Page 1

Fact Sheet

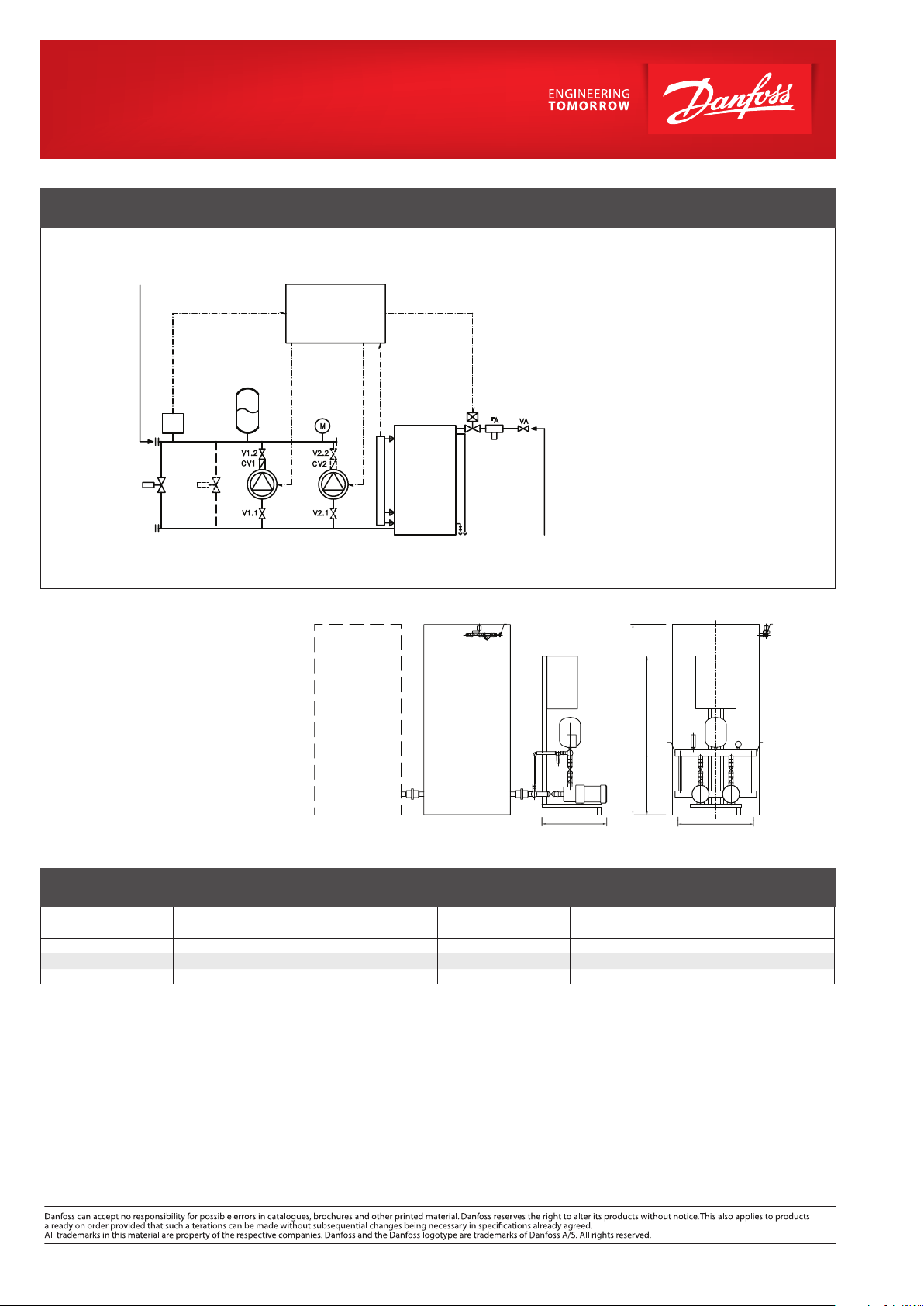

MAKE UP LINE Substations

A high performance system for make up, connecting to the secondary side of heating circuits

FEATURES AND BENEFITS

• Protection of the heating

circuit at overpressure

• Pressure maintaining in heating

system in very strict limits

• Controlled lling up of atmospheric

tank and of the heating circuit

• Short delivery time, easy to

install, minimal location site

Application

The Make Up Line is a range of systems

mounted on the secondary side (on

the interior building circuit) of district

heating systems or thermal plants with

maximum temperature of 115 °C and

PN 6 / PN 10. This system is suitable for

maintaining between an overpressure

given by water dilatation and an under

pressure limit given by loses of water

from dierent reasons in secondary

heating circuit. The dimensioning of

components in size and type is done

with a calculation method developed

by Schmidt-Bretten, member of Danfoss

Group.

Function

The Make Up system has the function to

discharge the soft water into an atmospheric tank via pressure relief valve(s) if

the heating circuit develops a pressure

value over the maximum set value or

has the function to ll up the heating

installation circuit via Make Up pump(s)

if the pressure decreases below the minimum set value. The volume of lling up

water or the leakage water from heating

circuit is automatically replaced in water

tank via solenoid valve.

Also, the system is able to protect the

pump in case of water lack, can assure

a sequential start of pumps, is able to

stop functioning pumps in case of pipe

breaking, can make automate switching on the second pump in case of failure function of the rst, assures the permanent monitoring of the water level

in the atmospheric tank (minimum,

normal and maximum) and assures the

ltering of water.

The entire system has an electric and

control panel connected to a pressure sensor and two level switches,

and function of received values commands the excess pressure valve(s), the

pump(s) or the solenoid valve opening/

closing.

Models

The Make Up system is available for

a wide range of standardized heating capacities between 500 kW and

8000 kW and for static pressures between 15 mwc and 60 mwc.

It has to be emphasized that this system is designed as an ecient two in

one pressure controller where control

is made automatic.

For all usually requests and for the

easier way of choosing the adequate

equipment, our specialists come with

standard solutions as shown in the

examples of the Make Up standard

range table. Although, other tailored

made equipment may be available on

demand.

Construction and installation

The pressure sensor, the closed pressure vessel, the level switches and

manometers are standard given for all

Make Up usually models. The pumps

are made of stainless steel. The atmospheric tank is made of steel. The

system equipment as valves, check

valves, strainers are made of brass.

The pipes of the system are made of

steel. The connections are made by

ange with gaskets, external and internal thread according to diameter.

In the construction can be integrated

optional modules for communications

via standardized RS485.

The MAKE UP LINE is delivered as

aunitary system, ready to be installed.

districtenergy.danfoss.com

Page 2

VD1

V1.1

VD2

PA1

V1.2

CV1

P

M

VTM

V2.1

V2.2

CV2

PA2 WTL

EVM

ELP

VA

FA

800 mm

800 mm

H

h

R1

WT

ELP

PA1

VTM

VD1

CIRCUIT DIAGRAM – EXAMPLE OF MAKE UP SYSTEM

R1 (R2): heating installation connection

Technical parameters:

Nominal pressure: PN 6 / PN 10

Maximum temperature: T

=115 °C

max

Make up source

Supply temperature: T

Nominal pressure: PN 6 / PN 10

max

= 80 °C

Electrical supply: 3~400 V /50Hz

PA1 (PA2) Make Up pump – one or two pieces

VD1 (VD2) Pressure relief valve

(pressure relief controller)

– one or two pieces

EVM Solenoid valve

P Pressure sensor

L Level switches

ELP Electric and control panel

V1 (V2) Shut o valve – pump circuit

VA Shut o valve – ll-up circuit

CV1 (CV2) Check valve

FA Strainer

M Manometer

WT Atmospheric water tank

VTM Closed pressure vessel

(against pressure shocks)

R3: soft water connection

R3: soft water connection

R3

(R2): heating

installation

connection

WT

additional

MAKE UP LINE (EXAMPLES):

Substation

type

EXP 203 2200 2 25 2 × 0,55 1 × 1000

EXP 405 4200 5 38 2 × 0,55 1 × 3500

EXP 805 6900 9 44 2 × 1,85 2 × 3000

SBT · Sos. Oltenitei no 208 · Popesti-Leordeni 077160 · Ilfov · România

Tel.: +4031 222 20 10 · Fax: +4031 222 22 99 · secretariat@schmidt.ro · www.schmidt.ro

© Danfoss | DHS-SRMT/ PL | 2016 . 02

Heating capacity

[kW]

Flow rate / one pump

[m3/h]

Static pressure

[mwc]

Electrical power

[kW]

Expansion tank pieces ×

volume, liters

VL.EH.E2.02

Loading...

Loading...