Page 1

Data Sheet

Series 40 Axial Piston Pumps

M46 HC EDC

For more than 40 years, Danfoss has been developing

state-of-the-art components and systems for mobile

machinery used in off-highway operations around the

world. We have become a preferred supplier by

offering the best of what really matters: The hardware

inside your vehicle application.

The M46, along with the high-current control is is

designed for quality and reliability and offers

expanded functionality, greater total effciency, and

easy installation.

The M46 high-current control option is PLUS+1

compliant.

PLUS+1® allows you to rapidly develop and customize

electronic machine control. It opens up the future by

combining machine controls and diagnostics in an

integrated operating network.

®

Features

Designed for Durability and Flexibility

•

Optimized for medium duty

applications

•

Single piece housing/end cap

•

Efficient axial piston design

Installation and Packaging benefits

•

Worldwide Support

•

Standard connector interfaces

•

Compact, optimized packaging

•

Low noise

•

Single, bolt together tandem

configurations

Wide Range of Options

•

Optional integrated charge pump

•

High pressure and charge relief valve

•

Displacement limiters

•

Variety of input shafts

•

Variety of auxiliary mounting pads

Wide Range of Options

•

PLUS+1® Compliant control

•

Consistent, flat and repeatable

deadband

•

Easier system compatibility

•

Improved controllability

Comprehensive technical literature online

at powersolutions.danfoss.com

©

Danfoss | May 2016 L1406335 | AI00000182en-US0103 | 1

Page 2

Technical Specifications

P108759

C2

C1

M4

M5

L2

L1

S M2

B

A

M1

DE

B

P108757

121.9 ± 2.5 103 ± 1.5

73 ± 0.18 (2x)

Ø 14.27

64 ± 1.5

79.8 ± 1.5

169.8 ± 2.5

80.8 ± 1.5

+0.25

-0.89

Case outlet

(alternate)

System ports

81.9 ± 1.5

Servo Gauge Port M4

ISO 11926-1 9/16-18

Ø 89.0 ± 0.13

78.7 ± 1.5

22.4 ± 0.5

45.1 ± 1.5

Spline Data

: 15

: 16/32

: 30°

: Ø 23.813

: Fillet root side

: ANSI B92.101970 Class 5

Number of teeth

Pitch fraction

Pressure angle

Pitch Ø

Ty t

Per

143.8 ± 2.5

211.8 ± 2.5

269.5 ± 2.5

33.5 ± 1.5

Control Solenoid Connector C1

Deutsch DT04-2P

ISO 11926-1 1-1/16-12

Case Outlet

Charge Pump Inlet

ISO 11926-1 1-5/16-12

Bypass Valve (full open at two revolutions)

193.5 ± 2.5

ISO 11926-1 9/16-18

System Gauge Port B

System Gauge Port A

5/8 inch hex

35.6 ± 1.5

16.8 ± 1

8.1 ±

1

42.2 ± 1.5

ISO 11926-1 9/16-18

ISO 11926-1 7/8-14

To

Fr

ISO 11926-1 7/8-14

210 ± 2.5

171.4 ± 2.5

185.4 ± 2.5

Control manual override C1

Depressing the plunger mechanically

moves the control spool. Actuation

allows full stroke pump response as

per coil and rotation dependent

control logic

Control manual override C2

Depressing the plunger mechanically

moves the control spool. Actuation

allows full stroke pump response as

per coil and rotation dependent

control logic

Case gauge port

ISO 11926-1 7/16-20

Ø21 max. clearance dia.

fo

195.6 ± 2.5

81.9 ± 1.5

Servo Gauge Port M5

ISO 11926-1 9/16-18

Control Solenoid Connector C2

Deutsch DT04-2P

System Port B

ISO 11926-1 1-5/16-12

30 ± 1.5

Case outlet

(alternate)

ISO 11926-1 1-1/16-12

78.7 ± 1.5

55.9 ± 1.5

43.7 ± 1.5

System Port A

ISO 11926-1 1-5/16-12

39.6 ± 1.5

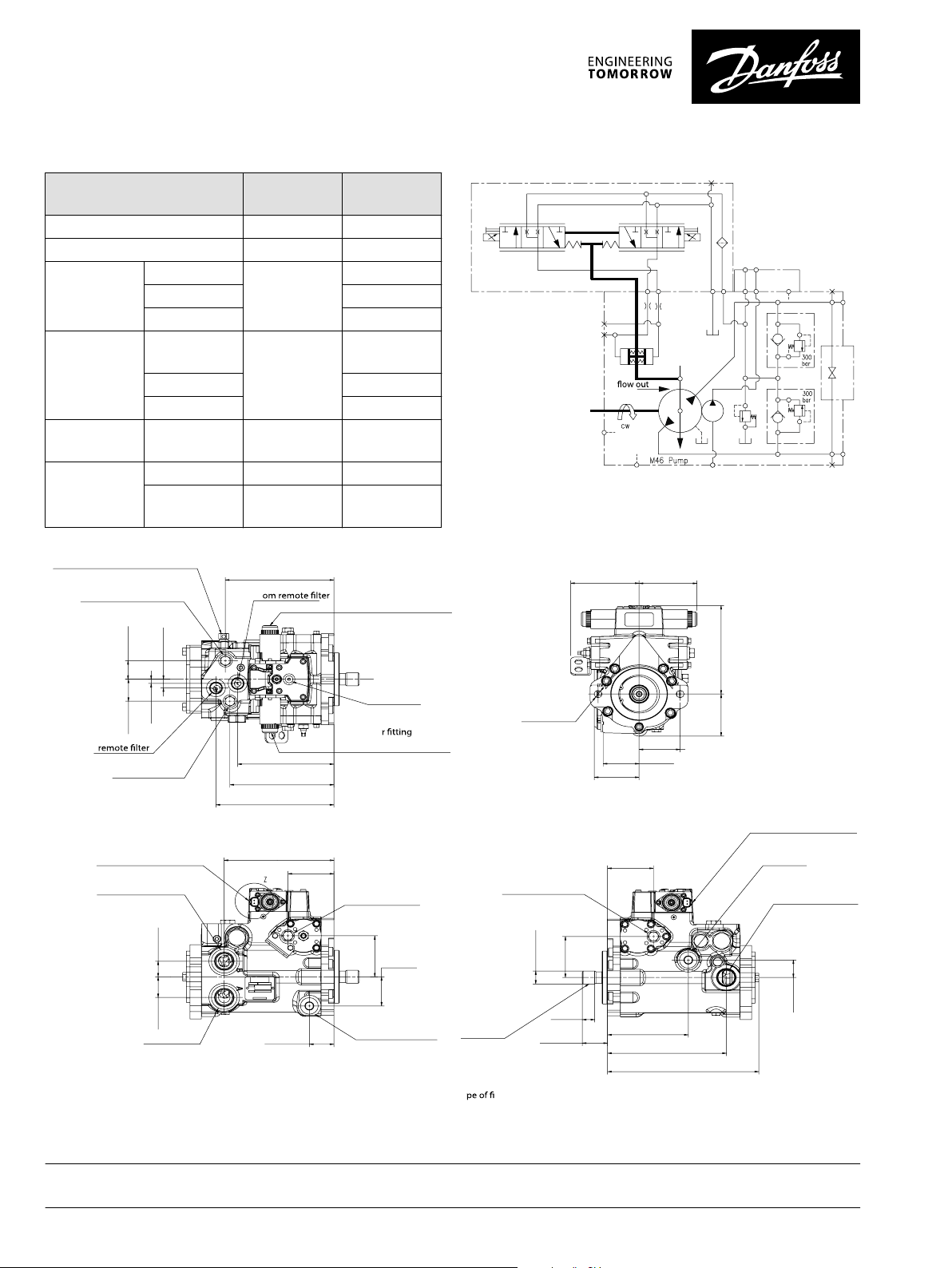

Features Unit M46 Single

Pump

Displacement cm3/rev [in3/rev] 45.9 [2.80]

Weight kg [lb] 33 [73]

Input Speed Minimum min-1 (rpm) 500

Rated 4000

Maximum 4100

System Pressure Max. Working

bar [psi] 345 [5000]

Pressure

Max. pressure 385 [5585]

Min. Low Loop 10 [145]

Control Pressure Minimum @

bar [psi] 21.5 [312]

corner power

Case Pressure Continuous bar [psi]

Maximum (cold

bar [psi] 5.2 [75]

start)

Dimensions

Schematic

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | May 2016 L1406335 | AI00000182en-US0103

Loading...

Loading...