Page 1

Data sheet

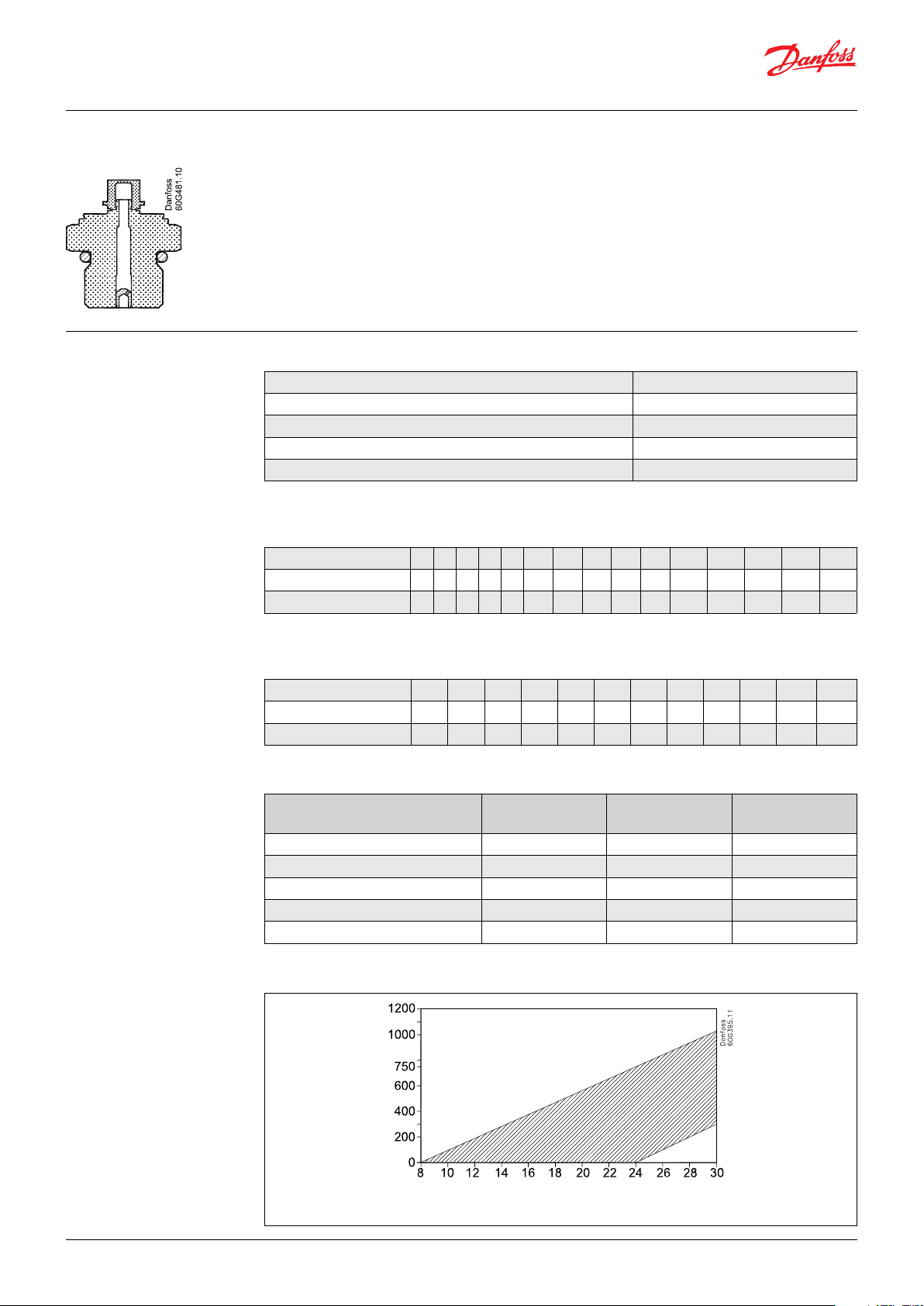

OEM Pressure transmitters for heavy-duty applications

MBS 1600 and MBS 1650

The compact OEM pressure transmitter

programme is designed for use in severe

hydraulic applications. The programme consists

of two series:

• MBS 1600 – without integrated pulse-snubber

• MBS 1650 – with integrated pulse-snubber

The integrated pulse-snubber offers a high

degree of protection against cavitations and

liquid hammer, and the well thought out design

results in excellent vibration stability and an

exceptional robustness. The high degree of EMI

protection equips the pressure transmitter to

meet most requirements.

Features • Designed for use in severe OEM applications

• For medium and ambient temperatures

up to 125 °C

• All standard output signals:

4 – 20 mA, 1 – 5 V, 1 – 6 V, 0 – 10 V

• Wetted parts made of stainless steel

• Immunity to electrical noise from VFD

• Immunity to direct coupled transients

• Immunity to pulse magnetic field

• Mis-wire protected

• Short circuit protected

• A wide range of pressure and electrical

connections

• EMC protection up to 100 V/m

• MTTFd > 100 years

© Danfoss | DCS (im) | 2020.07 520B7558 | AI204986442305en-000301 | 1

Page 2

Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650

Pulse-snubber in MBS 1650 Application

Cavitation, liquid hammer and pressure peaks

may occur in liquid filled systems with changes

in flow velocity, e.g. fast closing of a valve

or pump starts and stops.

The problem may occur on the inlet and outlet

side, even at rather low operating pressures.

Technical data

Performance (EN 60770)

Accuracy (incl. nonlinearity, hysteresis and repeatability) ± 0.5% FS

Thermal zero point shift <± 0.15% FS / 10K

Thermal span shift <± 0.15% FS / 10K

Response time liquids (10 – 90%) ~ 1 ms

Durability, P: 10 – 90% FS >10 × 10

1

) Further details please contact Danfoss

Overload and burst pressure – without pulse-snubber (MBS 1600)

Nominal pressure [bar] 6 10 16 25 40 60 100 160 250 400 500 600

Overload pressure 21 30 48 80 80 140 200 320 500 800 1400 1400 2000 2500 3000

Burst pressure 280 400 640 800 800 1400 2000 1600 2500 4000 >4000 >4000 >4000 >4000 >4000

2

) Only available with M12 × 1 1.5 P high pressure port, type FC06. Please contact Danfoss.

The media viscosity has only little effect on the

response time. Even at viscosities up to 100 cSt,

the response time will not exceed 4 ms.

1

)

6

cycles

10002) 16002) 22002)

Overload and burst pressure – with integrated pulse-snubber (MBS 1650)

Nominal pressure [bar] 6 10 16 25 40 60 100 160 250 400 500 600

Overload pressure 21 30 48 120 120 210 300 480 750 1200 2100 2100

Burst pressure 280 400 640 800 800 1400 2000 1600 2500 4000 >4000 >4000

Electrical specifications

Nom. output signal

(Short-circuit protected)

Supply voltage [U

], polarity protected 8 – 32 V 8 – 32 V 12 – 32 V

B

Supply – current consumption – 4.5 mA 4.5 mA

Output impedance – ≤ 90 Ω ≤ 90 Ω

] (connected to 0 V ) See chart below RL ≥ 10 kΩ RL ≥ 10 kΩ

Load [R

L

] (connected to + V ) See chart below Not possible Not possible

Load [R

L

4 – 20 mA

(2 wire)

0 – 5 V, 1 – 5 V

1 – 6 V

0 – 10 V

4 – 20 mA output - min. / max. resistance vs. supply voltage

Note:

Loop current should not

exceed 22 mA continuous or

25 mA temporarily due to

pressure peaks

2 | AI204986442305en-000301 | 520B7558

© Danfoss | DCS (im) | 2020.07

Page 3

Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650

Technical data

(continued)

Environmental conditions

Media temperature range - 40 – 125 °C

Ambient temperature range See page 5

Compensated temperature range - 40 – 125 °C

Transport temperature range -55 – 150 °C

EMC EN 61326-2-3: 2013

Directive 2014/30/EU

Radiated immunity 100 Vm

Surge

Line-Earth (1 Kv - 42 ohm); Line-Line (0.5 kV42 ohm)

ESD 8 Kv contact , 15 Kv air

Vibration stability 20 g, 10 – 2000 Hz, sinus EN 60068-2-6

Shock resistance 100 g EN 60068-2-27

Enclosure (depending on electrical connection) See page 5

Mechanical conditions

Wetted parts 17 – 4 PH

Materials

Enclosure AISI 304 or plastic

Pressure connection 17 – 4 PH

Electrical connection See page 5

Ordering standard

MBS 16..

Standard

with pulse-snubber

Measuring range

0 – 6 bar

0 – 10 bar

0 – 16 bar

0 – 25 bar

0 – 40 bar

0 – 60 bar

0 – 100 bar

0 – 160 bar

0 – 250 bar

0 – 400 bar

0 – 500 bar

0 – 600 bar

0 0

5 0

1)

(Gauge)

18

2 0

2 2

2 4 G B 0 4

2 6 A C 0 4

2 8 A C 0 2

3 0 B D 0 8

3 2 A F 0 4

3 4 A F 0 2

3 6 P T 0 4

3 7

3 8

Pressure reference

Gauge(relative) 1

Output signal

4 –

20 mA

0 – 5 V

1 – 5 V

1 – 6 V

0 – 10 V

–

1

–

Gasket

Defined type

–

of pressure connection

Pressure connections (HEX 22 mm)

2

G ¼ A DIN 3852-E

)

¼ – 18 NPT

⁄ – 27 NPT

2

⁄ – 20 UNF-2A

)

¼ – 18 NPTF

⁄

NPTF

– 27

¼ – 19 PT

Electrical connections

C 1

M12 × 1 EN60947-5-2

K 4

M12 × 1 EN60947-5-2 vented via thread

A 0

EN175301-803-A

1

1

)

2

3

For pressure range < 10 bar or >600 bar, please contact Danfoss

2

) Incl. Viton gasket. Min. medium temperature is -25 °C

3

) Mating connector, code.no 060G0008

3

)

4

5

© Danfoss | DCS (im) | 2020.07

520B7558 | AI204986442305en-000301 | 3

Page 4

Data sheet | OEM transmitters for heavy-duty applications, MBS 1600 and MBS 1650

M12X1P

28.4

Danfoss

60G391.11

28.4

M12X1P

Danfoss

60G497

Ø19.0

12.0

Dimension/Combination

Type code C1 K4 A0

M12 × 1 EN60947-5-2 M12 × 1 EN60947-5-2 vented via thread EN175301-803-A

Vent groove

(4 places)

10.0

27.7

Danfoss

60N9018.1

Ø19.0

Note:

HEX is 22 mm

across flats.

Type code BD08 PT04 AC04 / AF04 AC02 / AF02 GB04

Recommended

2

)

torque

* For other combinations please contact Danfoss.

2)

Depends of different parameters as packing material, mating material, thread lubrication and pressure level.

7/16 – 20 UNF-2A ¼ – 19 Pt ¼ – 18 NPT / NPTF 1/8 – 27 NPT / NPTF G ¼ A DIN 3852-E

18 – 20 Nm

2 – 3 turns after fnger

tightend

2 – 3 turns after fnger

tightend

2 – 3 turns after fnger

tightend

30 – 35 Nm

4 | AI204986442305en-000301 | 520B7558

© Danfoss | DCS (im) | 2020.07

Page 5

Electrical connections

Type code C1/K4 A0

1

Danfoss

60N9019.1

4

2

3

Ambient temperature

4 – 20 mA

Ambient temperature,

0 – 5 V, 1 – 5 V,

1 – 6 V, 0 – 10 V,

Enclosure

(IP protection fulfilled together with mating

connector)

Material

Electrical connections,

4 – 20 mA (2 wire)

Electrical connections,

0 – 5 V, 1 – 5 V,

1 – 6 V, 0 – 10 V,

C1: M12 × 1 EN60947-5-2

K4: M12 × 1 EN60947-5-2 vented via thread

- 40 – 100 °C - 40 – 100 °C

- 40 – 125 °C - 40 – 125 °C

IP67

IP54 with vented thread

SS, PBT 30% GFR

Gold (Au) plated

Pin 1: + supply

Pin 2: do not connect

Pin 3: ÷ supply

Pin 4: do not connect

Pin 1: + supply

Pin 2: output

Pin 3: ÷ supply

Pin 4: do not connect

EN175301-803-A

IP65

Glass filled PBT 30%

Tin (Sn) plated

Pin 1: + supply

Pin 2: do not connect

Pin 3: - supply connect

Pin 4: do not connect

Pin 1: +

Pin 2: output

Pin 3: - supply

Pin 4: do not connect

© Danfoss | DCS (im) | 2020.07 520B7558 | AI204986442305en-000301 | 5

Loading...

Loading...