Page 1

Document type Myriad Pro Semibold 7 pt.

Product name - Myriad Pro bold 12/12

Operation Manual

Product type - Myriad Pro light 12/12

Temperature transmitter

xxxRxxxx

MBT 9110 - 084Z7441

xxxRxxxx

bar code pl ace holder

bar code pl ace holder

© Danfoss | DCS (xxx) | YYYY.MM - Myriad Pro Regular 7 pt.

XXXX.XX.XXX.XX.XX.XXX | XXXAXXXX | 1

www.danfoss.com

Page 2

INDEX

2-Wire Programmable Transmitter Page 3 - UK

2-Tråds Programmerbar Transmitter Side 8 - DK

Transmetteur 2-Fils Programmable (Pt100) Page 13 - FR

Programmierbarer 2-Leiter Messumformer Seite 18 - DE

<

<

<

<

© Danfoss | DCS (im) | 2017.072 | 520B7737 | IC.PS.P40.A4.ML

Page 3

ENGLISH

2-wire installation

2-WIRE PROGRAMMABLE TRANSMITTER

MBT 9110 - 084Z7441

CONTENTS

Application ..............................................................................................................................................................................................3

Technical characteristics .....................................................................................................................................................................3

Mounting / installation .......................................................................................................................................................................3

Applications ............................................................................................................................................................................................3

Type / version .........................................................................................................................................................................................4

Electrical specifications ....................................................................................................................................................................... 4

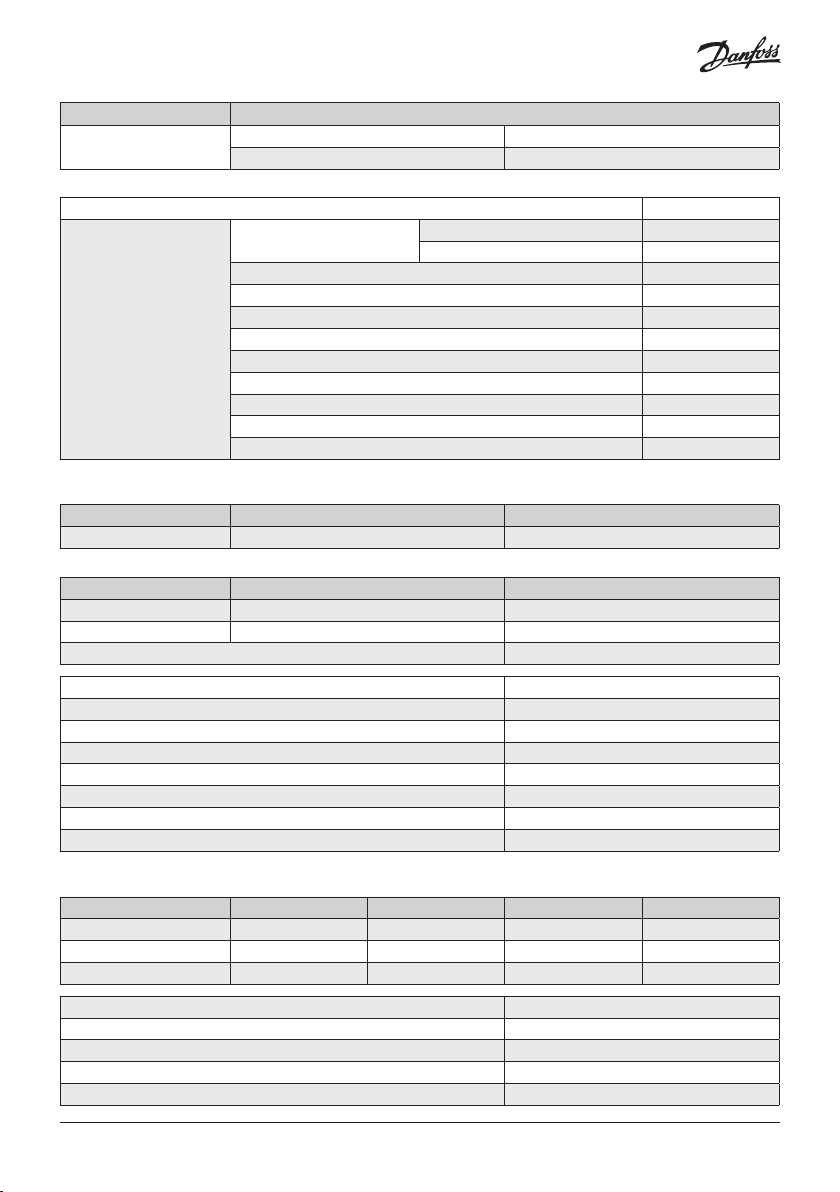

Connections ............................................................................................................................................................................................5

Block diagram .........................................................................................................................................................................................6

Programming ..........................................................................................................................................................................................6

Mechanical specifications ..................................................................................................................................................................6

Mounting of sensor wires ..................................................................................................................................................................6

Appendix ..................................................................................................................................................................................................7

- ATEX Installation drawing................................................................................................................................................................7

- Safety instructions .............................................................................................................................................................................. 7

• RTD or Ohm input

• High measurement accuracy

• 3-wire connection

• Programmable sensor error value

• Can be mounted in DIN form B sensor head

Application

• Linearised temperature measurement with Pt100 / Pt1000 or Ni100 / Ni1000 sensor

• Conversion of linear resistance variation to a standard analogue current signal, for instance from valves

or Ohmic level sensors

Technical characteristics

• The RTD and resistance inputs have cable compensation for 3-wire connection

Mounting / installation

• For DIN form B sensor head mounting

• In non-hazardous areas the transmitter can be mounted on a DIN rail with a special tting

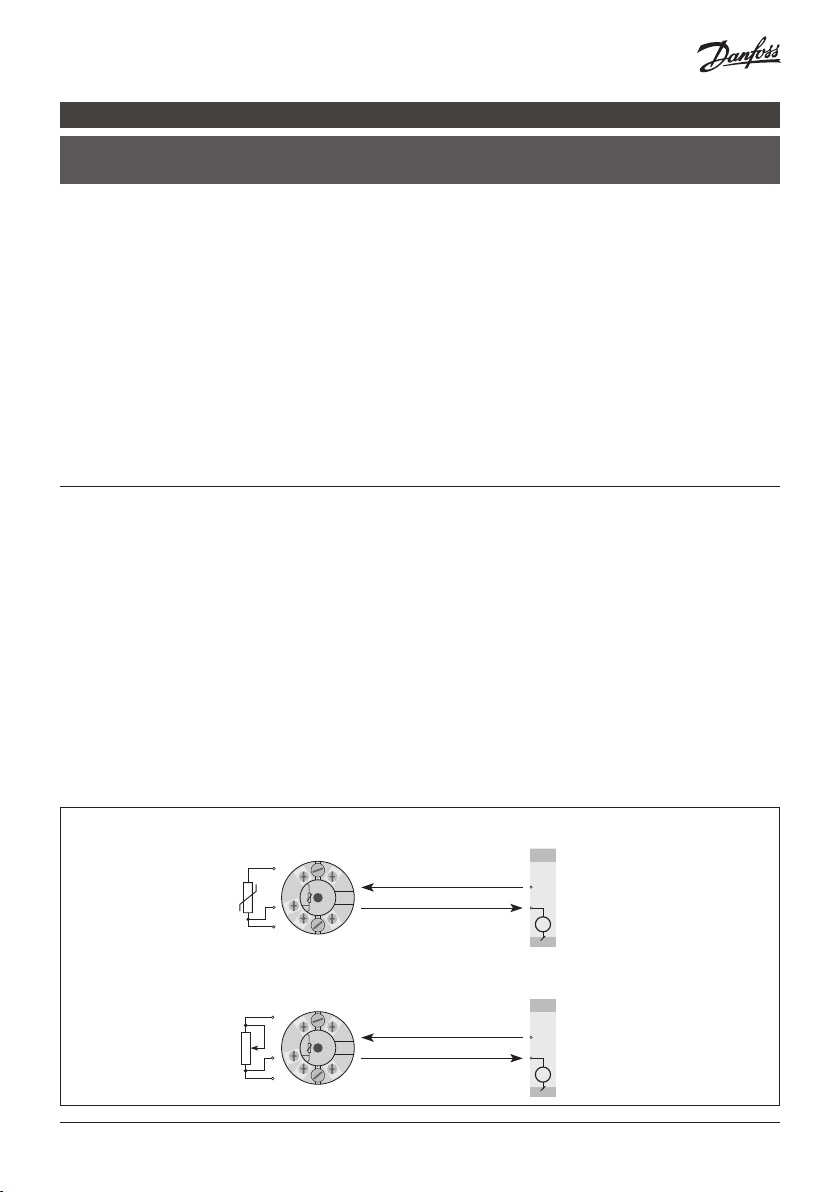

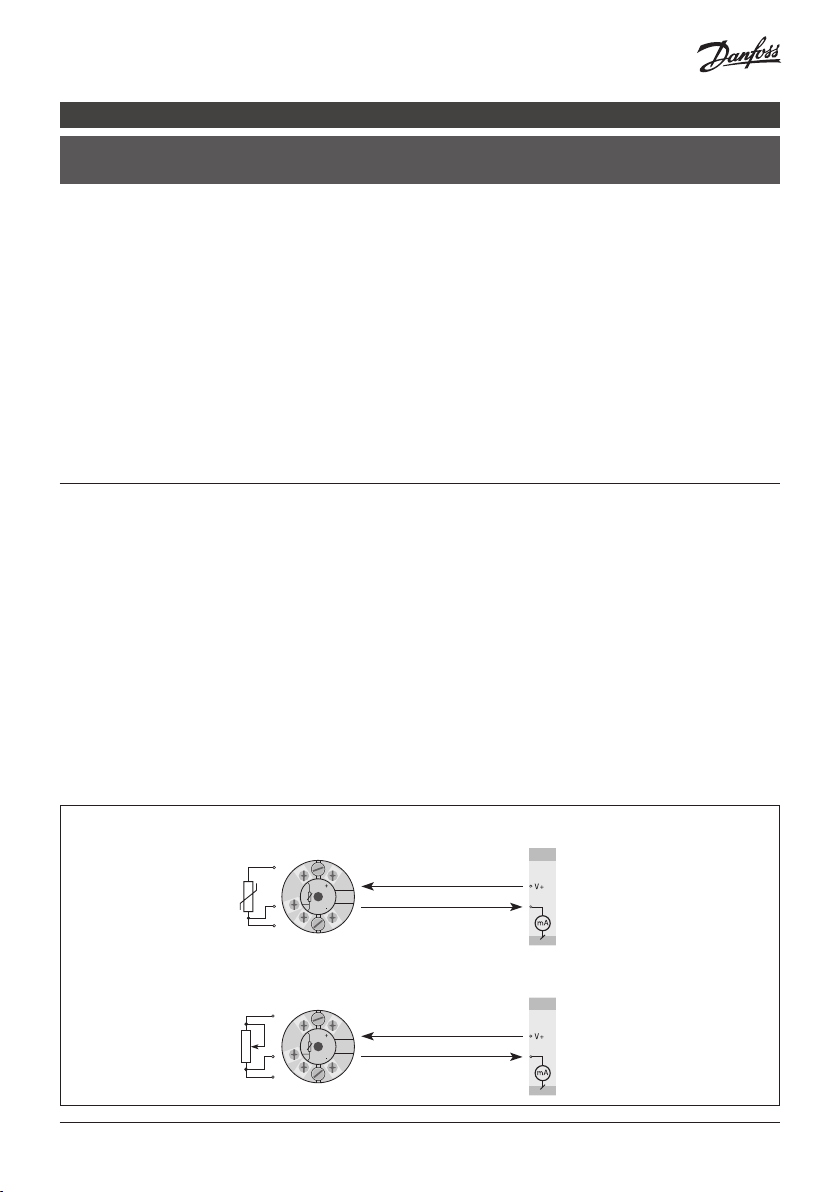

APPLICATIONS

RTD to 4 – 20 mA

+

Resistance to 4 – 20 mA

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 3

-

+

-

in control room

V+

mA

2-wire installation

in control room

V+

mA

Page 4

TYPE

VERSION

Standard 084Z7440

Standard Atex 084Z7441

MBT 9110

ELECTRICAL SPECIFICATIONS

Specications range -40 °C – 85 °C

MBT 9110, 084Z7440 8 – 35 V

Standard ATEX, MBT 9110, 084Z7441 8 – 30 V

Common specications

Supply voltage, DC

Internal consumption 25 mW – 0.8 W

Voltage drop 8 VDC

Warm-up time 5 min.

Communications interface Loop Link

Signal / noise ratio min. 60 dB

Response time (programmable) 0.33 – 60 s

Signal dynamics, input 19 bit

Signal dynamics, output 16 bit

Calibration temperature 20 – 28 °C

ACCURACY, THE GREATER OF GENERAL AND BASIC VALUES

GENERAL VALUES

Input type Absolute accuracy Temperature coefficient

All ≤ ± 0.1% of span ≤ ± 0.01% of span / °C

BASIC VALUES

Input type Basic accuracy Temperature coefficient

RTD ≤ ± 0.3 °C ≤ ± 0.01 °C / °C

Lin.R ≤ ± 0.2 Ω ≤ ± 20 m Ω / °C

EMC immunity inuence ≤ ± 0.5% of span

Eect of supply voltage variation ≤ 0,005% of span / VDC

Vibration IEC 60068-2-6 Test FC

Lloyd’s specication no. 1 4 g / 2 – 100 Hz

Max. wire size 1 x 1.5 mm2 stranded wire

Humidity < 95% RH (non-cond.)

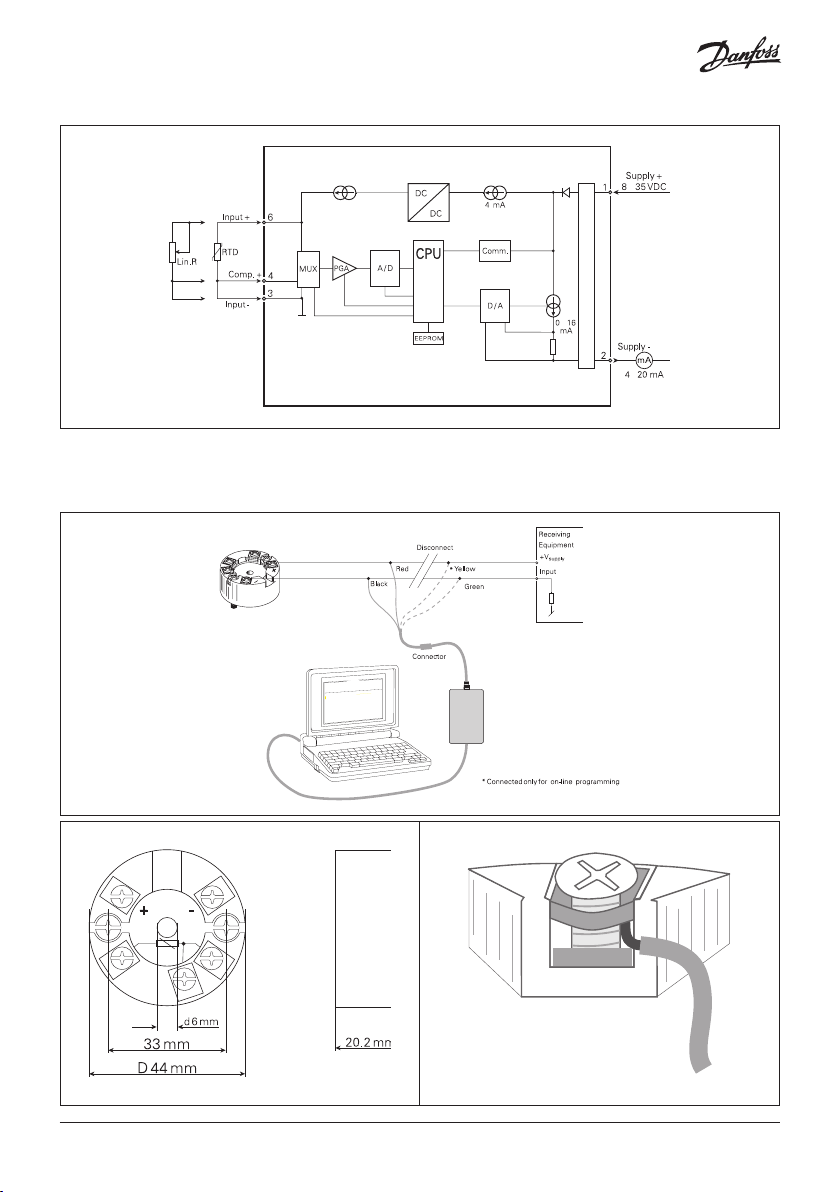

Dimensions ø44 x 20.2 mm

Tightness (enclosure / terminal) IP68 / IP00

Weight 50 g

ELECTRICAL SPECIFICATIONS, INPUT

RTD AND LINEAR RESISTANCE INPUT

RTD type Min. value Max. value Min. span Standard

Pt 100 -200 °C 850 °C 25 °C IEC 60751

Ni 100 -60 °C 250 °C 25 °C DIN 43760

Lin. R 0 Ω 10000 Ω 30 Ω –

Max. oset 50% of selec. max. value

Cable resistance per wire (max.) 10 Ω

Sensor current > 0.2 mA, < 0.4 mA

Eect of sensor cable resistance (3-wire) < 0.002 Ω / Ω

Sensor error detection Yes

© Danfoss | DCS (im) | 2017.074 | 520B7737 | IC.PS.P40.A4.ML

Page 5

OUTPUT

CURRENT OUTPUT

Signal range 4 – 20 mA

Min. signal range 16 mA

Updating time 135 ms

Load resistance ≤ (V

Load stability ≤ ±0.01% of span / 100 Ω

- 8) / 0.023 [Ω]

supply

SENSOR ERROR DETECTION

Programmable 3.5 – 23 mA

NAMUR NE43 Upscale 23 mA

NAMUR NE43 Downscale 3.5 mA

EEx approval MBT 9110, 084Z7441

KEMA 04ATEX1339

Max. amb. temperature for T4 85 °C

Max. amb. temperature for T6 60 °C

ATEX, applicable in zone 0, 1, 2, 20, 21 or 22

ATEX Installation Drawing No. MBT 9110 084Z7441

II 1 G Ex ia IIC T4 or T6

II 1 D Ex iaD

OBSERVED AUTHORITY REQUIREMENTS

STANDARD

EMC 2004/108/EF Emission and immunity EN 61326-1

EN 60079-0, EN 60079-11

ATEX 94/9/EC

Of span = Of the presently selected range

EN 60079-15, EN 60079-26

EN 61241-0, EN 61241-11

CONNECTIONS

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 5

Page 6

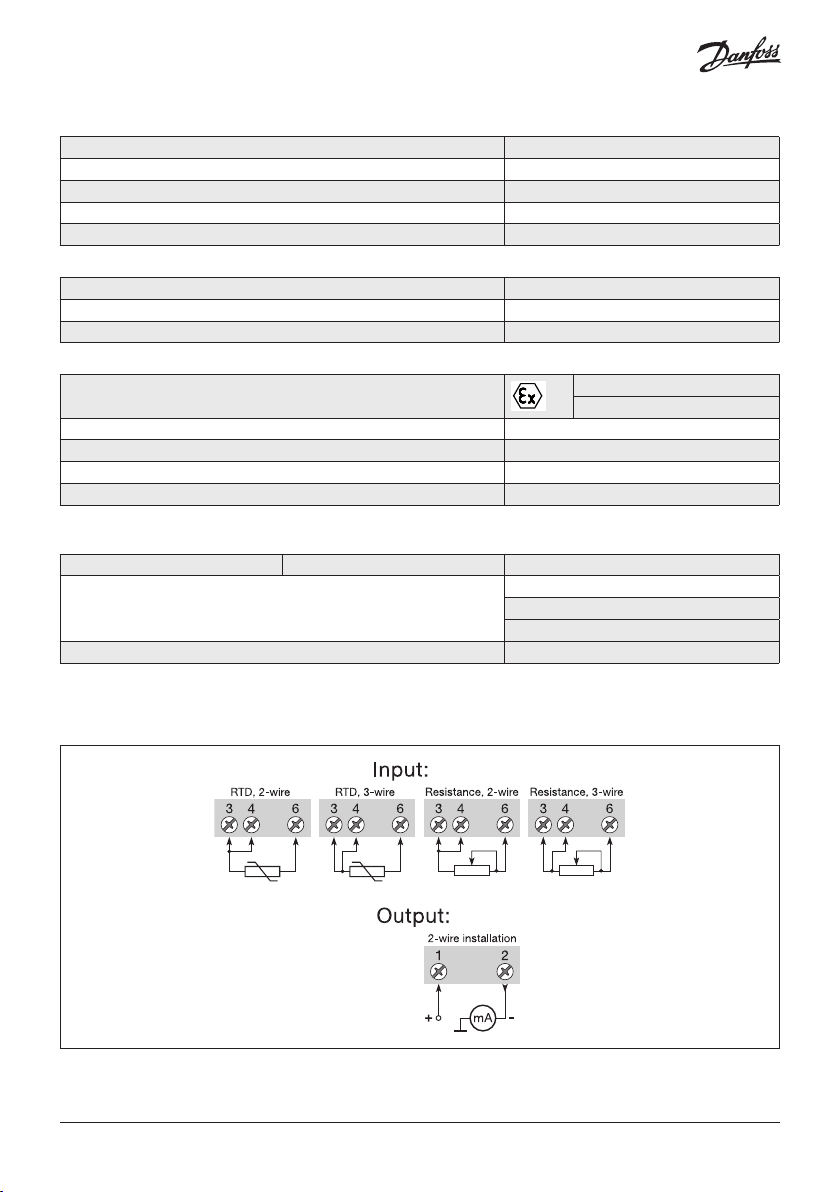

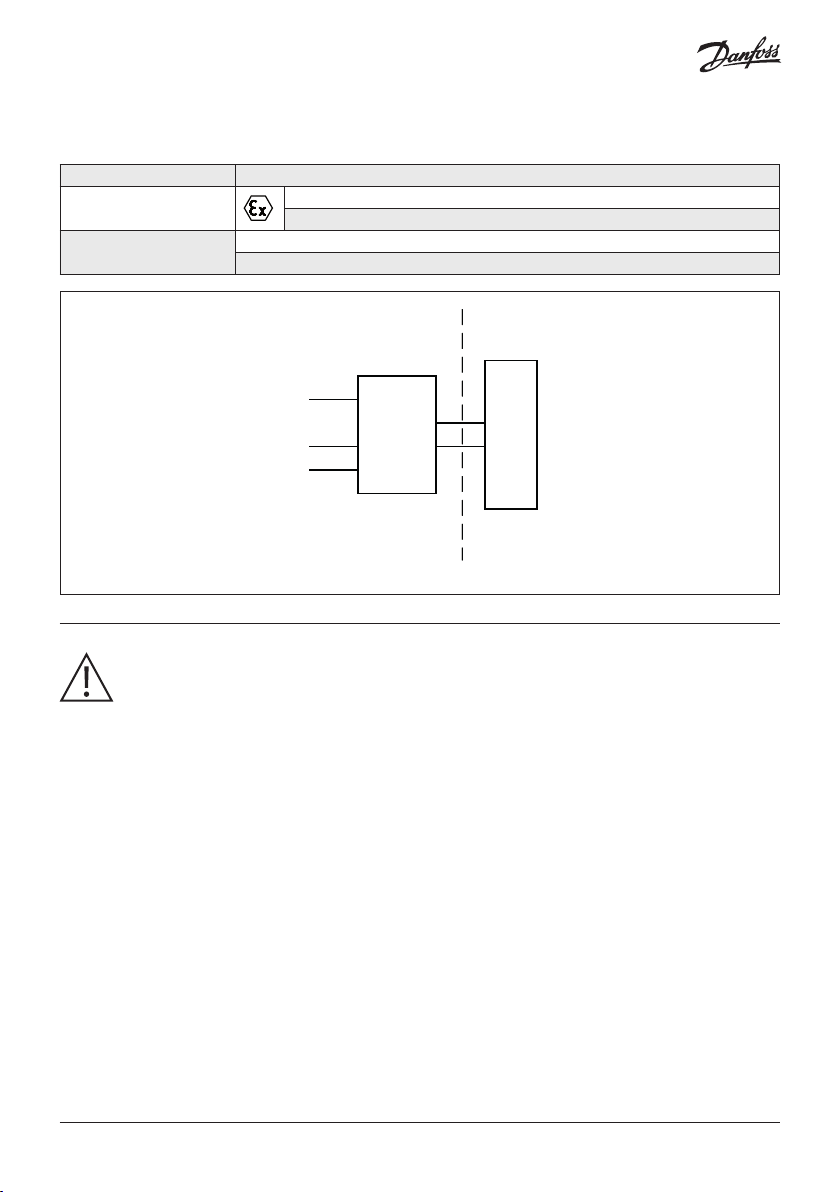

BLOCK DIAGRAM

Ex circuit, only 084Z7441

MBT 9110

084Z7440, 084Z7441

–

–

–

PROGRAMMING

• Loop Link is a communications interface that is needed for programming MBT 9110

• For programming please refer to the drawing below and the help functions in PReset

• Loop Link is not approved for communication with modules installed in hazard ous (EEx) areas

1

MBT 9110

2

File Product Input Output Communication Language Option 08:30:00

Pr etop 5331

Date: 2004-8.10

Serial No.: 043201594

Tag No.: PR electronics

Analog Input Analog Ouput

Input Type: Pt 100 DIN / IEC Output Type: 4 – 20 mA

Input Range: 0 – 50C Sensor error: Upscale

Connection: 3-wire

Cold junction comp: --------Response time: 1.00 sec

*

Loop

Link

5909 - USB

5905 - RS232

Mechanical specifications

Mounting of sensor wires

Wires must be mounted

between the metal plates

© Danfoss | DCS (im) | 2017.076 | 520B7737 | IC.PS.P40.A4.ML

Page 7

APPENDIX

ATEX Installation drawing

MBT 9110 - 084Z7441

ATEX Certicate KEMA 04ATEX 1339

Marking

Standards

II 1 G Ex ia IIC T6 – T4

II 1 D Ex iaD

EN 60079-0 : 2006, EN 60079-11 : 2007, EN 60079-26 : 2007,

EN 61241-0 : 2006, EN 61241-11 : 2006

Hazardous area

Non Hazardous Area

Zone: 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85 °C

T6: -40 ≤ Ta ≤ 60 °C

Terminal: 3,4,6

Uo: 27 VDC

Io: 7 mA

Po: 45 mW

Lo: 35 mH

Co: 90 nF

6

5

4

3

Terminal: 1,2

+

1

-

2

Barrier

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10μH

Ci: 1.0nF

INSTALLATION NOTES

SAFETY INSTRUCTIONS

For safe installation of MBT 9110 084Z 7441 the following must be observed. The module shall only be Installed by qualified

personnel who are familiar with the national and international laws, directives and standards that apply to this area.

Year of manufacture can be taken from the first two digits in the serial number.

In a potentially explosive gas atmosphere, the transmitter shall be mounted in an enclosure in order to provide a degree of

protection of at least IP20 according to EN60529.

If the transmitter is installed in an explosive atmosphere requiring the use of equipment of category 1G and if the enclosure is

made of aluminium, it must be installed such, that even in the event of rare incidents, ignition sources due to impact and friction,

sparks are excluded; if the enclosure is made of non-metallic materials, electrostatic charging shall be avoided.

For installation in a potentially explosive dust atmosphere, the following instructions apply:

The transmitter shall be mounted in a metal enclosure form B according to DIN43729 that is providing a degree of protection of

at least IP6X according to EN60529, that is suitable for the application and correctly installed.

Cable entries and blanking elements shall be used that are suitable for the application and correctly installed.

For an ambient temperature ≥ 60 °C, heat resistant cables shall be used with a rating of at least 20 K above the ambient

temperature.

The surface temperature of the enclosure is equal to the ambient temperature plus 20 K, for a dust layer with a thickness up to 5 mm.

Danfoss A/S

Danfoss Industrial Automation

DK 6430 Nordborg Denmark

Phone +45 7488 2222

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 7

Page 8

DANISH

2-trådsinstallation

2-TRÅDS PROGRAMMERBAR TRANSMITTER

MBT 9110 - 084Z7441

INDHOLDSFORTEGNELSE

Anvendelse ..............................................................................................................................................................................................8

Teknisk karakteristik .............................................................................................................................................................................8

Montage / installation .........................................................................................................................................................................8

Applikationer ..........................................................................................................................................................................................8

Typer / versioner ....................................................................................................................................................................................9

Elektriske specifikationer ....................................................................................................................................................................9

Tilslutninger ......................................................................................................................................................................................... 10

Blokdiagram ......................................................................................................................................................................................... 11

Programmering ................................................................................................................................................................................... 11

Mekaniske specifikationer .............................................................................................................................................................. 11

Montering af følerledninger ........................................................................................................................................................... 11

Appendix ............................................................................................................................................................................................... 12

- ATEX Installation drawing.............................................................................................................................................................12

- Sikkerheds instruktion ................................................................................................................................................................... 12

• Indgang for RTD eller Ohm

• Høj målenøjagtighed

• 3-leder tilslutning

• Programmerbar følerfejlsværdi

• Kan monteres i DIN form B følerhoved

Anvendelse

• Temperaturlineariseret måling med Pt100...Pt1000 eller Ni100 / Ni1000 føler

• Omsætning af lineær modstandsændring til standard analogt strømsignal, f.eks. fra ventiler eller

ohmske niveaustave

Teknisk karakteristik

• RTD- og modstandsindgangen har kabelkompensering for 3-leder tilslutning

Montage / installation

• Kan monteres i DIN form B følerhoved

• I ikke-eksplosionsfarlige områder kan transmitteren monteres på en DIN-skinne med et specielt beslag

APPLIKATIONER

RTD til 4 – 20 mA

Modstand til 4 – 20 mA

i kontrolrum

2-trådsinstallation

i kontrolrum

© Danfoss | DCS (im) | 2017.078 | 520B7737 | IC.PS.P40.A4.ML

Page 9

TYPE

VERSION

Standard 084Z7440

Standard Atex 084Z7441

MBT 9110

ELEKTRISKE SPECIFIKATIONER

Specikationsområde -40 °C – 85 °C

MBT 9110, 084Z7440 8 – 35 V

Standard ATEX, MBT 9110, 084Z7441 8 – 30 V

Fælles specikationer

Forsyningsspænding DC

Egetforbrug 25 mW – 0,8 W

Spændingsdrop 8 VDC

Opvarmningstid 5 min.

Kommunikationsinterface Loop Link

Signal- / støjforhold min. 60 dB

Reaktionstid (programmerbar) 0.33 – 60 s

Signaldynamik, indgang 19 bit

Signaldynamik, udgang 16 bit

Kalibreringstemperatur 20 – 28 °C

NØJAGTIGHED, STØRST AF GENERELLE OG BASISVÆRDIER

GENERELLE VÆRDIER

Indgangstype Absolut nøjagtighed Temperatur-koefficient

Alle ≤ ± 0,1% of span ≤ ± 0,01% of span / °C

BASISVÆRDIER

Indgangstype Basis-nøjagtighed Temperatur-koefficient

RTD ≤ ± 0,3 °C ≤ ± 0,01 °C / °C

Lin.R ≤ ± 0,2 Ω ≤ ± 20 m Ω / °C

EMC-immunitetspåvirkning ≤ ± 05% of span

Virkning af forsyningsspændingsændring ≤ 0,005% of span / VDC

Vibration IEC 60068-2-6 Test FC

Lloyd’s specikation nr. 1 4 g / 2 – 100 Hz

Max. ledningskvadrat 1 x 1.5 mm2 stranded wire

Luftfugtighed < 95% RH (non-cond.)

Mål ø44 x 20.2 mm

Tæthedsgrad (hus / klemme) IP68 / IP00

Vægt 50 g

ELEKTRISKE SPECIFIKATIONER INDGANG

RTD- OG LINEÆR MOD STANDSINDGANG

RTD type Min. værdi Max. værdi Min. span Standard

Pt 100 -200 °C 850 °C 25 °C IEC 60751

Ni 100 -60 °C 250 °C 25 °C DIN 43760

Lin. R 0 Ω 10000 Ω 30 Ω –

Max. nulpunktsforskydning (oset) 50% af valgt max. værdi

Kabelmodstand pr. leder (max.) 10 Ω

Følerstrøm > 0,2 mA, < 0,4 mA

Virkning af følerkabelmodstand (3-leder) > 0,002 Ω / Ω

Følerfejlsdetektering ja

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 9

Page 10

UDGANG

STRØMUDGANG

Signalområde 4 – 20 mA

Min. signalområde 16 mA

Opdateringstid 135 ms

Belastningsmodstand ≤ (V

Belastningsstabilitet ≤ ±0,01% af span / 100 Ω

- 8) / 0,023 [Ω]

forsyn.

FØLERFEJLSDETEKTERING

Programmerbar 3,5 – 23 mA

NAMUR NE43 Upscale 23 mA

NAMUR NE43 Downscale 3.5 mA

EEX-GODKENDELSE: MBT 9110, 084Z7441

KEMA 04ATEX1339

Max. omgivelsestemp. for T4 85 °C

Max. omgivelsestemp. for T6 60 °C

ATEX, må anvendes i zone 0, 1, 2, 20, 21 or 22

ATEX Installation Drawing No. MBT 9110 084Z7441

II 1 G Ex ia IIC T4 eller T6

II 1 D Ex iaD

OVERHOLDTE MYNDIGHEDSKRAV

STANDARD

EMC 2004/108/EF Emission og immunitet EN 61326-1

EN 60079-0, EN 60079-11

ATEX 94/9/EC

Af span = Af det aktuelt valgte område

EN 60079-15, EN 60079-26

EN 61241-0, EN 61241-11

TILSLUTNINGER

© Danfoss | DCS (im) | 2017.0710 | 520B7737 | IC.PS.P40.A4.ML

Page 11

BLOKDIAGRAM

MBT 9110

084Z7440, 084Z7441

Ex-kredsløb kun 084Z7441

–

–

–

PROGRAMMERING

• Loop Link er et batteridrevet kommunikationsinterface, der er nødvendigt for programmering af MBT 9110

• Ved programmering henvises til tegningen nedenfor og hjælpefunktionen i PReset programmet

• Loop Link må ikke benyttes til kommunikation med moduler installeret i EEx-område

1

MBT 9110

2

File Product Input Output Communication Language Option 08:30:00

Pr etop 5331

Date: 2004-8.10

Serial No.: 043201594

Tag No.: PR electronics

Analog Input Analog Ouput

Input Type: Pt 100 DIN / IEC Output Type: 4 – 20 mA

Input Range: 0 – 50 C Sensor error: Upscale

Connection: 3-wire

Cold junction comp: --------Response time: 1.00 sec

*

Loop

Link

5909 - USB

5905 - RS232

Mekaniske specifikationer

Montering af følerledninger

Ledninger monteres mellem

metalpladerne

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 11

Page 12

APPENDIX

ATEX Installation drawing

MBT 9110 - 084Z7441

ATEX Certicate KEMA 04ATEX 1339

Marking

Standards

II 1 G Ex ia IIC T6 – T4

II 1 D Ex iaD

EN 60079-0 : 2006, EN 60079-11 : 2007, EN 60079-26 : 2007,

EN 61241-0 : 2006, EN 61241-11 : 2006

Hazardous area

Non Hazardous Area

Zone: 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85 °C

T6: -40 ≤ Ta ≤ 60 °C

Terminal: 3,4,6

Uo: 27 VDC

Io: 7 mA

Po: 45 mW

Lo: 35 mH

Co: 90 nF

6

5

4

3

Terminal: 1,2

+

1

-

2

Barrier

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10μH

Ci: 1.0nF

INSTALLATION NOTES

SIKKERHEDSINSTRUKTION

Bemærkninger til installering:

For at gennemføre en sikker installering af MBT 9110 084Z7441 skal følgende overholdes. Modulet må kun installeres af

kvalificeret personale, der er bekendt med gældende nationale og internationale love, direktiver og standarder inden for dette

område. Produktionsåret fremgår af de første to cifre i serienummeret.

I en potentielt eksplosiv gasatmosfære skal transmitteren monteres i en kapsling, så man opnår en beskyttelsesgrad på

min. IP20 i henhold til EN 60529.

Installeres transmitteren i en eksplosiv atmosfære, der kræver udstyr i kategori 1G, og hvis kapslingen er lavet af aluminium, skal

den installeres således, at gnister fra antændelseskilder ved slag og friktion selv under usædvanlige omstændigheder

holdes ude. Er kapslingen lavet af ikke-metalliske materialer, skal elektrostatisk opladning undgås.

Ved installering i en atmosfære med potentielt eksplosivt støv følges disse anvisninger:

Transmitteren skal monteres i en metalkapsling form B i henhold til DIN 43729, der yder en beskyttelsesgrad på min.

IP6X i henhold til EN 60529. Kapslingen skal være egnet til applikationen og installeret korrekt.

Der må kun anvendes kabelindgange og blindstik, der er egnet til applikationen og installeret korrekt.

Ved en omgivende temperatur på ≥ 60º C skal der anvendes varmebestandige kabler med en klassificering på mindst 20 K over

den omgivende temperatur.

Kapslingens overfladetemperatur er lig med den omgivende temperatur plus 20 K ved et støvlag med en tykkelse på op til 5 mm.

Danfoss A/S

Danfoss Industrial Automation

DK 6430 Nordborg Denmark

Phone +45 7488 2222

© Danfoss | DCS (im) | 2017.0712 | 520B7737 | IC.PS.P40.A4.ML

Page 13

FRANÇAIS

Installation 2-ls

TRANSMETTEUR 2-FILS PROGRAMMABLE (Pt100)

MBT 9110 - 084Z7441

SOMMAIRE

Présentation ..........................................................................................................................................................................................13

Caractéristiques techniques ............................................................................................................................................................ 13

Montage / installation ....................................................................................................................................................................... 13

Applications ..........................................................................................................................................................................................13

Type / version .......................................................................................................................................................................................14

Spécifications électriques ................................................................................................................................................................ 14

Connexions ............................................................................................................................................................................................15

Schéma de principe............................................................................................................................................................................16

Programmation ....................................................................................................................................................................................16

Dimensions mécaniques .................................................................................................................................................................. 16

Montage des fils du capteur ........................................................................................................................................................... 16

Appendice ..............................................................................................................................................................................................17

- ATEX Installation drawing..............................................................................................................................................................17

- Consigne de sécurité .......................................................................................................................................................................17

• Entrée RTD ou résistance

• Grande précision de mesure

• Connexion aux sondes à 3 ls

• Valeur d’erreur du capteur programmable

• Pour tête de sonde DIN B

Présentation

• Mesure linéarisée de la température avec un capteur Pt100 / Pt1000 ou Ni100 / Ni1000.

• Conversion d’une résistance linéaire en un signal courant standard analogique pour mesurer par exemple

la position d’une vanne, ou la valeur homique d’une mesure de niveau

Caractéristiques techniques

• Le PR5333 peut être programmé de manière simple et rapide

• Compensation de ligne pour des entrées RTD et résistance avec un raccordement à 3 ls

Montage / installation

• Pour tête de sonde DIN B

• En zone non-dangereuse le transmetteur peut être monté sur rail DIN avec un support spécique

APPLICATIONS

RTD en 4 – 20 mA

+

-

Résistance en 4 – 20 mA

+

-

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 13

en salle de contrôle

V+

mA

Installation 2-ls

en salle de contrôle

V+

mA

Page 14

TYPE

VERSION

Standard 084Z7440

Standard Atex 084Z7441

MBT 9110

SPÉCIFICATIONS ÉLECTRIQUES

Plage des spécications -40 °C – 85 °C

MBT 9110, 084Z7440 8 – 35 V

Standard ATEX, MBT 9110, 084Z7441 8 – 30 V

Spécications communes

Tension d’alimentation, CC

Consommation 25 mW – 0,8 W

Chute de tension 8 VDC

Temps de chaue 5 min.

Programmation Loop Link

Signal / noise ratio min. 60 dB

Temps de réponse (programmable) 0,33 – 60 s

Dynamique du signal d’entrée 19 bit

Dynamique du signal de sortie 16 bit

Température d’étalonnage 20 – 28 °C

PRÉCISION, LA PLUS GRANDE DES VALEURS GÉNÉRALES ET DE BASE

VALEURS GÉNÉRALES

Type d’entrée Précision absolue Coefficient de température

Tous ≤ ± 0,1% de la bande ≤ ± 0,01% de la bande / °C

VALEURS DE BASE

Type d’entrée Précision absolue Coefficient de température

RTD ≤ ± 0,3 °C ≤ ± 0,01 °C / °C

Lin.R ≤ ± 0,2 Ω ≤ ± 20 m Ω / °C

Immunité CEM ≤ ± 0,5% de l’EC

Eet d’une variation de la tension d’alimentation ≤ 0,005% de la bande / VCC

Vibration IEC 60068-2-6 Test FC

Lloyd, spécication no. 1 4 g / 2 – 100 Hz

Taille max. des ls 1 x 1,5 mm2 càble multiconducteurs

Humidité < 95% HR (sans cond.)

Dimensions ø44 x 20,2 mm

Etanchéité (boîtier / bornier) IP68 / IP00

Poids 50 g

SPÉCIFICATIONS ÉLECTRIQUES, ENTRÉE

ENTRÉE RTD ET ENTRÉE RÉSISTANCE LINÉAIRE

Type RTD Valeur min. Valeur max. Plage Standard

Pt 100 -200 °C 850 °C 25 °C IEC 60751

Ni 100 -60 °C 250 °C 25 °C DIN 43760

R. Lin. 0 Ω 10000 Ω 30 Ω –

Décalage max 50% de la valeur max. sélectionnée

Résistance de ligne max. par l 10 Ω

Courant de sonde > 0,2 mA, < 0,4 mA

Eet de la résistance de ligne (3-ls) < 0,002 Ω / Ω

Détection de rupture sonde Oui

© Danfoss | DCS (im) | 2017.0714 | 520B7737 | IC.PS.P40.A4.ML

Page 15

SORTIE

SORTIE COURANT

Gamme de mesure 4 – 20 mA

Plage de mesure min. 16 mA

Temps de scrutation 135 ms

Résistance de charge ≤ (V

Stabilité de charge ≤ ±0,01% de l’EC / 100 Ω

- 8) / 0,023 [Ω]

alim.

DÉTECTION DE RUPTURE DE SONDE

Programmable 3,5 – 23 mA

NAMUR NE43 Haut d’échelle 23 mA

NAMUR NE43 Bas d’échelle 3,5 mA

Approbation EEx: MBT 9110, 084Z7441

KEMA 04ATEX1339

Température amb. max. (T4) 85 °C

Température amb. max. (T6) 60 °C

ATEX, applicable en zone 0, 1, 2, 20, 21 or 22

ATEX Installation Drawing No. MBT 9110 - 084Z7441

II 1 G Ex ia IIC T4 ou T6

II 1 D Ex iaD

AGRÉMENTS ET HOMOLOGATIONS

STANDARD

EMC 2004/108/EF Emission et immunité EN 61326-1

EN 60079-0, EN 60079-11

ATEX 94/9/EC

EC = Echelle congurée

EN 60079-15, EN 60079-26

EN 61241-0, EN 61241-11

CONNEXIONS

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 15

Page 16

SCHEMA DE PRINCIPE

Circuit S.I., seulement 084Z7441

MBT 9110

084Z7440, 084Z7441

–

–

–

VCC

PROGRAMMATION

• Loop Link est un kit de programmation permettant de programmer le MBT 9110

• Pour le raccordement du Loop Link, veuillez vous reporter au schéma cidessous et à l’aide en ligne du logiciel PReset

• Loop Link ne doit pas être utilisé avec des modules installés en zone dangereuse

1

MBT 9110

2

File Product Input Output Communication Language Option 08:30:00

Pr etop 5331

Date: 2004-8.10

Serial No.: 043201594

Tag No.: PR electronics

Analog Input Analog Ouput

Input Type: Pt 100 DIN / IEC Output Type: 4 – 20 mA

Sensor error: Upscale

Input Range: 0 – 50C

Connection: 3-wire

Cold junction comp: --------Response time: 1.00 sec

*

Loop

Link

5909 - USB

5905 - RS232

Dimensions mécaniques

Montage des fils du capteur

Les fils doivent être montés

entre les plaques métalliques

© Danfoss | DCS (im) | 2017.0716 | 520B7737 | IC.PS.P40.A4.ML

Page 17

APPENDICE

ATEX Installation drawing

MBT 9110 - 084Z7441

ATEX Certicate KEMA 04ATEX 1339

Marking

Standards

Hazardous area

II 1 G Ex ia IIC T6 – T4

II 1 D Ex iaD

EN 60079-0 : 2006, EN 60079-11 : 2007, EN 60079-26 : 2007,

EN 61241-0 : 2006, EN 61241-11 : 2006

Non Hazardous Area

Zone: 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85 °C

T6: -40 ≤ Ta ≤ 60 °C

Terminal: 3,4,6

Uo: 27 VDC

Io: 7 mA

Po: 45 mW

Lo: 35 mH

Co: 90 nF

6

5

4

3

Terminal: 1,2

+

1

-

2

Barrier

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10μH

Ci: 1.0nF

INSTALLATION NOTES

CONSIGNE DE SÉCURITÉ

Notes concernant l’installation: Pour l’installation sûre du MBT 9110 084Z 7441, il convient de suivre les instructions suivantes.

Le module ne doit être installé que par du personnel qualifié connaissant la législation nationale et internationale ainsi que les

directives et normes régissant ce domaine. L’année de production est indiquée par les deux premiers chiffres du numéro de série.

Dans les atmosphères gazeuses potentiellement explosives, le transmetteur doit être monté dans un boîtier afin de garantir un

degré de protection d’au moins IP20 conformément à la norme EN 60529.

Si le transmetteur est installé dans une atmosphère explosive nécessitant l’usage d’un équipement de catégorie 1G et si le boîtier

est en aluminium, il doit être monté d’une telle manière que, même dans le cas d’incidents rares, les sources d’inflammation dues

aux impacts et à la friction, et les étincelles ne puissent se produire. Si le boîtier est construit dans des matériaux non métalliques,

la charge électrostatique doit être évitée.

Pour l’installation dans des atmosphères poussiéreuses potentiellement explosives, les instructions suivantes s’appliquent:

Le transmetteur doit être monté dans un boîtier métallique de forme B conformément à DIN 43729 assurant un degré de

protection d’au moins IP6X conformément à la norme EN 60529. Ce boîtier doit convenir à l’application et il doit être

correctement installé.

Seuls des entrées de câble et des bouchons convenant à l’application et correctement installés doivent être utilisés.

Pour une température ambiante ≥ 60 °C, il faut utiliser des câbles résistant aux températures élevées avec une capacité nominale

d’au moins 20 K au-dessus de la température ambiante.

La température de surface du boîtier est égale à la température ambiante plus 20 K, pour une couche de poussière d’une épaisseur de 5 mm.

Danfoss A/S

Danfoss Industrial Automation

DK 6430 Nordborg Denmark

Phone +45 7488 2222

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 17

Page 18

DEUTSCH

2-Draht-Installation

PROGRAMMIERBARER 2-LEITER MESSUMFORMER

MBT 9110 - 084Z7441

INHALTSVERZEICHNIS

Verwendung..........................................................................................................................................................................................18

Technische Merkmale ........................................................................................................................................................................18

Montage / Installation ....................................................................................................................................................................... 18

Anwendungen......................................................................................................................................................................................18

Typ / Ausführungen ...........................................................................................................................................................................19

Elektrische Daten.................................................................................................................................................................................19

Elektrische Anschlüsse ...................................................................................................................................................................... 20

Blockdiagramm ....................................................................................................................................................................................21

Programmierung .................................................................................................................................................................................21

Abmessungen ......................................................................................................................................................................................21

Montage von Fühlerleitungen .......................................................................................................................................................21

Appendix ................................................................................................................................................................................................ 22

- ATEX Installation drawing..............................................................................................................................................................22

- Sicherheitsanweisung ..................................................................................................................................................................... 22

• Eingang für WTH oder Ohm

• Hohe Messgenauigkeit

• 3-Leiter-Anschluss

• Programmierbare Sensorfehleranzeige

• Für Einbau in DIN B Anschlusskopf

Verwendung

• Linearisierte Temperaturmessung mit Pt100 / Pt1000, Ni100 / Ni1000 Sensor

• Umwandlung von linearer Widerstandsänderung in ein analoges Standard-Stromsignal, z.B. von Ventilen

oder Niveau-Messwertgeber

Technische Merkmale

• Der WTH- und Widerstandseingang haben Leitungskompensation bei 3-Leiter-Anschluss

Montage / Installation

• Für Montage in DIN B Anschlusskopf

• In nicht explosionsgefährdeten Bereichen kann der Messumformer mittels einer speziellen Armatur auf

einer DIN-Schiene montiert werden.

ANWENDUNGEN

WTH in 4 – 20 mA

Widerstand in 4 – 20 mA

im Kontrollraum

+

-

+

-

V+

mA

2-Draht-Installation

im Kontrollraum

V+

mA

© Danfoss | DCS (im) | 2017.0718 | 520B7737 | IC.PS.P40.A4.ML

Page 19

TYP

AUSFÜHRUNG

Standard 084Z7440

Standard Atex 084Z7441

MBT 9110

ELEKTRISCHE DATEN

Temperaturbereich -40 °C – 85 °C

MBT 9110, 084Z7440 8 – 35 V

Standard ATEX, MBT 9110, 084Z7441 8 – 30 V

Common specications

Versorgungsspannung, DC

Eigenverbrauch 25 mW – 0,8 W

Spannungsabfall 8 VDC

Aufwärmzeit 5 min.

Kommunikationsschnittstelle Loop Link

Signal- / Rauschverhältnis min. 60 dB

Ansprechzeit (programmierbar) 0,33 – 60 s

Signalauösung, Eingang 19 bit

Signalauösung, Ausgang 16 bit

Kalibrierungstemperatur 20 – 28 °C

GENAUIGKEIT, HÖHERER WERT VON ALLGEMEINEN UND BASISWERTEN

ALLGEMEINE WERTE

Elektrischer Anschluss Absolute Genauigkeit Temperatur koeffizient

Alle ≤ ± 0,1% d. Messsp. ≤ ± 0,01% d. Messsp. / °C

BASISWERTE

Eingangsart Grund genauigkeit Temperatur koeffizient

WTH ≤ ± 0,3 °C ≤ ± 0,01 °C / °C

Lin.R ≤ ± 0,2 Ω ≤ ± 20 m Ω / °C

EMV-Immunitätseinwirkung ≤ ± 0,5% d. Messsp.

Auswirkung von Änderungen der Versorgungsspannung ≤ 0,005% d. Messsp. / VDC

Vibration IEC 60068-2-6 Test FC

Lloyd’s Spezikation Nr. 1 4 g / 2 – 100 Hz

Max. Leitungsquerschnitt 1 x 1,5 mm2 Mehraderkabel

Luftfeuchtigkeit < 95% RH (nicht kond.)

Maß ø44 x 20,2 mm

Schutzart (Gehäuse / Anschluss) IP68 / IP00

Gewicht 50 g

ELEKTRISCHE DATEN, EINGANG

WTH- UND LINEARER WIDERSTANDSEINGANG

WTH typ Min. wert Max. wert Min. spanne Norm

Pt 100 -200 °C 850 °C 25 °C IEC 60751

Ni 100 -60 °C 250 °C 25 °C DIN 43760

Lin. R 0 Ω 10000 Ω 30 Ω –

Max. Nullpunktverschiebung (Oset) 50% des gewählten Max.-Wertes

Leitungswiderstand pro Leiter (max.) 10 Ω

Fühlerstrom > 0,2 mA, < 0.4 mA

Wirkung des Fühlerkabelwiderstandes (3-Leiter) < 0,002 Ω / Ω

Fühlerfehlererkennung Ja

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 19

Page 20

AUSGANG

STROMAUSGANG

Signalbereich 4 – 20 mA

Min. Signalbereich 16 mA

Aktualisierungszeit 135 ms

Belastungswiderstand ≤ ( V

Belastungsstabilität ≤ ±0,01% d. Messsp. / 100 Ω

- 8) / 0,023 [Ω]

Vers.

FÜHLERFEHLERERKENNUNG

Programmierbar 3,5 – 23 mA

NAMUR NE43 aufsteuernd 23 mA

NAMUR NE43 zusteuernd 3,5 mA

EEx-Zulassung: MBT 9110, 084Z7441

KEMA 04ATEX1339

Max. Umgebungstemp. für T4 85 °C

Max. Umgebungstemp. für T6 60 °C

ATEX, für Anwendung in Zone 0, 1, 2, 20, 21 or 22

ATEX Installation Drawing No. MBT 9110 084Z7441

II 1 G Ex ia IIC T4 oder T6

II 1 D Ex iaD

EINHALTUNG BEHÖRDLICHER AUFLAGEN

NORM

EMC 2004/108/EF Emission und immunität EN 61326-1

EN 60079-0, EN 60079-11

ATEX 94/9/EC

d. Messspanne = der gewählten Messspanne

EN 60079-15, EN 60079-26

EN 61241-0, EN 61241-11

ELEKTRISCHE ANSCHLÜSSE

2-Leiter-Installation

© Danfoss | DCS (im) | 2017.0720 | 520B7737 | IC.PS.P40.A4.ML

Page 21

BLOCKDIAGRAMM

MBT 9110

084Z7440, 084Z7441

Ex-Kreislauf, nur 084Z7441

–

–

–

PROGRAMMIERUNG

• Loop Link ist eine batteriegespeiste Schnittstelle zur Programmierung des MBT 9110

• Bezüglich Programmierung verweisen wir auf die nachfolgende Zeichnung und die “Hilfe”-Funktion im

PReset-Programm

• Loop Link darf nicht zur Kommunikation mit Modulen, die in EEx-gefährdeten Bereichen installiert sind,

benutzt werden

1

2

MBT 9110

*

File Product Input Output Communication Language Option 08:30:00

Pr etop 5331

Date: 2004-8.10

Serial No.: 043201594

Tag No.: PR electronics

Analog Input Analog Ouput

Input Type: Pt 100 DIN / IEC Output Type: 4 – 20 mA

Input Range: 0 – 50C Sensor error: Upscale

Connection: 3-wire

Cold junction comp: ---------

Abmessungen

Response time: 1.00 sec

Montage von Fühlerleitungen

Loop

5909 - USB

5905 - RS232

Link

Die Leitungen müssen zwischen den

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 21

Metallplatten montiert werden

Page 22

APPENDIX

ATEX Installation drawing

MBT 9110 - 084Z7441

ATEX Certicate KEMA 04ATEX 1339

Marking

Standards

II 1 G Ex ia IIC T6 – T4

II 1 D Ex iaD

EN 60079-0 : 2006, EN 60079-11 : 2007, EN 60079-26 : 2007,

EN 61241-0 : 2006, EN 61241-11 : 2006

Hazardous area

Non Hazardous Area

Zone: 0, 1, 2, 20, 21, 22

T4: -40 ≤ Ta ≤ 85 °C

T6: -40 ≤ Ta ≤ 60 °C

Terminal: 3,4,6

Uo: 27 VDC

Io: 7 mA

Po: 45 mW

Lo: 35 mH

Co: 90 nF

6

5

4

3

Terminal: 1,2

+

1

-

2

Barrier

Ui: 30 VDC

Ii: 120 mA

Pi: 0.84 W

Li: 10μH

Ci: 1.0nF

INSTALLATION NOTES

SICHERHEITSANWEISUNG

Installationshinweise: Um den MBT 9110 084Z 7441 sicher zu installieren, sind die folgenden Hinweise zu beachten. Das Modul

ist von qualifizierten Technikern mit Kenntnissen über einschlägigen nationalen und internationalen Gesetzen, Richtlinien und

Standards zu installieren.

Das Baujahr entnehmen Sie den ersten beiden Ziffern der Seriennummer.

In explosionsfähigen Gasatmosphären ist der Messumformer in ein Gehäuse einzubauen, um mindestens die Schutzart IP20

gemäß EN 60529 zu gewährleisten.

Bei Installation des Messumformers in einer explosionsfähigen Atmosphäre, in der Geräte der Kategorie 1G erforderlich sind,

und wenn das Gehäuse aus Aluminium hergestellt ist, muss der Messumformer so installiert werden, dass selbst bei seltenen

Ereignissen – Zündquellen durch Schlägen oder Reibung – keine Funken auftreten können. Bei einem Gehäuse aus einem

nichtmetallischen Material sind elektrostatische Aufladungen zu vermeiden.

Bei Installation in einer explosionsfähigen Staubatmosphäre sind folgende Anweisungen zu beachten:

Der Messumformer ist in ein Metallgehäuse nach DIN 43729 Form B einzubauen, wobei mindestens die Schutzart IP6X gemäß

EN 60529 gewährleistet werden soll. Das Gehäuse muss für die Anwendung geeignet sein und ordnungsgemäß installiert werden.

Es sind Kabeleinführungen und Blindstopfen zu verwenden und ordnungsgemäß zu installieren, die für die Anwendung geeignet

sind.

Bei Umgebungstemperaturen von ≥ 60ºC sind hitzebeständige Kabel mit einem Rating von mindestens 20 K über der

Umgebungstemperatur zu verlegen.

Die Oberflächentemperatur des Gehäuses entspricht bei einer Staubschicht von 5 mm der Umgebungstemperatur plus 20K.

Danfoss A/S

Danfoss Industrial Automation

DK 6430 Nordborg Denmark

Phone +45 7488 2222

© Danfoss | DCS (im) | 2017.0722 | 520B7737 | IC.PS.P40.A4.ML

Page 23

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 23

Page 24

© Danfoss | DCS (im) | 2017.07 IC.PS.P40.A4.ML | 520B7737 | 24

Loading...

Loading...