ID CS OD-Index Sub-ind. Data

600+ID See following text 01 20 00 00 00 00 00

Table 3.6 Structure of a SDO-message (Request)

To restore default parameters the value “64616F6C” (load)

must be written to the appropriated sub-index in OD:

1011h

OD index Subindex Description

0 Number of entries

1011h

Table 3.10 Restoring OD Entries

* requires power cycle

1 Restore all parameters + OD entries*

2 Restore all communication parameters +

OD entries and restart

NOTICE

Frequency converter displays Alarm 80 “Drive initialised”

after restores.

The CS-eld contains the command and response

speciers. See Table 3.7 and Table 3.8.

Command CS

Write request 4 bytes 23h

Write request 2 bytes 2Bh

Write request 1 byte 2Fh

Read request (any) 40h

3.2 Congure the Master

3.2.1 EDS File

A large part area of the system conguration is the setting

of application-related parameters. EDS (electronic data

sheet) les simplify the setting up of most of the CANopen

congurable parameters. The EDS le contains all

Table 3.7 Command

supported communication-specic objects (OD 1000h

+ 1FFFh) and a selected number of manufacturer-specic

Response CS

Write response (any) 60h

Read response 4 bytes 43h

Read response 2 bytes 4Bh

Read response 1 byte 4Fh

Error response 80h

Table 3.8 Response

Saving OD entries

objects (frequency converter parameters) in the OD range

2000h–5FFFh.

Danfoss provides a generic English EDS le covering all

voltage and power sizes for o-line conguration.

Download the EDS le from www.danfoss.com/Busines-

sAreas/DrivesSolutions/Softwaredownload/

DDFieldbus_Setup_Files.htm.

In standard conguration, all parameters + OD entries are

stored in volatile (RAM) memory only. To store current

network conguration in non-volatile memory, use OD

index 1010h.

To save parameters, write the value 65766173 (save) to the

NOTICE

The EDS les do not contain all parameters but a

selected, limited number of parameters with generic

minimum, maximum, and default values.

appropriated sub-index in OD: 1010h.

OD index Subindex Description

0 Number of entries

1 Save all parameters + OD entries

1010h

Table 3.9 Saving OD Entries

10 Danfoss A/S © 06/2015 All rights reserved. MG92G102

2 Save all communication parameters + OD

entries

3 Reserved

4 Save edit set-up (Danfoss specic)

Page 13

130BA936.10

Conguration Programming Guide

3.2.2 Conguring the CANopen Master

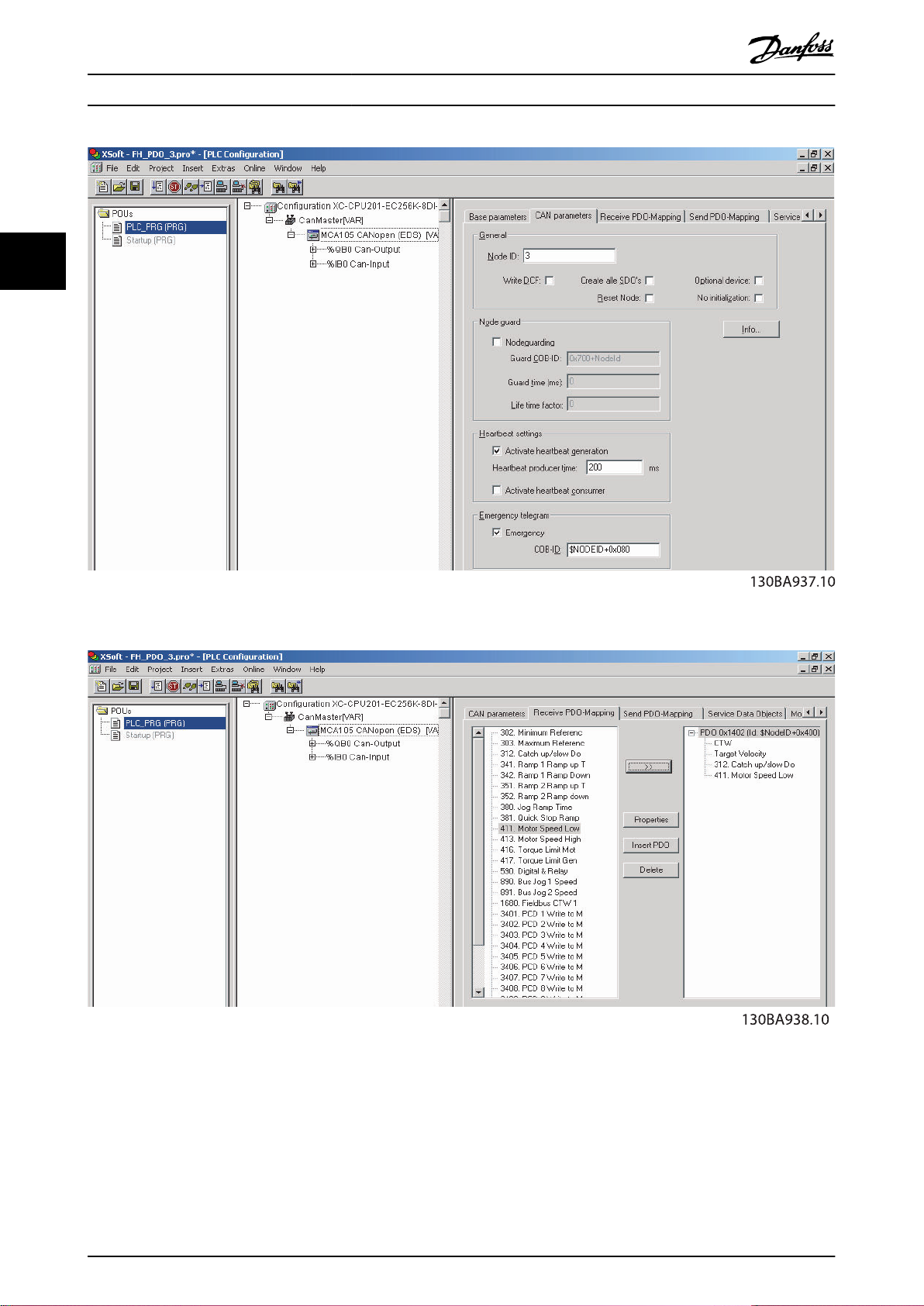

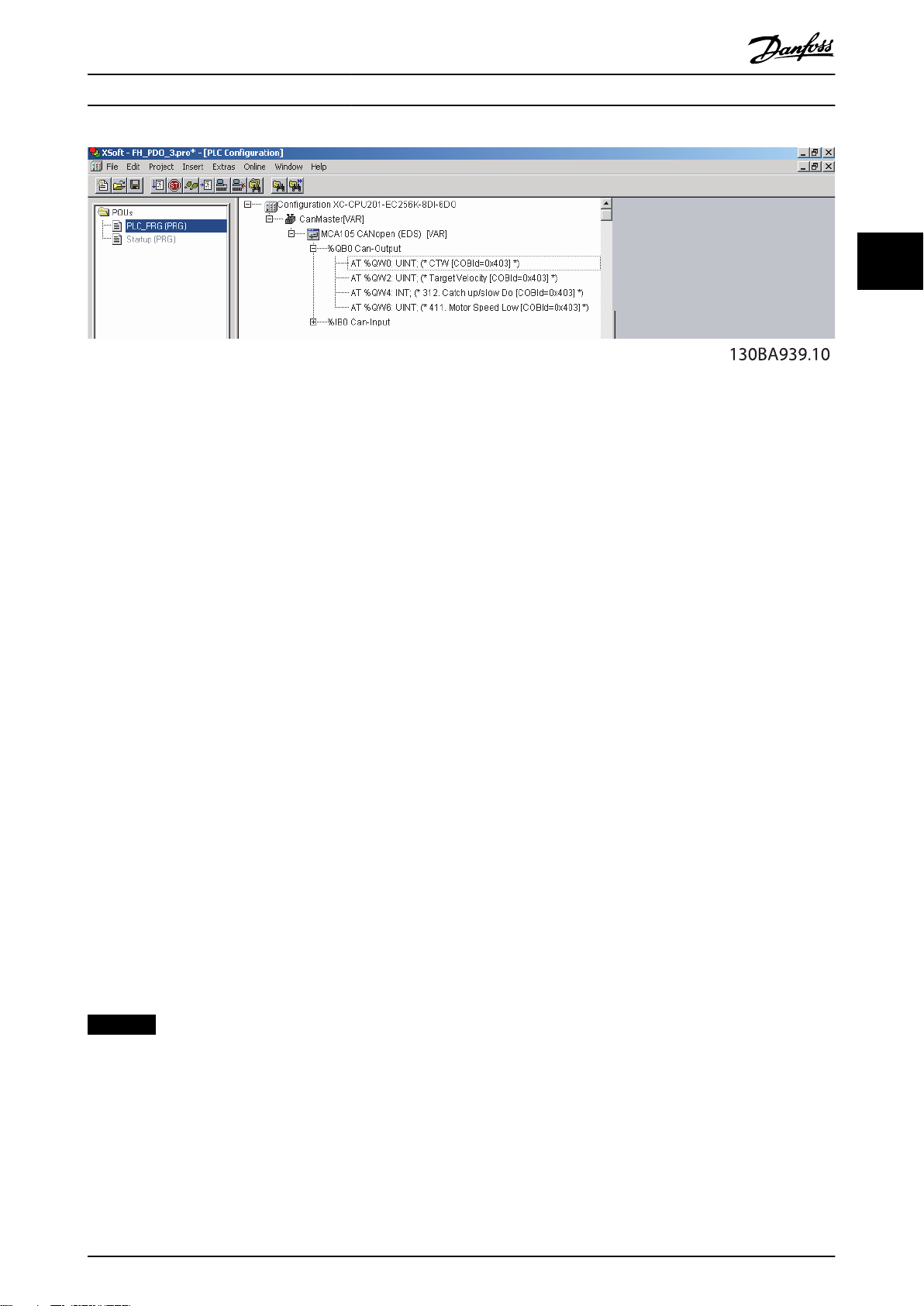

The following example shows the details in setting up the CANopen conguration on a Moeller XC-CPU201 PLC.

3 3

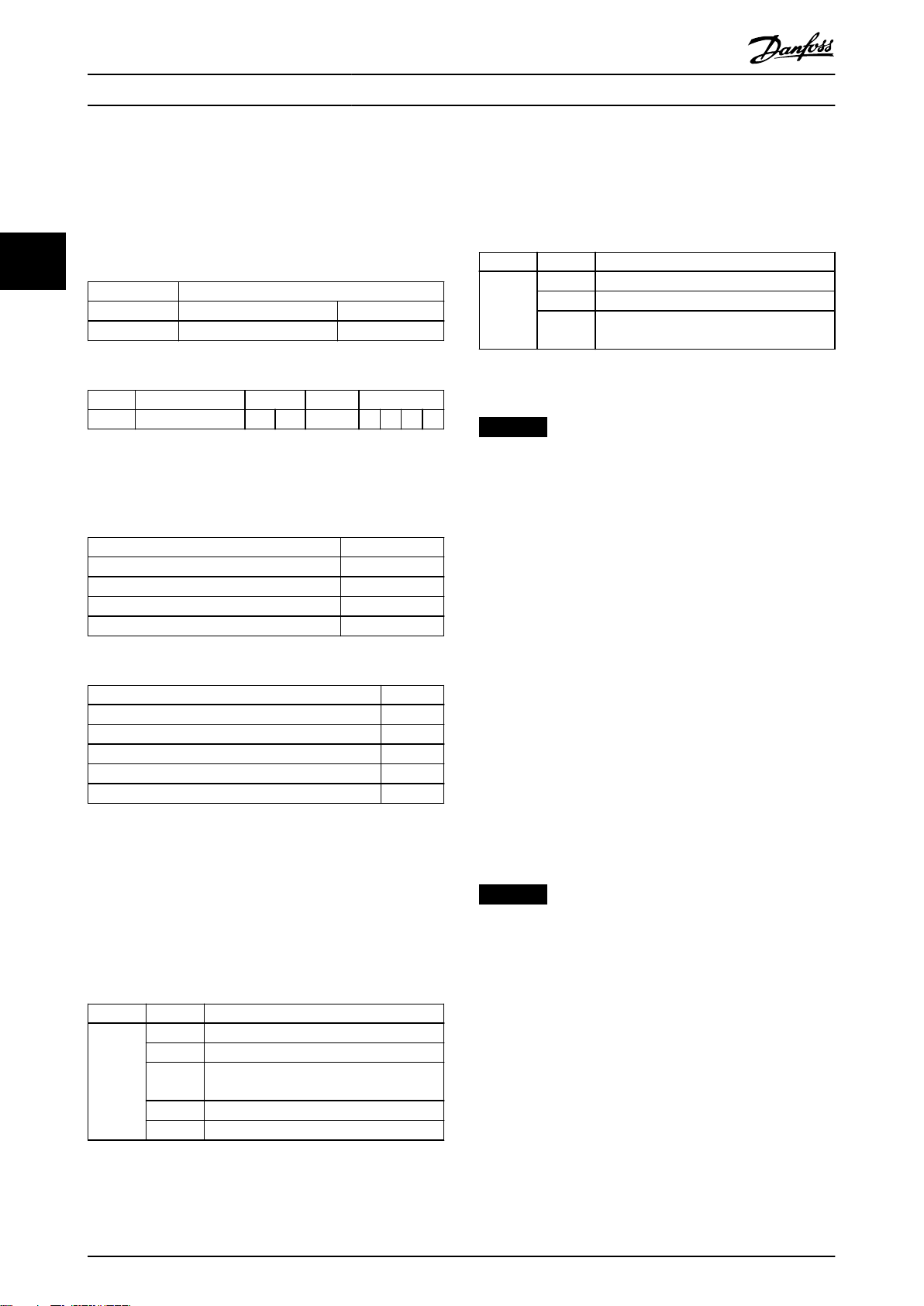

Illustration 3.5 Setting up the Baud Rate and Node-ID on the CanMaster (CANopen Scanner)

Illustration 3.6 Appending a CANopen Node, from EDS File Library, by Rght-clicking CanMaster

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 11

Page 14

Conguration

VLT® CANopen MCA 105

33

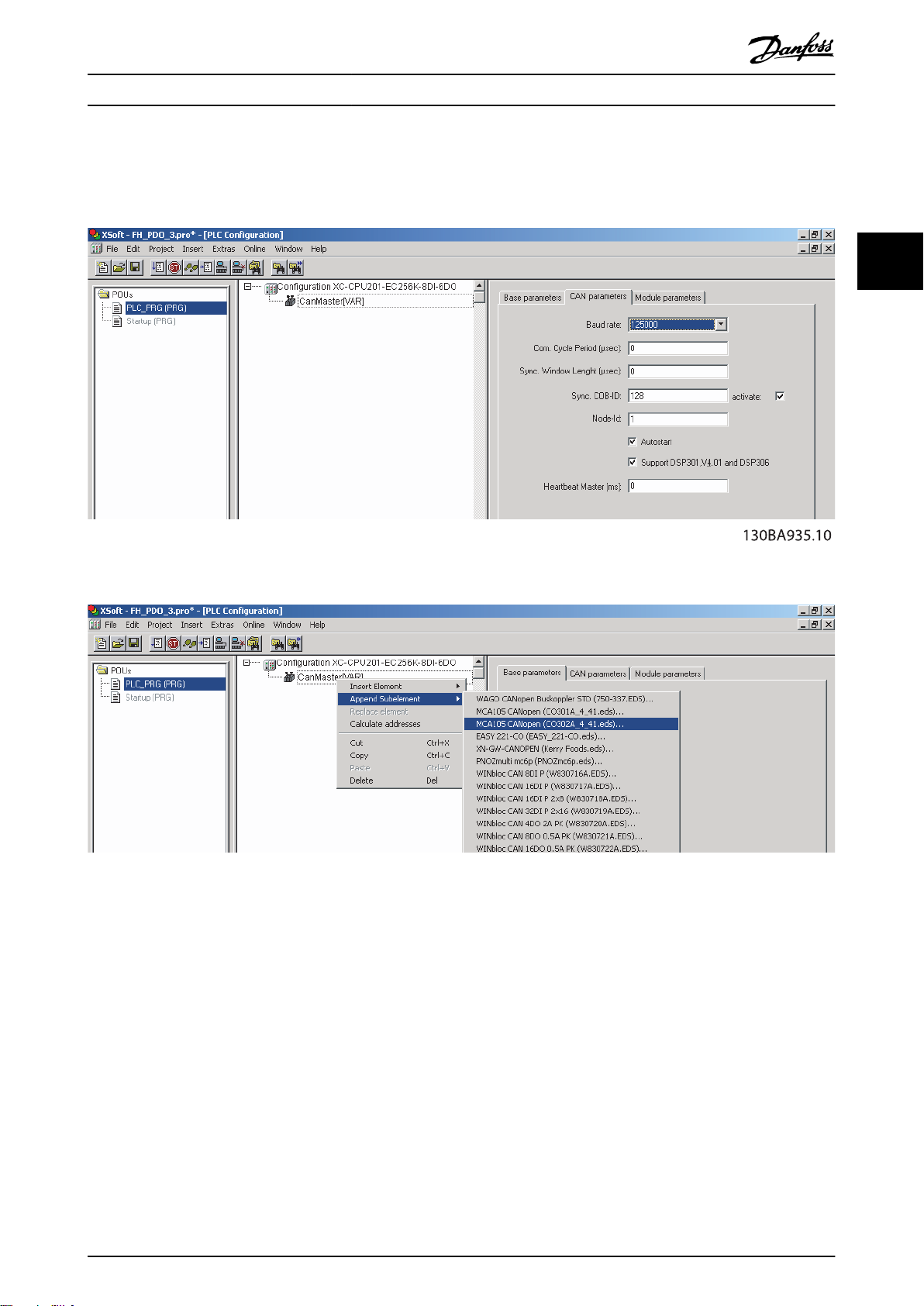

Illustration 3.7 Conguring the CAN Parameters like Node-ID, Node-guarding, Heartbeat, and so on, on Node

Illustration 3.8 Conguring Receive and Transmit PDO-mapping. Here PDO 1402 with Parameter 3-12 Catch up/slow Down Value and

Parameter 4-11 Motor Speed Low Limit [RPM]

12 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 15

Conguration Programming Guide

Illustration 3.9 PLC Memory Mapping

3 3

3.3 Congure the Frequency Converter

3.3.1 Frequency Converter Parameters

Pay particular attention to the following parameters when

conguring an VLT® AutomationDrive FC 300 with a

CANopen interface. Refer to chapter 6 Parameters for more

details about each parameter.

Parameter 0-40 [Hand on] Key on LCP

If the [Hand On] key on the frequency converter is pressed,

control of the frequency converter via the CANopen

interface is disabled.

Parameter 8-02 Control Word Source

After initial power-up, the frequency converter automatically detects whether a

A, and sets parameter 8-02 Control Word Source to [Option

A]. If an option is added to, changed in, or removed from

an already commissioned frequency converter, it does not

change parameter 8-02 Control Word Source.

Parameter 8-10 Control Word

Select between the Danfoss FC Prole and the DSP 402

prole for CANopen. Refer to chapter 4 Control.

Parameter 8-01 Control Site and parameter 8-50 Coasting

Select to parameter 8-56 Preset Reference Select

Refer to chapter 4 Control.

Selection of how to gate the CANopen control commands

with digital input command of the control card.

Set Parameter 8-01 Control Site to: [2] Control word onlyor

[0] Digital and ctrl. word.

eldbus option is installed in slot

Prole

Parameter 8-03 Control Word Timeout Time to

parameter 8-05 End-of-Timeout Function

The reaction in the event of a bus timeout is set via these

parameters:

Parameter 10-01 Baud Rate Select

•

Default is 125 kbps.

Parameter 10-02 MAC ID

•

Default is 127.

NOTICE

When parameter 8-01 Control Site is set to [2] Control

word only, the settings in parameter 8-50 Coasting Select

to parameter 8-56 Preset Reference Select are overruled,

and all act on bus-control.

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 13

Page 16

Control

VLT® CANopen MCA 105

4 Control

4.1 PDO Communication

The real-time data transfer is performed by process data objects (PDO).

The PDOs correspond to entries in the device object dictionary and provide the interface to the application objects.

44

Illustration 4.1 PDO Types

NOTICE

Control word (CTW), status word (STW), reference (REF), and Main Actual Value (MAV) are xed in PDO type 1–3. PDO

type 4 is free congurable.

All receive and transmit PDOs can be congured via the OD.

Map process data into receive and transmit PDOs via parameter 10-50 Process Data Cong Write. and parameter 10-51 Process

Data Cong Read. or via OD: 1600–1603 for receive PDOs and OD: 1A00–1A03 for transmit PDOs.

14 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 17

Control Programming Guide

4.1.1 PDO Conguration

Index Name Sub

index

1400h

1401h

1402h

1403h

1600h

1601h

1602h

1603h

1st receive PDO (PDO 1)

2nd receive PDO (PDO 2)

3rd receive PDO (PDO 3)

4th receive PDO (PDO 4)

1st receive PDO mapping

(PDO 1)

COB-ID 201h–27Fh

2nd receive PDO mapping

(PDO 2)

COB-ID 301h–37Fh

3rd receive PDO mapping

(PDO 3)

COB-ID 401h–47Fh

4th receive PDO mapping

(PDO 4)

COB-ID 501h–57Fh

0 Number of entries.

1 COB ID.

2 Transmission type.

0 Number of entries.

1

0 Number of entries

1

2

0 Number of entries.

1

2

3

4

0 Number of entries.

1

2

3

4

Description Value Sub index 2 Transmission type

⇒

⇒

⇒

1st mapped object (60400010h control word, xed) (parameter 10-50 Process Data Cong

Write. [0])

1st mapped object (60400010h control word, xed) (parameter 10-50 Process Data Cong

Write. [0])

2nd mapped object (60420010h target velocity, xed) (parameter 10-50 Process Data Cong

Write. [1])

1st mapped object (60400010h control word, xed) (parameter 10-50 Process Data Cong

Write. [0])

2nd mapped object (60420010h target velocity, xed) (parameter 10-50 Process Data Cong

Write. [1])

3rd mapped object (2000h + parameter number) (parameter 10-50 Process Data Cong

Write. [2])

4th mapped object (2000h + parameter number) (parameter 10-50 Process Data Cong

Write. [3])

5th mapped object (2000h + parameter number) (parameter 10-50 Process Data Cong

Write. [4])

6th mapped object (2000h + parameter number) (parameter 10-50 Process Data Cong

Write. [5])

7th mapped object (2000h + parameter number) (parameter 10-50 Process Data Cong

Write. [6])

8th mapped object (2000h + parameter number) (parameter 10-50 Process Data Cong

Write. [7])

⇒

1...240 SYNC

1...240 SYNC

254...255 COS

254...255 COS

4 4

Table 4.1 Receive PDO Conguration

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 15

Page 18

Control

VLT® CANopen MCA 105

Index Name Sub

0 Number of entries.

1800h

1801h

1802h

1803h

44

1A00h

1A01h

1A02h

1A03h

1st transmit PDO (PPO 1)

2nd transmit PDO (PPO 2)

3rd transmit PDO (PPO 3)

4th transmit PDO (PPO 4)

5 Event timer.

1st transmit PDO mapping

(PDO 1)

COB-ID 181h–1FFh

2nd transmit PDO mapping

(PDO 2)

COB-ID 281h–2FFh

3rd transmit PDO mapping

(PDO 3)

COB-ID 381h–3FFh

4th transmit PDO mapping

(PDO 4)

COB-ID 481h–4FFh

1

1

2

1

2

3

4

1

2

3

4

Description Value sub index 2 Transmission type

index

⇒

COB ID.

1

Transmission type.

2

Inhibit time.

3

Reserved.

4

0 Number of entries.

1st mapped object (60410010h status word, xed) (parameter 10-51 Process Data Cong

Read. [0])

0 Number of entries.

1st mapped object (60410010h status word, xed) (parameter 10-51 Process Data Cong

Read. [0])

2nd mapped object (60440010h control eort, xed) (parameter 10-51 Process Data Cong

Read. [1])

0 Number of entries.

1st mapped object (60410010h status word, xed) (parameter 10-51 Process Data Cong

Read. [0])

2nd mapped object (60440010h control eort, xed) (parameter 10-51 Process Data Cong

Read. [1])

3rd mapped object (2000h + parameter number) (parameter 10-51 Process Data Cong

Read. [2])

4th mapped object (2000h + parameter number) (parameter 10-51 Process Data Cong

Read. [3])

0 Number of entries.

5th mapped object (2000h + parameter number) (parameter 10-51 Process Data Cong

Read. [4])

6th mapped object (2000h + parameter number) (parameter 10-51 Process Data Cong

Read. [5])

7th mapped object (2000h + parameter number) (parameter 10-51 Process Data Cong

Read. [6])

8th mapped object (2000h + parameter number) (parameter 10-51 Process Data Cong

Read. [7])

⇒

⇒

⇒

⇒

⇒

0 SYNC, non-cyclic

0 SYNC, non-cyclic

1...240 SYNC

1...240 SYNC

254...255 COS

254...255 COS

Table 4.2 Transmit PDO Conguration

16 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 19

Control Programming Guide

4.1.2 PDO Mapping Syntax

Sub-index 1–4 contains the mapped objects.

Example: Object 6041 status word is xed in PDO 1 and

PDO 2 as the rst transmit-word.

That is, OD 1A00h and 1A01h sub-index 1 holds the value

of 60410010 (6041 = object number, 00 = sub-index, 10 =

length of data = 16 bits)

Example: To map parameter 16-14 Motor current (32-bit

data) in PDO 3, it must be mapped in 2 PDO-words.

Parameter 16-14 Motor current is according to manufacturer

object 264E.

1A02h [3] = 264E0020 (264E = object number, 00 = subindex, 20 = length of data = 32 bits)

1A02h [4] = 264E0020 (264E = object number, 00 = subindex, 20 = length of data = 32 bits)

4.1.3 PDO Transmission Modes

Sub-index 2 contains the setting of the transmission mode.

The following PDO transmission modes are distinguished:

Synchronous transmission.

•

Asynchronous transmission.

•

Remotely requested

The transmission of asynchronous PDO’s may be initiated

on receipt of a remote request initiated by another device.

Transmission

type

0 x x

1–240 x x

241–251 Reserved

252

253

254 x

255 x

Table 4.3 PDO Transmission

PDO transmission

Cyclic Acyclic Synchronous Asynchronous RTR

only

Not supported

4.1.5 Inhibit Time

Sub-index 3 contains the inhibit time.

This time denes a minimum interval for PDO transmission.

The value is dened as multiple of 0.1 ms.

Default value is 300 = 30 ms.

Minimum value is 0.

Maximum value is 32767 = 3.2 s.

Data length = 2 bytes.

4 4

4.1.4 PDO Triggering Modes

The CANopen communication prole distinguishes 2

message triggering modes:

Event driven.

•

Remotely requested.

•

Event driven

Message transmission is triggered by the occurrence of an

object-specic event.

For synchronous PDOs, this is the expiration of the

specied transmission period, synchronised by the

reception of the SYNC object.

For acyclically transmitted synchronous PDOs and

asynchronous PDO’s, the triggering of a message

transmission is an application-specic event specied in

the device prole.

4.1.6 Event Timer

Sub-index 5 contains the inhibit time for transmit PDOs.

If an event timer is congured for a TPDO (value not equal

to 0), the elapsed timer causes the transmission of this

TPDO.

The event timer can be congured as multiple of 1 ms.

Default value is 0.

Maximum value is 32767 = 32 s.

Data length = 2 bytes.

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 17

Page 20

Control

VLT® CANopen MCA 105

4.2 Control Prole

4.2.1 Control Word Prole 8–10

8–10 Control Prole

In parameter 8-10 Control Word Prole, it is possible to select:

Option: Function:

[0] * FC prole

44

4.2.2 DSP 402 State Transitions

8–10 Control Prole

In parameter 8-10 Control Word Prole, it is possible to select:

Option: Function:

[5] CANopen DSP

[0] FC Prole is the default control prole for VLT frequency

converters, whereas [5] CANopen DSP 402 is the CiA

standardised control prole, featuring the special DSP 402

transition state machine.

Illustration 4.2 DSP 402 State Machine

18 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 21

Control Programming Guide

Transition State Control word Status word Action

– Start condition 0000 0000

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Start-up⇒Not ready to switch on

Not ready to switch on⇒ Switch on disabled

Switch on disable⇒Ready to switched on

Ready to switch on⇒Switched on

Switched on⇒Operation enabled

Operation enabled⇒Switched on

Switched on⇒Ready to switch on

Ready to switch on⇒Switch on disable

Operation enable⇒Ready to switch on

Operation enable⇒Switch on disable

Switched on⇒Switched on disable

Operation enabled⇒Quick stop active

Quick stop activ⇒Switch on disabled

All states⇒Fault reaction active

Fault reaction active⇒Fault

Fault⇒Switch on disabled

Quick stop active⇒Operation enable (not

supported)

0000 0200

0000, 0001 0240

0006 0231

0007 0233

000F 0237

0007 0233

0006 0231

0001, 0000 0240

0006 0231

0001, 0000 0240

0001, 0000 0240

0002 0207

0001, 0000 0240

xxxx 023F

xxxx

0000 0240

023F (0238

by InterBus)

Motor ramps to 0 RPM with programmed

ramp-down parameter.

The power section is switched o immediately,

and the motor is free to rotate if unbraked.

The power section is switched o immediately,

and the motor is free to rotate if unbraked.

The power section is switched o immediately,

and the motor is free to rotate if unbraked.

The motor ramps to 0 RPM with programmed

quick-ramp parameter.

The power section is switched o immediately,

and the motor is free to rotate if unbraked.

4 4

Table 4.4 DSP 402 State Transitions

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 19

Page 22

Speed ref.CTW

Master-follower

130BA274.11

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit

no.:

Control

VLT® CANopen MCA 105

4.3 DSP 402 Control Prole

Bit 05, Freeze output frequency/run enable:

Bit 05 = 0 means that the given output frequency is

4.3.1 Control Word According to DSP 402

Prole

(parameter 8-10 = DSP 402 prole)

maintained even if the reference is changed.

Bit 05 = 1 means that the frequency converter is again

able to regulate, and the given reference is followed.

Bit 06, Ramp stop/start:

Bit 06 = 0 The frequency converter controls the motor

down to stop.

Bit 01 = 1 A start command to the frequency converter is

44

given.

Bit 07, No function/reset:

Illustration 4.3 Control Word

Reset of trip.

Bit 07 = 0 means that there is no reset.

Bit 07 = 1 means that a trip is reset.

Bit Bit value = 0 Bit value = 1

00 Switch o Switch on

01 Disable voltage Enable voltage

02 Quick stop Run

03 Disable operation Enable operation

04 Disable ramp Enable ramp

05 Freeze Run enable

06 Ramp stop Start

07 No function Reset

08 Reserved

09 Reserved

10 Reserved

11 Jog 1 OFF Jog 1 ON

12 Reserved

13 Setup select (LSB)

14 Setup select (MSB)

15 Forward Reversing

Bit 08, 09, and 10:

DSP402 reserved.

Bit 11, Jog 1 OFF/ON:

Activation of pre-programmed speed in parameter 8-90 Bus

Jog 1 Speed (bus jog 1).

Jog 1 is only possible if bit 04 = 0, and bits 00–03 = 1.

Bit 12:

Danfoss reserved.

Bits 13/14, Selection of setup:

Bits 13 and 14 are used for selecting among the 4 menu

set-ups in accordance with Table 4.6.

Set-up Bit 14 Bit 13

0 0 1

0 1 2

1 0 3

1 1 4

Table 4.5 Control Bits

Explanation of the control bits

Bit 00, Switch o/on:

Bit 00 = 0 executes transition 2, 6, or 8.

Bit 00 = 1 executes transition 3.

Bit 01, Disable/enable voltage:

Bit 01 = 0 executes transition 9, 10, or 12.

Bit 01 = 1 enables voltage.

Bit 02, Quick stop/run:

Bit 02 = 0 execute transition 7, 10, or 11.

Bit 02 = 1 Quick stop not active.

Bit 03, Disable/enable operation:

Bit 03 = 0 executes transition 5.

Bit 03 = 1 Enables operation.

Bit 04, Quick-stop/ramp:

Bit 04 = 0 executes transition 7 or 11, Quick stop.

Bit 04 = 1 Enables ramp.

20 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Table 4.6 4 Menu Set-ups

Bit 15, Forward/reversing:

Bit 15 = "0" leads to no reversing.

Bit 15 = "1" leads to reversing.

NOTICE

In factory setting, reversing is set to [0] Digital input in

parameter 8-54 Reversing Select.

Page 23

Output freq.STW

Bit

no.:

Follower-master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

130BA273.11

Control Programming Guide

4.3.2 Status Word According to DSP 402

Illustration 4.4 Status Word

Bit Bit value = 0 Bit value = 1

00 Not ready to switch

01 Switched OFF Switched ON

02 Operation disabled Operation enabled

03 No malfunction Malfunction

04 Voltage disabled Voltage enabled

05 Quick stop Run

06 Switch on disable Switch on enable

07 No warning Warning

08 Reserved

09 Remote disabled Remote enabled

10 Setpoint not reached Setpoint reached

11 Speed limit not

12 Reserved

13 Reserved

14 Not running Running

15 Reserved

Table 4.7 Status Bits

Explanation of the status bits

Bit 00, Not ready to switch on/ready to switch on:

Bit 00 = 0 state less than Ready to switch on.

Bit 00 = 1 state at least = Ready to Switch on.

Bit 01, Switch o/switch on:

Bit 00 = 0 state less than switched on.

Bit 00 = 1 state at least = switched on.

Bit 02, Operation disable/operation enable:

Bit 00 = 0 state less than operation enable.

Bit 00 = 1 state at least = operation enable.

Bit 03, No fault/trip:

Bit 03 = 0 means that the frequency converter is not in a

fault condition.

Bit 03 = 1 means that the frequency converter has tripped

and needs a reset signal to run.

Bit 04, Voltage disable/voltage enable:

Bit 04 = 0 means that control word bit 01 = 1.

Bit 04 = 1 means that control word bit 01 = 0.

Bit 05, Quick stop/run:

Bit 05 = 0 means that control word bit 02 = 1.

Bit 05 = 1 means that control word bit 02 = 0.

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 21

Prole

ON

active

Bit 06, Start enable/start disable:

Bit 06 = 0 state is not switch on disable.

Bit 06 = 1 state is switch on enable.

Bit 07, No warning/warning:

Bit 07 = 0 means that there is no warning. situation.

Bit 07 = 1 means that a warning has occurred.

Bit 08

Danfoss reserved.

Bit 09, Remote disable/remote enable:

4 4

Bit 09 = 0 means that the frequency converter has been

stopped with the [stop] key on the LCP, or that [Local] has

been selected in parameter 3-13 Reference Site.

Ready to switch ON

Bit 09 = 1 means that it is possible to control the

frequency converter via the serial port.

Bit 10, Setpoint not reached/setpoint reached:

Bit 10 = 0 means that the actual motor speed is dierent

from the speed reference set. This can be the case while

the speed is ramped up/down during start/stop.

Bit 10 = 1 means that the present motor speed equals the

speed reference set.

Bit 11, Speed limit not active/speed limit active:

Bit 11 = 0 means that the output frequency is out of the

range set in parameter 4-11 Motor Speed Low Limit [RPM]/

parameter 4-12 Motor Speed Low Limit [Hz] or

Speed limit active

parameter 4-13 Motor Speed High Limit [RPM]/

parameter 4-14 Motor Speed High Limit [Hz].

Bit 11 = 1 means that the output frequency is within the

mentioned range.

Bit 12

DSP 402 reserved.

Bit 13

DSP 402 reserved.

Bit 14, Running/not running:

Bit 14 = 0 means that the motor is not running.

Bit 14 = 1 means that the frequency converter has a valid

start signal or that the output frequency is greater than 0

Hz.

Bit 15

Danfoss reserved.

Page 24

Speed ref.CTW

Master-follower

130BA274.11

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Bit

no.:

Control

VLT® CANopen MCA 105

4.4 Danfoss FC control prole

4.4.1 Control Word according to FC Prole

(parameter 8-10 = FC prole)

44

Illustration 4.5 Control Word

Bit Bit value = 0 Bit value = 1

00 Reference value External selection lsb

01 Reference value External selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output

frequency

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 04 active

13 Parameter set-up Selection lsb

14 Parameter set-up Selection msb

15 No function Reverse

Table 4.8 Control Bits

Explanation of the control bits

Bits 00/01

Bits 00 and 01 are used to select between the 4 reference

values, which are pre-programmed in parameter 3-10 Preset

Reference according to Table 4.9.

Set-up Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

Table 4.9 Set-up

Use ramp

Bit 02, DC brake:

Bit 02 = 0 leads to DC brake and stop. Braking current and

duration are set in parameter 2-01 DC Brake Current and

parameter 2-02 DC Braking Time.

Bit 02 = 1 leads to ramping.

Bit 03, Coasting:

Bit 03 = 0 causes the frequency converter to immediately

release the motor (the output transistors are "shut o"), so

that it coasts to a standstill.

Bit 03 = 1 enables the frequency converter to start the

motor if the other starting conditions are fullled.

NOTICE

In parameter 8-50 Coasting Select, a selection is made to

dene how bit 03 gates with the corresponding function

on a digital input.

Bit 04, Quick stop:

Bit 04 = 0 causes a stop, in which the motor speed is

ramped down to stop via parameter 3-81 Quick Stop Ramp

Time.

Bit 05, Hold output frequency:

Bit 05 = 0 causes the present output frequency (in Hz) to

freeze. The frozen output frequency can then be changed

only with the digital inputs (parameter 5-10 Terminal 18

Digital Input to parameter 5-15 Terminal 33 Digital Input)

programmed to speed up and speed down.

NOTICE

If freeze output is active, the frequency converter can

only be stopped by the following:

Bit 03 Coasting stop.

•

Bit 02 DC braking.

•

Digital input (parameter 5-10 Terminal 18 Digital

•

Input to parameter 5-15 Terminal 33 Digital

Input) programmed to DC braking, coasting stop

or reset and coasting stop.

Bit 06, Ramp stop/start:

Bit 06 = 0 causes a stop, in which the motor speed is

ramped down to stop via the selected ramp-down

parameter.

Bit 06 = 1 permits the frequency converter to start the

motor, if the other starting conditions are fullled.

NOTICE

In parameter 8-56 Preset Reference Select a selection is

made to dene how bit 00/01 gates with the

corresponding function on the digital inputs.

NOTICE

In parameter 8-53 Start Select a selection, is made to

dene how bit 06 Ramp stop/start gates with the

corresponding function on a digital input.

22 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 25

Output freq.STW

Bit

no.:

Follower-master

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

130BA273.11

Control Programming Guide

Bit 07, Reset:

Bit 07 = 0 does not cause a reset.

Bit 07 = 1 causes the reset of a trip. Reset is activated on

the signal’s leading edge, for example, when changing

from logic 0 to logic 1.

Bit 08, Jog:

Bit 08 = 1 causes the output frequency to be determined

by parameter 3-19 Jog Speed [RPM].

Bit 09, Selection of ramp 1/2:

Bit 09 = 0 means that ramp 1 is active

(parameter 3-40 Ramp 1 Type to parameter 3-47 Ramp 1 S-

ramp Ratio at Decel. Start).

Bit 09 = 1 means that ramp 2 (parameter 3-50 Ramp 2 Type

to parameter 3-57 Ramp 2 S-ramp Ratio at Decel. Start) is

active.

Bit 10, Data not valid/data valid:

Is used to tell the frequency converter whether the control

word is to be used or ignored.

Bit 10 = 0 causes the control word to be ignored.

Bit 10 = 1 causes the control word to be used. This

function is relevant, because the control word is always

contained in the telegram, regardless of which type of

telegram is used, for example, it is possible to turn o the

control word if it is not to be used it with updating or

reading parameters.

Bit 11, Relay 01:

Bit 11 = 0 Relay 01 is not activated.

Bit 11 = 1 Relay 01 activated, provided control word bit 11

is selected in parameter 5-40 Function Relay.

Bit 12, Relay 04:

Bit 12 = 0 Relay 04 is not activated.

Bit 12 = 1 Relay 04 is activated, provided control word bit

12 has been selected in parameter 5-40 Function Relay.

Bit 13/14, Selection of set-up:

Bits 13 and 14 are used to select from the four menu setups according to Table 4.10.

Set-up Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

NOTICE

In parameter 8-55 Set-up Select, a selection is made to

dene how bit 13/14 gates with the corresponding

function on the digital inputs.

Bit 15 Reverse:

Bit 15 = 0 causes no reversing.

Bit 15 = 1 causes reversing.

NOTICE

In the factory setting reversing is set to digital in

parameter 8-54 Reversing Select.

Bit 15 causes reversing only when Ser. communication,

Logic or, or Logic and is selected.

4.4.2 Status Word according to FC Prole

(parameter 8-10 = FC prole)

Illustration 4.6 Status Word

’Bit Bit value = 0 Bit value = 1

00 Control not ready Control ready

01 Frequency converter

not ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved -

06 No error Trip lock

07 No warning Warning

08

Speed ≠ reference

09 Local operation Bus control

10 Out of frequency

limit

11 No operation In operation

12 Frequency converter

ok

13 Voltage ok Voltage exceeded

14 Torque ok Torque exceeded

15 Timer ok Timer exceeded

Frequency converter ready

Speed = reference

Frequency limit ok

Stopped, auto start

4 4

Table 4.10 Selection of Set-up

The function is only possible when [9] Multi set-ups are

selected in parameter 0-10 Active Set-up

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 23

Table 4.11 Status Bits

Page 26

Control

VLT® CANopen MCA 105

Explanation of the status bits

Bit 00, Control not ready/ready:

Bit 00 = 0 means that the frequency converter has tripped.

Bit 00 = 1 means that the frequency converter controls are

ready, but that the power component is not necessarily

receiving any power supply (in case of 24 V external

supply to controls).

Bit 01, Frequency converter ready:

44

Bit 01 = 1. The frequency converter is ready for operation,

but there is an active coasting command via the digital

inputs or via serial communication.

Bit 02, Coasting stop:

Bit 02 = 0 The frequency converter has released the motor.

Bit 02 = 1 The frequency converter can start the motor

when a start command is given.

Bit 03, No error/trip:

Bit 03 = 0 means that the frequency converter is not in

fault mode.

Bit 03 = 1 means that the frequency converter is tripped,

and that a reset signal is required to re-establish operation.

Bit 04, No error/error (no trip):

Bit 04 = 0 means that the frequency converter is not in

fault mode.

Bit 04 = 1 means that there is a frequency converter error

but no trip.

Bit 05, Not used:

Bit 05 is not used in the status word.

Bit 06, No error/triplock:

Bit 06 = 0 means that the frequency converter is not in

fault mode.

Bit 06 = 1 means that the frequency converter is tripped,

and locked.

Bit 07, No warning/warning:

Bit 07 = 0 means that there are no warnings.

Bit 07 = 1 means that a warning has occurred.

Bit 08, Speed ≠ reference/speed = reference:

Bit 08 = 0 means that the motor is running, but that the

present speed is dierent from the preset speed reference.

It might, for example, be the case while the speed is being

ramped up/down during start/stop.

Bit 08 = 1 means that the present motor present speed

matches the preset speed reference.

Bit 09, Local operation/bus control:

Bit 09 = 0 means that [STOP/RESET] is pressed on the

control unit, or that local control in

parameter 3-13 Reference Site is selected. It is not possible

to control the frequency converter via serial communication.

Bit 09 = 1 means that it is possible to control the

frequency converter via the eldbus/ serial communication.

Bit 10, Out of frequency limit:

Bit 10 = 0 if the output frequency has reached the value in

parameter 4-11 Motor Speed Low Limit [RPM] or

parameter 4-13 Motor Speed High Limit [RPM].

Bit 10 = 1 means that the output frequency is within the

dened limits.

Bit 11, No operation/in operation:

Bit 11 = 0 means that the motor is not running.

Bit 11 = 1 means that the frequency converter has a start

signal or that the output frequency is greater than 0 Hz.

Bit 12, Frequency converter OK/stopped, auto start:

Bit 12 = 0 means that there is no temporary overtemperature on the inverter.

Bit 12 = 1 means that the inverter has stopped because of

overtemperature, but that the unit has not tripped and will

resume operation once the overtemperature stops.

Bit 13, Voltage OK/limit exceeded:

Bit 13 = 0 means that there are no voltage warnings.

Bit 13 = 1 means that the DC voltage in the frequency

converter’s DC link is too low or too high.

Bit 14, Torque OK/limit exceeded:

Bit 14 = 0 means that the motor current is lower than the

torque limit selected in parameter 4-18 Current Limit.

Bit 14 = 1 means that the torque limit in

parameter 4-18 Current Limit has been exceeded.

Bit 15, Timer OK/limit exceeded:

Bit 15 = 0 means that the timers for motor thermal

protection and frequency converter thermal protection,

respectively, have not exceeded 100%.

Bit 15 = 1 means that 1 of the timers has exceeded 100%.

24 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 27

Control Programming Guide

4.5 Reference Handling

In both FC prole and CANopen DSP 402, the reference is scaled as a normalised relative value in percent. The value is

transmitted in hexadecimal:

0% = 0 hex.

•

100% = 4000 hex.

•

-100% = C000 hex.

•

Depending of the setting of parameter 3-00 Reference Range, the reference is scaled from – Maximum to + Maximum or from

Minimum to Maximum.

Illustration 4.7 Reference Handling

4 4

The actual reference [Ref. %] in the frequency converter

depends on the settings in the following parameters:

Parameter 1-23 Motor Frequency.

•

Parameter 1-25 Motor Nominal Speed.

•

Parameter 3-02 Minimum Reference.

•

Parameter 3-03 Maximum Reference.

•

All references provided to the frequency converter are

added to the total reference value.

If a reference is to be controlled by the eldbus only,

ensure that all other reference inputs are 0.

This means that digital and analog input terminals should

not be used for reference signals.

Maintain the default setting (0%) for preset references in

parameter 3-10 Preset Reference.

If the bus speed reference is negative, and the control

word contains a run reverse signal, the frequency converter

runs clockwise (- - is +).

MAV is scaled in the same way as the reference.

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 25

Page 28

Parameter Access

VLT® CANopen MCA 105

5 Parameter Access

5.1 Danfoss Specic Objects (2000h-5FFFh)

All frequency converter parameters are accessible as ODentries:

OD index = Frequency converter parameter + 2000h.

Frequency converter parameter CANopen OD index

1 2001h

55

2 2002h

... ...

0-10 200Ah

0-11 200Bh

... ...

1-00 2064h

1-01 2065h

... ...

10-00 23E8h

10-01 23E9h

... ...

Table 5.1 Example of Converting of Frequency Converter

Parameters

Access the indexed parameters by accessing the

appropriate subindex of the OD index.

26 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 29

Parameters Programming Guide

6 Parameters

8-01 Control Site

Option: Function:

The setting in this parameter overrides the

settings in parameter 8-50 Coasting Select to

parameter 8-56 Preset Reference Select.

[0] Digital and

ctrl.word

[1] Digital only Control by using digital inputs only.

[2] Controlword

only

Control by using both digital input and

control word.

Control by using control word only.

8-02 Control Word Source

Option: Function:

NOTICE

This parameter cannot be adjusted

while the motor runs.

Select the source of the control word: 1 of 2

serial interfaces or 4 installed options. During

initial power-up, the frequency converter

automatically sets this parameter to [3] Option

A, if it detects a valid

in slot A. When the option is removed, the

frequency converter detects a conguration

change, sets parameter 8-02 Control Word

Source to default setting RS485, and trips. If

an option is installed after initial power-up,

the setting of parameter 8-02 Control Word

Source does not change, but the frequency

converter trips and shows: Alarm 67, Option

Changed.

When retrotting a bus option into a

frequency converter that did not have a bus

option installed earlier, change the control to

bus-based. This change is required for safety

reasons to avoid an unintended change.

[0] None

[1] FC RS485

[2] FC USB

[3] Option A

[4] Option B

[5] Option C0

[6] Option C1

[30] External Can

8-03 Control Word Timeout Time

Range: Function:

1 s* [ 0.1 -

18000 s]

Enter the maximum time expected to pass

between the reception of 2 consecutive

telegrams. If this time is exceeded, it indicates

eldbus option installed

8-03 Control Word Timeout Time

Range: Function:

that the telegram communication has stopped.

The function selected in parameter 8-04 Control

Word Timeout Function is then carried out. A

valid control word triggers the timeout counter.

8-04 Control Word Timeout Function

Select the timeout function. The timeout function activates when

the control word fails to be updated within the time period

specied in parameter 8-03 Control Word Timeout Time.

Option: Function:

NOTICE

To change the set-up after a timeout,

congure as follows:

Set parameter 0-10 Active Set-up to [9]

Multi set-up and select the relevant

link in parameter 0-12 This Set-up

Linked to.

[0] O Resumes control via eldbus (eldbus or

standard), using the most recent control

word.

[1] Freeze output Freezes output frequency until communi-

cation resumes.

[2] Stop Stops with auto restart when communi-

cation resumes.

[3] Jogging Runs the motor at jog frequency until

communication resumes.

[4] Max. speed Runs the motor at maximum frequency until

communication resumes.

[5] Stop and trip Stops the motor, then resets the frequency

converter to restart:

Via the eldbus.

•

Via [Reset].

•

Via a digital input.

•

[7] Select setup1Changes the set-up after reestablishment of

communication following a control word

timeout. If communication resumes after a

timeout, parameter 8-05 End-of-Timeout

Function denes whether to resume the set-

up used before the timeout, or to retain the

set-up endorsed by the time-out function.

[8] Select setup2See [7] Select set-up 1.

[9] Select setup3See [7] Select set-up 1.

6

6

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 27

Page 30

Parameters

VLT® CANopen MCA 105

6

8-04 Control Word Timeout Function

Select the timeout function. The timeout function activates when

the control word fails to be updated within the time period

specied in parameter 8-03 Control Word Timeout Time.

Option: Function:

[10] Select setup4See [7] Select set-up 1.

[26] Trip

8-05 End-of-Timeout Function

Option: Function:

Select the action after receiving a valid control

word following a timeout. This parameter is

active only when parameter 8-04 Control

Timeout Function is set to:

[7] Set-up 1.

•

[8] Set-up 2.

•

[9] Set-up 3.

•

[10] Set-up 4.

•

[0] Hold set-upRetains the set-up selected in

parameter 8-04 Control Timeout Function and

shows a warning until parameter 8-06 Reset

Control Timeout toggles. Then the frequency

converter resumes its original set-up.

[1] * Resume

set-up

Resumes the set-up active before the timeout.

8-06 Reset Control Word Timeout

This parameter is active only when [0] Hold set-up has been

selected in parameter 8-05 End-of-Timeout Function.

Option: Function:

[0] * Do not reset Retains the set-up specied in

parameter 8-04 Control Word Timeout Function,

following a control word timeout.

[1] Do reset Returns the frequency converter to the

original set-up following a control word

timeout. The frequency converter performs

the reset and then immediately reverts to the

[0] Do not reset setting.

8-07 Diagnosis Trigger

Option: Function:

This parameter enables and controls the

frequency converter diagnosis function and

permits expansion of the diagnosis data to 24

byte.

8-07 Diagnosis Trigger

Option: Function:

•

•

•

The content of the extended diagnosis frame is

as follows:

Byte Content Description

0 - 5 Standard DP

6 PDU lengthxxHeader of extended

7 Status type =

8 Slot = 0 Header of extended

9 Status info =0Header of extended

10 - 13 VLT

14 - 17 VLT

18 - 21 VLT

22 - 23 VLT

[0] Disable: Do not send extended

diagnosis data even if they appear in

the frequency converter.

[1] Trigger on alarms: Send extended

diagnosis data when one or more

alarms appear in alarm

parameter 16-90 Alarm Word or

parameter 9-53 Probus Warning Word.

[2] Trigger alarms/warn.: Send extended

diagnosis data if one or more alarms or

warnings appear in alarm

parameter 16-90 Alarm Word,

parameter 9-53 Probus Warning Word,

or warning parameter 16-92 Warning

Word.

Standard DP Diagnose

Diagnose

Data

0x81

parameter 16-

92 Warning

Word

parameter 16-

03 Status

Word

parameter 16-

90 Alarm

Word

parameter 9-5

3 Probus

Warning Word

Data

diagnostic data

Header of extended

diagnostic data

diagnostic data

diagnostic data

VLT warning word

VLT status word

VLT alarm word

Communication

warning word (Probus)

NOTICE

Table 6.1

This is only valid for Probus.

Enabling diagnosis may cause increased bus

trac. Diagnosis functions are not supported by

all eldbus types.

[0]*Disable

28 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 31

Parameters Programming Guide

8-07 Diagnosis Trigger

Option: Function:

[1] Trigger

on

alarms

[2] Trigger

alarm/

warn.

8-08 Readout Filtering

If the speed feedback value readouts on eldbus are uctuating,

this function is used. Select ltered, if the function is required. A

power cycle is required for changes to take eect.

Option: Function:

[0] Motor Data

Std-Filt.

[1] Motor Data

LP-Filter

Normal eldbus readouts.

Filtered eldbus readouts of the following

parameters:

Parameter 16-10 Power [kW ].

•

Parameter 16-11 Power [hp].

•

Parameter 16-12 Motor Voltage.

•

Parameter 16-14 Motor current.

•

Parameter 16-16 Torque [Nm].

•

Parameter 16-17 Speed [RPM].

•

Parameter 16-22 Torque [%].

•

Parameter 16-25 Torque [Nm]

•

High.

8-10 Control Word Prole

Select the interpretation of the control and status words

corresponding to the installed eldbus. Only the selections valid

for the eldbus installed in slot A are visible in the LCP display.

For guidelines in selection of [0] Frequency converter prole and

[1] PROFIdrive prole, refer to the design guide of the related

product.

For more guidelines in the selection of [1] PROFIdrive prole, [5]

ODVA and [7] CANopen DSP 402, see the installation guide for the

installed eldbus.

Option: Function:

[0] * FC prole

[1] PROFIdrive prole

[5] ODVA

[7] CANopen DSP 402

[8] MCO

8-13 Congurable Status Word STW

Option: Function:

This parameter enables conguration of bits

12–15 in the status word.

[0] No function

[1] * Prole Default Function corresponds to the prole default

selected in parameter 8-10 Control Prole.

8-13 Congurable Status Word STW

Option: Function:

[2] Alarm 68

Only

[3] Trip excl.

Alarm 68

[10] T18 DI status. The bit indicates the status of terminal 18.

[11] T19 DI status. The bit indicates the status of terminal 19.

[12] T27 DI status. The bit indicates the status of terminal 27.

[13] T29 DI status. The bit indicates the status of terminal 29.

[14] T32 DI status. The bit indicates the status of terminal 32.

[15] T33 DI status. The bit indicates the status of terminal 33.

[16] T37 DI status The bit indicates the status of terminal 37.

[21] Thermal

warning

[30] Brake fault

(IGBT)

[40] Out of ref.

range

[60] Comparator 0 See parameter group 13-1* Comparators. If

[61] Comparator 1 See parameter group 13-1* Comparators. If

[62] Comparator 2 See parameter group 13-1* Comparators. If

[63] Comparator 3 See parameter group 13-1* Comparators. If

[64] Comparator 4 See parameter group 13-1* Comparators. If

Only set in case of an Alarm 68.

Set in case of a trip, except if Alarm 68

executes the trip.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

0 indicates that the terminal is low.

1 indicates that the terminal is high.

0 indicates terminal 37 is low (Safe Torque

stop).

1 indicates terminal 37 is high (normal).

The thermal warning turns on when the

temperature exceeds the limit in the motor,

the frequency converter, the brake resistor,

or the thermistor.

Output is logic 1 when the brake IGBT is

short-circuited. Use this function to protect

the frequency converter if there is a fault

on the brake modules. Use the output/relay

to cut out the main voltage from the

frequency converter.

comparator 0 is evaluated as TRUE, the

output goes high. Otherwise, it is low.

comparator 1 is evaluated as TRUE, the

output goes high. Otherwise, it is low.

comparator 2 is evaluated as TRUE, the

output goes high. Otherwise, it is low.

comparator 3 is evaluated as TRUE, the

output goes high. Otherwise, it is low.

comparator 4 is evaluated as TRUE, the

output goes high. Otherwise, it is low.

6

6

MG92G102 Danfoss A/S © 06/2015 All rights reserved. 29

Page 32

Parameters

VLT® CANopen MCA 105

6

8-13 Congurable Status Word STW

Option: Function:

[65] Comparator 5 See parameter group 13-1* Comparators. If

comparator 5 is evaluated as TRUE, the

output goes high. Otherwise, it is low.

[70] Logic Rule 0 See parameter group 13-4* Logic Rules. If

logic rule 0 is evaluated as TRUE, the output

goes high. Otherwise, it is low.

[71] Logic Rule 1 See parameter group 13-4* Logic Rules. If

logic rule 1 is evaluated as TRUE, the output

goes high. Otherwise, it is low.

[72] Logic Rule 2 See parameter group 13-4* Logic Rules. If

logic rule 2 is evaluated as TRUE, the output

goes high. Otherwise, it is low.

[73] Logic Rule 3 See parameter group 13-4* Logic Rules. If

logic rule 3 is evaluated as TRUE, the output

goes high. Otherwise, it is low.

[74] Logic Rule 4 See parameter group 13-4* Logic Rules. If

logic rule 4 is evaluated as TRUE, the output

goes high. Otherwise, it is low.

[75] Logic Rule 5 See parameter group 13-4* Logic Rules. If

logic rule 5 is evaluated as TRUE, the output

goes high. Otherwise, it is low.

[80] SL Digital

Output A

[81] SL Digital

Output B

[82] SL Digital

Output C

[83] SL Digital

Output D

[84] SL Digital

Output E

[85] SL Digital

Output F

See parameter 13-52 SL Controller Action. The

output goes high whenever the smart logic

action [38] Set digital out A high is executed.

The output goes low whenever the smart

logic action [32] Set digital out A low is

executed.

See parameter 13-52 SL Controller Action. The

input goes high whenever the smart logic

action [39] Set digital out B high is executed.

The input goes low whenever the smart

logic action [33] Set digital out B low is

executed.

See parameter 13-52 SL Controller Action. The

input goes high whenever the smart logic

action [40] Set digital out C high is executed.

The input goes low whenever the smart

logic action [34] Set digital out C low is

executed.

See parameter 13-52 SL Controller Action. The

input goes high whenever the smart logic

action [41] Set digital out D high is executed.

The input goes low whenever the smart

logic action [35] Set digital out D low is

executed.

See parameter 13-52 SL Controller Action. The

input goes high whenever the smart logic

action [42] Set digital out E high is executed.

The input goes low whenever the smart

logic action [36] Set digital out E low is

executed.

See parameter 13-52 SL Controller Action. The

input goes high whenever the smart logic

action [43] Set digital out F high is executed.

8-13 Congurable Status Word STW

Option: Function:

The input goes low whenever the smart

logic action [37] Set digital out F low is

executed.

8-14 Congurable Control Word CTW

Option: Function:

This parameter is not valid in software versions

below 4.93.

[0] None The information in this bit is ignored by the

frequency converter.

[1]*Prole

default

[2] CTW

Valid,

active

low

[3] Safe

Option

Reset

[4] PID error

inverse

[5] PID reset

I part

[6] PID

enable

The functionality of the bit is depending on the

selection parameter 8-10 Control Word Prole.

If set to 1, the frequency converter ignores the

remaining bits of the Control Word.

This function is only available in bits 12-15 of the

control word, if a a safe option is mounted in

the frequency converter. The reset is executed on

a 0->1 transition, and reset the safe option as set

in parameter 42-24.

When enabled, it inverts the resulting error from

the process PID controller. Available only if

parameter 1-00 Conguration Mode is set to [6]

Surface Winder, [7] Extended PID Speed OL or [8]

Extended PID Speed CL.

When enabled, resets the I-part of the process

PID controller. Equivalent to

parameter 7-40 Process PID I-part Reset. Available

only if parameter 1-00 Conguration Mode is set

to [6] Surface Winder, [7] Extended PID Speed OL

or [8] Extended PID Speed CL.

When enabled, enables the extended process

PID controller. Equivalent to

parameter 7-50 Process PID Extended PID.

Available only if parameter 1-00 Conguration

Mode is set to [6] Surface Winder, [7] Extended PID

Speed OL or [8] Extended PID Speed CL.

8-17 Congurable Alarm and Warningword

The congurable alarm and warning word has 16 bits (0-15).

Each of those bits can be congured to any of the following

options.

Option: Function:

[0] * O

[1] 10 Volts low warning

[2] Live zero warning

[3] No motor warning

[4] Mains phase loss warning

[5] DC link voltage high warning

[6] DC link voltage low warning

[7] DC overvoltage warning

30 Danfoss A/S © 06/2015 All rights reserved. MG92G102

Page 33

Parameters Programming Guide

8-17 Congurable Alarm and Warningword

The congurable alarm and warning word has 16 bits (0-15).

Each of those bits can be congured to any of the following

options.

Option: Function:

[8] DC undervoltage warning

[9] Inverter overloaded warning

[10] Motor ETR overtemp warning

[11] Motor thermistor overtemp warning

[12] Torque limit warning

[13] Over current warning

[14] Earth fault warning

[17] Controlword timeout warning

[19] Discharge temp high warning

[22] Hoist mech brake warning

[23] Internal fans warning

[24] External fans warning

[25] Brake resistor short circuit warning

[26] Brake powerlimit warning

[27] Brake chopper short circuit warning

[28] Brake check warning

[29] Heatsink temperature warning

[30] Motor phase U warning

[31] Motor phase V warning

[32] Motor phase W warning

[34] Fieldbus communication warning

[36] Mains failure warning

[40] T27 overload warning

[41] T29 overload warning

[45] Earth fault 2 warning

[47] 24V supply low warning

[58] AMA internal fault warning

[59] Current limit warning

[60] External interlock warning

[61] Feedback error warning

[62] Frequency max warning

[64] Voltage limit warning

[65] Controlboard overtemp warning

[66] Heatsink temp low warning

[68] Safe stop warning

[73] Safe stop autorestart warning

[76] Power unit setup warning

[77] Reduced powermode warning

[78] Tracking error warning

[89] Mech brake sliding warning

[163] ATEX ETR cur limit warning

[165] ATEX ETR freq limit warning

[10002] Live zero error alarm

[10004] Mains phase loss alarm

[10007] DC overvoltage alarm

[10008] DC undervoltage alarm

[10009] Inverter overload alarm

[10010] ETR overtemperature alarm

[10011] Thermistor overtemp alarm

8-17 Congurable Alarm and Warningword

The congurable alarm and warning word has 16 bits (0-15).

Each of those bits can be congured to any of the following

options.