Page 1

User Manual

PLUS+1® Compliant

MBS 1250 Pressure Sensor Function

Blocks

powersolutions.danfoss.com

Page 2

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

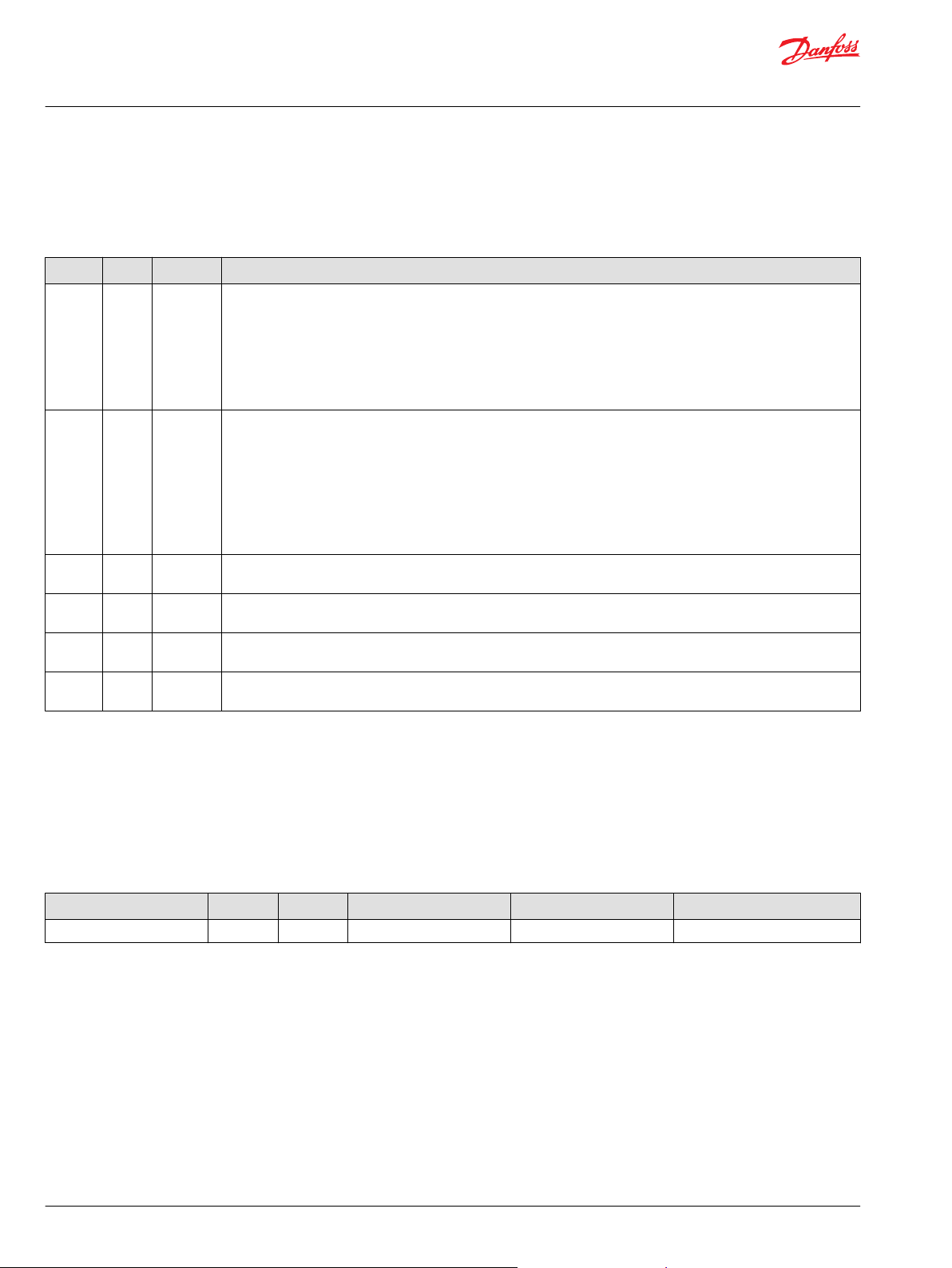

Revision history Table of revisions

Date Changed Rev

March 2018 Added Prs_Snsr550b and Prs_Snsr_Gen function block. 0401

April 2016 CA

November 2011 BA

2 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 3

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Contents

Prs_Snsr40b Function Block

Inputs....................................................................................................................................................................................................5

Outputs................................................................................................................................................................................................ 5

Status and Fault Logic.....................................................................................................................................................................6

Status Logic...................................................................................................................................................................................6

Fault Logic..................................................................................................................................................................................... 6

Relationship Between Function Block Input and Output Signals...................................................................................7

Function Block Connections.........................................................................................................................................................8

MC Controller—Input Configuration........................................................................................................................................ 8

Configure the MFIn.....................................................................................................................................................................9

Configure the DigAn..................................................................................................................................................................9

SC Controller—Input Configuration....................................................................................................................................... 10

Configure the MFIn..................................................................................................................................................................10

Configure the DigAn................................................................................................................................................................11

Prs_Snsr160b Function Block

Inputs..................................................................................................................................................................................................12

Outputs..............................................................................................................................................................................................13

Status and Fault Logic..................................................................................................................................................................13

Status Logic.................................................................................................................................................................................13

Fault Logic...................................................................................................................................................................................14

Relationship Between Function Block Input and Output Signals................................................................................ 14

Function Block Connections...................................................................................................................................................... 15

MC Controller—Input Configuration......................................................................................................................................15

Configure the MFIn..................................................................................................................................................................16

Configure the DigAn................................................................................................................................................................16

SC Controller—Input Configuration....................................................................................................................................... 17

Configure the MFIn..................................................................................................................................................................17

Configure the DigAn................................................................................................................................................................18

Prs_Snsr250b Function Block

Inputs..................................................................................................................................................................................................19

Outputs..............................................................................................................................................................................................20

Status and Fault Logic..................................................................................................................................................................20

Status Logic.................................................................................................................................................................................20

Fault Logic...................................................................................................................................................................................21

Relationship Between Function Block Input and Output Signals................................................................................ 21

Function Block Connections...................................................................................................................................................... 22

MC Controller—Input Configuration......................................................................................................................................22

Configure the MFIn..................................................................................................................................................................23

Configure the DigAn................................................................................................................................................................23

SC Controller—Input Configuration....................................................................................................................................... 24

Configure the MFIn..................................................................................................................................................................24

Configure the DigAn................................................................................................................................................................25

Prs_Snsr400b Function Block

Inputs..................................................................................................................................................................................................26

Outputs..............................................................................................................................................................................................27

Status and Fault Logic..................................................................................................................................................................27

Status Logic.................................................................................................................................................................................27

Fault Logic...................................................................................................................................................................................28

Relationship Between Function Block Input and Output Signals................................................................................ 28

Function Block Connections...................................................................................................................................................... 29

MC Controller—Input Configuration......................................................................................................................................29

Configure the MFIn..................................................................................................................................................................30

Configure the DigAn................................................................................................................................................................30

SC Controller—Input Configuration....................................................................................................................................... 31

Configure the MFIn..................................................................................................................................................................31

Configure the DigAn................................................................................................................................................................32

Prs_Snsr500b Function Block

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 3

Page 4

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Contents

Inputs..................................................................................................................................................................................................33

Outputs..............................................................................................................................................................................................34

Status and Fault Logic..................................................................................................................................................................34

Status Logic.................................................................................................................................................................................34

Fault Logic...................................................................................................................................................................................35

Relationship Between Function Block Input and Output Signals................................................................................ 35

Function Block Connections...................................................................................................................................................... 36

MC Controller—Input Configuration......................................................................................................................................36

Configure the MFIn..................................................................................................................................................................37

Configure the DigAn................................................................................................................................................................37

SC Controller—Input Configuration....................................................................................................................................... 38

Configure the MFIn..................................................................................................................................................................38

Configure the DigAn................................................................................................................................................................39

Prs_Snsr550b Function Block

Inputs..................................................................................................................................................................................................40

Outputs..............................................................................................................................................................................................41

Status and Fault Logic..................................................................................................................................................................41

Status Logic.................................................................................................................................................................................41

Fault Logic...................................................................................................................................................................................42

Relationship Between Function Block Input and Output Signals................................................................................ 42

Function Block Connections...................................................................................................................................................... 43

MC Controller—Input Configuration......................................................................................................................................43

Configure the MFIn..................................................................................................................................................................44

Configure the DigAn................................................................................................................................................................44

SC Controller—Input Configuration....................................................................................................................................... 45

Configure the MFIn..................................................................................................................................................................45

Configure the DigAn................................................................................................................................................................46

Prs_Snsr600b Function Block

Inputs..................................................................................................................................................................................................47

Outputs..............................................................................................................................................................................................48

Status and Fault Logic..................................................................................................................................................................48

Status Logic.................................................................................................................................................................................48

Fault Logic...................................................................................................................................................................................49

Relationship Between Function Block Input and Output Signals................................................................................ 49

Function Block Connections...................................................................................................................................................... 50

MC Controller—Input Configuration......................................................................................................................................50

Configure the MFIn..................................................................................................................................................................51

Configure the DigAn................................................................................................................................................................51

SC Controller—Input Configuration....................................................................................................................................... 52

Configure the MFIn..................................................................................................................................................................52

Configure the DigAn................................................................................................................................................................53

Prs_Snsr_Gen Function Block

Inputs..................................................................................................................................................................................................54

Outputs..............................................................................................................................................................................................54

Status and Fault Logic..................................................................................................................................................................55

Status Logic.................................................................................................................................................................................55

Fault Logic...................................................................................................................................................................................55

Relationship Between Function Block Input and Output Signals................................................................................ 56

Function Block Connections...................................................................................................................................................... 57

MC Controller—Input Configuration......................................................................................................................................57

Configure the MFIn..................................................................................................................................................................58

Configure the DigAn................................................................................................................................................................58

SC Controller—Input Configuration....................................................................................................................................... 59

Configure the MFIn..................................................................................................................................................................59

Configure the DigAn................................................................................................................................................................60

4 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 5

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

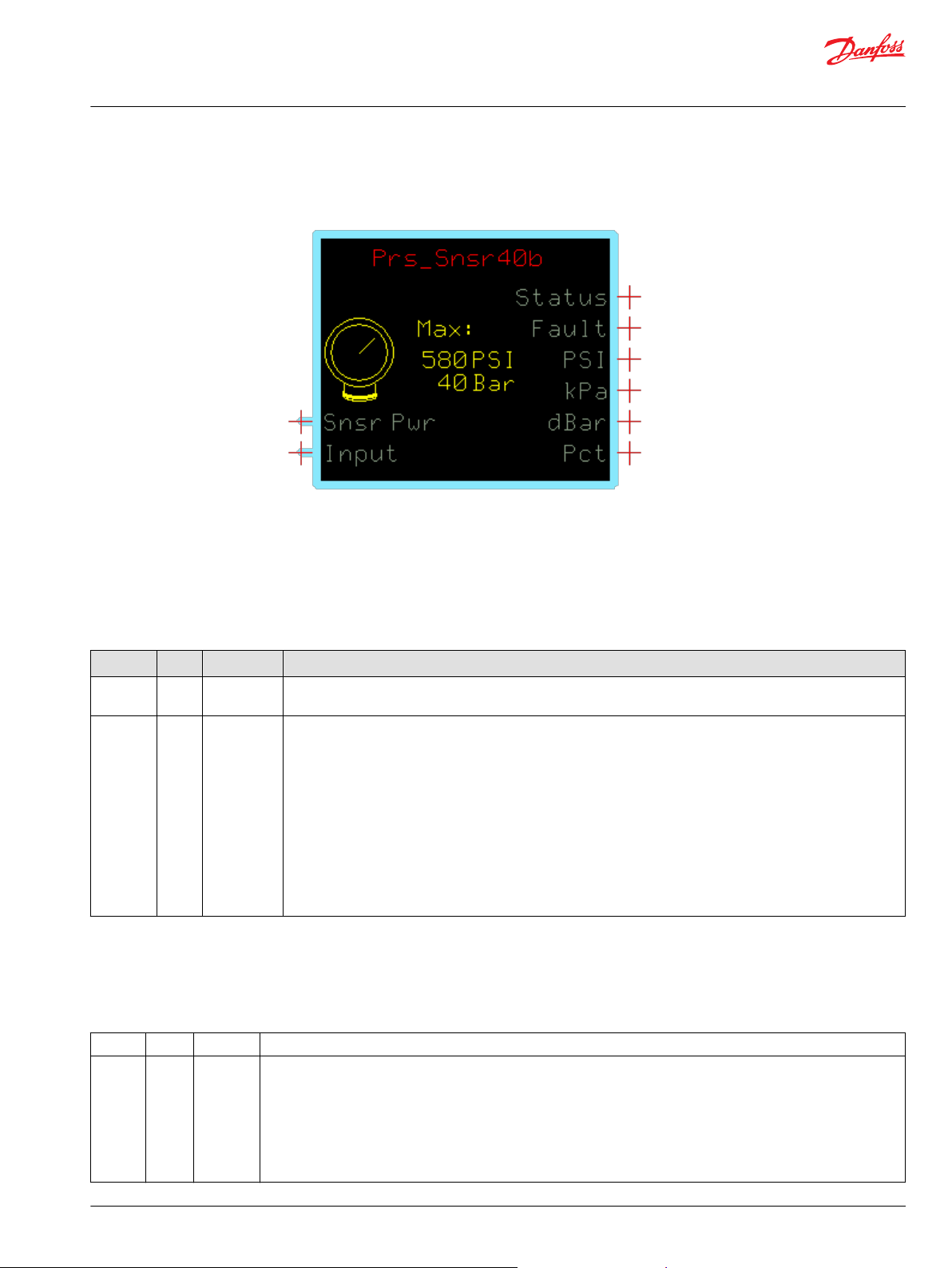

Prs_Snsr40b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–40 bar [4000

kPa/580 PSI] range.

Inputs

Find out how the function block uses a reference voltage and a changing input voltage to produce PSI,

kPa, dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr U16 0–5250 mV Inputs a reference voltage that the PLUS+1® controller also applies to the Pin 1 (+ Supply) on the pressure

transmitter.

Input U16 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of PSI and kPa. The

maximum nominal output is specified by Bar and is limited to 2200.

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of PSI and kPa

at 112.50% of the output defined by Bar.

The maximum over-pressure output equals 112.50% of the maximum nominal output. The generic function

block allows you to specify the pressure range allowed.

Outputs

Learn how the outputs of the general function block work.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 5

Page 6

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr40b Function Block

Function Block Outputs (continued)

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–35896 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U16 0–247500 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–24750

Pct U16 0–11250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex

Input value is too low. 0x8001 0001

Input value is too high. 0x8002 0010

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Volt(age) is less than [10% of

Snsr Pwr] - [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr less than 0. Ensure correct software input is

Volt(age) is greater than [90% of

Snsr Pwr] + [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr greater than 5250.

Output = 0.

Output is extrapolated beyond

the maximum value up to 11250

(112.50%).

Output = 0.

Inspect for open circuit in wire

connections to sensor.

made in the application.

Inspect for short circuit in wire

•

connections to sensor.

Verify the correct pressure

•

sensor is used for the

application.

Ensure correct software input is

made in the application.

6 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 7

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr40b Function Block

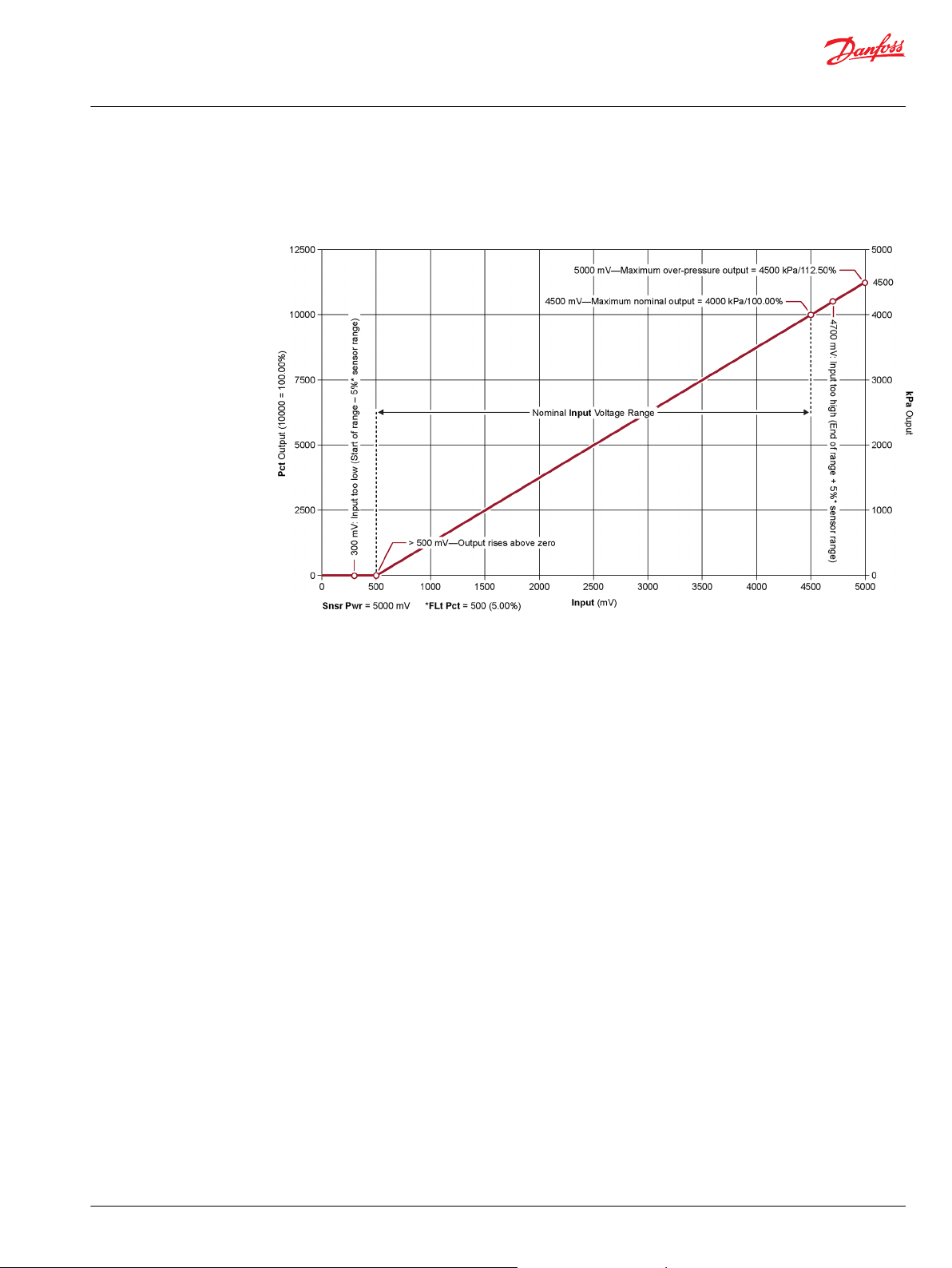

Relationship Between Function Block Input and Output Signals

Use the plot to find out the relationships between the function block's Input voltages and its kPa and Pct

outputs.

This function block’s:

Flt Pct value = 500 (5.00%) and its Snsr Pwr value = 5000 mV.

•

Nominal Input voltage ranges between 10.00% (500 mV) and 90.00% (4500 mV) of the Snsr Pwr

•

voltage.

Nominal pressure output ranges between zero with the Input voltage at 500 mV and a maximum

•

nominal 4000 kPa/100.00% with the Input voltage at 4500 mV.

Maximum over-pressure output = 4500 kPa with the Input voltage at 5000 mV. (4000 maximum

•

nominal pressure x 112.50% = 4500 kPa maximum over-pressure)

When the Input voltage:

•

Drops below 300 mV, the function block outputs an input too low fault. (500 mV – 5% of the 4000 mV

nominal input voltage range = fault at 300 mV)

•

Rises above 4700 mV, the function block outputs an input too high fault. (4500 mV + 5% of the 4000

mV nominal input voltage range = fault at 4700 mV)

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 7

Page 8

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr40b Function Block

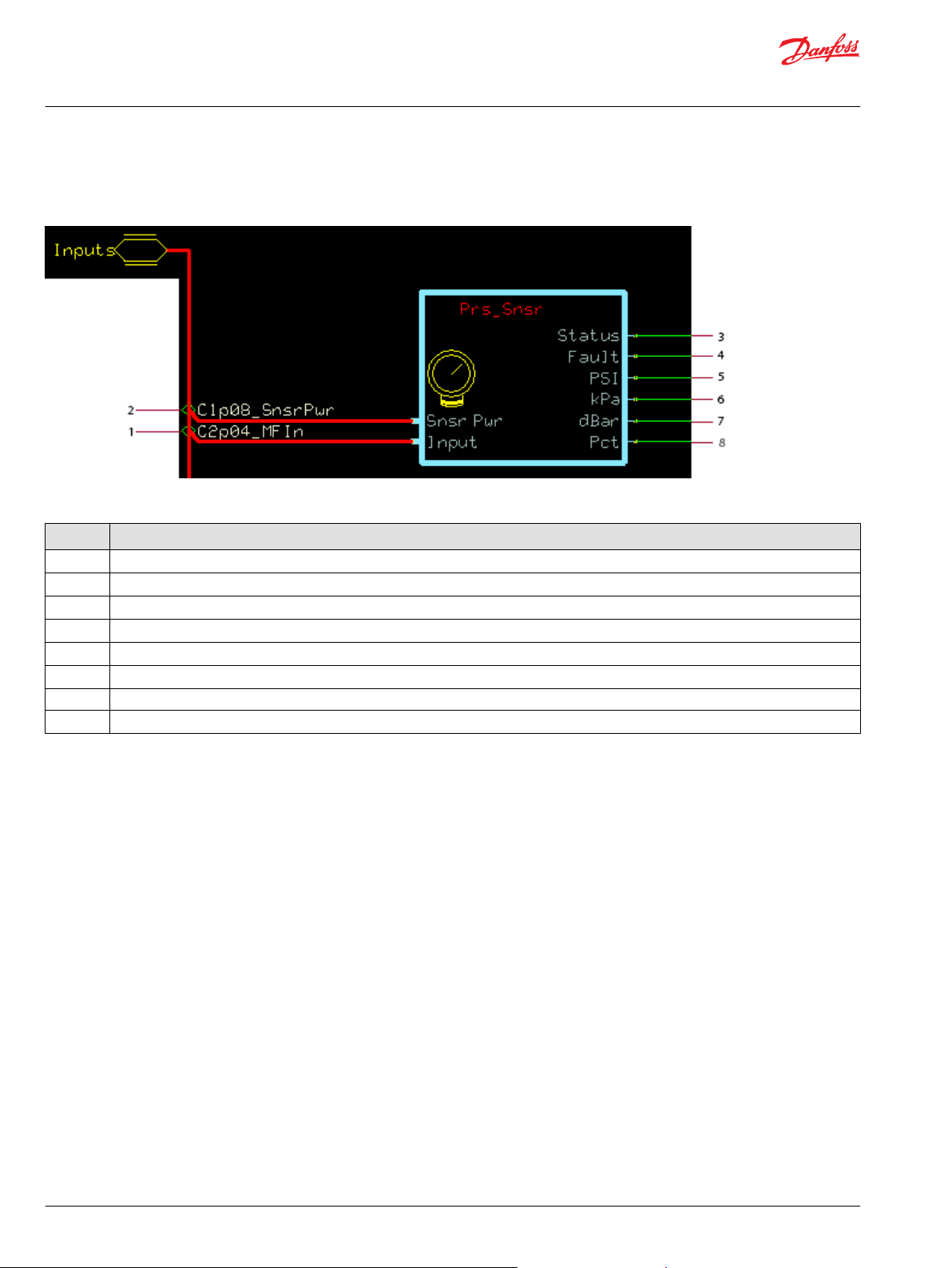

Function Block Connections

Connections you can make with the function block are described.

Function block connections

Item Description

1 Sensor voltage (varies with pressure).

2 Sensor reference power voltage.

3 Function block status.

4 Function block faults.

5 Pressure in PSI.

6 Pressure in kPa.

7 Pressure in decibar (dBar)

8 Pressure in % of range.

MC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

For MC Controllers, you route the function block’s Input through an MFIn or a DigAn.

You must change the MFIn and DigAn default configurations to accept this input.

8 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 9

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr40b Function Block

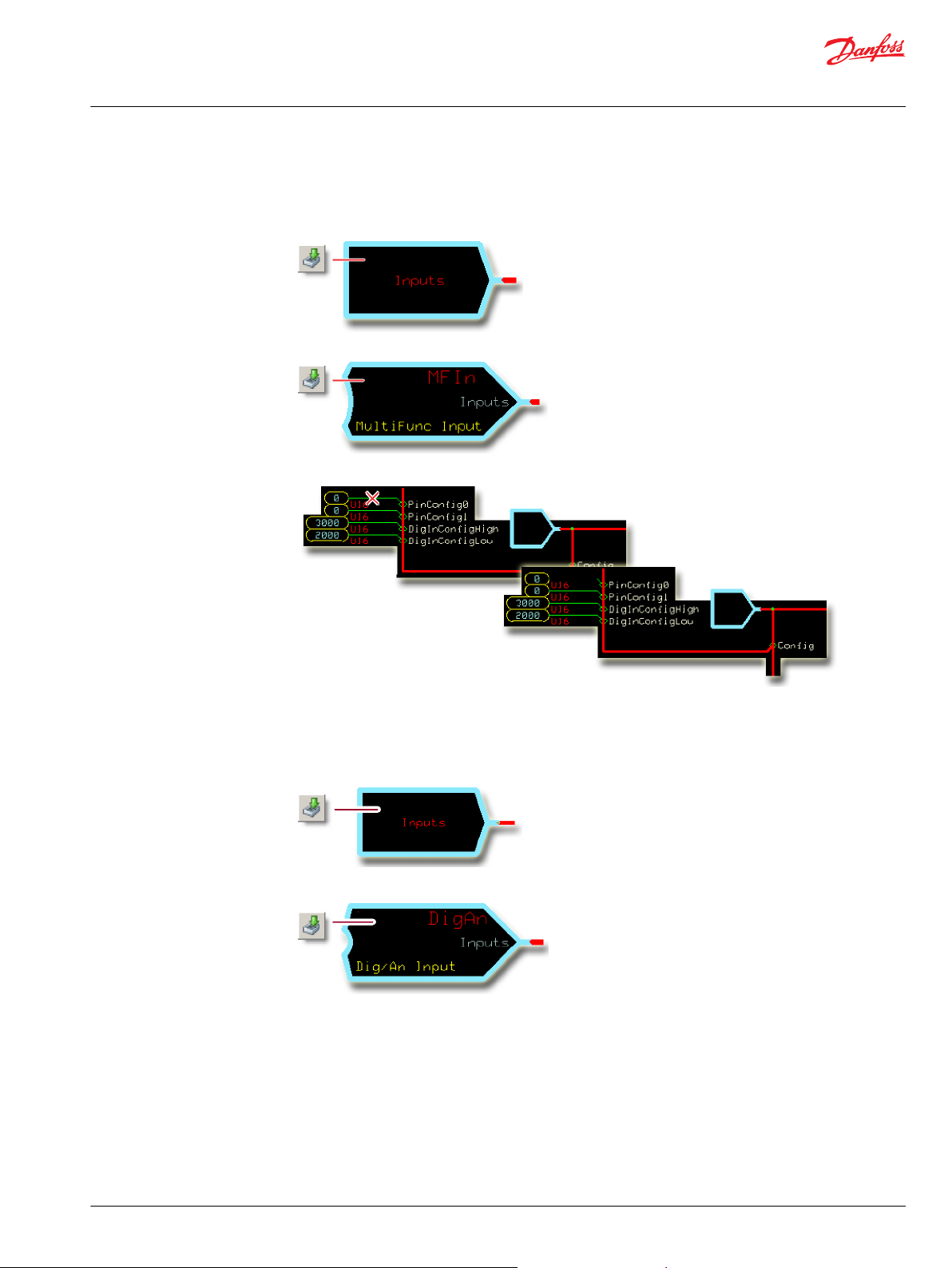

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn that receives the input.

3. Make the changes that are shown in this figure.

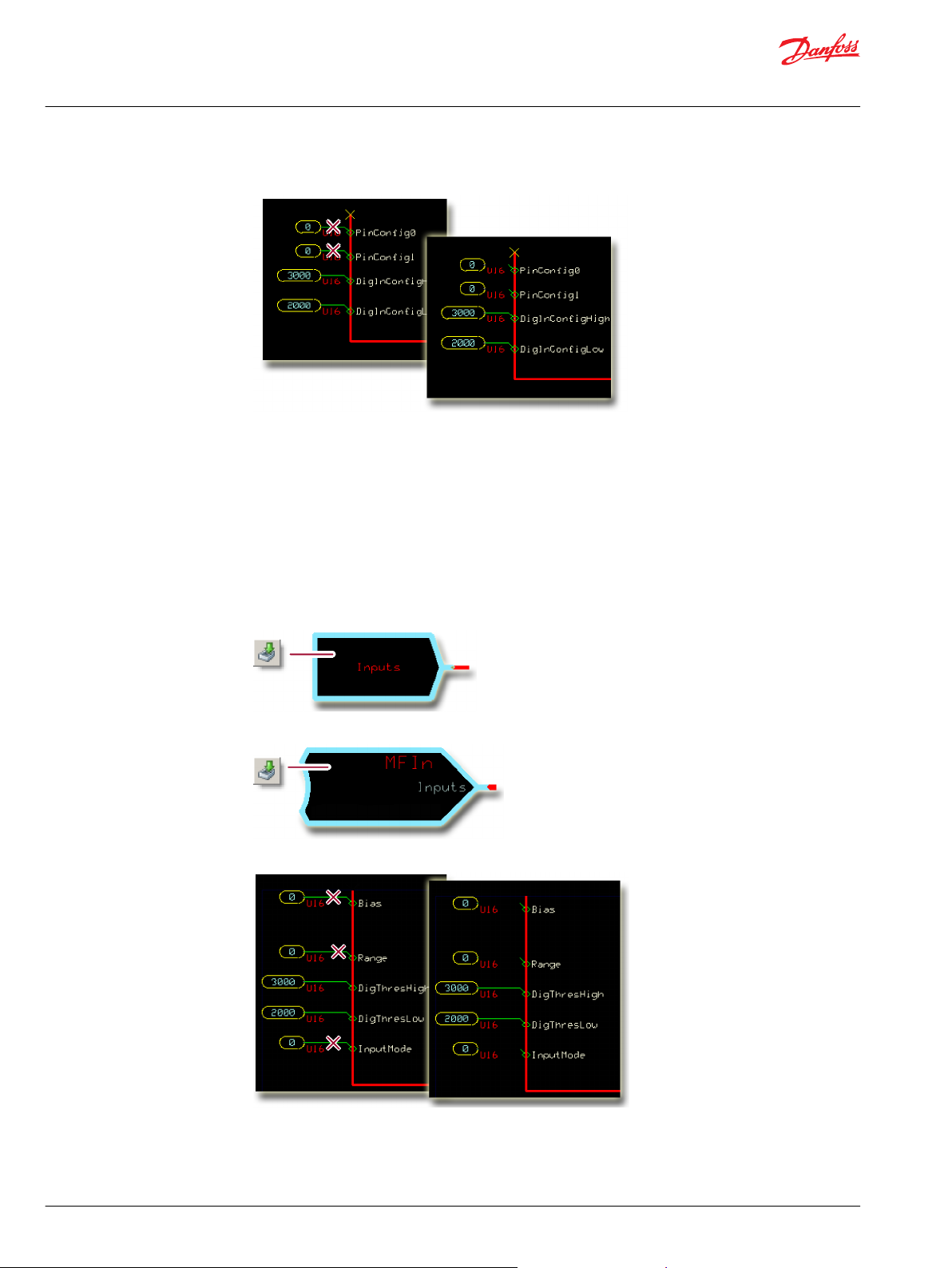

Configure the DigAn

Learn how to configure DigAn to accept input.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 9

Page 10

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr40b Function Block

3. Make the changes that are shown in the following figure.

SC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

You route the function block’s Input through an MFIn or a DigAn. You must change the MFIn and

DigAn default configurations to accept this input.

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

10 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 11

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr40b Function Block

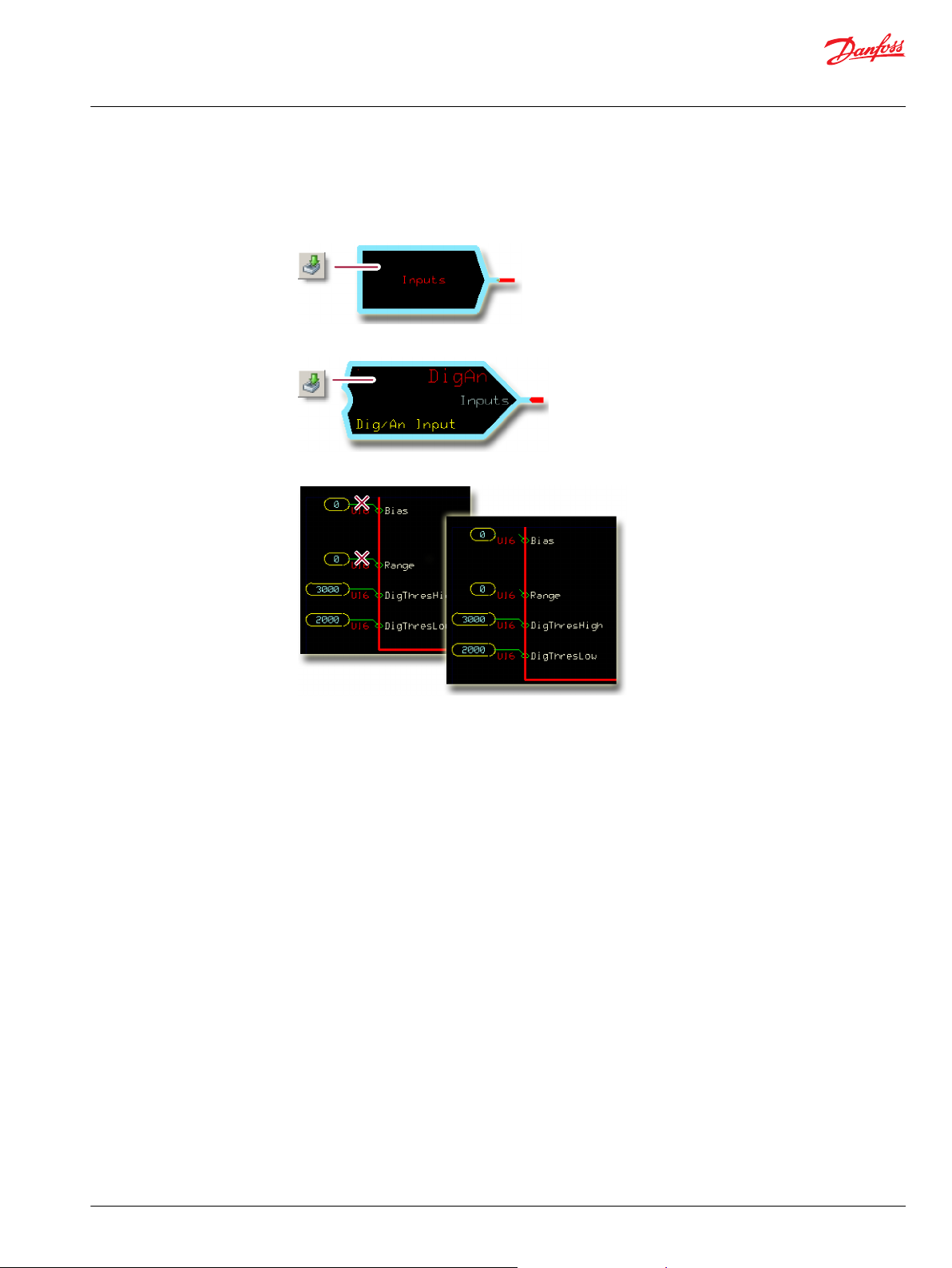

Configure the DigAn

Learn how to configure DigAn to receive input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 11

Page 12

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

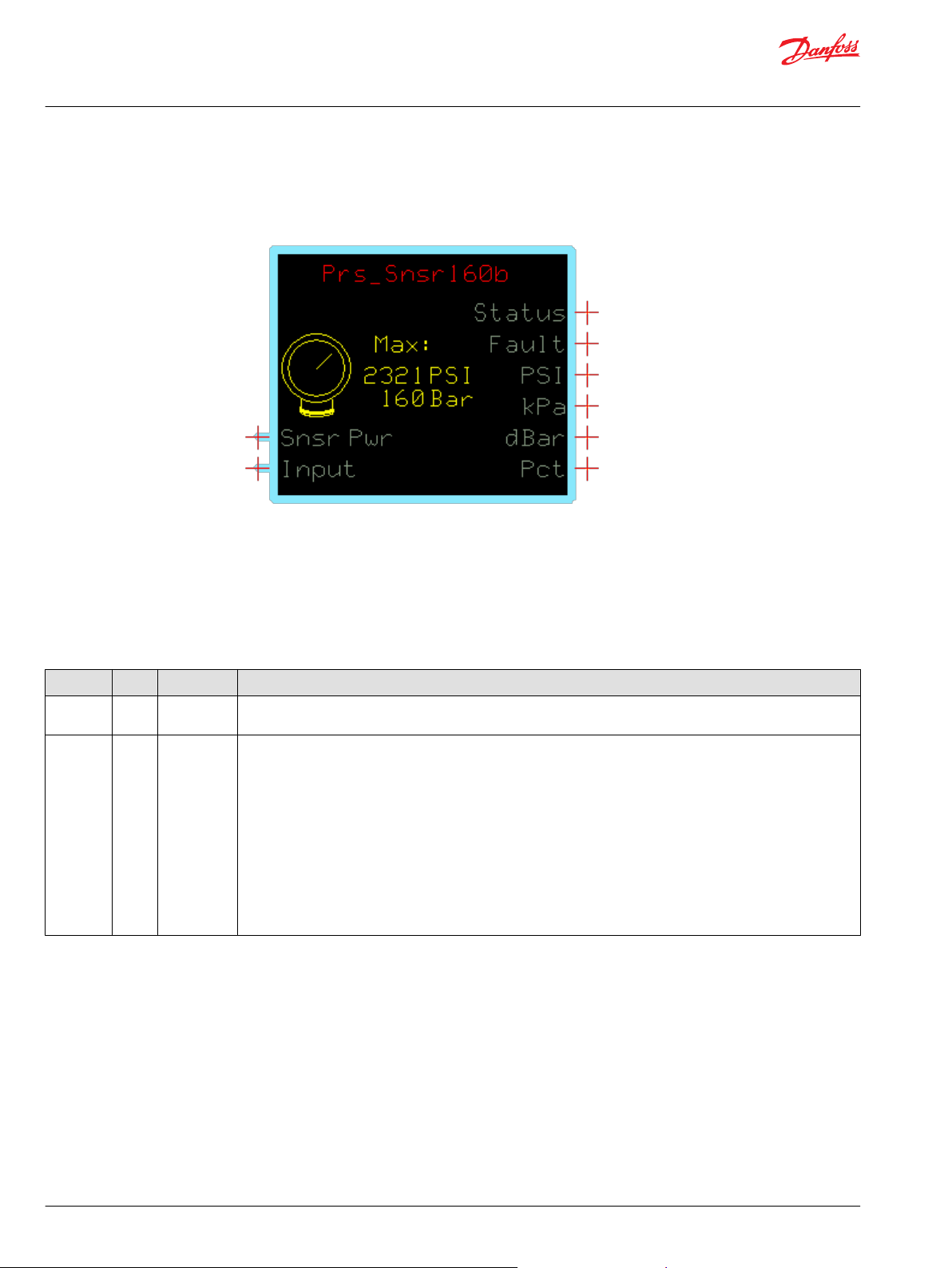

Prs_Snsr160b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–160 bar [16000

kPa/2320 PSI] range.

Inputs

Find out how the function block uses a reference voltage and a changing input voltage to produce PSI,

kPa, dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr —— 0–5250 mV Inputs a reference voltage that the PLUS+1 controller also applies to the Pin 1 (+ Supply) on the Pressure

Transmitter.

Input —— 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar, and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of 2320 PSI/16000

kPa/10000 (100.00%).

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of 2610 PSI/

18000 kPa/11250 (112.50%).

The maximum over-pressure output equals 112.50% of the maximum nominal output (16000 kPa x 112.50% =

18000 kPa).

12 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 13

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr160b Function Block

Outputs

Learn about the outputs of the Prs_Snsr160b function block.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–2610 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U16 0–18000 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–1800

Pct U16 0–11250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 13

Page 14

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr160b Function Block

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex

Input value is too low. 0x8001 0001

Input value is too high. 0x8002 0010

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Volt(age) is less than [10% of

Snsr Pwr] - [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr less than 0. Ensure correct software input is

Volt(age) is greater than [90% of

Snsr Pwr] + [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr greater than 5250.

Output = 0.

Output is extrapolated beyond

the maximum value up to 11250

(112.50%).

Output = 0.

Inspect for open circuit in wire

connections to sensor.

made in the application.

Inspect for short circuit in wire

•

connections to sensor.

Verify the correct pressure

•

sensor is used for the

application.

Ensure correct software input is

made in the application.

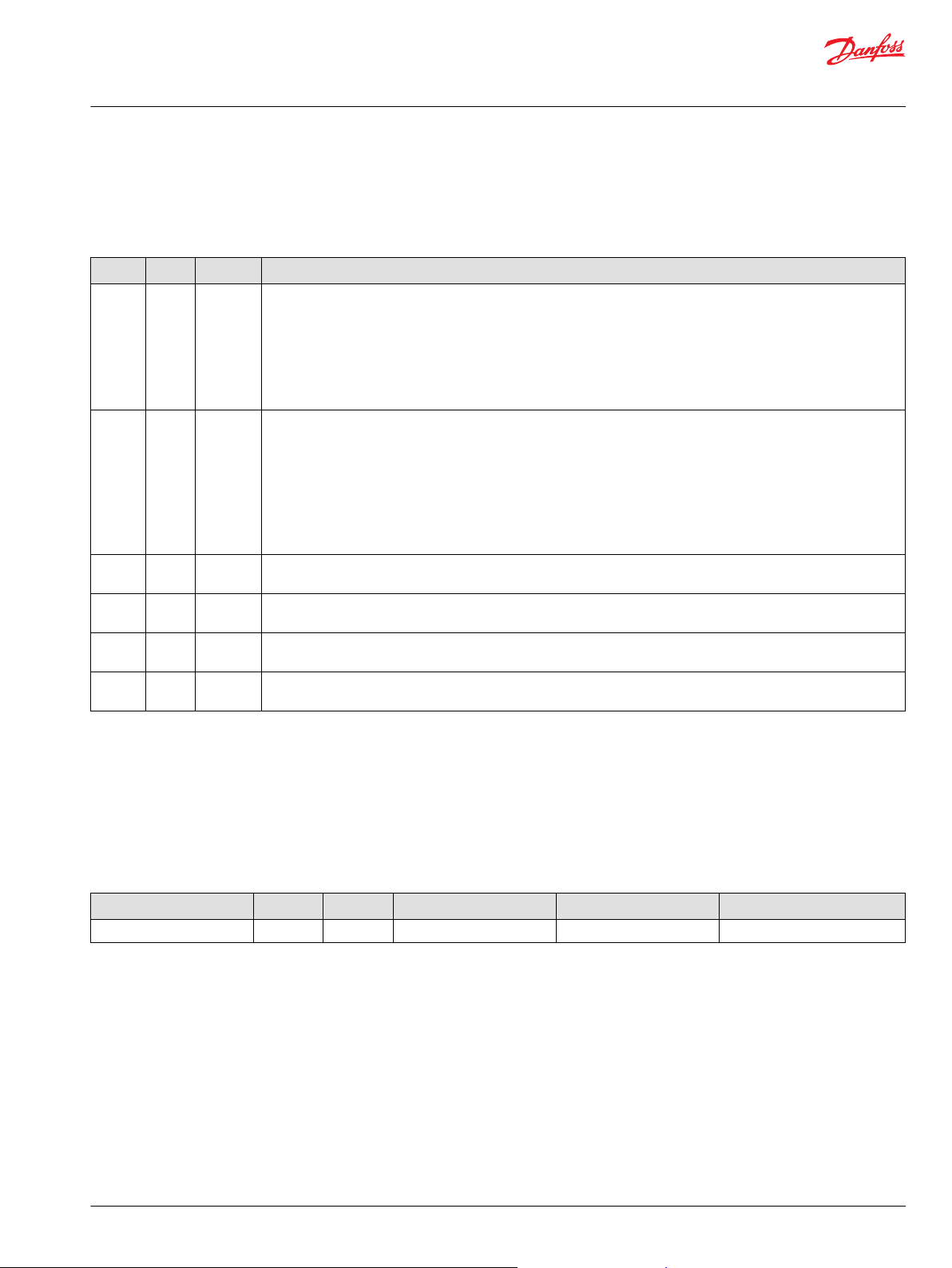

Relationship Between Function Block Input and Output Signals

Use the plot to find out the relationships between the function block's Input voltages and its kPa and Pct

outputs.

This function block’s:

Flt Pct value = 500 (5.00%) and its Snsr Pwr value = 5000 mV.

•

Nominal Input voltage ranges between 10.00% (500 mV) and 90.00% (4500 mV) of the Snsr Pwr

•

voltage.

Nominal pressure output ranges between zero with the Input voltage at 500 mV and a maximum

•

nominal 16000 kPa/100.00% with the Input voltage at 4500 mV.

Maximum over-pressure output = 18000 kPa with the Input voltage at 5000 mV.

•

(16000 maximum nominal pressure x 112.50% = 18000 kPa maximum over-pressure)

When the Input voltage:

14 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 15

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr160b Function Block

Drops below 300 mV, the function block outputs an input too low fault. (500 mV – 5% of the 4000 mV

•

nominal input voltage range = fault at 300 mV)

Rises above 4700 mV, the function block outputs an input too high fault. (4500 mV + 5% of the 4000

•

mV nominal input voltage range = fault at 4700 mV)

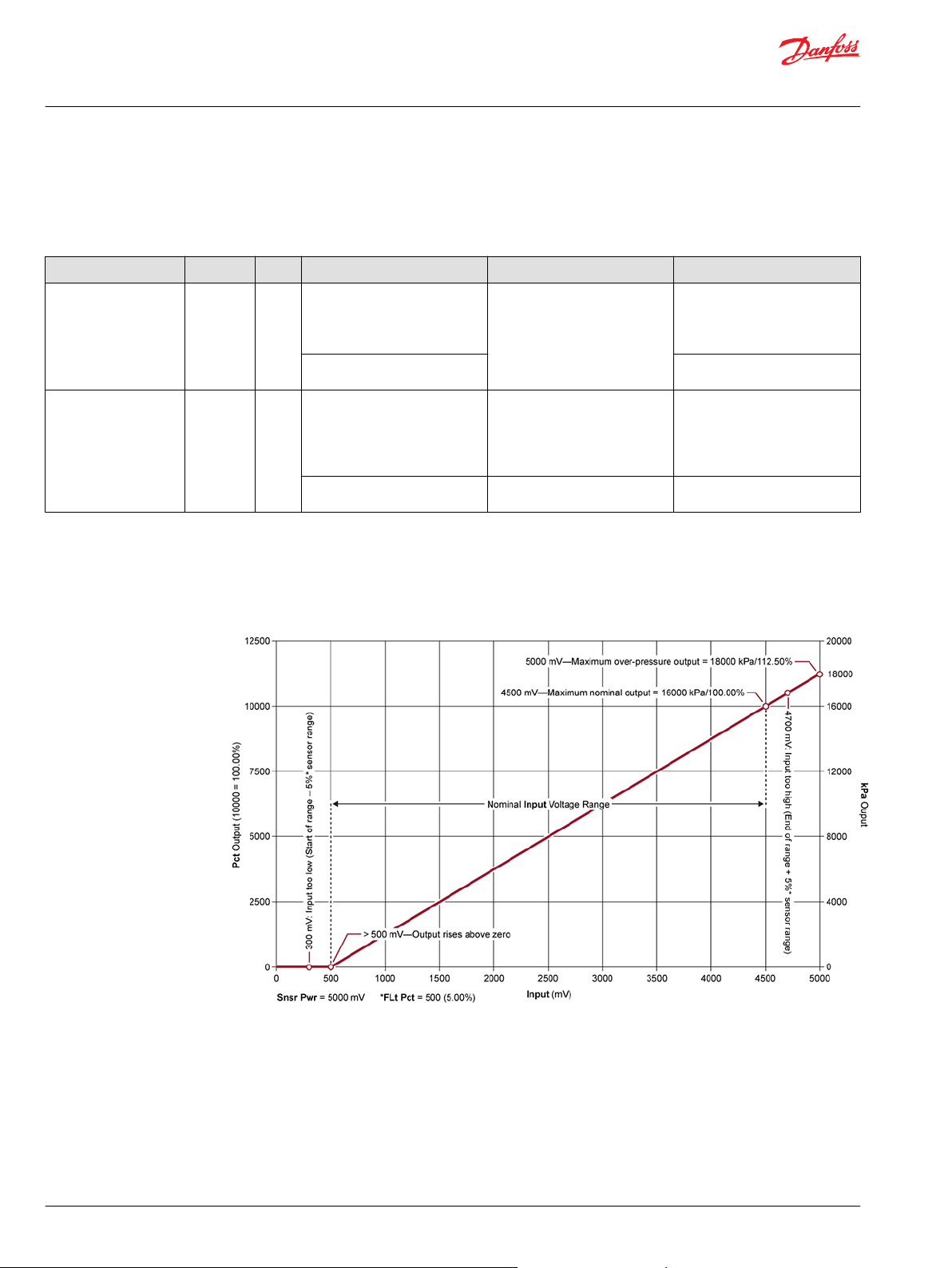

Function Block Connections

Connections you can make with the function block are described.

Function block connections

Item Description

1 Sensor voltage (varies with pressure).

2 Sensor reference power voltage.

3 Function block status.

4 Function block faults.

5 Pressure in PSI.

6 Pressure in kPa.

7 Pressure in decibar (dBar)

8 Pressure in % of range.

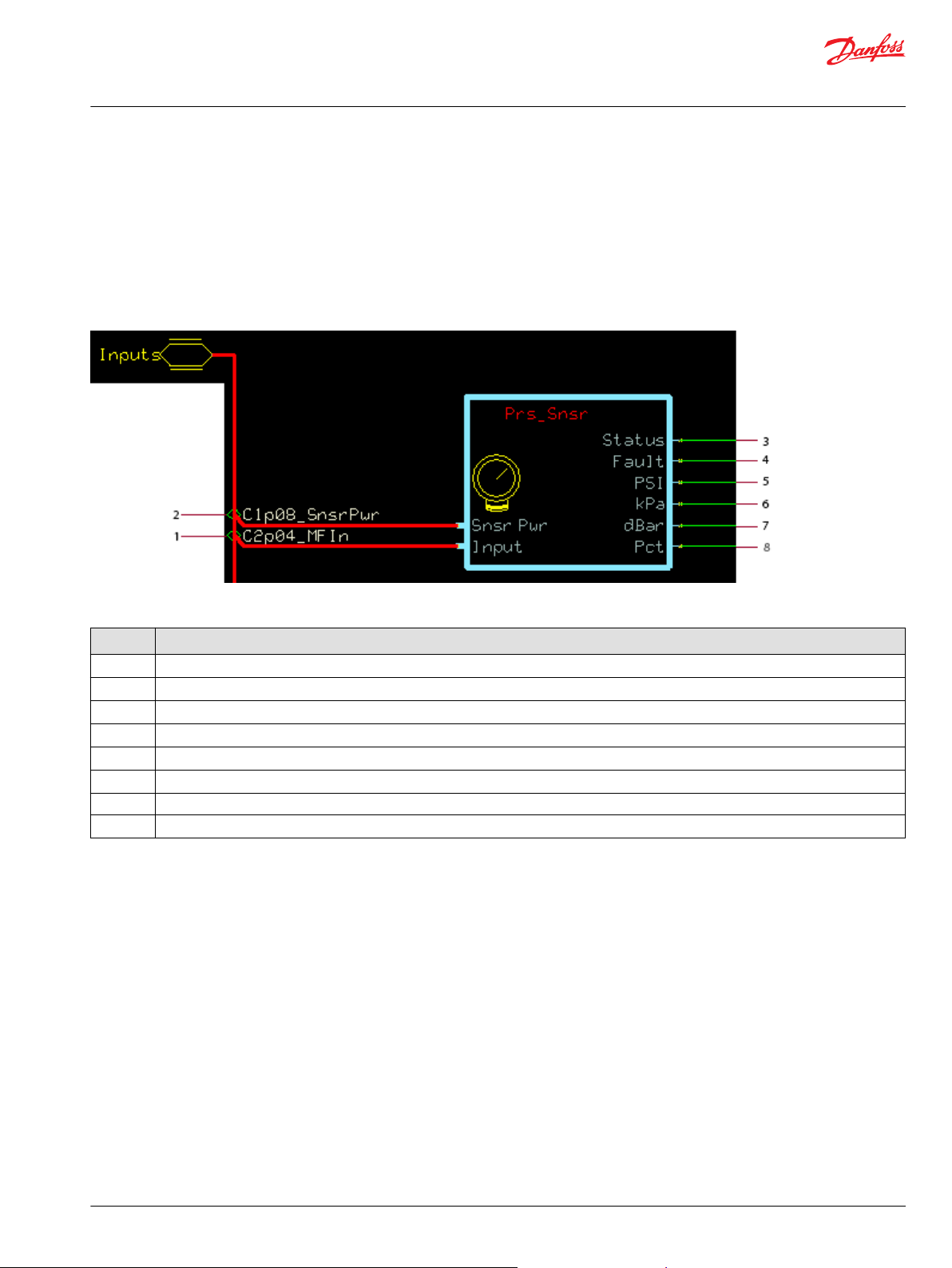

MC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

For MC Controllers, you route the function block’s Input through an MFIn or a DigAn.

You must change the MFIn and DigAn default configurations to accept this input.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 15

Page 16

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr160b Function Block

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn that receives the input.

3. Make the changes that are shown in this figure.

Configure the DigAn

Learn how to configure DigAn to accept input.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

16 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 17

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr160b Function Block

3. Make the changes that are shown in the following figure.

SC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

You route the function block’s Input through an MFIn or a DigAn. You must change the MFIn and

DigAn default configurations to accept this input.

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 17

Page 18

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr160b Function Block

Configure the DigAn

Learn how to configure DigAn to receive input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

18 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 19

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

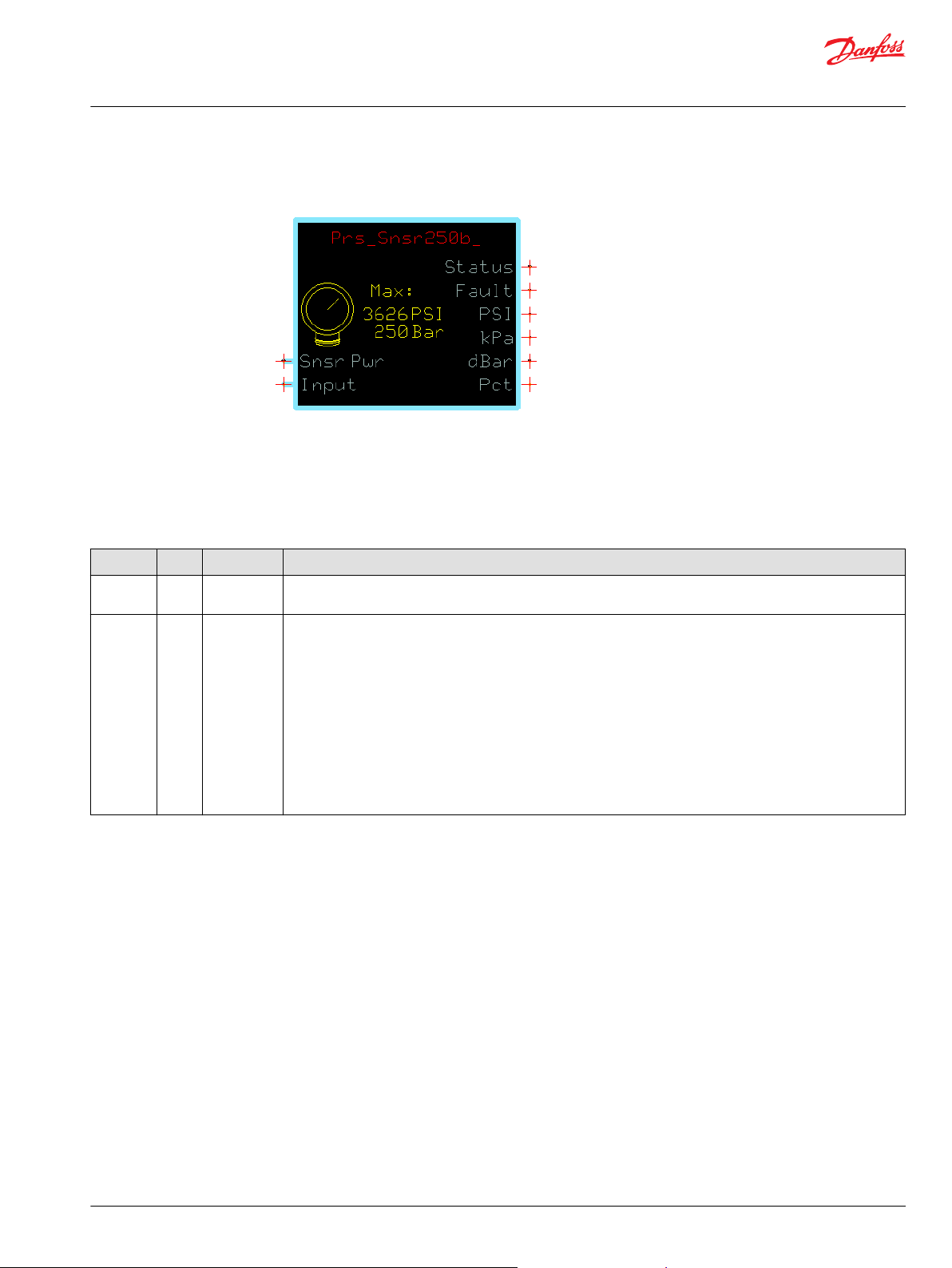

Prs_Snsr250b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–250 bar [25000

kPa/3626 PSI] range.

Inputs

Learn how the function block uses a reference voltage and a changing input voltage to produce PSI, Kpa,

dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr —— 0–5250 mV Inputs a reference voltage that the PLUS+1 controller also applies to the Pin 1 (+ Supply) on the Pressure

Transmitter.

Input —— 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar , and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of 3626 PSI/25000

kPa/10000 (100.00%).

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of 4080 PSI/

28125 kPa/11250 (112.50%).

The maximum over-pressure output equals 112.50% of the maximum nominal output. (25000 kPa x 112.50% =

28125 kPa)

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 19

Page 20

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr250b Function Block

Outputs

Learn about the outputs of the Prs_Snsr250b function block.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating

range without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating

range without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–4080 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U16 0–28125 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–2812

Pct U16 0–11250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

20 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 21

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr250b Function Block

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex

Input value is too low. 0x8001 0001

Input value is too high. 0x8002 0010

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Volt(age) is less than [10% of

Snsr Pwr] - [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr less than 0. Ensure correct software input is

Volt(age) is greater than [90% of

Snsr Pwr] + [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr greater than 5250.

Output = 0.

Output is extrapolated beyond

the maximum value up to 11250

(112.50%).

Output = 0.

Inspect for open circuit in wire

connections to sensor.

made in the application.

Inspect for short circuit in wire

•

connections to sensor.

Verify the correct pressure

•

sensor is used for the

application.

Ensure correct software input is

made in the application.

Relationship Between Function Block Input and Output Signals

Use the plot to find out the relationships between the function block's Input voltages and its kPa and Pct

outputs.

This function block’s:

Flt Pct value = 500 (5.00%) and its Snsr Pwr value = 5000 mV.

•

Nominal Input voltage ranges between 10.00% (500 mV) and 90.00% (4500 mV) of the Snsr Pwr

•

voltage.

Nominal pressure output ranges between zero with the Input voltage at 500 mV and a maximum

•

nominal 25000 kPa/100.00% with the Input voltage at 4500 mV.

Maximum over-pressure output = 28125 kPa with the Input voltage at 5000 mV. (25000 maximum

•

nominal pressure x 112.50% = 28125 kPa maximum over-pressure)

When the Input voltage:

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 21

Page 22

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr250b Function Block

•

Drops below 300 mV, the function block outputs an input too low fault. (500 mV – 5% of the 4000 mV

nominal input voltage range = fault at 300 mV)

•

Rises above 4700 mV, the function block outputs an input too high fault. (4500 mV + 5% of the 4000

mV nominal input voltage range = fault at 4700 mV)

Function Block Connections

Connections you can make with the function block are described.

Function block connections

Item Description

1 Sensor voltage (varies with pressure).

2 Sensor reference power voltage.

3 Function block status.

4 Function block faults.

5 Pressure in PSI.

6 Pressure in kPa.

7 Pressure in decibar (dBar)

8 Pressure in % of range.

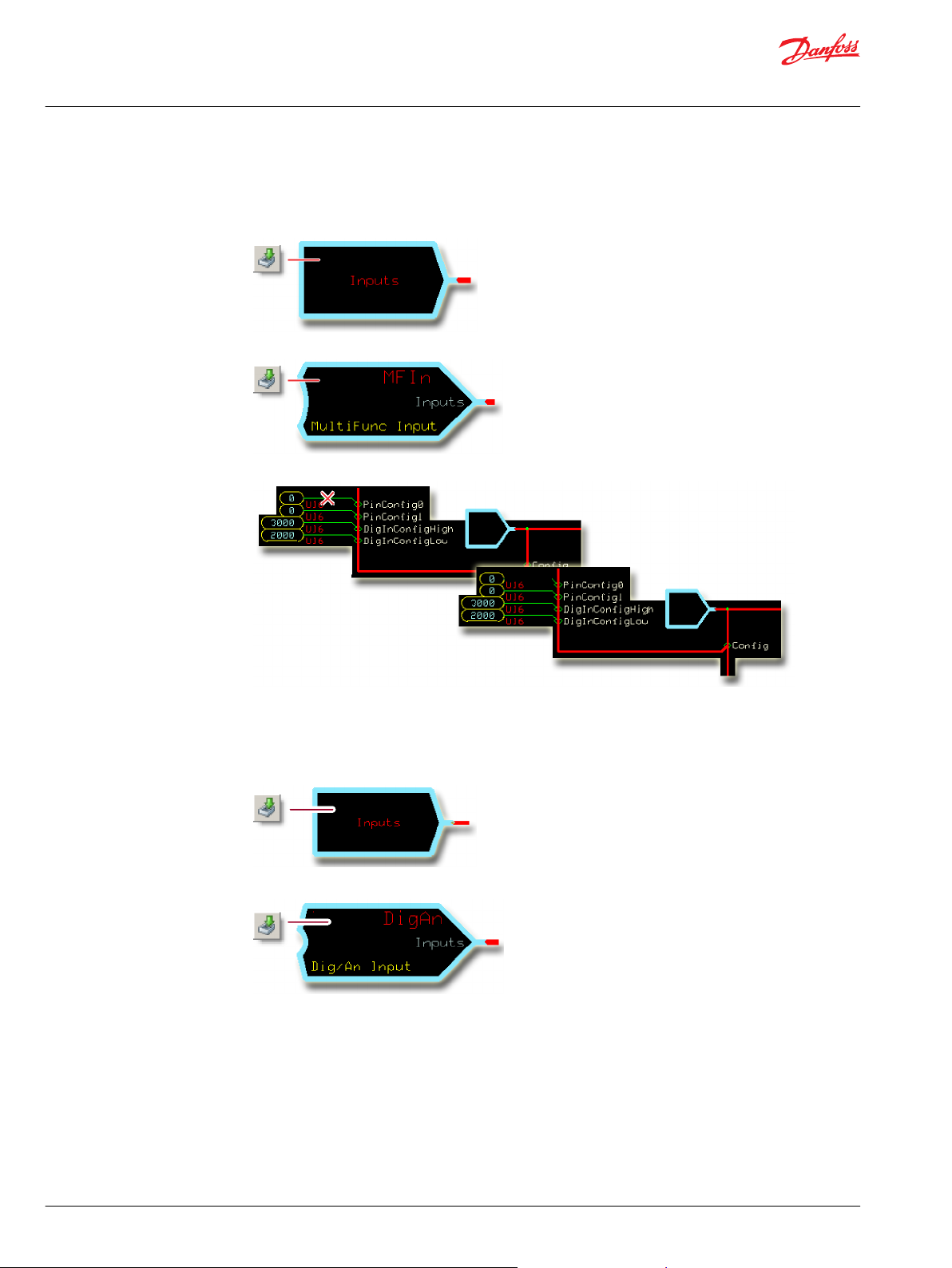

MC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

For MC Controllers, you route the function block’s Input through an MFIn or a DigAn.

You must change the MFIn and DigAn default configurations to accept this input.

22 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 23

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr250b Function Block

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn that receives the input.

3. Make the changes that are shown in this figure.

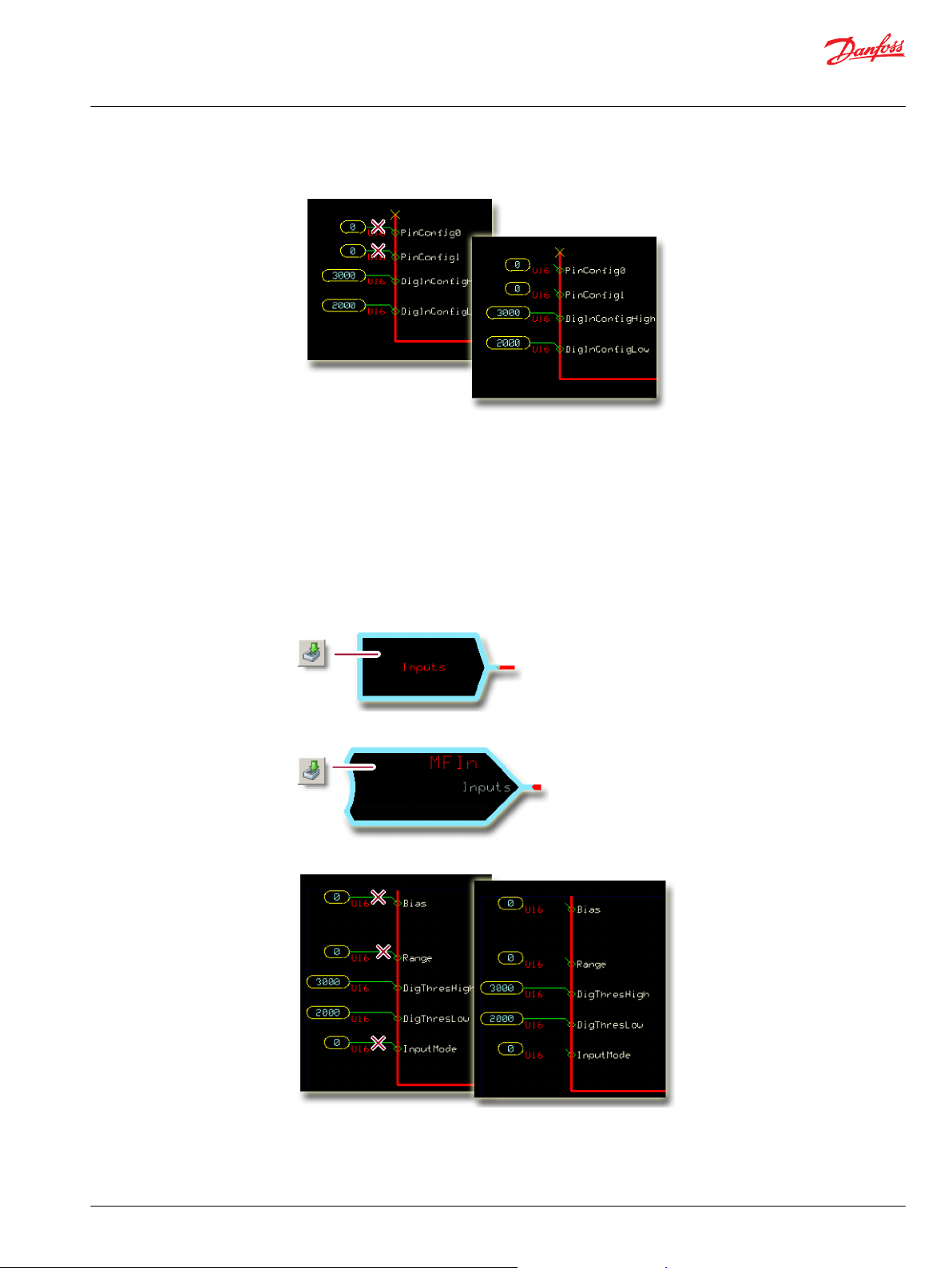

Configure the DigAn

Learn how to configure DigAn to accept input.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 23

Page 24

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr250b Function Block

3. Make the changes that are shown in the following figure.

SC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

You route the function block’s Input through an MFIn or a DigAn. You must change the MFIn and

DigAn default configurations to accept this input.

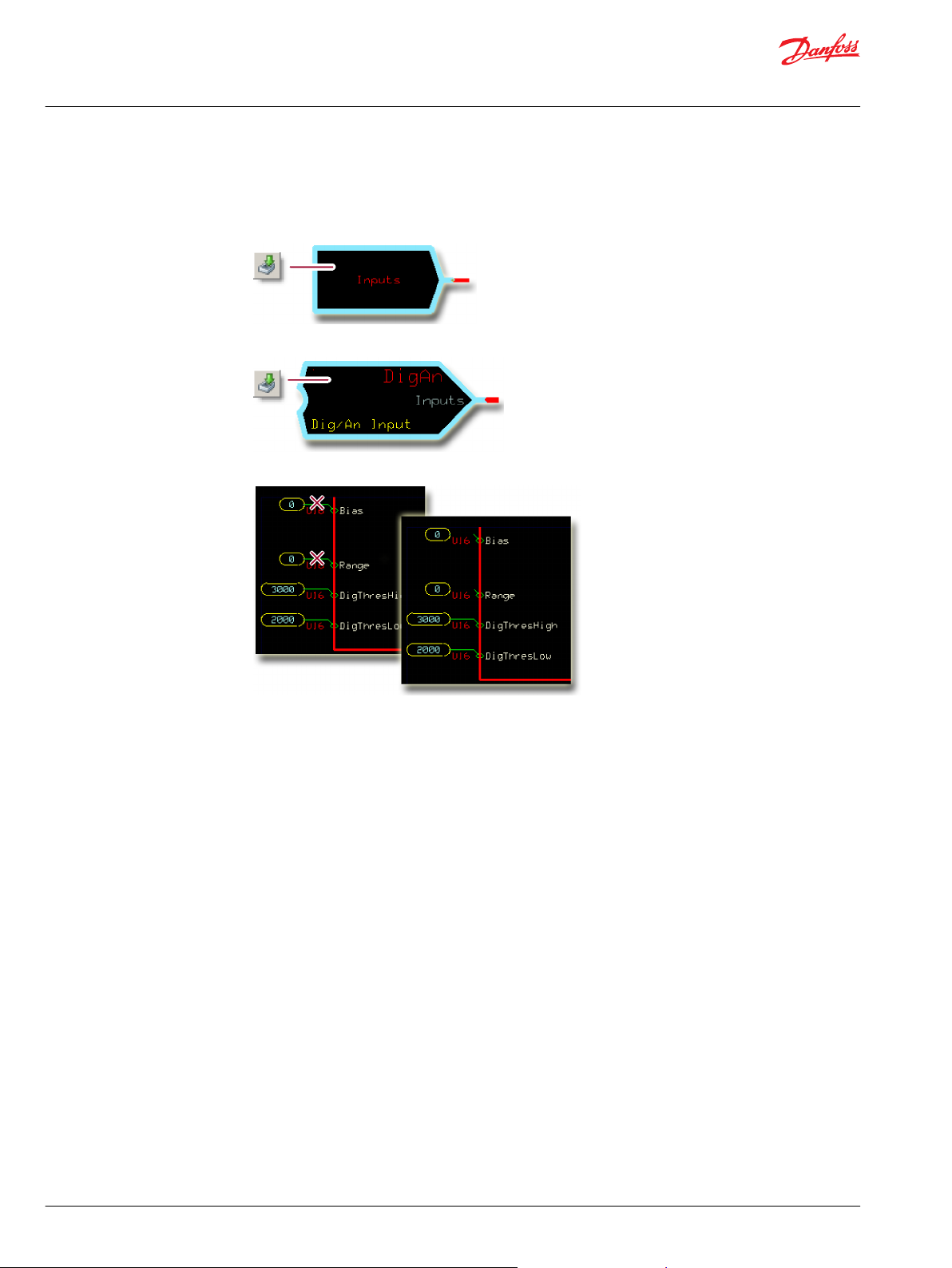

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

24 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 25

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr250b Function Block

Configure the DigAn

Learn how to configure DigAn to receive input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 25

Page 26

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–400 bar [40000

kPa/5800 PSI] range.

Inputs

Learn how the function block uses a reference voltage and a changing input voltage to produce PSI, kPa,

dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr —— 0–5250 mV Inputs a reference voltage that the PLUS+1 controller also applies to the Pin 1 (+ Supply) on the Pressure

Transmitter.

Input —— 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar , and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of 5800 PSI/40000

kPa/10000 (100.00%).

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of 6525 PSI/

45000 kPa/11250 (112.50%).

The maximum over-pressure output equals 112.50% of the maximum nominal output. (40000 kPa x 112.50% =

45000 kPa)

26 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 27

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

Outputs

Learn about the outputs of the Prs_Snsr400b function block.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating

range without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating

range without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–6525 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U16 0–45000 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–4500

Pct U16 0–111250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 27

Page 28

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex

Input value is too low. 0x8001 0001

Input value is too high. 0x8002 0010

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Volt(age) is less than [10% of

Snsr Pwr] - [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr less than 0. Ensure correct software input is

Volt(age) is greater than [90% of

Snsr Pwr] + [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr greater than 5250.

Output = 0.

Output is extrapolated beyond

the maximum value up to 11250

(112.50%).

Output = 0.

Inspect for open circuit in wire

connections to sensor.

made in the application.

Inspect for short circuit in wire

•

connections to sensor.

Verify the correct pressure

•

sensor is used for the

application.

Ensure correct software input is

made in the application.

Relationship Between Function Block Input and Output Signals

Use the plot to find out the relationships between the function block's Input voltages and its kPa and Pct

outputs.

This function block’s:

Flt Pct value = 500 (5.00%) and its Snsr Pwr value = 5000 mV.

•

Nominal Input voltage ranges between 10.00% (500 mV) and 90.00% (4500 mV) of the Snsr Pwr

•

voltage.

Nominal pressure output ranges between zero with the Input voltage at 500 mV and a maximum

•

nominal 40000 kPa/100.00% with the Input voltage at 4500 mV.

Maximum over-pressure output = 45000 kPa with the Input voltage at 5000 mV.

•

(40000 maximum nominal pressure x 112.50% = 45000 kPa maximum over-pressure)

When the Input voltage:

28 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 29

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

Drops below 300 mV, the function block outputs an input too low fault.

•

(500 mV – 5% of the 4000 mV nominal input voltage range = fault at 300 mV)

Rises above 4700 mV, the function block outputs an input too high fault.

•

(4500 mV + 5% of the 4000 mV nominal input voltage range = fault at 4700 mV)

Function Block Connections

Connections you can make with the function block are described.

Function block connections

Item Description

1 Sensor voltage (varies with pressure).

2 Sensor reference power voltage.

3 Function block status.

4 Function block faults.

5 Pressure in PSI.

6 Pressure in kPa.

7 Pressure in decibar (dBar)

8 Pressure in % of range.

MC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

For MC Controllers, you route the function block’s Input through an MFIn or a DigAn.

You must change the MFIn and DigAn default configurations to accept this input.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 29

Page 30

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn that receives the input.

3. Make the changes that are shown in this figure.

Configure the DigAn

Learn how to configure DigAn to accept input.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

30 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 31

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

3. Make the changes that are shown in the following figure.

SC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

You route the function block’s Input through an MFIn or a DigAn. You must change the MFIn and

DigAn default configurations to accept this input.

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 31

Page 32

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr400b Function Block

Configure the DigAn

Learn how to configure DigAn to receive input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

32 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 33

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–500 bar [50000

kPa/7250 PSI] range.

Inputs

Learn how the function block uses a reference voltage and a changing input voltage to produce PSI, kPa,

dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr —— 0–5250 mV Inputs a reference voltage that the PLUS+1® controller also applies to the Pin 1 (+ Supply) on the pressure

transmitter.

Input —— 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of 7250 PSI/50000 kPa/

10000 (100.00%).

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of 8156 PSI/

56250 kPa/11250 (112.50%).

The maximum over-pressure output equals 112.50% of the maximum nominal output. (50000 kPa x 112.50% =

56250 kPa)

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 33

Page 34

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

Outputs

Learn about the outputs of the Prs_Snsr500b function block.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–8156 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U16 0–56250 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–5625

Pct U16 0–11250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

34 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 35

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex

Input value is too low. 0x8001 0001

Input value is too high. 0x8002 0010

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Volt(age) is less than [10% of

Snsr Pwr] - [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr less than 0. Ensure correct software input is

Volt(age) is greater than [90% of

Snsr Pwr] + [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr greater than 5250.

Output = 0.

Output is extrapolated beyond

the maximum value up to 11250

(112.50%).

Output = 0.

Inspect for open circuit in wire

connections to sensor.

made in the application.

Inspect for short circuit in wire

•

connections to sensor.

Verify the correct pressure

•

sensor is used for the

application.

Ensure correct software input is

made in the application.

Relationship Between Function Block Input and Output Signals

Use the plot to find out the relationships between the function block's Input voltages and its kPa and Pct

outputs.

This function block’s:

Flt Pct value = 500 (5.00%) and its Snsr Pwr value = 5000 mV.

•

Nominal Input voltage ranges between 10.00% (500 mV) and 90.00% (4500 mV) of the Snsr Pwr

•

voltage.

Nominal pressure output ranges between zero with the Input voltage at 500 mV and a maximum

•

nominal 50000 kPa/100.00% with the Input voltage at 4500 mV.

Maximum over-pressure output = 56250 kPa with the Input voltage at 5000 mV. (50000 maximum

•

nominal pressure x 112.50% = 56250 kPa maximum over-pressure)

When the Input voltage:

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 35

Page 36

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

Drops below 300 mV, the function block outputs an input too low fault.

•

(500 mV – 5% of the 4000 mV nominal input voltage range = fault at 300 mV)

Rises above 4700 mV, the function block outputs an input too high fault.

•

(4500 mV + 5% of the 4000 mV nominal input voltage range = fault at 4700 mV)

Function Block Connections

Connections you can make with the function block are described.

Function block connections

Item Description

1 Sensor voltage (varies with pressure).

2 Sensor reference power voltage.

3 Function block status.

4 Function block faults.

5 Pressure in PSI.

6 Pressure in kPa.

7 Pressure in decibar (dBar)

8 Pressure in % of range.

MC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

For MC Controllers, you route the function block’s Input through an MFIn or a DigAn.

You must change the MFIn and DigAn default configurations to accept this input.

36 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 37

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn that receives the input.

3. Make the changes that are shown in this figure.

Configure the DigAn

Learn how to configure DigAn to accept input.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 37

Page 38

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

3. Make the changes that are shown in the following figure.

SC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

You route the function block’s Input through an MFIn or a DigAn. You must change the MFIn and

DigAn default configurations to accept this input.

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

38 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 39

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr500b Function Block

Configure the DigAn

Learn how to configure DigAn to receive input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 39

Page 40

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–550 bar [55000

kPa/7977 PSI] range.

Inputs

Learn how the function block uses a reference voltage and a changing input voltage to produce PSI, kPa,

dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr —— 0–5250 mV Inputs a reference voltage that the PLUS+1® controller also applies to the Pin 1 (+ Supply) on the pressure

transmitter.

Input —— 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of 7250 PSI/50000 kPa/

10000 (100.00%).

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of 8156 PSI/

56250 kPa/11250 (112.50%).

The maximum over-pressure output equals 112.50% of the maximum nominal output. (50000 kPa x 112.50% =

56250 kPa)

40 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 41

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

Outputs

Learn about the outputs of the Prs_Snsr550b function block.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–8156 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U16 0–56250 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–5625

Pct U16 0–11250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 41

Page 42

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex

Input value is too low. 0x8001 0001

Input value is too high. 0x8002 0010

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

Volt(age) is less than [10% of

Snsr Pwr] - [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr less than 0. Ensure correct software input is

Volt(age) is greater than [90% of

Snsr Pwr] + [Flt Pct of nominal

signal range (which is 80% of

Snsr Pwr)].

Snsr Pwr greater than 5250.

Output = 0.

Output is extrapolated beyond

the maximum value up to 11250

(112.50%).

Output = 0.

Inspect for open circuit in wire

connections to sensor.

made in the application.

Inspect for short circuit in wire

•

connections to sensor.

Verify the correct pressure

•

sensor is used for the

application.

Ensure correct software input is

made in the application.

Relationship Between Function Block Input and Output Signals

Use the plot to find out the relationships between the function block's Input voltages and its kPa and Pct

outputs.

This function block’s:

42 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 43

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

Flt Pct value = 500 (5.00%) and its Snsr Pwr value = 5000 mV.

•

Nominal Input voltage ranges between 10.00% (500 mV) and 90.00% (4500 mV) of the Snsr Pwr

•

voltage.

Nominal pressure output ranges between zero with the Input voltage at 500 mV and a maximum

•

nominal 50000 kPa/100.00% with the Input voltage at 4500 mV.

Maximum over-pressure output = 50000 kPa with the Input voltage at 5000 mV. (61875 maximum

•

nominal pressure x 112.50% = 18000 kPa maximum over-pressure)

When the Input voltage:

Drops below 300 mV, the function block outputs an input too low fault. (500 mV – 5% of the 4000 mV

•

nominal input voltage range = fault at 300 mV)

Rises above 4700 mV, the function block outputs an input too high fault. (4500 mV + 5% of the 4000

•

mV nominal input voltage range = fault at 4700 mV)

Function Block Connections

Connections you can make with the function block are described.

Function block connections

Item Description

1 Sensor voltage (varies with pressure).

2 Sensor reference power voltage.

3 Function block status.

4 Function block faults.

5 Pressure in PSI.

6 Pressure in kPa.

7 Pressure in decibar (dBar)

8 Pressure in % of range.

MC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

For MC Controllers, you route the function block’s Input through an MFIn or a DigAn.

You must change the MFIn and DigAn default configurations to accept this input.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 43

Page 44

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn that receives the input.

3. Make the changes that are shown in this figure.

Configure the DigAn

Learn how to configure DigAn to accept input.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

44 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 45

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

3. Make the changes that are shown in the following figure.

SC Controller—Input Configuration

Configure MFIn and DigAn to accept the input of the function block.

You route the function block’s Input through an MFIn or a DigAn. You must change the MFIn and

DigAn default configurations to accept this input.

Configure the MFIn

Learn how to configure MFIn to accept input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 45

Page 46

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr550b Function Block

Configure the DigAn

Learn how to configure DigAn to receive input from the function block.

1. In the GUIDE template, enter the Inputs page.

2. Enter the page that receives the input.

3. Make the changes that are shown in the following figure.

46 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 47

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr600b Function Block

This function block configures the output of MBS 1250 pressure sensors with a nominal 0–600 bar [60000

kPa/8700 PSI] range.

Inputs

Learn how the function block uses a reference voltage and a changing input voltage to produce PSI, kPa,

dBar and Pct outputs.

Function Block Inputs

Input Type Range Description

Snsr Pwr —— 0–5250 mV Inputs a reference voltage that the PLUS+1 controller also applies to the Pin 1 (+ Supply) on the Pressure

Transmitter.

Input —— 0–5250 mV The function block compares the changing Input voltage with the constant Snsr Pwr reference voltage to produce

PSI, kPa, dBar, and Pct outputs.

The function block’s nominal operating range is between 10.00% and 90.00% of Snsr Pwr voltage.

When the Input voltage reaches:

•

10.00% of the Snsr Pwr voltage, the function block’s output starts rising above zero.

•

90.00% of the Snsr Pwr voltage, the function block outputs its maximum nominal outputs of 8700 PSI/60000

kPa/10000 (100.00%).

•

100.00% of the Snsr Pwr voltage, the function block outputs its maximum over-pressure outputs of 9788 PSI/

67500 kPa/11250 (112.50%).

The maximum over-pressure output equals 112.50% of the maximum nominal output. (8700 PSI x 112.50% =

9788 PSI)

©

Danfoss | March 2018 11062069 | AQ00000100en-US0401 | 47

Page 48

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr600b Function Block

Outputs

Learn about the outputs of the Prs_Snsr600b function block.

Function Block Outputs

Output Type Range Description

Status U16 —— Indicates if the Flt Pct value is within range or is set too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Status output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8008 = Flt Pct value is too high.

Fault U16 —— Indicates if the voltage on the function block’s Input pin is too low or too high.

The Flt Pct sets the percentage that the Input voltage can rise above or fall below the function block’s operating range

without setting a fault condition.

You can change the Flt Pct value (1000 = 10.00%) on the inner page of the Prs_Snsr function block.

The Fault output uses the bitwise scheme.

•

0x0000 = Block is OK.

•

0x8001 = Input value is too low.

•

0x8002 = Input value is too high.

PSI U16 0–9788 Indicates pressure in pounds per square inch (PSI).

1 = 1 PSI.

kPa U32 0–67500 Indicates pressure in kilopascals (kPa).

1 = 1 kPa.

dBar U16 0–6750

Pct U16 0–11250 Indicates pressure as a percent of the function block’s operating range.

Indicates pressure in decibars (dBar).

1 = 1 dBar.

10000 = 100.00%.

Status and Fault Logic

This topic describes how status logic and fault logic are indicated for the function block.

Status Logic

The status code indicates the calibration state of the function block.

Status logic

Condition Hex

Invalid setup. 0x8008 1000 Flt Pct > 1000 (10.00%). Output = 0. Reduce Flt Pct.

*

Bit 16 set to 1 identifies a standard Danfoss status or fault code.

*

Binary Cause Response Correction

48 | © Danfoss | March 2018 11062069 | AQ00000100en-US0401

Page 49

User Manual

PLUS+1® Compliant MBS 1250 Pressure Sensor Function Blocks

Prs_Snsr600b Function Block

Fault Logic

Learn how fault logic can indicate problems, causes of problems, and solutions.

Fault logic

Condition Hex