Page 1

Managing Harmonic Distortion with Quasi 12-pulse

■■

■ Conventional Reduction Techniques

■■

For many years, the most commonly used method for

reducing harmonic distortion caused by Variable Frequency Drives in electrical systems has been to add

AC line reactors at the drives' input terminals. This reduces the harmonic distortion to a level which will be

sufficient in most installations. There is however a

practical limit to the size of the reactors which can be

installed and therefore also to the possible reduction

in harmonics which can be obtained by using this

technique.

The reason is that the drives' ability to supply full output torque is reduced as a result of voltage drop

across the reactors. The only way to compensate

for this is to increase the current supplied to the motor. This means that the motors must be able to

manage higher currents at the same torque requirement. Larger drives may also be required. However,

this causes a waste of resources as a result of increased generation of heat. This must be considered

when dimensioning the system in order to avoid overheating.

Managing Harmonic Distortion with Quasi 12-pulse

Another well-known technique is to implement DC

reactors in the intermediate circuit. This is however

not very practical if large reactors are needed, since

these reactors would produce a lot of heat in the

drives and reduce the drives' efficiency.

In order to avoid the unfortunate side effects of AC

or DC reactors in installations where high requirements to the reduction of harmonic distortion exist,

it has become the norm in certain markets to utilise

12 pulse drives. These drives consist of two 6 pulse

rectifiers and either a phase shifting transformer in

front of one of the rectifiers or a three winding transformer in front of the combined rectifier. See Figure

1 for schematic.

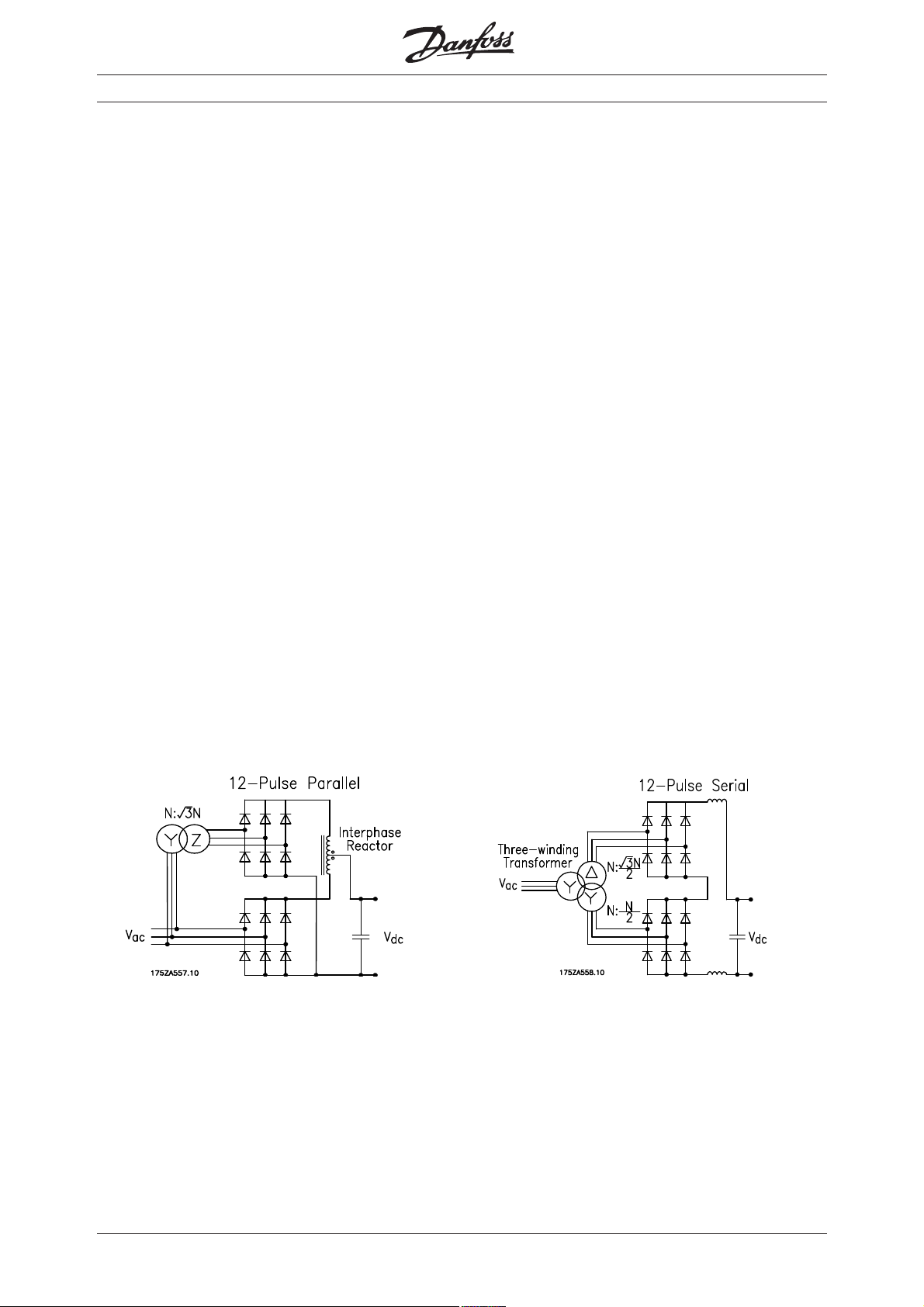

Figure 1: 12 Pulse Drives with Rectifiers in Parallel and in Series

This design provides excellent harmonic performance. The 5

celled almost completely. The two rectifiers and

either a phase shifting transformer and an interface

reactor (left solution in Figure 1) or a three winding

transformer

th

and 7th harmonic currents are can-

(right solution in Figure 1) makes this solution at least

50% more expensive than a standard drive with

built-in DC reactors. Therefore a more wide spread

use of it would mean a drastic increase in the cost per

drive installed.

MN.90.J2.02 - VLT is a registered Danfoss trademark

Page 2

■■

■ The alternative solution

■■

Managing Harmonic Distortion with Quasi 12-pulse

An alternative solution would be to use phase shifting transformers in front of 50% of the drive load and

then leave the other drives connected to the normal

mains.

The cost of this solution is only about 16% higher

than the cost of a standard Danfoss VLT frequency

converter. Since a transformer is only required on

every second drive, the total impact on the frequency converter cost is reduced to 8%. This is,

however, compared to a standard solution without

any additional harmonic filtering.

When considering this type of harmonic filtering, a

comparison with a solution where a 5% AC line reactor is used would be more realistic. This will not

nearly give the performance of the quasi 12 pulse,

but it is the largest AC line reactor which can be recommended installed in front of a Danfoss VLT Frequency Converter. A 5% AC line reactor will increase

Managing Harmnic Distortion with Quasi 12-pulse

the drive cost by approx. 2%. This means that the actual additional cost to a project would come to

approx. 6%.

The argument against this solution compared to a

true 12-pulse solution is that the balance of the

load is important to the performance, because the

improved performance is a result of the cancellation

of the 5

phase shift.

When the load is not balanced, the harmonics on

the drives with high load are not cancelled. This is

because the whole basis for the cancellation is that

the current vectors are of equal amplitude and that

the angle between them is 180°. The angle is maintained by the phase shifting transformer, but the

amplitude varies as the load decreases. When the

load only decreases on one of the drives, the length

of the vectors becomes unequal and full cancellation

is not achieved.

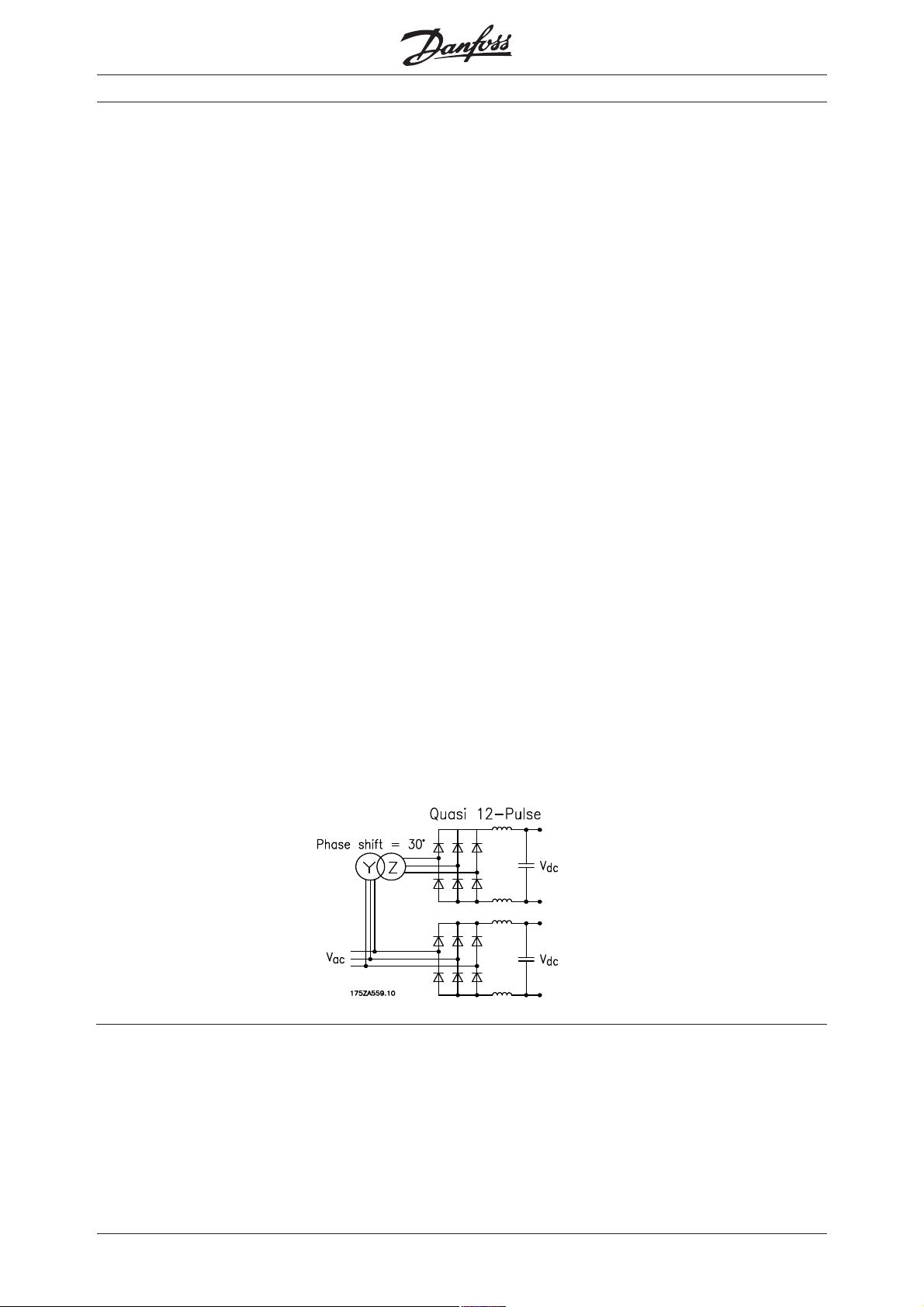

Figure 2 shows the system configuration for an installation using quasi 12-pulse. Please notice that standard 6 pulse frequency converters are used and that

the estimated load on each drive group should be as

close to equal as possible to achieve the best effect.

See the following sections to get a general impression

of the performance of quasi 12 pulse on the 2 drive

groups.

th

and 7th harmonic current due to the 30°

Figure 2: System Configuration for Quasi 12 Pulse

■■

■ Simulation of the Effects of Varying Load

■■

The research at Danfoss Drives into the significance

of load variations has revealed that there is a significant advantage to be obtained by using quasi 12

Pulse as long as all drives are above 20% load.

Whether or not the load is the same is less important.

Table 1 and Figure 3 on the following page show the

results of a simulation of the Total Harmonic Current

Distortion (THCD) as a function of the load on two

drive groups.

MN.90.J2.02 - VLT is a registered Danfoss trademark

Page 3

Managing Harmonic Distortion with Quasi 12-pulse

Table 1: Total Harmonic Current Distortion as a Function of Varying Load

Drive group 1

Load 100% 80% 60% 40% 20% 0%

100% 10.7% 11.6% 13.4% 16.7% 22.3% 37.4%

80% 10.6% 11.1% 12.4% 15.5% 21.8% 41.3%

60% 11.7% 11.5% 12.1% 14.8% 21.9% 48.6%

40% 13.9% 13.2% 13.0% 14.8% 22.8% 63.6%

20% 18.4% 17.5% 16.1% 14.7% 16.6% 88.5%

Drive group 2

0% 32.2% 34.7% 38.9% 47.0% 74.5% (100.0%)

Figure 3: Total Harmonic Current Distortion as a Function of Varying Load

100,0%

Managing Harmonic Distortion with Quasi 12-pulse

80,0%

60,0%

20%

40,0%

20,0%

0,0%

0%

Drive group 2

20%

60%

100%

100%

80%

60%

40%

Drive group 1

The impact on the Total Harmonic Voltage Distortion (THVD) in the system was also simulated under the same

conditions and the results are shown below in Table 2 and Figure 4.

Table 2: Total Harmonic Voltage Distortion as a Function of Varying Load

Drive group 1

Load 100% 80% 60% 40% 20% 0%

100% 2.3% 2.2% 2.3% 2.1% 2.2% 2.4%

80% 2.1% 1.9% 1.8% 1.7% 1.7% 2.0%

60% 2.0% 1.8% 1.8% 1.7% 1.7% 1.9%

40% 1.6% 1.4% 1.3% 1.2% 1.1% 1.4%

20% 1.5% 1.2% 1.1% 0.8% 0.7% 0.9%

Drive group 2

0% 1.7% 1.4% 1.3% 1.0% 0.7% 0.0%

MN.90.J2.02 - VLT is a registered Danfoss trademark

!

Page 4

Figure 4: Total Harmonic Voltage Distortion as a Function of Varying Load

00%

60%

Drive group 2

■ ■

■ Comments to the Simulation Results

■ ■

20%

Table 2 and Figure 4 show that the Total Harmonic

Voltage Distortion level never exceeds 5% when quasi

Managing Harmonic Distortion with Quasi 12-pulse

12 pulse is used in combination with a Danfoss drive.

This will be true in most systems as long as the transformer's drive load (in kVA) does not exceed 90% of

transformer's nominal power.

Furthermore the Total Harmonic Current Distortion will

never exceed 25% under the same conditions provided that there is a load balance between drives on

the phase shifting transformer and the drives connected directly to the main transformer which is always 1:5 or better. This does not mean that the

load on each individual drive cannot go below 20%,

only that if 50% of the drives are at no load, the

other 50% must be at least at 40% load for each of

the two drive groups.

It is a precondition for this solution to be valid that

the nominal drive load can be distributed equally between the phase shifting transformer and the drive

group directly connected to the main transformer.

Alternatively, a phase shifting transformer is connected to every second drive in the installation.

More accurate information about the voltage distortion

generated in a specific system where this solution is

used, requires a detailed simulation including the

Managing Harmonic Distortion with Quasi 12-pulse

2,5%

2,0%

1,5%

%

th

and 7th harmonics gener-

20%

40%

0%

Drive group 1

1,0%

0,5%

0,0%

80%

60%

100%

background distortion and single-phase non-linear

loads.

Knowledge about the single-phase non-linear loads

is more critical in a 12-pulse installation, since there

is no cancellation of the 5

ated by these loads. This applies to installations

where the drives are equipped with 12-pulse rectifiers as well as in installations where a quasi 12-pulse

installation is made.

Single phase non-linear loads could be equipment

such as computers, Xerox machines, faxes, fluorescent light, radios, televisions and small air-conditioners all of which use a rectifier to generate a DC

voltage supply. Some of these machines use active

filters which do not produce harmonics, but this is

not the norm yet. Also fluorescent light can have

balanced or electronic ballasts which do not produce harmonic distortion.

In installations where standard 6-pulse rectifiers are

used, the 5th and 7th harmonics generated are

counterphased to those of the single-phase loads and

background distortion. Information about the singlephase loads and background distortion is therefore

not as critical in a 6-pulse installation.

■ ■

■ Conclusion

■ ■

In installations where it is very important to achieve

low voltage distortion, quasi 12 pulse will give the

optimum results at the lowest cost.

"

MN.90.J2.02 - VLT is a registered Danfoss trademark

Loading...

Loading...