MAKING MODERN LIVING POSSIBLE

Programming Guide

VLT® DeviceNet MCA 104

VLT® Frequency Converter Series • FC 102 • FC 202 • FC 301/302

vlt-drives.danfoss.com

Contents Programming Guide

Contents

1 Introduction

1.1 Purpose of the Manual

1.2 Additional Resources

1.3 Document and Software Version

1.4 Product Overview

1.5 Approvals and Certications

1.6 Symbols, Abbreviations and Conventions

2 Safety

2.1 Safety Symbols

2.2 Qualied Personnel

2.3 Safety Precautions

3 Conguration

3.1 Congure the DeviceNet Network

3.2 Congure the Master

3.3 Congure the Frequency Converter

3

3

3

3

3

4

4

5

5

5

5

7

7

8

8

4 Control

4.1 DeviceNet Process Control Modes

4.2 I/O Assembly Instances

4.3 Process Data

4.4 ODVA Control Prole

4.5 FC Control Prole

5 Parameter Access

5.1 Explicit Messages

5.2 Object Classes

5.3 DeviceNet Object Classes

5.4 Danfoss Object Classes

6 Parameters

6.1 Parameter Description

6.2 Parameter List

6.3 Data Types Supported

9

9

10

10

11

13

17

17

17

18

27

28

28

36

37

7 Application Examples

7.1 Example: Working with Instance 101/151 Process

8 Troubleshooting

8.1 LED Status

8.2 No Communication with the Frequency Converter

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 1

38

38

40

40

41

Contents

VLT® DeviceNet MCA 104

8.3 Frequency Converter Does Not Respond to Control Signals

8.4 Warnings and Alarms

Index

41

44

46

2 Danfoss A/S © 12/2015 All rights reserved. MG92F102

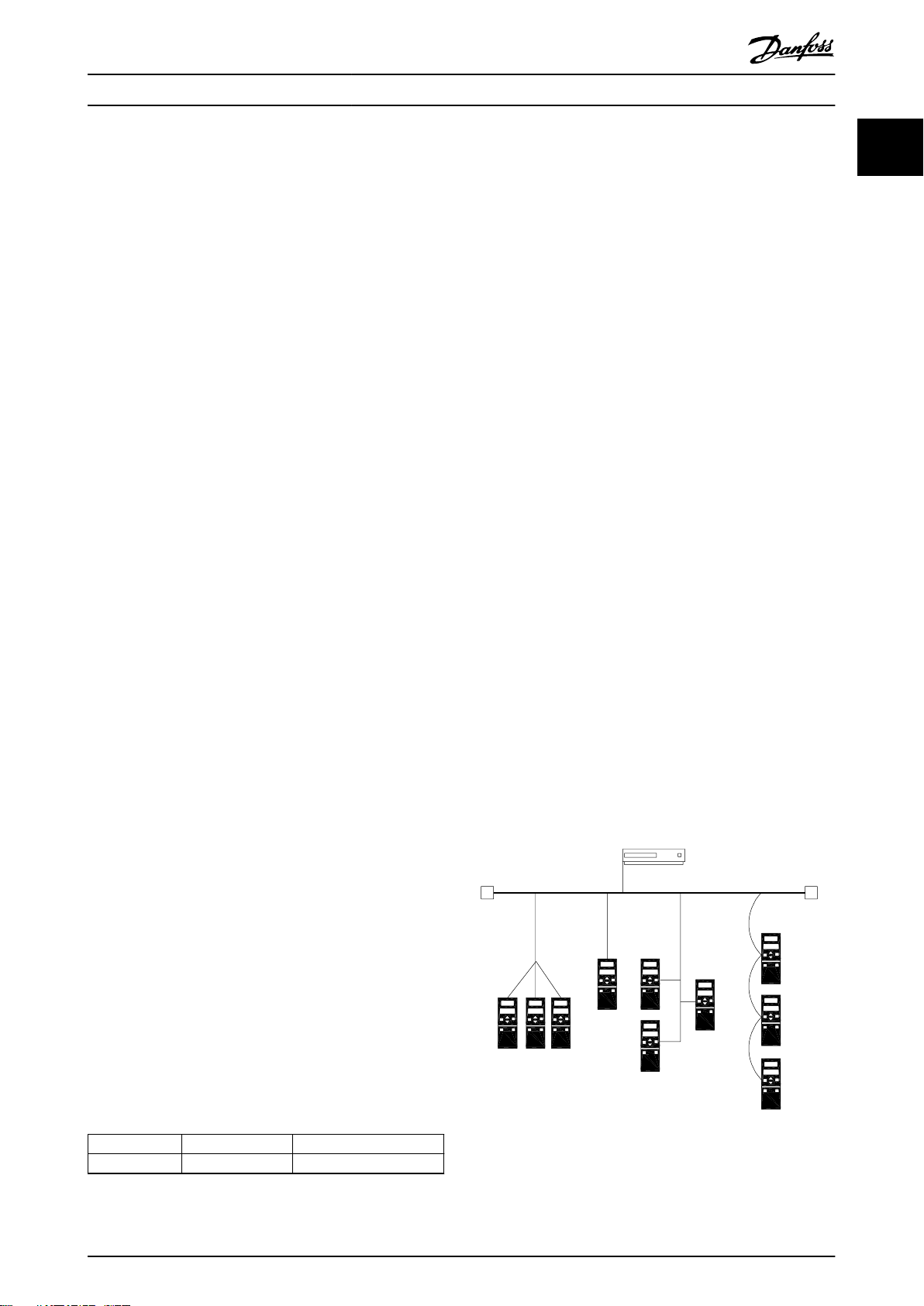

24 V

Trunk line

Power supply

Drop lines 1

RT=Termination resistors

R

T

R

T

195NA228.10

1 1 1

1

Introduction Programming Guide

1 Introduction

1.1 Purpose of the Manual

The VLT® DeviceNet MCA 104 Programming Guide provides

information about conguring the system, controlling the

frequency converter, parameter access, programming,

troubleshooting, and some typical application examples.

The programming guide is intended for use by qualied

personnel who are familiar with the VLT® frequency

converter, with DeviceNet technology, and with the PC or

PLC that is used as a master in the system.

Read the instructions before programming and follow the

procedures in this manual.

VLT® is a registered trademark.

1.2 Additional Resources

Resources available for the VLT® frequency converter and

optional equipment:

The VLT® Operating Instructions provide the

•

necessary information for getting the VLT

frequency converter up and running.

The VLT® Design Guide provides detailed

•

information about capabilities and functionality

to design motor control systems.

The VLT® Programming Guide provides greater

•

detail on working with parameters and many

application examples.

The VLT® DeviceNet MCA 104 Installation Guide

•

provides information about installing the

DeviceNet and troubleshooting.

The VLT® DeviceNet MCA 104 Programming Guide

•

provides information about conguring the

system, controlling the VLT® frequency converter,

parameter access, programming, troubleshooting,

and some typical application examples.

Supplementary publications and manuals are available

from Danfoss. See vlt-drives.danfoss.com/Support/Technical-

Documentation/ for listings.

®

Product Overview

1.4

This programming guide relates to the DeviceNet interface.

Ordering number:

130B1102 (non-coated version).

•

130B1210 (conformal coated version).

•

DeviceNet is a low-level network that standardizes

communications between industrial devices (sensors, limit

switches, motor controls) and high-level devices

(controllers). DeviceNet follows the Open Systems Interconnection (OSI) model and is based on CAN technology for

media access control and physical signaling.

DeviceNet systems can be congured to operate in a

master/slave or a distributed control architecture using

peer-to-peer communication. Up to 63 nodes in a multidrop network topology are supported. By using the same

cable for communication, communication options can be

powered directly from the bus. Nodes can be removed or

inserted without powering down the network.

Each node on the network has its own unique media

access control identier (MAC ID) to distinguish it on the

network. The access control is based on the CSMA/CA

(carrier sense multiple access/collision avoidance) principle,

meaning that all nodes may have access to the network at

the same time. When 2 nodes attempt to get control of

the network bus simultaneously, the CAN protocol resolves

the issue by arbitration. In this way, collisions on the

network are avoided.

DeviceNet denes device proles for devices belonging to

specic classes. For other devices, dene a custom class to

make it DeviceNet compatible. All the above enhances the

interchangeability and interoperability of the network.

1 1

1.3

This manual is regularly reviewed and updated. All

suggestions for improvement are welcome. Table 1.1 shows

the document version and the corresponding software

version.

Table 1.1 Document and Software Version

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 3

Document and Software Version

Edition Remarks Software version

MG92F1xx First edition. 4.4x

Illustration 1.1 Topology

Introduction

VLT® DeviceNet MCA 104

11

VLT® DeviceNet MCA 104 is designed to communicate with

any master abiding by the DeviceNet standard. It is

intended for use with:

VLT® HVAC Drive FC 102

•

VLT® AQUA Drive FC 202

•

VLT® AutomationDrive FC 301/FC 302

•

1.5 Approvals and Certications

More approvals and certications are available. For more

information, contact a local Danfoss partner.

1.6 Symbols, Abbreviations and

Conventions

Abbreviation Denition

ACK ACKnowledge

BOC Bus o counter

BOOL Boolean expression

CAN Controller area network

CSMA/CA Carrier sense multiple access/collision avoidance

COS Change of state

CTW Control word

EDS Electronic data sheet

EMC Electromagnetic compatibility

ETR Electronic thermal relay

FIFO First in rst out

HF High frequency

HPFB High performance eldbus

I/O Input/output

ISO International standards organization

LCD Liquid crystal display

LED Light emitting diode

LSB Least signicant bit

MAC ID Media access control identier

MAV Main actual value

MRV Main reference value

MSB Most signicant bit

N/A Not applicable

ODVA Open DeviceNet Vendor Association

OSI Open systems interconnection

PC Personal computer

PCD Process data

PIW Peripheral input word

PLC Programmable logic control

PNU Parameter number

PPO Parameter-process data object

QW Peripheral output word

Abbreviation Denition

SINT Signed integer

STW Status word

VSD Variable speed drive

UDINT Unsigned double integer

UNIT Unsigned integer

USINT Unsigned short integer

Table 1.2 Symbols and Abbreviations

Conventions

Numbered lists indicate procedures.

Bullet lists indicate other information.

Italicized text indicates:

Cross reference.

•

Link.

•

Parameter name.

•

Parameter group name.

•

Parameter option.

•

Footnote.

•

4 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Safety Programming Guide

2 Safety

2.1 Safety Symbols

The following symbols are used in this manual:

WARNING

Indicates a potentially hazardous situation that could

result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation that could

result in minor or moderate injury. It can also be used to

alert against unsafe practices.

NOTICE

Indicates important information, including situations that

can result in damage to equipment or property.

2.2 Qualied Personnel

Correct and reliable transport, storage, installation,

operation, and maintenance are required for the troublefree and safe operation of the frequency converter. Only

qualied personnel are allowed to install and operate this

equipment.

Qualied personnel are dened as trained sta, who are

authorized to install, commission, and maintain equipment,

systems, and circuits in accordance with pertinent laws and

regulations. Additionally, the qualied personnel must be

familiar with the instructions and safety measures

described in these operating instructions.

Safety Precautions

2.3

WARNING

HIGH VOLTAGE

Frequency converters contain high voltage when

connected to AC mains input, DC supply, or load sharing.

Failure to perform installation, start-up, and maintenance

by qualied personnel can result in death or serious

injury.

Only qualied personnel must perform instal-

•

lation, start-up, and maintenance.

WARNING

UNINTENDED START

When the frequency converter is connected to AC mains,

DC supply, or load sharing, the motor may start at any

time. Unintended start during programming, service, or

repair work can result in death, serious injury, or

property damage. The motor can start with an external

switch, a eldbus command, an input reference signal

from the LCP or LOP, via remote operation using MCT 10

Set-up Software, or after a cleared fault condition.

To prevent unintended motor start:

Press [O/Reset] on the LCP before

•

programming parameters.

Disconnect the frequency converter from the

•

mains.

Completely wire and assemble the frequency

•

converter, motor, and any driven equipment

before connecting the frequency converter to

AC mains, DC supply, or load sharing.

WARNING

DISCHARGE TIME

The frequency converter contains DC-link capacitors that

can remain charged even when the frequency converter

is not powered. Failure to wait the specied time after

power has been removed before performing service or

repair work can result in death or serious injury.

Stop the motor.

•

Disconnect the AC mains and remote DC-link

•

supplies, including battery back-ups, UPS, and

DC-link connections to other frequency

converters.

Disconnect or lock the PM motor.

•

Wait for the capacitors to discharge fully before

•

performing any service or repair work. The

waiting time is specied in the relevant

frequency converter operating instructions,

Chapter 2 Safety.

WARNING

LEAKAGE CURRENT HAZARD

Leakage currents exceed 3.5 mA. Failure to ground the

frequency converter properly can result in death or

serious injury.

Ensure the correct grounding of the equipment

•

by a certied electrical installer.

2 2

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 5

Safety

VLT® DeviceNet MCA 104

WARNING

EQUIPMENT HAZARD

22

Contact with rotating shafts and electrical equipment

can result in death or serious injury.

Ensure that only trained and qualied personnel

•

perform installation, start-up, and maintenance.

Ensure that electrical work conforms to national

•

and local electrical codes.

Follow the procedures in this guide.

•

CAUTION

INTERNAL FAILURE HAZARD

An internal failure in the frequency converter can result

in serious injury when the frequency converter is not

properly closed.

Ensure that all safety covers are in place and

•

securely fastened before applying power.

6 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Conguration Programming Guide

3 Conguration

3.1 Congure the DeviceNet Network

All DeviceNet stations that are connected to the same bus

network must have a unique station address. Select the

DeviceNet address of the frequency converter via:

Address switches (default 63).

•

Parameter 10-02 MAC ID (default 63).

•

Class code 0X03, instance 1, attribute 1.

•

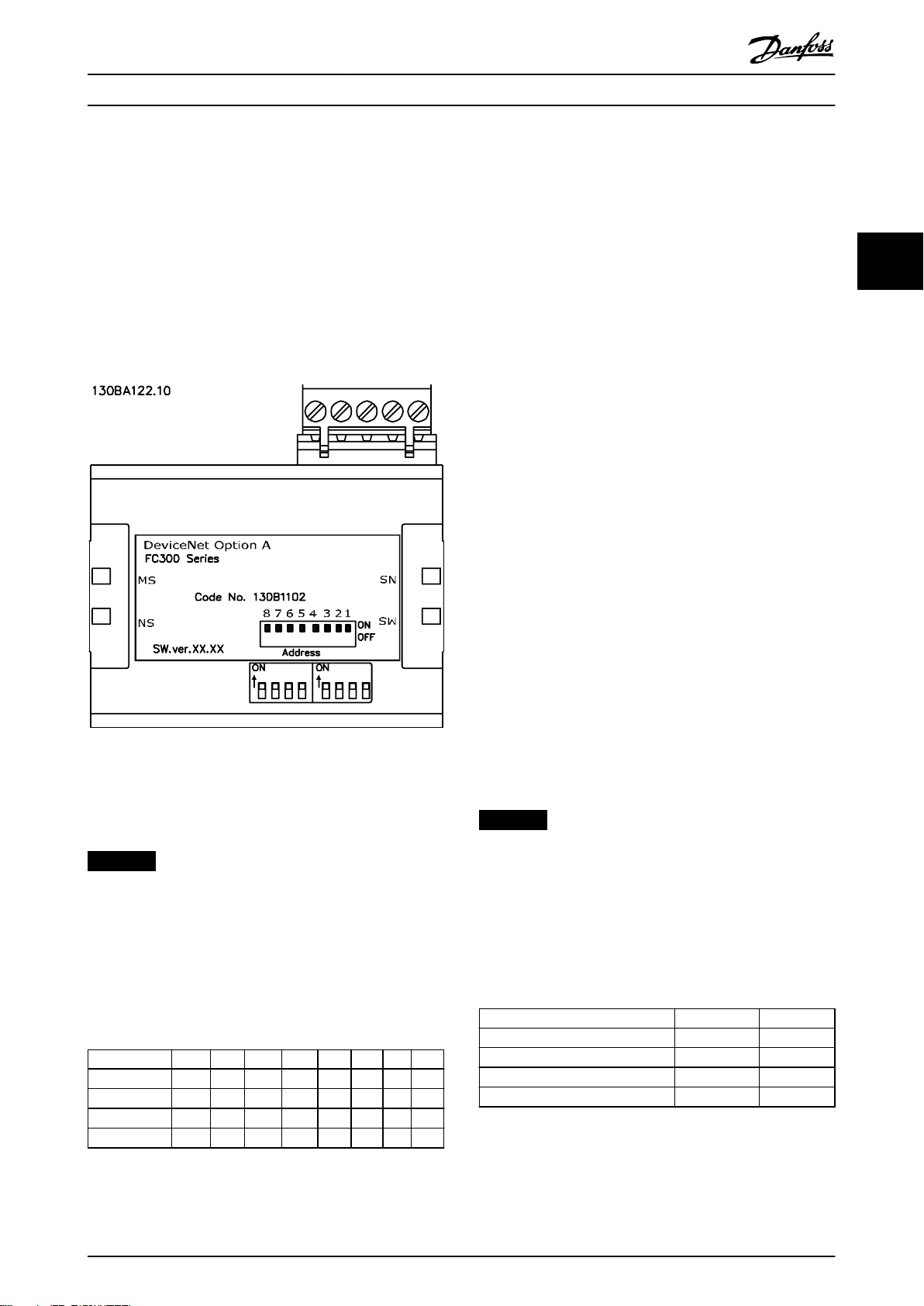

Illustration 3.1 VLT

®

DeviceNet MCA 104 Interface

3.1.1 Setting the DeviceNet Address using

the Address Switches

NOTICE

Switch o the power supply before changing the address

switches. The address change comes into eect at the

next power-up, and can be read in parameter 10-02 MAC

ID.

Set the address switches to give the option a unique ID.

Select an address range from 0–63 (factory setting 63)

according to Table 3.1.

Switch 8 7 6 5 4 3 2 1

Address value – – +32 +16 +8 +4 +2 +1

5 – – OFF OFF OFF ON OFF ON

20 – – OFF ON OFF ON OFF OFF

35 – – ON OFF OFF OFF ON ON

3.1.2 Setting the DeviceNet Address via

Parameter 10-02 MAC ID

Set the address via parameter 10-02 MAC ID if the hardware

switches are set to 63 (factory setting). The address change

comes into eect at the next power-up.

3.1.3 Setting the DeviceNet Address with

the Object Class Code 0x03, Instance

1, Attribute 1

Set the address via the DeviceNet object class code 0x03

attribute 1 command when the address switch is set to 63

(factory setting). A new address becomes eective

immediately after the class code 0x03, instance 1, attribute

1 command.

3.1.4 Setting the Baud Rate

All DeviceNet stations connected to the same bus network

must have the same baud rate. Select the baud rate of the

frequency converter via:

Address switches.

•

Parameter 10-01 Baud Rate Select (default 125

•

kBd).

Object class code 0x03, instance 1, attribute 2.

•

3.1.5 Setting the DeviceNet Baud Rate

using the Address Switches

NOTICE

Switch o the power supply before changing the address

switches. The baud rate change comes into eect at the

next power-up, and can be read in parameter 10-01 Baud

Rate Select.

Use the address switches to select a baud rate of 125 k

baud (factory setting), 250 k baud, or 500 k baud, see

Table 3.2:

Baud rate switch 8 7

Parameter 10-01 Baud Rate Select 1 1

125 kBd 0 0

250 kBd 0 1

500 kBd 1 0

Table 3.2 Address Switches

3 3

Table 3.1 Settings for the Address Switches

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 7

Conguration

VLT® DeviceNet MCA 104

3.1.6 Setting the DeviceNet Baud Rate via

3.3 Congure the Frequency Converter

Parameter 10-01 Baud Rate Select

3.3.1 Frequency Converter Parameters

Set the baud rate via parameter 10-01 Baud Rate Select if

the address switches 1 and 2 are set to ON (factory

33

setting). The baud rate change comes into eect at the

next power-up.

3.1.7 Setting the DeviceNet Baud Rate with

the Object Class Code 0x03, Attribute

2

Set the baud rate via the DeviceNet object class code 0x03

attribute 2 command, when the address switches 1 and 2

are set to ON (factory setting). A new baud rate becomes

eective immediately after the class code 0x03 attribute 2

command.

3.2 Congure the Master

3.2.1 EDS File

A large part area of the system conguration is the setting

of application-related parameters. EDS (Electronic Data

Sheet) les simplify the setting up of most of the

DeviceNet congurable parameters. For o-line congu-

ration, Danfoss provides a generic English EDS le covering

all voltage and power sizes. Download the EDS le from

www.danfoss.com/drives.

NOTICE

The EDS le does not contain all parameters. It contains

only a selected, limited number of parameters with

generic minimum, maximum, and default values.

Note the following parameters when conguring the

frequency converter with a DeviceNet interface. Refer to

chapter 6 Parameters for more details of each parameter.

Parameter 0-40 [Hand on] Key on LCP.

•

If the Hand key on the frequency converter is

activated, control of the frequency converter via

the DeviceNet interface is disabled. After initial

power-up the frequency converter automatically

detects whether a eldbus option is installed in

slot A, and sets parameter 8-02 Control Word

Source to [3] Option A. If an option is added to,

changed in, or removed from an already commissioned frequency converter, it does not change

parameter 8-02 Control Word Source but enters trip

mode, and the frequency converter shows an

error.

Parameter 8-10 Control Word Prole (see

•

chapter 4 Control). Select between the Danfoss FC

Prole and the ODVA prole. Select the desired

DeviceNet instance in parameter 10-10 Process

Data Type Selection.

Parameter 8-50 Coasting Select to

•

parameter 8-56 Preset Reference Select (see

chapter 6 Parameters). Selection of how to gate

the DeviceNet control commands with digital

input command of the control card.

NOTICE

When parameter 8-01 Control Site is set to [2] Control

word only, the settings in parameter 8-50 Coasting Select

to parameter 8-56 Preset Reference Select is overruled,

and all act on bus control.

Parameter 8-03 Control Word Timeout Time to

•

parameter 8-05 End-of-Timeout Function. The

reaction in the event of a bus timeout is set via

these parameters.

Parameter 10-10 Process Data Type Selection.

•

Default is 125 kbps.

Parameter 10-02 MAC ID. Default is 63.

•

8 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Control Programming Guide

4 Control

4.1 DeviceNet Process Control Modes

This section describes 2 of 3 possible process control

modes:

Polling.

•

Change of state (COS).

•

The 3rd FC control mode uses the acyclic mode explicit

messaging via the standard DeviceNet control supervisory

object class 29H. The control supervisory object is

described in chapter 5.3 DeviceNet Object Classes.

4.1.1 Polling

Table 4.1 is a classic master/slave connection and the

standard DeviceNet operating mode. The master controls

the data exchange by sending cyclic poll-requests to the

connected slave, and the slave answers by sending a pollresponse to the master. The master can control and

monitor the frequency converter by polling the DeviceNet

or Danfoss objects (I/O instances).

Master

Slave

Table 4.1 Standard DeviceNet Operation Mode - Polled I/O

Slave

⇒

Master

⇒

CTW MRV

STW MAV

4.1.2 Change of State, COS

COS is an event-controlled operating mode used to minimize network trac. Messages are transmitted only if a dened

state or value has changed. The condition for triggering a COS message is determined by the insertion of COS-lters

(parameter 10-20 COS Filter 1 to parameter 10-23 COS Filter 4), for each bit in the dierent PCD words. The lter acts like a

logical AND function: If a bit in the lter is set to 1, the COS function triggers after a change to the corresponding bit for

the PCD word.

4 4

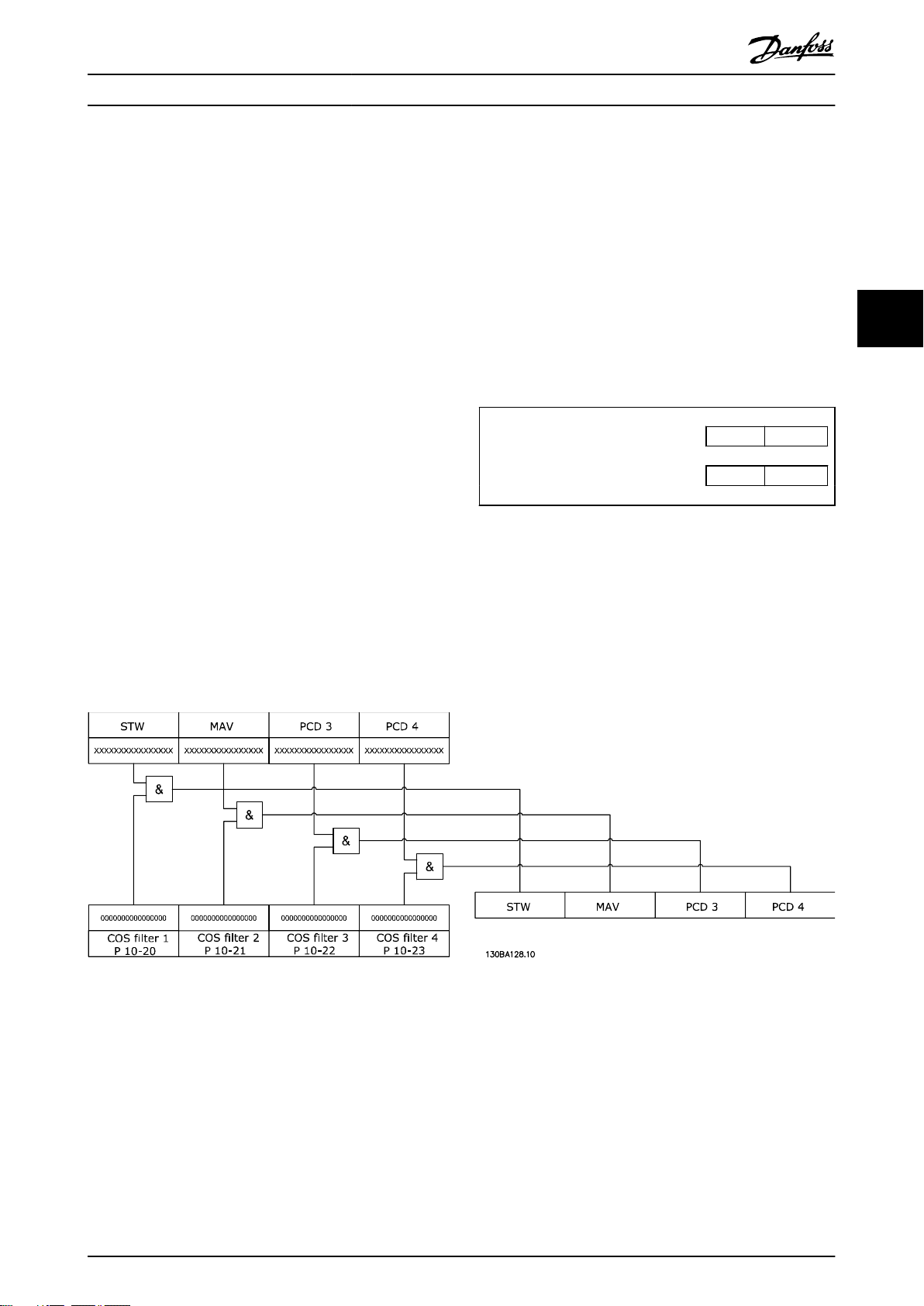

Illustration 4.1 Dierent PCDs and the Corresponding Filter Parameters

Parameter 10-20 COS Filter 1 to parameter 10-23 COS Filter 4 can be used to lter out undesired events for COS. If a lter bit is

set to 0, the corresponding I/O instance bit is unable to produce a COS message. By default, all bits in the COS lters are set

to 0.

To signal that the connection has not been interrupted, or the device is not powered o, a heartbeat message is

transmitted within a specied time interval (heartbeat interval). This interval is dened in attribute heartbeat time of the

connection object, class code 0x05.

To prevent the device from producing heavy network trac if a value changes frequently, the production inhibit time (an

attribute of the connection object) is dened. This parameter denes the minimum time between 2 COS messages.

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 9

Control

The attribute expected package rate denes the maximum time between 2 COS messages even when the value is

unchanged. In the event of COS connection, the explicit package rate is identical with the heartbeat interval mentioned

above. This timer is used both as transmission trigger and inactivity watchdog, depending on whether the connection is

producer or consumer.

VLT® DeviceNet MCA 104

4.2 I/O Assembly Instances

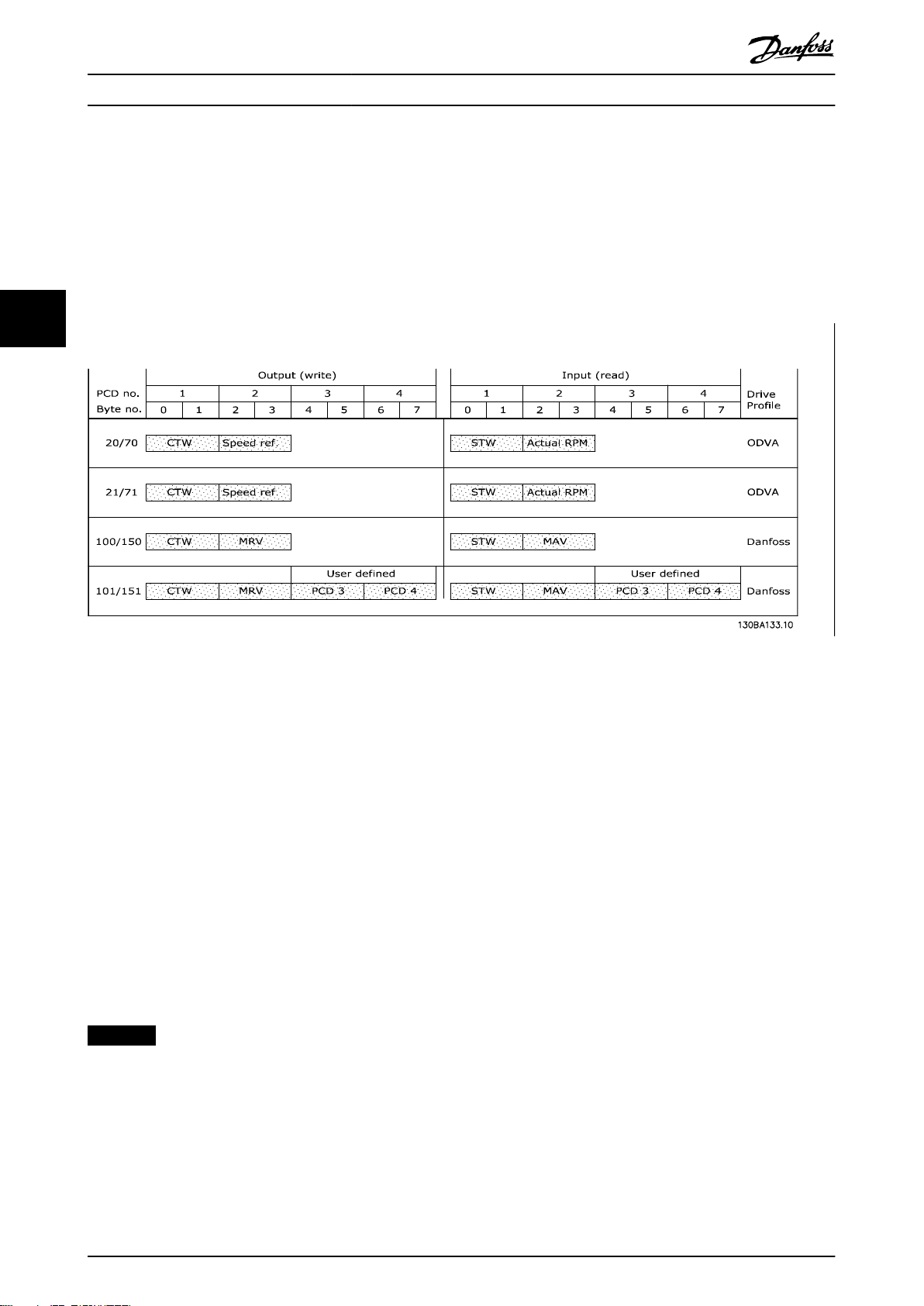

I/O assembly instances are several

information. Illustration 4.2 shows the I/O assembly instance options for controlling and monitoring the frequency converter.

dened process control objects with dened content comprising control and status

44

Illustration 4.2 I/O Assembly Instance Options

4.3 Process Data

Process data comprises the control and status data in the I/O assembly instances.

The CTW, MRV, STW, and MAV have

4 are freely congurable, for instance 101/151 via parameter 10-11 Process Data Cong Write and parameter 10-12 Process

Data Cong Read.

All PCDs are freely congurable for instance 102/152.

DeviceNet provides a exible way to customize the number of process data (I/O words) and the functionality of each word.

To activate the user denable process data, select the I/O instance 101/151 in parameter 10-10 Process Data Type Selection.

This changes the I/O size to 4 words in the input and output area. This selection uses the Danfoss-specic prole for the

control word and status word as well as for the main reference value/main actual value.

The rst 2 words are xed on the DeviceNet, whereas PCD 3 and PCD 4 are user congurable. The number of PCDs active in

a system is xed to 2 words.

dened formats and functions, depending on the I/O instance selected. PCD 3 and PCD

NOTICE

To select [1] Instance 101/151 in parameter 10-10 Process Data Type Selection, set parameter 8-10 Control Word Prole to

[0] FC prole.

To enable use of PCD data from the DeviceNet, congure the contents of each single PCD word in parameter 10-11 Process

Data Cong Write and parameter 10-12 Process Data Cong Read. Changes to parameter 10-11 Process Data Cong Write and

parameter 10-12 Process Data Cong Read are eected immediately in the PCD data.

10 Danfoss A/S © 12/2015 All rights reserved. MG92F102

CTW

REF

CTW

REF

PCD 2

write

PCD 3

write

STW MAV

STW MAV

PCD 2

read

PCD 3

read

Instance

100

101

150

151

Originator (PLC) --> Target (Drive)

Fixed contents User dened contents

Instance

STW MAV

70

STW MAV

71

CTW

REF

20

CTW

REF

21

Byte #

Byte #

Word #

Word #

Target (Drive) --> Originator (PLC)

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

1 2 3 4 1 2 3 4

130BE709.10

Control Programming Guide

Illustration 4.3 Process Data

4 4

4.4 ODVA Control Prole

4.4.1 Control Word under Instances 20/70

and 21/71

Set parameter 8-10 Control Word Prole to ODVA and select

the instance in parameter 10-10 Process Data Type Selection.

Illustration 4.4 The Control Word in Instances 20 and 21

NOTICE

The bits 00 and 02 in instance 20 are identical with bits

00 and 02 in the more extensive instance 21.

Bit Instance 20 Instance 21

Bit = 0 Bit = 1 Bit = 0 Bit = 1

00 Stop Run Fwd Stop Run Fwd

01 – – Stop Run Rev

02 No function Fault reset No function Fault reset

03 – – – –

04 – – – –

05 – – – Net Ctrl

06 – – – Net Ref

07–15 – – – –

Explanation of the bits:

Bit 0, Run Fwd

Bit 0 = 0: The frequency converter has a stop command.

Bit 0 = 1: Leads to a start command, and the frequency

converter runs the motor clockwise.

Bit 1, Run Rev

Bit 1 = 0: Leads to a stop of the motor.

Bit 1 = 1: Leads to a start reverse of the motor, and the

frequency converter runs the motor counterclockwise.

Bit 2, Fault Reset

Bit 2 = 0: There is no reset of a trip.

Bit 2 = 1: A trip is reset.

Bit 3, No function

Bit 3: No function.

Bit 4, No function

Bit 4: No function.

Bit 5, Net Control

Bit 5 = 0: The frequency converter is controlled via the

standard inputs.

Bit 5 = 1: The DeviceNet controls the frequency converter.

NOTICE

Changes aect parameter 8-50 Coasting Select to

parameter 8-56 Preset Reference Select.

Bit 6, Net Reference

Bit 6 = 0: Reference is from the standard inputs.

Bit 6 = 1: Reference is from DeviceNet.

Table 4.2 Bits in Instances 20 and 21

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 11

Control

VLT® DeviceNet MCA 104

NOTICE

Changes aect parameter 3-15 Reference Resource 1 to

parameter 3-17 Reference Resource 3.

For the speed reference, see chapter 4.4.3 Bus Speed

Reference Value under Instances 20/70 and 21/71.

4.4.2 Status Word under Instances 20/70

44

and 21/71

Illustration 4.5 Status Word in Instances 70 and 71

NOTICE

The bits 00 and 02 in instance 70 are identical with bits

00 and 02 in the more extensive instance 71.

Bit Instance 70 Instance 71

Bit = 0 Bit = 1 Bit = 0 Bit = 1

00 – Fault – Fault

01 – – – Warning

02 – Running 1

Fwd

03 – – – Running 2

04 – – – Ready

05 – – – Control

06 – – – Reference

07 – – – At

08–15 – – State attribute

– Running 1

Fwd

Rev.

from Net

from Net

reference

Bit 3, Running 2

Bit 3 = 0: The frequency converter is not in the running

reverse state, or run 2 is not set.

Bit 3 = 1: The frequency converter state attribute is

enabled or stopping, or fault-stop and bit 0 (run 2) of the

control word are set at the same time.

Bit 4, Ready

Bit 4 = 0: The state attribute is in another state.

Bit 4 = 1: The state attribute is ready, enabled, or stopping.

Bit 5, Control from net

Bit 5 = 0: The frequency converter is controlled from the

standard inputs.

Bit 5 = 1: The DeviceNet has control (start, stop, reverse) of

the frequency converter.

Bit 6, Ref from net

Bit 6 = 0: The reference comes from inputs to the

frequency converter.

Bit 6 = 1: The reference comes from the DeviceNet.

Bit 7, At reference

Bit 7 = 0: The motor is running, but the present speed is

dierent from the preset speed reference, for example, the

speed is being ramped up/down during start/stop.

Bit 7 = 1: The frequency converter and reference speeds

are equal.

Bit 8–15, State attribute

(Instance 71 only)

Represents the state attribute of the frequency converter,

as indicated in Table 4.4.

Bit number Meaning

8 (Vendor specic)

9 Start up

10 Not ready

11 Ready

12 Enabled

13 Stopping

14 Fault stop

15 Faulted

Table 4.3 Bits in Instances 70 and 71

Explanation of the bits:

Bit 0, Fault

Bit 0 = 0: There is no fault in the frequency converter.

Bit 0 = 1: There is a fault in the frequency converter.

Bit 1, Warning

Bit 0 = 0: There is no unusual situation.

Bit 0 = 1: An abnormal condition has arisen.

Bit 2, Running 1

Bit 2 = 0: The frequency converter is not in the running

forward state, or run 1 is not set.

Bit 2 = 1: The frequency converter state attribute is

enabled or stopping, or that fault-stop and bit 0 (run 1) of

the control word are set at the same time.

12 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Table 4.4 State Attribute (Instance 71)

For more details of the actual output speed, see

chapter 4.4.4 Actual Output Speed under Instances 20/70 and

21/71.

4.4.3 Bus Speed Reference Value under

Instances 20/70 and 21/71

The speed reference value is transmitted to the frequency

converter as a 16-bit word. The value is transmitted as a

whole number. Negative gures are formatted by 2’s

complement.

Control Programming Guide

Illustration 4.6 Speed Reference Value

The bus speed reference has the following format:

Parameter 3-00 Reference Range = 0 [ref

MIN

to ref

MAX

] 0

(0000 hex) [RPM] to + 32767 (7FFF hex) [RPM]

Parameter 3-00 Reference Range = 1 [-ref

MAX

to +ref

MAX

]

-32767 (8001 hex ) to +32767 [RPM] (7FFF hex)

The actual reference [Ref. %] in the frequency converter

depends on the settings in the following parameters:

Parameter 1-23 Motor Frequency

Parameter 1-25 Motor Nominal Speed

Parameter 3-03 Maximum Reference

NOTICE

When the bus speed reference is negative, and the

control word contains a run reverse signal, the frequency

converter runs clockwise (- - is +).

Example:

Parameter 1-25 Motor Nominal Speed = 1420 RPM

Parameter 1-23 Motor Frequency = 50 Hz

Parameter 3-03 Maximum Reference = 1420 RPM

To run the motor at 25%, the reference transmitted must

be: (1420x0.25) = 355 = 16.3 hex

163 hex ⇒ 25% ⇒ F

4.4.4 Actual Output Speed under Instances

20/70 and 21/71

= 12.5 Hz

out

FC Control Prole

4.5

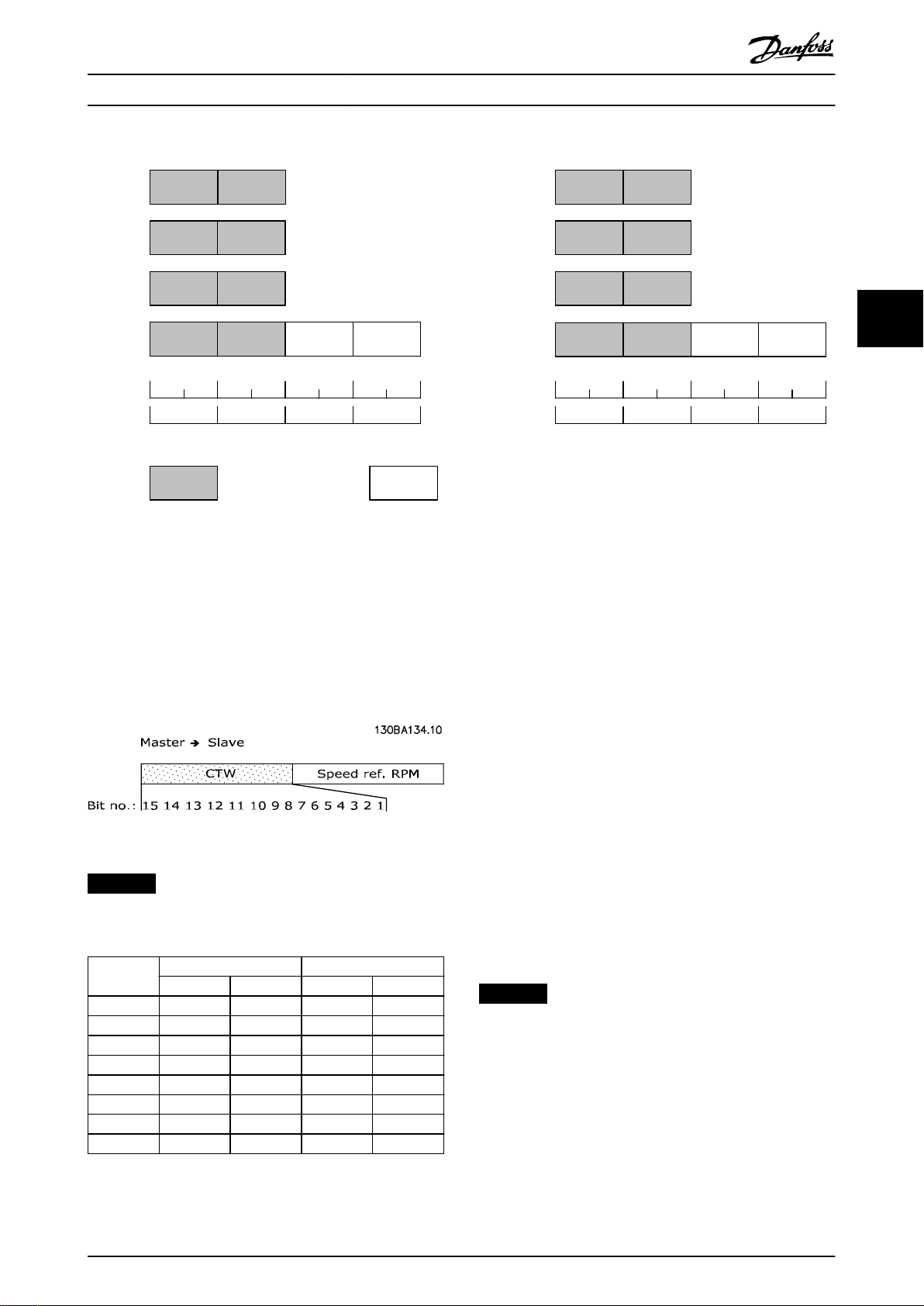

4.5.1 Control Word under Instances

100/150, 101/151, and 102/152

To select FC protocol in the control word, set

parameter 8-10 Control Word Prole to [0] FC prole. The

control word is used to send commands from a master

(PLC or PC) to a slave (frequency converter).

Illustration 4.8 Control Words in Instances 100, 101, and 102

Bit Bit value = 0 Bit value = 1

00 Reference value External selection lsb

01 Reference value External selection msb

02 DC brake Ramp

03 Coasting No coasting

04 Quick stop Ramp

05 Hold output frequency Use ramp

06 Ramp stop Start

07 No function Reset

08 No function Jog

09 Ramp 1 Ramp 2

10 Data invalid Data valid

11 No function Relay 01 active

12 No function Relay 04 active

13 Parameter set-up Selection lsb

14 Parameter set-up Selection msb

15 No function Reverse

4 4

Table 4.5 Bits in Instances 100, 101, and 102

Explanation of the control bits:

Bits 00/01

Bits 00 and 01: Select between the 4 reference values,

Illustration 4.7 Actual Output Speed Value

which are pre-programmed in parameter 3-10 Preset

Reference according to Table 4.6.

The value of the actual speed of the motor, is transmitted

in the form of a 16-bit word.

The value is transmitted as a whole number (negative

gures are formed with 2's complement).

-32767 (8000 hex) [RPM] to +32767 [RPM] (7FFF hex) [RPM]

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 13

Programmed

reference

value

1 3-10 [0] 0 0

2 3-10 [1] 0 1

3 3-10 [2] 1 0

4 3-10 [3] 1 1

Table 4.6 Reference Values

Parameter Bit 01 Bit 00

Control

VLT® DeviceNet MCA 104

NOTICE

In parameter 8-56 Preset Reference Select, a selection is

made to dene how bit 00/01 gates with the

corresponding function on the digital inputs.

Bit 02, DC brake

Bit 02 = 0: Leads to DC braking and stop. Braking current

and duration are set in parameter 2-01 DC Brake Current

44

and parameter 2-02 DC Braking Time.

Bit 02 = 1: Leads to ramping.

Bit 03, Coasting

Bit 03 = 0: Causes the frequency converter to immediately

release the motor (the output transistors are disabled), and

coasts to a standstill.

Bit 03 = 1: Enables the frequency converter to start the

motor if the other starting conditions are fullled.

NOTICE

In parameter 8-50 Coasting Select, a selection is made to

dene how bit 03 gates with the corresponding function

on a digital input.

Bit 04, Quick stop

Bit 04 = 0: Causes a stop, in which the motor speed is

ramped down to stop via parameter 3-81 Quick Stop Ramp

Time.

Bit 05, Hold output frequency

Bit 05 = 0: Causes the present output frequency (in Hz) to

freeze. The frozen output frequency can then be changed

only with the digital inputs (parameter 5-10 Terminal 18

Digital Input to parameter 5-15 Terminal 33 Digital Input)

programmed to speed up and speed down.

NOTICE

If hold output is active, only the following can stop the

frequency converter:

Bit 03 coasting stop.

•

Bit 02 DC braking.

•

Digital input (parameter 5-10 Terminal 18 Digital

•

Input to parameter 5-15 Terminal 33 Digital

Input) programmed to DC braking, coasting

stop, or reset and coasting stop.

Bit 06, Ramp stop/start

Bit 06 = 0: Causes a stop, in which the motor speed is

ramped down to stop via the selected ramp down

parameter.

Bit 06 = 1: Allows the frequency converter to start the

motor, if the other starting conditions are fullled.

NOTICE

In parameter 8-53 Start Select, a selection is made to

dene how bit 06 ramp stop/start gates with the

corresponding function on a digital input.

Bit 07, Reset

Bit 07 = 0: Does not cause a reset.

Bit 07 = 1: Resets a trip. Reset is activated on the leading

edge of the signal, that is, when changing from logic 0 to

logic 1.

Bit 08, Jog

Bit 08 = 1: The frequency converter ramps up/ramps down

according to the setting in parameter 3-19 Jog Speed [RPM].

Bit 09, Selection of ramp 1/2

Bit 09 = 0: Ramp 1 is active (parameter 3-40 Ramp 1 Type to

parameter 3-47 Ramp 1 S-ramp Ratio at Decel. Start).

Bit 09 = 1: Ramp 2 is active (parameter 3-50 Ramp 2 Type to

parameter 3-57 Ramp 2 S-ramp Ratio at Decel. Start).

Bit 10, Data not valid/Data valid

Tells the frequency converter whether to use or to ignore

the control word.

Bit 10 = 0: Ignores the control word.

Bit 10 = 1: Uses the control word to be used. This function

is relevant, because the control word is always contained

in the telegram, regardless of the type of telegram. It is

possible to turn o the control word if you do not wish to

use it with updating or reading parameters.

Bit 11, Relay 01

Bit 11 = 0: Relay not activated.

Bit 11 = 1: Relay 01 activated, provided [36] control word

bit 11 is selected in parameter 5-40 Function Relay.

Bit 12, Relay 04

Bit 12 = 0: Relay 04 is not activated.

Bit 12 = 1: Relay 04 is activated, provided [37] control word

bit 12 is selected in parameter 5-40 Function Relay.

Bit 13/14, Selection of set-up

Bits 13 and 14 are used to select from the 4 menu set-ups

according to Table 4.7.

Set-up Bit 14 Bit 13

1 0 0

2 0 1

3 1 0

4 1 1

Table 4.7 Menu Set-up

The function is only possible when [9] Multi Set-up is

selected in parameter 0-10 Active Set-up.

NOTICE

In parameter 8-55 Set-up Select, a selection is made to

dene how bits 13/14 gate with the corresponding

function on the digital inputs.

Bit 15 Reverse

Bit 15 = 0: No reversing.

Bit 15 = 1: Reversing.

14 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Control Programming Guide

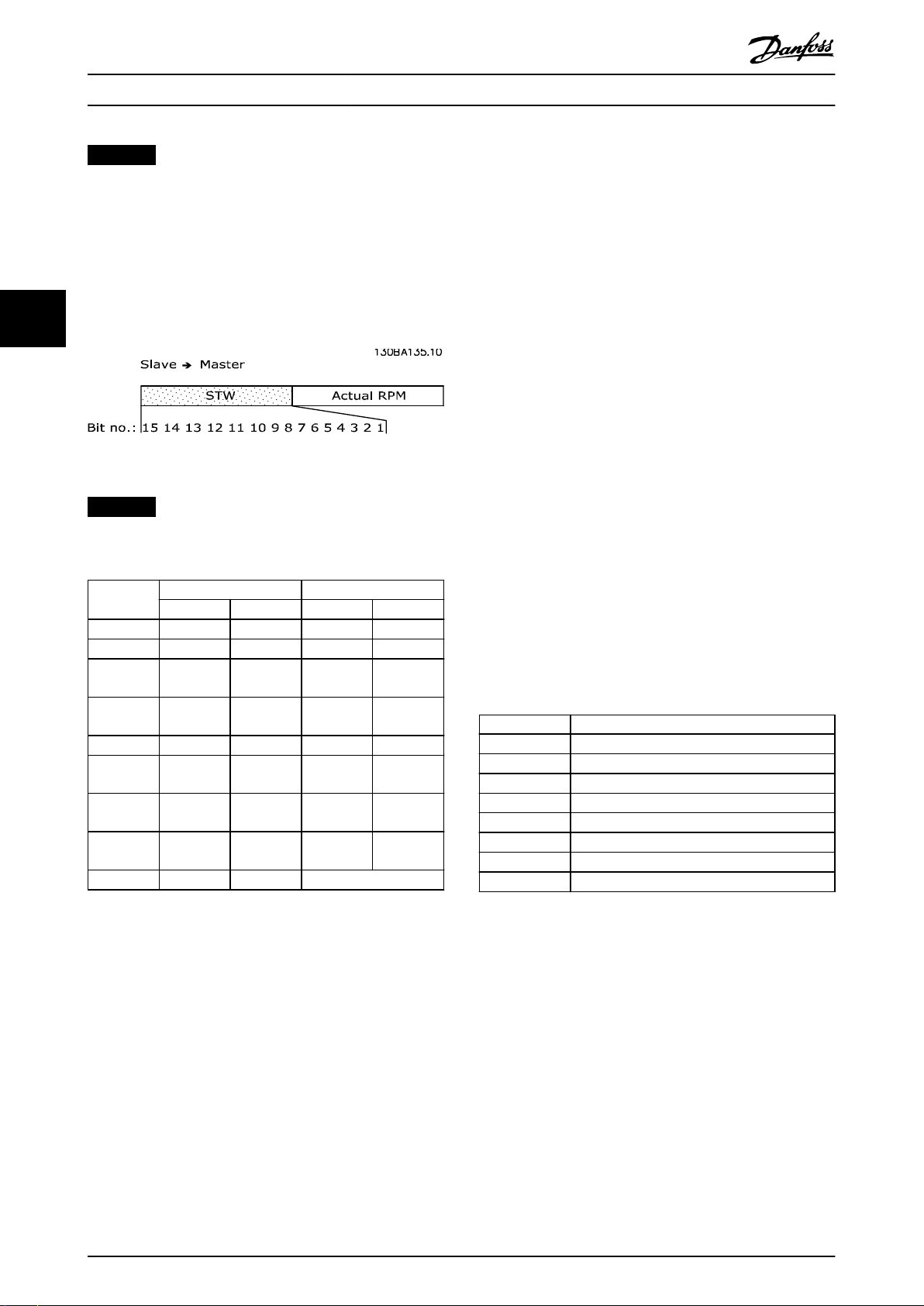

4.5.2 Status Word under Instances 100/150,

101/151, and 102/152

Illustration 4.9 Status Words in Instances 150/151/152

Bit Bit = 0 Bit = 1

00 Control not ready Control ready

01 Drive not ready Drive ready

02 Coasting Enable

03 No error Trip

04 No error Error (no trip)

05 Reserved –

06 No error Trip lock

07 No warning Warning

08 Speed reference Speed = reference

09 Local operation Bus control

10 Out of frequency limit Frequency limit ok

11 No operation In operation

12 Drive ok Stopped, auto start

13 Voltage ok Voltage exceeded

14 Torque ok Torque exceeded

15 Timer ok Timer exceeded

Table 4.8 Status Bits

Explanation of the status bits:

Bit 00, Control not ready/ready

Bit 00 = 0: The frequency converter has tripped.

Bit 00 = 1: The frequency converter controls are ready, but

the power component is not necessarily receiving any

power supply (if there is 24 V external supply to controls).

Bit 01, Drive ready

Bit 01 = 1: The frequency converter is ready for operation.

Bit 02, Coasting stop

Bit 02 = 0: The frequency converter has released the motor.

Bit 02 = 1: The frequency converter can start the motor

when a start command is given.

Bit 03, No error/trip

Bit 03 = 0: The frequency converter is not in fault mode.

Bit 03 = 1: The frequency converter is tripped, and a reset

signal is required to re-establish operation.

Bit 04, No error/error (no trip)

Bit 04 = 0: The frequency converter is not in fault mode.

Bit 04 = 1: There is a frequency converter error but no trip.

Bit 05, Not used

Bit 05: Not used in the status word.

Bit 06, No error/trip lock

Bit 06 = 0: The frequency converter is not in fault mode.

Bit 06 = 1: The frequency converter is tripped and locked.

Bit 07, No warning/warning

Bit 07 = 0: There are no warnings.

Bit 07 = 1: A warning has occurred.

Bit 08, Speed reference/speed = reference

Bit 08 = 0: The motor is running, but the present speed is

dierent from the preset speed reference. For example, it

could be the case while the speed is being ramped up/

down during start/stop.

Bit 08 = 1: The present motor speed matches the preset

speed reference.

Bit 09, Local operation/bus control

Bit 09 = 0: [STOP/RESET] is activated on the control unit, or

[2] Local in parameter 3-13 Reference Site is selected. It is

not possible to control the frequency converter via serial

communication.

Bit 09 = 1: It is possible to control the frequency converter

via the eldbus/serial communication.

Bit 10, Out of frequency limit

Bit 10 = 0: The output frequency has reached the value in

parameter 4-52 Warning Speed Low or

parameter 4-53 Warning Speed High.

Bit 10 = 1: The output frequency is within the dened

limits.

Bit 11, No operation/in operation

Bit 11 = 0: The motor does not run.

Bit 11 = 1: The frequency converter has a start signal, or

the output frequency is greater than 0 Hz.

Bit 12, Drive OK/stopped, auto start

Bit 12 = 0: There is no temporary overtemperature on the

inverter.

Bit 12 = 1: The inverter has stopped because of overtemperature, but the unit has not tripped and resumes

operation once the overtemperature stops.

Bit 13, Voltage OK/limit exceeded

Bit 13 = 0: There are no voltage warnings.

Bit 13 = 1: The DC voltage in the frequency converters DC

link is too low or too high.

Bit 14, Torque OK/limit exceeded

Bit 14 = 0: The motor current is lower than the torque limit

selected in parameter 4-16 Torque Limit Motor Mode or

parameter 4-17 Torque Limit Generator Mode.

Bit 14 = 1: The torque limits in parameter 4-16 Torque Limit

Motor Mode and parameter 4-17 Torque Limit Generator

Mode are exceeded.

Bit 15, Timer OK/limit exceeded

Bit 15 = 0: The timers for motor thermal protection and

frequency converter thermal protection, respectively, have

not exceeded 100%.

Bit 15 = 1: One of the timers has exceeded 100%.

4 4

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 15

Control

VLT® DeviceNet MCA 104

4.5.3 Bus Reference Value under Instances

100/150 and 101/151

The frequency reference value is transmitted to the

frequency converter in the form of a 16-bit word. The

value is transmitted as a whole number (-32767 to

+32767). Negative gures are formatted by 2’s

complement.

44

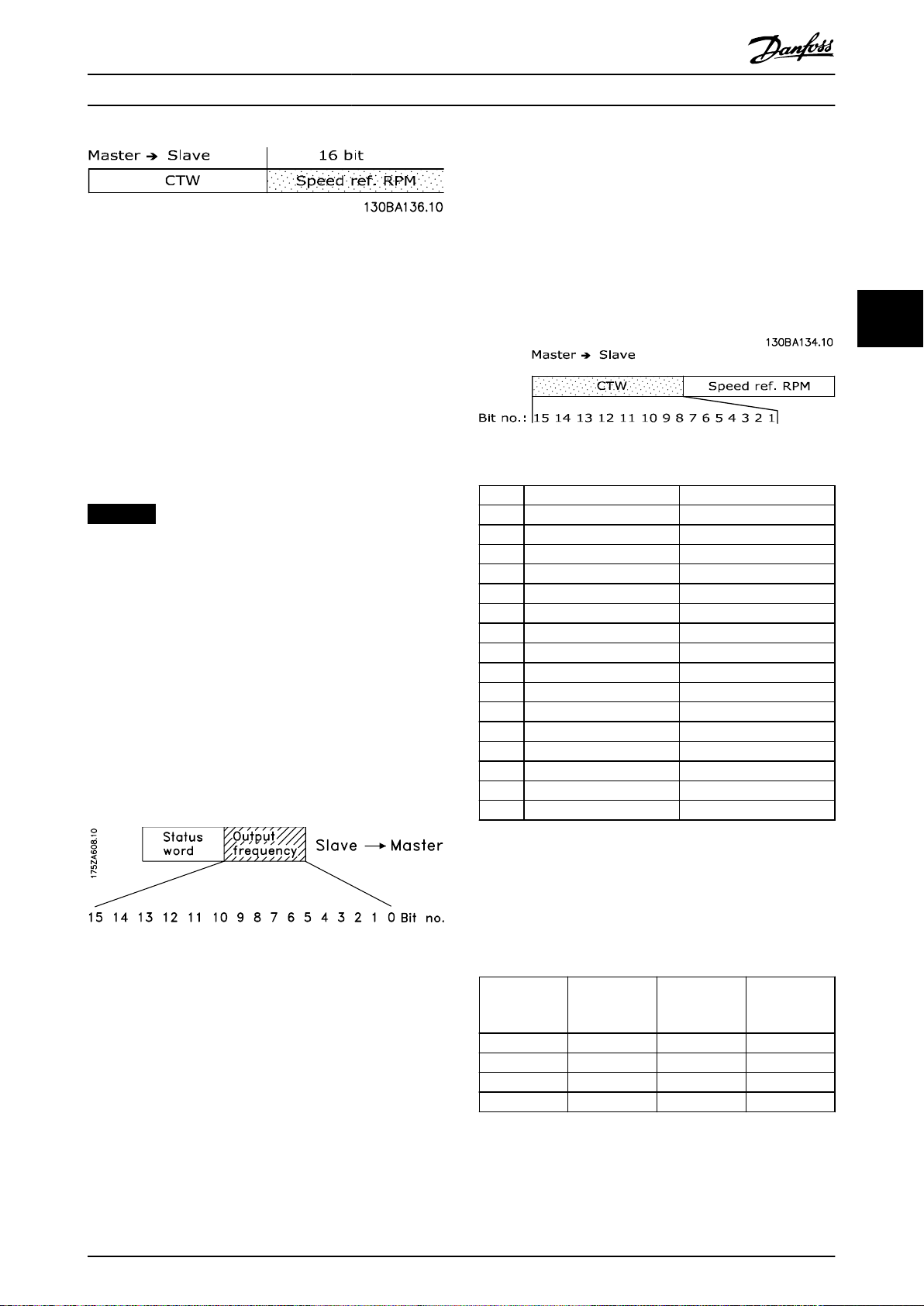

Master ⇒ slave

CTW Speed reference RPM

Table 4.9 Speed Reference Value

The bus reference has the following format:

100% = 4000 hex

Parameter 3-00 Reference Range = 0 [ref

16384 (4000 hex) ~ 0 ⇒ 100%

Parameter 3-00 Reference Range = 1 [- ref

-16384 (C000 hex) ⇒ +16384 (4000 hex) ~ -100% ⇒ +100%

16 bit

MIN

⇒ ref

MAX

MAX

⇒ + ref

] 0 ⇒

MAX

]

4.5.4 Actual Output Frequency under

Instances 100/150 and 101/151

The value of the actual output frequency of the frequency

converter is transmitted in the form of a 16-bit word. The

value is transmitted as a whole number (-32767 to

+32767). Negative gures are formed by 2’s complement.

Slave ⇒ master

STW Actual reference RPM

Table 4.10 Actual Output Frequency

16 bit

The actual output frequency has the following format:

-32767 to +32767.

-16384 (C000 hex) corresponds to -100%, and 16384 (4000

hex) corresponds to 100%.

16 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameter Access Programming Guide

5 Parameter Access

5.1 Explicit Messages

DeviceNet is based on the CAN protocol. Every message contains an 11 bit CAN identier eld to dene the connection ID.

These CAN identiers are also used to determine access priority.

The MAC ID is stored in the header of the message, which is split into 4

10 9 8 7 6 5 4 3 2 1 0 Identier bits

0 Group 1 ID Source MAC ID Message group 1

1 0 MAC ID Group 2 ID Message group 2

1 1 Group 3 ID Source MAC ID Message group 3

1 1 1 1 1 Group 4 ID Message group 4

1 1 1 1 1 1 1 X X X X Invalid CAN identiers

Table 5.1 MAC ID

It is possible to access frequency converter parameters via the standard DeviceNet service explicit message. Two classes of

explicit messages are supported:

Message group 2: Explicit messages take place via

Message group 3: Explicit messages take place via dynamically established lower prioritized connections.

Object Classes

5.2

Access is available to the following standard DeviceNet objects.

Class ID 01h Identity object Class ID 10h Parameter group object

Class ID 03h DeviceNet object Class ID 28h Motor data object

Class ID 04h Assembly object Class ID 29h Control supervisory object

Class ID 05h Connection object Class ID 2Ah AC/DC drive object

Class ID 0Fh Parameter object Class ID 2Bh Acknowledge handler object

pre-dened master/slave connections.

dierent message groups, see Table 5.1.

5 5

Table 5.2 Standard DeviceNet Objects

The following DeviceNet vendor-specic objects are also available:

Class ID 100d to 119d Danfoss classes.

The object classes are described in chapter 5.3 DeviceNet Object Classes and chapter 5.4 Danfoss Object Classes.

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 17

Parameter Access

VLT® DeviceNet MCA 104

5.3 DeviceNet Object Classes

5.3.1 Class ID 01h Identity Object

Class ID 01h identity object is a standard DeviceNet object for identication of the device (frequency converter). Set the

heartbeat interval in this object. The attributes supported for this class are listed in Table 5.3.

Attribute Access Name Data type Minimum/

Maximum

1 Get Vendor USINT – – 97 Danfoss Drives Vendor

55

2 Get Device Type UNIT – – 2 AD/DC Motor.

3 Get Product Code UNIT – – 100 See chapter 3.2.1 EDS File.

4 Get Revision UNIT – – – Software version on FC

5 Get Status UNIT – – –

6 Get Serial Number UDINT – – – From frequency

7 Get Product Name String – – – FC 100, FC 202, or FC

10 Get/Set Heartbeat

Interval

Table 5.3 Class ID 0x01

USINT 0–255 s 0 O.

Units Default Description

code.

102, FC 202, or FC 300.

converter.

300.

5.3.2 Class ID 03h DeviceNet Object

Class ID 03h DeviceNet object is a standard DeviceNet object for conguration and status of the DeviceNet connection. The

attributes supported for this class are listed in Table 5.4.

Attribute Access Name Data type Minimum/

Maximum

1 Get/Set MAC ID USINT 0–63 – 63 Node address.

2 Get/Set Baud rate USINT 0–2 – 0 0=125

4 Get BOC – – – – Bus-o counter.

5 Get Allocate

information

6 Get MAC ID switch

changed

7 Get Baud rate

switched from

last power-up

– – – – Only required if

BOOL 0–1 – 0 The node address switch

BOOL 0–1 – 0 The baud rate switch has

Units Default Description

1=250

2=500

predened master/slave

is implemented.

has changed since the

last power-up/reset.

changed since the last

power-up.

Table 5.4 Class ID 0x03

18 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameter Access Programming Guide

5.3.3 Class ID 04h Assembly Object

Class ID 04h assembly object is a standard DeviceNet object for transfer of the I/O instances (process data) described in

chapter 4 Control. Using class ID 04h assembly object to send or read any of the dened instances, either by polling or

explicit messaging. The attributes supported for this class are listed in Table 5.5.

Attribute Access Name Data type Minimum/

Maximum

3 Set Data ARRAY – – – –

Table 5.5 Class ID 0x04

Instance Access Size Description Parameter 10-10 selection

20 Set 2 words DeviceNet AC/DC prole Instance 20/70

21 Set 2 words DeviceNet AC/DC prole Instance 21/71

70 Get 2 words DeviceNet AC/DC prole Instance 20/70

71 Get 2 words DeviceNet AC/DC prole Instance 21/71

100 Set 2 words Danfoss specic, no PCD words Instance 100/150

101 Set 4 words Danfoss specic, 2 PCD words Instance 101/151

150 Get 2 words Danfoss specic, no PCD words Instance 100/150

151 Get 4 words Danfoss specic, 2 PCD words Instance 101/151

Table 5.6 Instances

Units Default Description

5 5

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 19

Parameter Access

VLT® DeviceNet MCA 104

5.3.4 Class ID 05h Connection Object

Class ID 05h connection object is a standard DeviceNet object for allocation and managing I/O and explicit messaging

connections. For this class, 3 instances are supported:

Explicit messages.

•

Polled I/O.

•

Change of state.

•

The attributes supported for the

Attribute Access Name Data type Description

55

1 Get State USINT State of the object.

2 Get Instance type USINT Indicates either I/O or explicit message.

3 Get Transport class

4 Get Produced

5 Get Consumed

6 Get Initial

7 Get Produced

8 Get Consumed

9 Get/Set Expected

12 Get Watchdog

13 Get Produced

14 Get Produced

15 Get Consumed

16 Get Consumed

17 Get Production

dierent instances are listed in Table 5.7, Table 5.8, and Table 5.9.

USINT Denes behavior of the connection.

trigger

UINT CAN identier eld when the connection transmits.

connection ID

UINT CAN identier eld value that denotes message to be received.

connection ID

USINT Denes the message group/groups across which productions and

communication

characteristics

UINT Maximum number of bytes transmitted across this connection.

connection size

UINT Maximum number of bytes received across this connection.

connection size

UINT Denes value used in transmission trigger timer and inactivity/

package rate

USINT Denes how to handle inactivity/watchdog timeout.

timeout action

UINT Number of bytes in the produced connection path attribute.

connection path

length

Array of USINT Species the application object/objects whose data is to be produced

connection path

UINT Number of bytes in the consumed connection path attribute.

connection path

length

Array of USINT Species the application object/objects that are to receive the data

connection path

UINT Denes minimum time between new data production. This attribute is

inhibit time

consumptions associated with this connection occur.

watchdog timer.

by these connection objects.

consumed by this connection object.

required for I/O client connection.

Table 5.7 Instance 1 Attributes: Explicit Message Instance

20 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameter Access Programming Guide

Attribute Access Name Data type Description

1 Get State USINT State of the object.

2 Get Instance type USINT Indicates either I/O or explicit message.

3 Get Transport class

trigger

4 Get Produced

connection ID

5 Get Consumed

connection ID

6 Get Initial

communication

characteristics

7 Get Produced

connection size

8 Get Consumed

connection size

9 Get/Set Expected

package rate

12 Get Watchdog

timeout action

13 Get Produced

connection path

length

14 Get Produced

connection path

15 Get Consumed

connection path

length

16 Get Consumed

connection path

17 Get Production

inhibit time

USINT Denes behavior of the connection.

UINT CAN identier eld when the connection transmits.

UINT CAN identier eld value that denotes message to be received.

USINT Denes the message group/groups across which productions and

consumptions associated with this connection occur.

UINT Maximum number of bytes transmitted across this connection.

UINT Maximum number of bytes received across this connection.

UINT Denes value used in transmission trigger timer and inactivity/

watchdog timer.

USINT Denes how to handle inactivity/watchdog timeout.

UINT Number of bytes in the produced connection path attribute.

Array of USINT Species the application object/objects whose data is to be produced

by these connection objects.

UINT Number of bytes in the consumed connection path attribute.

Array of USINT Species the application object/objects that are to receive the data

consumed by this connection object.

UINT Denes minimum time between new data production. This attribute is

required for I/O client connection.

5 5

Table 5.8 Instance 2 Attributes: Polled I/O

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 21

Parameter Access

Attribute Access Name Data type Description

1 Get State USINT State of the object.

2 Get Instance type USINT Indicates either I/O or explicit message.

3 Get Transport class

trigger

4 Get Produced

connection ID

5 Get Consumed

connection ID

6 Get Initial

communication

55

7 Get Produced

8 Get Consumed

9 Get/Set Expected

12 Get Watchdog

13 Get Produced

14 Get Produced

15 Get Consumed

16 Get Consumed

17 Get Production

characteristics

connection size

connection size

package rate

timeout action

connection path

length

connection path

connection path

length

connection path

inhibit time

VLT® DeviceNet MCA 104

USINT Denes behavior of the connection.

UINT CAN identier eld when the connection transmits.

UINT CAN identier eld value that denotes message to be received.

USINT Denes the message group/groups across which productions and

consumptions associated with this connection occur.

UINT Maximum number of bytes transmitted across this connection.

UINT Maximum number of bytes received across this connection.

UINT Denes value used in transmission trigger timer and inactivity/

watchdog timer.

USINT Denes how to handle inactivity/watchdog timeout.

UINT Number of bytes in the produced connection path attribute.

Array of USINT Species the application object/objects whose data is to be produced

by these connection objects.

UINT Number of bytes in the consumed connection path attribute.

Array of USINT Species the application object/objects that are to receive the data

consumed by this connection object.

UINT Denes minimum time between new data production. This attribute is

required for I/O client connection.

Table 5.9 Instance 4: Change of State/Cycle

22 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameter Access Programming Guide

5.3.5 Class ID 0F4 Parameter Object

Class ID 0F4 parameter object is an interface to the parameters of the frequency converter. It identies congurable

parameters and supplies their description, including minimum and maximum values and a descriptive text. The attributes

supported are listed in Table 5.10.

Attribute Access Stub/Full Name Data type Description

1 Set/Get Stub Parameter value

2 Get Stub Link path size USINT Size of link path.

3 Get Stub Link path ARRAY DeviceNet's path to origin of the parameters.

– – – Segment type/port BYTE –

– – – Segment address Path –

4 Get Stub Descriptor WORD Description of parameter.

5 Get Stub Data type EPATH Data type code.

6 Get Stub Data size USINT Number of bytes in parameter value.

7 Get Full Parameter name

string

8 Get Full Units string SHORT

9 Get/Set Full Help string SHORT

10 Get Full Minimum value

11 Get Full Maximum value

12 Get Full Default value

13 Get Full Scaling multiplier UINT Multiplier for scaling factor.

14 Get Full Scaling divisor UINT Divisor for scaling factor.

15 Get Full Scaling base UINT Base for scaling formula.

16 Get Full Scaling oset INT Oset for scaling formula.

17 Get Full Multiplier link UINT Parameter instance of multiplier source.

18 Get Full Divisor link UINT Parameter instance of divisor source.

19 Get Full Base link UINT Parameter instance of base source.

20 Get Full Oset link UINT Parameter instance of oset source.

21 Get Full Decimal precision USINT Species parameter value format.

Data type

SHORT

STRING

STRING

STRING

Data type

Data type

Data type

1)

1)

1)

1)

Actual value of parameter.

Text string representing the parameter name.

Text string representing the parameter name.

Text string representing the parameter name.

Minimum valid value.

Maximum valid value.

Parameters default value.

5 5

Table 5.10 Attributes Supported for Class ID 0F4 Parameter Object

1) Same data type as the parameter.

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 23

Parameter Access

VLT® DeviceNet MCA 104

5.3.6 Class ID 10h Parameter Group Object

Class ID 10h parameter group object denes 14 parameter groups for all parameters of the frequency converters. One class

instance exists for each parameter group. A readout of an instance contains the name of the current parameter group.

Group Instance Name (maximum 16 characters)

0 1 O P E R A T I O N D I S P L .

1 2 L O A D – M O T O R – – – – – –

2 3 B R A K E S – – – – – – – – – –

3 4 R E F E R E N C E – R A M P S –

4 5 L I M I T S – W A R N I N G S –

55

5 6 D I G I T A L – I N – O U T – –

6 7 A N A L O G – I N – O U T – – –

7 8 C O N T R O L L E R S – – – – –

8 9 C O M M . – A N D – O P T I O N

9 10 C A N – F I E L D B U S – – – –

10 11 S P E C I A L – F U N C T I O N

Table 5.11 Class ID 10h Parameter Group Object

5.3.7 Class ID 28h Motor Data Object

In class ID 28h motor data object, the current motor data can be congured and readout. The instances, attributes, and

services supported for this class are listed in Table 5.12.

Attribute Access Name Data

type

3 Get/set Motor

type

6 Get/set Rated

current

7 Get/set Rated

voltage

8 Get/set Rated

power

9 Get/set Rated

frequency

1)

12

15 Get/set Base

Get/set Pole

count

speed

USINT 7 – 7 7 = Squirrel cage

UNIT 0–100.00 100 mA Drive dependent Stator current rating (from

UNIT 200–500 Volt Drive dependent Base voltage rating (from

UDINT 0–18500 Watt Drive dependent Power rating at rated

UNIT 1–1000 Hz Drive dependent Elec. frequency rating

UINT – – Drive dependent Pole numbers in the

UNIT 100–60000 RPM Drive dependent Nominal motor speed

Generic

maximum

values

Units Default Description Parameter

reference

Parameter 1-10 Motor

asynchronous motor

motor nameplate)

motor nameplate)

frequency (from motor

nameplate)

(from motor nameplate)

motor

(from motor nameplate)

Construction

Parameter 1-24 Motor

Current

Parameter 1-22 Motor

Voltage

Parameter 1-20 Motor

Power [kW]

Parameter 1-23 Motor

Frequency

Parameter 1-39 Motor

Parameter 1-25 Motor

Nominal Speed

Poles

Table 5.12 Class ID 0x28

24 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameter Access Programming Guide

5.3.8 Class ID 29h Control Supervisory Object

The control supervisory object can be used for process control and monitoring of the frequency converter as an alternative

to the I/O instances dened in chapter 4 Control. The attributes supported for this class are listed in Table 5.13.

Attribute Access Name Data type Minimum/

Maximum

3 Get/Set Run 1 Bool 0–1 – Run fwd, see note below

4 Get/Set Run 2 Bool 0–1 – Run rev, see note below

5 Get/Set NetCtrl Bool 0–1 1 0 = Local control

6 Get State USINT 0–7 – 0 = Vendor specic

7 Get Running 1 Bool 0–1 0 0 = Other state

8 Get Running 2 Bool 0–1 0 0 = Other state

9 Get Ready Bool 0–1 – 0 = Other state

10 Get Fault Bool 0–1 0 0 = No faults present

12 Get/Set Fault Rst Bool 0–1 – 0 = No action

13 Get Fault Code UINT – –

15 Get Ctrl From Net Bool 0–1 1 0 = Control is local

16 Get/Set DN Fault Mode UINT 0–2 1 Action on loss of DeviceNet

Default Description

1 = Control from network

1 = Start-up

2 = Not ready

3 = Ready

4 = Enabled

5 = Stop

6 = Fault stop

7 = Fault

1 = (Enable and Run 1)

or (Stopping and Running 1)

or (Fault Stop and Running 1)

1 = (Enable and Run 2)

or (Stopping and Running 2)

or (Fault Stop and Running 2)

1 = Ready or Enabled or Stopping

1 = Fault occurred (latched)

1 ->1 = Reset fault

1 = Control is from network

0 = Fault + Stop

1 = Ignore (warning optional)

2 = Danfoss specic

5 5

Table 5.13 Class ID 0x29

NOTICE

The ODVA drive prole selected in parameter 1-10 Motor Construction is available only when instances 20/70 or 21/71

are selected.

Illustration 5.1 shows how the frequency converter responds to the various command attributes associated with class ID

0x29.

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 25

Parameter Access

VLT® DeviceNet MCA 104

55

Illustration 5.1 State – Transition Diagram

5.3.9 Class ID 2Ah AC/DC Drive Object

To set and read out a range of frequency converters control and status information, use this object. The attributes

supported for this class are listed in Table 5.14.

Attribute Access Name Data

type

3 Get At reference Bool 0–1 – 0 = Drive not at reference

4 Get/Set Net ref Bool 0–1 1 0 = Set reference at non-DeviceNet

6 Get/Set Drive mode USINT 0–1 1 0 = Vendor specic mode

7 Get Speed actual INT –

8 Get/Set Speed ref INT –

22 Get/Set Speed scale SINT -128–127 – Speed scaling factor

29 Get Ref from net Bool 0–1 – 0 = Local speed reference

Minimum/

Maximum

Default Description

1 = Drive at reference

reference

1 = Set reference at DeviceNet reference

1 = Open-loop speed (frequency)

2 = Closed-loop speed control

RPM/2

RPM/2

Speed Scale

Speed Scale

Actual drive speed

(best approximation)

Speed reference

1 = DeviceNet speed reference

Table 5.14 Class ID 0x2A

26 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameter Access Programming Guide

5.3.10 Class ID 2Bh Acknowledge Handler Object

To manage message reception acknowledgements, necessary for change-of-state support, use class ID 2Bh acknowledge

handler object. The attributes supported for this class are listed in Table 5.15.

Attribute Access Name Data

type

1 Set ACK timer UINT 0–65535 16 Time to wait for ACK before resending.

2 Get/Set Retry timer USINT 0–255 1 Number of ACK-timeouts to wait before

3 Get/Set COS UINT – – Connection instance ID

Table 5.15 Class ID 0x2B

5.4 Danfoss Object Classes

Use the Danfoss classes for read and write of all parameter

values of the frequency converters. A corresponding object

class is dened for each parameter group. Table 5.16 shows

the classes supported, and their relationship to the

parameters.

The class instance and attribute act in the following way:

100 added to the parameter group = the value

•

for the class.

100 added to the remaining parameter number =

•

the value for the instance.

100 added to the array index of the parameter =

•

the value for the attribute.

Parameter range Class

Parameter 0-00 – 0-99 Class 100

Parameter 1-00 – 1-99 Class 101

Parameter 2-00 – 2-99 Class 102

Parameter 3-00 – 3-99 Class 103

Parameter 4-00 – 4-99 Class 104

Parameter 5-00 – 5-99 Class 105

Parameter 6-00 – 6-99 Class 106

Parameter 7-00 – 7-99 Class 107

Parameter 8-00 – 8-99 Class 108

Parameter 10-00 – 10-99 Class 110

Parameter 11-00 – 11-99 Class 111

Parameter 13-00 – 13-99 Class 113

Parameter 14-00 – 14-99 Class 114

Parameter 15-00 – 15-99 Class 115

Parameter 16-00 – 16-99 Class 116

Minimum/

Maximum

Default Description

producing.

RetryLimit_Reache event.

5.4.1 Examples

Examples: (ctitious parameters) (all values in decimal)

Parameter 0-01 Language [index 0] = Class 100;

•

instance 101; attribute 100

Parameter 1-00 Conguration Mode [index 0] =

•

Class 101; instance 100; attribute 100

Parameter 3-41 Ramp 1 Ramp Up Time [index 0] =

•

Class 103; instance 141; attribute 100

Parameter 1-55 U/f Characteristic - U [index 3] =

•

Class 101; instance 155; attribute 103

Parameter 6-54 Terminal 42 Output Timeout Preset

•

[index 9] = Class 106; instance 154; attribute 109

Parameter 10-01 Baud Rate Select [index 0] = Class

•

110; instance 101; attribute 100

5 5

Table 5.16 Danfoss Classes

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 27

Parameters

6 Parameters

VLT® DeviceNet MCA 104

6

6.1 Parameter Description

8-01 Control Site

Option: Function:

The setting in this parameter overrides the

settings in parameter 8-50 Coasting Select to

parameter 8-56 Preset Reference Select.

[0] Digital and

ctrl.word

[1] Digital only Control by using digital inputs only.

[2] Controlword

only

Control by using both digital input and

control word.

Control by using control word only.

8-02 Control Word Source

Option: Function:

NOTICE

This parameter cannot be adjusted

while the motor is running.

Select the source of the control word: 1 of 2

serial interfaces or 4 installed options. During

initial power-up, the frequency converter

automatically sets this parameter to [3] Option

A, if it detects a valid

in slot A. When the option is removed, the

frequency converter detects a conguration

change, sets parameter 8-02 Control Word

Source to default setting [1] FC RS485, and

trips. If an option is installed after initial

power-up, the setting of

parameter 8-02 Control Word Source does not

change, but the frequency converter trips and

shows: Alarm 67, Option Changed.

When retrotting a bus option into a

frequency converter that did not have a bus

option installed earlier, change the control to

bus-based. This change is required for safety

reasons to avoid an unintended change.

[0] None

[1] FC RS485

[2] FC USB

[3] Option A

[4] Option B

[5] Option C0

[6] Option C1

[30] External Can

eldbus option installed

8-03 Control Word Timeout Time

Range: Function:

1 s* [ 0.1 -

18000 s]

Enter the maximum time expected to pass

between the reception of 2 consecutive

telegrams. If this time is exceeded, it indicates

that the telegram communication has stopped.

The function selected in parameter 8-04 Control

Word Timeout Function is then carried out. A

valid control word triggers the timeout counter.

8-04 Control Word Timeout Function

Select the timeout function. The timeout function activates when

the control word fails to be updated within the time period

specied in parameter 8-03 Control Word Timeout Time.

Option: Function:

NOTICE

To change the set-up after a timeout,

congure as follows:

Set parameter 0-10 Active Set-up to [9]

Multi set-up and select the relevant

link in parameter 0-12 This Set-up

Linked to.

[0] O Resumes control via eldbus (eldbus or

standard), using the most recent control

word.

[1] Freeze output Freezes output frequency until communi-

cation resumes.

[2] Stop Stops with auto restart when communi-

cation resumes.

[3] Jogging Runs the motor at jog frequency until

communication resumes.

[4] Max. speed Runs the motor at maximum frequency until

communication resumes.

[5] Stop and trip Stops the motor, then resets the frequency

converter to restart:

Via the eldbus.

•

Via [Reset].

•

Via a digital input.

•

[7] Select setup 1 Changes the set-up after a control word

timeout. If communication resumes after a

timeout, parameter 8-05 End-of-Timeout

Function denes whether to resume the set-

up used before the timeout, or to retain the

set-up endorsed by the timeout function.

[8] Select setup 2 See [7] Select set-up 1.

[9] Select setup 3 See [7] Select set-up 1.

[10] Select setup 4 See [7] Select set-up 1.

28 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameters Programming Guide

8-04 Control Word Timeout Function

Select the timeout function. The timeout function activates when

the control word fails to be updated within the time period

specied in parameter 8-03 Control Word Timeout Time.

Option: Function:

[26] Trip

8-05 End-of-Timeout Function

Option: Function:

Select the action after receiving a valid control

word following a timeout.

This parameter is active only when

parameter 8-04 Control Timeout Function is set

to:

[7] Set-up 1.

•

[8] Set-up 2.

•

[9] Set-up 3.

•

[10] Set-up 4.

•

[0] Hold set-upRetains the set-up selected in

parameter 8-04 Control Timeout Function and

shows a warning until parameter 8-06 Reset

Control Timeout toggles. Then the frequency

converter resumes its original set-up.

[1] * Resume

set-up

Resumes the set-up that was active before the

timeout.

8-06 Reset Control Word Timeout

This parameter is active only when [0] Hold set-up has been

selected in parameter 8-05 End-of-Timeout Function.

Option: Function:

[0] * Do not reset Retains the set-up specied in

parameter 8-04 Control Word Timeout Function,

following a control word timeout.

[1] Do reset Restores the frequency converter to the

original set-up following a control word

timeout. The frequency converter performs

the reset and then immediately reverts to the

[0] Do not reset setting.

8-07 Diagnosis Trigger

This parameter has no function for DeviceNet.

Option: Function:

[0] * Disable

[1] Trigger on alarms

[2] Trigger alarm/warn.

8-08 Readout Filtering

If the speed feedback value readouts on eldbus are uctuating,

this function is used. Select ltered, if the function is required. A

power cycle is required for changes to take eect.

Option: Function:

[0] Motor Data

Std-Filt.

Normal eldbus readouts.

8-08 Readout Filtering

If the speed feedback value readouts on eldbus are uctuating,

this function is used. Select ltered, if the function is required. A

power cycle is required for changes to take eect.

Option: Function:

[1] Motor Data

LP-Filter

Filtered eldbus readouts of the following

parameters:

Parameter 16-10 Power [kW ].

•

Parameter 16-11 Power [hp].

•

Parameter 16-12 Motor Voltage.

•

Parameter 16-14 Motor current.

•

Parameter 16-16 Torque [Nm].

•

Parameter 16-17 Speed [RPM].

•

Parameter 16-22 Torque [%].

•

Parameter 16-25 Torque [Nm] High.

•

8-10 Control Word Prole

Instances 20/70 and 21/71 are selectable in

parameter 10-10 Process Data Type Selection.

Option: Function:

[0] * FC prole Instances 100/150 and 101/151 are

selectable in parameter 10-10 Process

Data Type Selection.

[1] PROFIdrive prole

[5] ODVA

[7] CANopen DSP 402

[8] MCO

8-13 Congurable Status Word STW

The status word has 16 bits (0–15). Bits 5 and 12–15 are cong-

urable. Each of these bits can be congured to any of the

following options.

Option: Function:

[0] No function The input is always low.

[1] Prole Default Depending on the prole set in

parameter 8-10 Control Prole.

[2] Alarm 68 Only The input goes high whenever

alarm 68, Safe Stop activated is

active, and goes low whenever

alarm 68 Safe Stop activated is not

activate.

[3] Trip excl Alarm 68

[10] T18 DI status

[11] T19 DI status

[12] T27 DI status

[13] T29 DI status

[14] T32 DI status

[15] T33 DI status

[16] T37 DI status The input goes high whenever

terminal 37 has 0 V and goes low

whenever terminal 37 has 24 V.

6

6

MG92F102 Danfoss A/S © 12/2015 All rights reserved. 29

Parameters

VLT® DeviceNet MCA 104

6

8-13 Congurable Status Word STW

The status word has 16 bits (0–15). Bits 5 and 12–15 are cong-

urable. Each of these bits can be congured to any of the

following options.

Option: Function:

[21] Thermal warning

[30] Brake fault (IGBT)

[40] Out of ref range

[41] Load throttle active

[60] Comparator 0

[61] Comparator 1

[62] Comparator 2

[63] Comparator 3

[64] Comparator 4

[65] Comparator 5

[70] Logic Rule 0

[71] Logic Rule 1

[72] Logic Rule 2

[73] Logic Rule 3

[74] Logic Rule 4

[75] Logic Rule 5

[80] SL digital out A

[81] SL digital out B

[82] SL digital out C

[83] SL digital out D

[84] SL digital out E

[85] SL digital out F

[86] ATEX ETR cur. alarm

[87] ATEX ETR freq. alarm

[88] ATEX ETR cur. warning

[89] ATEX ETR freq. warning

[90] Safe Function active

[91] Safe Opt. Reset req.

[92] IGBT-cooling See 5-3* Digital Outputs.

8-14 Congurable Control Word CTW

Array [15]

Option: Function:

This parameter is not valid in software versions

before 4.93.

[0] None The frequency converter ignores the information

in this bit.

[1]*Prole

default

[2] CTW

Valid,

active

low

[3] Safe

Option

Reset

The functionality of the bit is depending on the

selection parameter 8-10 Control Word Prole.

If set to 1, the frequency converter ignores the

remaining bits of the control word.

This function is only available in bits 12–15 of

the control word, if a safety option is mounted

in the frequency converter. The reset is executed

on a 0⇒1 transition, and resets the safety option

as set in parameter 42-24 Restart Behaviour.

8-14 Congurable Control Word CTW

Array [15]

Option: Function:

[4] PID error

inverse

[5] PID reset

I part

[6] PID

enable

Inverts the resulting error from the process PID

controller. Available only if

parameter 1-00 Conguration Mode is set to [6]

Surface Winder, [7] Extended PID Speed OL, or [8]

Extended PID Speed CL.

Resets the I-part of the process PID controller.

Equivalent to parameter 7-40 Process PID I-part

Reset. Available only if parameter 1-00 Congu-

ration Mode is set to [6] Surface Winder, [7]

Extended PID Speed OL, or [8] Extended PID Speed

CL.

Enables the extended process PID controller.

Equivalent to parameter 7-50 Process PID

Extended PID. Available only if

parameter 1-00 Conguration Mode is set to [6]

Surface Winder, [7] Extended PID Speed OL, or [8]

Extended PID Speed CL.

8-19 Product Code

Range: Function:

Size

related*

[0 -

2147483647]

Select 0 to read out the actual

eldbus product code according

to the mounted eldbus option.

Select 1 to read out the actual

vendor ID.

8-46 BTM Transaction Status

Option: Function:

[0] * O

[1] Transaction Started

[2] Transaction Comitting

[3] Transaction Timeout

[4] Err. Non-existing Par.

[5] Err. Par. Out of Range

[6] Transaction Failed

8-47 BTM Timeout

Range: Function:

60 s* [1 - 360 s] Select the BTM timeout after a BTM

transaction has been started.

8-48 BTM Maximum Errors

Range: Function:

21* [0 - 21] Selects the maximum allowed number of bulk

transfer mode errors before aborting. If it is set to

maximum, there is no abort.

30 Danfoss A/S © 12/2015 All rights reserved. MG92F102

Parameters Programming Guide

8-49 BTM Error Log

Range: Function:

0.255* [0.000 -

9999.255]

List of parameters that failed during

bulk transfer mode. The value after the

decimal break is the fault code (255

stands for no error).

8-50 Coasting Select

Option: Function:

Select control of the coasting function via the

terminals (digital input) and/or via the bus.

[0] Digital

input

[1] Bus Activates start command via the serial

[2] Logic AND Activates start command via the eldbus/serial

[3] * Logic OR Activates start command via the eldbus/serial

Activates start command via a digital input.

communication port or eldbus option.

communication port and 1 extra digital input.

communication port or via 1 of the digital

inputs.

8-51 Quick Stop Select

Select control of the quick stop function via the terminals (digital

input) and/or via the bus.

Option: Function:

[0] Digital input

[1] Bus

[2] Logic AND

[3] * Logic OR

8-52 DC Brake Select

Option: Function:

Select control of the DC brake via the terminals

(digital input) and/or via the eldbus.

NOTICE

When parameter 1-10 Motor Construction is