Page 1

District heating application guide

Making applications

future proof all our

knowledge – is now yours

+30

years of experience

in district heating

applications, with

more than 5 million

installations worldwide.

www.districtenergy.danfoss.com

Page 2

Structure

Recommended solution for heating systems / New construction 4

Recommended solution for heating systems / Renovation 6

1 Introduction 8

1.1 District Heating nets in China Yesterday, Today and Tomorrow 10

1.2 Common problems of the current District Heating systems in China and their causes 11

1.2.1 Heat losses in networks 11

1.2.2 Hydraulically unbalanced networks 12

1.2.3 Over specied pumps 14

1.2.4 Lack of centralized hot water treatment for DHW systems 14

1.2.5 General energy ineciency of the heat supply system 15

2 Connection to the grid 16

2.1 Central substation equipped by weather compensator, no controls in the building – direct connection of the buildings 16

2.2 Central substation equipped by weather compensator. Few buildings had Mixing units or substation at the entrance 18

2.3 Central Substations with mixing loops at each building or every connection 19

2.4 Substations in each building 20

2.5 Flat stations in each at for the same district 25

2.6 Conclusion 22

3 Direct connection of Heating system (connected via Central substations) 24

3.1 Mixing loop with Weather compensation and Combination valves for the Heating systems 21

3.2 Mixing-loop for Heating system, recommended than dP less than 2 bar 26

3.3 Mixing loop with 3-way valves to be used if the temperature in primary and secondary systems are equal 28

3.4 Mixing loop for Heating system with Weather compensation, Motorized Control Valves and Manual Balancing valves 30

3.5 Mixing loop for Heating system with Weather compensation and motorized control valves for the systems with

T in secondary side equal to T on primary side 32

2

Page 3

4 Indirect connection of Heating system (Direct connection to the primary circuit) 34

4.1 Indirect connection of Heating system with DPC and MCV. DPC play also role of Flow limiter 34

4.2 Indirect connection of Heating system with DPCQ and MCV. DPCQ secure automatic ow limitation 36

4.3 Indirect connection of HE system with PIBCV 38

4.4 Indirect connection of HE system with MBV and MCV 40

4.5 Indirect connection of heating system with MCV only 42

5 Indirect connection of Heating and Domestic Hot water systems – directly to the primary side 44

5.1 Indirect connection of HE and DHW with common DPC 44

5.2 Indirect connection of HE and DHW with DPC on each circuit 46

5.3 Indirect connection of Heating and DHW system with DPCQ on each circuit 48

5.4 Indirect connection of HE and DHW systems with PIBCV used as control valve 50

5.5 Indirect connection HE and DHW systems with no DPC 52

5.6 Heating System connected thru Central substation via DPC on the entrance 54

6 Overall classication of Direct and Indirect Heating and Domestic Hot water 56

6.1 Direct heating system connection 56

6.2 Direct heating system connection 57

6.3 Domestic Hot Water Systems / Indirect DHW system connection 60

7 Product overview 62

7.1 Weather compensators - WC 62

7.2 Motorized Control Valves - MCV 62

7.3 Actuators for MCV and PICV 63

7.4 Pressure Independent Control Valves - PICV 63

7.5 Dierential Pressure (and Flow) Controllers - DPC (DPCQ) 64

7.6 Steel manual balancing valve and Ball valves 64

7.7 Temperature controllers 65

7.8 Energy meters 65

3

Page 4

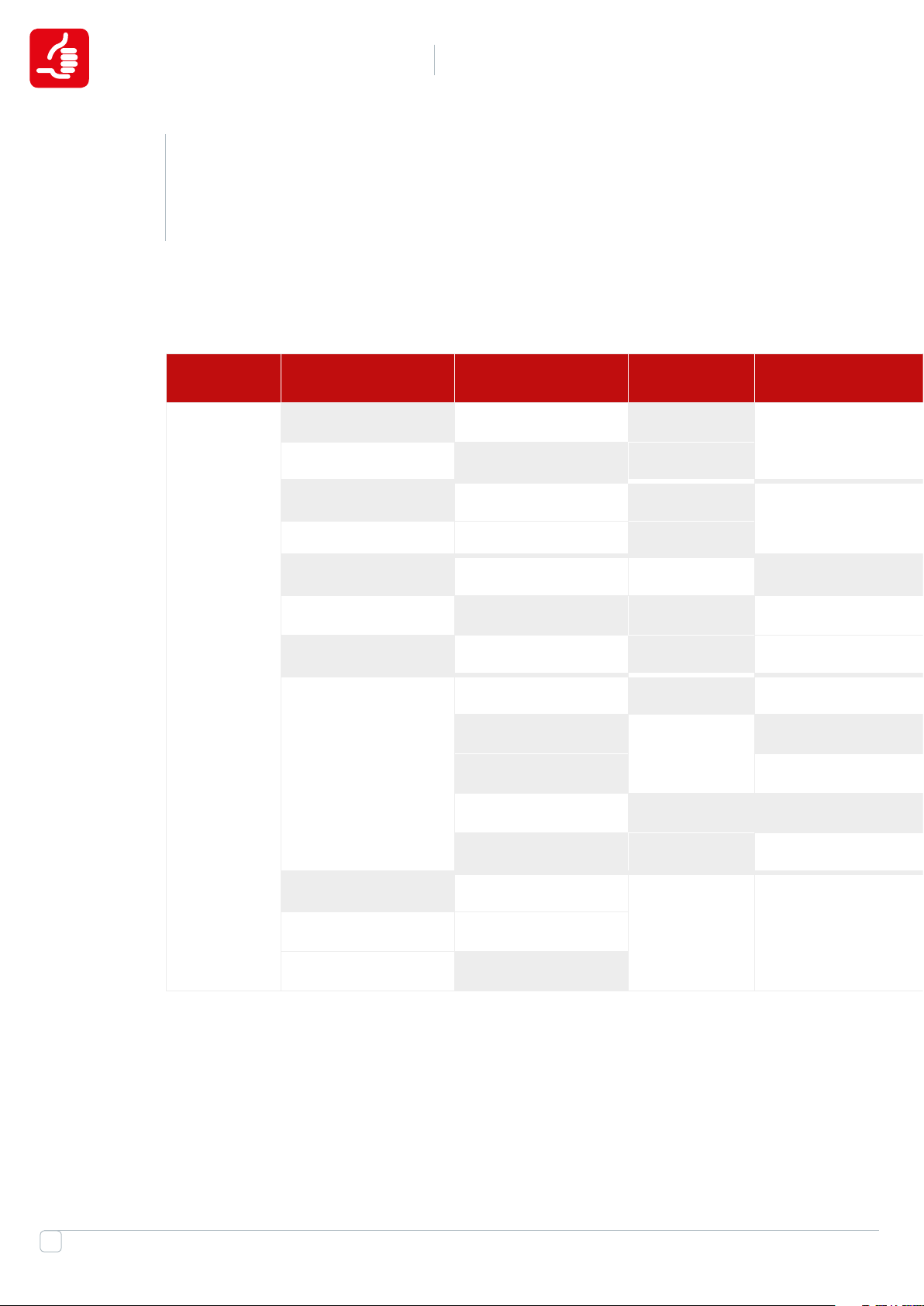

RECOMMENDED SOLUTION

Recommended solution for heating systems

NEW CONSTRUCTION

for heating systems

Source Distrubution/

transporatation

Distribution station *****

Distribution station Mixing loop FH + RT ****

Distribution station DPC Two pipe horizon + TRV ***

Heating

source

Distribution station

New construction:

Entrance of Building

Substation

Substation

Substation DPC Two pipe raise + TRV ****

Substation PIBCV Horizon / FH ***

Mixing loop PIBCV

DPC ** Up to 6 oors

Raiser Entrance of

Apartment

Flat station

DPC

DPC

MBV

PIBCV Horizon **

Substation

Distribution station Mixing loop FH **

4

DPC ON/OFF CV

Page 5

In the Apartment Recommend index Note

*****

Two pipe horizon + TRV / FH + RT

Two pipe horizon + TRV / FH + RT ****

FH ***

Two pipe raise + TRV ***

** More than 6 oors

Two pipe horizon + TRV / FH + RT

Horizon / FH **

Horizon *

Recommend index

5

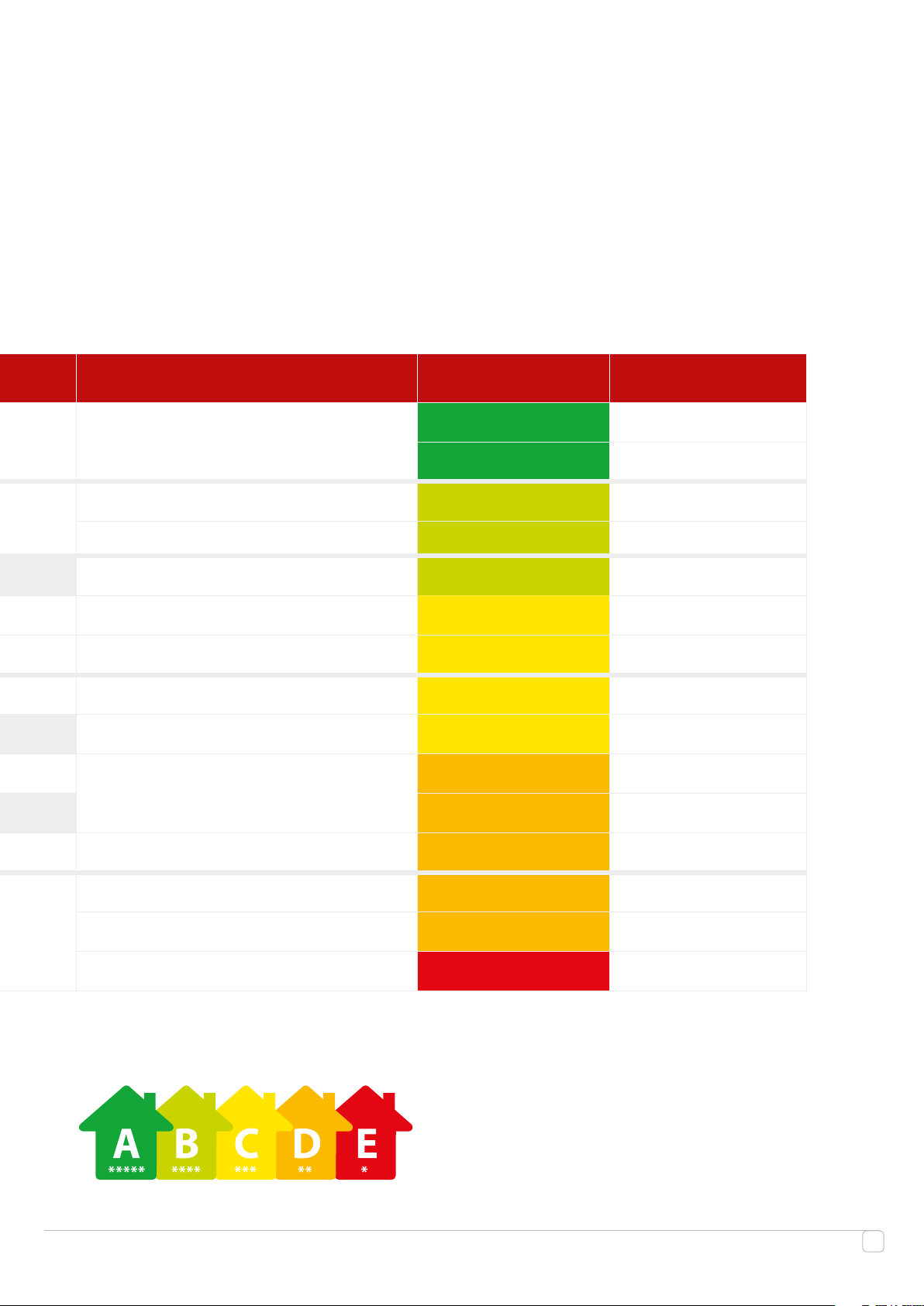

Page 6

RECOMMENDED SOLUTION

Recommended solution for heating systems

RENOVATION

for heating systems

Source Distribution and

Transportation

CHP or Boiler

house

Distribution station

Entrance of Building Raiser Entrance of

Mixing loop

DPC

Mixing loop

DPC Two pipe raise + TRV ***

PIBCV+T One pipe raise + TRV ***

DPC MBV

DPC ** Up to 6 oors

Mixing loop MBV One pipe horizon + TRV **

DPC

Mixing loop

Flat station

DPC **

Mixing loop **

DPC

DPC ON/OFF CV * Up to 6 oors

Mixing loop *

Mixing loop Riser system *

Flat station MBV One pipe raise + TRV *

6

Page 7

In the Apartment Recommend index Note

Apartment

FH + RT ****

DPC

Two pipe horizon + TRV

/ FH + RT

***

MBV FH + RT ***

PIBCV FH ***

Two pipe horizon + TRV

** More than 6 oors

/ FH + RT

PIBCV Horizon / FH **

** More than 6 oors

ON/OFF CV FH

** Up to 6 oors

**

One pipe raise + TRV

FL One pipe horizon + TRV *

ON/OFF CV with

preset

Horizon / FH * More than 6 oors

Recommend index

7

Page 8

1

Introduction

With every day it becomes more and more obvious that energy eciency is one of the main trends in

the 21st century economic development. All branches of modern industry, from microelectronics to

heavy engineering, are striving to reduce energy losses. Today there is no other way: we may just go

forward or step aside of the progress.

This may seem incredible, but it is our unbounded household power inputs that cause the global

warming. In Europe, about 40% of fuel-energy resources are consumed by communal consumers,

while transport and industry consume 32% and 28% respectively. Notwithstanding the fact that

energy saving is an integral part of public policy of Western countries for many years. First of all,

this was favoured by the energy crisis which took place in 1970s and signicantly aected those

countries. Last year’s many of developed countries have achieved signicant results in this eld. In 25

years, they turned from consumers into suppliers of energy resources, rising to the rst places in the

world in energy eciency.

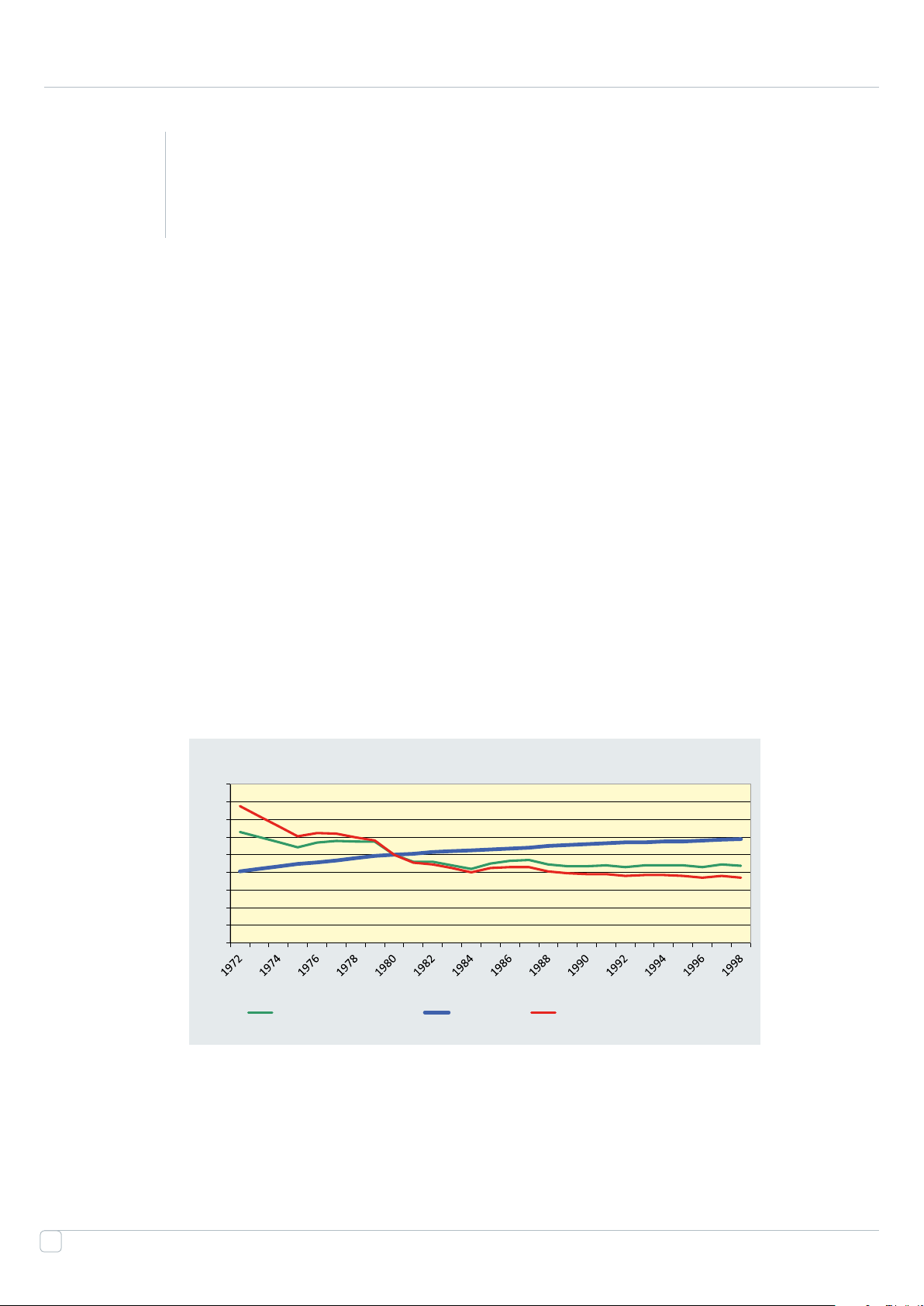

Index: 1980 = 100

180

160

140

120

100

80

60

40

20

0

Total energy consumption Heated area Energy consumption per m2

Figure 1:

8

Page 9

Realizing that in future, high energy costs will be necessary to maintain high rates of growth, the

China Government has begun to implement a large-scale plan of radical increase of energy eciency

and decrease of fast-growing demand for coal from energy-consuming industries. For each level

of the government administration a target for decrease of energy consumption, which must be

achieved, is set. In addition to that, the Government has begun to implement a "large-scale program

of closing of ineective companies". Eorts, which China applies, striving to raise its energy ecien-

cy, are probably the most resolute ones among those that have been ever applied in this eld by any

country. They will be discussed for years. But in spite of this trend there are several other problems,

for example, in heat-power engineering, particularly concerning heat distribution. Unfortunately,

the current condition of heat networks is far from the ideal, while it is not possible to carry out the

necessary replacements instantly. In this book, the main issues will be discussed and solutions,

related to Danfoss, its equipment and experience, will be proposed.

9

Page 10

1.1

District Heating nets in China

Yesterday, Today and Tomorrow.

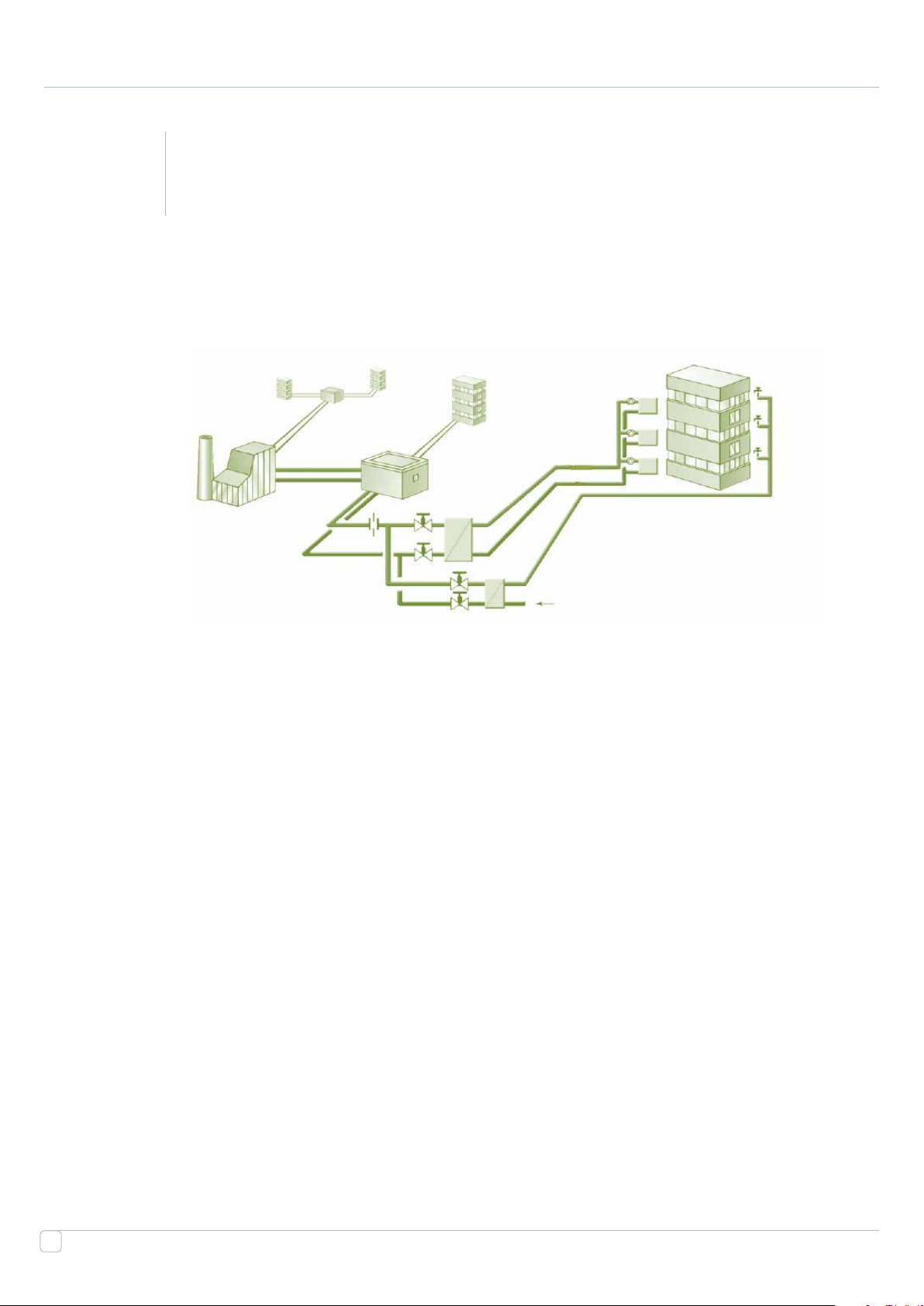

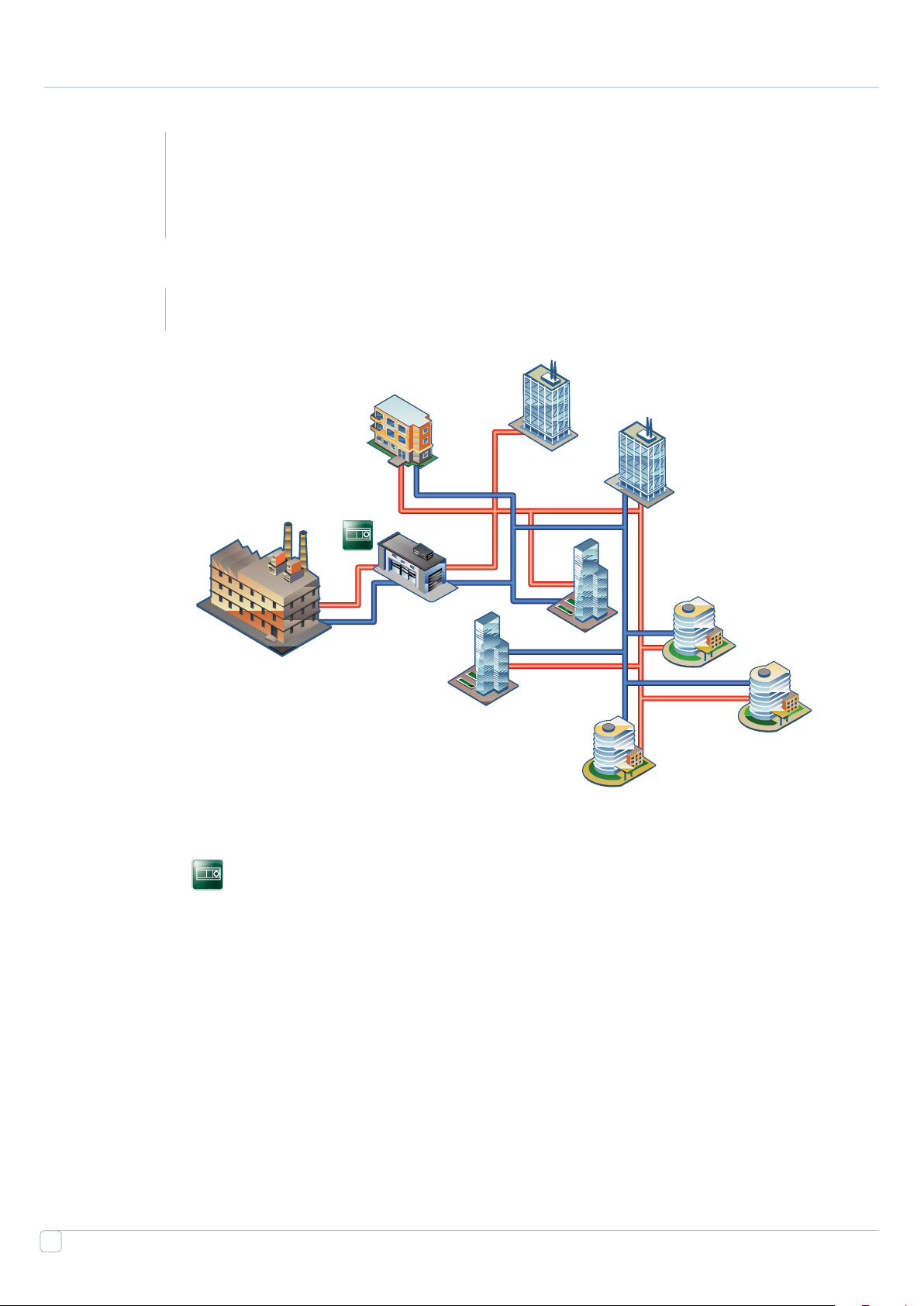

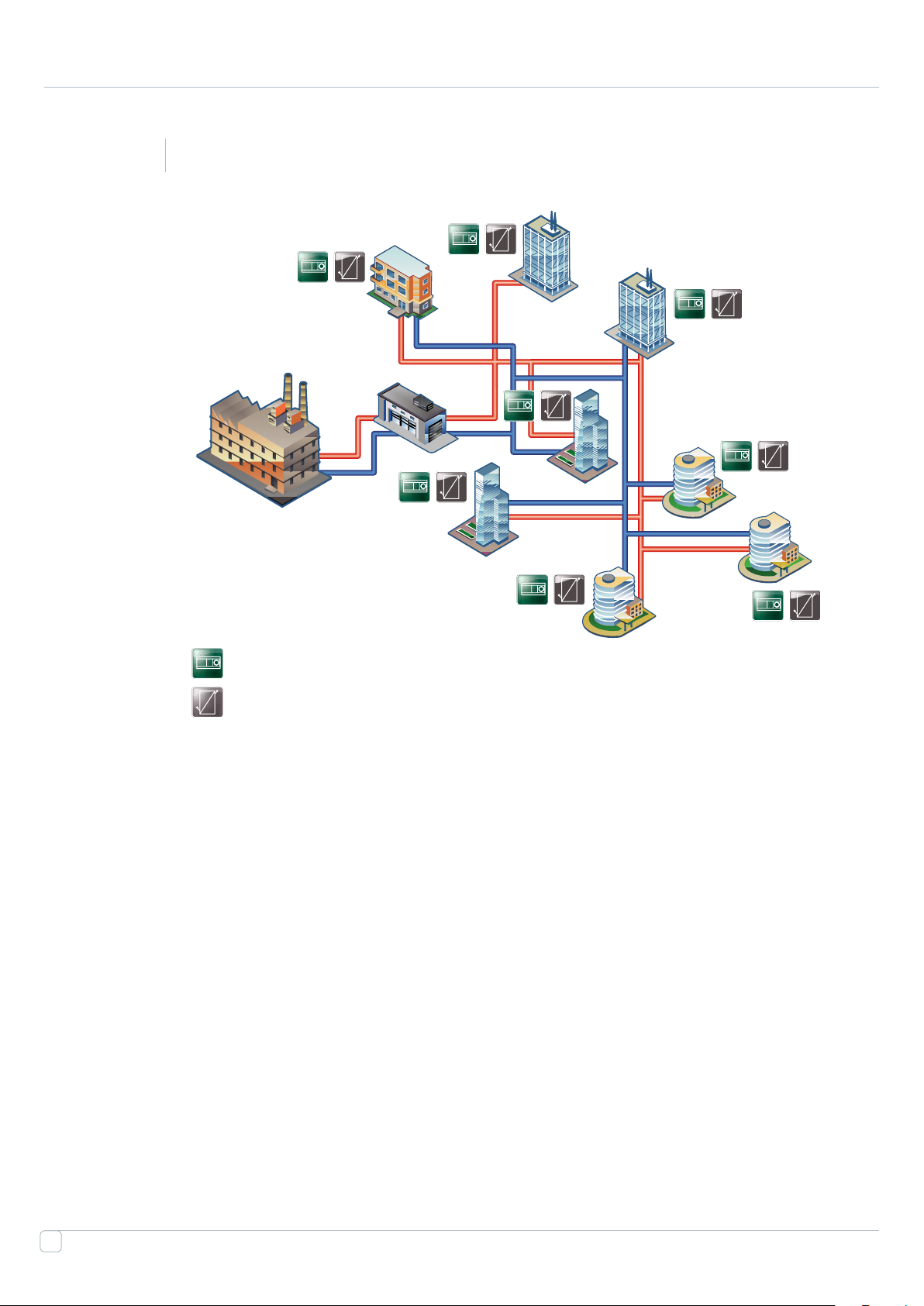

Connection of the building to the grid designed at 80ths old constructed District heating systems with network

structure as presented on the pic. 2 still have a high presence on the market.

Distribution

station

Building sub-

Source

station

Figure 2: District heating network

A brief overview of old District Heating Nets can be characterized by following:

• Weather compensated temperature control only at the heat source (combined heat power plants, boiler

installations)

• High level of heat losses

• High cola consumptions

• High demand for better water treatment

• Constant ow in primary and secondary circuits.

• Overspecied pumps

• Excessive consumption of heat and electric power

• Lack of comfort conditions for end-users

• High return temperature on Primary Side

• Hydraulic unbalance

• Energy ineciency

Domestic hot water system (DHW)not-connected to the District heating system and prepared by electrical /gas

10

boiler. In the regions Solar panels also used for DHW systems

Page 11

1.2

Common problems of the current District Heating

systems in China and their causes.

1.21

Heat losses in networks

Generally, the heat networks has been designed and constructed in 80s years of the last century. Since then

constant economic growth and industrial development required continual construction of new networks, while

the old ones practically were not reconstructed. Total heat losses reach ~ of the consumer heat load.

It is possible to distinguish two components of heat losses:

Heat losses

Leakage

Figure 3: Type of heat loses

Losses due to leakages:

This issues caused by all-round wearing of the heat networks. Corrosion makes holes in pipeline walls, bad seal

Loses from surface -

non insulated

in valves and between ange connections, which results in leaks.

Losses from pipeline surfaces:

Heat network pipelines are made of steel, which is an excellent thermal conductor. As it can be seen from the

following expression, this type of losses depends on a number of factors; among those are thermal conductivity

of the material and the dierence between the external air and the heat carrier temperatures.

Q =λ· (t1– t2) · F.

Lack of insulation, as well as the heat carrier temperature in the supply pipe, which is as high as 130 C, results in

2

heat losses of ~ Gcal per m

Insulation of the pipeline and decrease of the operating parameters allows lowering the losses down to ~ per

1 running meter

Conclusion:

Total heat losses reach 273 million Gcal per year, which amounts to 34.745 billion RMB in cash equivalent.It is

11

Page 12

impossible to solve the issue by mere replacement of pipelines: this will require huge manpower,

material and time resources. Measures, which can be taken now, are reduction of the temperature

curve and all-round insulation of pipelines. This will signicantly reduce the heat losses and grant

additional time, required for gradual reconstruction and replacement of heat networks.

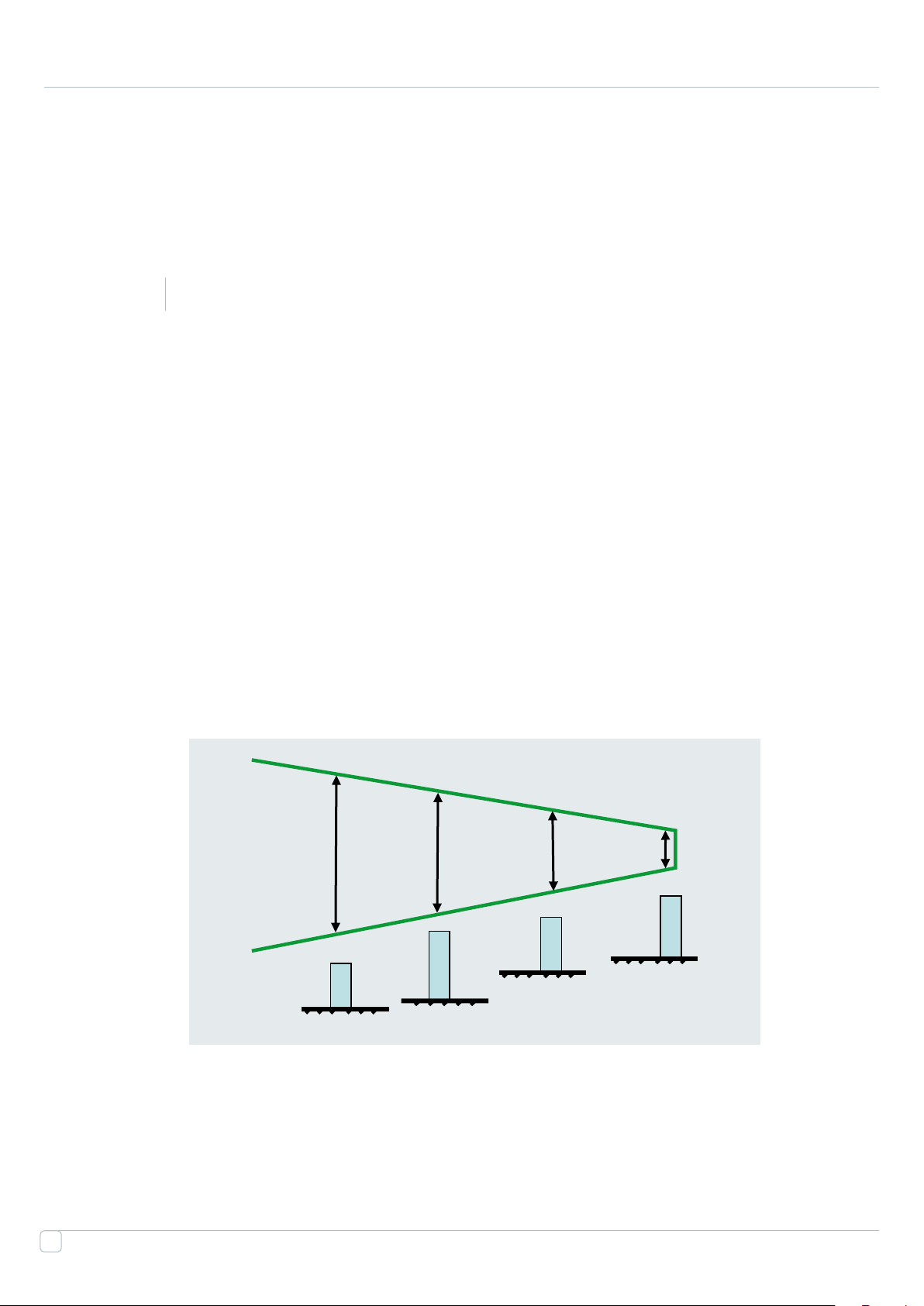

1.22

Hydraulically unbalanced networks

Present-day heat supply systems of residential, production and administration buildings are con-

nected to heat networks via central substations. Consumer heat loads are unstable and, as a result of

quantity and quality regulation, which takes place at the heat source. This is a serious issue obviously

take place in heavily branched heat networks, due to their unbalance. Function of limitation of

maximal heat carrier ow by end consumer is also quite hard to implement.

Currently, hydraulic balancing of a heat network is carried out at the design conditions by means of

throttling orices or, at the best, by means of manual balancing valves or circulating pumps with

variable frequency converters. Resistance of the latter can be calculated by the following expression:

However, it is impossible to achieve balance between the quantity and quality regulated heat

network and consumers by means of the throttling devices, because as the ow changes from G1

to G2, hydraulic resistance of an orice or a manual balancing valve, which have constant hydraulic

characteristics (Kv), changes as square of the ow.

12

ΔРа ΔРb

А

ΔРc ΔРd

С

В

D

Figure 4: Standard piezometric diagram

Orices and manual valves can be used for balancing in systems with constant ow only. Quantity

and quality regulation in heat networks balanced by means of these devices results in oating piezo-

Page 13

metric curve and, as a consequence, variable local pressure drops at building connection.

Similarly, usage of circulating pumps with variable frequency converters does not meet the expectations laid

on it. Indeed, total pressure of an unbalanced network does not change; excessive pressure and ow (which are

built up locally as the result of operation of automatic equipment and local decrease of the heat carrier ow)

are simply redistributed to the nearest objects. Thus variable frequency driving actuators do not perform their

primary function

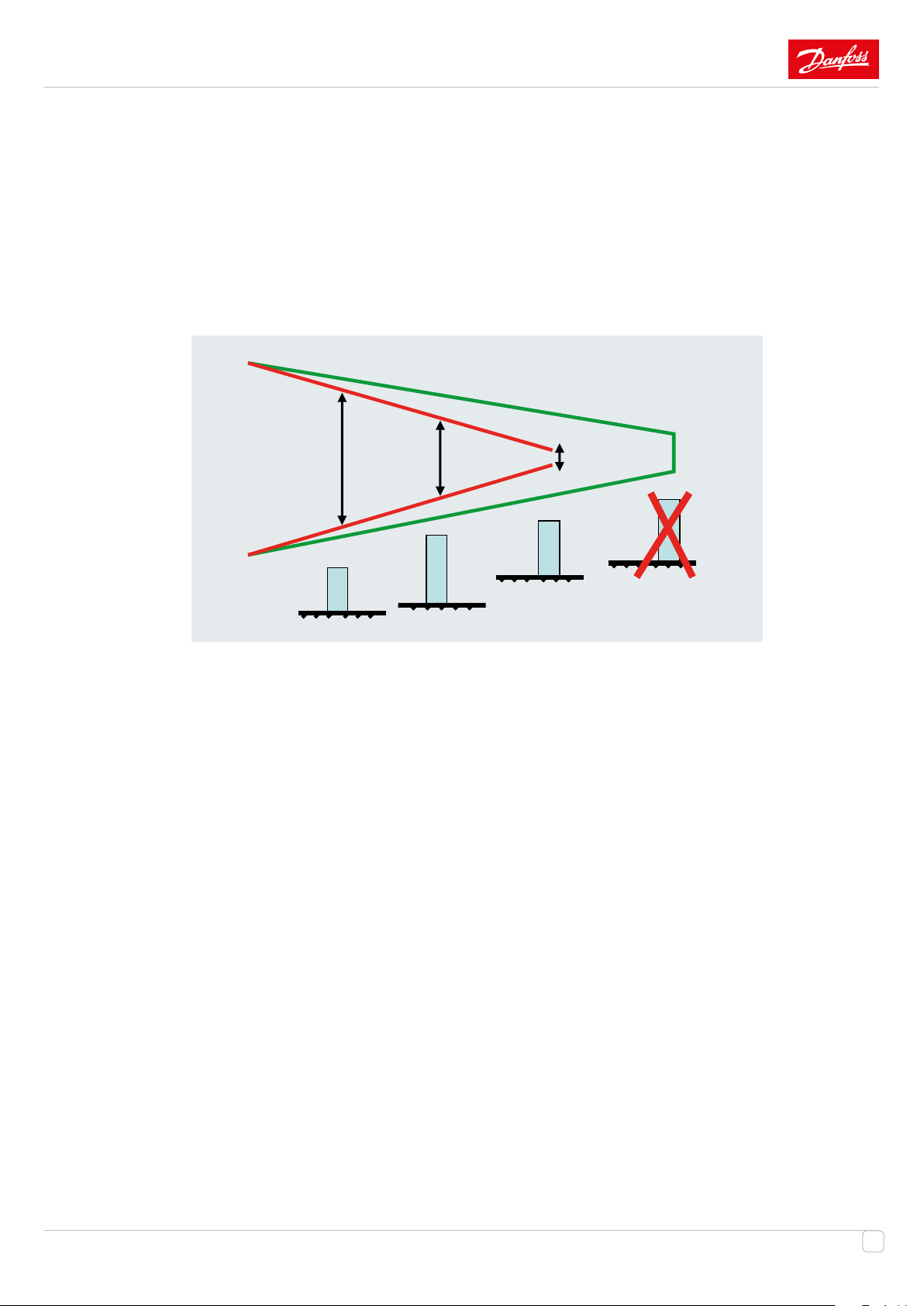

ΔРа

ΔРb ΔРc

В

А

С

ΔРd=0

D

.

Figure 5: Piezometricschedulefor peakheat loadsperiod

Existence of the oating piezometric curve makes it impossible to limit the maximal ow by means of orices

and manual balancing valves. Limitation of maximal ow, as well as hydraulic balancing of systems with varia-

ble ow can be carried out by means dierential pressure controllers only. Such controllers are capable to main-

tain the stable pressure drop in the regulated variable ow system. In case of increase of the input pressure they

ensure stable limitation of the maximal heat carrier ow. With usage of such controllers, "internal" hydraulic

balancing of heat networks at every central substation and building substation is no longer required. Orices

and manual balancing valves can be removed from pipelines: balanced distribution of the heat is achieved due

to additional hydraulic resistance of the DP controllers located at heat stations in each building.

Dismissal of quarterly balancing of heat networks invalidates the piezometric curve (there is no more local loss-

es at orices and manual balancing valves), the former "problem" objects receive local pressure drop required

for their operation. In centralized thermal supply systems these measures lead to signicant economic eect.

Circulation pumps of the heat networks instantly obtain the required pressure. Such heat power reserves make

it possible to connect additional consumers to the existing networks without considerable capital costs.

13

Page 14

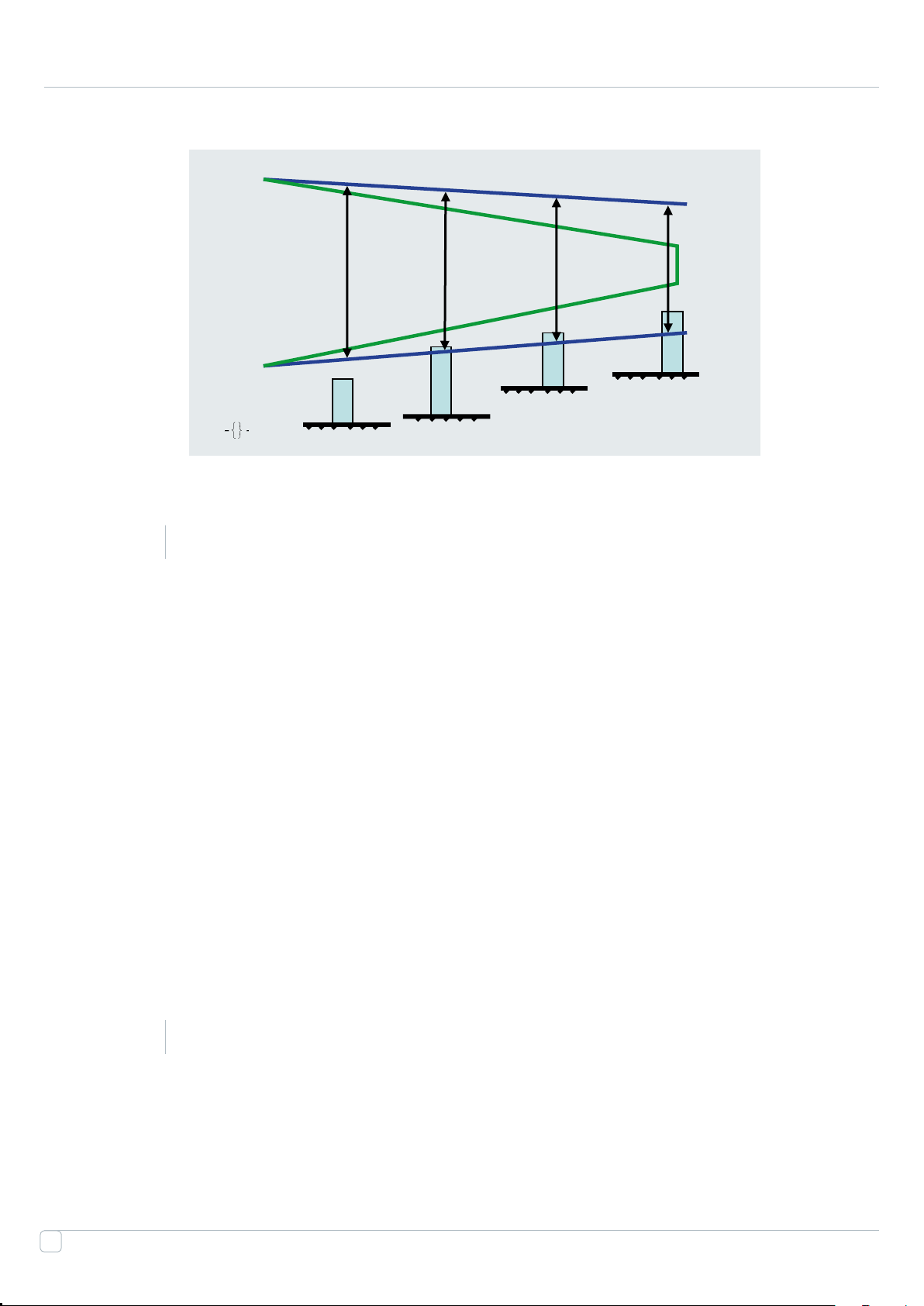

ΔРа ΔРb ΔРd

А

В

ΔРc

С

Figure 6: The reduction of the circulationowinheating systems

D

1.23

Over specied pumps

Another important issue, which requires attention, is over specied pumps installed at the heat

source thermal chambers and central heat supply stations. What is the reason of this problem? Why

does it have an negative inuence? The pumps are selected in assumption that the most distant

consumer must receive the heat carrier at the maximal ow, i.e. taking into account the maximal

hydraulic resistance. As the result, consumers located closer to the heat source or the central heat

supply station experience signicant "harmful" pressure, which must be decreased (wasting of

energy). Large safety factors stipulated by the network design are also not always useful. An over

specied pump operates in non-optimal conditions, which lowers its eciency (ref. the gure

above), increases electric energy consumption, decreases the life-time and heightens the noise level.

Currently, more and more systems are transferred to dynamic model of operation, and installation of

variable frequency converters becomes a requirement. If it is not possible to replace the pump itself,

the frequency converter will maximally optimize its operation in various operating modes.

In addition to all the mentioned above, usage of Overspecied pumps results in increase of capital

and operating costs.

14

1.24

Lack of centralized hot water treatment for DHW systems

Currently, only local water heaters installed directly in consumers' buildings are used. This results not

just in increased consumption of electric energy and gas, which can be used much more eectively.

It is well known that heating is not needed in summer, and the corresponding network pipelines are

Page 15

drained. As the result, internal pipe surface contacts with air, which speeds up corrosion in several times, which,

in turn, ruins leak-proofness of the pipes and increases heat losses resulted by leaks.

1.25

General energy ineciency of the heat supply system

All the above mentioned issues make a common image of the situation. Unfortunately, it is necessary to state

that the heat supply system stays generally inecient in spite of the eorts being applied. Renewal and recon-

struction of the large-scale systems require huge amounts of resources: time, money, manpower. Besides, the

problems of the heat supply system aect the allied industries:

Electric power industry (additional loads: water heaters in buildings, pump driving actuators)

Mining operations (additional loads: fuel for combined heat power plants and boiler installations)

Objective set by the Government of China is real and achievable. The future and economy of the country

depends on achievement of this objective. Yes, the capital costs are relatively high, however, in 5 - 10 years

benets of the modernization will signicantly exceed this value and open new horizons of development.

Danfoss has capabilities, experience and complete solutions which solving these issues. Some solutions,

described below, are widespread in Europe and also in Russia. Advantages of Danfoss' solution is:

• Decreased environmental impact,

• Energy saving,

• Decreased pay-back time,

• Improved comfort for tenants.

15

Page 16

2

2.1

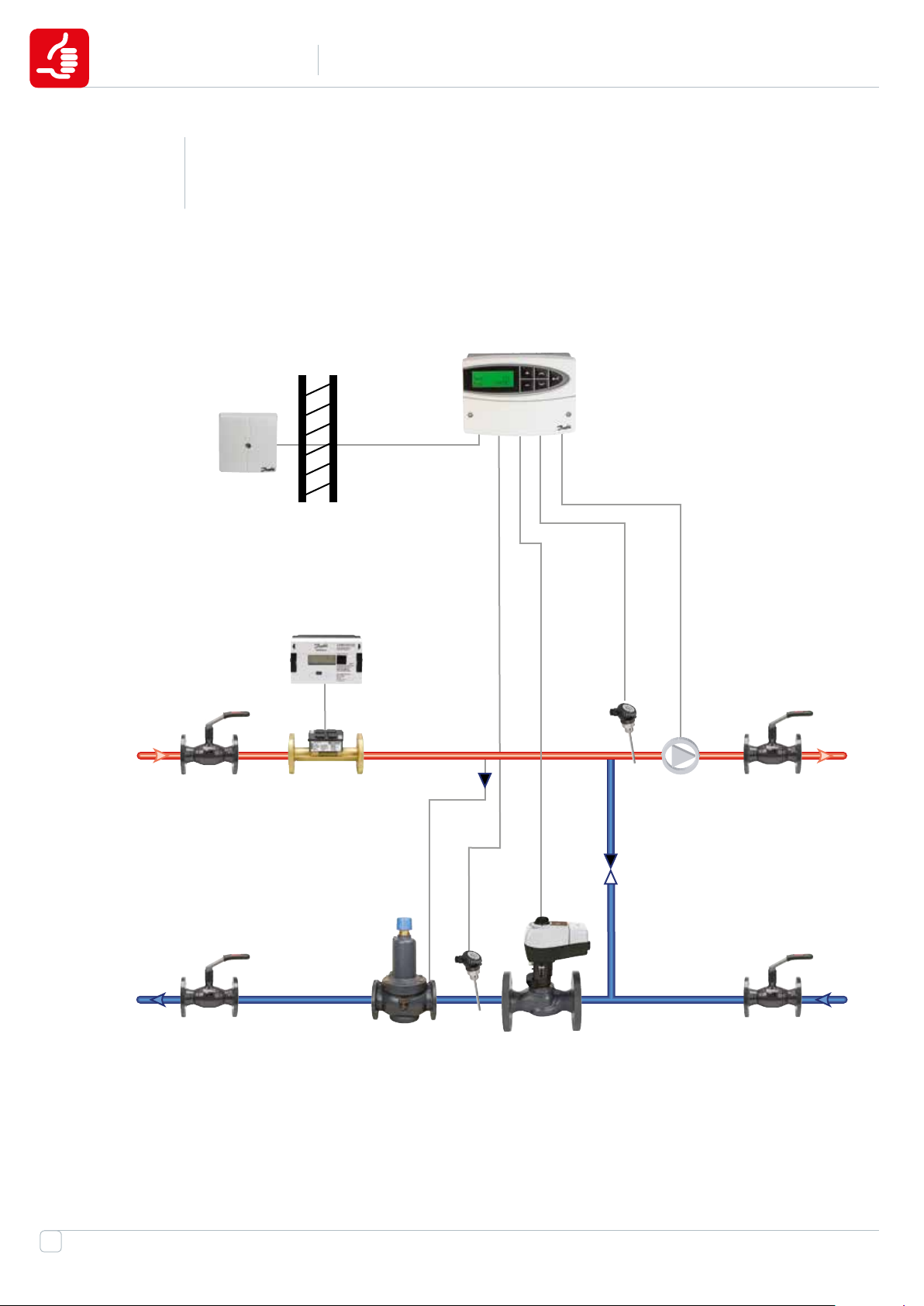

Connection to the grid

Central substation equipped by weather compensator, no controls in the building – direct connec-

tion of the buildings

16

Weather Compensation

Page 17

One of the solution,

Weather compensated temperature control at the heat source (combined heat power plants, boiler

installations)

• Weather dependent temperature control at central substations

• Local temperature control: thermostats installed on end consumers' radiators

• Variable ow in primary and secondary circuits.

• Manual balancing valves at building connections

• Domestic hot water system not connected to the District heating system and prepared by electri-

cal /gas boiler. In the regions Solar panels also used to control the water

The main disadvantage of such model is that the consumer is provided with sucient amount of

heat only in case the necessary specications of the network and the heat source are precisely met

and constant (because consumers are unable to adjust ow and, consequently, temperature)

Such model could be deemed viable earlier, prior to total upgrade of heat sources, Heat networks

and heating systems. However, usage of such models gets more and more undesirable. Consumers

and the Heat network experience almost all the problems mentioned above, like:

• Excessive consumption of heat and electric power

• Excessive temperature of the returning heat carrier

• Hydraulic unbalance

• Energy ineciency

• High rates of corrosion in the summer months

17

Page 18

2.2

Central substation equipped by weather compensator. Few buildings had Mixing units or

substation at the entrance

Weather Compensation

The second case is inseparably linked with progressive partial automation of buildings and end users, which,

as it was mentioned in section 1, threatens the whole system. Weather compensators close and open valves

in order to achieve the conditions conformable for the user. If such consumers become too large in number,

the other consumers become aected. Consumers not equipped with automation or even Dierential pressure

controllers may face with the following diculties and problems:

• Increase of pressure in return pipelines

• Pressure oscillation

• Overheating of premises

• Insucient heating

18

Page 19

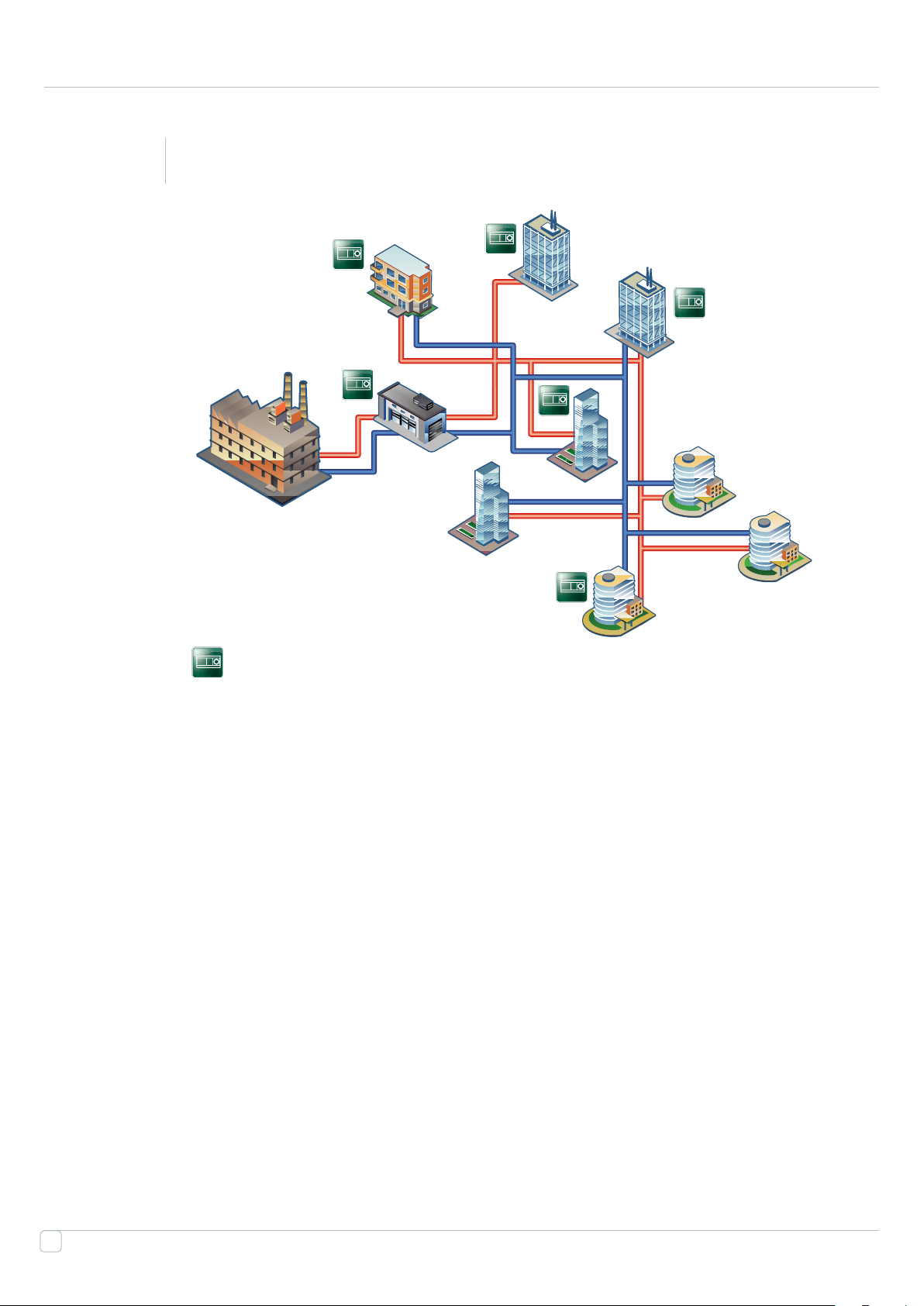

2.3

Central Substations with mixing loops at each building or every connection

Weather Compensation

For the renovation of the District Heating Nets, one of the compromised solutions might be installation in each

building the mixing loops for Heating system with keeping the Central Substations for the group of buildings.

Temperature and heat controlled based on the weather compensation principle to the consumer (right in the

building) compare to the previous solutions. Thus lead to increased energy-eciency and energy savings on the

level of 15-20%.

PICV or combination of DPC + MCV secure the hydronic stability, ow limitation and reduce the risk for cavita-

tion and pressure oscillations in the system. Needles to mark that by using DPC, hydronic stability achieved as

for primary as for secondary sides.

19

Page 20

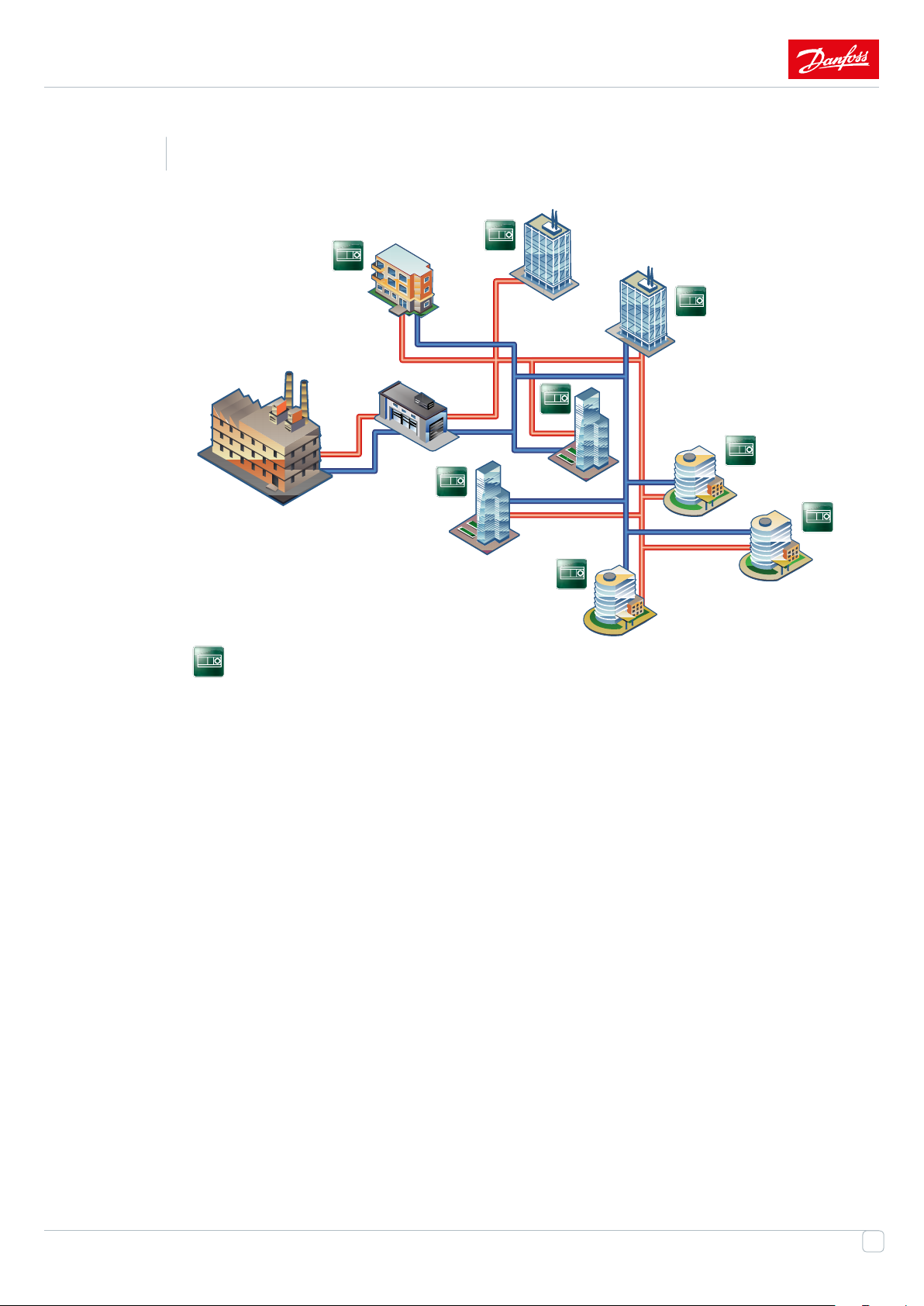

2.4

Substations in each building

Weather Compensation

HEX

Indirect connections are used regardless of pressure value in the point of connection to the Heat network, which

means that such models are versatile. Hydraulic insulation between the heating systems and the Heat network

signicantly raises reliability of thermal supply systems, protects local systems from increase and decrease of

pressure in the Heat network, and allows keeping water in the heating system in case of emergency, because it

is prevented from freezing due to circulating pumps operation..

For consumer benets are:

• Comfort parameters due to the weather compensation

• Stable and accurate controls of parameters as in on the secondary as on primary sides

• Independence of system from other buildings

• HIGH energy eciency – for heat and for electricity

• HIGH energy savings – up to 25%

20

Page 21

2.5

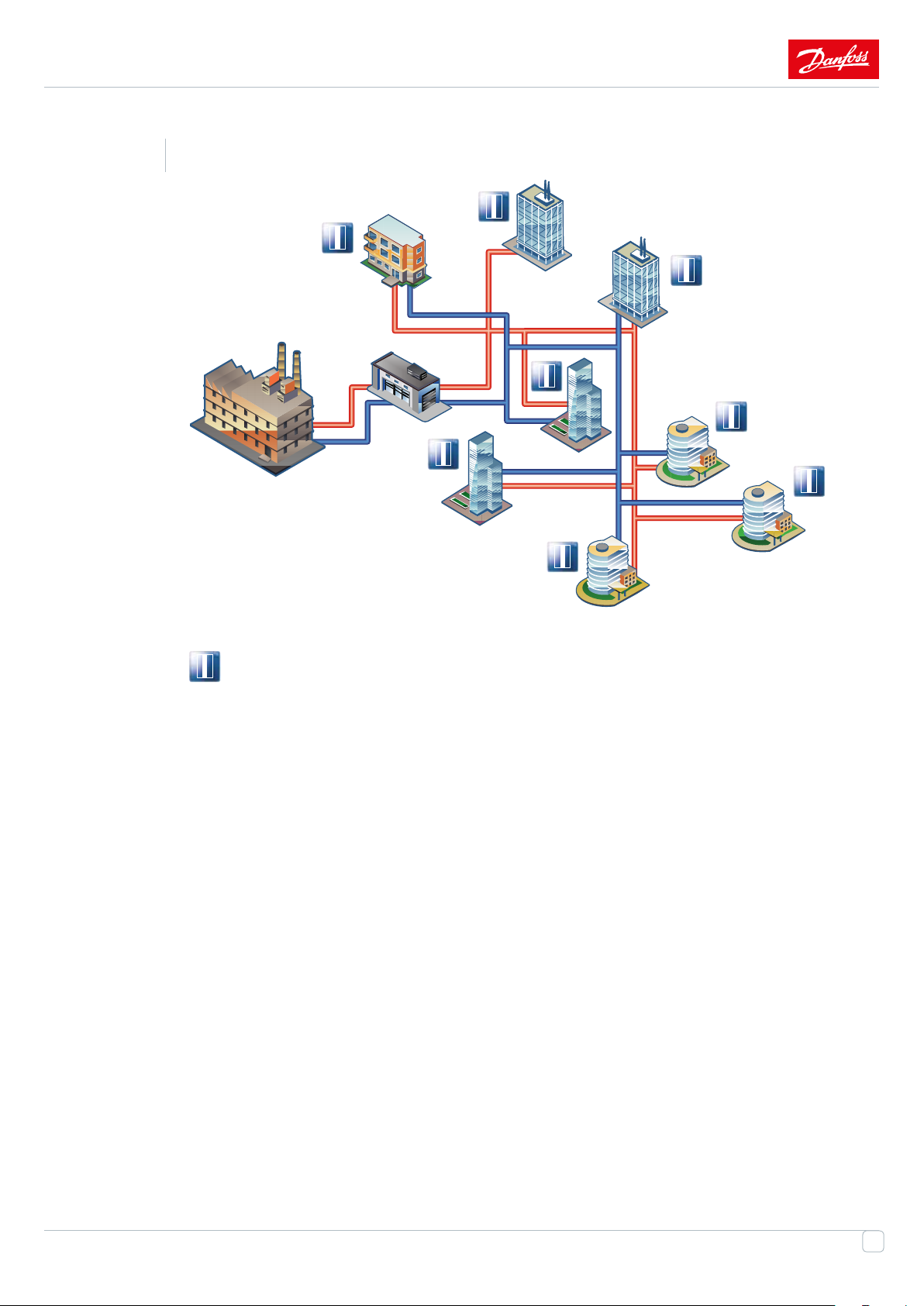

Flat stations in each at for the same district

Icon of Flat station

The decentralized heating system comprises an installation, for which at stations built into each apartments

that are supplied from a central energy source. These units normally incorporate a compact plate heat ex-

changer, which delivers instantaneous DHW on demand and a dierential pressure control valve to control the

heating ow to the tenants’ radiators or oor heating.

The essence of decentralized heating systems is in moving certain processes from the central substation to the

individual ats.

In order to secure optimum system performance of the at station it is important to dimension the system

correctly. A dimensioning tool provided by Danfoss provides an easy way for correctly dimensioning the at station.

Ref: eFlat dimensioning tool at danfoss.com

Decentralized systems can operate with all available energy sources. The most frequently used are either an

indirect DH substation, any other directly connected substation or boiler installation. All the sources can be

combined with solar.

The benets of having a at stations compared to traditional systems include

• Accurate individual energy metering

21

Page 22

Space-saving and easy to install

•

• Increased energy eciency through improved system operation and low operational

temperatures, suitable for low temperature systems

• Hydraulic balance in the system

• Reduced maintenance costs due to simple and reliable technology

• Individual setting of room temperature and independent instantaneous DHW preparation in

sucient quantities provides maximum comfort

• Independency of energy source

2.6

Conclusion

Objective set by the Government of China is real and achievable. The future and economy of the

country depends on achievement of this objective. Yes, the capital costs are relatively high, howev-

er, in 5 - 10 years benets of the modernization will signicantly exceed this value and open new

horizons of development.

Danfoss has capabilities, experience and complete solutions which solving these issues. Some solu-

tions, described below, are widespread in the world. . Advantages of Danfoss' solution:

• Decreased environmental impact,

• Energy saving,

• Decreased pay-back time,

• Improved comfort for tenants.

Classication of solutions Level of energy-eciency

No control Very low

Control in few buildings LOW

CHP with ML MEDIUM

IHP HIGH

Flat stations in each apartment VERY HIGH

22

Page 23

23

Page 24

RECOMMENDED*

Direct connection of Heating system

Application

3

3.1

(connected via Central substations)

Mixing loop with Weather compensation and Combination valves for

the Heating systems

ECL

TS

HM

BV

BV TS

TS

BV

PICV

BV

24

Page 25

System analysis

Design / Sizing

1

• SIMPLIFIED HYDRONIC CALCULATION REQUIRED

• Pump head calculation according nominal ow

• Place on Pump installation depends on Static pressure in the net and

system

Operational cost

2

• Limited operational cost due to unstable hydraulic balance (no stabiliza-

tion of DP)

• Low periodical Check-up costs due to the limited amount of equipment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

Investment

3

• Investment cost – LOW (Weather compensator +combined valves )

• Installation cost – VERY LOW

• Commissioning cost for weather compensator and combi-valve - ME

DIUM

4

5

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation and low

• LOW RISK OF OVERFLOW due to the ow limitation on combi valves,

• HIGH HEAT CONSUMPTION than outside temperature higher than calcu-

lated

Control stability

• Stability at full load, and very good stability on partial load

• MEDIUM risk of emergency – internal Dp controller in PICV protect sec-

ondary side from pressure uctuations on primary side

• LOW RISK of pressure oscillation in DH Nets due to the integrated DPC in

PIBCV

• LOW RISK FOR CAVITATION

25

Page 26

RECOMMENDED*

Mixing-loop for Heating system, recommended than dP less than 2

3.2

bar

Application

ECL

TS

BV

BV

HM

DPC

TS

TS

BV

BV

MCV

26

Page 27

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPC

• PLACE OF THE DPC AND MCV INSTALLATION DEPENDS ON THE CUR

RENT PIEZOMETER

• Pump head calculation according nominal ow

• Place of pump installation depends on available dierential pressure

Operational cost

2

• LOW operational cost due to stable hydraulic balance (stabilization of dP)

• MEDIUM periodical check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• MEDIUM amortization costs due to amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM

• Installation cost – MEDIUM

• Commissioning cost for weather compensator and combi-valve -

MEDIUM

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation

• LOW RISK OF OVERFLOW due to the ow limitation obtained by special

presetting procedure of DPC

Control stability

• Stability at full load, and very good stability on partial load

• LOW risk of emergency – DPC protect secondary side from pressure uc-

tuations on primary side

• LOW risk of pressure oscillation in the DH net due to the DPC

• LOW risk for cavitation

27

Page 28

RECOMMENDED*

3.3

Application

Mixing loop with 3-way valves to be used if the temperature in

primary and secondary systems are equal

ECL

TS

HM

DPC

BV

BV TS

MCV

BVTS

BV

28

Page 29

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPC

• PLACE OF THE DPC INSTALLATION DEPENDS ON THE CURRENT

PIEZOMETER

• Pump head calculation according nominal ow

• Place of pump installation depends on available dierential pressure

Operational cost

2

• Low operational cost due to stable hydraulic balance (stabilization of dP)

• Medium periodical check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• MEDIUM amortization costs due to amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM

• Commissioning cost - HIGH for weather compensator and DPC

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation

• LOW RISK OF OVERFLOW due to the ow limitation obtained by special

presetting procedure of DPC

Control stability

• Stability at full load, and very good stability on partial load

• Low risk of emergency – DPC protect secondary side from pressure uc-

tuations on primary side

• Low risk of pressure oscillation in the DH net due to the DPC

29

Page 30

ACCEPTABLE*

Mixing loop for Heating system with Weather compensation, Motor-

3.4

ized Control Valves and Manual Balancing valves

TS

Application

ECL

SMBV

BV

HM

TS

MCV

BV

TS

BV

30

Page 31

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV: Kvs and authority of

the valves

• Presetting calculation of Balancing valves is needed

• Pump head calculation according nominal ow

• Place on Pump installation depends on Static pressure in the net and

system

Operational cost

2

• HIGH operational cost due to unstable hydraulic balance (no stabilization

of DP)

• Medium periodical Check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM (control valve + Weather compensator +

Manual Balancing valves) installation cost - MEDIUM

• Commissioning cost – AVERAGE for weather compensator and balancing

valves

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation and max

ow limitation

• RISK OF OVERFLOW due to the ow limitation by balancing valve

• HIGH HEAT CONSUMPTION than outside temperature lower

Control stability

• Stability only at full load, but on partial load VERY LOW

• HIGH risk of emergency – non protection of secondary side from pressure

uctuations

• VERY HIGH risk of cavitation

• HIGH risk of pressure oscillation in DH Nets

31

Page 32

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED*

Application

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

Mixing loop for Heating system with Weather compensation and

3.5

motorized control valves for the systems with T in secondary side

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

equal to T on primary side

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

ECL

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

HM

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED .RECOMMENDED NOT RECOMMENDED

32

BV

MCV

BV

Page 33

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV: Kvs and authority of

the valves

• Pump head calculation according nominal ow

• Place on Pump installation depends on Static pressure in the net and

system

Operational cost

2

• HIGH operational cost due to unstable hydraulic balance (no stabilization

of DP)

• MEDIUM periodical Check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM (control valve + Weather compensator +

pump)

• Low installation cost - - MCV + Strainer + shut-o valves

• Low commissioning cost for weather compensator

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation

• HIGH RISK OF OVERFLOW due to the lack of ow limitation (no hydraulics

balance products on the loop),

• HIGH HEAT CONSUMPTION than outside temperature higher than

Control stability

• LIMITED stability, only in case when ow on secondary side is const. and

pressure on primary is also stable

• HIGH risk of emergency – non protection of secondary side from pressure

uctuations

• HIGH risk of pressure oscillation in DH Nets

• VERY HIGH risk of cavitation

33

Page 34

RECOMMENDED

Indirect connection of Heating system

Application

4

4.1

(Direct connection to the primary circuit)

Indirect connection of Heating system with DPC and MCV. DPC play

also role of Flow limiter

ECL

TS

34

BV

BV

HM

HM

DPC

TS

BVTS

BV

MCV XG

Page 35

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPC

• Pump head calculation according nominal ow

• Place of valves installation depends on available dierential pressure in

the primary side.

Operational cost

2

• Low operational cost due to stable hydraulic balance (stabilization of DP)

• Medium periodical check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM

• High commissioning cost for weather compensator and DP controller

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation and

• LOW RISK OF OVERFLOW due to the ow limitation obtained by special

presetting procedure of DPC

Control stability

• Stability at full load, and very good stability on partial load

• LOW risk of pressure oscillation on DH nets

• LOW risk for cavitation

35

Page 36

RECOMMENDED*

Indirect connection of Heating system with DPCQ and MCV. DPCQ

4.2

secure automatic flow limitation

TS

Application

ELC 110

ECL

DPCQ

BV

BV HM TS

BVTS

BV

MCV XG

36

Page 37

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPC

• Pump head calculation according nominal ow

• Place of valves installation depends on available dierential pressure in

the primary side.

Operational cost

2

• Low operational cost due to stable hydraulic balance (stabilization of DP)

• Medium periodical check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM

• High commissioning cost for weather compensator and DPCQ controller

Energy savings

• ENERGY SAVING due to the Weather compensation

• NO RISK OF OVERFLOW due to the ow limitation obtained by DPCQ

Control stability

• Very good stability of control as at full as on partial load

• VERY LOW risk of pressure oscillation on DH nets

• VERY LOW risk for cavitation

37

Page 38

RECOMMENDED*

Indirect connection of HE system with PIBCV

4.3

TS

Application

ECL

BV

BV

HM

TS

PICV

XG

TS

BV

BV

38

Page 39

System analysis

Design / Sizing

1

• SIMPLIFIED HYDRONIC CALCULATION REQUIRED

• Pump head calculation according nominal ow

• Place of the installation of PICV depends on the evaluable dierential pres-

sure. Installation on return pipe is preferable due to the low parameters

Operational cost

2

• Limited operational cost due to unstable hydraulic balance (no stabiliza-

tion of DP)

• Low periodical Check-up costs due to the limited amount of equipment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

Investment

3

• Investment cost – LOW (Weather compensator +combi valves )

• Installation cost - LOW

• Commissioning cost -LOW for weather compensator and PICV

4

5

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation and max

ow limitation

• LOW RISK OF OVERFLOW due to the ow limitation

• HIGH HEAT CONSUMPTION than outside temperature lower than calcu-

lated one

Control stability

• Stability at full load, and very good stability on partial load

• LOW risk of pressure oscillation on DH nets

• LOW risk for cavitation

39

Page 40

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

ACCEPTABLE*

Application

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

Indirect connection of HE system with MBV and MCV

4.4

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

ECL

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

HM

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

SMBV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

BV

BV

MCV

XG

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED .RECOMMENDED NOT RECOMMENDED

40

Page 41

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND MBV: Kvs and

authority of the valves

• Presetting calculation of Balancing valves is needed

• Pump head calculation according nominal ow

Operational cost

2

• High operational cost due to unstable hydraulic balance (no stabilization

of DP)

• Medium periodical Check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM (control valve + Weather compensator +

Manual Balancing valves)

• Low installation cost - - MCV + Strainer + shut-o valves+ MBV

• Commissioning cost for weather compensator and balancing valves

Energy savings

• LOW ENERGY SAVING due to the Weather compensation

• RISK OF OVERFLOW due to the ow limitation

• HIGH HEAT CONSUMPTION than outside temperature lower than calcu-

lated one

Control stability

• Stability only at full load, but on partial load VERY LOW

• HIGH risk of emergency – non protection of HEX from pressure uctu-

ations

• HIGH Risk of pressure oscillation on DH nets

• HIGH risk for cavitation

41

Page 42

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED*

Application

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

Indirect connection of heating system with MCV only

4.5

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

ECL

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

HM

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

MCV

XG

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED .RECOMMENDED NOT RECOMMENDED

42

Page 43

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV: Kvs and authority of

the valves

• Pump head calculation according nominal ow

• Place on Pump installation depends on Static pressure in the net and

system

Operational cost

2

• HIGH operational cost due to unstable hydraulic balance (no stabilization

of DP)

• MEDIUM periodical Check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM (control valve + Weather compensator +

pump)

• Low installation cost - - MCV + Strainer + shut-o valves

• Low commissioning cost for weather compensator

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation

• HIGH RISK OF OVERFLOW due to the lack of ow limitation (no hydraulics

balance products on the loop),

• HIGH HEAT CONSUMPTION than outside temperature higher than calcu-

lated

Control stability

• LIMITED stability, only in case when ow on secondary side is const. and

pressure on primary is also stable

• HIGH risk of emergency – non protection of HEX from pressure uctu-

ations

43

Page 44

RECOMMENDED*

Indirect connection of Heating and Domestic Hot

Application

5

5.1

water systems – directly to the primary side.

Indirect connection of HE and DHW with common DPC

ECL

TS

HM

DPC

BV

BV

BV

TS

TS

MCV

MCV

XG

XG

TS

TS

BVBV

BV

44

Page 45

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPC

• Pump head calculation according nominal ow

Operational cost

2

• Limited operational cost due to unstable hydraulic balance (no stabiliza-

tion of DP)

• Low periodical Check-up costs due to the limited amount of equipment

• Power consumption of pump depends on system and place of installation

• VERY HIGH amortization costs due to the amount of equipment

Investment

3

• Investment cost – AVERAGE

• installation costs - AVERAGE

• Commissioning cost - HIGH for weather compensator and DPC

4

5

Energy savings

• HIGH ENERGY SAVING due to the Weather compensation and ow limita-

tion

• LOW RISK OF OVERFLOW due to the ow limitation on DP valves in

Control stability

• Stable and accurate control of parameters on full, partial and extreme

“parameters” load

• NO risk for cavitation

• NO risk for pressure oscillation

45

Page 46

RECOMMENDED*

Indirect connection of HE and DHW with DPC on each circuit

5.2

TS

Application

ECL

HM

BV

BV

BV

DPC

DPC

TS

MCV

XG

TS

TS

BVBV

BV

46

TS

MCV

XG

Page 47

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPC

• Pump head calculation according nominal ow

Operational cost

2

• Low periodical Check-up costs due to the limited amount of equipment

• Power consumption of pump depends on system and place of installation

• VERY HIGH amortization costs due to the amount of equipment

Investment

3

• Investment cost – VERY HIGH

• installation costs - VERY HIGH

• Commissioning cost - VERY HIGH for weather compensator and DPC’s

4

5

Energy savings

• HIGH ENERGY SAVING due to the Weather compensation and ow

limitation

• LOW RISK OF OVERFLOW due to the ow limitation on DP valves

Control stability

• Stable and accurate control of parameters as on full as on partial load

47

Page 48

ACCEPTABLE*

Indirect connection of Heating and DHW system with DPCQ on each

5.3

circuit

TS

Application

ECL

HM

BV

BV

DPCQ

DPCQ

TS

MCV

XG

TS

BV

BV

48

TS

MCV

XG

Page 49

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV AND DPC: Kvs and

authority of the valves, dP presetting for DPCQ

• Pump head calculation according nominal ow

• Place of DPCQ and MCV installation depend on the available dierential

pressure

Operational cost

2

• Limited operational cost due to unstable hydraulic balance (no stabiliza-

tion of DP)

• Low periodical Check-up costs due to the limited amount of equipment

• Power consumption of pump depends on system and place of installation

• VERY HIGH amortization costs due to the amount of equipment

3

4

5

Investment

• Investment cost – VERY HIGH

• installation cost – VERY HIGH

• Commissioning cost - VERY HIGH for weather compensator and DPCQ

REGULATORS

Energy savings

• HIGH ENERGY SAVING due to the Weather compensation and automatic

ow limitation

• NO RISK OF OVERFLOW due to the automatic ow limitation on DPCQ

valves

Control stability

• Stable and accurate control of parameters on full, partial and extreme

“parameters” load

• NO risk for cavitation

• NO risk for pressure oscillation

49

Page 50

RECOMMENDED*

Indirect connection of HE and DHW systems with PIBCV used as con-

5.4

trol valve

ESMT

Application

ECL

BV

HM

TS

MCV

PICV

XG

TS

BVBV

BV

50

BV BV

TS

XG

PICV

Page 51

System analysis

Design / Sizing

1

• SIMPLIFIED HYDRONIC CALCULATION REQUIRED

• Pump head calculation according nominal ow

• Place of the installation of PIBCV depends on the evaluable dierential

pressure. Installation on return pipe is preferable due to the low parameters

Operational cost

2

• Limited operational cost due to unstable hydraulic balance (no stabiliza-

tion of DP)

• Low periodical Check-up costs due to the limited amount of equipment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – Above AVERAGE (Weather compensator +PIBCV’s )

• Installation cost - LOW

• Commissioning cost - LOW for weather compensator and PIBCVs

Energy savings

• MEDIUM ENERGY SAVING due to the Weather compensation and max

ow limitation

• RISK OF OVERFLOW due to absence of Flow limitation

• HIGH HEAT CONSUMPTION than outside temperature lower than calcu-

lated (set point)

Control stability

• Stability at full load, and very good stability on partial load

• LOW risk of pressure oscillation on DH nets

• LOW risk for cavitation

51

Page 52

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED*

Application

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

Indirect connection HE and DHW systems with no DPC

5.5

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

ECL

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

HM

MCV

TS

BVBV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV

BV

TS

XG

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

TS

MCV

XG

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED .RECOMMENDED NOT RECOMMENDED

52

Page 53

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR MCV's: Kvs and authority of

the valves

• Pump head calculation according nominal ow for both systems

• Place of the valves installation depends on the available dierential pres-

sure and Piezometer

Operational cost

2

• High operational cost due to unstable hydraulic balance (no stabilization

of DP)

• Medium periodical Check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• MEDIUM amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – MEDIUM (control valve + Weather compensator +

Manual Balancing valves)

• Installation cost - MEDIUM

• Commissioning cost - LOW

Energy savings

• LOW ENERGYSAVING due to the Weather compensation

• HIGH RISK OF OVERFLOW due to absence of Flow limitation

• HIGH HEAT CONSUMPTION than outside temperature low

Control stability

• Stability only at full load, but on partial load NOT STABLE.

• High risk of emergency – non protection of HEX from pressure uctuations

• VERY HIGH risk of pressure oscillation in DH nets

• VERY HIGH risk of cavitation

53

Page 54

ACCEPTABLE*

Heating System connected thru Central substation via DPC on the

5.6

entrance

Application

HM

BV

BV

DPC

54

Page 55

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR DPC: Kvs of the valve, dP

presetting for DPC

• PLACE OF THE DPC INSTALLATION DEPENDS ON THE CURRENT

PIEZOMETER

Operational cost

2

• Low operational cost due to stable hydraulic balance (stabilization of dP)

and obsolesce of pump

• Medium periodical check-up costs due to the limited amount of equip-

ment

• Low amortization costs due to amount of equipment

Investment

3

• Investment cost – LOW

• Commissioning cost - LOW ( DPC)

4

5

Energy savings

• NO ANY ENERGYSAVING

• LOW RISK OF OVERFLOW due to the ow limitation obtained by special

presetting procedure of DPC

Control stability

• VERY stable system

• LOW risk of emergency – DPC protect secondary side from pressure uc-

tuations on primary side

• LOW risk of pressure oscillation in the DH net due to the DPC

55

Page 56

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED*

Application

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

Heating System connected directly to Central substation with Ther-

5.7

mostatic controller (TC)

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

HM

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV BV

TC

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

BV BV

XG

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED

NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED NOT RECOMMENDED .RECOMMENDED NOT RECOMMENDED

56

Page 57

System analysis

Design / Sizing

1

• TRADITIONAL CALCULATION REQUIRED FOR VALVE: Kvs

• Pump head calculation according nominal ow

Operational cost

2

• HIGH operational cost due to unstable hydraulic balance (no stabilization

of dP)

• MEDIUM periodical Check-up costs due to the limited amount of equip-

ment

• Power consumption of pump depends on system and place of installation

• Very low amortization costs due to limited amount of equipment

3

4

5

Investment

• Investment cost – LOW(Thermostatic valve + pump)

• Installation cost- LOW

• Commissioning cost – VERY LOW

Energy savings

• LOW ENERGY SAVING due to the temperature control

• HIGH RISK OF OVERFLOW due to the lack of ow limitation (no hydraulics

balance products on the loop),

Control stability

• Stable only on full load

• HIGH risk of pressure oscillation in DH Nets

• VERY HIGH risk of cavitation

57

Page 58

RECOMMENDED*

Overall classication of Direct and Indirect

Application

6

6.1

Heating and Domestic Hot water

Direct heating system connection

ECL

TS

HM

DPC

MCV

BV

BV TS

Capital costs - low; small quantity of equipment, simple automatics

Operational costs - low; small quantity of equipment, no water treatment

Operations - in case of availability of automatics - average; any Heat network emergency cases

reects on consumers; the system is not protected from pressure uctuation in the network;

maximal operating pressure (or maximal radiator pressure) is no more than 6 bar; quantity power

control is not possible, because it may ruin the circulation regime. In absence of automation it is

impossible to provide any comfortable conditions for end users.

TS

BV

BV

58

Page 59

System analysis

6.2

Direct heating system connection

ELC 110

TS

DPC

BV

BV HM

Capital costs - high; rst of all a heat exchanger, in some cases - including reserve HEX; a lot of automatics

Operating costs - average, if the design is performed correctly (no overspecied valves and pumps),

compared to the direct model; increased power of circulation pumps of the primary (heat network) and

the secondary (consumer) circuits

Operations - Indirect connection models are used regardless of pressure value in the point of connection to the Heat network, which means that such models are versatile. Hydraulic insulation between the

heating systems and the Heat network signicantly raises reliability of thermal supply systems, protects

local systems from increase and decrease of pressure in the Heat network, and allows keeping water in

the heating system in case of emergency, because it is prevented from freezing due to circulating pumps

operation. The model allows to use quantity regulation of Heat network and signicantly decrease of the

coolant temperature in case of emergency without concern of failure of the heating system circulation

regime. Provide of maximal comfortable conditions for end users

TS

MCV XG

BVTS

BV

59

Page 60

RECOMMENDED*

Domestic Hot Water Systems.

6.3

Indirect DHW system connection.

TS

Application

ECL

HM

BV

DPCQ

DPCQ

TS

MCV

TS

TS

BVBV

BV

60

TS

MCV

XG

Page 61

System analysis

Capital costs - high, costs for heat exchanger and the secondary circuit circulation pump

Operating costs - average, constant power consumption by the secondary circuit circulation pump

Operations - Indirect connection models are used regardless of pressure value in the point of connec-

tion to the Heat network, which means that such models are versatile. Hydraulic insulation between the

DHW system and the Heat network signicantly raises reliability of thermal supply systems, protects local

systems from increase and decrease of pressure in the Heat network, and also eliminates problems with

water treatment in the Heat network. The model allows to use quantity regulation of Heat network and

signicantly decrease of the coolant temperature in case of emergency without concern of failure of the

DHW system circulation regime. Provides maximal comfortable conditions and timely hot water supply

of end users.

61

Page 62

7. Product overview

7.1 Weather compensators - WC

Picture Name Description

ECL310

ECL110 One circuit controller

ESMT Outside temperature sensor PT1000

ESMU Temperature sensor PT1000 Temp. reg.

Wheather compensator with possibility to

control 3 circuits

Charcteristic

3 circuits max, 3

point ouput or 0-10 V,

preprogrammed

1 circuit only

(HE or DHW),

preprogrammed

Appl. RH-C/

HVAC*

Electronic

control

Electronic

control

Outside temp

monit

7.2 Motorized Control Valves - MCV

Picture Name Description Size mm Kvs (m3/h) Applications Comments

Comments

Can be connected to

SCADA system

Stand alone

-

More dierent shape sensors

availiable

VF2

VF3

VFM2

Pressure reliefed 2-way control valve with

log-lin control characteristics

3-way control valve with log-lin control

characteristics

Pressure reliefed 2-way control valve with

log-lin control characteristics

15-150 0,63-320 All High control ratio

15-150 0,63-320 All Tmax=130C

65-250

63-900

All

Highes working dP

and Kvs

62

62

Page 63

7.3 Actuators for MCV and PICV

Picture Name Description Usage with Control type Speed (S/mm) Comments

AMV/E 435

AMV/E 655/658

Gear push'pull actuator with 24V and 230

V power supply, manial operation, LED

signalization, Anti -oscilation fuction

Gear push-pull actuator with 24V and

230 V power supply, manual operation

(mechanical and electrical), LED

signalization, Anti -oscilation fuction

VF2&3

Dn15-80

VFM 3-6 3-point, 0-10 V

7,5-15 3-point, 0-10 V

7.4 Pressure Independent Control Valves - PICV

Picture Name Description Size mm Kvs (m3/h) PN, bar Comments

AHQM

Flow controller with intergrated

conrol valves

12,5-90 0,63-320 16

Fastest and easiest

installation

Spring return SD and SU

avaliable on 658 version

only

T=120C, thread version

for small dimension

availiable

AFQM and AFQM6

Flow controller with intergrated

conrol valves

65-125 50-160 16/25/40 T=150C

63

Page 64

7.5 Dierential Pressure (and Flow) Controllers - DPC (DPCQ)

Picture Name Description Size mm Setting range Applications Comments

AHP

Dierential pressure controller with

adjustable pressure setting

50-100 - All

Used with BaBV or

other MBV in the ow

pipe for shut-o, ow

limiting and impulse

tube connection

0,15-1,5

0,1-0,7

0,05-0,35

1-6

0,5-3

0,1-0,7/0,2

0,1-0,7/0,5

0,15-1,5/0,2

0,1-1,5/0,5

All

All

AFP

AFPQ

Dierential pressure controller with

adjustable pressure setting

Dierential pressure controller with

adjustable pressure setting and ow

limitation

15-250

15-250

7.6 Steel manual balancing valve and Ball valves

Picture Name Description Size mm PN Applications Comments

BaBV

With presetting, with measuring nipples,

Steel valve body, closing with ball valves

50-100 - All

Used in combination

with VFG2 or VFGS2

valves .Required

additional impulse

tubes

Used in combination

with VFG2 or VFGS2

valves .Required

additional impulse

tubes

Used with BaBV or

other MBV in the ow

pipe for shut-o, ow

limiting and impulse

tube connection

64

64

BV Ball valve 15-600 16/25/40 All

availiable in FF , WW

and other versions

Page 65

7.7 Temperature controllers

Picture Name Description Size mm Setting range Applications Comments

20-90

AFT Selfacting temperature controller 15-250

40-110

60-130

Heating

7.8 Energy meters

Picture Name Description Qp (m3/h) PN Applications Comments

SONO 1500

Sonometer 1500 with heat

calculator Infocall

15-100 0,6-60

Heating/

Cooling

More versions of

Temperature controllers

availiable. Used in

combination with VFG

valves

Bigger sizes availiable

65

Page 66

NOTES

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................

.......................................................................................................................................................................................................................................................................................................................................................................................................................................................................