Page 1

Technical Information

Axial Piston Pumps

Series 40 M46

powersolutions.danfoss.com

Page 2

Technical Information

Series 40 M46 Pumps

Revision history Table of revisions

Date Changed Rev

March 2017 Minor updates - FNR Control options 0209

October 2016 Minor updates 0208

May 2015 more corrections to tandem pumps model code BG

March 2015 correction to tandem pumps model code BF

January 2015 minor edits BE

January 2015 added port callouts - HC EDC drawings BD

November 2014 corrections to shaft options BC

July 2014 Edits to HC EDC Schematic BB

April 2014 Danfoss layout BA

2 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 3

Technical Information

Series 40 M46 Pumps

Contents

Specifications

General Information

Features and Options

Operating Parameters

System Design Parameters

Model Code - Single Pumps

Model Code - Tandem Pumps

Options

Design Specifications......................................................................................................................................................................5

Technical Specifications.................................................................................................................................................................5

Operating Parameters.....................................................................................................................................................................5

Options.................................................................................................................................................................................................6

Fluid specifications.......................................................................................................................................................................... 6

M46 Pumps.........................................................................................................................................................................................7

M46 Variable Pumps........................................................................................................................................................................7

System Circuit Diagram..................................................................................................................................................................8

Schematic Diagram..........................................................................................................................................................................8

Features................................................................................................................................................................................................9

Options.................................................................................................................................................................................................9

Fluids.................................................................................................................................................................................................. 10

Viscosity........................................................................................................................................................................................10

Temperature...............................................................................................................................................................................10

Charge Pressure..............................................................................................................................................................................10

Control Pressure............................................................................................................................................................................. 10

Case Pressure...................................................................................................................................................................................11

System Pressure..............................................................................................................................................................................11

Speed Ratings..................................................................................................................................................................................11

Inlet Pressure................................................................................................................................................................................... 12

Sizing Equations............................................................................................................................................................................. 13

Filtration............................................................................................................................................................................................ 13

Suction Filtration.......................................................................................................................................................................14

Charge Pressure Filtration..................................................................................................................................................... 14

Redundant Braking System Requirement.............................................................................................................................15

Loop Flushing..................................................................................................................................................................................15

Reservoir............................................................................................................................................................................................15

Case Drain Usage for Tandem Pumps.................................................................................................................................... 15

Bearing Life and External Shaft Loading................................................................................................................................16

Hydraulic Unit Life......................................................................................................................................................................... 17

Mounting Flange Loads...............................................................................................................................................................17

Shaft Torques...................................................................................................................................................................................19

Shaft selection........................................................................................................................................................................... 19

Shaft torque and spline lubrication................................................................................................................................... 19

Shaft torque for tapered shafts............................................................................................................................................19

Single Pumps...................................................................................................................................................................................20

Tandem Pumps...............................................................................................................................................................................24

Shaft options....................................................................................................................................................................................28

Single pumps............................................................................................................................................................................. 28

Tandem pumps......................................................................................................................................................................... 30

Charge Pump...................................................................................................................................................................................31

Charge Pump Output Flow...................................................................................................................................................32

Charge Pump Power Requirements.................................................................................................................................. 32

Charge Relief Valve........................................................................................................................................................................32

High Pressure Relief Valve (HPRV) and Charge Check......................................................................................................33

Bypass Function..............................................................................................................................................................................34

Displacement Limiters................................................................................................................................................................. 34

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 3

Page 4

Technical Information

Series 40 M46 Pumps

Contents

Auxiliary Mounting Pads and Auxiliary Pumps................................................................................................................... 35

Manual Displacement Control (MDC) - Options AB, AC, AK, AW, and GB..................................................................36

Hydraulic Displacement - Options BA, BB and BC..............................................................................................................38

Electrical Displacement Control- Options CE, CG, CM, and CN..................................................................................... 41

High Current Electric Displacement Control - Options HA (12Vdc) and HB (24Vdc).............................................44

Response times..........................................................................................................................................................................46

Manual OverRide (MOR).............................................................................................................................................................. 46

Three-position Electrical Control - Options DA and DB................................................................................................... 47

Port Locations

Single Pump.....................................................................................................................................................................................50

Tandem Pump.................................................................................................................................................................................51

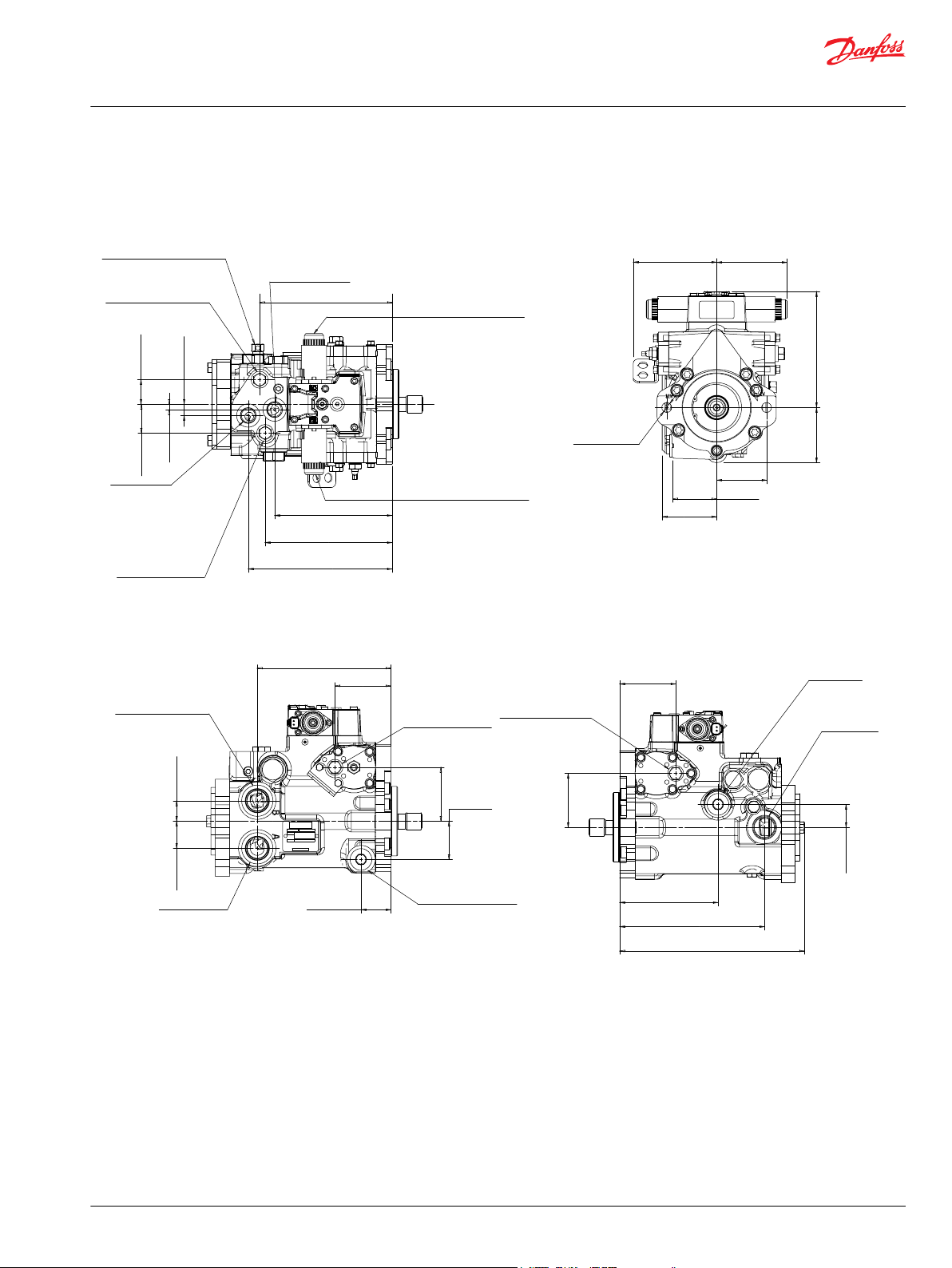

Installation Drawings - Single Pump Dimensions

Auxiliary Mounting Flanges....................................................................................................................................................... 52

Pump, filtration/charge pump options, MDC, displacement limiter...........................................................................53

Installation Drawings - Tandem Pump Dimensions

Auxiliary mounting flange..........................................................................................................................................................54

Rear mounting boss......................................................................................................................................................................55

Pumps, filtration/charge pump options, MDC, displacement limiters.......................................................................56

Control Options - Installation Drawings

Control options, AC, AK............................................................................................................................................................... 57

Option GB......................................................................................................................................................................................... 57

Options AB, AW...............................................................................................................................................................................58

HC EDC Control...............................................................................................................................................................................59

Hydraulic displacement control (HDC).................................................................................................................................. 60

Option CE..........................................................................................................................................................................................61

Options CG, CN............................................................................................................................................................................... 61

Options DA, DB............................................................................................................................................................................... 62

Reference Literature

Literature...........................................................................................................................................................................................63

4 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 5

Technical Information

Series 40 M46 Pumps

Specifications

Design Specifications

Technical Specifications

Product line

Pump type

Direction rotation

Installation position

Filtration configuration

Other system requirements

Model

Displacement

Shaft Speed Minimum

Rated

Maximum

System Pressure Maximum working*

Maximum

Minimum low loop

Weight (MDC without aux pad)

Mass moment of inertia of the rotating

components

Charge Pressure Minimum

Maximum

Control Pressure

Case Pressure Continuous

Inlet Pressure Rated

Minimum @ corner

power

Maximum (cold

start)

Minimum

Series 40 Pumps

In-line, axial piston, variable, positive displacement pumps

Clockwise (CW) or counterclockwise (CCW) available

Discretionary, the housing must be filled with hydraulic fluid

Suction or charge pressure filtration

Independent braking system, suitable reservoir and heat exchanger

Unit M46 Single Pump M46 Tandem Pump

cm3/rev [in3/rev] 45.9 [2.80] 45.9 x 2 [2.80 x 2]

min-1 (rpm)

min-1 (rpm) 4000

min-1 (rpm) 4100

bar [psi] 345 [5000]

385 [5585]

10 [145]

kg [lb] 33 [73] 59 [131]

kg ·m2 [slug·ft2] 0.0050 [0.0037] 0.0100 [0.0073]

bar [psi] 6 [87]

31 [450]

bar [psi] 21.5 [312]

bar [psi] 1.7 [25]

5.2 [75]

bar absolute [inches

of Mercury vacuum]

0.8 [6]

6 [9.2 Maximum]

* Operation above maximum working pressure is permissible with Danfoss application approval.

Operating Parameters

Fluid Viscosity

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 5

Minimum mm2/s (cSt) [SUS] 7 [49]

Continuous

Maximum (cold start)

Intermittent

1

12-16 [70-278]

1600 [7500]

6 [46]

Page 6

Technical Information

Series 40 M46 Pumps

Specifications

Options

Fluid Temperature

(1) Intermittent equals a short period of time at less than one minute per incident and not exceeding two percent of

duty cycle based on load life.

Mounting Flange

Input Shaft Ø 25.4 mm [1.000 in] straight keyed

Auxillary Mounting

Flange

Main Port Configuration

Minimum (intermittent cold

start)

Continuous

Maximum Intermittent

SAE - B X X

Ø 25.4 mm [1.000 in] 1:8 taper (SAE J501)

13-tooth, 16/32 pitch (ANSI B92.1 1970 - Class 5)

15-tooth, 16/32 pitch (ANSI B92.1 1970 - Class 5)

19-tooth, 16/32 pitch (ANSI B92.1 1970 - Class 5)

9-tooth internal spline, 16/32 pitch (SAE A)

11-tooth internal spline, 16/32 pitch (SAE A)

13-tooth internal spline, 16/32 pitch (SAE B)

15 - tooth internal spline, 16/32 pitch (SAE BB)

1-5/16 - 12 SAE A straight thread O-ring Ports (SAE J514) X X

degrees C [degrees F] - 40° C [- 40° F]

82.2° C [180° F]

1

104.4° C [220° F]

Single Tandem

X X

X X

X -

X X

- X

X X

X X

X X

- X

Fluid specifications

Ratings and data are based on operation with premium petroleum-based hydraulic fluids reftaining

oxidation, rust, and foam inhibitors.

Parameter Unit Minimum reftinuous Maximum

Viscosity mm /sec (cSt)

Temperature °C [°F] -40 [-40] 82 [180] 104 [220]

Cleanliness ISO 4406 Class 18/13 or better

Filtration

efficiency

suction filtration β

charge filtration β

[SUS]

7 [47] 12-60 [70-278] 1600 [7500]

=75 (β10≥1.5)

35-44

=75 (β10≥10)

15-20

6 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 7

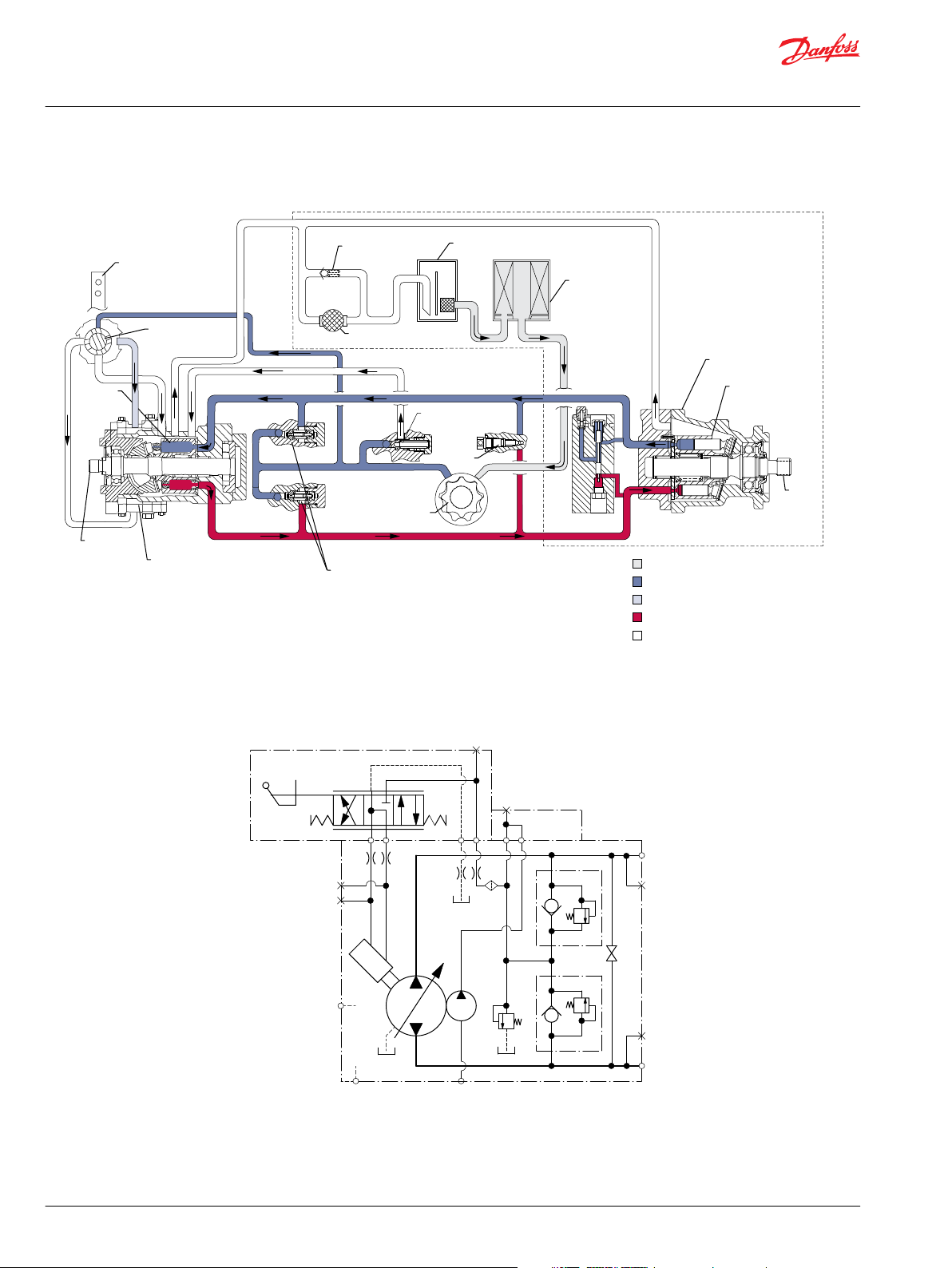

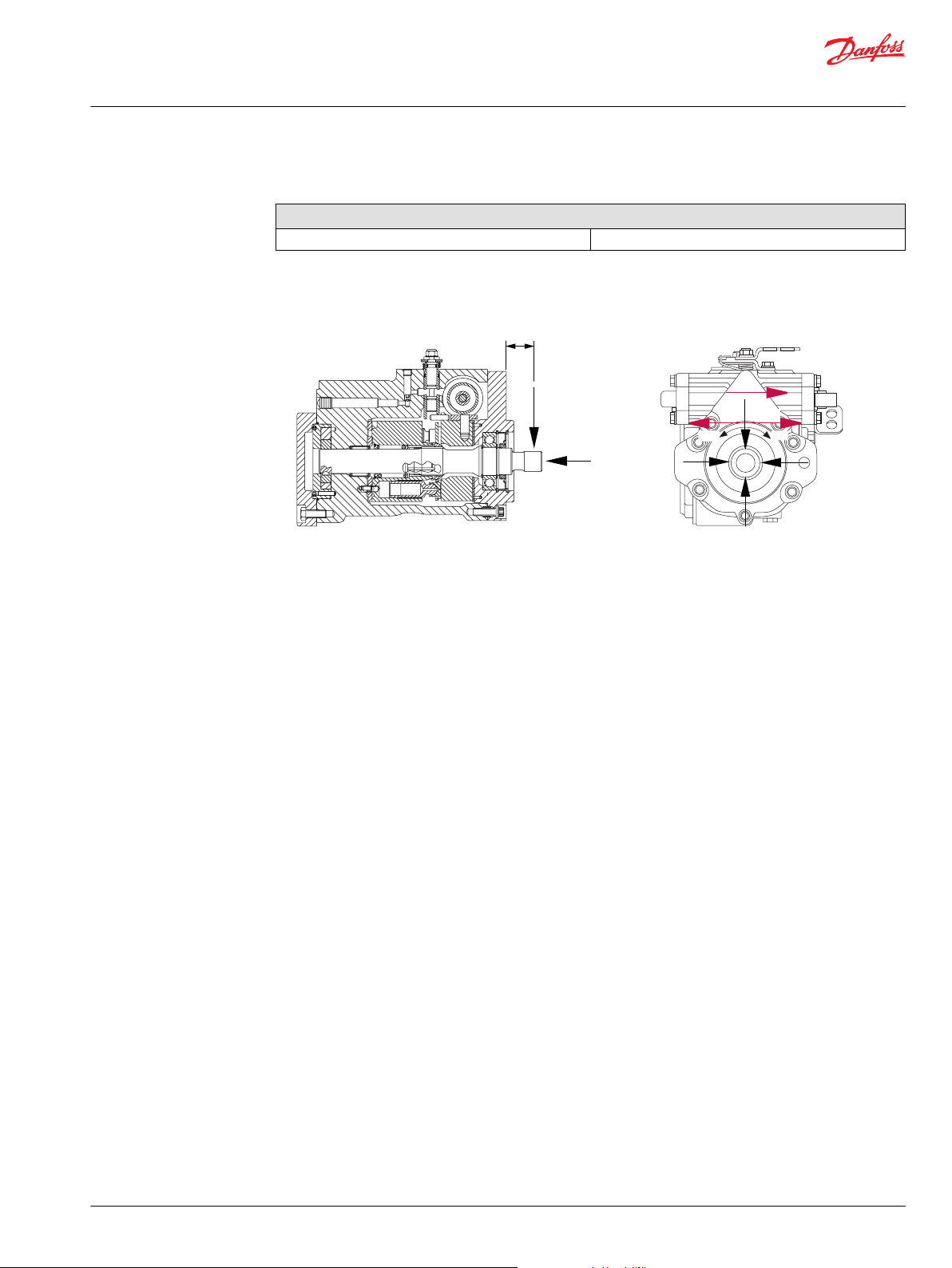

Input

shaft

Auxiliary

pad

Control

Charge check/

high pressure relief

valve

Charge relief

valve

Charge

pump

Valve plate

Piston

Cylinder

block

Cradle

swashplate

Ball

bearing

P100 585E

Technical Information

Series 40 M46 Pumps

General Information

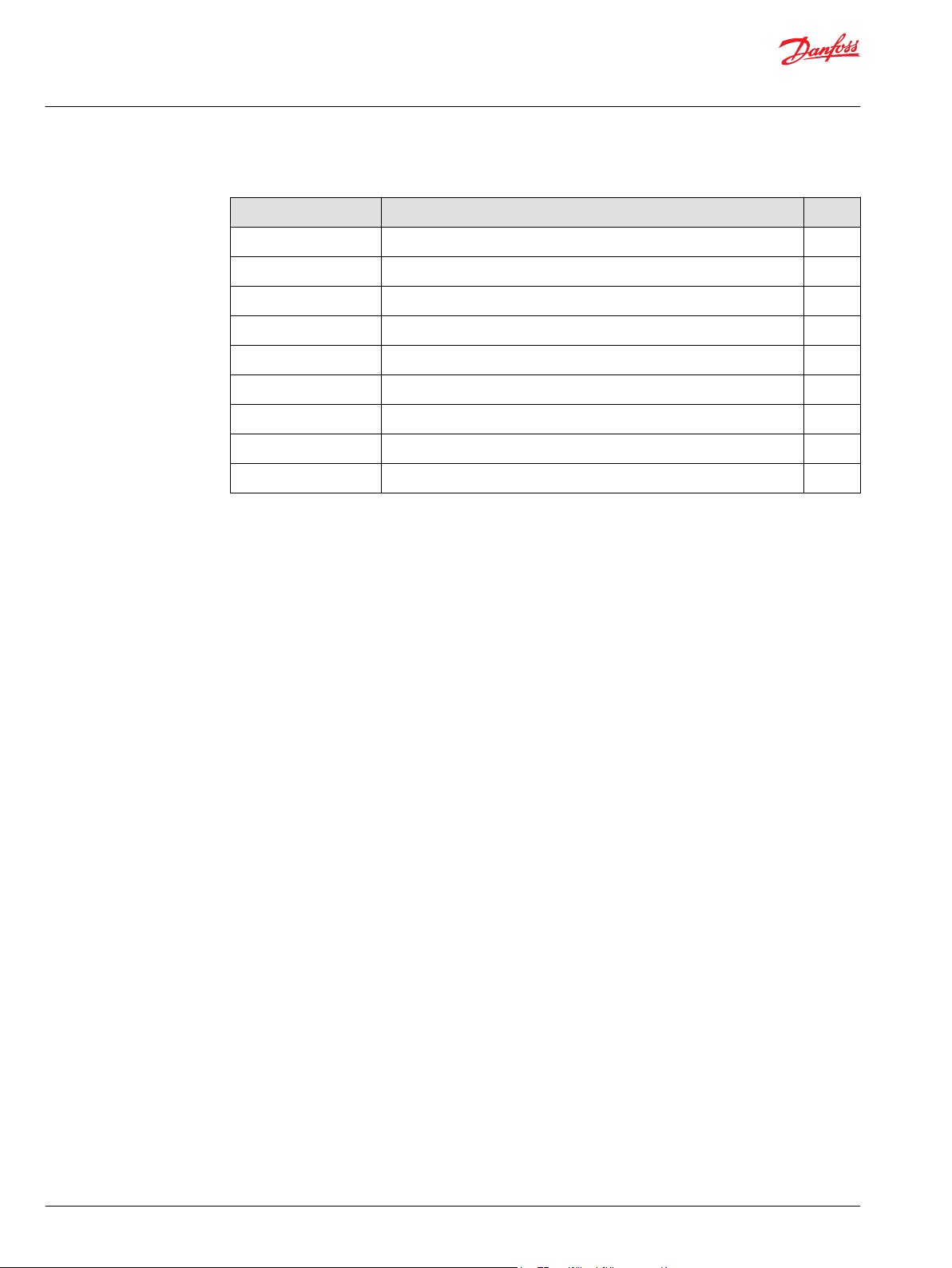

M46 Pumps

M46 Variable Pumps

M46 pumps are designed for medium power applications with maximum loads of 345 bar [5000 psi].

These pumps can be combined with other products in a system to transfer and control hydraulic power.

M46 pumps provide an infinitely variable speed range between zero and maximum in both forward and

reverse modes of operation.

M46 pumps are compact, high power density units. All models use the parallel axial piston / slipper

concept in conjunction with a tiltable swashplate to vary the pump’s displacement. Reversing the angle

of the swashplate reverses the flow of fluid from the pump, reversing the direction of rotation of the

motor output.

M46 pumps may include an integral charge pump to provide system replenishing and cooling fluid flow,

as well as servo control fluid flow. M46 pumps feature a range of auxiliary mounting pads to accept

auxiliary hydraulic pumps for use in complementary hydraulic systems.

M46 pumps offer proportional controls with either manual, hydraulic, or electronic actuation. An electric

three-position control is also available.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 7

Page 8

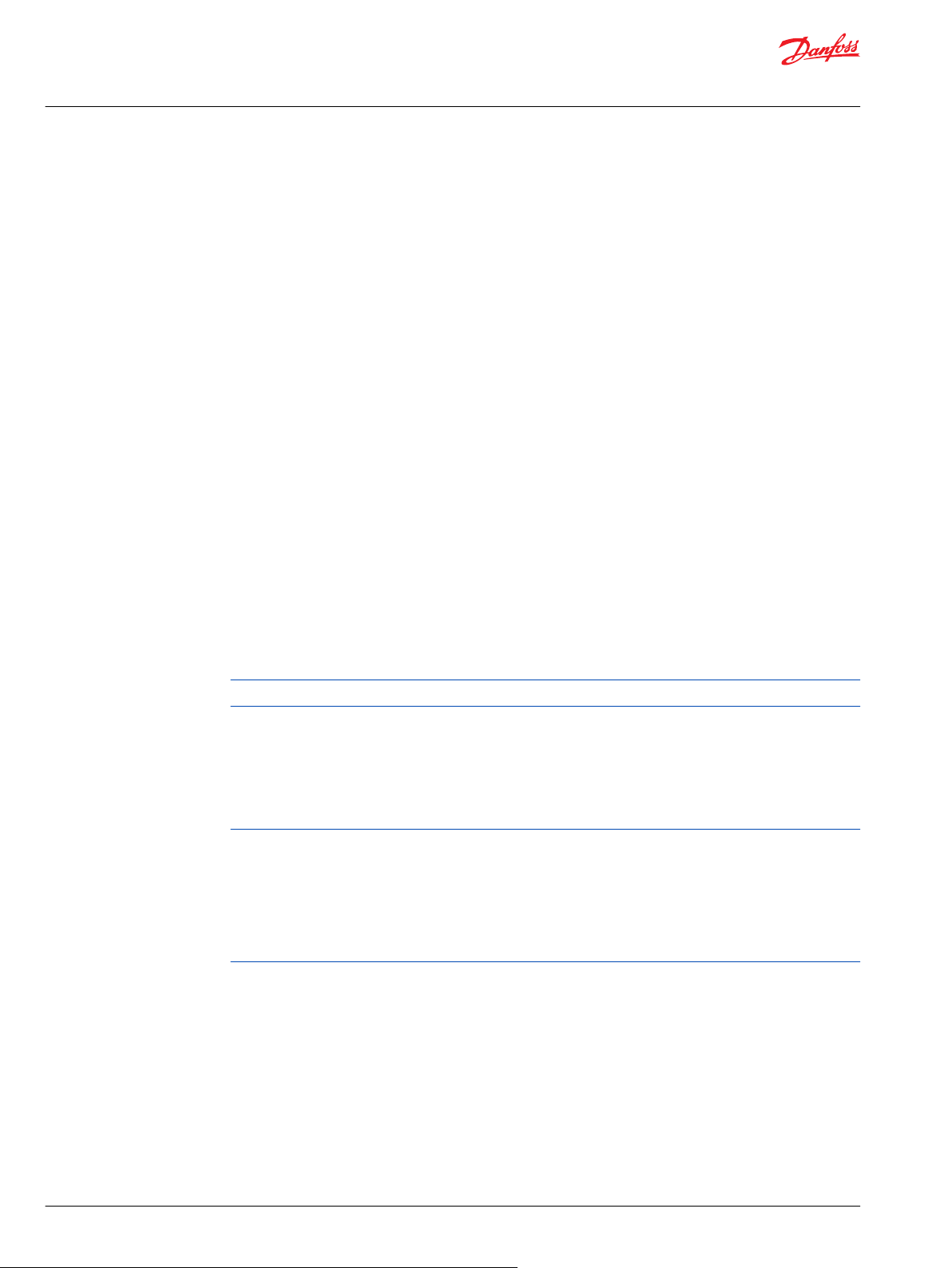

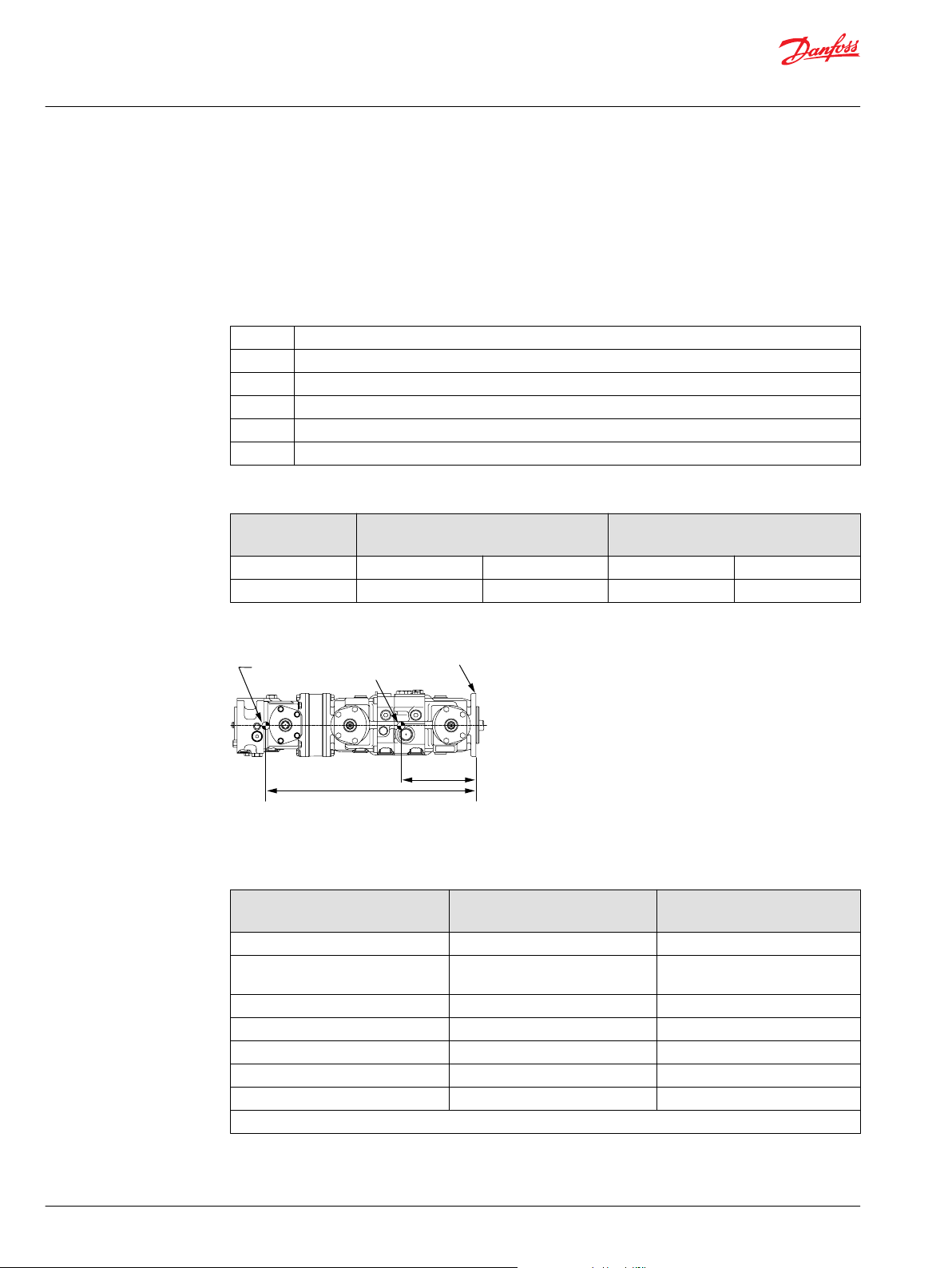

Input

shaft

Suction flow

Servo pressure

High pressure

Case flow

Charge pressure

Output

shaft

Cylinder

block

assembly

Filter

Charge

pump

Reservoir

Fixed displacement

motor

Cylinder

block

assembly

Heat

exchanger

Check valves

w/ high pressure

relief valve

Variable

displacement

pump

Heat exchanger

bypass

Charge relief

valve

Displacement

control

valve

Control

handle

Bypass

valve

Loop flushing

module

P100586

B

M2

M1

A

E

L1

L2

M5

M4

S

M3

B N A

P100587

Technical Information

Series 40 M46 Pumps

General Information

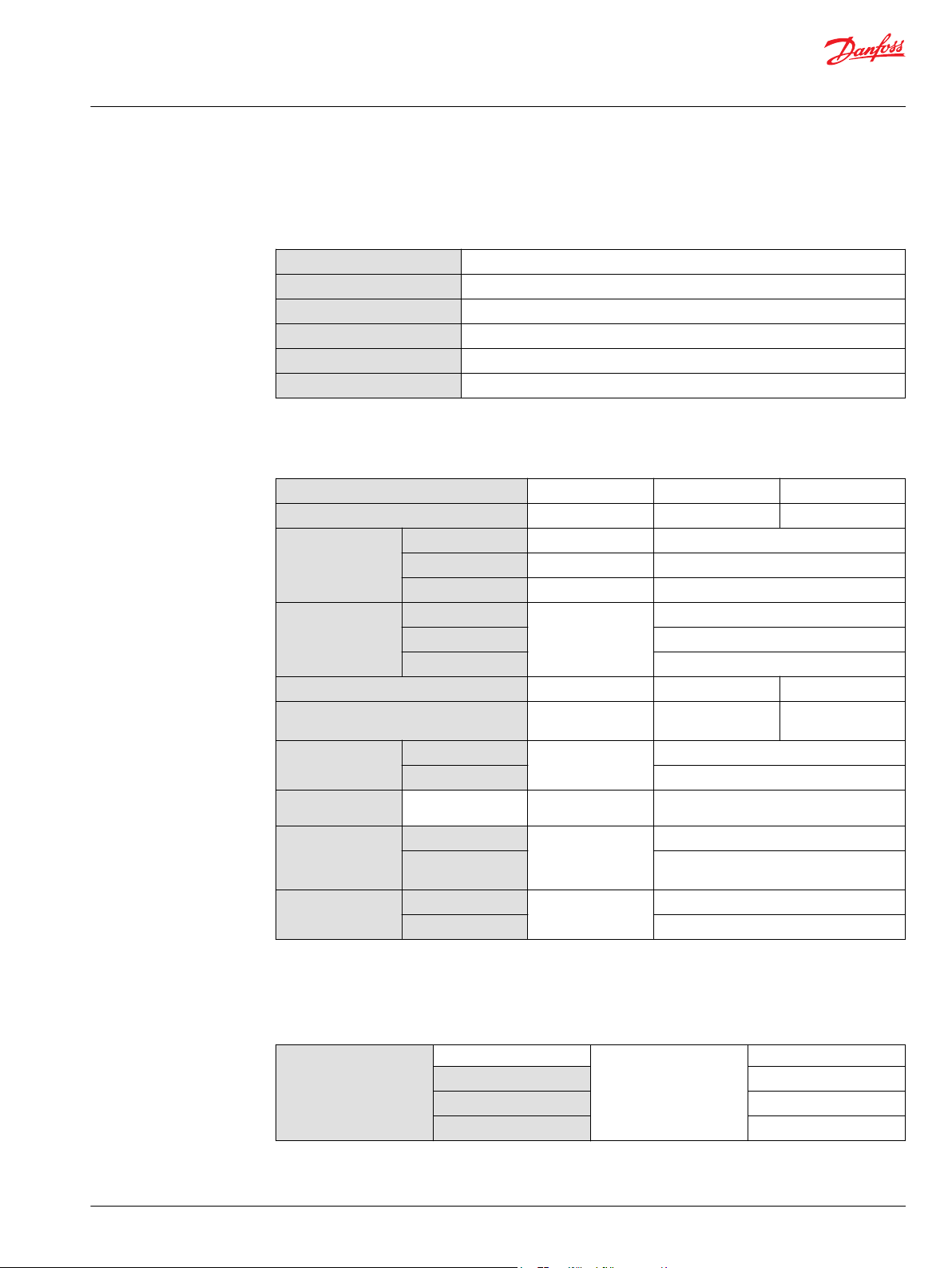

System Circuit Diagram

Schematic Diagram

8 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 9

Technical Information

Series 40 M46 Pumps

Features and Options

Features

Options

•

Efficient Axial Piston Design

•

Compact, Lightweight Pumps

•

Worldwide Support

•

Low Noise

•

Single and Tandem Integrated Tandem Configurations

•

Manual, Hydraulic or Electric Control

High Pressure Relief Valve (HPRV) - A high pressure relief valve limits the system pressure to protect

the system from over-pressure.

Charge Relief Valve - The charge pressure relief valve regulates charge pressure.

Displacement Limiters - Optional displacement limiters allow maximum displacement adjustment to

allow for fine tuning of the propel system.

Auxiliary Mounting Pads - Several auxiliary mounting pad options allow for adding a second pump.

Control Options - Control options include manual displacement control (MDC), hydraulic displacement

control (HDC), electric displacement control (EDC), and threeposition electric displacement control (FNR).

Input Shafts - Straight keyed, tapered keyed, and several splined shaft options are available.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 9

Page 10

Technical Information

Series 40 M46 Pumps

Operating Parameters

Fluids

Ratings and performance data are based on operating with premium hydraulic fluids containing

oxidation, rust, and foam inhibitors. These include premium turbine oils, API CD engine oils per SAE J183,

M2C33F or G automatic transmission fluids (ATF), Dexron II (ATF) meeting Allison C-3 or Caterpillar T0‑2

requirements, and certain specialty agricultural tractor fluids. For more information on hydraulic fluid

selection, see Danfoss publications: Hydraulic Fluids and Lubricants, Technical Information, 520L0463 and,

Experience with Biodegradable Hydraulic Fluids, Technical Information,520L465.

Viscosity

For maximum efficiency and bearing life, ensure the fluid viscosity remains in the recommended range.

The minimum viscosity should be encountered only during brief occasions.

Maximum temperature is based on material properties. Measure maximum temperature at the hottest

point in the system. This is usually the case drain. The maximum viscosity should be encountered only at

cold start, and is merely a reflection of a viscosity condition supporting an engine start, at idle. Normal

vehicle operation and performance should not occur until the fluid viscosity improves with increrased

temperature. For more information on viscosity, see Danfoss publication, Hydraulic Fluids and Lubricants,

Technical Information 520L0463.

Charge Pressure

Temperature

Maintain fluid temperature within the limits shown in the table. Minimum temperature relates to the

physical properties of the component materials. Cold oil will not affect the durability of the pump

components. However, it may affect the ability of the pump to transmit power.

Maximum temperature is based on material properties. Measure maximum temperature at the hottest

point in the system. This is usually the case drain.

Ensure fluid temperature and viscosity limits are concurrently satisfied.

An internal charge relief valve regulates charge pressure. Charge pressure supplies the control with

pressure to operate the swashplate and to maintain a minimum pressure in the low side of the

transmission loop.

The charge pressure setting listed in the order code is the set pressure of the charge relief valve with the

pump in neutral, operating at 1800 min-1 [rpm], and with a fluid viscosity of 32 mm2/s [150 SUS]. Pumps

configured with no charge pump (external charge supply) are set with a charge flow of 19 l/min [5 US gal/

min] (single pumps), 38 l/ min [10 US gal/min] (tandem pumps), and a fluid viscosity of 32 mm2/s [150

SUS].

The charge pressure setting is referenced to case pressure. Charge pressure is the differential pressure

above case pressure.

Minimum charge pressure is the lowest pressure allowed in order to maintain a safe working condition

in the low side of the loop. Minimum control pressure requirements are a function of speed, pressure,

and swashplate angle, and may be higher than the minimum charge pressure shown in the Specifications

section.

Maximum charge pressure is the highest charge pressure allowed by the charge relief adjustment, and

which provides normal component life. Elevated charge pressure can be used as a secondary means to

reduce the swashplate response time.

Control Pressure

Control pressure is the pressure in the servo system needed to position and hold the pump on stroke.

Servo pressure depends on system pressure and speed.

10 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 11

C

Technical Information

Series 40 M46 Pumps

Operating Parameters

Case Pressure

System Pressure

At minimum control pressure, the pump will run at reduced stroke depending on speed and pressure.

Minimum control pressure at corner power holds the pump on full stroke at maximum speed and

maximum pressure.

Maximum control pressure is the highest pressure typically given by the charge pressure setting.

Under normal operating conditions, do not exceed rated case pressure. During cold start, keep case

pressure below maximum intermittent case pressure.

CAUTION

Operating outside of charge and case pressure limits will damage the pump. To minimize this risk, use full

size inlet and case drain plumbing, and limit line lengths.

System pressure is the differential pressure between high pressure system ports. It is the dominant

operating variable affecting hydraulic unit life. High system pressure, which results from high load,

reduces expected life. Hydraulic unit life depends on the speed and normal operating, or weighted

average, pressure that can only be determined from a duty cycle analysis.

Application pressure is the high pressure relief or pressure limiter setting normally defined within the

order code of the pump. This is the applied system pressure at which the driveline generates the

maximum calculated pull or torque in the application.

Maximum Working pressure is the highest recommended application pressure. Maximum working

pressure is not intended to be a continuous pressure. Propel systems with application pressures at, or

below, this pressure should yield satisfactory unit life given proper component sizing.

Maximum pressure is the highest allowable application pressure under any circumstance. Application

pressures above maximum working pressure will only be considered with duty cycle analysis and factory

approval.

Minimum low loop pressure must be maintained under all operating conditions to avoid cavitation.

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

Speed Ratings

Minimum speed is the lowest input speed recommended during engine idle condition. Operating below

minimum speed limits the pump’s ability to maintain adequate flow for lubrication and power

transmission.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed should yield satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Operating conditions between rated speed and maximum speed should be restricted to less than full

power and to limited periods of time. For most drive systems, maximum unit speed occurs during

downhill braking or negative power conditions.

For more information consult Pressure and Speed Limits BLN-9884, when determining speed limits for a

particular application.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 11

Page 12

W

Technical Information

Series 40 M46 Pumps

Operating Parameters

Inlet Pressure

During hydraulic braking and downhill conditions, the prime mover must be capable of providing

sufficient braking torque in order to avoid pump over speed. This is especially important to consider for

turbocharged and Tier 4 engines.

Warning

Unintended vehicle or machine movement hazard.

The loss of hydrostatic drive line power, in any mode of operation (forward, neutral, or reverse) may cause

the system to lose hydrostatic braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

Achieving acceptable pump life and performance requires proper charge pump inlet design. A

continuous inlet pressure of not less than 0.8 bar absolute (not more than 6.3 inches Hg vacuum) is

recommended. Normal pressure less than the minimum inlet pressure of 0.7 bar absolute (greater than

9.2 inches Hg vacuum) indicates inadequate inlet design or a restricted filter. Pressures less than 0.7 bar

absolute (greater than 9.2 inches Hg vacuum) during cold start are likely, but should improve quickly as

the fluid warms.

12 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 13

Based on SI units

= (l/min)

Input torque M = (N•m)

Input power P = = (kW )

Based on US units

= (US gal/min)

Input torque M = (lbf•in)

Input power P = = (hp)

Vg • n • η

v

1000

Vg • ∆p

20 • π • η

m

Q • ∆p

600 • η

t

M • n • π

30 000

Vg • n • η

v

231

Vg • ∆p

2 • π • η

m

Q • ∆p

1714 • η

t

M • n • π

198 000

Flow

Torque

Power

Technical Information

Series 40 M46 Pumps

System Design Parameters

Sizing Equations

Use these equations to help choose the right pump size and displacement for your application.

Variables

SI units [US units]

Vg = Displacement per revolution cm3/rev [in3/rev]

pO = Outlet pressure bar [psi]

pi = Inlet pressure bar [psi]

∆p = pO - pi (system pressure) bar [psi]

n = Speed min-1 (rpm)

ηv = Volumetric efficiency

ηm = Mechanical efficiency

ηt = Overall efficiency (ηv • ηm)

Filtration

Ensure fluid entering pump is free of contaminants to prevent damage (including premature wear) to the

system. M46 pumps require system filtration capable of maintaining fluid cleanliness at ISO 4406-1999

class 22/18/13 or better.

Consider these factors when selecting a system filter:

•

Cleanliness specifications

•

Contaminant ingression rates

•

Flow capacity

•

Desired maintenance interval

Locate filter either on the inlet (suction filtration) or discharge (charge pressure filtration) side of the

charge pump.

Filter efficiency can be measured with a Beta ratio¹ (βX). For simple suction-filtered closed circuit

transmissions and open circuit transmissions with return line filtration, a filter with a β-ratio within the

range of β35-45 = 75 (β10 ≥ 2) or better has been found to be satisfactory. Systems with multiple

cylinders that are feed from a single reservoir require a more efficient filter. This also applies to systems

with gears or clutches using a common reservoir.

For high volume systems, use a charge pressure or return filtration system with a filter β-ratio in the range

of β15-20 = 75 (β10 ≥ 10) or better.

Because each system is unique, only a thorough testing and evaluation program can fully validate the

filtration system. Please see Design Guidelines for Hydraulic Fluid Cleanliness Technical Information

520L0467 for more information.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 13

Page 14

C

Reservoir

Filter

Charge

pump

Charge relief

valve

To pump case

To low pressure

side of loop

and servo control

Strainer

P100588

Technical Information

Series 40 M46 Pumps

System Design Parameters

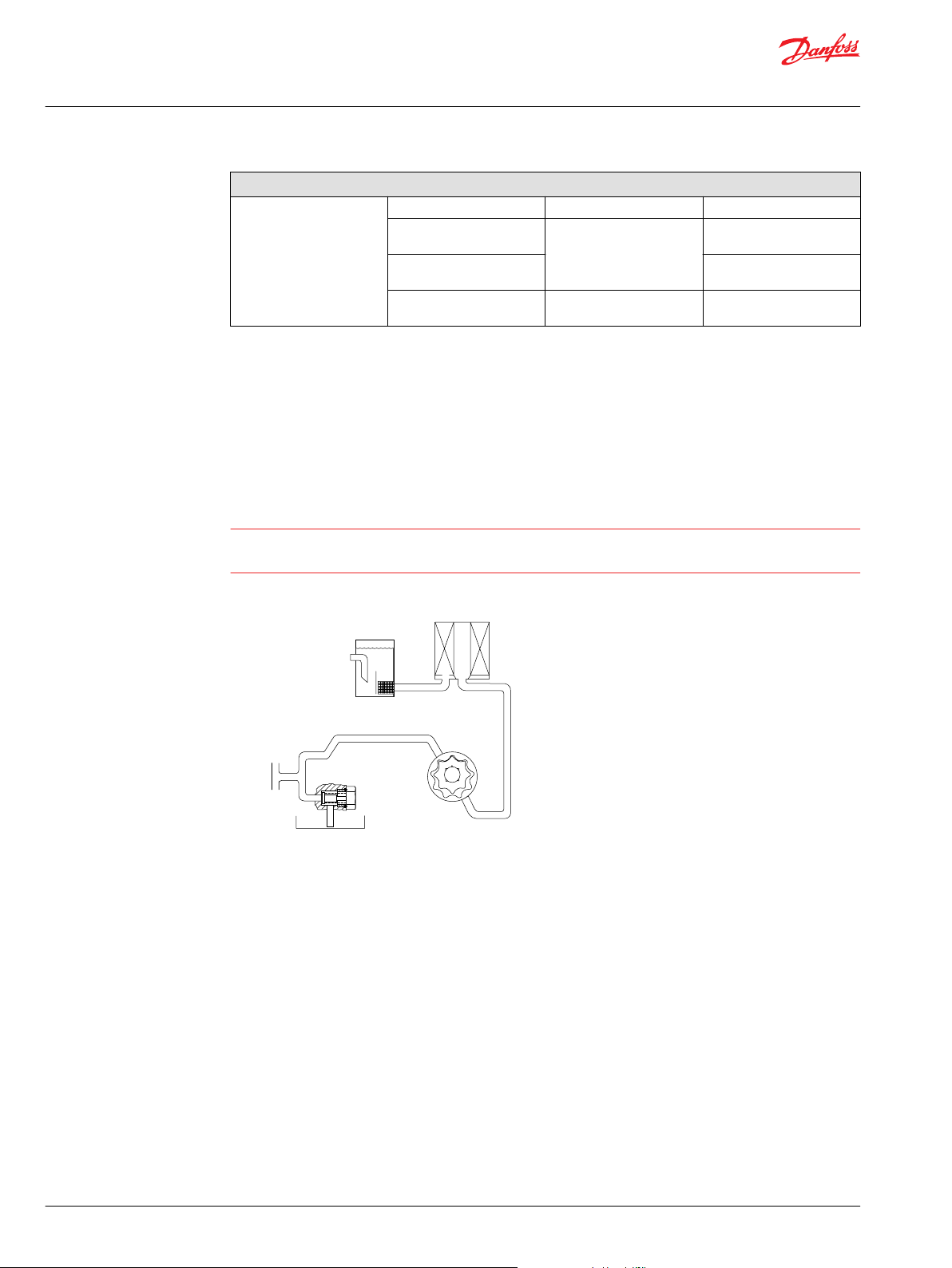

Cleanliness level and βx-ratio

Filtration (recommended

minimum)

1

Filter βx-ratio is a measure of filter efficiency defined by ISO 4572. It is defined as the ratio of the number

Cleanliness per ISO 4406 22/18/13

Efficiency (charge pressure

filtration)

Efficiency (suction and

return line filtration)

Recommended inlet screen

mesh size

β-ratio β

μm 100 – 125

= 75 (β10 ≥ 10)

15-20

β

= 75 (β10 ≥ 2)

35-45

of particles greater than a given diameter (“x” in microns) upstream of the filter to the number of these

particles downstream of the filter.

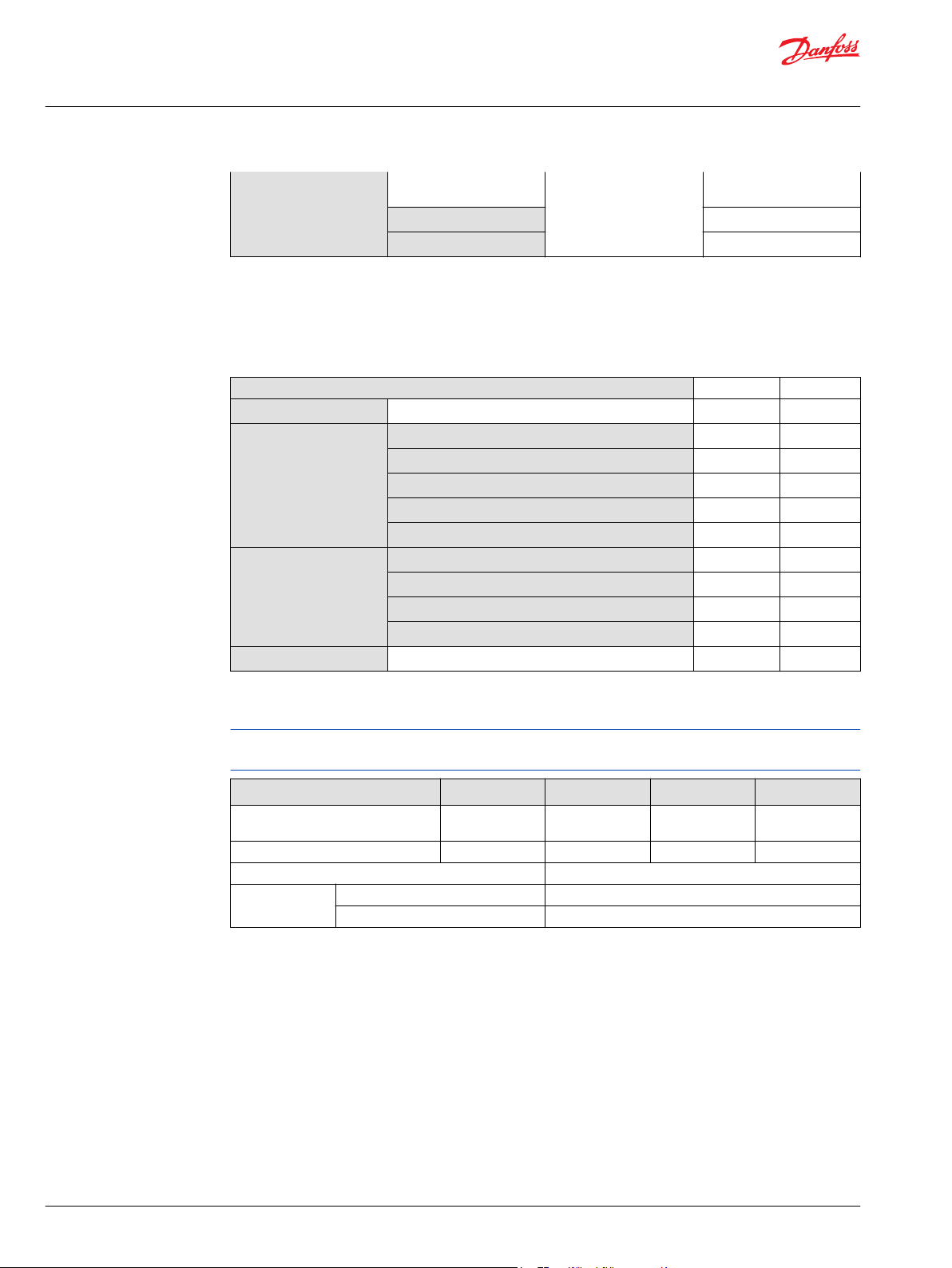

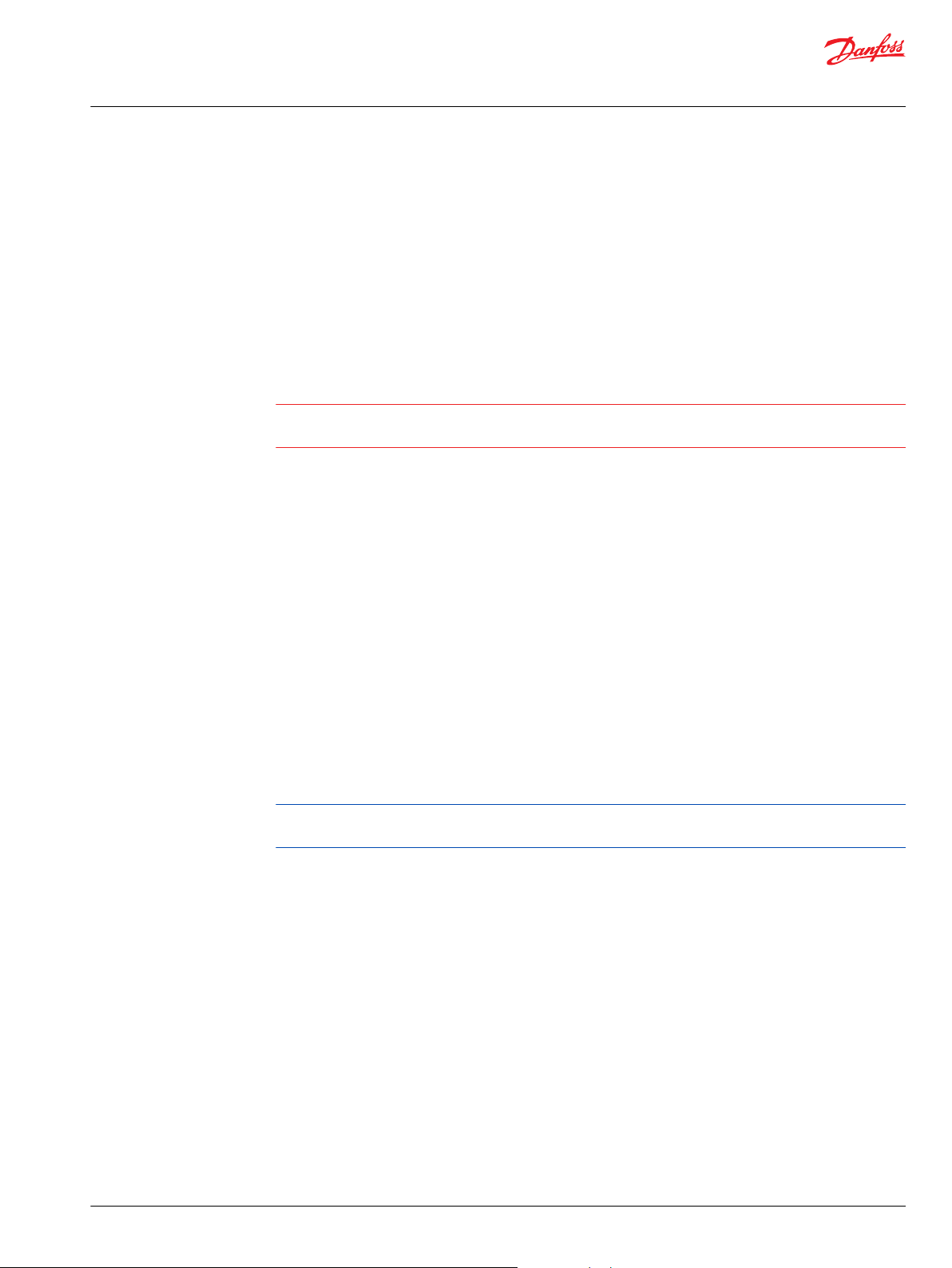

Suction Filtration

The filter is located between the reservoir and the charge pump inlet, as shown in the accompanying

illustration.

CAUTION

Operating outside of charge and case pressure limits will damage the pump. To minimize this risk, use full

size inlet and case drain plumbing, and limit line lengths.

Suction filtration

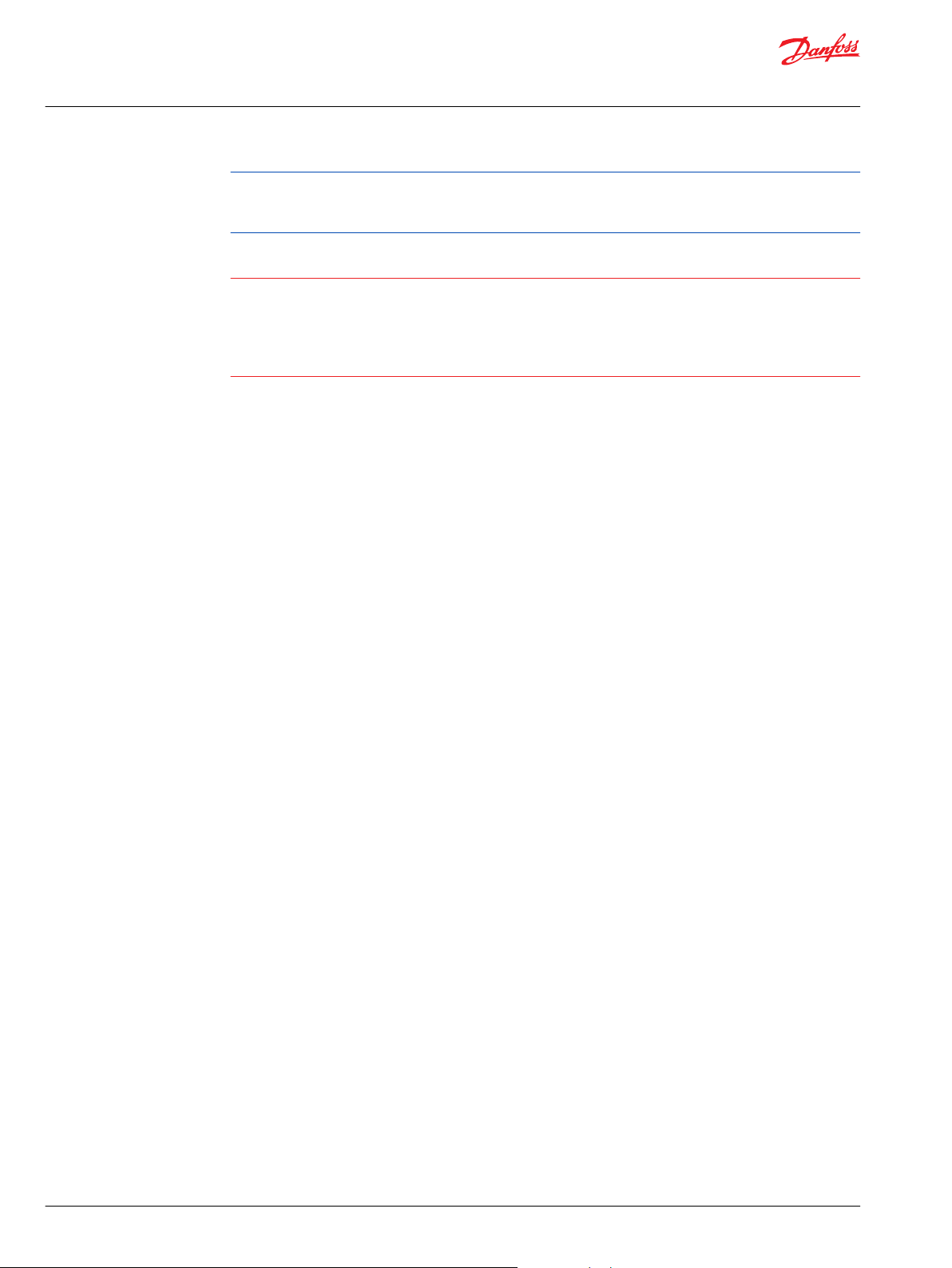

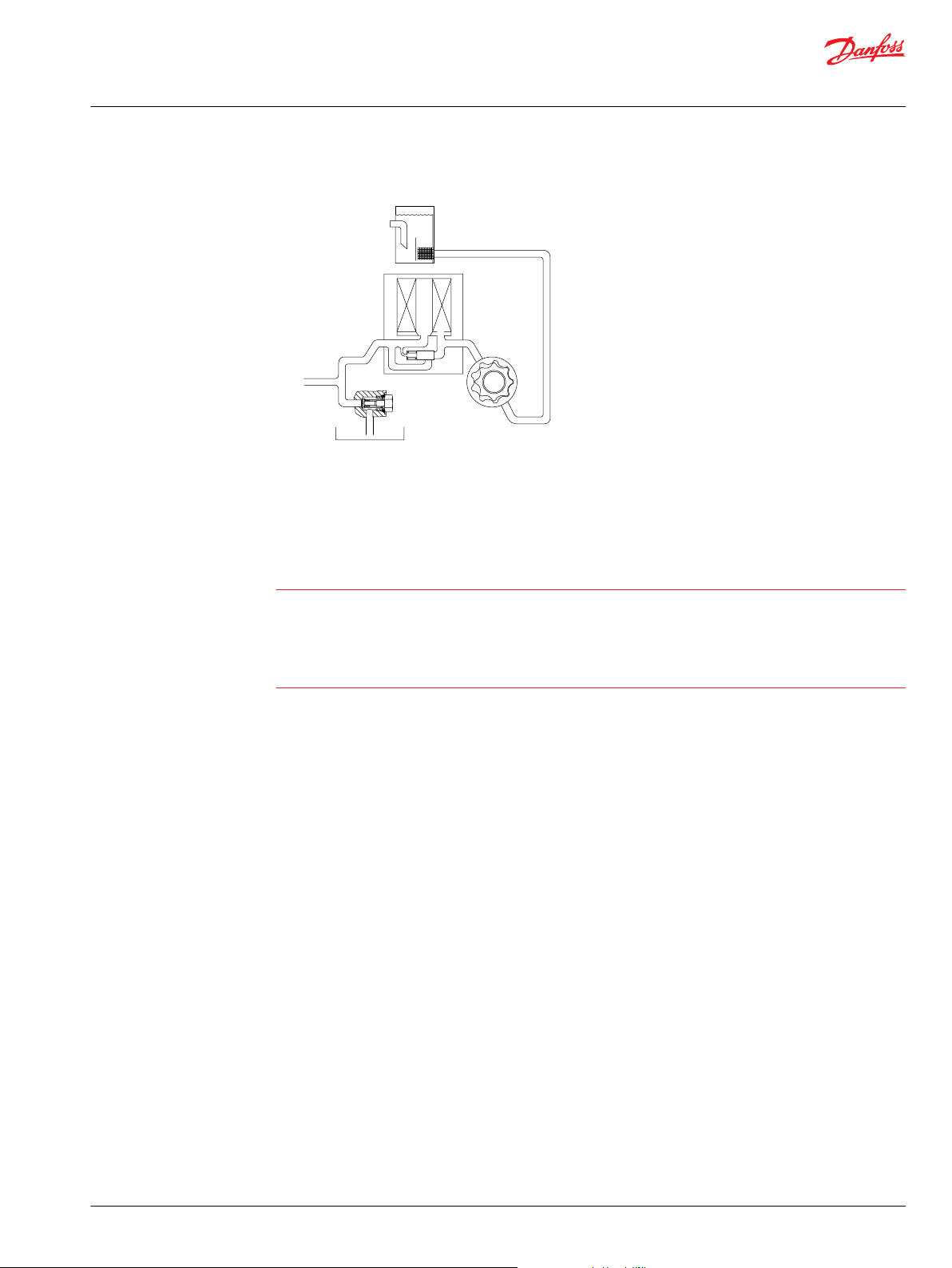

Charge Pressure Filtration

The filter is mounted remotely after the charge pump outlet, as shown in the accompanying illustration.

For charge pressure filtration, use a filter that is rated to at least 34.5 bar [500 psi] pressure. Use a 100 -

125 μm screen in the reservoir or charge inlet line.

A bypass valve is necessary to prevent filter damage and to avoid contaminants from being forced

through the filter by high pressure. In the event of high pressure drop associated with a blocked filter or

cold start-up conditions, fluid will bypass the filter. Avoid working with an open bypass for an extended

period. We recommend a visual or electrical bypass indicator. Proper filter maintenance is mandatory.

14 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 15

Reservoir

Filter

with bypass

Charge

pump

Charge relief

valve

To pump case

To Low Pressure

side of loop

and servo control

Strainer

P106102

W

Technical Information

Series 40 M46 Pumps

System Design Parameters

Charge filtration

Redundant Braking System Requirement

Warning

Unintended vehicle or machine movement hazard

The loss of hydrostatic drive line power, in any mode of operation (forward, neutral, or reverse) may cause

the system to lose hydrostatic braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

Loop Flushing

Closed circuit systems may require loop flushing to meet temperature and cleanliness requirements. A

loop flushing valve removes hot fluid from the low pressure side of the system loop for additional cooling

and filtering. Ensure the charge pump provides adequate flow for loop flushing and the loop flushing

valve does not cause charge pressure to drop below recommended limits.

Reservoir

The reservoir provides clean fluid, dissipates heat, and removes entrained air from the hydraulic fluid. It

allows for fluid volume changes associated with fluid expansion and cylinder differential volumes.

Minimum reservoir capacity depends on the volume needed to perform these functions. Typically, a

capacity of one half the charge pump flow (per minute) is satisfactory for a closed reservoir. Open circuit

systems sharing a common reservoir require greater fluid capacity.

Locate the reservoir outlet (suction line) near the bottom, allowing clearance for settling foreign particles.

Use a 100 - 125 μm screen covering the outlet port.

Place the reservoir inlet (return lines) below the lowest expected fluid level, as far away from the outlet as

possible.

Use a baffle (or baffles) between the reservoir inlet and outlet ports to promote de-aeration and reduce

fluid surging.

Case Drain Usage for Tandem Pumps

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 15

The tandem housings are connected through the center section via a drilled hole. The charge relief valve

discharges oil into the front housing. In order to provide positive flow through both housings, use a case

Page 16

Technical Information

Series 40 M46 Pumps

System Design Parameters

drain in the rear housing. The front housing case drain ports should only be used if the pump is used as a

common drain manifold for the vehicle where external drain flow is brought into the rear housing and

discharged out the front.

Allowable case pressure limits must be satisfied.

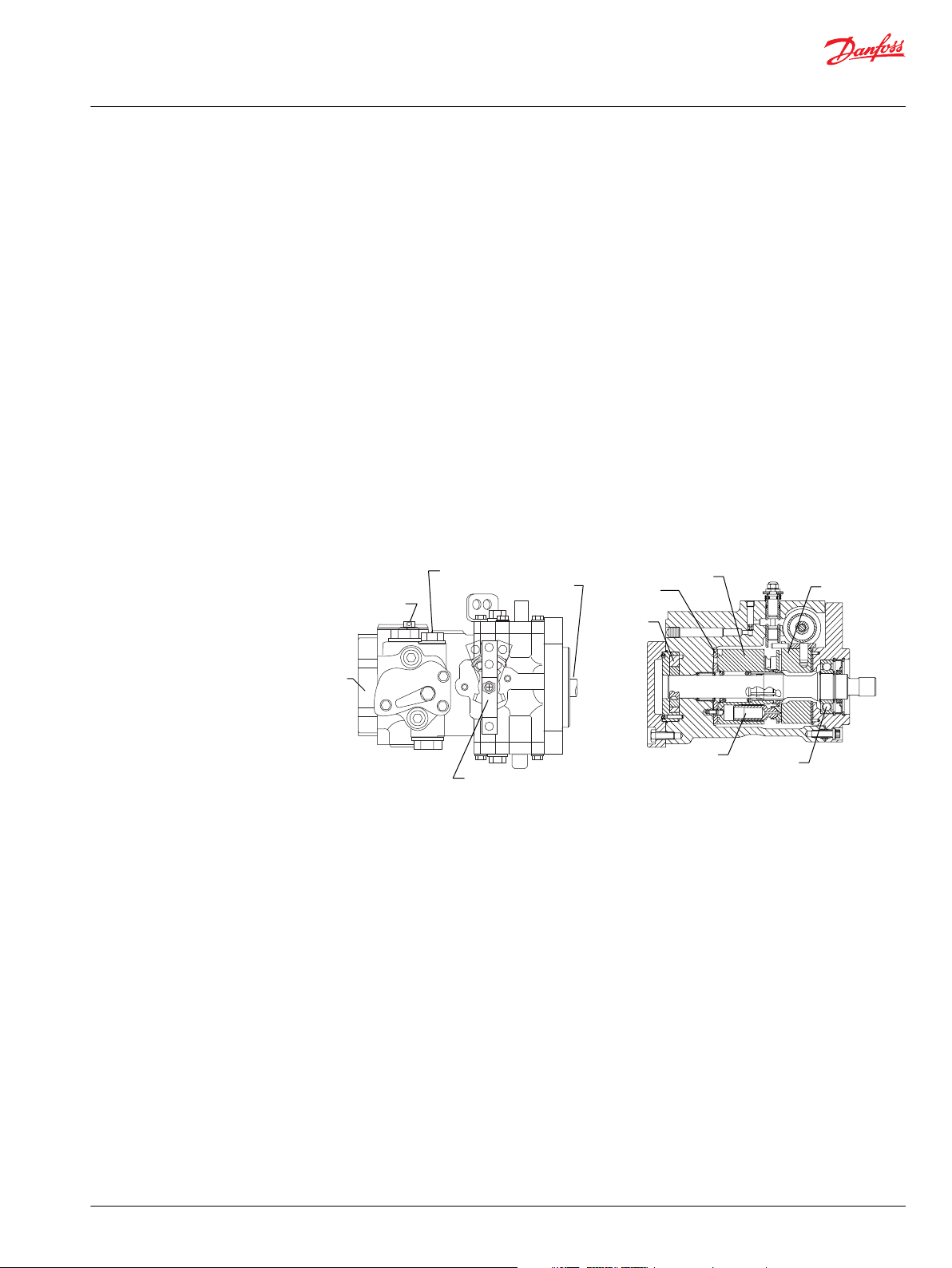

Bearing Life and External Shaft Loading

Bearing life is a function of speed, system pressure, charge pressure, and swashplate angle, plus any

external side or thrust loads. Other life factors include oil type and viscosity. The influence of swashplate

angle includes displacement as well as direction. External loads are found in applications where the

pump is driven with side/thrust load (belt or gear) as well as in installations with misalignment and

improper concentricity between the pump and drive coupling.

In vehicle propel drives with no external shaft loads and where the system pressure and swashplate angle

are changing direction and magnitude regularly, the normal L20 bearing life (80% survival) will exceed

the hydraulic load-life of the unit.

In non propel drives such as vibratory drives, conveyor drives, or fan drives, the operating speed and

pressure are often nearly constant and the swashplate angle is predominantly at maximum. These drives

have a distinctive duty cycle compared to a propulsion drive. In these types of applications a bearing life

review is recommended.

M46 pumps are designed with bearings that can accept some external radial and thrust loads. When

external loads are present, the allowable radial shaft loads are a function of the load position relative to

the mounting flange, the load orientation relative to the internal loads, and the operating pressures of

the hydraulic unit. In applications where external shaft loads can not be avoided, the impact on bearing

life can be minimized by proper orientation of the load. Optimum pump orientation is a consideration of

the net loading on the shaft from the external load, the pump rotating group, and the charge pump load.

A high capacity (cylindrical roller) input shaft bearing is available for applications with high external shaft

loads. Contact your Danfoss representative.

In applications where the pump is operated such that nearly equal amounts of forward vs reverse

•

swashplate operation is experienced; bearing life can be optimized by orientating the external side

load to the 0 or 180 deg position (90 deg to rotating group load Fb). See drawing.

In applications where the pump is operated such that the swashplate is predominantly (>75%) on

•

one side of neutral (e.g. vibratory, conveyor, typical propel); bearing life can be optimized by

orientating the external side load generally opposite of the internal rotating group load, Fb. The

direction of the internal loading is a function of rotation and system port, which has flow out.

Avoid axial thrust loads in either direction.

•

The maximum allowable radial loads (Re), based on the maximum external moment (Me) and the

distance (L) from the mounting flange to the load, may be determined from the tables below and the

cross section drawing.

The maximum allowable radial load is calculated as: Re = Me / L

Contact your Danfoss representative for an evaluation of unit bearing life if continuously applied external

radial loads are 25% or more of the maximum allowable, or if thrust loads are known to exist.

Shaft loading parameters

Re Maximum external radial load

Me Me Maximum external moment

L Distance from mounting flange to point of load

Fb Force of cylinder block

Te Thrust external load

Fcp Force of charge pump

16 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 17

L

Re

Te

P100594

270

Re

0

Re

90

Re

180

Re

CW

CCW

F

cp

F

b

Technical Information

Series 40 M46 Pumps

System Design Parameters

Maximum external shaft moments

Standard Bearing

Me/N•m [in·lbf ] 186 [1650]

External radial shaft load

Hydraulic Unit Life

Mounting Flange Loads

Hydraulic unit life is defined as the fatigue life expectancy of the hydraulic components. It is a function of

speed and system pressure; however, system pressure is the dominant variable. High pressure, which

results from high load, reduces expected hydraulic unit life.

System component selection is based on determination of the application maximum loads and speeds.

Testing is recommended to secure duty cycle data in which to predict hydraulic unit life. Contact your

Danfoss representative for assistance in unit life determination. If duty cycle data is not available, normal

input power and maximum pump displacement can be used to determine an application pressure in

which to predict life.

M46 pumps will meet most application hydraulic unit life expectancies if applied within the parameters

specified in this manual and chosen considering the guidelines within Danfoss publication Selection of

Driveline Components BLN-9885. For more detailed information on hydraulic unit life, see Danfoss

publication Pressure and Speed Limits BLN-9884.

Shock load moment is the result of an instantaneous jolt to the system. Continuous load moments are

generated by the typical vibratory movement of the application. Avoid excessive loading of the

mounting flange such as adding tandem mounted auxiliary pumps and/or subjecting pumps to high

shock loads. Design pump applications to stay within the allowable shock load moment and allowable

continuous load moment.

Use the following formulas to estimate overhung load moment for multiple pump mountings:

MS = GS (W1L1 + W2L2 + ... +WnLn)

MC = GC (W1L1 + W2L2 + ... +WnLn)

Refer to the Installation Drawings section to find pump length (L). Refer to the table Technical

Specifications in the Specifications section, to find pump weight (W). An exact measure of W will depend

on the pump’s features.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 17

Page 18

Mounting

flange

CG

Pump 1

CG

Pump 2

L1

L2

P100 596E

Technical Information

Series 40 M46 Pumps

System Design Parameters

The tables below show allowable overhung load moment values. If system parameters exceed these

values add additional pump support.

Estimated maximum and continuous acceleration factors for some typical Series 40 applications are

shown. Applications which experience extreme resonant vibrations may require additional pump

support. Typical continuous (vibratory) values can vary significantly due to changes in engine and pump

configuration and mounting methods.

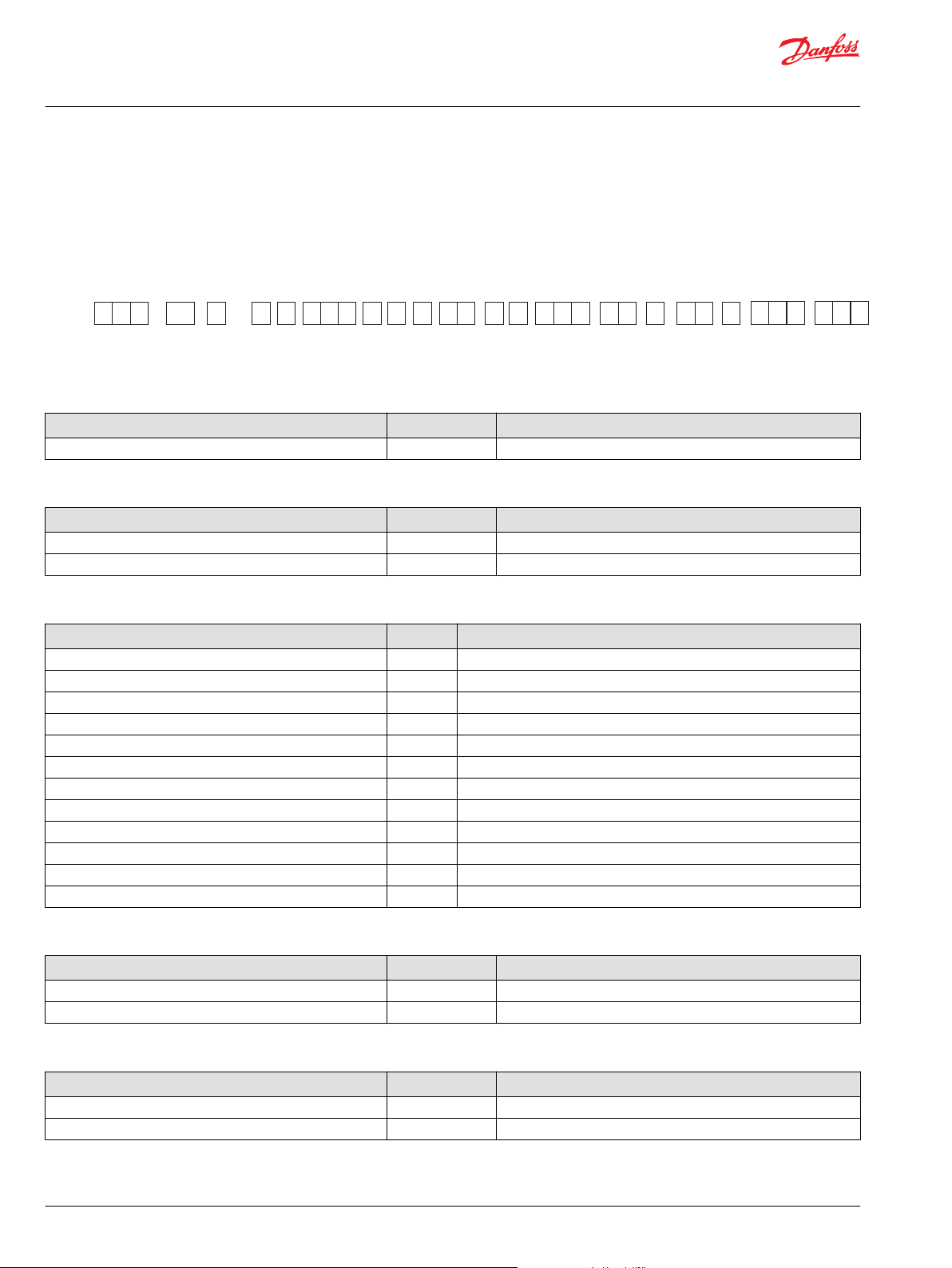

Overhung loading parameters

M

s

M

c

G

s

G

c

W

n

L

n

Shock load moment

Continuous load moment

Maximum shock acceleration (Gs)

Continuous (vibratory) acceleration (Gs)

Weight of nth pump

Distance from mounting flange to center of gravity of nth pump

Allowable overhung parameters

Frame size Continuous load moment (Mc) 107 cycles

N•m [in·lbf]

M46 PV 517 [4600] 832 [7400]

M46 PT 517 [4600] 754 [6700]

Shock load moment (Ms) 103 cycles

N•m [in·lbf]

Shaft loading parameters

The illustration shows a tandem plus a single pump.

G-factors for sample applications

Application Continuous (vibratory)

acceleration (Gc)

Skid steer loader 4 10

Trencher

(rubber tires)

Asphalt paver 2 6

Windrower 2 5

Aerial lift 1.5 4

Turf care vehicle 1.5 4

Vibratory roller 6 10

* Applications which experience extreme resonant vibrations require addition pump support.

3 8

Maximum (shock) acceleration

(Gs)

18 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 19

Technical Information

Series 40 M46 Pumps

System Design Parameters

Shaft Torques

Shaft selection

Base shaft selection on a review of the maximum torque required by the application and the maximum

torque available from the prime mover. Application duty cycle and continuous torque rating of the prime

mover are the main variable to consider when selecting a shaft.

Shaft torque and spline lubrication

The rated torque is a measure of tooth wear and is the torque level at which a normal spline life of 1 x

107 shaft revolutions can be expected. The rated torque presumes a regularly maintained minimum level

of lubrication via a moly-disulfide grease in order to reduce the coefficient of friction and to restrict the

presence of oxygen at the spline interface. It is also assumed that the mating spline has a minimum

hardness of Rc 55 and full spline depth. The rated torque is proportional to the minimum active spline

length.

However, a spline running in oil-flooded environment provides superior oxygen restriction in addition to

contaminant flushing. The rated torque of a flooded spline can increase to that of the maximum

published rating. A flooded spline would be indicative of a pump driven by a pump drive or plugged into

an auxiliary pad of a pump.

Maximum torque ratings are based on torsional fatigue strength considering 1 x 105 full load reversing

cycles.

Maintaining a spline engagement at least equal to the pitch diameter will also maximize spline life. Spline

engagements of less than ¾ pitch diameter are subject to high contact stress and spline fretting.

Shaft torque for tapered shafts

The rated torque is based on the contact pressure between the shaft and hub surfaces with poor contact

areas. With increased quality of the contact areas, the contact pressure between shaft and hub is

increased, allowing higher torque to be transmitted.

A key is intended as an installation aid only. Any torque carried by the key as a result of poor contact area

or mis-alignment will limit the torque carrying capability of the shaft significantly.

Maximum torque rating is based on an ideal contact area of 100% and the retaining nut properly

torqued. This allows for the highest contact pressure between the shaft and the mating hub.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 19

Page 20

C D E F G H J L N

P

R

T Z

K

M

S

Product Frame

Type

MPV 046

C

Technical Information

Series 40 M46 Pumps

Model Code - Single Pumps

Single Pumps

C Swashplate

Description Code Remarks

Standard B

D - Seal Group

Description Code Remarks

Seal group for MDC A Must select an MDC control

Seal group for EDC/HDC/FNR B Must select an EDC/HDC/FNR control

E - Input Shaft/Auxiliary Spline

Description Code Remarks

13T 16/32 Spline / None A Requires S: None aux.. pad

13T 16/32 Spline / 9T 16/32 SplineR B Requires S: SAE-A aux.. pad

13T 16/32 Spline / 11T 16/32 Spline L Requires S: SAE-A aux.. pad

13T 16/32 Spline / 13T 16/32 Spline D Requires S: SAE-B aux.. pad

15T 16/32 Spline / None G Requires S: None aux.. pad

15T 16/32 Spline / 9T 16/32 Spline H Requires S: SAE-A aux.. pad

15T 16/32 Spline / 11T 16/32 Spline J Requires S: SAE-A aux.. pad

15T 16/32 Spline / 13T 16/32 Spline K Requires S: SAE-B aux.. pad

Tapered, 1 inch dia., 1.5 in/foot, square key/9T 16/32 Spline P Requires S: SAE-A aux.. pad. Includes key and nut

Tapered, 1 inch dia., 1.5 in/foot, square key/ 13T 16/32 Spline S Requires S: SAE-B aux.. pad. Includes key. Nut is customer supplied

Straight key, 1 inch diamater / None V Requires S: None aux.. pad. Includes key.

Straight key, 1 inch diameter / 9T 16/32 Spline W Requires S: SAE-A aux.. pad, includes key.

F - Rotation and valve plate

Description Code Remarks

CW, Quiet (Standard) S CP15; 3 deg. index. Requires charge pressure > 19.5 bar.

CCW, Quiet (Standard) T CP15; 3 deg. index. Requires charge pressure > 19.5 bar.

G - Charge pump

Description Code Remarks

None A Charge relief set at 19 l/min, external supply

13.9 cc [0.85 in./cu] B Charge relief set at 1800 rpm

20 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 21

Technical Information

Series 40 M46 Pumps

Model Code - Single Pumps

H - Charge pressure

Description Code Remarks

19.5 bar B

21.5 bar J

25.0 bar S EDC/HDC controls calibrated at 20.7 bar charge

J - Filtration

Description Code Remarks

Suction, with charge pump AA Requires G: with charge pump

Remote pressure, with charge pump BA Requires G: with charge pump

Remote (external) pressure , without charge pump BC Requires G: no charge pump

Suction, with charge pump (HC EDC housing) HA requires G: with charge pump, N: with HC EDC

Remote pressure with charge pump(HC EDC housing) HB requires G: with charge pump, N: with HC EDC

Remote (external) pressure, without charge pump (HC EDC

housing)

HC requires G: no charge pump, N: with HC EDC

K - Displacement limiters

Description Code Remarks

Full displacement, 46 cc/rev [2.8 cu. in./rev] A

46 cc/rev [2.8 cu. in./rev] with adj. limiter, side #2 only,

centered side #2

V

L - Bypass valve

Description Code

Bypass valve A

M - System pressure protection, A and B ports

Port protection

Plug type Letter Port A Port B

Standard B Relief/Check Relief/Check

Second and Third Letter

M 140 bar

B 175 bar

C 100 bar

D 210 bar

E 230 bar

F 250 bar

G 280 bar

H 300 bar

R 325 bar

J 345 bar

Contact your Danfoss representative for configurations or pressures not shown.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 21

Page 22

Technical Information

Series 40 M46 Pumps

Model Code - Single Pumps

N - Control type

Description Code Remarks

MDC handle with (2) 10 mm diameter holes, standard spring AB Recommend AW with metered spool

MDC with (3) 10 mm diameter holes, standard spring AC Recommend AK with metered spool

MDC with (3) 10 mm diameter holes, U shaped, standard

spring, metered spool

MDC handle with (2) 10 mm diameter holes, standard spring,

metered spool

MDC heavy duty handle with (4) 10 mm diameter holes, heavy

spring, metered spool

HDC 1.3-11.7 bar BA 19-170 psi

HDC 3.0-13.8 bar BB 44-200 psi

HDC 4.8-15.2 bar BC 70-220 psi

EDC dual coil, oil filled, Packard connector, 4-pin, 23-132 mA CE

EDC dual coil, oil filled, MS connector, 4-pin, 23-132 mA CG

EDC dual coil, oil filled, Deutsch connector, 4-pin, 23-132 mA CN

FNR 12 volt, DIN 43650 connector DA

FNR 24 volt, DIN 43650 connector DB

EDC, high current, 12 volt, Deutsch connector, 2-pin HA

EDC, high current, 24 volt, Deutsch connector, 2-pin HB

AK

AW

GB P; handle position to be B

P - Handle position

Description Code Remarks

Not applicable (EDC, HDC, FNR) A

Both, up and down B N: MDC to include heavy duty 4-hole handle. Handle is symmetric

Down (MDC) D 2, or 3 hole handles only. Handle oriented away from suction port.

Up (MDC) U 2, or 3 hole handles only. Handle oriented towards from suction

over spool

port.

R - Control orifice (contact factory for orifice options not shown)

MDC

Supply Drain (Supply and drain

F - None F - None

A - 0.031 inch A - 0.031 inch

B - 0.036 inch B - 0.036 inch

C - 0.041 inch D - 0.041 inch

D - 0.046 inch

EDC/HDC/FNR - Servo A and B

Servo A&B

GG - 0.055 inch

HH 0.037 inch

JJ None

orifice chosen

independently)

22 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 23

Technical Information

Series 40 M46 Pumps

Model Code - Single Pumps

HC EDC - Servo A and B

Servo A&B

HA - 0.046 inch

HB 0.055 inch

HC 0.037 inch

HD 0.024 inch

HE None

S - Auxiliary mounting flange

Description Code Remarks

SAE A, side #2 lift bracket location A E: Shaft to include 9T or 11T aux.. spline

SAE B, side #2 lift bracket location B E: Shaft to include 13T aux.. spline

None, side #2 lift bracket location C E: Shaft to include no aux.. pad

T - Special hardrare

Description Code Remarks

Black paint, Danfoss tag, Layout A NNN

High capacity shaft bearing, black paint, Danfoss tag, Layout A NNR

Z - Special features, Non hardware

Description Code Remarks

None ***

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 23

Page 24

C D L N P R

T Z

K M

S

Front Section

Rear Section

X

Y Z

WU

V

Q D

Product Frame Type

M P

T 046

C

E F G H

J

Technical Information

Series 40 M46 Pumps

Model Code - Tandem Pumps

Tandem Pumps

E - Input Shaft

Description Code Remarks

15T 16/32 Spline A Requires S: None aux.. pad

19T 16/32 Spline B Requires S: SAE-B aux.. pad

Tapered, 1 inch dia., 1.5 in/foot, square key without thru hole H Includes key and nut.

Straight key, 1 inch diamater D Includes key.

F - Rotation and valve plate

Description Code Remarks

CW, without charge pump. Quiet (Standard) S CP15; 3 deg. index. Requires charge pressure > 19.5 bar.

CCW, without charge pump. Quiet (Standard) T CP15; 3 deg. index. Requires charge pressure > 19.5 bar.

CW, with 22.9 cc charge pump. Quiet (Standard) V CP15; 3 deg. index. Requires charge pressure > 19.5 bar.

CCW, with 22.9 cc charge pump. Quiet (Standard) Z CP15; 3 deg. index. Requires charge pressure > 19.5 bar.

G - Charge pump

Description Code Remarks

None A Charge relief set at 38 l/min, external supply

22.9 cc [1.4 in./cu] C Charge relief set at 1800 rpm. Filtration and rotation must include

charge pump

H - Charge pressure

Description Code Remarks

19.5 bar B

21.5 bar J

25.0 bar S EDC/HDC controls calibrated at 20.7 bar charge

J - Filtration

Description Code Remarks

Suction, with charge pump AA Requires a charge pump

Remote pressure, with charge pump BA Requires a charge pump

Remote (external) pressure, without charge pump BC Requires no charge pump

24 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 25

Technical Information

Series 40 M46 Pumps

Model Code - Tandem Pumps

C - Swashplate group, front pump/Q - Swashplate group, rear pump

Description Code Remarks

Balanced B

D - Seal Group

Description Code Remarks

Seal group for MDC - Front pump A Must select an MDC control

Seal group for EDC/HDC/FNR - Front pump B Must select an EDC/HDC/FNR control

Seal group for MDC - Rear pump C Must select an MDC control

Seal group for EDC/HDC/FNR - Rear pump D Must select an EDC/HDC/FNR control

K - Displacement limiters, front pump, U- Displacement limiters, rear pump

Description Code Remarks

Full displacement, 46 cc/rev [2.8 cu. in./rev] A

46 cc/rev [2.8 cu. in./rev] with adj. limiter, side #2 only,

centered side #2

V

L/X - Bypass valve

Description Code

Bypass valve A

M - System pressure protection, A and B ports V - System pressure protection, rear pump, A and B ports

Port protection

Plug type First Letter Port A Port B

Standard B Relief/Check Relief/Check

Second and Third Letter

M 140 bar

B 175 bar

C 100 bar

D 210 bar

E 230 bar

F 250 bar

G 280 bar

H 300 bar

R 325 bar

J 345 bar

Contact your Danfoss representative for configurations or pressures not shown.

N - Control type, front pump /Y - Control type, rear pump

Description Code Remarks

MDC handle with (2) 10 mm diameter holes, standard spring AB Recommend AW with metered spool

MDC with (3) 10 mm diameter holes, standard spring AC Recommend AK with metered spool

MDC with (3) 10 mm diameter holes, U shaped, standard

spring, metered spool

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 25

AK

Page 26

Technical Information

Series 40 M46 Pumps

Model Code - Tandem Pumps

N - Control type, front pump /Y - Control type, rear pump (continued)

Description Code Remarks

MDC handle with (2) 10 mm diameter holes, standard spring,

metered spool

MDC heavy duty handle with (4) 10 mm diameter holes, heavy

spring, metered spool

HDC 1.3-11.7 bar BA 19-170 psi

HDC 3.0-13.8 bar BB 44-200 psi

HDC 4.8-15.2 bar BC 70-220 psi

EDC dual coil, oil filled, Packard connector, 4-pin, 23-132 mA CE

EDC dual coil, oil filled, MS connector, 4-pin, 23-132 mA CG

EDC dual coil, oil filled, Deutsch connector, 4-pin, 23-132 mA CN

FNR 12 volt, DIN 43650 connector DA

FNR 24 volt, DIN 43650 connector DB

P/Z - Handle position

Description Code Remarks

Not applicable (EDC, HDC, FNR) A EDC, HDC, FNR only

Both, up and down B N: MDC to include heavy duty 4-hole handle. Handle is symmetric

Down (MDC) D 2, or 3 hole handles only. Handle oriented away from suction port.

Up (MDC) U 2, or 3 hole handles only. Handle oriented towards from suction

AW

GB P; handle position to be B

over spool

port.

R - Control orifice, front pump, W- Control orifice, rear pump

MDC

Supply Drain (Supply and

F - None F - None

A - 0.031 inch A - 0.031 inch

B - 0.036 inch B - 0.036 inch

C - 0.041 inch D - 0.041 inch

D - 0.046 inch

EDC/HDC/FNR - Servo A and B

Servo A&B

GG - 0.055 inch

HH 0.037 inch

JJ None

S - Auxiliary mounting flange and coupling

Description Code Remarks

None C

SAE A, 9 tooth 16/32 spline A

drain orifice

chosen

independently)

26 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 27

Technical Information

Series 40 M46 Pumps

Model Code - Tandem Pumps

S - Auxiliary mounting flange and coupling (continued)

Description Code Remarks

SAE A, 11 tooth 16/32 spline D

SAE B, 11 tooth 16/32 spline B

T - Special hardrare

Description Code Remarks

Black paint, Danfoss tag, Layout A NNN

High capacity shaft bearing, black paint, Danfoss tag, Layout A NNR

Z - Special features, Non hardware

Description Code Remarks

None ***

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 27

Page 28

69.6

[2.74]

Coupling must not

protrude beyond

this surface

2.85 [0.112] max.

6.35 [0.250] Sq. key

44.4 [1.75] long

0.38 [0.015] min. R on edges

25.4 [1.00] dia.

7.4 [0.29]

Mounting flange

(ref.)

P104415

3/4-16 UNF-2B thd.

42.4 [1.67]

1.50 taper per

foot

SAE standard J501

25.4 [1.000] nominal

shaft dia.

26.9

[1.06]

22.2 [0.875] gauge dia.

33.3 [1.311] Gauge Dim.

Coupling must not

protrude beyond

36.3 [1.44] max.

Mounting flange

(ref.)

12.7

[0.50]

Customer supplied

nut.

Torque nut to

149 to 190 Nm

[110 to 140 Lbf •f

t ]

Thds. to be

cleaned and

lubricated

P104417

6.35 [0.250] Sq. key

19.05 [0.75] long

0.38 [0.015] min. R on edges

2.84 [0.112] max.

Technical Information

Series 40 M46 Pumps

Options

Shaft options

Recommended mating splines for Series 40 splined output shafts should be in accordance with

ANSIB 92.1 Class 5. Danfoss external splines are modified Class 5 Fillet Root Side Fit. The external splined

Major Diameter and Circular Tooth Thickness dimensions are reduced in order to assure a clearance fit

with the mating spline. Other shaft options may exist. Contact your Danfoss representative for

availability.

Single pumps

Code Description Maximum torque

rating Nm [lbf in]

V, W Ø 25.4 mm [1.000 in]

362 [3200]

Straight keyed Shipped with key

P, S Ø 25.4 mm [1.000 in]

497 [4400]

1:8 taper (SAE J501) No thru hole Shipped with key only

Drawing

28 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 29

W pitch dia.

Y teeth, 16/32 pitch

30° pressure angle

fillet root side fit

per ANSI B92.1-1970

class 5

also mates with

flat root side fit

T

V

U

S

7.4 [0.29]

Coupling must not protrude

beyond this surface

Mounting flange

(ref.)

P104416

Technical Information

Series 40 M46 Pumps

Options

Code Description Maximum torque rating

Nm [lbf in]

A, B, L, D 13-tooth 16/32 pitch (ANSI

226 [2000] 124 [1100]

B92.1 1970 - Class 5)

G, H, J, K 15-tooth 16/32 pitch (ANSI

362 [3200] 153 [1350]

B92.1 1970 - Class 5)

Shaft options Length Shaft

diameter

S T U V W Y

A, B, D, L 32.9 [1.297] 20.3 [0.80] 16.26 [0.64] 21.72 [0.8550] 20.64 [0.8125] 13

G, H, J, K 37.7 [1.485] 22.3 [0.88] 23.4 [0.92] 24.89 [0.9800] 23.81 [0.9375] 15

Other shaft options may exist. Contact your Danfoss representative for availability and for specific

installation drawings.

Rated torque

Nm [lbf in

Full spline Major

Drawing

diameter

Pitch

diameter

No. teeth

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 29

Page 30

69.47

[2.735]

Coupling must not

protrude beyond

this surface

6.35 [0.250] sq. key

44.45 [1.75] long

0.38 [0.015] min. R. on edges

25.4 [1.00] dia.

7.47 [0.294]

Mounting flange

(ref.)

P104412

3/4-16 UNF-2 thd.

42.8 [1.685]

1.50 taper per foot

per SAE

standard J501

25.4 [1.000] Nominal

shaft dia.

26.9

[1.06]

22.2 [0.875] Gauge dia.

33.3 [1.311] gauge dim.

Coupling must not

protrude beyond

25.4 [1.000] max.

Mounting flange

(ref.)

P104414

6.35 [0.250] Sq. key

19.05 [0.75] long

0.38 [0.015] min. R on edges

2.84 [0.112] max.

1 inch

Hex nut

torque to

149 to 190 Nm

[110 to 140 Lbf •f

t.]

Threads to be

cleaned and

lubricated

W pitch dia.

Y teeth, 16/32 pitch

30° pressure angle

fillet root side fit

per ANSI B92.1-1970

class 5

also mates with

flat root side fit

T

V

U

S

7.4 [0.29]

Coupling must not protrude

beyond this surface

Mounting flange

(ref.)

P104416

Technical Information

Series 40 M46 Pumps

Options

Tandem pumps

Code Description Maximum torque

rating Nm [lbf in]

D Ø 25.4 mm [1.000 in]

362 [3200]

Straight keyed Shipped with key

H Ø 25.4 mm [1.000 in]

497 [4400]

1:8 taper (SAE J501) No thru hole Shipped with key only

Drawing

Code Description Maximum torque

rating Nm [lbf in]

Rated

torque

Drawing

Nm [lbf

in

A 15-tooth 16/32

pitch (ANSI B92.1

362 [3200] 153

[1350]

1970 - Class 5)

B 19-tooth 16/32

pitch (ANSI B92.1

734 [6500] 305

[2700]

1970 - Class 5)

30 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 31

P100589

Technical Information

Series 40 M46 Pumps

Options

Charge Pump

Shaft options Length Shaft

diameter

S T U V W Y

A 37.7 [1.485] 22.3 [0.88] 23.4 [0.92] 24.89 [0.9800] 20.638 [0.9375] 15

B 37.7 [1.497] 28.7 [1.13] 24.1 [0.95] 31.24 [1.230] 30.163 [1.1875] 19

Full spline Major

diameter

Pitch

diameter

No. teeth

Other shaft options may exist. Contact your Danfoss representative for availability and for specific

installation drawings.

Charge flow is required on all M46 units to make up for internal leakage, maintain positive pressure in the

main circuit, provide flow for cooling, replace any leakage losses from external valving or auxiliary

systems, and to provide flow and pressure for the control system.

Maintain minimum charge pressure under all conditions of operation to prevent damage to the

transmission.

Charge pump

Many factors influence the charge flow requirements and the resulting charge pump size selection. These

factors include system pressure, pump speed, pump swashplate angle, type of fluid, temperature, size of

heat exchanger, length and size of hydraulic lines, control response characteristics, auxiliary flow

requirements, hydraulic motor type, etc. Charge pump displacement should be equal to or greater than

10% of the total displacement of all units in the system.

The total charge flow requirement is the sum of the charge flow requirements of each of the components

in the system. Use the information provided on the following pages to make a charge pump selection for

a given application.

System features and conditions that may invalidate the 10% of displacement rule include (but are not

limited to):

•

Operation at low input speeds (below 1500 RPM)

•

Shock loading

•

Excessively long system lines

•

Auxiliary flow requirements

•

Use of low speed high torque motors

If a charge pump of sufficient displacement to meet the 10% of displacement rule is not available or if any

of the above conditions exist which could invalidate the 10% rule, contact your Danfoss representative. A

charge pump sizing worksheet is available in Selection of Driveline Components BLN-9885.

When an integral charge pump is not used, an external charge supply is required to ensure adequate

charge pressure and cooling.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 31

Page 32

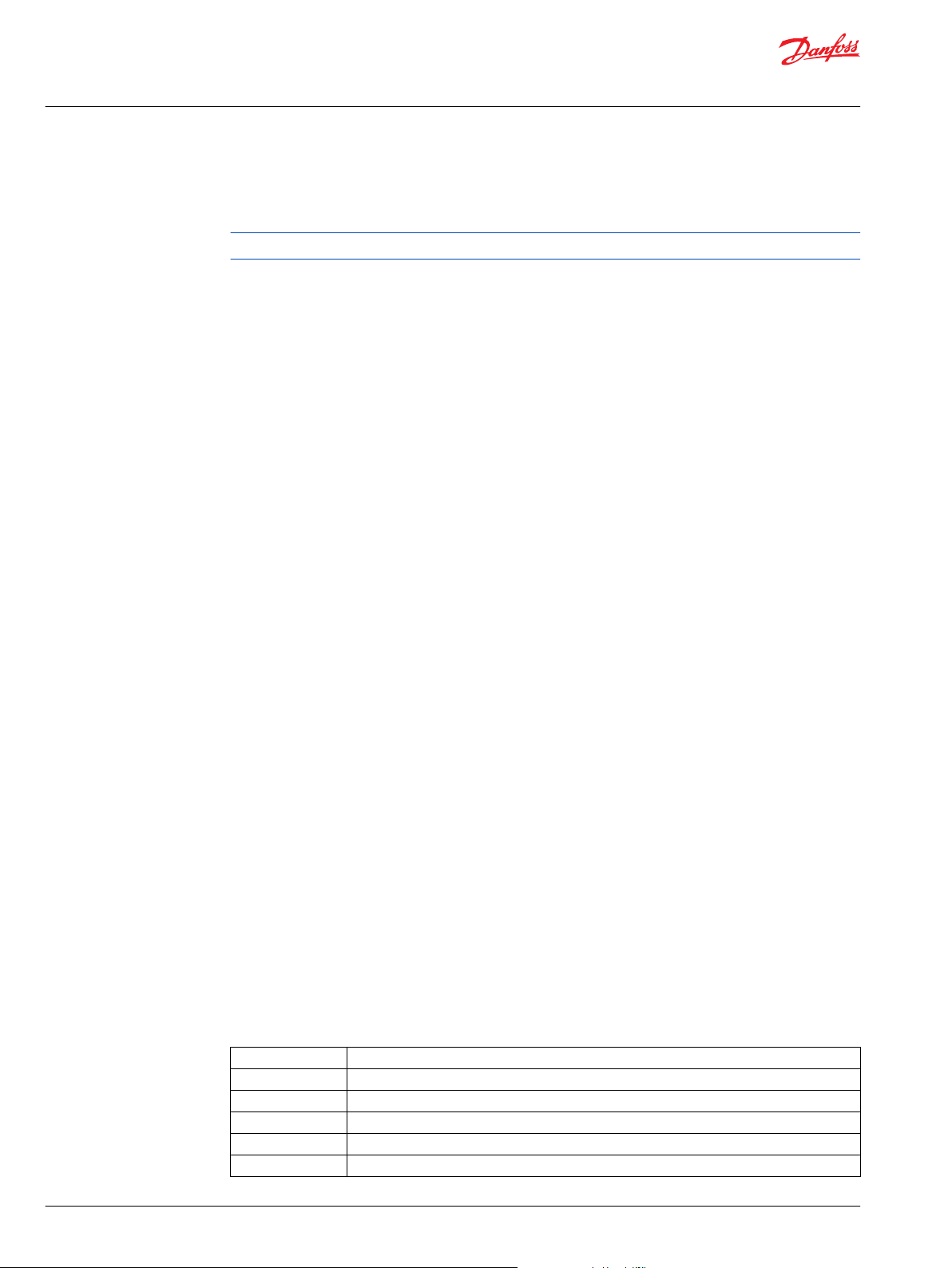

90

0

75

60

45

30

15

24

0

20

16

12

8

4

l/min

US Gal/min

0 1000 2000 3000 4000

Speed min (rpm)

M46 PT

M46 PV

T101302

-1

0 1000 2000 3000 4000

0

1

2

3

4

5

6

0

1

2

3

4

hpkW

Speed min (rpm)

M46PT

M46PV

T101303

-1

Technical Information

Series 40 M46 Pumps

Options

Charge Pump Output Flow

Flow at 19.5 bar charge relief setting, 70°C [160°F] inlet

Charge Pump Power Requirements

Power at 19.5 bar charge relief setting, 70°C [160°F] inlet

Higher charge pressure will influence charge flow and power.

Charge Relief Valve

An integral charge pressure relief valve provides a relief outlet for charge flow. This valve, in effect, sets

charge pressure. Flow through the valve is ported to case.

The M46 PV/PT uses a cone-style poppet valve which dumps hydraulic fluid to the front pump.

32 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

The nominal charge relief setting is referenced to case pressure. It is factory set at 1800 min-1 (rpm) with

the pump in neutral position. A proper charge relief setting takes into account input speeds and control

requirements.

The charge pressure setting for pumps without an internal charge pump is set with an externally supplied

charge flow of 19 l/min [5 US gal/min] on pumps and 38 l/min [10 US gal/min] on tandem pumps. These

units must have adequate charge flow supplied to the charge inlet in order to maintain charge pressure

at all times.

Incorrect charge pressure settings may result in the inability to build required system pressure and/or

inadequate loop flushing flows. Ensure correct charge pressure under all conditions.

Page 33

M46 PV

Charge Relief Valve

P100591

C

Technical Information

Series 40 M46 Pumps

Options

The charge relief valve is factory set. If necessary, it can be field adjusted with shims.

Charge Relief Valve Specs

M46

Type Cone poppet valve

Available Setting 19.5-26.2 bar [285-380 psi]

Adjustment Via shims inside of valve cartridge*

Rise Rate Adjustment 2.3 bar [33 psi]/mm

Performance 1.8 bar [26 psi]/10 lpm (Approx.)

*Shimming offers adjustment over a limited range. A spring change may be required to reach a higher

setting.

Contact your Danfoss representative for further information regarding charge pressure relief valve

options.

Charge relief valve location

High Pressure Relief Valve (HPRV) and Charge Check

All M46 pumps are equipped with a combination high pressure relief and charge check valve. The highpressure relief function is a dissipative (with heat generation) pressure control valve for the purpose of

limiting excessive system pressures. The charge check function acts to replenish the low-pressure side of

the working loop with charge oil. Each side of the transmission loop has a dedicated HPRV valve that is

non-adjustable with a factory set pressure. When system pressure exceeds the factory setting of the

valve, oil is passed from the high pressure loop, into the charge gallery, and into the low pressure loop via

the charge check.

High pressure relief valves are a differential pressure valve referencing high system to charge (low

system). The numeric model code represents the differential pressure setting, in bar. The model code

allows for different pressure settings to be specified at each system port.

HPRV´s are factory set at a low flow condition. Any application or operating condition which leads to

elevated HPRV flow will cause a pressure rise with flow above a valve setting. Consult factory for

application review. Excessive operation of the HPRV will generate heat in the closed loop and may cause

damage to the internal components of the pump.

CAUTION

High pressure relief valves are intended for transient overpressure protection and are not intended for

continuous pressure control. Flow over relief valves for extended periods of time may result in severe

heat build up. High flows over relief valves may result in pressure levels exceeding the nominal valve

setting and potential damage to system components.

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 33

Page 34

Bypass valve

High pressure

relief valve

P100590

C

W

Technical Information

Series 40 M46 Pumps

Options

Check/high pressure relief valve specs

Type

Setting

Option

High pressure relief valve locations

Cartridge-style poppet valve

140-345 bar (2030-5000 psi)

Check only - no relief valve

Bypass Function

Displacement Limiters

All M46 pumps are equipped with a loop bypass valve that connects the A and B sides of the working

loop. The bypass function allows a machine to be moved without rotating the pump shaft or prime

mover. To open the bypass valve turn it counterclockwise 2 full turns. Do not open past 2 full turns. Use a

5/8 inch hex wrench to open the valve. To return to normal operation, close the valve and torque to 20

Nm [15 ft•lbs]. Do not over torque the valve.

CAUTION

Do not move the machine faster than 20% of maximum speed or for more than 3 minutes. Towing faster

or longer than described may result in damage to the drive motor(s). To return to normal operation,

carefully close and torque the bypass valve.

M46 single or tandem units are designed with optional non-adjustable mechanical displacement (stroke)

limiters located in the servo piston. You can limit maximum displacement of the pump to a certain

percent of its maximum displacement. These displacement limiters are fixed physical stops inside the

pump, are not externally adjustable, and limit the pump symmetrically across both sides. Contact your

Danfoss representative for a list of available settings.

It is also possible to configure an M46 pump with an externally adjustable displacement limiter screw on

side #2 only. The screw is located on the side of the servo piston opposite the neutral adjustment screw.

Warning

Unintended vehicle or machine movement hazard

Take care in adjusting displacement limiters to avoid an undesirable condition of output flow or speed.

Re-torque the sealing lock nut after every adjustment to prevent an unexpected change in output

conditions and to prevent external leakage during pump operation.

One full revolution of the adjustment screw produces a change in displacement of approximately 4.4

cm3/rev [0.27 in3/rev]. Full unit displacement is attained with the adjustment screw at its maximum

extension from servo cover. All pumps are shipped with the limiter set for maximum pump displacement.

34 | © Danfoss | March 2017 L1001029 | BC00000176en-US0209

Page 35

Neutral

adjustment

screw

Fixed

displacement

limiter

Adjustable

displacement

limiter screw

P100 592E

Technical Information

Series 40 M46 Pumps

Options

M46 Displacement limiter (side #2)

Auxiliary Mounting Pads and Auxiliary Pumps

Auxiliary mounting pads are available on all pumps. A sealed shipping cover is included as standard

equipment on all mounting pads.

An O-ring seals the auxiliary pump mounting flange to the pad. The drive spline is lubricated (flooded)

with oil from the main pump case.

Spline specifications and torque ratings are shown in the accompanying table.

•

All auxiliary mounting pads meet SAE J744 specifications

•

Do not exceed the maximum pump input shaft rating shown in the Shaft availability and torque

ratings table in the Shaft Options section

•

Applications subject to severe vibratory or high G loading require an additional structural support.

This is necessary to prevent leaks and possible mounting flange damage. Refer to Mounting flange

loads in the System Design Parameters section, for additional information

Auxiliary mounting pad specs

Internal spline size Pad size Maximum Torque Rating

Nm [in lbf]

9T 16/32P SAE A 107 [950]

11T 16/32P SAE A 147 [1300]

13T 16/32P SAE B 248 [2200]

The drawing and table below show the dimensions of the auxiliary pump mounting flanges and shafts.

Auxiliary pump mounting flanges and shafts with the dimensions noted are compatible with the auxiliary

mounting pads on the Series 40 pumps.

Auxiliary pump mating dimensions mm [in.]

Pad size P B C D E F

SAE A 82.55 [32.50] 6.35 [0.250] 12.70 [0.500] 58.2 [2.29] 15.0 [0.59] 13.5 [0.53]

SAE B 101.60 [4.000] 9.65 [0.380] 15.2 [0.60] 53.1 [2.09] 17.5 [0.69] 14.2 [0.56]

©

Danfoss | March 2017 L1001029 | BC00000176en-US0209 | 35