Page 1

Data Sheet

Hydraulic motor - high speed

MAH 6.3 - MAH 12.5

hpp.danfoss.com

Page 2

Data sheet | Motor, High Speed, MAH 6.3 and MAH 12.5

Application

Characteristic features

Application examples

MAH 6.3 and 12.5 are high-speed motors

operated by water hydraulics. The hydraulic

medium is ordinary tap water. The motors base

on the axial piston principle that enables a light

and compact design. The water lubricates all

movable parts in the motor, and there is thus no

need for special oil lubrication.

• Smooth running within a large operating

parameters.

• Constant torque over a wide speed range.

• High starting torque

• Long life under severe operating conditions.

• Compact design.

• For use in both open and closed systems.

• Food industry

• Mining equipment

• Humid and wet environments

• Pharmaceutical industry

The motors vary in size from 6.3 cm³ to 12.5 cm³

per revolution (rated displacement).

The maximum operating torques vary from

12.5 Nm to 25 Nm and maximum outputs from

5 kW to 8 kW.

• Quiet in operation.

• Few wear parts and low maintenance

costs.

• No oil lubrication.

• Non-corroding materials.

• Easy-to-clean design.

• Chemical industry

• Water treatment

• Nuclear industry

2 | © Danfoss | DCS (im) | 2019.09

AI318932232163en-001001 | 521B0750

Page 3

Data Sheet | Motor, High Speed, MAH 6.3 and MAH 12.5

Technical data

Function principle

Type MAH 6.3 MAH 12.5

Code number - CW version 180F0003

Code number - CCW version 180F0105 180F0004

Geometric displacement (cm3) 6.3 12.5

Max. speed (min-1) kont. 4000* 3000

Min. speed (min

Max. torque (Nm) kont 12.5 25

Starting torque at max. pressure drop (Nm) kont 3.5 12.5

Starting pressure at unloaded shaft (bar) 80 50

Max. power at max. speed. (kW) kont 5.2 7.8

Max. pressure drop and inlet pressure (bar) kont 140* 140

Max. waterow (l/min) kont 26.8 40

Return line pressure at pin = 140 bar, no shaft load (bar) 80 50

Return line pressure at pin = 140 bar, max. shaft load (bar) 10 10

Max. system press.at serial operation, no shaft load

Drain ow at 140 bar/1500 min-1 (l/min) < 1 < 1.5

Weight kg 4.1 6.3

* MAH 6.3: ∆p (pressure drop) up to 3100 min-1 = 140 bar, there is then a linear reduction in ∆p to 100 bar at 4000 min-1

Water-hydraulic motors convert hydraulic energy

(pressure, water ow) to mechanical energy

-1)

(bar)

kont

300 300

115 105

Two sizes of housing cover the entire range: One

for 6.3 cm3 motors, and one 12.5 cm³ motors.

(torque, speed).

The axial piston principle gives a light and com-

Danfoss water-hydraulic motors are high-speed

pact design in relation to actual power output.

units with xed displacement. A given water ow

and a given pressure, determine the displacement (motor size), speed and torque. For a given

The motors are designed to ensure that all

moving parts are lubricated by water.

displacement (motor size) speed is determined

by the water ow and torque is determined by

the pressure.

Furthermore, the motor design is such that

ordinary drinking water is used, i.e. water with no

additives whatsoever.

The motors are axial piston units which operate

on the swashplate principle.

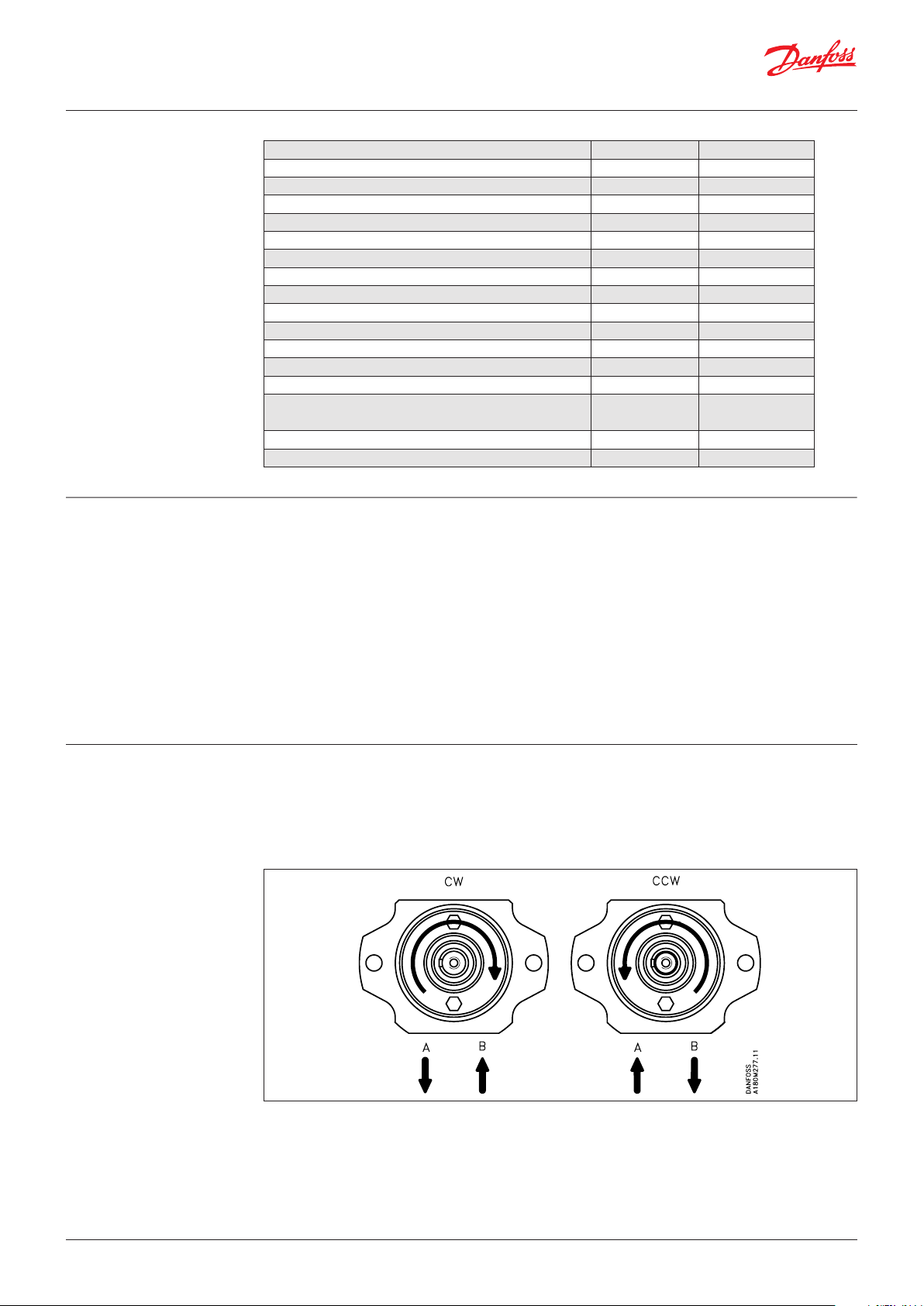

Direction of rotation

Connections and direction of rotation appear

from the product label on the motors (see also

the below drawing).

The motors can be reversed for shorter periods,

but will run with slightly less eciency and

starting torque.

If reversible operation for longer periods is

required, please contact your loacl Danfoss Sales

representative.

© Danfoss | DCS (im) | 2019.09

AI318932232163en-001001 | 521B0750 | 3

Page 4

Data sheet | Motor, High Speed, MAH 6.3 and MAH 12.5

Sealing element

Shaft load

Drain line

Temperature

USIT ring, ttings with O-ring connection or

similar.

Minimum speed at the loads stated below is 400

-1

min

Max. pressure = 6 bar absolute.

Drain pressure must never exceed return pressure

by more than 1 bar.

Fluid temperature:

Min. +3°C to max. +50°C. at max. pressure

Min. +3°C to max. +60°C. at max. 100 bar

FA daN FR daN

MAH 6.3 30 65

MAH 12.5 50 100

Installing the drain line

The drain line/motor must be positioned so that

the motor cannot empty itself during standstill.

In case of lower operating tempera tures,

please contact the Danfoss Sales

Organization for Water Hydraulics.

Ambient temperature:

Min. 0°C to max. 50°C.

Motor variants MAH motors are optimized for operation in one

direction and are therefore available in CW and

CCw versions.

Filtration

The water supplied to the valve must be ltered:

10 µm absolute, ß10-value > 5000 lter is

recommended.

Storage temperature:

Min. -40°C to max. +70°C.

For further information on lters, please

contact the Danfoss sales department for water

hydraulics.

4 | © Danfoss | DCS (im) | 2019.09

AI318932232163en-001001 | 521B0750

Page 5

Data Sheet | Motor, High Speed, MAH 6.3 and MAH 12.5

Orientation

The drawing shows preferred acceptable, and not

acceptable orientations of the motor.

Installation

It is recommended to use a exible coupling and

ensure that the gap between the two metal parts

of the coupling is min. 3 mm, even though the

motor can handle a limited shaft load.

© Danfoss | DCS (im) | 2019.09

AI318932232163en-001001 | 521B0750 | 5

Page 6

Data sheet | Motor, High Speed, MAH 6.3 and MAH 12.5

Dimensions

MAH 6.3

6 | © Danfoss | DCS (im) | 2019.09

A: Port G ¼, 12 deep

B: Port G ¼, 12 deep

C: Drain G 1/8, 11 deep

D: Parallel key 5 x 5 x 20, DIN 6885

AI318932232163en-001001 | 521B0750

Page 7

Data Sheet | Motor, High Speed, MAH 6.3 and MAH 12.5

MAH 12.5

A: Port G 3/8, 13.5 deep

B: Port G 3/8, 13.5 deep

C: Port G ¼, 13.5 deep

D: Parallel key 5 x 5 x 20, DIN 6885

© Danfoss | DCS (im) | 2019.09

AI318932232163en-001001 | 521B0750 | 7

Page 8

Danfoss A/S

High Pressure Pumps

Nordborgvej 81

DK-6430 Nordborg

Denmark

© Danfoss | DCS (im) | 2019.09

AI318932232163en-001001 | 521B0750 | 8

Loading...

Loading...