Page 1

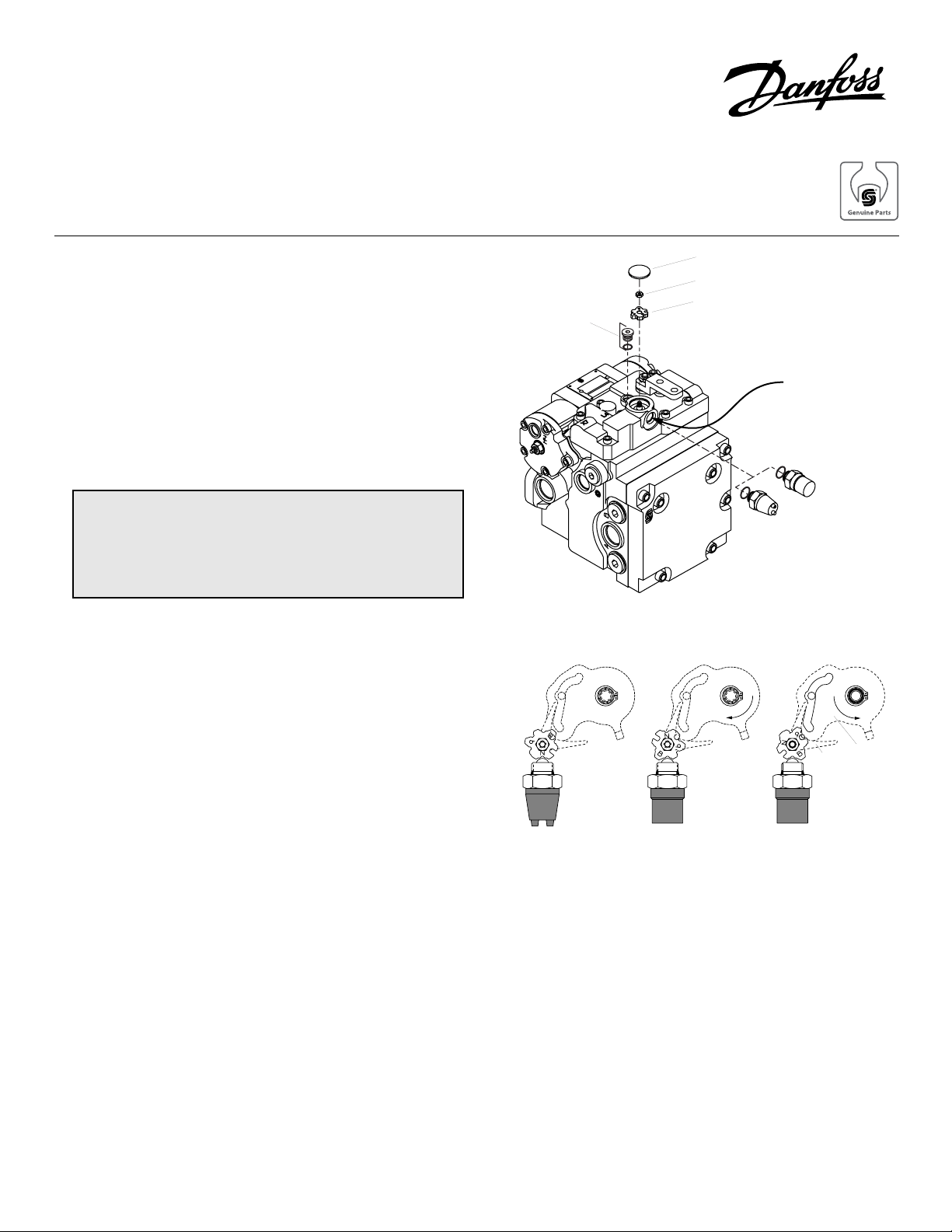

i.

ii.

iii.

Service Kit Instructions

Series 42

Manual displacement control neutral start switch

The Neutral Start Switch (NSS) prevents the engine from

being started when the pump control handle is out of neutral.

The NSS should be wired in series with the engine starting

circuit. The switch contact is closed at the handle’s neutral

position and opens when the control handle is rotated 1.5°

to 2° from neutral.

The Backup Alarm Switch (BUA) outputs an electronic

signal when the control handle is in a reverse position. This

switch is normally wired in series with an audio output. The

switch contact is open until the control handle is rotated 2.6°

to 3.75° in the reverse direction.

WARNING:

The control handle’s neutral position must agree

with the pump’s neutral position for the NSS/BUA to

work effectively.

The Neutral Start/Backup Alarm Switch assembly can be

configured for three different setting.

i. A Neutral Start Switch only.

ii. A Neutral Start Switch with Backup Alarm for units

where clockwise (CW) handle rotation results in

“reverse” motion.

iii. A Neutral Start Switch with Backup Alarm for units

where counterclockwise (CCW) handle rotation

results in “reverse” motion

The setting must be in accordance with the configuration of

the unit. See the model code if uncertain of the type of NSS

you have.

Alignment

Plug

NSS only

NSS Cover

NSS Control Nut

NSS Cam

NSS with Screw

Terminals

NSS Assembly on MDC

NSS with BUA

(CW = Reverse)

NSS Cavity

NSS with

Weatherpack

Control

Yolk

Cam

NSS with BUA

(CCW = Reverse)

Top View of NSS Showing Cam Positions

© Danfoss, 2013 BLN-10123 • Rev AA • September 2013 1

Page 2

Note:

Adjustment is normally required unless the function

of the NSS is changed (between i, ii, and iii).

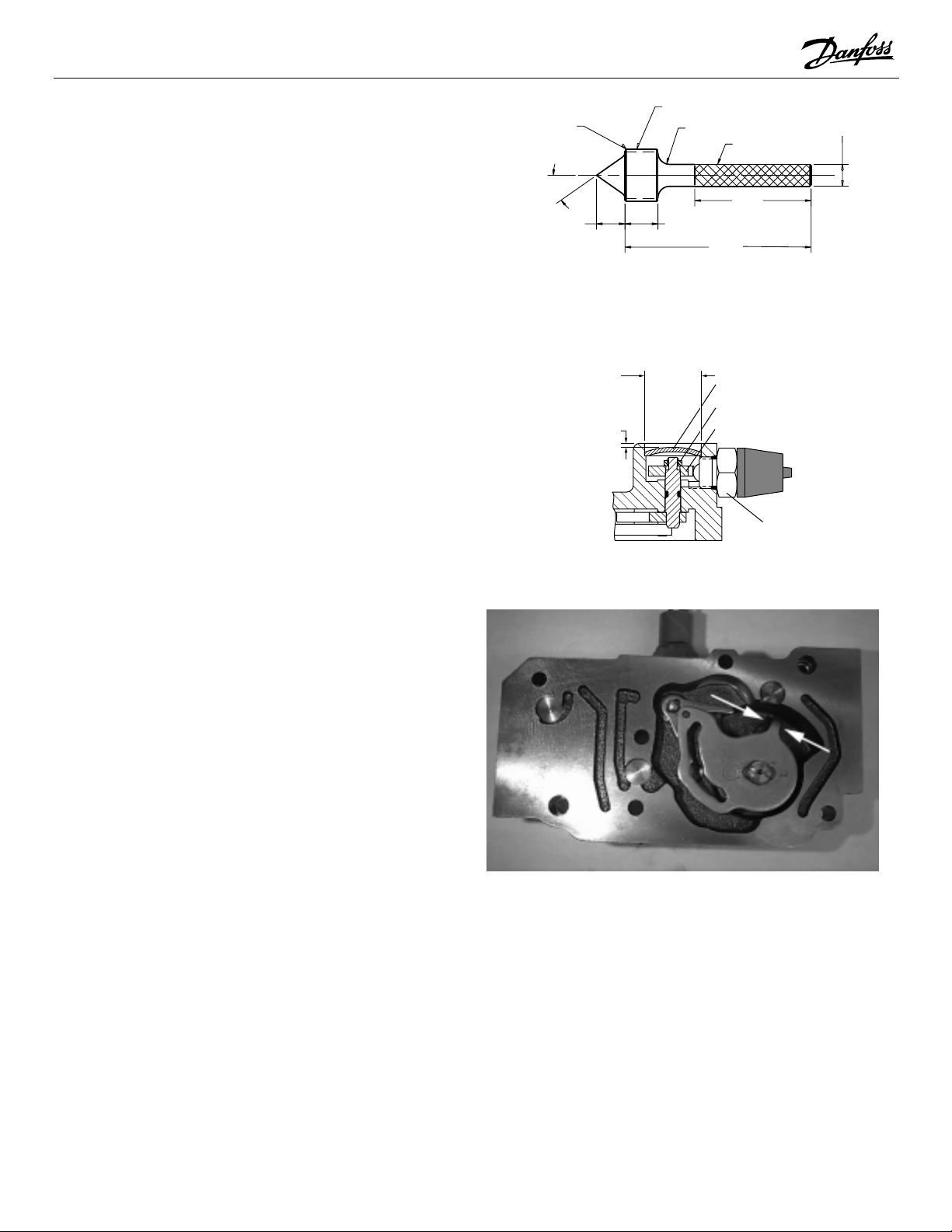

.04 x 45 Chamfer

9/16 -18UNF 2A THD

R.125

Knurl

ø .236

–.030

Adjustment of the NSS or NSS and BUA requires a special

alignment tool. Dimension are give at right.

Adjustment is performed by setting the cam positions within

the NSS assembly

1. The Manual Displacement Control (MDC) must be

removed from the housing.

2. Remove the NSS (

7

/8 inch hex).

3. Remove and discard the NSS cover by inserting a

screwdriver into the NSS cavity and popping off the

cover with a hammer. Be careful not to damage the

internal hardware.

4. Remove the control nut (8 mm hex).

5. Use a screwdriver to pop off the cam.

6. On the underside of the MDC, gently clamp a pair of

locking pliers around the spring contacts of the

control cam. Be careful not to dambe the spring

wires. The pliers should hold the nub on the control

cam to the pin underneath. This will hold the

control cam in neutral position.

7. Set cam in proper orientation according to the unit’s

configuration.

8. Screw special alignment tool in NSS cavity to hold

cam in place.

9. Place control nut on cam and torque to 4.1 to 6.8

Nm (3 - 5 ft•lbf).

10. Press new cover on top of cam cavity. This requires either an arbor

press or a full-sized punch.

The tool diameter should be 23.3 mm (0.916 in).

Press the new cover so that it sits 1.06 mm (0.0417

in) below the cast surface as illustrated at right.

11. Remove the alignment tool and locking pliers.

12. Place a new lubricated O-ring on NSS.

13. Reconnect the NSS to the MDC. Torque to 25 - 29

Nm (18 - 22 ft•lbf).

14. Reinstall MDC onto pump housing.

35.0

.306

.354

Material: .75 DIA x 3 ETD150

(All Dimensions in inches)

1.250

2.000

Alignment Tool

23.3 mm

(0.916 in.)

1.06 mm

(0.0417 in.)

NSS Cover

NSS Control Nut

NSS Cam

NSS

Side View of NSS and NSS Cavity

Underside of MDC Showing Clamping Position

of Locking Pliers

© Danfoss, 2013 BLN-10123 • Rev AA • September 2013 2

Loading...

Loading...