Page 1

Data sheet

Bearing temperature sensor

MBT 3310

The MBT 3310 temperature sensor series is specially designed for measuring the temperature in

bearings where there is a risk of overheating.

To get a very short reaction time the measuring

element is placed in a way to secure a reaction

time of down to t

The sensor is tted with a spring loaded protection tube which ensures metallic contact between

bearing and sensor at all times.

= 6 sec. in water.

0.5

Features • For monitoring of bearing temperatures where

there is risk of overheating, in applications

such as:

– Wind Turbines

– Engines

– Gearboxes

• Based on Pt 100 / Pt 1000 technology

for use up to 200 °C

• Spring loaded to ensure good contact

with the bearing

© Danfoss | DCS (im) | 2020.08

AI311332849350en-000201 | 1

Page 2

Data sheet | Bearing temperature sensor, MBT 3310

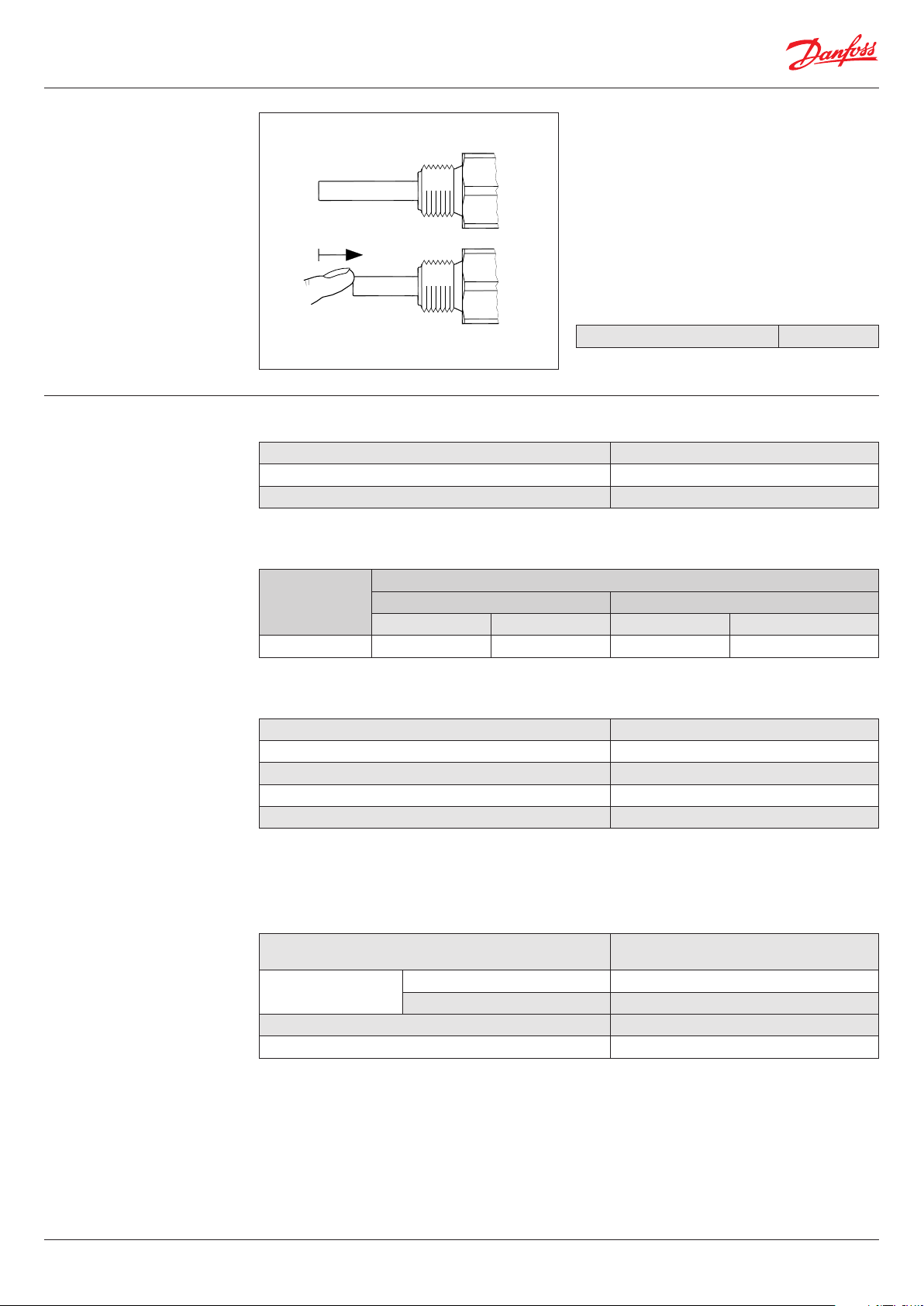

Spring function

0 - A mm

Stainless steel process connection A = 15 mm

Technical Data

General data

Measuring range -50 – 200 °C

Sensing element Pt 100, Pt 1000

Protection tube ø8 × 1 mm

Response time

Indicative response times

Protection tube

Water 0.2 m/s Air 1 m/s

t

0.5

t

0.9

t

0.5

ø8 × 1 mm 6 s 20 s 35 s 140 s

Materials

Protection tube in contact with the media AISI 316

O-ring FPM

Process connection AISI 316 / Brass

Gasket Silicone

Electrical connection M12 x 1 4-pin Au, PA (max. 125 °C)

t

0.9

2 | AI311332849350en-000201

Mechanical and environmental specifications

Sensor tolerance

Vibration stability

Shock 100 g/6 ms

Vibrations 4 g sine function 2 – 100 Hz, acc. to IEC 60068-2-6

Enclosure IP65 according to IEC 60529

Electrical connection M12 x 1 4-pin Au, EN 60947-5-2

EN 60751 Class B: ± (0.3 °C + 0.005 × t)

t = temperature of medium, numerical value

© Danfoss | DCS (im) | 2020.08

Page 3

Data sheet | Bearing temperature sensor, MBT 3310

Ordering standard

M12 x 1

Type MBT 3310

Resistance value Tolerance

1 × Pt 100

1 × Pt 1000

Other

Protection Tube,

W.nr. 1.4571 (AISI 316 Ti)

Acid-proof steel, ø8 × 1mm

Other

Insertion length

(working range)

Stainless

45 – 60 mm

57 – 72 mm

85 – 100 mm

105 – 120 mm

200 – 215 mm

245 – 260 mm

290 – 305 mm

310 – 325 mm

Other

0 0 EN 60751 Class B

2

9 Process connection

0 G ½ A Stainless steel

7 ½ –14 NPT Stainlees steel

9 Other

0

9

Electrical Connections

A M12 plug, 2-wire, 4 pins

60

72 B M12 plug, 4-wire, 4 pins

100

120

215

260

305

325

xxx

Preferred versions

© Danfoss | DCS (im) | 2020.08

AI311332849350en-000201 | 3

Page 4

Electrical connection and

dimensions [mm]

15 ± 2

50 ± 3

17 ± 0.5

L ± 2

Electrical connections

© Danfoss | DCS (im) | 2020.08 AI311332849350en-000201 | 4

Loading...

Loading...