Page 1

Data sheet

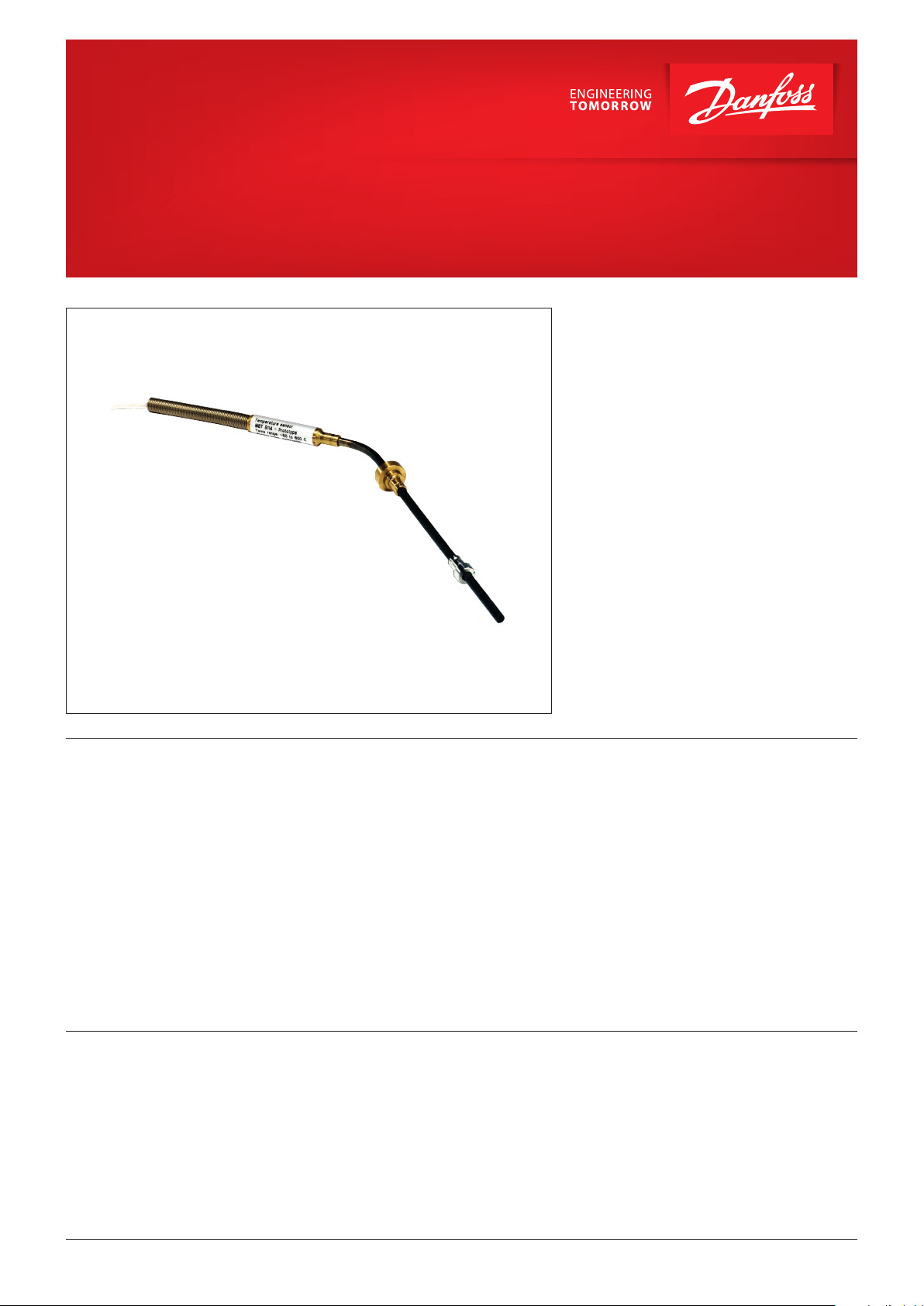

Exhaust gas temperature sensor

MBT 5114

MBT 5114 is a series of exhaust gas temperature

sensors used for performance optimization and

environmental impact control of large 4 stroke

engines.

By utilizing RTD sensing elements the MBT 5114

provides a modern and total cost attractive

alternative to the thermo couple exhaust gas

sensors.

Features

Approvals

• For measuring exhaust gas in stationary and

marine:

– diesel and gas engines

– turbines

– compressors

• Up to 600 °C media temperature (peak 700 °C)

• Fixed or adjustable insertion length

Lloyds Register of Shipping, LR

Germanischer Lloyd, GL

Det Norske Veritas, DNV

Registro Italiano Navara, RINA

• 1 or 2 Pt 1000 elements

• No need for special compensation cable.

• Less noise sensitive

• No cold junction compensation

• Resistant to moisture (works from day one)

• No polarity on the cable (easy to install)

• Linear signal

Nippon Kaiji Kyokai, NKK

American Bureau of Shipping, ABS

Korean Register of Shipping, KRS

China Classification Society, CCS

Bureau Veritas, BV

© Danfoss | DCS (im) | 2016.12

IC.PD.P30.T3.02 | 520B7543 | 1

Page 2

Data sheet | Exhaust gas temperature sensor, MBT 5114

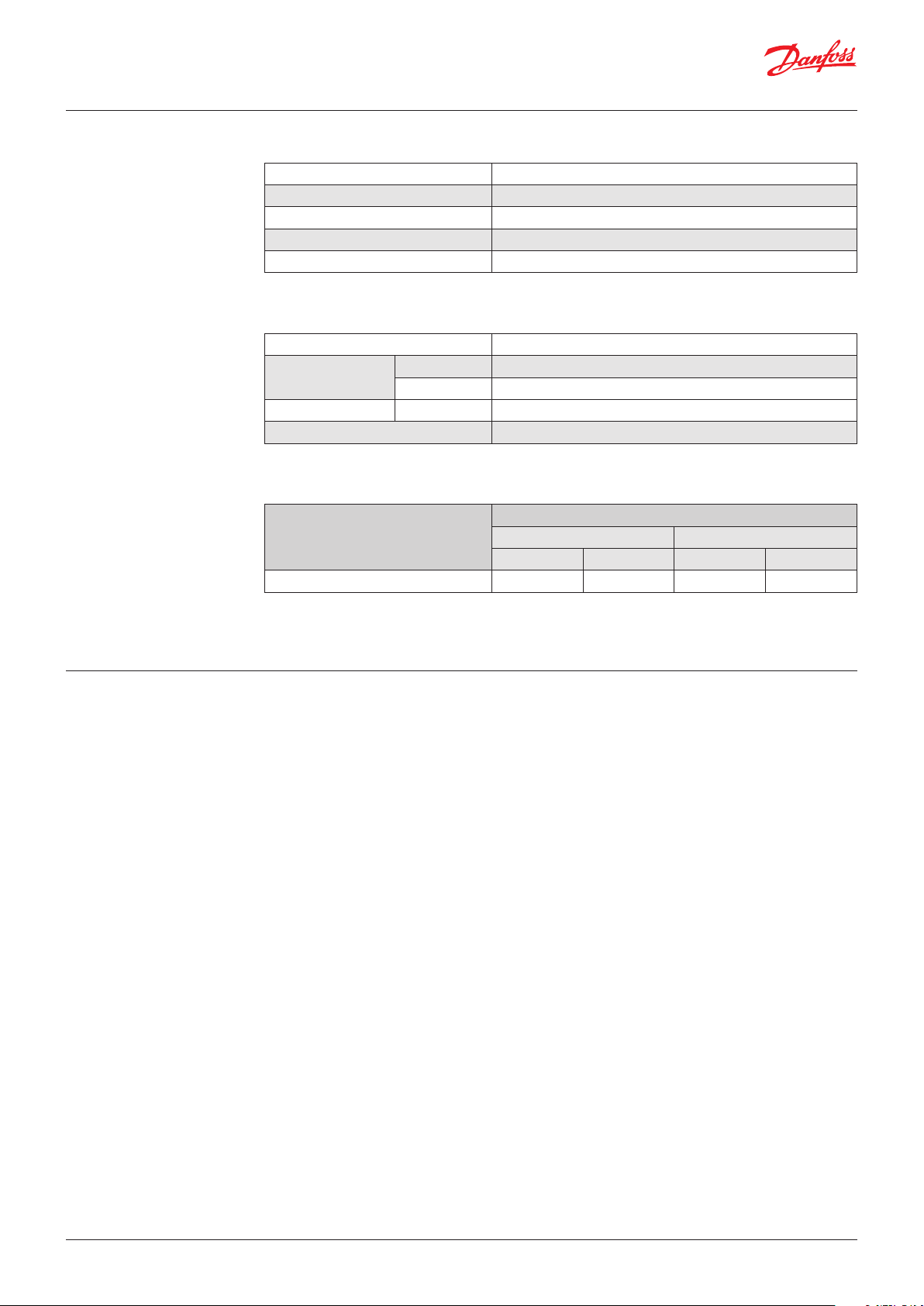

Technical data

Main specifications

Measuring range -50 – 600 °C

Short time temperature (15 min.) 650 °C

Max. peak temperature (1 min.) 700 °C

Element type Pt 1000

Tolerances EN 60751, class B

Mechanical and enviromental specifications

Ambient temperature

Vibration stability

Materials Protection tube W. no. 1.4571 (AISI 316 Ti)

Enclosure IP65 according to IEC 60529

Shock 100 g / 6 ms

Vibrations 4 g sine function 2 – 100 Hz, measured acc. to IEC 60068-2-6

Max 200 °C on the sensor housing, cable depending on type (See Page 3)

Response times

Indicative response times. Typical measured values.

Type

MBT 5114

Water 0.2 m/s Air 6 m/s

t

0.5

1 s 3.5 s 15 s 50 s

t

0.9

t

0.5

t

0.9

Mounting

The free insertion length may not exceed

25 × sensor diameter, e.g. 150 mm

with a 6 mm sensor diameter.

However, it is generally recommended that the

sensor is supported close to the tip either by the

mounting hole or by a sensor pocket.

The sensor might break in case it is mounted

without a proper support in a vibrating

application like exhaust gas monitoring.

The free insertion length is defined as the

part of the outermost sensor end that is not

supported by a pocket or a drilled hole in the

machinery.

The free length of the cable must be supported

for every ½ meter (= 100 × cable diameter).

Especially for turbo inlet/outlet applications it

is necessary to mount the sensor in a pocket to

prevent sensor damage due to high media

velocity and vibrations.

2 | 520B7543 | IC.PD.P30.T3.02

© Danfoss | DCS (im) | 2016.12

Page 3

Data sheet | Exhaust gas temperature sensor, MBT 5114

Ordering standard

Type MBT 5114

Application Length of flexible tube

1 × Pt 1000 2-wire

2 × Pt 1000 2-wire

1 × Pt 100 2-wire

2 × Pt 100 2-wire

1 × Pt 100 4-wire

Other

Protection Tube Accessories

ø4,5 mm

ø6 mm

Other

Tolerance

EN 60751 Class B

Other

Design

Straight protection tube

Bended protection tube

Insertion length L1

100 mm 0100

500 mm 0500

1000 mm 1000

xxxx mm xxxx Cable length L2

Connection type 0100 01.0 m

None

Ajustable fitting, 1 piece

Clamp

Other

Connection thread

None

¼" – 18NPT

G ½ A

Other

0

1

2

3

4

9

0 0

1 1

9

Sensor Cable Accessories

0

9

0

1

0

1

5

9

0

1 2

4 3

9 9

0500 05.0 m

1000 10.0 m

xxxx xx,x m

0

1

0000 None

0030 0.3 m

0100 1.0 m

1000 10 m

xxx0 Other

None

Flexible tube

2

9

0

9

0

1

3

9

Spring

Other

Ajustable fitting for cable

None

Other

Connection (plug)

None

Jäger 4 pins, straight

ITT Cannon 4 pins

Other

Cable type

None

PFA cable, screen, 260 °C

FEP cable, screen, 205 °C

Polyolefine cable, screen, 150 °C

Other

Preferred versions

© Danfoss | DCS (im) | 2016.12

IC.PD.P30.T3.02 | 520B7543 | 3

Page 4

Dimensions [mm]

MBT 5114 straight version, adjustable

Spring

Shield

Ferrule w.o. Collar

MBT 5114 angle version, fixed clamp

Spring

Shield

Ferrule w.o. Collar

Net weight

MBT 5114 0.1 kg

1 m cable increases net weight with approx. 40 g

© Danfoss | DCS (im) | 2016.12 IC.PD.P30.T3.02 | 520B7543 | 4

Loading...

Loading...