Page 1

Page 2

01.02.00 © Danfoss| Energy Meters| 2018.02| 2

1 Basic information .................................................................................................... 4

1.1 The physical layer ............................................................................................. 4

1.2 Wake up process and baud rate changes (IR) ....................................................... 4

1.3 Baud rate changes ............................................................................................ 4

1.3.1 Wait time before reply after correct message reception .................................... 5

1.4 Data Link layer (DLL) ......................................................................................... 5

1.4.1 C field (Control field, Function field) – Field size 1 byte ................................... 5

1.4.2 A Field (Address Field) – 1 byte .................................................................... 6

1.4.3 L Field – 2 fields with a size of 1 byte ............................................................ 7

1.4.4 CS field – 1 byte ......................................................................................... 7

1.5 Combined Transportation and application layer ..................................................... 8

1.5.1 CI Field (Control information field) ................................................................ 8

1.5.2 Long header ............................................................................................... 9

1.5.3 Status byte and error handling ................................................................... 10

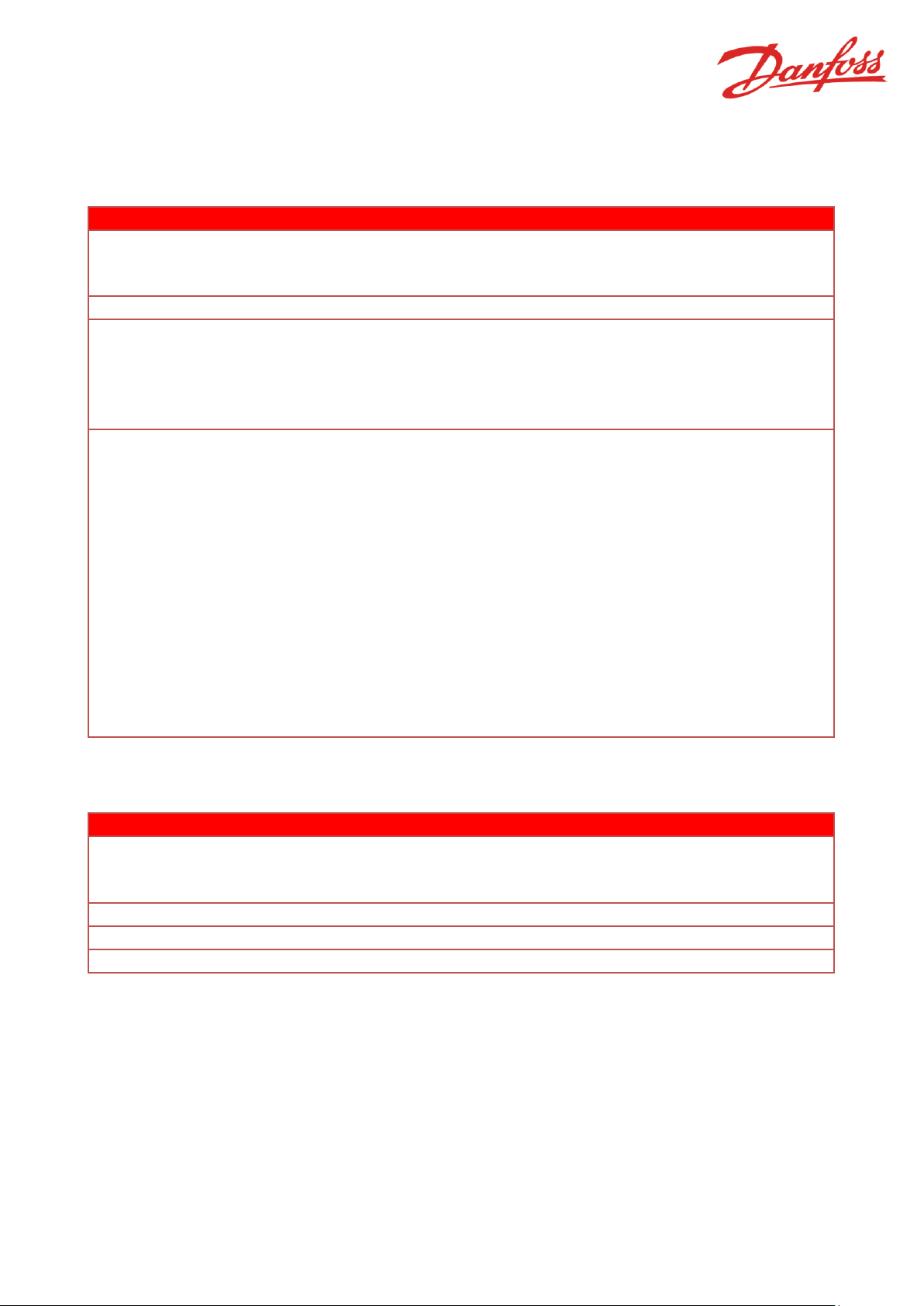

1.5.4 DIF & VIF configuration of data records ........................................................ 11

1.6 The standard read out ..................................................................................... 13

2 Communication process ......................................................................................... 16

2.1 M-Bus EN 13757 data frames ........................................................................... 16

2.2 Pulse readout ................................................................................................. 17

2.3 Application reset ............................................................................................. 17

2.4 Send/Confirm procedures available using the Danfoss Meter ................................. 21

2.4.1 SND_NKE ................................................................................................. 21

2.4.2 SND_UD .................................................................................................. 22

2.4.3 REQ_UD2 ................................................................................................. 34

2.4.4 RSP_UD ................................................................................................... 35

Annex A ..................................................................................................................... 36

Page 3

01.02.00 © Danfoss| Energy Meters| 2018.02| 3

Identify the needed telegrams from the EN13757 standard and determine how to implement

the SonoSelect 10 and SonoSafe 10 communication protocol into an M-Bus telegram. This

document contains the description the M-Bus protocol implemented for SonoSelect 10 and

SonoSafe 10. The M-Bus protocol will follow the EN13757 standard.

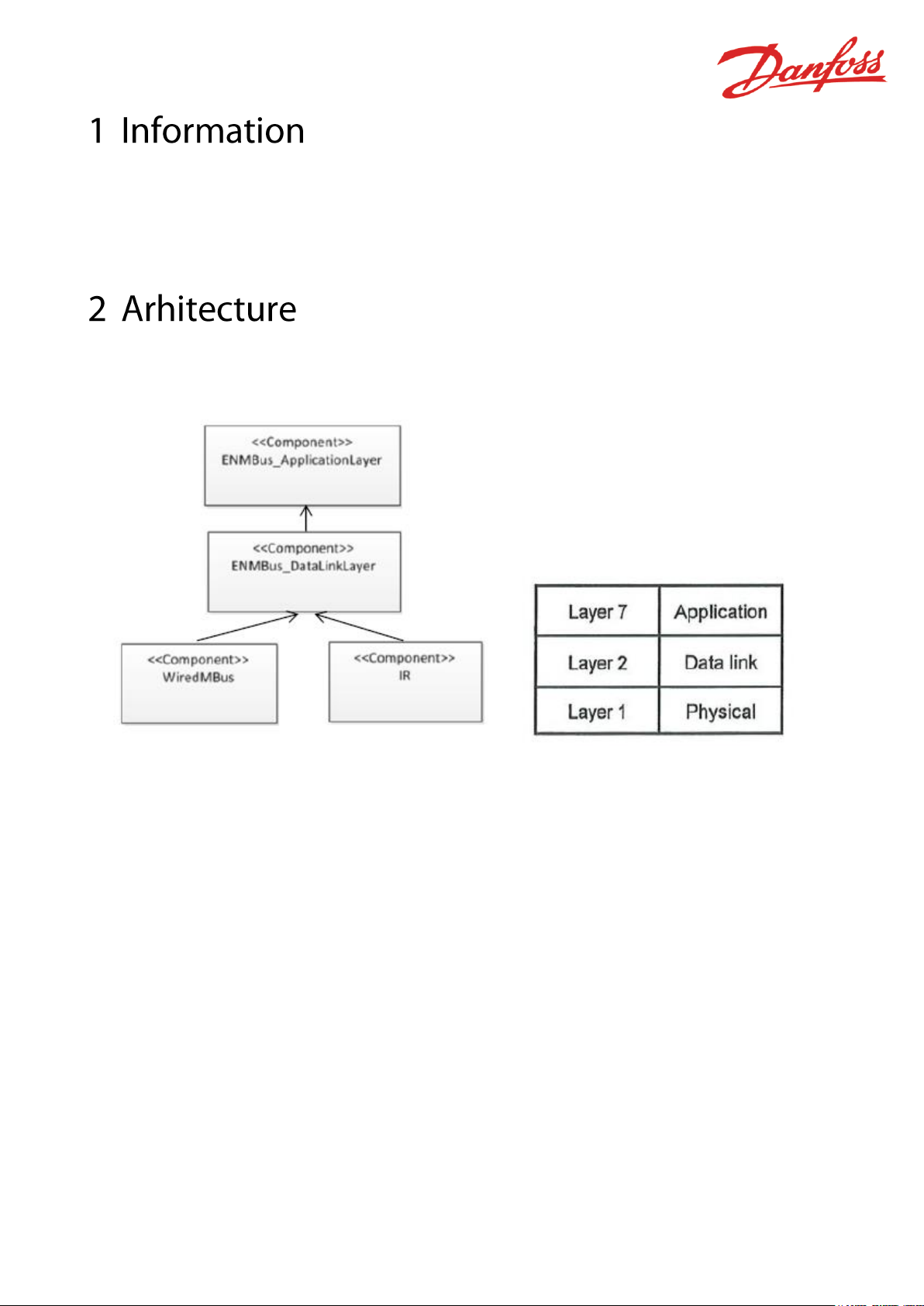

According to the software architecture of the SonoSelect 10 and SonoSafe 10 the

communication shall be split into three layers.

Figure 1 - OSI model and architecture of HM

The M-Bus protocol for the IR and Wired communication will be identical and therefore these

two components will share the same data-link and application layer. The M-Bus will only

support physical, data-link and combined transportation and application layer. The other layers

stated in EN13757-3 are optional and will not be part the wired M-Bus implementation of the

SonoSelect 10 and SonoSafe 10. According to the EN13757-1 standard the transportation layer

must be handled in an Application Layer.

Page 4

01.02.00 © Danfoss| Energy Meters| 2018.02| 4

The physical layer is a serial asynchronous half-duplex communication.

The meter act as a slave and each character communicated consist of 11-bits as shown below:

• 1 start bit (‘Space’)

• 8 data bits

• 1 parity bit (even)

• 1 stop bit (‘Mark’)

The master issues a request and the slave respond.

Since the optical interface uses the EN 13757-2 protocol, a wake-up message can be sent after

every ¡die time of> 330 bit times to the heat meter. The wake up message consists of zeroes

and ones alternating at the desired baud rate for a duration of (2,2 ± 0,1) s. After an idle time

of 33 bit times to 330 bit times, the communication can start.

The baud rate requirements from EN13757-3 are as follows:

• The IR supports 2400 and 4800 Baud

• The wired baud rate supports 300, 2400, 4800 and 9600

• Baud rate is kept after reset of device.

Meters with hardware issue 5 have auto baudrate detection on both the IR and Wired M-Bus

interface.

Maximum data records:

The maximum data record length is 235 bytes

Wildcard search (Secondary address)

Secondary address is found by using a wildcard search (CI = 52H). The top positions are run

through in ten selections from 0-9 (0FFFFFFF – 9FFFFFFF). If slave is found it answers with an

ACK and the master requests the full secondary address which is returned in a RSP_UD from

the slave. Any collisions and the master vary the next positions and hold the existing one.

Page 5

01.02.00 © Danfoss| Energy Meters| 2018.02| 5

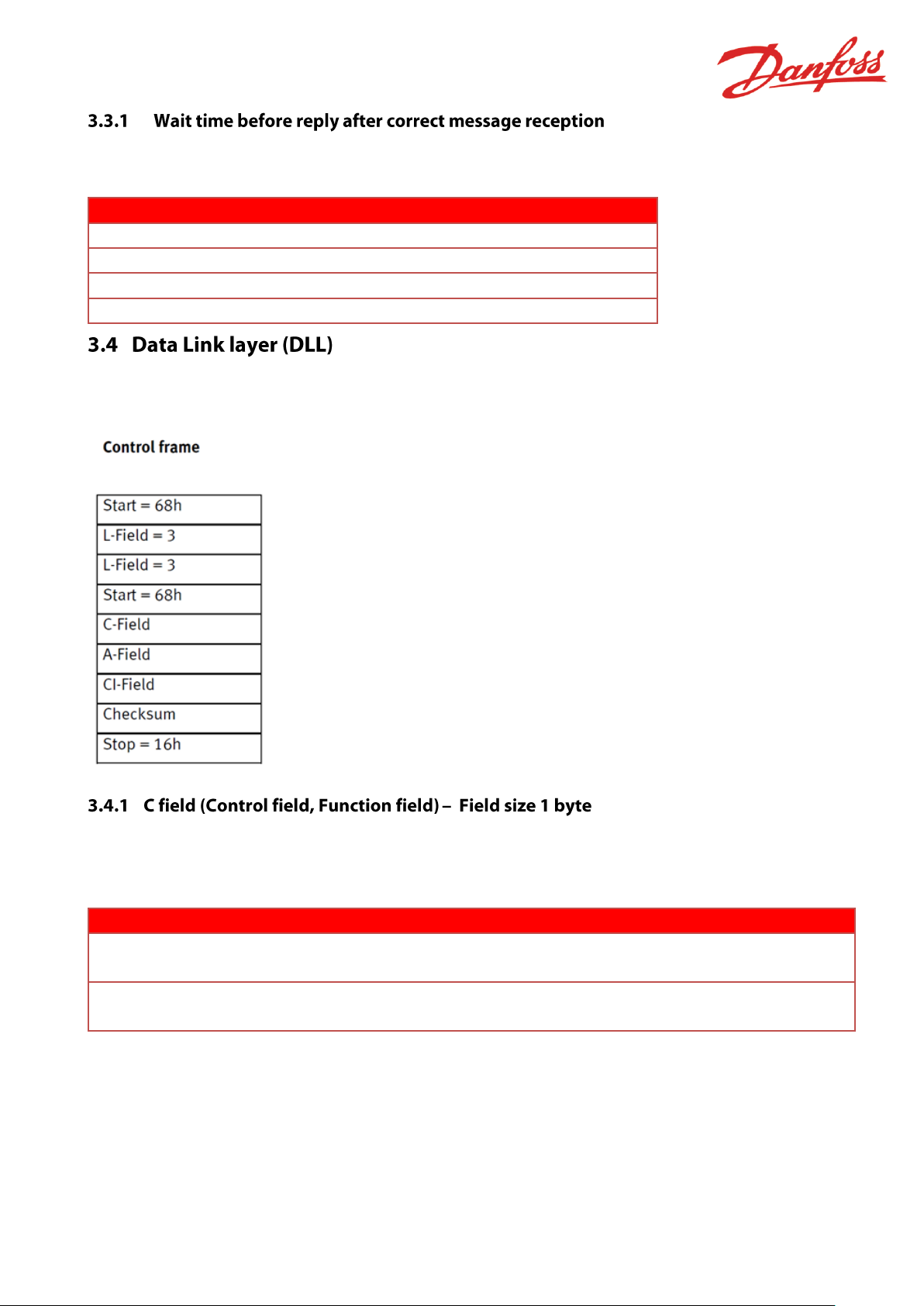

After reception of valid telegram the slave has to wait between 11bit time and (330 bit times +

50ms) before answering (EN1434-3)

Baud rate

Min.

Max.

300 Baud

36,7ms

1150ms

2400 Baud

4,6ms

187,5ms

4800 Baud

2,3ms

118,8ms

9600 Baud

1,2ms

84,4ms

In this section the data link layer is described. One of the frames used in the M-Bus standard is

shown below. The other M-Bus frames can be found in section 4.1.

The function field specifies the direction of the data flow and has various additional tasks in

both calling and replying directions but many of these are optional and therefore not

implemented.

Bit Number

7 6 5 4 3 2 1

0

Calling

direction

0 1 FCB

FCV

F3

F2

F1

F0

Reply

Direction

0

0

ACD

DFC

F3

F2

F1

F0

• Bit7 reserved for future use.

• Bit6 specifies the direction of the data flow. If it is set to 1 the communication has the

direction Master to slave and vice versa if it is set to 0.

• FCB The slave do not act on this bit and is always sending new data.

• FCV The slave ignores this bit.

• DFC (data flow control) Not supported must be 0.

• ACD (Access demand) Not supported must be 0.

Page 6

01.02.00 © Danfoss| Energy Meters| 2018.02| 6

• Control field F3-F0 the control field code tells the function or action of the message.

The control field has 7 predefined control field shown below.

Name

C field binary

C field

(HEX)

Telegram

Description

SND_NKE

0100 0000

40

Short frame

Initialization of slave

SND_UD

01F1 0011

53/73

Long/Control

Send user data to slave

REQ_UD1

01F1 1010

5A/7A

Short frame

Request class 1 data

REQ_UD2

01F1 1011

5B/7B

Short frame

Request class 2 data

REQ_SKE

0100 1001

49

Short frame

Status request

RSP_SKE

0000 1011

0B

Short frame

Status data, slave to

master

RSP_UD

00AD 1000

08

Long/Control

Data transfer from slave

to master after request

REQ_UD1 telegrams are answered with ACK because the Alarm protocols are not supported.

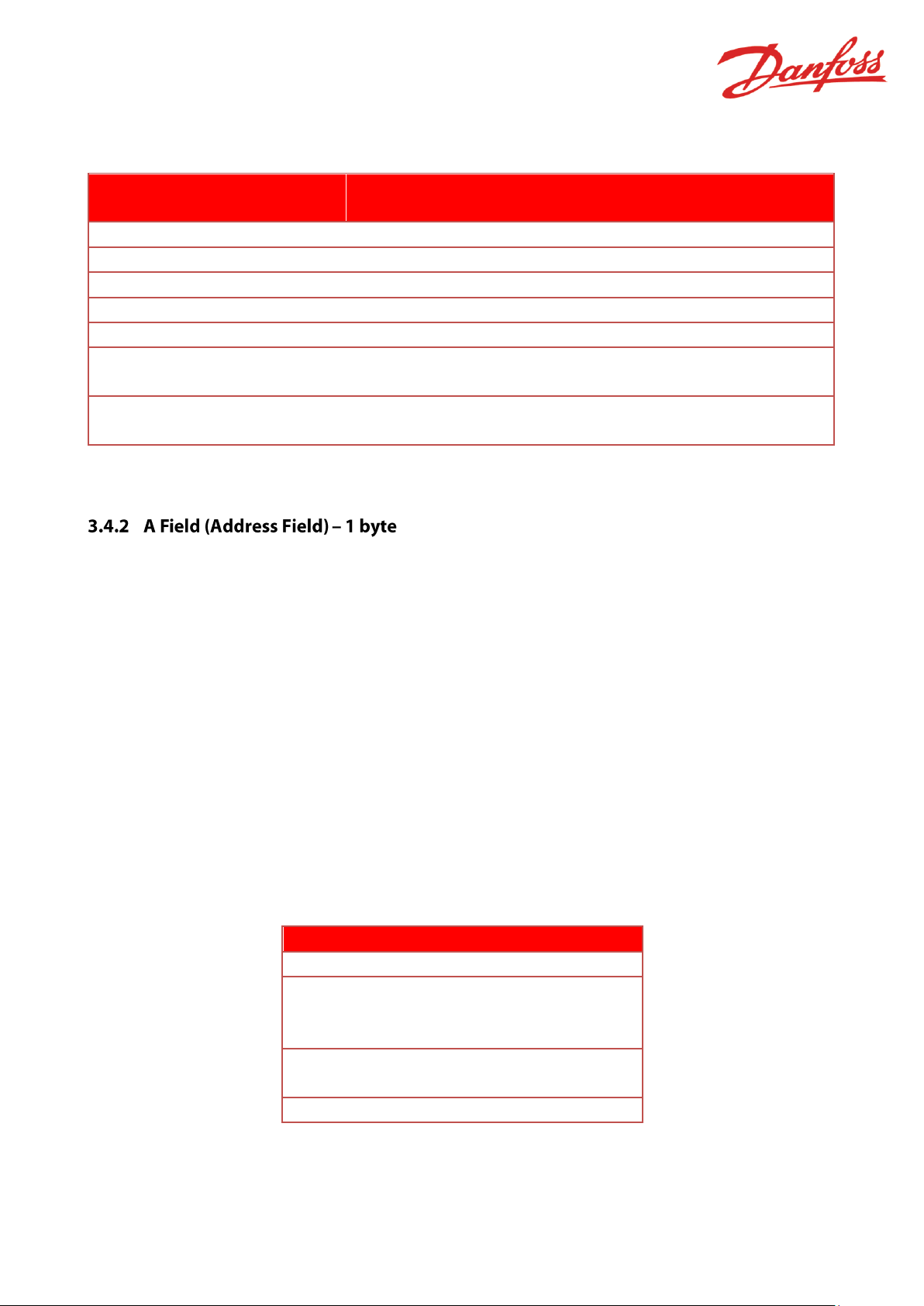

The primary address of the meter can be set to a value from 0-250. The default primary

address is part of the serial number (red letters: ssssswwNNyyww) and is always a number

from 00-99. To change the primary address either use the SonoApp or M-Bus command

described later in this document.

Point-to-point addressing (0xFE) is intended for communication using the infrared eye or for

network with only one slave (used for test of network with one slave).

Broadcast (0xFF) is used to communicate across the network to all the slaves e.g. to set a new

baud rate on all slaves at the same time. Be aware that no acknowledge byte is replied from

the slave in broadcast mode.

The secondary address can be used to select a slave. This slave can then afterwards be

contacted using the primary address FDH. All slaves have an unique secondary address which

ensures only a single slave answers.

Addressing Form

Slave Addressing

Primary addressing

0-250

Secondary

addressing and

selected slave

253 (FDH)

Point-to-Point

addressing

254 (FEH)

Broadcast

255 (FFH)

Page 7

01.02.00 © Danfoss| Energy Meters| 2018.02| 7

The Length Field (L Field) defines the number of bytes (expressed in hex value) of the Active

Data making up the telegram, plus 3 bytes for the C, A and Cl Fields.

This field is always transmitted twice in Long Telegrams (RSP_UD) see 4.1.

The Checksum (CS Field) serves to recognize transmission and synchronization faults. The

checksum is calculated on the Active Data making up the telegram, plus 3 bytes for the C, A

and Cl Fields. All bytes are added together in a 8 bit unsigned integer, which means that when

the value gets larger than FFh it will wrap around and start all over.

Page 8

01.02.00 © Danfoss| Energy Meters| 2018.02| 8

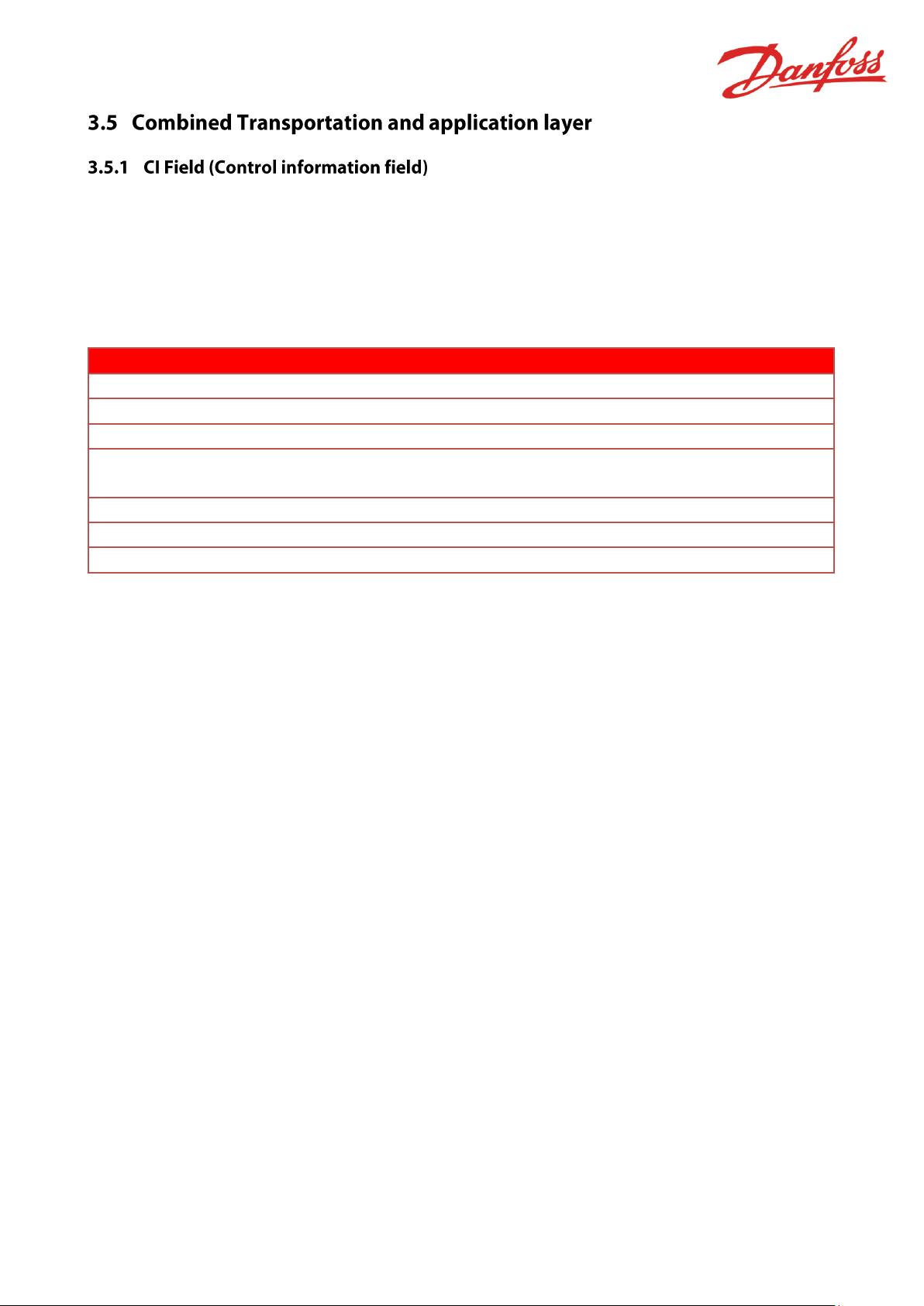

The CI-Field declares the transportation direction and the Application protocol (if exists). The

CI-Field declares also which type of Transport Layer (“None”, “Short” and “Long” header) is

applied.

In the SonoSelect/Safe meters with wired M-Bust the long header (0x72) is always used.

The SonoSelect/Safe meters supports the following CI-Fields.

CI-field (HEX)

Direction

50

Application reset

51

Data send to device

52

Slave select (no header)

72

The telegram contains data for the master

with long header

B8

Set baud rate 300 (only wired M-Bus)

BB

Set Baud Rate to 2400

BD

Set Baud Rate to 9600

Page 9

01.02.00 © Danfoss| Energy Meters| 2018.02| 9

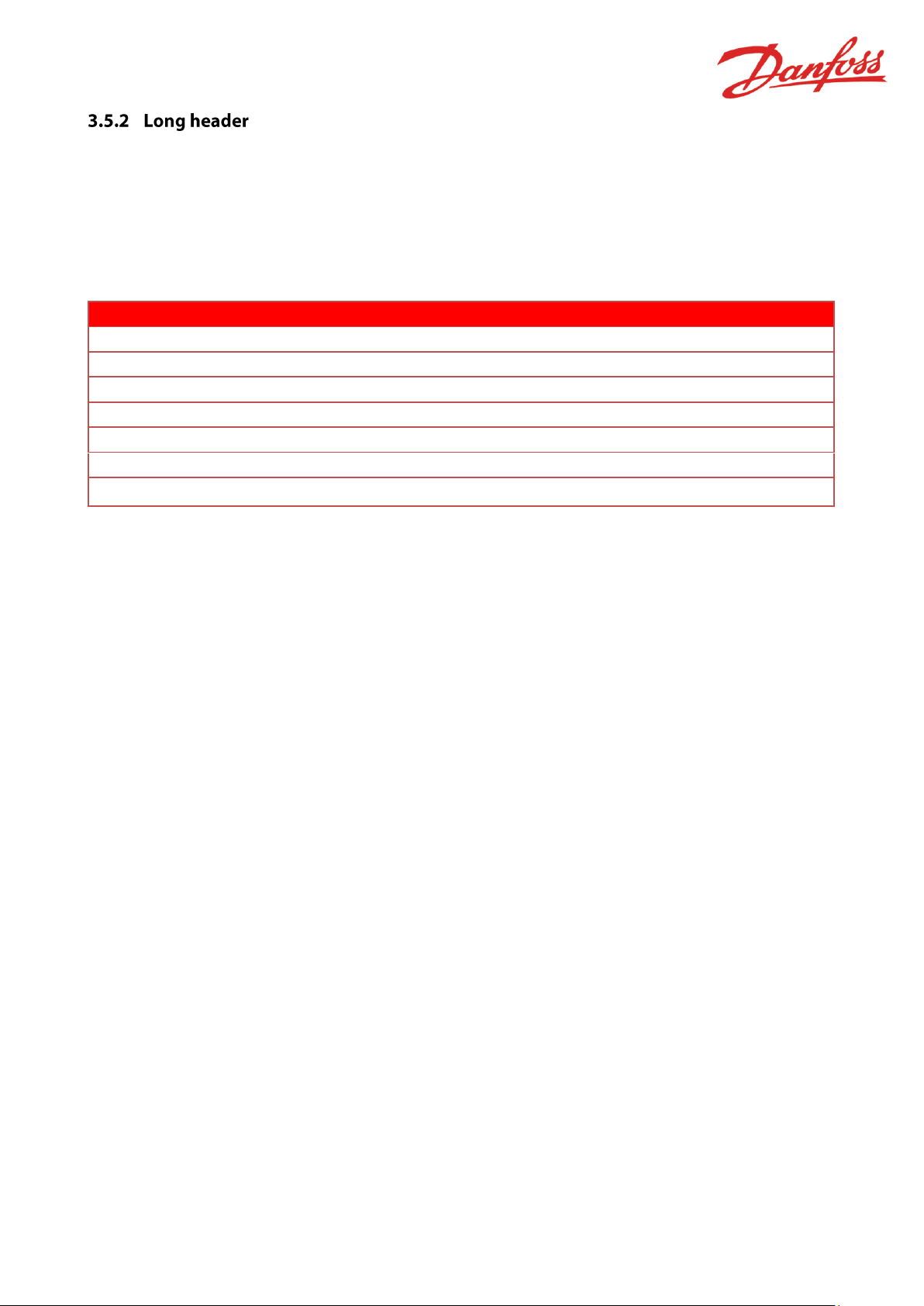

The long header contains 12 bytes which is used to identify the Meter, hold track of new or old

message and to apply encryption.

The encryption is not currently available for wired Danfoss Meters which means the

configuration field always is 0000H.

The 12 byte long header is shown in the table below:

Byte Nr.

Size(Byte)

Value(Hex)

Description

1-4

4

xx xx xx xx

Meter identification number

5-6 2 D310

Manufacturer’s ID (DFS Danfoss 10D3h)

7 1 xx

Version number firmware (00-FF)

8 1 04/0C

Medium: Heat outlet/inlet

9 1 xx

Access Number (00-FF-> 00)

10 1 xx

Status

11-12 2 0000

Configuration

The identification number (secondary address) is a non-changeable (according to OMS)

number in between 00000000 and 99999999. The identification number is part of the Danfoss

Meters serial number and is unique. (In installations with other meters where same address is

present the address can be change with SonoApp or M-Bus command shown later)

The secondary address is derived from the serial number. The serial number has the following

format:

ssssswwNNyyww

The secondary address has the following format

ywwsssss

The manufactures ID is used to identify the manufacture of the Meter. Each manufacture has a

flag consisting of three capital letters which can be combined to two bytes according to

EN13757-3. The Danfoss manufacture flag is DFS (10D3h) and this flag is always part of the

long header.

The version number is used to identify if the meter is of type:

• SonoSafe (0x01)

• SonoSelect (0x02).

The medium byte identifies the flow sensor installation of the Meter and has two settings for

each meter type:

• Heat Inlet meters (supply 0x0C)

• Heat Outlet meters (return 0x04).

• Cooling Meter (Volume measured at return temperature: outlet)

Page 10

01.02.00 © Danfoss| Energy Meters| 2018.02| 10

• Cooling Meter (Volume measured at flow temperature: inlet)

• Combined meter

• Water meter (For pulse readout only)

The Access Number has an unsigned binary coding and is incremented (modulo 256) by one

after each RSP-UD is send from the slave.

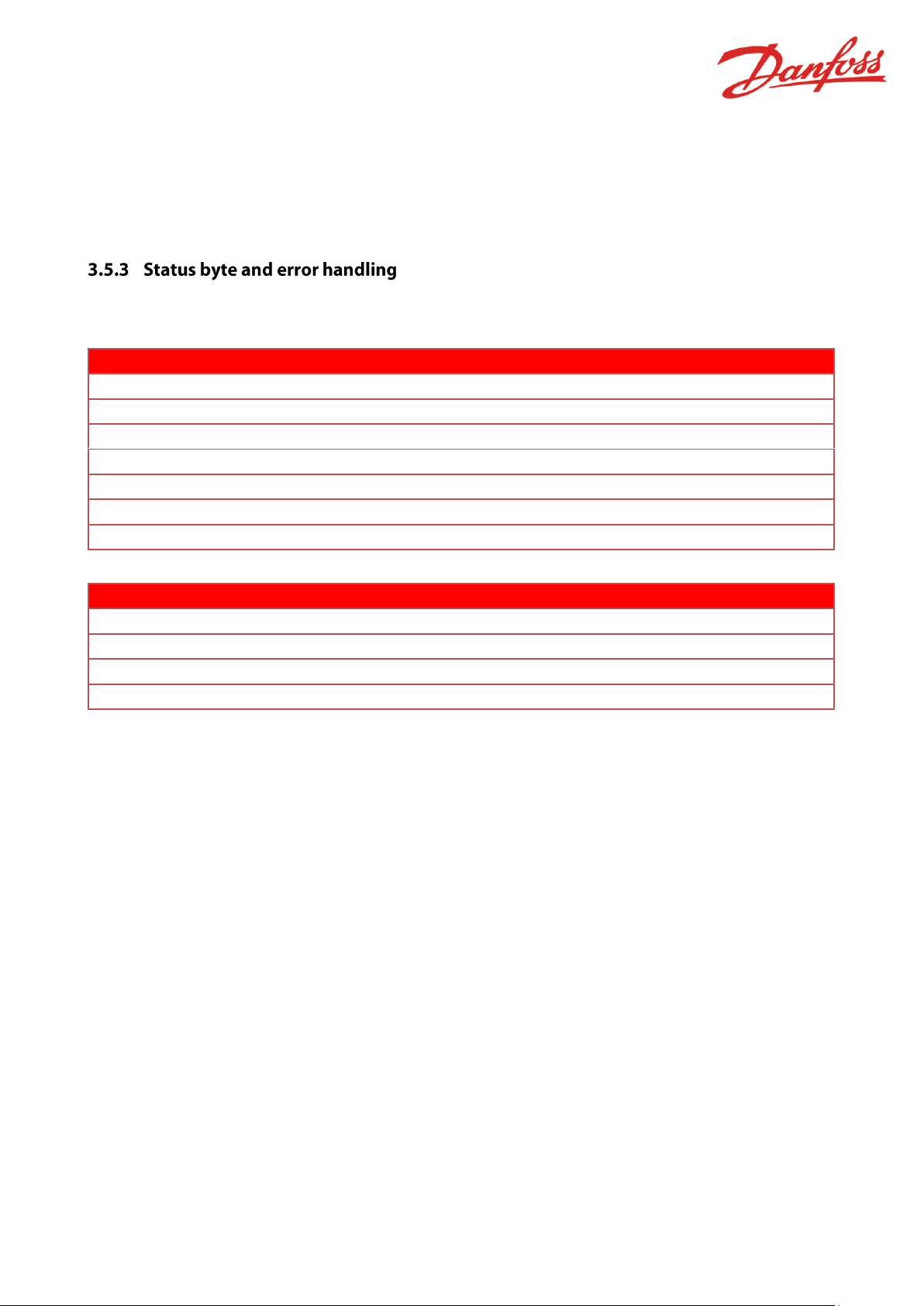

The status byte is used to indicate different potential errors in the Meter. The errors are stated

in the table below:

Bit

Meaning with bit set

Significance with bit not set

0,1

See table 5

See table 5

2

Power Low

Power Ok

3

Permanent error

No Permanent error

4

Temporary error

No Temporary error

5

Specific to manufacturer

Specific to manufacturer

6

Specific to manufacturer

Specific to manufacturer

7

Specific to manufacturer

Specific to manufacturer

Status bit 1 bit 0

0 0

No Error

0 1

Application busy

1 0

Any application error

1 1

Abnormal condition/alarm

The status bit shall be used in this meaning:

Power low:

Warning – The bit “Power Low” is set only to signal interruption of external power supply or

end of battery life time

Permanent error:

Failure – The bit “Permanent error” is set only if the meter signals a fatal device error which

requires a service action.

Temporary error:

Warning – The bit “Temporary error” is set only if the meter signals a slight error condition

which not immediately requires a service action. This could be an error which may later

disappear.

Any application error:

The application error shall be used to communicate a failure during the interpretation or

execution of a received command, e.g. a message which could not be decrypted.

Page 11

01.02.00 © Danfoss| Energy Meters| 2018.02| 11

Abnormal conditions:

Shall be used if a correct working application detects an abnormal behavior like a permanent

high flow.

The most critical active E-number (Error shown in the display) is sent as the status byte. The

most critical error is E1 and least critical is E32.

Below is a table showing the bit pattern.

ENumber

E1

E2

E3

E4

E5

E6

E7

E8

E9

E10

E11

E12

E13

Hex

code

0x08

0x10

0x28

0x04

0x24

0x30

0x50

0x70

0x90

0xB0

0xD0

0xF0

0x48

ENumber

E14

E15

E16

E17

E18

E32

Hex

code

0x40

0x44

0x60

0x62

0x13

0x92

Error type

E number

Power Low

E4, E5, E15

Permanent error

E1, E3, E13

Temporary error

E2, E6, E7, E8, E9, E10, E11, E12, E14, E16,

E17, E18, E32

The application layer contains the data sent from the slave to the master or vice versa.

Every data record sent which is not manufacture specific have the following data record header

(DRH)

Data Information Block (DIB)

Value Information Block (VIB)

DIF

DIFE

VIF

VIFE

Data

1 Byte

0-10Byte(s)

1 Bytes

0-10 Byte(s)

0-n Bytes

Page 12

01.02.00 © Danfoss| Energy Meters| 2018.02| 12

The Data Information Block (DIB) contains at least one DIF but can be extended by 10 DIFE if

needed.

The DIFs supported by the Danfoss Meters:

Bit

Name

Description

7

Extension Bit

Specifies if a DIFE byte follows:

0 = No

1 = Yes

6

LSB of Storage Number

0 if log is not send

5-4

Function Field

Specifies the kind of value

00 = instantaneous value

01 = Maximum value

10 = Minimum Value

11 = Value during error state

3-0

Data Field

Length and Coding of Data:

0001 (0x01): 8 Bit Integer

0010 (0x02): 16 Bit Integer

0011 (0x03): 24 Bit Integer

0100 (0x04): 32 Bit Integer

0110 (0x06): 48 bit Integer (only for record)

0111 (0x07): 64 Bit Integer (only for record)

1001 (0x09): 2 digit BCD

1010 (0x0A): 4 digit BCD

1011 (0x0B) 6 digit BCD

1100 (0x0C): 8 digit BCD

1101 (0x0D): Variable length (Only for TX)

1111 (0x0F): Manufacture Specific Data

The DIFE supported by Danfoss Meters:

Bit

Name

Description

7

Extension Bit

Specifies if a DIFE byte follows:

0 = No

1 = Yes

6

Unit

Specifies if it is pulse counter or cooling value

5-4

Tariff

Used oC*m^3 records

3-0

Storage number

0000 (only used for logs)

The DIFE is used for selection of pulse 1 and pulse 2 counters. If first DIFE has the unit set to

1, it is pulse counter 1 and if the unit is set in the second DIFE, it is pulse counter 2 (see

4.4.2.7). The DIFE unit 3 is used for cooling records (Energy, Volume, Max Flow, Max Power).

The DIFE storage number is used to show the log values and which type of log there are sent.

The storage number 1 & 2 are used for year log 1 and 2.

The storage number from 3-26 is used for month log 1-24.

Page 13

01.02.00 © Danfoss| Energy Meters| 2018.02| 13

The Value Information Block (VIB) contains minimum 1 VIF but can be extended by 10 VIFE if

needed (Danfoss Meters support only one VIF and up to 4 VIFEs).

The coding of the VIF is:

Bit

Name

Description

7

Extension Bit

Specifies if a VIFE byte follows the VIF

6-0

Value Information

Contains information for a single value.

Unit and multiplier of each data record

The coding of the VIFE is:

Bit

Name

Description

7

Extension Bit

Specifies if a VIFE byte follows the VIFE

6-0

Value Information

Contains information for a single value.

Unit, multiplication, etc.

• Energy

• Volume

• Flow rate

• Power

• Forward temperature

• Return temperature

• Difference temperature

• External temperature

• Current time

• Operation hours

• Hour Counter OK

Page 14

01.02.00 © Danfoss| Energy Meters| 2018.02| 14

The VIF & VIFE combination used in the SonoSelect/Safe meters:

VIF (HEX)

VIFE (HEX)

Description

Unit

00

-

Energy

0.000001 kWh

01

-

Energy

0.00001 kWh

02

-

Energy

0.0001 kWh

03

-

Energy

0.001 kWh

04

-

Energy

0.01 kWh

05

-

Energy

0.1 kWh

06

-

Energy

1 kWh

03

-

Energy

0.000001 MWh

04

-

Energy

0.00001 MWh

05

-

Energy

0.0001 MWh

06

-

Energy

0.001 MWh

07

-

Energy

0.01 MWh

FB

00

Energy

0.1 MWh

FB

01

Energy

1 MWh

0B

-

Energy

0.000001 GJ

0C

-

Energy

0.00001 GJ

0D

-

Energy

0.0001 GJ

0E

-

Energy

0.001 GJ

0F

-

Energy

0.01 GJ

FB

08

Energy

0.1 GJ

FB

09

Energy

1 GJ

FB

8C 74

Energy

0.000001 GCal

FB

8C 75

Energy

0.00001 GCal

FB

0C

Energy

0.0001 GCal

FB

0D

Energy

0.001 GCal

FB

0E

Energy

0.01 GCal

FB

0F

Energy

0.1 GCal

FB

8F 77

Energy

1 GCal

90

70

Volume

0.000000000001 m3

(full resolution pico m

3)

10

-

Volume

0.000001 m3

11

-

Volume

0.00001 m3

12

-

Volume

0.0001 m3

13

-

Volume

0.001 m3

14

-

Volume

0.01 m3

15

-

Volume

0.1 m3

16

-

Volume

1 m

3

98

70

Mass

0.000000001 kg

38

-

Flow rate

0.001 l/h

39

-

Flow rate

0.01 l/h

Page 15

01.02.00 © Danfoss| Energy Meters| 2018.02| 15

3A

-

Flow rate

0.1 l/h

3B

-

Flow rate

1 l/h

3B

-

Flow rate

0.001 m3/h

3C

-

Flow rate

0.01 m3/h

3D

-

Flow rate

0.1 m3/h

3E

-

Flow rate

1 m3/h

2B

-

Power

0.001 kW

2C

-

Power

0.01 kW

2D

-

Power

0.1 kW

2E

-

Power

1 kW

58 - Forward temperature

0.001 °C

59 - Forward temperature

0.01 °C

5A - Forward temperature

0.1 °C

5B - Forward temperature

1 °C

5C - Return temperature

0.001 °C

5D - Return temperature

0.01 °C

5E - Return temperature

0.1 °C

5F - Return temperature

1 °C

64 - External temperature

0.001 °C

65 - External temperature

0.01 °C

66 - External temperature

0.1 °C

67 - External temperature

1 °C

60 - Difference temperature

0.001K

61 - Difference temperature

0.01K

62 - Difference temperature

0.1K

63 - Difference temperature

1K

FD

09

Device type

Meter type

FD

3A

Without unit

FWChecksum

26 - Hour Counter OK

1h

22 - Factory hour counter hours

1h

6C

-

Date

Date (Type G)

6D

Current time

Date and time (type F)

A6

18

Hour counter Alarm

1h

FD

70

Battery change date

Date (Type G)

FD

6C

Operating time battery

hours

FD

74

Remaining battery life time

days

EC

7E

Next accounting date

Date (type G)

FD

BA 70

Multiplicative correction factor

10^(-6)

Page 16

01.02.00 © Danfoss| Energy Meters| 2018.02| 16

There are 4 different data frame formats (See table below) available for communicating

between the master and slave using the EN 13757-3 M-Bus standard and these are supported

by the Danfoss Meters.

• Single character frame, slave uses this frame to send an acknowledgement for the

data received from the master.

• Short frame which is used to e.g. make a data request master to slave

• Control frame is used to e.g. change the baud rate of a slave

• Long frame is used to e.g. change which data the slave should return and is used as

response frame for the slave containing the data requested by the master.

M-Bus is an asynchronous serial bit transmission in half-duplex mode, which means that it is

only possible to transmit in one direction at a time. The standard way of communicating is to

send a SND which the slave will answer with an acknowledgement (ACK) or a request (REQ)

which the slave will respond on with a RSP.

The communication process will follow one of the following two kinds of transmissions:

Master send / Slave confirm : SND/ACK

Master request / Slave respond : REQ/RSP

The standard communication between an M-Bus master and an M-Bus slave is:

Command

Master

Slave

Deselect old slave

SND_NKE

ACK

Select new slave

SND_UD

ACK

Request data

REQ_UD2

RSP_UD

Page 17

01.02.00 © Danfoss| Energy Meters| 2018.02| 17

The meter supports up to two pulse input when a module is inserted. Each of the pulse

interfaces can be configured by SonoApp, to obtain a separate secondary address in the meter.

The configuration of the Pulse interface is done using SonoApp.

It is possible to readout each of these pulse meters individually using the RSP_UD command.

The meters returns an accumulated volume register and a month log record with accumulated

volume and a timestamp.

The pulse addresses only support readout (+ Slave select and SND_NKE) and not the rest of

the commands in this document. Primary addressing is also not supported to obtain the pulse

values.

4.3.1.1 Application reset

The master is capable of changing the current readout temporary, using the command in

4.4.2.9. The Application Reset, resets the access number to 0 and returns the readout to a

normal standard readout telegram. The Application reset telegram is below:

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

04H

2nd Start to Checksum

L Field

1

04H

2nd Start to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FDH

Primary Address

CI 1 50H

Application reset byte

TPL

Reset byte

1

00H

Application reset subcode

Checksum

1

C0H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

The SonoSelect and SonoSafe with the FW 01.03 or above supports multiple application reset

telegrams, which changes the outputted registers until another reset arrives.

If the meter is a Combined Meter (Heat and Cooling), the telegrams contains both the heat

and cooling accumulated registers.

Page 18

01.02.00 © Danfoss| Energy Meters| 2018.02| 18

The M-Bus standard supports the following application resets:

Application reset subcode

Telegram data

0x00

Standard Danfoss output

(Diagnosis data will only

be part of this telegram)

Accumulated Energy (heat and cooling for combined)

Accumulated Volume (heat and cooling for combined)

Flow Rate

Power

Supply Temperature

Return Temperature

Difference Temperature

External Temperature (Enclosure)

Current Time

Hour counter factory (operating hours since factory)

Hour counter ok (Operating hours without error)

0x10

User Data

Accumulated Energy (heat and cooling for combined)

Accumulated Volume (heat and cooling for combined)

Current Time

Hour counter factory (operating hours since factory)

Month log 1 (newest year log) (storage number = 3)

• Date

• Accumulated Energy

• Accumulated Volume

• Optional (max power and flow)

Year log 1 (newest year log) (storage number = 1)

• Date

• Accumulated Energy (heat and cooling for combined)

• Accumulated Volume (heat and cooling for combined)

• Optional (max power and flow)

0x20

Simple billing

Accumulated Energy (heat and cooling for combined)

Accumulated Volume (heat and cooling for combined)

Flow Rate

Power

Supply Temperature

Return Temperature

Difference Temperature

Hour counter factory (operating hours since factory)

Current Time

0x30

Enhanced billing,

historical energy registers

(Combined meter will

only return 6 months and

1 year)

Accumulated Energy (heat and cooling for combined)

Accumulated Volume (heat and cooling for combined)

Year log 1 (newest year log) (storage number = 1)

• Date

• Accumulated Energy (heat and cooling for combined)

Year log 2 (storage number = 2)

• Date

Page 19

01.02.00 © Danfoss| Energy Meters| 2018.02| 19

Combined meter has both

cooling and heat energy

• Accumulated Energy

Month log 1 (newest month log) (storage number = 3)

• Date

• Accumulated Energy (heat and cooling for combined)

Month log 2 (storage number = 4)

• Date

• Accumulated Energy (heat and cooling for combined)

Month log 3 (storage number = 5)

• Date

• Accumulated Energy (heat and cooling for combined)

Month log 4 (storage number = 6)

• Date

• Accumulated Energy (heat and cooling for combined)

Month log 5 (storage number = 7)

• Date

• Accumulated Energy (heat and cooling for combined)

Month log 6 (storage number = 8)

• Date

• Accumulated Energy (heat and cooling for combined)

Month log 7 (storage number = 9)

• Date

• Accumulated Energy

Month log 8 (storage number = 10)

• Date

• Accumulated Energy

Month log 9 (storage number = 11)

• Date

• Accumulated Energy

Month log 10 (storage number = 12)

• Date

• Accumulated Energy

Month log 11 (storage number = 13)

• Date

• Accumulated Energy

Month log 12 (storage number = 14)

• Date

• Accumulated Energy

0x40

Enhanced billing,

historical volume

registers

(Combined meter will

only return 6 months and

1 year)

Accumulated Energy

Accumulated Volume

Year log 1 (newest year log) (storage number = 1)

• Date

• Accumulated Volume (heat and cooling for combined)

Year log 2 (storage number = 2)

• Date

• Accumulated Volume

Page 20

01.02.00 © Danfoss| Energy Meters| 2018.02| 20

Combined meter has both

cooling and heat volume

Month log 1 (newest month log) (storage number = 3)

• Date

• Accumulated Volume (heat and cooling for combined)

Month log 2 (storage number = 4)

• Date

• Accumulated Volume (heat and cooling for combined)

Month log 3 (storage number = 5)

• Date

• Accumulated Volume (heat and cooling for combined)

Month log 4 (storage number = 6)

• Date

• Accumulated Volume (heat and cooling for combined)

Month log 5 (storage number = 7)

• Date

• Accumulated Volume (heat and cooling for combined)

Month log 6 (storage number = 8)

• Date

• Accumulated Volume (heat and cooling for combined)

Month log 7 (storage number = 9)

• Date

• Accumulated Volume

Month log 8 (storage number = 10)

• Date

• Accumulated Volume

Month log 9 (storage number = 11)

• Date

• Accumulated Volume

Month log 10 (storage number = 12)

• Date

• Accumulated Volume

Month log 11 (storage number = 13)

• Date

• Accumulated Volume

Month log 12 (storage number = 14)

• Date

• Accumulated Volume

0x50

Instant values

Accumulated Energy (heat and cooling for combined)

Accumulated Volume (heat and cooling for combined)

Flow Rate

Power

Supply Temperature

Return Temperature

Difference Temperature

External Temperature (Enclosure)

Current time

Page 21

01.02.00 © Danfoss| Energy Meters| 2018.02| 21

Hour counter factory (operating hours since factory)

Hour counter ok (Operating hours without error)

Hour counter alarm (Operating hour with error)

0x90

Testing

High resolution Accumulated Energy

(heat and cooling for combined)

High resolution Accumulated Volume

(heat and cooling for combined)

Flow Rate

Power

Supply Temperature

Return Temperature

Difference Temperature

This command is used after an interrupts or as a beginning of communication. A slave selected

for secondary addressing is deselected, if a SND_NKE to address 253 or a command to a nonmatching secondary address is received.

The selected slave acknowledges the deselection if a SND_NKE is received on address 253.

Field name

# of

Bytes

Value

Description

Layer

Start

1

10H

Start of short frame

Data Link

Layer (DLL)

C Field

1

40H

SND_NKE

A Field

1

FDH

Primary Address

Checksum

1

4AH

Checksum

End of Frame

1

16H

Answer of the Slave: E5h

Page 22

01.02.00 © Danfoss| Energy Meters| 2018.02| 22

These telegrams are used to send data from the master to the slave. The slave confirms any

correct receptions (requires correct address, primary or secondary) of these telegrams also if

the command received is not supported.

4.4.2.1 Set primary address

This telegram changes a Meters primary address using its current primary address:

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

06H

C field to Checksum

L Field

1

06H

C field to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FEH

Current Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 01H

8-bit integer

APL

VIF 1 7AH

Change primary address

Value

1

05H

New Primary Address (address 5)

Checksum

1

42H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 23

01.02.00 © Danfoss| Energy Meters| 2018.02| 23

4.4.2.2 Set secondary address

The secondary address has the following structure:

Byte Nr.

Size(Byte)

Value(Hex)

Description

1-4

4

xx xx xx xx

HM identification number

5-6 2 10D3

Manufacturer’s ID (DFS Danfoss)

7 1 xx

Version number firmware (00-FF)

8 1 04/0C

Medium: Heat

The secondary address is unique but in installations with other meter types with matching

secondary access, it is possible to change the secondary address using this command or

SonoAPP.

Field name

# of

Bytes

Value

Description

Start of Frame

1

68H

Start of control frame

Data Link Layer (DLL)

L Field

1

09H

C field to Checksum

L Field

1

09H

C field to Checksum

Start 1 68H

C Field

1

73H

SND_UD

A Field

1

FEH

Primary address (00-FA = 0-

250), FE(point to point), FD

selected slave

CI Field

1

51H

TPL

DIF 1 0CH

8 digits BCD, 4 byte

Application Layer

(APL)

VIF 1 79H

Set secondary address

New secondary

address

1

78H

Digit 7 and 8

Range: 00-99

New secondary

address

1

56H

Digit 5 and 6

Range: 00-99

New secondary

address

1

34H

Digit 3 and 4

Range: 00-99

New secondary

address

1

12H

Digit 1 and 2

Range: 00-99

Checksum

1

3BH

Checksum

DLL

End of Frame

1

16H

Stop character

The secondary address can be changed using one of the following DIF types:

• INT32

• 8 Digit BCD

• INT64 (Most data concentrators are using the INT64)

The address must in all types be entered as a BCD code. (e.g. address 12345678 is

0x12345678). The last four bytes in the INT64 will not change anything in the Meter.

Page 24

01.02.00 © Danfoss| Energy Meters| 2018.02| 24

4.4.2.3 Set Baud Rate

The Meter supports the Baud Rates 300, 2400, 4800 and 9600 (Meters with Hardware Issue 5

have auto baudrate detection).

The Meter answers with single character acknowledgement (E5h) using the old baud rate.

When the ACK is transmitted, the Meter switch to the new baud rate.

The master makes sure that the Meter has changed into the correct baud rate. To do this the

master sends a command to the Meter within 2 min of the baud rate change. If the Meter

doesn’t answer with an ACK after 3 retry, the master has to return to the old baud rate.

If the Meter doesn’t support the new baud rate it stays on the old baud rate after sending an

ACK.

The command for changing baud rate is:

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data link Layer

(DLL)

L Field

1

03H

2nd Start to Checksum

L Field

1

03H

2nd Start to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

XXH

Primary Address

CI Field

1

B8H

BBH

BCH

BDH

300 Baud

2400 Baud

4800 Baud

9600 Baud

TPL

Checksum

1

??H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 25

01.02.00 © Danfoss| Energy Meters| 2018.02| 25

4.4.2.4 Slave select

To select a Meter the following command must be used:

Field name

# of

Bytes

Value

Description

Start 1 68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

0BH

2nd Start to Checksum

L Field

1

0BH

2nd Start to Checksum

Start 1 68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FDH

Use secondary address

CI Field

1

52H

TPL

Secondary

address

8

xx xx xx

xx xx xx

xx xx

Current secondary address

Checksum

1

??H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 26

01.02.00 © Danfoss| Energy Meters| 2018.02| 26

4.4.2.5 Date and time

The date and time can be changed using the following SND_UD frame.

This command requires the Meter to have an access level “Installation”.

Example of setting the date and time to: 22/03/2011 08:30 (4 byte M-Bus Type F)

Field name

# of

Bytes

Value

Description

Start

1

68H

Start of Frame

Data

Link Layer

(DLL)

L Field

1

09H

C field to Checksum

L Field

1

09H

C field to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FEH

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 04H

32 Bit Integer

Applicatio

n

Layer

(APL)

VIF 1 6DH

Time Point (Date and time)

Date Time

1

1EH

Date & time (Type F data)

Date Time

1

28H

Date & time (Type F data)

Date Time

1

76H

Date & time (Type F data)

Date Time

1

13H

Date & time (Type F data)

Checksum

1

02H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 27

01.02.00 © Danfoss| Energy Meters| 2018.02| 27

4.4.2.6 Set accounting date

The master can change the accounting date of each slave on the network. The accounting date

is send as a M-Bus type G format. The following frame sets the date to 01 june 2012.

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data Link layer

(DLL)

L Field

1

08H

C field to Checksum

L Field

1

08H

C field to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FEH

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 02H

16-bit integer

Application

Layer

(APL)

VIF 1 ECH

Time Point (Date)

VIFE

1

7EH

Future value

Value

1

81H

Date (Type G)

Value

16H

Date (Type G)

Checksum

1

C5H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 28

01.02.00 © Danfoss| Energy Meters| 2018.02| 28

4.4.2.7 Set Pulse counter 1 and 2

The two pulse counters accumulated values can be configured by the master. The two

telegrams below show examples:

Counter 1:

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

0AH

C field to Checksum

L Field

1

0AH

C field to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FEH

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 84H

32 bit integer DIFE follows

Application layer (APL)

DIFE

1

40H

Sub unit 1 (Counter 1)

VIF 1 14H

Volume 0.01 m3

Vol. LSB

1

4EH

e.g. 123456,78 m3

Vol. 1 61H

Vol. 1 BCH

Vol. MSB

1

00H

Checksum

1

05H

Checksum

End of Frame

1

16H

D

L

L

Answer of the Slave: E5h

Answer of the Slave: E5h

Page 29

01.02.00 © Danfoss| Energy Meters| 2018.02| 29

Counter 2:

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

0BH

C field to Checksum

L Field

1

0BH

C field to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

FEH

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 8CH

8 digit BCD DIFE follows

Application layer (APL)

DIFE

1

80H

DIFE follows

DIFE

1

40H

Sub unit 2 (Counter 2)

VIF 1 14H

Volume 0.01 m3

Vol. LSB

1

78H

e.g. 123456,78 m3

Vol. 1 56H

Vol. 1 34H

Vol. MSB

1

12H

Checksum

1

36H

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 30

01.02.00 © Danfoss| Energy Meters| 2018.02| 30

4.4.2.8 Set Correction factor

The correction factor can be changed using the telegram below. The Meter must be in Re-

verification mode to run this function. The value send is multiplied with 10^-6 and the values

must not deviated more than +-5% from 1.0.

Field name

# of

Bytes

Value

Description

Layer

Start

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

0BH

C field to Checksum

L Field

1

0BH

C field to Checksum

Start

1

68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

XXH

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 04H

32 bit integer DIFE follows

Application layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE

1

BAH

No Unit

VIFE

1

70H

Correction factor * 10^-6

LSB 1 47H

e.g 1.034567

1 C9H

1

0FH

MSB 1 00H

Checksum

1

0CH

Checksum

DLL

End of Frame

1

16H

Page 31

01.02.00 © Danfoss| Energy Meters| 2018.02| 31

4.4.2.9 Read out desired data

It is possible to configure the read out to any customer requirements without having to change

the code. To do so it is possible to configure the read out to contain 1-24 data records. The

records can be found in Annex A.. After a change the read out will be the chosen until an

application reset is made or until the Slave has a power reset. It will then return to default

settings. To make a permanent change use the SonoAPP.

The data record 00H is interpreted as no record and shall be used if a field is not used.

The 8 first records must be used before the next 8 records (9-16, 17-24) can be occupied and

the data must be sent MSB.

The telegram for setting 1-8 records is:

Field name

# of

Bytes

Value

Description

Start of Frame

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

0FH

C field to Checksum

L Field

1

0FH

C field to Checksum

Start 1 68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

xx

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 07H

64 bit Integer, 8 byte

Application Layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE 1 8BH

Parameter Set Identification

VIFE 1 0CH

Add to readout list

Read out record

1

xx

Record 1

Read out record

1

xx

Record 2

Read out record

1

xx

Record 3

Read out record

1

xx

Record 4

Read out record

1

xx

Record 5

Read out record

1

xx

Record 6

Read out record

1

xx

Record 7

Read out record

1

xx

Record 8

Checksum

1

xx

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Telegram for setting 1-16 records is:

Page 32

01.02.00 © Danfoss| Energy Meters| 2018.02| 32

Field name

# of

Bytes

Value

Description

Start of Frame

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

1BH

C field to Checksum

L Field

1

1BH

C field to Checksum

Start 1 68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

xx

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 07H

64 bit Integer, 8 byte

Application Layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE 1 8BH

Parameter Set Identification

VIFE 1 0CH

Add to readout list

Read out record

1

Xx

Record 1

Read out record

1

Xx

Record 2

Read out record

1

Xx

Record 3

Read out record

1

Xx

Record 4

Read out record

1

Xx

Record 5

Read out record

1

Xx

Record 6

Read out record

1

Xx

Record 7

Read out record

1

Xx

Record 8

DIF 1 07H

64 bit Integer, 8 byte

Application Layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE 1 8BH

Parameter Set Identification

VIFE 1 8CH

Add to readout list

VIFE 1 0CH

Add to readout list

Read out record

1

xx

Record 9

Read out record

1

xx

Record 10

Read out record

1

xx

Record 11

Read out record

1

xx

Record 12

Read out record

1

xx

Record 13

Read out record

1

xx

Record 14

Read out record

1

xx

Record 15

Read out record

1

xx

Record 16

Checksum

1

xx

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

Page 33

01.02.00 © Danfoss| Energy Meters| 2018.02| 33

Telegram for setting 1-24 records is:

Field name

# of

Bytes

Value

Description

Start of Frame

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

2AH

C field to Checksum

L Field

1

2AH

C field to Checksum

Start 1 68H

Start of Frame

C Field

1

73H

SND_UD

A Field

1

xx

Primary Address

CI Field

1

51H

Data from Master to Slave

TPL

DIF 1 07H

64 bit Integer, 8 byte

Application Layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE 1 8BH

Parameter Set Identification

VIFE 1 0CH

Add to readout list

Read out record

1

xx

Record 1

Read out record

1

xx

Record 2

Read out record

1

xx

Record 3

Read out record

1

xx

Record 4

Read out record

1

xx

Record 5

Read out record

1

xx

Record 6

Read out record

1

xx

Record 7

Read out record

1

xx

Record 8

DIF 1 07H

64 bit Integer, 8 byte

Applicati

on Layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE 1 8BH

Parameter Set Identification

VIFE 1 8CH

Add to readout list

VIFE 1 0CH

Add to readout list

Read out record

1

xx

Record 9

Read out record

1

xx

Record 10

Read out record

1

xx

Record 11

Read out record

1

xx

Record 12

Read out record

1

xx

Record 13

Read out record

1

xx

Record 14

Read out record

1

xx

Record 15

Read out record

1

xx

Record 16

DIF 1 07H

64 bit Integer, 8 byte

Application

Layer (APL)

VIF 1 FDH

True VIF is given in next VIFE

VIFE 1 8BH

Parameter Set Identification

VIFE 1 8CH

Add to readout list

VIFE 1 8CH

Add to readout list

VIFE 1 0CH

Add to readout list

Page 34

01.02.00 © Danfoss| Energy Meters| 2018.02| 34

Read out record

1

xx

Record 17

Read out record

1

xx

Record 18

Read out record

1

xx

Record 19

Read out record

1

xx

Record 20

Read out record

1

xx

Record 21

Read out record

1

xx

Record 22

Read out record

1

xx

Record 23

Read out record

1

xx

Record 24

Checksum

1

xx

Checksum

DLL

End of Frame

1

16H

Answer of the Slave: E5h

This command is used by the master to request data from the slave. The slave must confirm

the reception of a correct telegram with a RSP_UD answer.

Field name

# of

Bytes

Value

Description

Start 1 10H

Start Request

Data Link Layer

(DLL)

C Field

1

5B/7BH

01FV1011b

F = FCB-Bit

V = FCV-Bit (must be 1 in

REQ_UD2 request)

A Field

1

??H

Primary Address or FDH

Checksum

1

??H

Checksum

End of Frame

1

16H

Answer of the Slave: RSP_UD

Page 35

01.02.00 © Danfoss| Energy Meters| 2018.02| 35

The slave answers the REQ_UD2 with a RSP_UD telegram. The telegram has the following

structure:

Field name

# of

Bytes

Value

Description

Start of Frame

1

68H

Start of Frame

Data Link Layer

(DLL)

L Field

1

??H

C Field to Checksum

L Field

1

??H

C Field to Checksum

Start

1

68H

Start of Frame

C Field

1

08H

RSP_UD (Long frame)

A Field

1

??H

Primary Address

CI Field

1

72h

Variable data response

72h: 12 bytes data header

Transportation Layer (TPL)

Identification

number

4

??H

Product serial number (Secondary

address)

Manufacturer’s

mark

2

??H

Manufacturer’s mark

Version number

1

??H

Version number (00-FF)

Medium

1

04H

Medium: Heat

Access number

1

??H

Incremented after each REQ_UD2

(00-FF->00)

Status

1

??H

Status

Configuration

2

??H

Always 0000H i.e. not used)

Data

0-235

xx..xx

Read-out data

Data record 1-24

APL

Checksum

1

??H

Checksum

DLL

End of Frame

1

16H

End frame

Page 36

01.02.00 © Danfoss| Energy Meters| 2018.02| 36

The table below holds the list of parameters which can be used in the read out of desired data.

Parameter

HEX

No record

0x0

Heat Energy

0x1

Heat Volume

0x2

Flow Rate

0x3

Power

0x4

Forward Temperature

0x5

Return Temperature

0x6

Difference temperature

0x7

External temperature (Enclosure)

0x8

Current time

0x9

Hour Counter Factory

0xA

Hour Counter OK

0xB

Hour Counter Alarm

0xC

Remaining Battery Life Time

0xD

Time On Battery

0xE

Accounting Date

0xF

Meter Type

0x10

Year log 1

0x11

Year log 2

0x12

Month Log 1

0x13

Month Log 2

0x14

Month Log 3

0x15

Month Log 4

0x16

Month Log 5

0x17

Month Log 6

0x18

Month Log 7

0x19

Month Log 8

0x1A

Month Log 9

0x1B

Month Log 10

0x1C

Month Log 11

0x1D

Month Log 12

0x1E

Month Log 13

0x1F

Month Log 14

0x20

Month Log 15

0x21

Month Log 16

0x22

Month Log 17

0x23

Month Log 18

0x24

Month Log 19

0x25

Page 37

01.02.00 © Danfoss| Energy Meters| 2018.02| 37

Month Log 20

0x26

Month Log 21

0x27

Month Log 22

0x28

Month Log 23

0x29

Month Log 24

0x2A

Energy Cooling

0x2B

Volume Cooling

0x2C

High Resolution Energy Cooling

0x2D

High Resolution Volume Cooling

0x2E

Mass

0x2F

Pulse Counter One

0x30

Pulse Counter Two

0x31

FWChecksum

0x32

Correction Factor

0x33

High Resolution Heat Energy

0x34

High Resolution Heat Volume

0x35

Tariff Register One

0x36

Tariff Register Two

0x37

Year Log Energy 1 (Only Energy record)

0x38

Year Log Energy 2 (Only Energy record)

0x39

Month Log Energy 1 (Only Energy record)

0x3A

Month Log Energy 2 (Only Energy record)

0x3B

Month Log Energy 3 (Only Energy record)

0x3C

Month Log Energy 4 (Only Energy record)

0x3D

Month Log Energy 5 (Only Energy record)

0x3E

Month Log Energy 6 (Only Energy record)

0x3F

Month Log Energy 7 (Only Energy record)

0x40

Month Log Energy 8 (Only Energy record)

0x41

Month Log Energy 9 (Only Energy record)

0x42

Month Log Energy 10 (Only Energy record)

0x43

Month Log Energy 11 (Only Energy record)

0x44

Month Log Energy 12 (Only Energy record)

0x45

Month Log Energy 13 (Only Energy record)

0x46

Month Log Energy 14 (Only Energy record)

0x47

Month Log Energy 15 (Only Energy record)

0x48

Month Log Energy 16 (Only Energy record)

0x49

Month Log Energy 17 (Only Energy record)

0x4A

Month Log Energy 18 (Only Energy record)

0x4B

Month Log Energy 19 (Only Energy record)

0x4C

Month Log Energy 20 (Only Energy record)

0x4D

Month Log Energy 21 (Only Energy record)

0x4E

Month Log Energy 22 (Only Energy record)

0x4F

Month Log Energy 23 (Only Energy record)

0x50

Page 38

01.02.00 © Danfoss| Energy Meters| 2018.02| 38

Month Log Energy 24 (Only Energy record)

0x51

Year Log Volume 1 (Only Volume record)

0x52

Year Log Volume 2 (Only Volume record)

0x53

Month Log Volume 1 (Only Volume record)

0x54

Month Log Volume 2 (Only Volume record)

0x55

Month Log Volume 3 (Only Volume record)

0x56

Month Log Volume 4 (Only Volume record)

0x57

Month Log Volume 5 (Only Volume record)

0x58

Month Log Volume 6 (Only Volume record)

0x59

Month Log Volume 7 (Only Volume record)

0x5A

Month Log Volume 8 (Only Volume record)

0x5B

Month Log Volume 9 (Only Volume record)

0x5C

Month Log Volume 10 (Only Volume record)

0x5D

Month Log Volume 11 (Only Volume record)

0x5E

Month Log Volume 12 (Only Volume record)

0x5F

Month Log Volume 13 (Only Volume record)

0x60

Month Log Volume 14 (Only Volume record)

0x61

Month Log Volume 15 (Only Volume record)

0x62

Month Log Volume 16 (Only Volume record)

0x63

Month Log Volume 17 (Only Volume record)

0x64

Month Log Volume 18 (Only Volume record)

0x65

Month Log Volume 19 (Only Volume record)

0x66

Month Log Volume 20 (Only Volume record)

0x67

Month Log Volume 21 (Only Volume record)

0x68

Month Log Volume 22 (Only Volume record)

0x69

Month Log Volume 23 (Only Volume record)

0x6A

Month Log Volume 24 (Only Volume record)

0x6B

Ultra-High Resolution Heat Volume

0x6C

Ultra-High Resolution Cooling Volume

0x6D

Max Flow rate heat timestamp

0x6E

Max flow rate heat

0x6F

Max flow rate Cooling timestamp

0x70

Max flow rate Cooling

0x71

Max power heat timestamp

0x72

Max power heat

0x73

Max power cooling timestamp

0x74

Max power Cooling

0x75

Ultra-High resolution Heat energy

0x76

Ultra-High resolution Cooling energy

0x77

Loading...

Loading...