Page 1

MBT 5250

MBT 5260

MBT 5252

MBT 5250

MBT 5260

MBT 5252

Data Sheet

Temperature sensor

Types MBT 5250, MBT 5260

and MBT 5252

Heavy-duty marine approved temperature sensor.

Heavy-duty temperature sensors for controlling

cooling water, lubrication oil, hydraulic oil and

refrigeration plants within general industry and

marine applications. These temperature

sensors are based on a standardized Pt 100 or

Pt 1000 element, which gives a reliable and

accurate measurement. All three sensor types

can be delivered with NTC / PTC elements on

request.

In the low temperature version (-50 – 200 °C)

the measuring insert is based on a silicone

cable, which makes the sensor very resistant

towards vibrations. The MBT 5250 with

changeable measuring insert and MBT 5260

with xed measuring insert are equipped with

EN 175301-803-A, Pg 9 as standard. The MBT

5252 is equipped with a B-head as standard,

but can also be delivered with B-mini Head on

request.

If needed, a transmitter (MBT 9110) can be

ordered as an integrated part of the MBT 5252

sensor.

Features:

• Gaseous or liquid media, e.g. air, gas, vapour,

water or oil

• Up to 200 °C media temperature (MBT 5250

and MBT 5260)

• Up to 200 °C or 400 °C media temperature

(MBT 5252)

• Pt 100 or Pt 1000 sensing element

• Can be used with 2 or 3 wire connections

• Gold plated male and female connector (MBT

5250 and MBT 5260)

• MBT 5250 and MBT 5252 with

interchangeable measuring insert

• MBT 5260 with xed measuring insert

• Available with built-in transmitter (MBT 5252)

AI208386431879en-000801

Page 2

Features

Description

Measuring range

-50 – 200 °C

Sensing element

Pt 100, Pt 1000

Protection tube

ø8 × 1 mm

Permissible media velocity

Air

25 m/s

Water

3 m/s

Process connection

G ¼ A

G ¼ A

G ³⁄₈ A – M18

G ¾ A

M24

Max. tightening torque

25 Nm

50 Nm

100 Nm

Type

Protection tube

Indicative response times

Water 0.2 m/s

Air 1 m/s

t

0.5t0.9t0.5t0.9

MBT 5250 with interchangeable measuring insert

ø8 × 1 mm

9 s

33 s

95 s

310 s

MBT 5260 with xed meas. ins.

ø8 × 1 mm

6 s

20 s

35 s

140 s

Features

Description

Sensor tolerances

EN 60751 Class B: ± (0.3 + 0.005 × t)

t = temperature of medium, numerical value

Vibration stability

Shock:

100 g / 6 ms

Vibrations:

4 g sine function 5 – 200 Hz, measured acc. to IEC 60068-2-6

Enclosure

IP65 according to IEC 60529

Cable entry EN 175301-803

Pg 9, Pg 11 or Pg 13.5

Features

Description

Protection tube in contact with media

W.no. 1.4571 (AISI 316 Ti)

Process connection

W.no. 1.4404 (AISI 316 L)

Extension length

W.no. 1.4571 (AISI 316 Ti)

Union

Nickel plated brass

Gasket

Silicone

Plug EN 175301-803

PA 6.6 (max 125 °C)

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Product specication

Technical data

MBT 5250, MBT 5260

Table 1: General data

Table 2: Connection

Table 3: Response times

Table 4: Mechanical and environmental specications

Table 5: Materials

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 2

Page 3

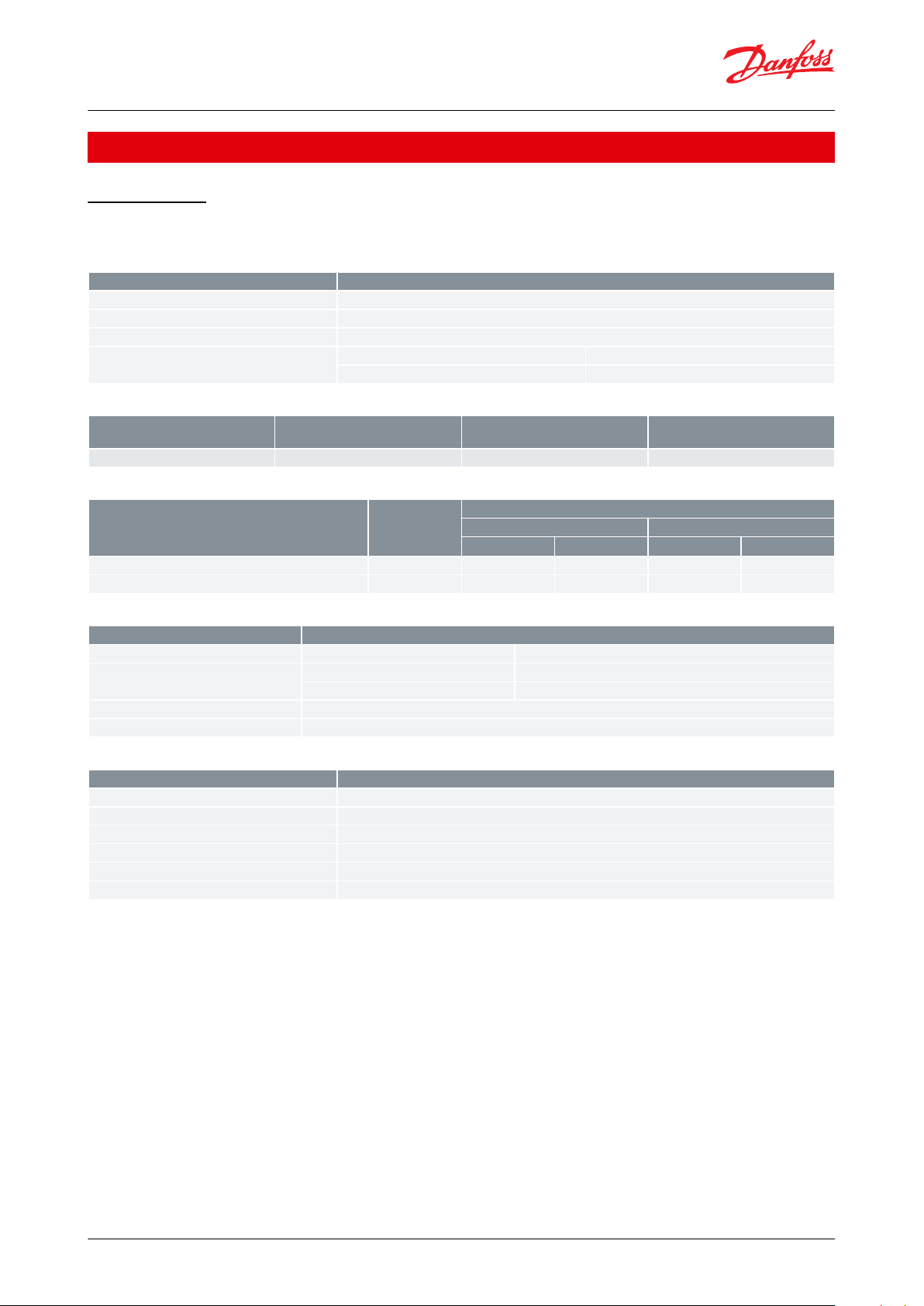

L

TmTpT

A

Max. temperature (Ext. length “None”) Plug EN 175301-803

Max. load on protection tube (ø8 × 1, ø10 × 2) acc. to EN 175301-803

Danfoss

93Z99

Insertion length

Media temperature

Temperature for electric plug

Ambient temperature

Features

Description

Measuring range

-50 – 200 °C or -50 – 400 °C

Sensing element

Pt 100, Pt 1000

Protection tube

Low temperature: ø10 × 2 mm

High temperature: ø11 × 1 mm

Permissible media velocity

Air

25 m/s

Stream

25 m/s

Water

3 m/s

Process connection

G ¼

G ¼ A – G ½ A

G ³⁄₈ A – M18

G ¾ A

M24

Max. tightening torque

25 Nm

50 Nm

100 Nm

Type

Protection tube

Indicative response times

Water 0.2 m/s

Air 1 m/s

t

0.5t0.9t0.5t0.9

MBT 5252

ø10 × 2 mm

14 s

42 s

110 s

390 s

MBT 5252 (HT)

ø11 × 1 mm

25 s

80 s

150 s

450 s

Features

Description

Protection tube in contact with media

W.no. 1.4571 (AISI 316 Ti)

Process connection

W.no. 1.4404 (AISI 316 L)

Extension length

W.no. 1.4571 (AISI 316 Ti)

Union

Nickel plated brass

Connection head

Die cast aluminium

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Table 6: Max. temperature and load

NOTE:

For extension length = 50 mm no limitations up to 200 °C media temperature and 90 °C ambient temperature.

MBT 5252

Table 7: General data

Table 8: Connection

Table 9: Response times

Table 10: Materials

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 3

Page 4

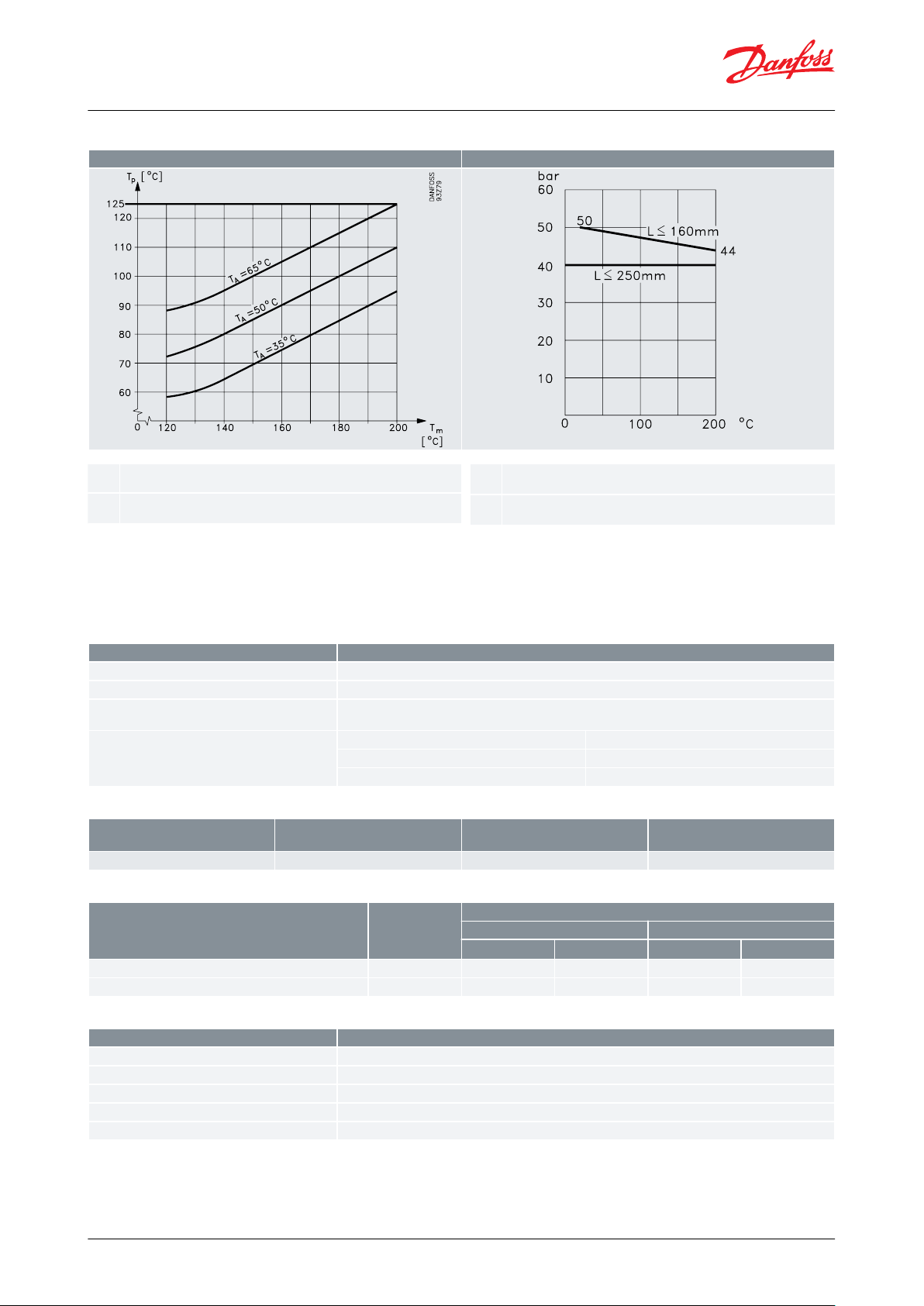

LABCD

E

Features

Description

Max. ambient temperature

(1)

Sensors without transmitter

90 °C

Sensors with transmitter

85 °C

Sensor tolerance

EN 60751 Class B: ± (0.3 + 0.005 × t)

t = temperature of medium, numerical value

Vibration stability

Shock:

100 g / 6 ms

Vibrations:

4 g sine function 5 – 200 Hz, measured acc. to IEC 60068-2-6

Enclosure

IP65 according to IEC 60529

Cable entry B-head

Pg16

Cable entry BM

Pg 9

Temperature transmitter MBT 9110

Supply voltage:

8 – 35 V DC

Output:

4 – 20 mA

ø11 × 1

ø8 × 1, ø10 × 2

Danfoss

93Z99

Insertion length

Without extension length

With extension length

Extension length

Insertion length

Protection tube

Process connection

Union

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Table 11: Mechanical and environmental specications

(1)

(1)

The temperature of the transmitter is inuenced by media temperature, ambient temperature and ventilation in the engine room. If the

The temperature of the transmitter is inuenced by media temperature, ambient temperature and ventilation in the engine room. If the

temperature of the transmitter exceeds the max. allowed temperature the transmitter must be data placed in a separated enclosure, as

temperature of the transmitter exceeds the max. allowed temperature the transmitter must be data placed in a separated enclosure, as

described in the separate sheet for MBT 9110.

described in the separate sheet for MBT 9110.

Table 12: Max. load on protection tube according to DIN 43763

Dimensions

MBT 5250, MBT 5260

Table 13: Extension length

NOTE:

• Tightening torque for the mounting screw at the rear end of the electrical connection plug: 25 Ncm

• Tightening torque for the union (position “E”): 17 Nm

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 4

Page 5

ABCDE

FGH

I

Gasket

Plugs

33

34

39

50

34,5

Process connection

G ¼

G ¼ A – G ½ A

G ³⁄₈ A – M18

G ¾ A

M24

Width across ats

HEX 22

HEX 27

HEX 32

A B

C

ø10 x 2

50

75

16

D

E

F

G

H

I

Danfoss

93Z160

Insertion length

Extension length

Welded

Protection tube

Union nut

Process connection

Transmitter type MBT 9110, as

terminal block

Connection head, type B

Pg 16

Process connection

G ½ A, ½–14 NPT

G ¾ A

Width across

ats

HEX 27

HEX 32

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Table 14: Gasket and Plugs

Units: mm

Table 15: Connection

MBT 5252

Unit: mm

Figure 1: Dimension and parts

Also available with:

Figure 2: Type BM

Table 16: Connection

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 5

Page 6

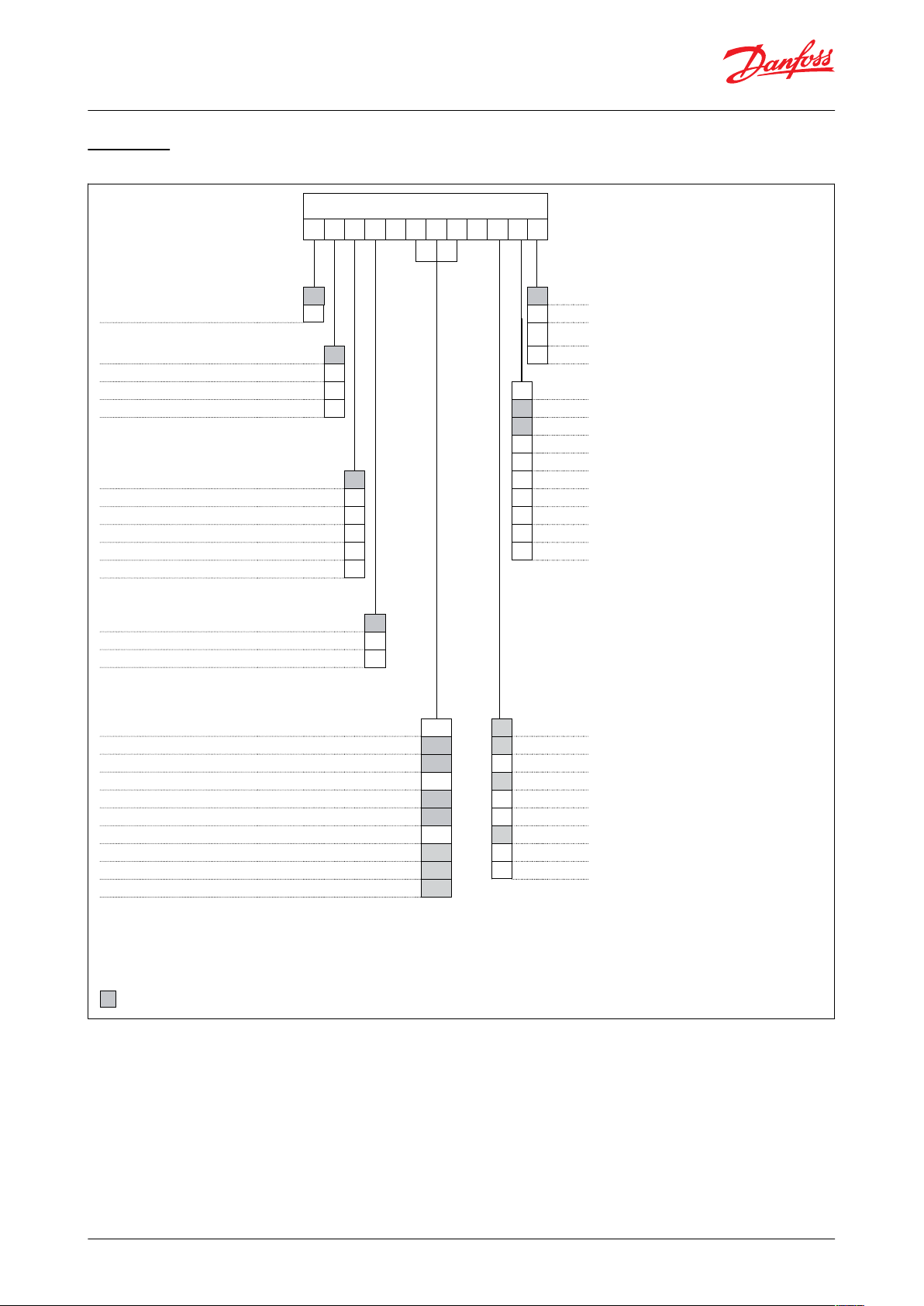

A

BCDEF

G

Danfoss

93Z78A

With temperature transmitter

Without temperature transmitter 1 x Pt100

Without temperature transmitter 2 x Pt100

A

B

C

D

E

F

G

A

C

D

E

F

G

A

C

F

G

A

Jumper

Termocuple

2-Wire

3-Terminals

Jumper connected

4-Wire

3-Wire

2-Wire

Connection

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Electrical connection

MBT 5250, MBT 5260

Figure 3: Electrical connection

2-wire, 3 terminals

(Ground not connected)

MBT 5252

Table 17: Electrical connection

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 6

Page 7

Type MBT 5250

Sensor

– –

Measuring range, sensor element Tolerance

-50 – 200 °C

0 0

EN 60751 Class B

1

1/3 EN 60751 Class B

2

1/6 EN 60751 Class B

3

EN 60751 Class A

4

B-value (25°/85° C): 3540 ± 1%

Sensing element

1 × Pt 100

0

1 × Pt 1000 (Class B only)

1

Process connection

2 × Pt 100

2 0

None

2 × Pt 1000 (Class B only)

3 1

1 x NTC 2055 ± 1% Ohm

4 2

3

Protection Tube, W.nr. 1.4571 (AISI 316 Ti)

4

G ¾ A

Acid-proof steel, ø8 × 1mm

0 5

M18 × 1.5

Solid drilled, tapered, ø12 to ø14.5

1 6

M24 x 2

Acid-proof steel, ø10 x 2 mm

2 7

G 3/8 A

Acid-proof steel, ø10 x 2 mm

3 8

M33 x 2

9

Extension length

A

M22 x 1.5

None

0 B

M16 x 1.5

50 mm

1 C

M14 x 1.5

D

Insertion length

E

3/4 – 16 UNF

050 mm 050

F

060 mm 060

G

M20 x 1.5

080 mm 080

100 mm 100 Electrical Connections

120 mm 120

0

EN 175301/803 excl. female plug

150 mm 150

1

EN 175301/803 Plug Pg 9 (IP65)

200 mm 200

2

EN 175301/803 Plug Pg 11 (IP65)

250 mm 250

3

EN 175301/803 Plug Pg 13.5 (IP65)

4

APD plug ISO 15170-1

5

DIN 0627, M12

6

7

EN 175301/803 Plug Pg 9 (IP65) special

8

ITT Cannon 4 pins Au

9

Other

A

EN 175301/803 GL plug Pg 13.5 (IP65) Sn pins

B

EN 175301/803 plug Pg 9, 4 pins without earth (IP65)

C

EN 175301/803 plug Pg 11, 4 pins without earth (IP65)

D

Hunnel HSK-M/Pg 9 (IP68) Metal

E

EN 175301/803 plug M16 (IP 65)

Preferred versions

1)

Only ø8 x 1 mm tube

Adjustable fitting, Brass G 1/4 A

1)

1/4 – 18 NPT

1/4 – 18 NPT

1/2 – 14 NPT

G 1/4 A

1)

G 1/2 A

EN 175301/803 Plug Pg 11 (IP65) with finger screw

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Ordering

MBT 5250

Figure 4: Ordering for MBT 5250

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 7

Page 8

Type MBT 5260

Sensor

– –

Measuring range, sensor eleme nt Tolerance

-50 – 200 °C

0 0

EN 60751 Class B

-30 – 150 °C 1

1

1/3 EN 60751 Class B

Sensing eleme nt 2 1/6 EN 60751 Classs B

1 × Pt 100

0

9 Other

1 × Pt 1000 (Class B only)

1

Process conne ction

2 × Pt 100

2 0

None

Other

9 1

2

3

Protection Tube, W.nr. 1.4571 (AISI 316 Ti)

4

G ¾ A

Acid-proof steel, ø8 × 1mm

0 5

M18 × 1.5

Solid drilled, tapered, Ø12 to Ø14.5

1 6

M24 x 2

Acid-proof steel ø10 x 2 mm

2 7

G 3/8 A

Acid-proof steel, ø9.5 x 1 mm

3 8

M14 x 1.5

Solid drilled, ø4.2

4 9

Other

Other

9

Extension length

None

0

50 mm

1

Other

9

Insertion length Electri cal Connections

030 mm 030

1

EN175301/803 plug Pg 9 (IP65)

040 mm 040

2

EN175301/803 plug Pg 11 (IP65)

050 mm 050

3

EN175301/803 plug Pg 13.5 (IP65)

060 mm 060

4

M12 plug, 4 wire, 4 pins

080 mm 080

5

DIN 72585 Bayonet plug

100 mm 100

7

DIN 43650, Plug Pg9 (IP65) Special

120 mm 120

8

M12 plug, 2 wire, 4 pins

150 mm 150

C

EN175301/803 Pg 11 – 4 pins without earth (IP65)

200 mm 200

9

Other

250 mm 250

1)

G 1/4 A only for ø8 mm protection tube

Preferred versions

G 1/4 A

1)

G 1/2 A

1/2 – 14 NPT

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

MBT 5260

Figure 5: Ordering for MBT 5260

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 8

Page 9

Preferred versions

Type MBT 5252

Sensor Transmit ter

– –

–

Measuring range, sensor eleme nt

Transmitter settin g, end of r ange

-50 – 200 °C

0 0 0

0 °C (or none)

-50 – 400 °C

1 1 1

2 2

Sensing eleme nt

3 3

Temperature range 220 °C = 22

1 × Pt 100

0 9 4

Temperature range 150 °C = 15

1. digit defines 100’s

2. digit defines 10’s

2 × Pt 100 (-50 – 200 °C)

1 5

1 × Pt 1000

2 6

2 × Pt 1000 (-50 – 200 °C)

3 7

Other

9 8

9 9

Other

Protection Tube, W.nr. 1.4571 (AISI 316 Ti)

Acid-proof steel, ø8 mm (-50 – 200 °C)

0

Transmitter setting,

start of rangeAcid-proof steel, ø10 mm (-50 – 200 °C)

1

Acid-proof steel, ø11mm (-50 – 400 °C)

2 0

None

Other

9 1

0 °C

4

-50 °C

Extension length

9

Other

None

0

50 mm

1

100 mm

2

Other

9

Transmitter type

Insertion length As terminal bl ock

50 mm 0050

0

None

100 mm 0100

G

Standard

150 mm 0150

L

Standard EEx ia IIC T4/T6

200 mm 0200 In hightened lid

250 mm 0250

A

Standard

300 mm 0300

J

Standard EEx ia IIC T4/T6

400 mm 0400

B

Galvanically isolated

500 mm 0500

9

Other

xx0 mm xxx0

Connection head Connection

B (IP65)

0 0

2-wire, 3 terminals

B-mini (IP65) (only up to 4 terminals) (transmitter not possible)

1 1

4-wire, also to be used for 3 wire

Other

9 2

2 wire, 2 terminals

Process conne ction Tolerance

G ¼ A (only ø8 mm protection tube)

0 0

EN 60751 Class B

1 3

EN 60751 Class A

G ½ A

G 3/8 A

2 9

Other

G ¾ A

3

½ –14 NPT

7

Other

9

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

MBT 5252

Figure 6: Ordering for MBT 5252

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 9

Page 10

File name

Document type

Document topic

Approval authority

DLN 34014-AE002

Marine - Safety Certicate

–KRTA18505M

Marine - Safety Certicate

–

NKK

06839-E0 BV

Marine - Safety Certicate

–BV17-LD1597279-PDA

Marine - Safety Certicate

–

ABS

TAA000006F Rev. 2

Marine - Safety Certicate

–

DNV GL

ELE-061415XG

Marine - Safety Certicate

–

RINA

GB19PTB00025

Marine - Safety Certicate

–

CCS

14-20066 (E1)

Marine - Safety Certicate

–LRDK.C.32.004.A 41461

Measuring - Performance Certicate

–

GOST

097R0004.01

Manufacturers Declaration

RoHS

Danfoss

084R1022.01

Manufacturers Declaration

China RoHS

Danfoss

SMS.W.II-2179-B.0

Marine - Manufacturing Permission

–BV12CA69359

Explosive - Safety Certicate

ATEX

DEMKO

087R0017.00

Manufacturers Declaration

Simple apparatus

Danfoss

OC.C.32.004.A 75977

Measuring - Performance Certicate

–

GOST

File name

Document type

Document topic

Approval authority

DLN 34014-AE002

Marine - Safety

Certicate

–KRELE-061415XG

Marine - Safety

Certicate

–

RINA

17-LD1597279-PDA

Marine - Safety

Certicate

–

ABS

06839-E0 BV

Marine - Safety

Certicate

–BVTAA000006F Rev. 2

Marine - Safety

Certicate

–

DNV GL

TA18505M

Marine - Safety

Certicate

–

NKK

14-20066 (E1)

Marine - Safety

Certicate

–LRDK.C.32.004.A 41461

Measuring - Performance

Certicate

–

GOST

097R0004.01

Manufacturers Declaration

RoHS

Danfoss

084R1022.01

Manufacturers Declaration

China RoHS

Danfoss

TAA000012M

Marine - Safety

Certicate

–

DNV GL

SMS.W.II-2179-B.0

Marine - Manufacturing Permission

–BV12CA69359

Explosive - Safety

Certicate

ATEX

DEMKO

087R0017.00

Manufacturers Declaration

Simple apparatus

Danfoss

OC.C.32.004.A 75977

Measuring - Performance

Certicate

–

GOST

File name

Document type

Document topic

Approval authority

GB19PTB00025

Marine - Safety

Certicate

–

CCS

DLN 34014-AE002

Marine - Safety

Certicate

–KRELE-061415XG

Marine - Safety

Certicate

–

RINA

17-LD1597279-PDA

Marine - Safety

Certicate

–

ABS

06839-E0 BV

Marine - Safety

Certicate

–BVTAA000006F Rev. 2

Marine - Safety

Certicate

–

DNV GL

TA18505M

Marine - Safety

Certicate

–

NKK

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

MBT 5250

Table 18: MBT 5250

MBT 5260

Table 19: MBT 5260

MBT 5252

Table 20: MBT 5252

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 10

Page 11

File name

Document type

Document topic

Approval authority

14-20066 (E1)

Marine - Safety Certicate

–LR084R1019.01

EU Declaration

EMCD/ROHS

Danfoss

DK.C.32.004.A 41460

Measuring - Performance Certicate

–

GOST

DK.C.32.004.A 41461

Measuring - Performance Certicate

–

GOST

RU Д-DK.АЛ87.В.00022_19

EAC Declaration

EMC

EAC

084R1022.01

Manufacturers Declaration

China RoHS

Danfoss

097R0004.01

Manufacturers Declaration

RoHS

Danfoss

SMS.W.II-2179-B.0

Marine - Manufacturing Permission

–BV12CA69359

Explosive - Safety Certicate

ATEX

DEMKO

087R0017.00

Manufacturers Declaration

Simple apparatus

Danfoss

OC.C.32.004.A 75977

Measuring - Performance Certicate

–

GOST

Temperature sensor, Types MBT 5250, MBT 5260 and MBT 5252

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 11

Page 12

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI208386431879en-000801 | 12

Loading...

Loading...