Data Sheet

Pressure switch

Type MBC 5000 and MBC 5100

For heavy-duty marine applications

MBC pressure switches are used in industrial

and marine applications where space and

reliability are the most important features.

MBCs are compact pressure switches, designed

according to our block design to survive in the

harsh conditions known from machine rooms

onboard ships.

MBCs have high vibration resistance and MBC

5100 features all common marine approvals.

The xed, but low dierential guarantees

accurate monitoring of critical pressures.

MBV test valves can be delivered as standard

option for MBC.

Features

• Designed for use in severe industrial,

environments

• High vibration stability

• Part of the Danfoss block system, consisting

of MBC pressure controls, MBS pressure

transmitters and MBV test valves

• MBC 5100 with all major ship approvals

• High repeatability

• Optimal compact design for machine

building purposes

• Intended for alarm indication, shut down,

control and diagnostics in many applications

- motors, gears, thrusters, pumps, lters,

compressors, etc.

AI235886441161en-001001

Repeatability

Bellows versions

± 0.2 % FS (typ.)

± 0.5 % FS (max.)

Diaphragm versions

± 0.5 % FS (typ.)

± 1.0 % FS (max.)

Piston versions

± 1.0 % FS (typ.)

± 1.0 % FS (max.)

Max. switch frequency

10/min (0.16 Hz)

Dierential

See page 6

Permissible operating pressure

See page 6

Burst pressure

See page 6

Lifetime

Mechanical for diaphragm and bellows

Mechanical for piston type

Electrical at max. contact load

> 400,000 cycles

>1 million cycles

> 100,000 cycles

Switch

Utilization category

SPDT

Contact load

AC 15

0.5 A, 250 V

DC 13

12 W, 125 V

Temperature

Operation

Bellows versions

Diaphragm versions

Piston versions

-40 – 85 °C

-10 – 85 °C

-40 – 85 °C

Transport

Bellows versions

Diaphragm versions

Piston versions

-50 – 85 °C

-50 – 85 °C

-40 – 85 °C

Enclosure

IP65, EN 60529

Vibration stability

Sinusoidal

20 g, 25 – 2 kHz

EN 60068-2-6

Piston type 4.4 g, 25 – 200 Hz

IEC 60068-2-27

Pressure connection

Standard

G

1

⁄4 female (ISO 228-1) or ange

Option

See specication form, page 4

Electrical connection

Plug

DIN 43650, Pg 9 / Pg 11 / Pg 13.5

Wetted parts material

Housing

Anodized AIMgSi1, AW-6082T6

Stainless steel 1.4306 (18/8), acc. to EN10088-3

Bellows

Stainless steel 1.4306 (18/8), acc. to EN10088-2

Diaphragm

FKM

Piston

Stainless steel 1.4028 (3H13), acc. to EN10088-2

O-ring

NBR

Hole plug (ange version)

Nickel plated brass or zinc plated steel

Seal (piston version)

Turcon T05

Enclosure material

Housing

Anodized AIMgSi1, AW-6082T6

Plug xture

Glass lled polyamid, PA 6.6

Contact system

Silver (AG) microprole

Net weight

0.25 kg

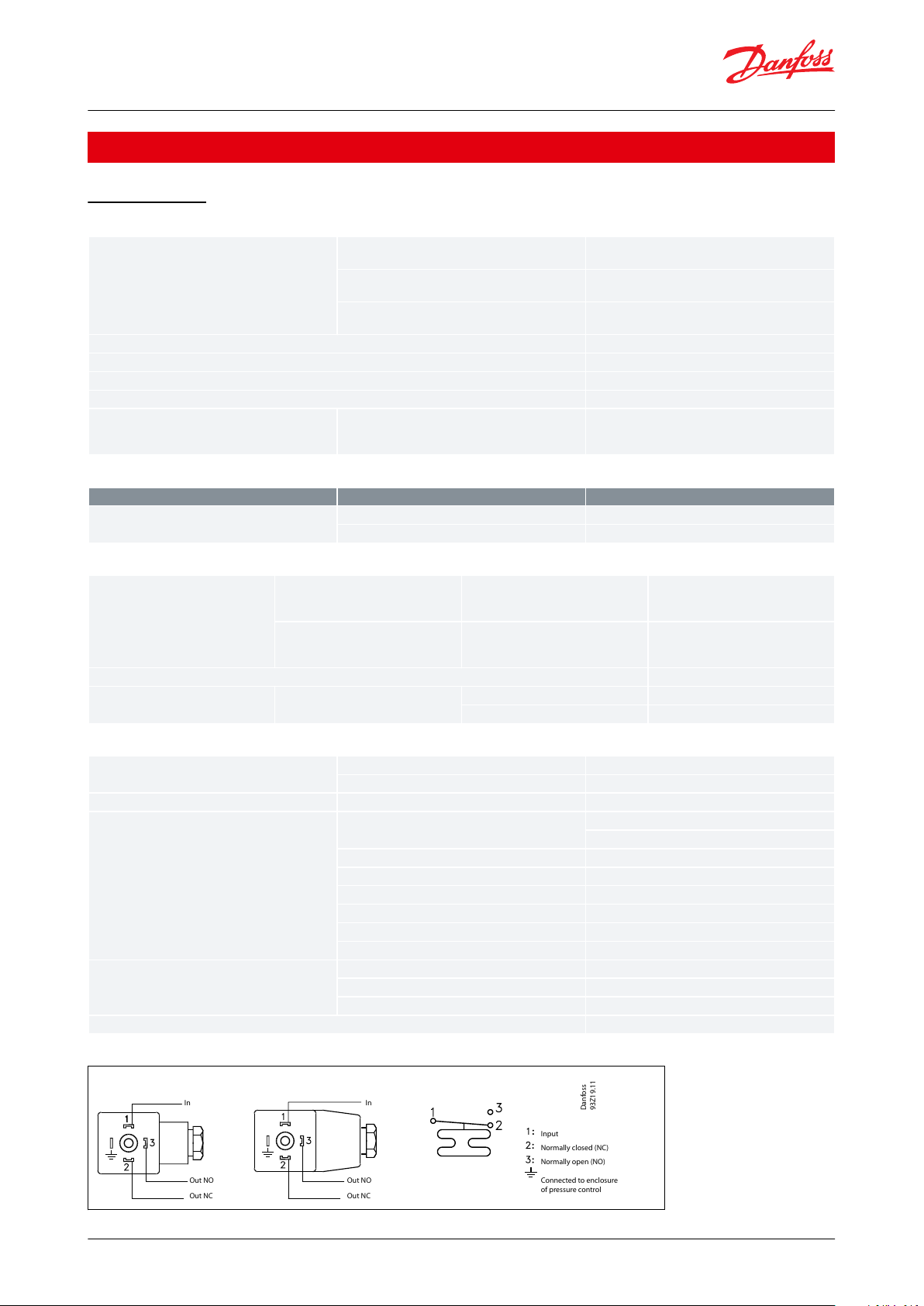

In

In

Out NO

Out NC

Out NO

Out NC

Danfoss

93Z19.11

Input

Normally closed (NC)

Normally open (NO)

Connected to enclosure

of pressure control

Pressure switch, MBC 5000 and MBC 5100

Product specication

Technical data

Table 1: Performance

Table 2: Electrical specications

Table 3: Environmental conditions

Table 4: Mechanical characteristics

Figure 1: Electrical connection

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 2

Pressure switch, MBC 5000 and MBC 5100

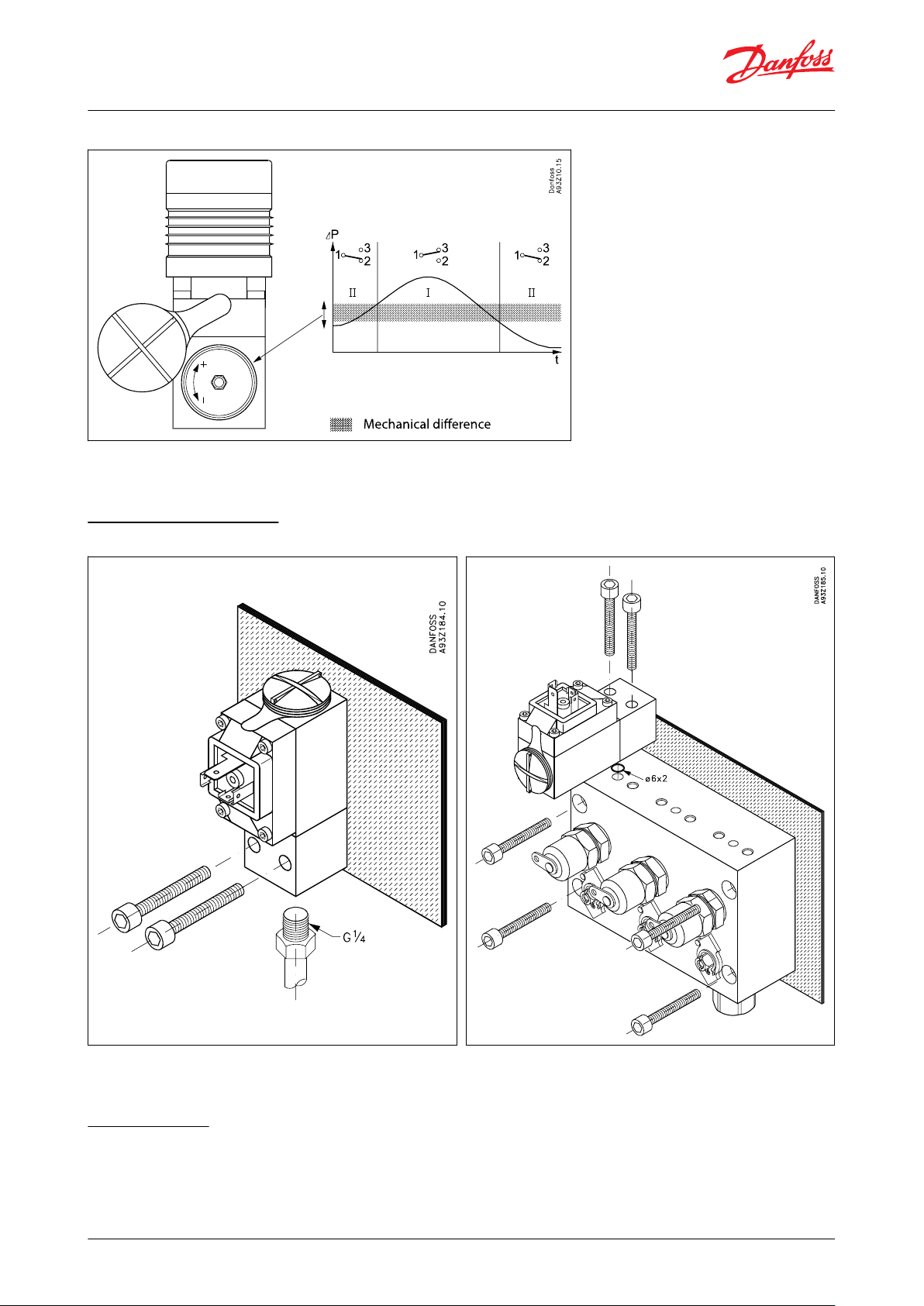

Figure 2: Adjustment

NOTE:

One full turn (360°) of MBC setting screw is approx. equal to 7% of the setting range

Mechanical connection

Figure 3: Thread Figure 4: Flange connection on MBV 5000 Test Valve

NOTE:

Flange connection is not applicable for piston type MBC

How to choose

To achieve the best operating conditions for MBC pressure controls, it is recommended to apply the following rules

of thumb.

Choose:

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 3

93

Danfoss

93Z05.15

93

Danfoss

93Z14.18

Pressure switch, MBC 5000 and MBC 5100

• The MBC type/types which meet the demands for the operating pressure

• The MBC version with the lowest possible setting range

• A diaphragm type, if pressure peaks and pulsations occur in the system (if possible)

• Bellows type, if low dierential is needed

• Piston type for high pressure

Dimensions and weights

Figure 5: MBC 5000, Net weight: 0.25 kg

Figure 6: MBC 5100, Net weight: 0.25 kg

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 4

Type: LP Low

pressure / HP

High pressure

Setting range

Pe [bar]

Di. at min.

range

(1)

Pe [bar]

Di. at max.

range

(1)

Pe [bar]

Permissible oper‐

ating pressure

Pe [bar]

Min. burst pres‐

sure

Pe [bar]

Type designation

MBC 5000-

/MBC 5100-

MBC 5100

Ship approved

Code no.

LP bellows

-0.20 – 1.00

0.30

0.451530

1011-1DB04

061B000566

LP bellows

-0.20 – 4.00

0.30

0.451530

1211-1DB04

061B000466

(2)

LP bellows

-0.20 – 10.00

0.40

0.601530

1411-1DB04

061B000266

(2)

LP bellows

-0.20 – 10.00

0.40

0.601530

1411-1CB04

061B000066

LP bellows

0.50 – 3.00

0.25

0.301530

2011-1DB04

061B002966

LP bellows

1.00 – 6.00

0.30

0.451530

2211-1DB04

061B000766

HP bellows

5.00 – 30.00

0.90

2.004590

3421-1DB04

061B000366

(2)

LP diaphragm

0.50 – 3.00

0.50

0.80

150

300

2031-1DB04

061B101766

LP diaphragm

1.00 – 6.00

1.00

2.50

150

300

2231-1DB04

061B100966

LP diaphragm

1.00 – 10.00

1.00

2.50

150

300

2431-1DB04

061B100466

(2)

LP diaphragm

5.00 – 20.00

1.00

2.50

150

300

3231-1DB04

061B100266

(2)

LP diaphragm

5.00 – 25.00

1.00

2.50

150

300

3331-1DB04

061B102466

HP diaphragm

5.00 – 40.00

2.00

7.00

150

300

3641-1DB04

061B100566

(2)

HP diaphragm

10.00 – 100.00

4.00

12.00

150

300

4241-1DB04

061B100366

(2)

HP piston

16.00 – 160.00

15.00

30.00

600

1200

5251-1CB04

061B510066

HP piston

25.00 – 250.00

20.00

40.00

600

1200

5451-1CB04

061B510166

HP piston

40.00 – 400.00

20.00

50.00

600

1200

5651-1CB04

061B510266

Type: LP Low

pressure / HP

High pressure

Setting range

Pe [bar]

Di. at min.

range

(1)

Pe [bar]

Di. at max.

range

(1)

Pe [bar]

Permissible oper‐

ating pressure

Pe [bar]

Min. burst pres‐

sure

Pe [bar]

Type designation

MBC 5000- /

MBC 5100-

MBC 5100

Ship approved

Code no.

LP bellows

-0.20 – 10.00

0.40

0.601530

1411-1DB04S

061B025066

LP bellows

-0.20 – 4.00

0.30

0.451530

1211-1DB04S

061B025166

LP bellows

-0.20 – 10.00

0.40

0.601530

1411-2DB04S

061B025266

LP bellows

-0.20 – 4.00

0.30

0.451530

1211-2DB04S

061B025366

Pressure switch, MBC 5000 and MBC 5100

Ordering

Ordering standard types

Table 5: Standard types

(1)

(1)

Max value, all values lower or equal are correct

Max value, all values lower or equal are correct

(2)

(2)

Preferred versions

Preferred versions

Ordering stainless steel types

Table 6: Stainless steel types

(1)

(1)

Max value, all values lower or equal are correct

Max value, all values lower or equal are correct

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 5

Setting range

-0.2 – 1 bar.......................................... 1 0

-0.2 – 4 bar.......................................... 1 2

-0.2 – 10 bar ....................................... 1 4

0.5 – 3 bar ........................................... 2 0

1 – 6 bar .............................................. 2 2

1 – 10 bar ............................................ 2 4

2 – 6 bar .............................................. 2 6

5 – 0 bar .............................................. 3 2

5 – 25 bar ............................................ 3 3

5 – 30 bar ............................................ 3 4

5 – 40 bar ............................................ 3 6

10 – 100 bar ....................................... 4 2

16 – 160 bar ....................................... 5 2

25 – 250 bar ....................................... 5 4

40 – 400 bar ....................................... 5 6

Others .................................................. x x

Type

Low pressure bellows (-0.2 – 10 bar) ....................... 1

High pressure bellows (2 – 30 bar) ........................... 2

Low pressure diaphragm (0.5 – 25 bar) .................. 3

High pressure diaphragm (5 – 100 bar) .................. 4

High pressure piston (40 – 400 bar) ......................... 5

noitcennoc erusserP

C A 0 5 .......... M10x1 female

C B 0 4 .......... G ¼ female

D A 0 5 .......... M10x1 female with flange connection

D B 0 4 .......... G ¼ female with flange connection

x x x x .......... Others

Electrical connection

0 .................................................................. No plug (DIN 43650 A)

1 .................................................................. Pg 11 plug (DIN 43650 A)

2 .................................................................. Pg 13.5 plug (DIN 43650 A)

3 .................................................................. Pg 9 plug (DIN 43650 A)

x .................................................................. Others

Microswitch

1 ..................................................................................... 0.5 A, 250 V (AC 15)

12 W, 125 V (DC 13)

x ..................................................................................... Others

......... 6082 (AIMgSi1) version

.......... Stainless steel (1.4306)

version

MBC 5100-

MBC 5000-

S

Part

Description

Code number

Danfoss

61B42.10

Male, G

1

⁄4A, length 20 mm

061B400166

Danfoss

61B41.10

Male, G

1

⁄4A, length 34 mm

061B400266

Danfoss

61B40.10

For

ange connection

061B722166

Pressure switch, MBC 5000 and MBC 5100

Ordering customized types

Figure 7: Customized types

Accessories

Table 7: Pulse snubber

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 6

File name

Document type

Document topic

Approval authority

2003010305069847

Electrical - Safety Certicate

-

CCC

EU 060-9680.AA

EU Declaration

LVD

Danfoss

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

060-9639.AB

Manufacturers Declaration

China RoHS

Danfoss

2020970305003455

CCC Declaration

-

Danfoss

File name

Document type

Document topic

Approval authority

17.20389.258

Marine - Safety Certicate

RMRS

HMB 17529-AE001

Marine - Safety Certicate

KR

14-20046(E1)

Marine - Safety Certicate

LR

GB19PTB00011_05

Marine - Safety Certicate

CCS

TAA00002BB

Marine - Safety Certicate

DNV GL

TA20287M

Marine - Safety Certicate

NKK

16-LD1581072-PDA

Marine - Safety Certicate

ABS

11676-D1 BV

Marine - Safety Certicate

BV

ELE-364617XG

Marine - Safety Certicate

RINA

060-9680.AA

EU Declaration

LVD

Danfoss

2003010305069847

Electrical - Safety Certicate

CCC

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

060-9639.AB

Manufacturers Declaration

China RoHS

Danfoss

2020970305003455

CCC Declaration

Danfoss

Pressure switch, MBC 5000 and MBC 5100

Certicates, declarations and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 8: MBC 5000

Table 9: MBC 5100

CE-marked in accordance with:

LVD 2014/35/EU (EN 60947-1, EN 60947-4-1, EN 60947-5-1)

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 7

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.04 AI235886441161en-001001 | 8

Loading...

Loading...