Data Sheet

Pressure transmitter

Type MBS 9300

For marine applications

Compact pressure transmitter programme, MBS

9300 gauge version is designed for use in

marine applications e.g. crankcase and

turbocharger lters monitoring as well as

applications within level measurement.

The programme covers 4 – 20 mA and

ratiometric 10-90% of supply output signals,

pressure span from 40 – 400 mbar as well as

bidirectional ranges.

Excellent vibration stability, robust

construction, and a high degree of EMC/EMI

protection equip the pressure transmitter to

meet the most stringent industrial

requirements.

Features

• Compact design

• Full scale span from 40 – 400 mbar

◦ bidirectional ranges available, e.g. -40 – 70

mbar etc.

◦ lowest zero point –150 mbar

◦ max full scale 250 mbar

• Digital temperature compensated

• Output signals 4-20 mA and Ratiometric 10-

90% of supply

• Excellent shock and vibration robustness

• Reverse polarity protection

• With build-in clipping function and self-

diagnostic features on request

• Enclosure and wetted parts of stainless steel

(AISI 316L)

• EU RO Mutual Recognition

• Customer specic versions on request

• For use in Zone 2 explosive atmosphere

AI176386432536en-000801

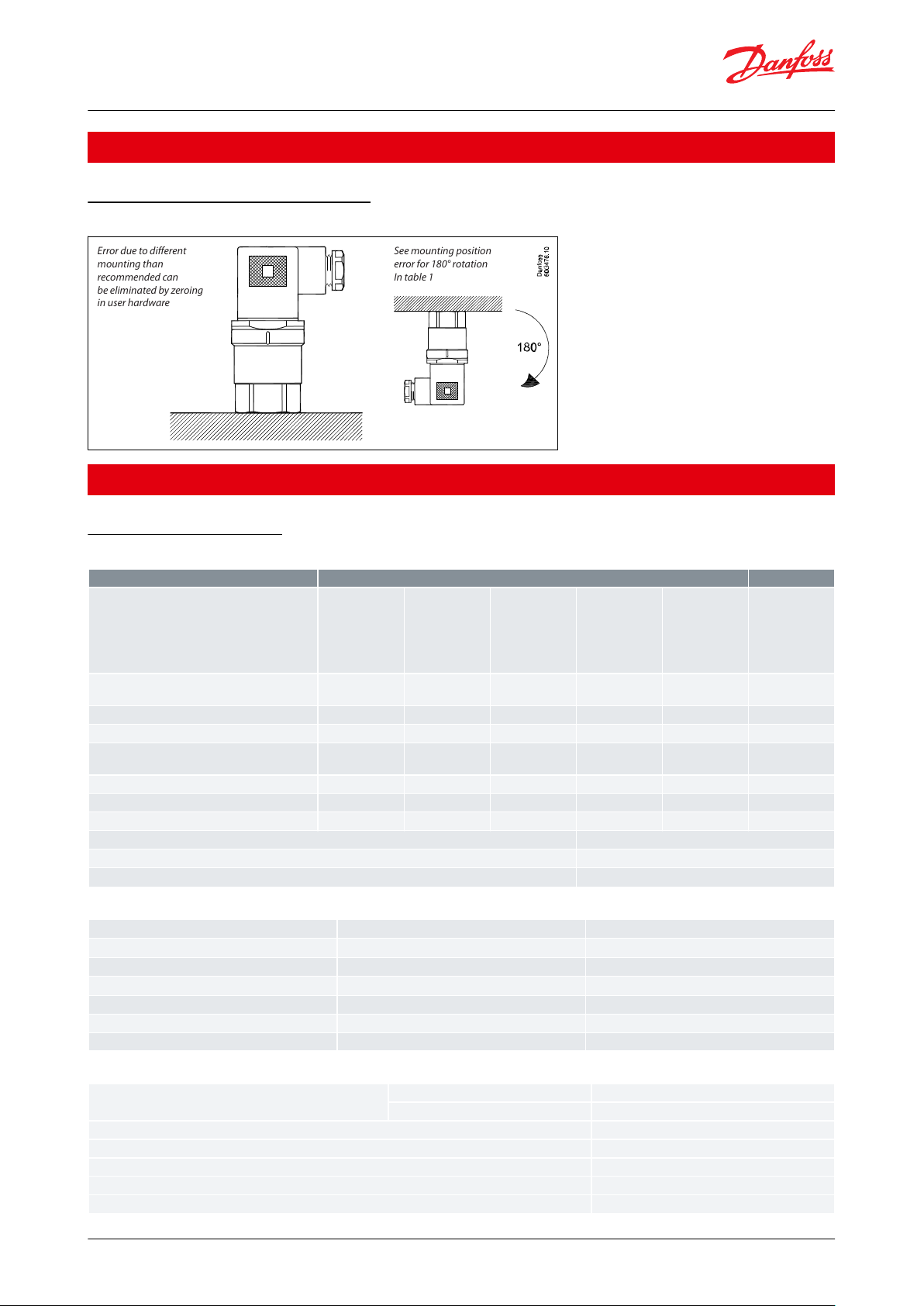

Error due to different

mounting than

recommended can

be eliminated by zeroing

in user hardware

See mounting position

error for 180° rotation

In table 1

Description

Value range

Units

Full-scale span (FSS)

Full-Scale Span (FSS) is the dierence between

the upper limit and the lower limit of the

pressure range.

(e.g. for pressure range -30 – 30 mbar, FSS = 60

mbar.)

4060100/140

150

250/400

mbar

Accuracy @ 25 °C

(incl. non-linearity, hysteresis and repeatability)

≤ ± 2

≤ ± 1.5

≤ ± 1

≤ ± 0.5

≤ ± 0.5

% FSS typ.

Non-linearity (BFSL)

≤ ± 0.2

≤ ± 0.2

≤ ± 0.2

≤ ± 0.2

≤ ± 0.2

% FSS

Hysteresis and repeatability

≤ ± 0.1

≤ ± 0.1

≤ ± 0.1

≤ ± 0.1

≤ ± 0.1

% FSS

Total error band (TEB)

within compensated temperature range

≤ ± 5

≤ ± 3

≤ ± 2

≤ ± 1.5

≤ ± 1.5

% FSS

Mounting position error for 180° rotation

≤ ± 1.25

≤ ± 0.8

≤ ± 0.5

≤ ± 0.35

≤ ± 0.2

% FSS

Overload pressure (static)

3.5

3.5

3.5

3.5

3.5

bar

Burst pressure5050505050bar

Response time

< 2 ms

Resolution

Innite

Durability P: 10 – 90% FS

10 × 106 pressure cycles

Nom. output signal (short circuit protected)

4 – 20 mA

Ratiometric 10-90% supply

Supply voltage [UB], reverse polarity protected

9 – 32 V DC

5 V DC +/- 10%

Supply voltage dependency

< ± 0.05% FSS / 10 V

-

Load [RL] (load connected to 0 V)

RL ≤ (UB - 8 V) / 0.02 A

RL ≥ 1.5 kΩ

Supply current consumption

-

≤ 6 mA

Sink / Source

-

3.3 mA

Output impedance

-

≤ 25 Ω

Media temperature range

FPM gasket

-20 °C – 100 °C

NBR gasket

-25 °C – 85 °C

Ambient temperature range

See Electrical connection

Compensated temperature range

0 °C – 80 °C

Transport / storage temperature range

-40 °C – 125 °C

EMC - Emission

EN 61000-6-3 and EN61236-1

EMC Immunity

EN 61000-6-2 and EN61236-1

Pressure transmitter, type MBS 9300

Applications

Recommended mounting position

Figure 1: Mounting position

Product specication

Technical specications

Table 1: Performance (EN 60770)

Table 2: Electrical specications

Table 3: Environmental specications

© Danfoss | Climate Solutions | 2021.03 AI176386432536en-000801 | 2

Vibration stability

Sinusoidal

15.9 mm-pp, 2 Hz – 25 Hz

IEC 60068-2-6

20 g, 25 Hz – 2 kHz

Random

7.5 g

rms

, 5 Hz – 1 kHz

IEC 60068-2-64

Shock resistance

Shock

500 g / 1 ms

IEC 60068-2-27

Free fall

1 m

IEC 60068-2-32

Enclosure (depending on electrical connection)

See Electrical connection

Zone 2 applications

(1)

EN60079-0; EN60079-15

Net weight

0.2 – 0.3 kg

Electrical connector

See Electrical connection

Pressure connection

See Electrical connection

Materials, wetted parts

EN 10088; 1.4404 (AISI 316 L)

Type code:

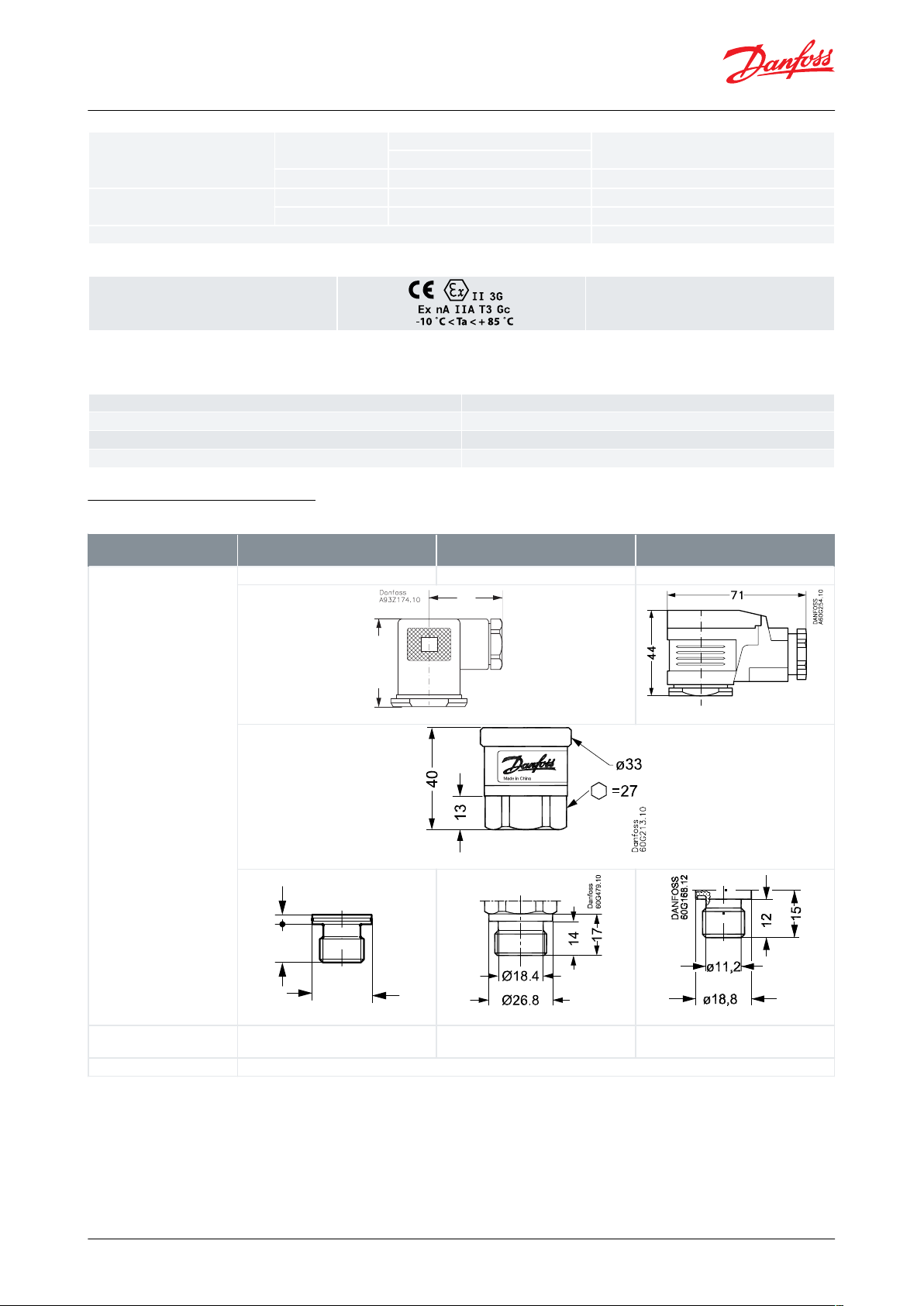

Electrical connection

A1A6A9

EN 175301-803-A, Pg 9

EN 175301-803-A, Pg 11

EN 175301-803-A, Pg 13.5

39.5

34

3

12

Ø 18,8

Type code:

Pressure connection

DIN 3852-E, M14x1.5

DIN 3852-E, G½

DIN 3852-E, G¼

Recommended torque:

20 – 25 Nm

Pressure transmitter, type MBS 9300

Table 4: Explosive atmospheres

(1)

(1)

When used in ATEX Zone 2 areas at low temperatures the cable and plug must be protected against impact.

When used in ATEX Zone 2 areas at low temperatures the cable and plug must be protected against impact.

Table 5: Mechanical specications

Dimensions / Combinations

Table 6: Connections dimensions / combinations

© Danfoss | Climate Solutions | 2021.03 AI176386432536en-000801 | 3

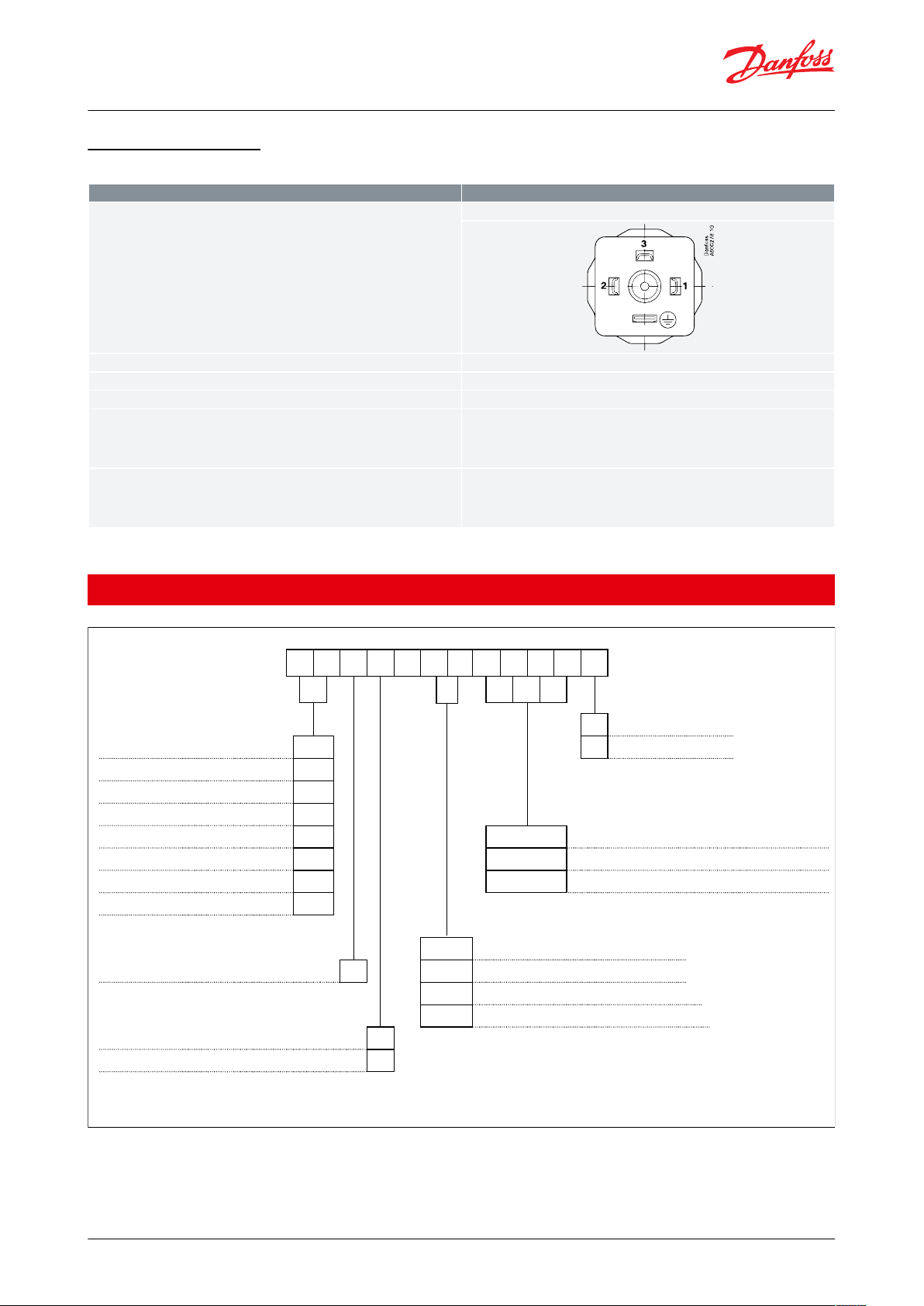

Type code

A0, A1, A6 and A9

EN 175301-803-A

Ambient temperature

-25 °C – 100 °C (ATEX zone 2 = -10 °C – 85 °C)

Enclosure

IP65

Materials

Glass lled polyamid, PA 6.6

Electrical connection

4-20 mA (2 wire)

Pin 1: + supply

Pin 2: - supply

Pin 3: Not used

Earth: Connected to transmitter enclosure

Electrical connection

Ratiometric 10-90% supply

Pin 1: + supply

Pin 2: - common

Pin 3: Output

Earth: Connected to transmitter enclosure

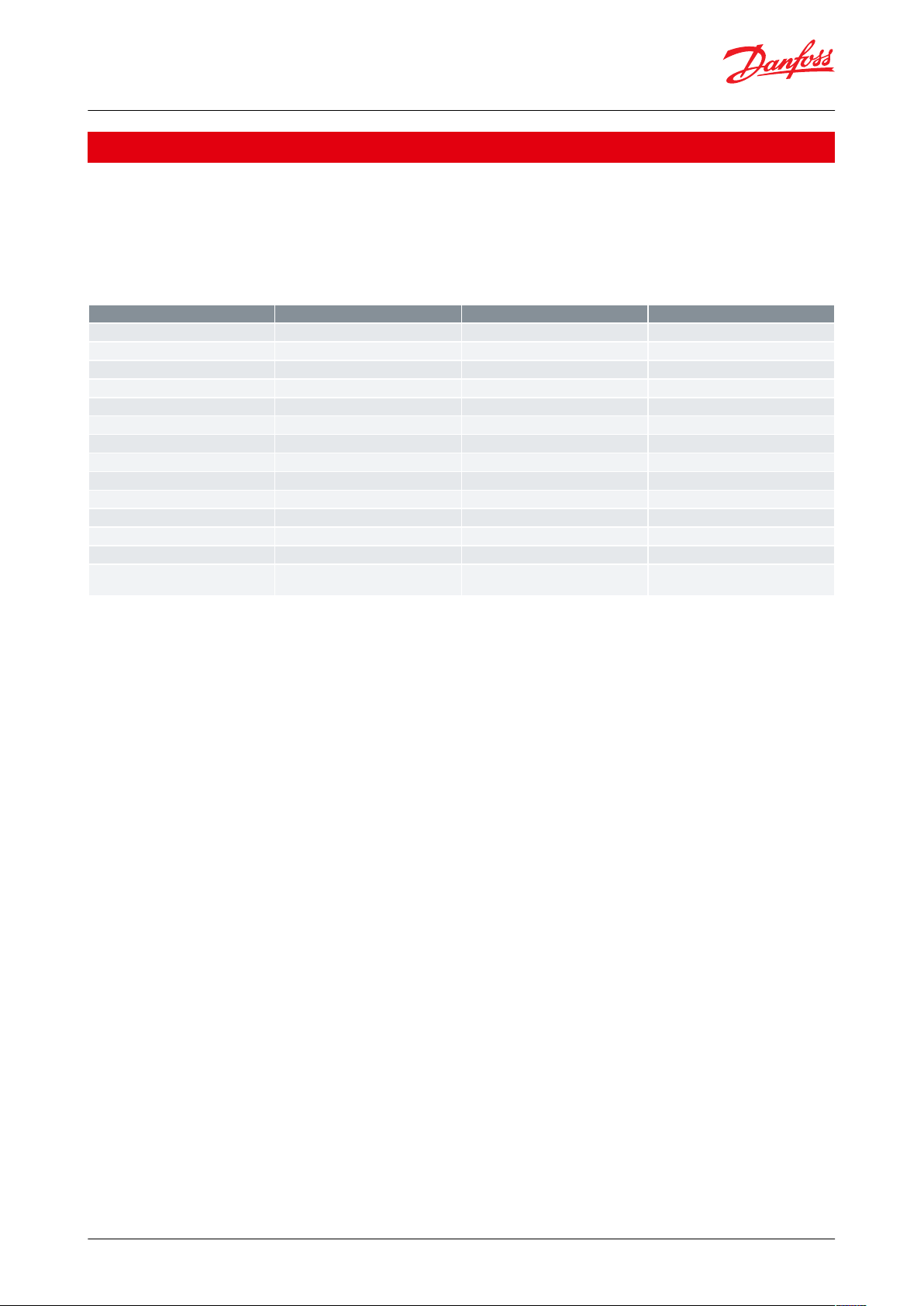

Type 9300 1 –

Gasket

Pressure range

1

Gasket, FPM

-20 –

20 mbar

A 1 2 Gasket, NBR

-30 –

30 mbar

A 2

-70 –

70 mbar

A 3

0 –

40 mbar

B 1 Pressure connection

0 –

60 mbar

B 2 G B 0 8

DIN 3852-E-G1/2, gasket DIN 3869-21

0 –

100 mbar

B 3 G B 0 4 DIN 3852-E-G1/4, gasket DIN 3869-14

0 –

150 mbar

B 4 F A 0 9 DIN 3852-E-M14 x1.5, gasket DIN 3869-14

0 –

250 mbar

B 5

Electrical connection

Pressure reference

A 0

No plug (EN175301-803-A)

Gauge (relative)

1 A 1 Plug Pg 9 (EN 175301-803-A)

A 6 Plug Pg 11 (EN175301-803-A)

Output signal

A 9 Plug Pg 13.5 (EN175301-803-A)

4 - 20 mA

1

Ratiometric 10 - 90% of supply

6

Non-standard build-up codes on request. However, minimum order quantities may apply.

Please contact your Danfoss officer for further information.

Pressure transmitter, type MBS 9300

Electrical connection

Table 7: Electrical connection

For proper ventilation of atmospheric reference pressure a vented cable is recommended.

Ordering

© Danfoss | Climate Solutions | 2021.03 AI176386432536en-000801 | 4

File name

Document type

Document topic

Approval authority

064G9615.06

EU Declaration

ATEX/EMCD/RoHS

Danfoss

TAA00000W0

Marine - Safety Certicate

-

DNV GL

ELE-311018XG

Marine - Safety Certicate

-

RINA

08472-D0 BV

Marine - Safety Certicate

-BV20-LD1952235-PDA

Marine - Safety Certicate

-

ABS

HTS-ETS 39049-19

Marine - Safety Certicate

-LRCPH 04967-AE006

Marine - Safety Certicate

-KRMRA000001Z

Marine - Safety Certicate

EU RO Mutual Recognition

DNV GL

E311982

Electrical - Safety Certicate

-ULE227388

Explosive - Safety Certicate

Hazardous Locations

UL

064R9402.00

Manufacturers Declaration

PED

Danfoss

064R9401.00

Manufacturers Declaration

China RoHS

Danfoss

SMS.W.II-2179-B.0

Marine - Manufacturing Permission

-

BV

B-BK-60210-1170_19

Food and Health - Performance Certi-

cate

-

PZH

Pressure transmitter, type MBS 9300

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: Certicates and declarations

© Danfoss | Climate Solutions | 2021.03 AI176386432536en-000801 | 5

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.03 AI176386432536en-000801 | 6

Loading...

Loading...