Page 1

Connection and operating instructions

Plug-in Display MBD 1000

Introduction

The MBD 1000 is a microprocessor controlled

plug-in display that can be universally applied to

all MBS, AKS and MBT transmitters with a

4-20 mA output. The display provides a simple

and eective solution for local monitoring of

pressure and temperature. It does not require its

own auxiliary voltage source but can be supplied

directly from the measuring current.

The measuring value is displayed on a 4-digit LCD

with the max. display area ranging from

−1999 to +9999 digits.

The operating range of the display device can

be directly adjusted to the transmitter range by

simply entering the maximum and minimum

measuring range limits as well as the decimal

point position.

Parameters and limit values are entered via

three keys which are accessible after removal of the

cover.

All programmable parameters of the MBD 1000

are stored in an EEPROM; in the event of a

current failure they will remain there for at least

10 years.

The MBD 1000 is equipped with a self-diagnosis

system which continuously monitors the

essential parts of the device.

Sensor operational performance is continuously

monitored.

The MBD 1000 is tested and completely

calibrated.

The MBD 1000 must be congured to the specic

application.

Please refer to chapter "Conguration".

In accordance with EN50081-1

and EN50082-2 for unrestricted

use in housing and industrial

areas

Safety advice

In order to exclude any risk whatsoever for the

operator the following points have to be

observed:

a) Immediately switch o the unit in the event

of visible damage or obvious malfunction.

b) Always disconnect the MBD 1000 before

opening it up. All electrical connections

must be securely connected and touch proof after installation.

Attention: When running electric devices parts of these devices will always be highly

energised. Unless the warnings are observed serious personal injuries or damage

to property may result. Skilled personnel only should be allowed to work with this

device. For trouble-free and safe operation of the device please ensure professional

transport, storage, installation and connection as well as proper operation an maintenance.

c) Standard regulations for operation and

safety for electrical, light and heavy current

equipment have to be observed, with

particular attention having to be paid to

national safety regulations (e.g. VDE 0100).

IC.PI.P20.E2.02/ 520B1359 © Danfoss A/S 07-2007

Page 2

MBD 1000 Connection and operating instructions

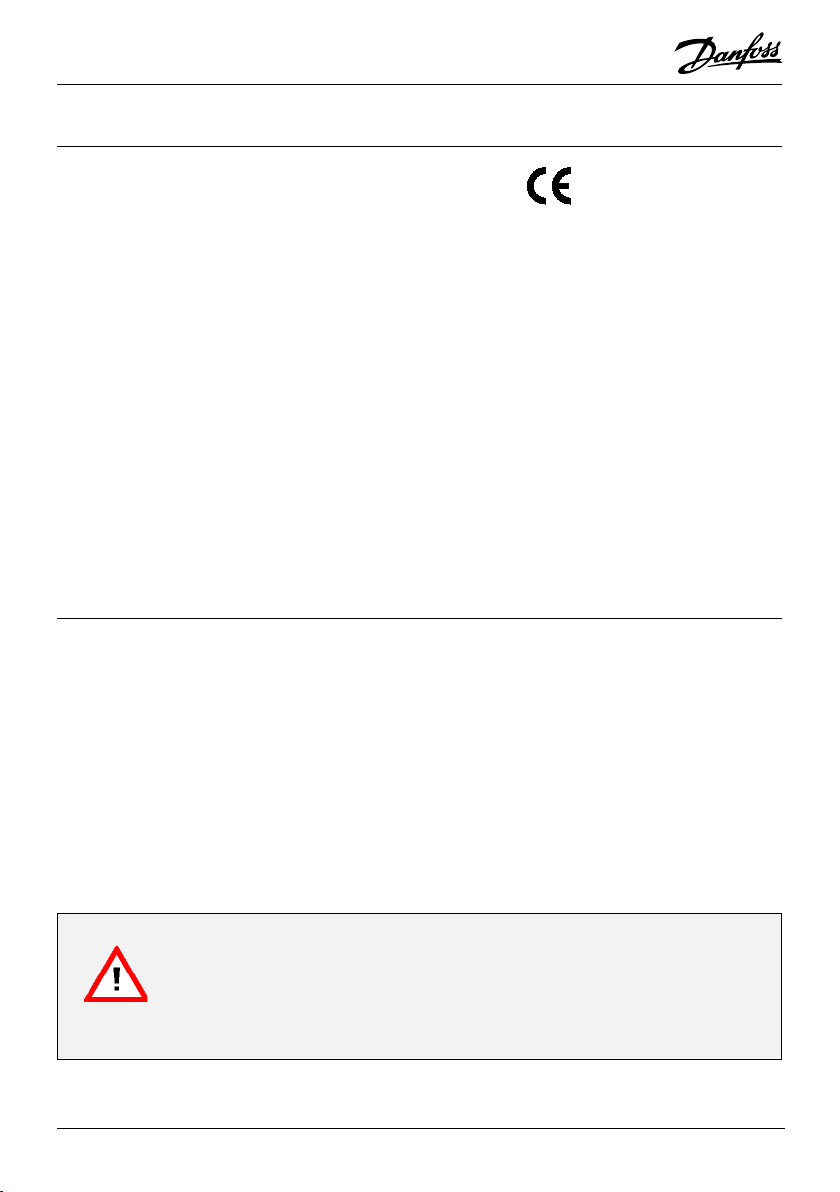

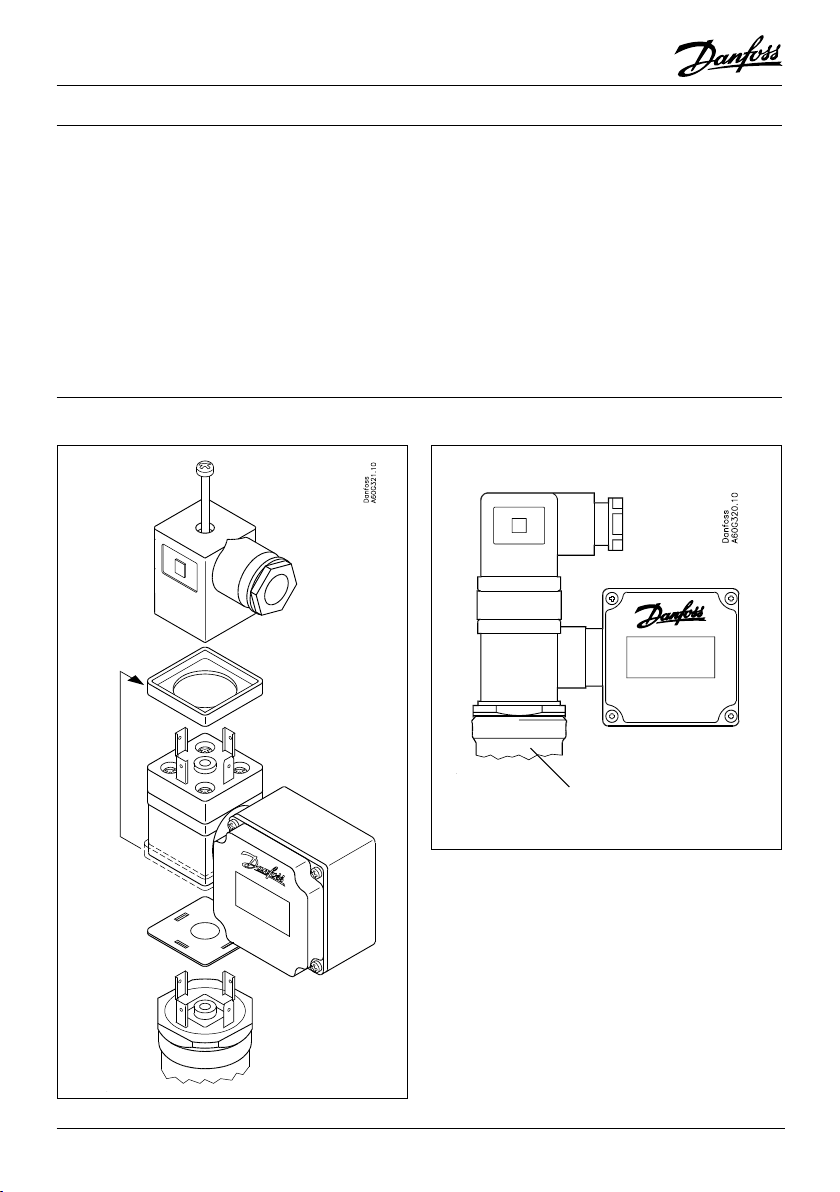

Electric connection

The MBD 1000 is simpy plugged into a transmitter by means of a special adaptor for the cubic

plug according to DIN43650.

Electric connection and commissioning of the

device must be carried out by trained and skilled

personnel.

Terminal assignment:

Use male plugs 1 and 2.

Supply voltage:

The display takes power directly from measuring

current.

Assembly

Wrong connection may lead to the destruction of

the display device. Danfoss cannot assume any

responsibility for this !!

Observe the maximum input current rating of

40mA under all circumstances !!

MBS/ AKS/ MBT

Transmitter connector

DIN 43650

2 IC.PI.P20.E2.02

© Danfoss A/S

Page 3

MBD 1000 Connection and operating instructions

Technical specication

Input signal 4 ... 20 mA (2-wire)

Max. allowed input current 40 mA

Reverse voltage protection polarized installation

Voltage drop across display approx. 3 V

Display 10 mm high LCD-display

Display range starting and end value freely selectable

Maximum display value 9999 digits

Minimum display value -1999 digits

Decimal point any position

Measuring accuracy 0.2% ± 1 digit

Temperature drift 100 ppm / °C

Measuring interval approx. 5 measurements / sec.

Filter 3 stages can be switched on

Nominal temperature 25°C

Amibent temperature 0 to 50°C

Relative atmospheric humidity 0 to 80% (non condensing)

Eletromagnetic compatibility:

Additional error:

Housing ABS. Front screen made of polycarbonate.

Connection specially designed adaptor for cubic plug

IP rating front side IP65

Fault codes

In case of unacceptable conditions in the system a fault code will be displayed.

Fault codes have been dened as follows:

In accordance with EN50081-1 and EN50082-2

< 1%

48.5 x 48.5 x 35.5 mm (L x W x D)

DIN43650 for simple connection.

Length of screw has to be adjusted.

FE 1: Measuring range has been exceeded

This fault code indicates that the measuring range of the A/D converter has been exceeded.

Potential fault cause: transmitter damaged

short-circuit in transmitter connection

MBD 1000 not/incorrectly congurated

Remedies: FE 1 will be reset as soon as the measuring values are back within

their permissible range. Please check your transmitter and transmitter

connecting cables.

FE 2: Measuring values have fallen below permissible range

This fault code indicates that the measuring values of the A/D converter have fallen below the

permissible range.

Potential fault cause: transmitter damaged

transmitter connection interrupted

MBD 1000 not/incorrectly congurated

Remedies: FE 2 will be reset as soon as the measuring values are back within

their permissible range. Please check your transmitter and transmitter

connecting cables.

© Danfoss A/S IC.PI.P20.E2.02 3

Page 4

MBD 1000 Connection and operating instructions

Conguration

Please note: measuring current should be

at least 4 mA during conguration!

1. Press button 1, "dP" (decimal point) will be

displayed.

Select decimal point position desired using

buttons 2 and 3.

Acknowledge decimal point position by

pressing button 1. "dP" will be displayed

again.

2. Press button 1 once again, "An 4" (display

for 4mA) will be displayed.

Use buttons 2 and 3 to set value to be

displayed on the MBD 1000 for an input

signal of 4mA.

Buttons 2 and 3 are equipped with a scrolling

function, i.e. the value will be increased

respectively decreased by 1 digit when

button 2 respectively button 3 is pressed

briey (no more than 1 s). When pressing

these buttons for a longer time (over 1 s)

the values will start „scrolling“ upwards

respectively downwards with the scrolling

speed being increased after approx. 6s.

Acknowledge value displayed by pressing

button 1. "An 4" will be displayed again.

3. Switch over to the next parameter by

pressing button 1 once again. "An20" will be

displayed (display for 20mA).

Use buttons 2 and 3 to set value to be

displayed on the MBD 1000 for an input

signal of 20mA.

Acknowledge value displayed by pressing

button 1. "An20" will be displayed again.

4. Press button 1 once again. "LI" (limit) will be

displayed.

Select measuring range limits desired using

buttons 2 and 3.

0 = Values exceeding/falling below limits are

acceptable. (FE1, FE2 displayed for

hardware limits)

1 = Values exceeding/falling below limits are

not acceptable. (FE1, FE2 displayed for

area limits)

Acknowledge selection made by pressing

button 1. "LI" will be displayed again. For

pressure and temperature measuring

transducers always enter "LI 0".

5. Press button 1 once again. "FILt" (lter) will

be displayed.

Select input lter 0, 1, 2 or 3 desired using

buttons 2 and 3.

0 = no lter

1 = lter 1 active

2 = lter 2 active

3 = lter 1 and lter 2 active

Filter 1: for ltering short pikes occurring when

relays and contactors are switched.

Make sure to always activate lter 1 if

high loads are switched in the vicinity

of the MBD 1000 (wires or sensor or if

large spikes are to be expected).

Additional display delay: approx. 0.5s

Filter 2: prevents ”jumping” of the last gure, a

phenomenon often found with digital

displays and controllers. Make sure to

always activate lter 2 if the display

range exceeds 2000 digits.

Additional display delay: approx. 1s

Acknowledge selection made by pressing button

1. "FILt" will be displayed again.

The adjustment of the MBD 1000 to the transmitter is now completed. The MBD 1000 can be

immediately switched over to display the current

measuring vlaue by pressing button 1.

IC.PI.P20.E2.02

© Danfoss A/S (DE-BD) 07-2007

Loading...

Loading...