Page 1

Data sheet

Pressure transmitters for CO2 food retail applications

MBS 8250

MBS 8250 is a series of compact pressure

transmitters developed and thoroughly tested to

ensure excellent operation in CO

It monitors the suction and discharge pressure

in a CO

sub- and transcritical cycle and oers a

2

reliable pressure measurement.

The technology combining piezo resistive sensor

element and programmable gain ampliers

makes the MBS 8250 the obvious choice for

applications demanding highest accuracy and

insensitiveness like controlling the pressures

in CO

applications. Further this technology

2

enhances the functional safety by limiting the

output signal at excess pressure conditions, it

allows excellent sink/source capabilities and it

leave the pressure transmitters unaected by

electromagnetic elds up to 100 V/m.

MBS 8250 with integrated pulse-snubber is

designed for protection against cavitation,liquid

hammering and pressure peaks.

applications.

2

Features

Approvals

• Designed for use in CO

industrial environments

• EMC protection 100 V/m up to 2 GHz;

20 V/m up to 4 GHz

• For media and ambient temperatures up to

125 °C

• 3.3 mA sink / source

• Reverse polarity protected

UL 508: Industrial control equipment,

le no. E311982

UL 873: Temperature indicating equipment,

le no. E31024

UL 1604 Hazloc: Class I, Div. 2, Group A, B, C and D,

le no. E227388

CRN 0F18477.5CL

plants and demanding

2

• Version with integrated pulse-snubber.

Protected against cavitation, liquid hammering

and pressure peaks

• Enclosure and wetted parts of AISI 316L

• Digitally temperature calibrated

• Self-diagnostic features on demand

(with output clipping)

• RoHS conformity

IC.PD.P21.I4.02 | 520B7845 | 1© Danfoss | DCS (im) | 2017.03

Page 2

Data sheet | Pressure transmitters for CO2 food retail applications, MBS 8250

MBS 8250

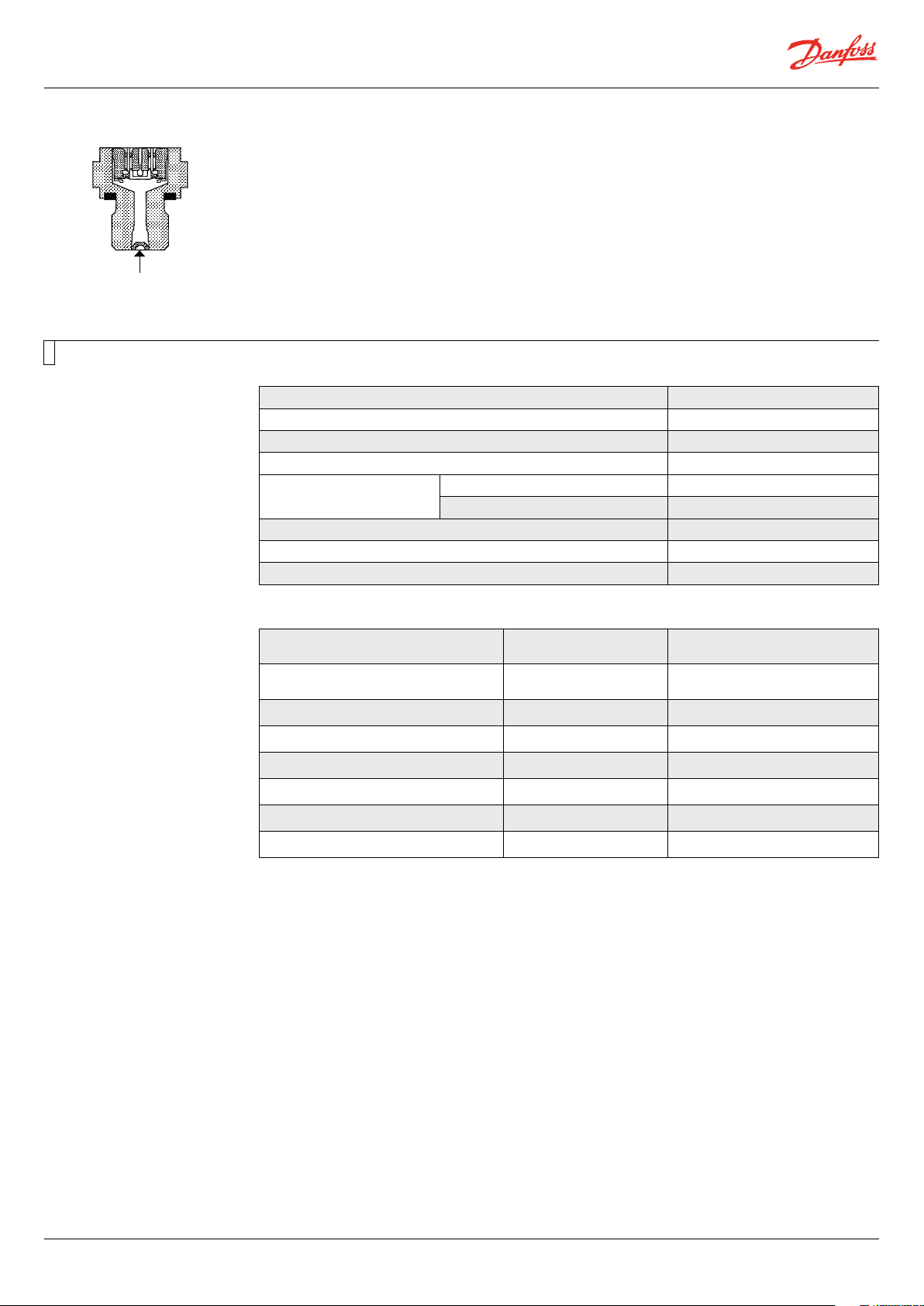

Pulse-snubber

Technical data

Application

Cavitation, liquid hammer and pressure peaks may

occur in CO

systems with changes in the ow

2

velocity of the gas e.g. fast closing of a valve or

The media viscosity has only little eect on the

response time. Even with CO

response time will not exceed 35 ms

(liquid state < 4ms).

compressor starts and stops.

The problem may occur on the inlet and outlet

side, even at rather low operating pressures.

Performance (EN 60770)

Accuracy @ 25 °C (incl. non-linearity, hysteresis and repeatability) ± 0.5% FS (max.)

Non-linearity BFSL (conformity) ≤ ± 0.2% FS

Hysteresis and repeatability ≤ ± 0.1% FS

Total error band inside the compensated temperature range ≤ ± 1% FS

Response time MBS 8250

(10 – 90%)

Overload pressure (static) 6 × FS

Burst pressure > 6 × FS

Durability, P: 10 – 90% FS > 10 × 10

Liquids with viscosity < 100 cSt < 4 ms

Air and gases < 35 ms

6

cycles

in gas form, the

2

Electrical specifications

Nom. output signal

(short-circuit protected)

Supply voltage [U

], polarity protected

B

Supply – current consumption – ≤ 6 mA

Supply voltage dependency ≤ ± 0.05% FS / 10 V –

Current limitation 22 mA ± 0.5 mA –

Sink / source – 3.3 mA

Output impedance – ≤ 25 Ω

Max load [R

] (load connected to 0 V) RL ≤ (U

L

4 – 20 mA (2-wire) Ratiometric 10 – 90% of supply

9 – 32 V DC

> 32 V: Contact Danfoss

- 9 V) / 0.02 A RL ≥ 1.5 kΩ

B

5 V DC ± 0.5 V

© Danfoss | DCS (im) | 2017.032 | 520B7845 | IC.PD.P21.I4.02

Page 3

Data sheet | Pressure transmitters for CO2 food retail applications, MBS 8250

Technical data

(continued)

Environmental conditions

Media temperature range -40 – 125 °C

Ambient temperature range See page 6

Storage temperature -50 – 125 °C

EMC - Emission EN 61000-6-3

EMC Immunity

Surge protection 1 Kv @ 42 Ω; Line-Earth and Line-Line EN 61000-6-2

Insulation resistance > 100 MΩ at 500 V DC

Vibration stability

Shock resistance

Enclosure IP67

20 V/m, 80 MHz – 4 GHz EN 61000-6-2

100 V/m, 20 MHz – 2 GHz ISO 11452-2

Sinusoidal

Random 11 g

Shock 500 g / 1ms IEC 60068-2-27

Free fall 1 m IEC 60068-2-32

15.9 mm-pp, 5 Hz – 25 Hz

25 g, 25 Hz – 2 kHz

, 5 Hz – 1 kHz (3 × 8 h) IEC 60068-2-64

rms

IEC 60068-2-6

Mechanical characteristics

Wetted parts EN 10088-1; 1.4404 (AISI 316 L)

Materials

Net weight (depending on pressure connection) < 0.07 kg

Enclosure EN 10088-1; 1.4404 (AISI 316 L)

Pressure connection EN 10088-1; 1.4404 (AISI 316 L)

Electrical connections Glass filled polyamide, PA 6.6 Sn-coated contacts

Compensated temperature range: -20 – 100 °C.

Thermal shift outside the compensated temperature range: ≤ ± 0.2% FS / 10 °K

© Danfoss | DCS (im) | 2017.03

IC.PD.P21.I4.02 | 520B7845 | 3

Page 4

Data sheet | Pressure transmitters for CO2 food retail applications, MBS 8250

Ordering

MBS 82

Type Gasket

With pulse snubber.

Measuring range Pressure connection

-1 – 59 bar

-1 – 99 bar

-1 – 159 bar

Compensated

temperature range

-20 – 100 °C 33

Pressure reference

Absolute

– – –

5 0

95 G B 0 4

96 A C 0 4

97

0

No gasket

1

Gasket, Viton, media temp. - 20 – 125 °C

G ¼, DIN 3852-E / ISO 1179-2

¼ – 18 NPT, ANSI/ASME B 1.20.1

B D 0 8

F A 0 8

⁷⁄₁₆ – 20 UNF-2A, ISO 11926-2

M14 × 1.5, ISO 6149-2

Electrical connection (connections see page 4)

C 2

Round Packard Metri-Pack, 3-pin, male, excl. female plug

2

1

6

Please contact your local

Danfoss oce for further

Output signal

4 – 20 mA

Ratiometric, 10 – 90%

information or request on other

versions.

Dimensions/Combinations

Type code C2

Electrical connection Round Packard Metri-Pack

Housing:

ø = 19 mm

Preferred versions

Pressure connection

22 mm

G¼ – DIN 3852-E

Gasket: DIN 3869-14 ¼ – 18 NPT

⁷⁄₁₆ – 20 UNF-2A

O-ring

M14 × 1,5 – ISO 6149-2

O-ring

Type code GB04 AC04 BD08 FA08

2

Recommended torque

2

) Depends of dierent parameters as packing material, mating material, thread lubrication and pressure level.

) 30 – 35 Nm

2 – 3 turns after finger

teightend

30 – 35 Nm 30 – 35 Nm

© Danfoss | DCS (im) | 2017.034 | 520B7845 | IC.PD.P21.I4.02

Page 5

Electrical connections

Type code C2

Round Packard

Metri-Pack, male

Ambient

temperature

Enclosure (IP protection fulfilled

together

with mating connector)

Materials

Electrical

connection

4 – 20 mA - 40 – 105 °C

Ratiometric - 40 – 125 °C

4 – 20 mA

(2 wire)

Ratiometric

IP67

Glass filled polyamide,

PA 6.6

Sn-coated contacts

Pin1(A): ÷ supply

Pin 2(B): + supply

Pin 3(C): not used

Pin 1(A): ÷ supply

Pin 2(B): + supply

Pin 3(C): output

© Danfoss | DCS (im) | 2017.03 IC.PD.P21.I4.02 | 520B7845 | 5

Loading...

Loading...