Page 1

Data Sheet

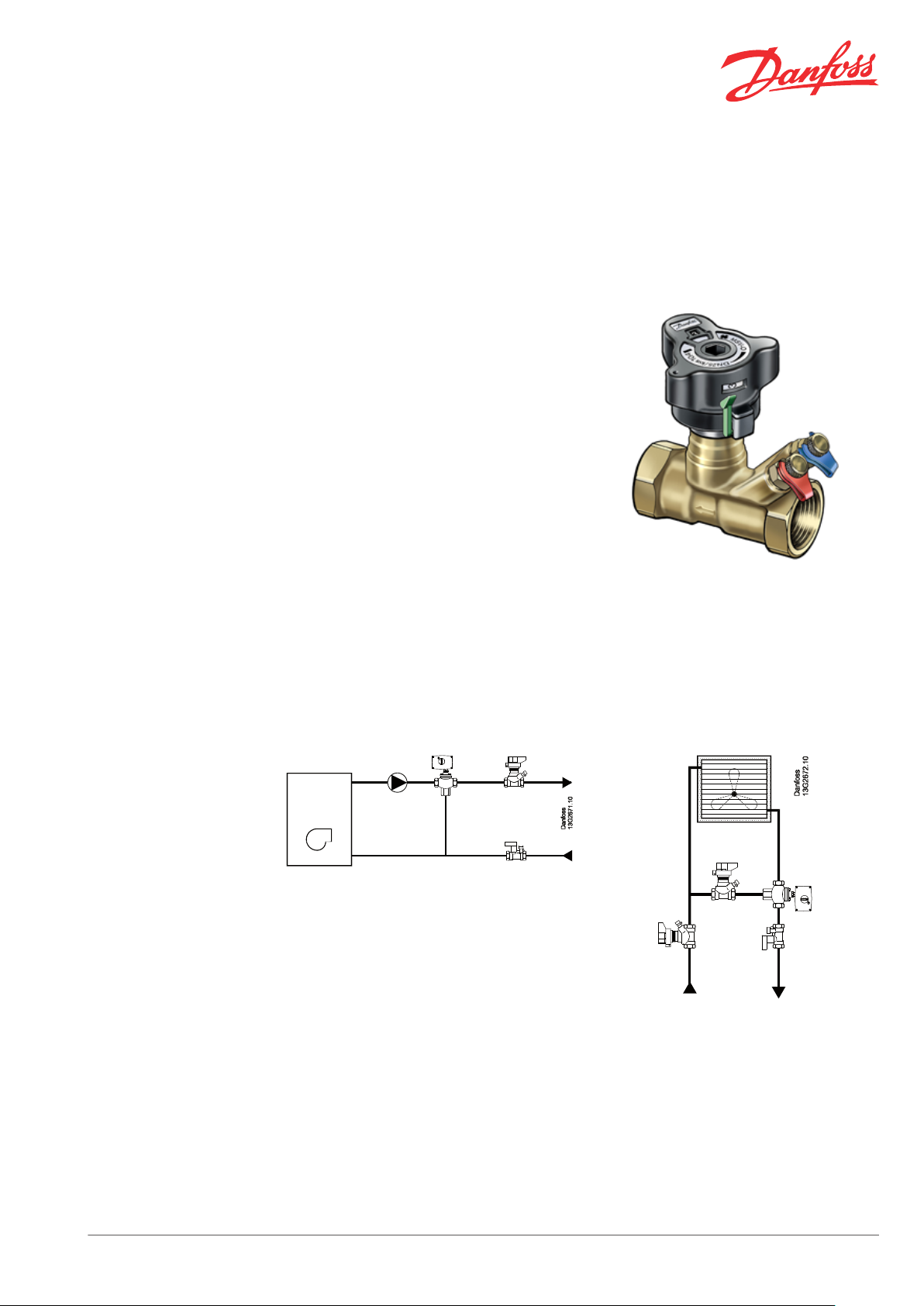

Manual Presetting Valves LENO™ MSV-O

Description

Application

LENO™ MSV-O is a new generation of manual

valves for balancing flow in heating, cooling and

domestic hot water systems.

LENO™ MSV-O is a combined presetting and shut

off valve with a range of unique features:

Fixed venturi orifice.

▪

Removable hand wheel for easy mounting.

▪

Numeric presetting scale, visible from more

▪

angles.

Easy locking of presetting.

▪

Built-in measuring nipples for 3mm needles.

▪

Open-close with Allen key in emergency.

▪

Open-closed colour indicator.

▪

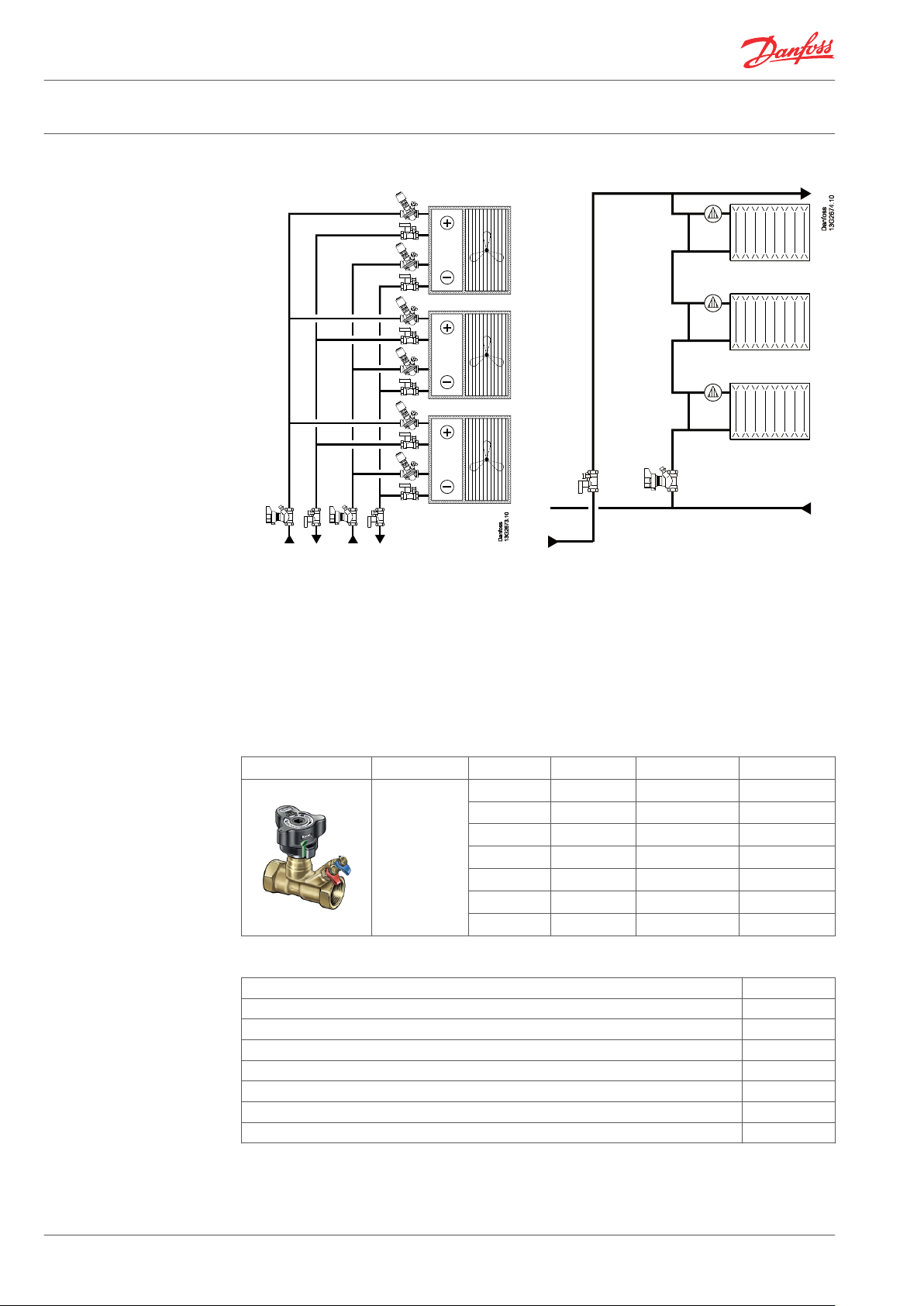

It is recommended to use LENO™ MSV-O in constant flow systems in front of boilers, flat stations

or heat pumps in one-family houses for balancing, shut-off function for service and repair, flow

verification, one pipe systems. The valve may be

mounted in flow or return.

All dimensions are available with internal thread.

Danfoss PFM 5000/100 measuring instruments

contain valve data for LENO™ MSV-O in memory.

Boiler, flat station or heat pump in 1-family houses.

For balancing.

▪

Shut-off function for service/repair.

▪

Air handling unit

For constant flow.

▪

For balancing.

▪

Shut-off function for service/ repair.

▪

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 1

Page 2

Data Sheet Manual Presetting Valves LENO™ MSV-O

Ordering

Fan coils

For flow verification.

▪

Shut-off function for service/ repair.

▪

LENO™ MSV-O valve with internal thread

Type Material Size kvs (m³/h) Connection Code no.

DN 15 LF 0.63 Rp ½" 003Z4020

DN 15 2.8 Rp ½" 003Z4021

DN 20 5.7 Rp ¾" 003Z4022

DZR* Brass

Accessories

Type Code no.

Standard measuring nipples, 2 pcs. 003Z4662

Extended measuring nipples, 60 mm, 2 pcs. 003Z4657

Operating handle 003Z4652

Flow measuring instrument PFM 100 003L8260

Flow measuring instrument PFM 5000, PN10 003L8331

Flow measuring instrument PFM 5000 Multi Source, PN10 003L8333

Identification tag & strips, 10 pcs. 003Z4660

DN 25 9.7 Rp 1" 003Z4023

DN 32 16.6 Rp 1¼" 003Z4024

DN 40 25.4 Rp 1½" 003Z4025

DN 50 37.9 Rp 2" 003Z4026

1-pipe system

For balancing.

▪

Shut-off function for service/repair.

▪

2 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 3

Data Sheet Manual Presetting Valves LENO™ MSV-O

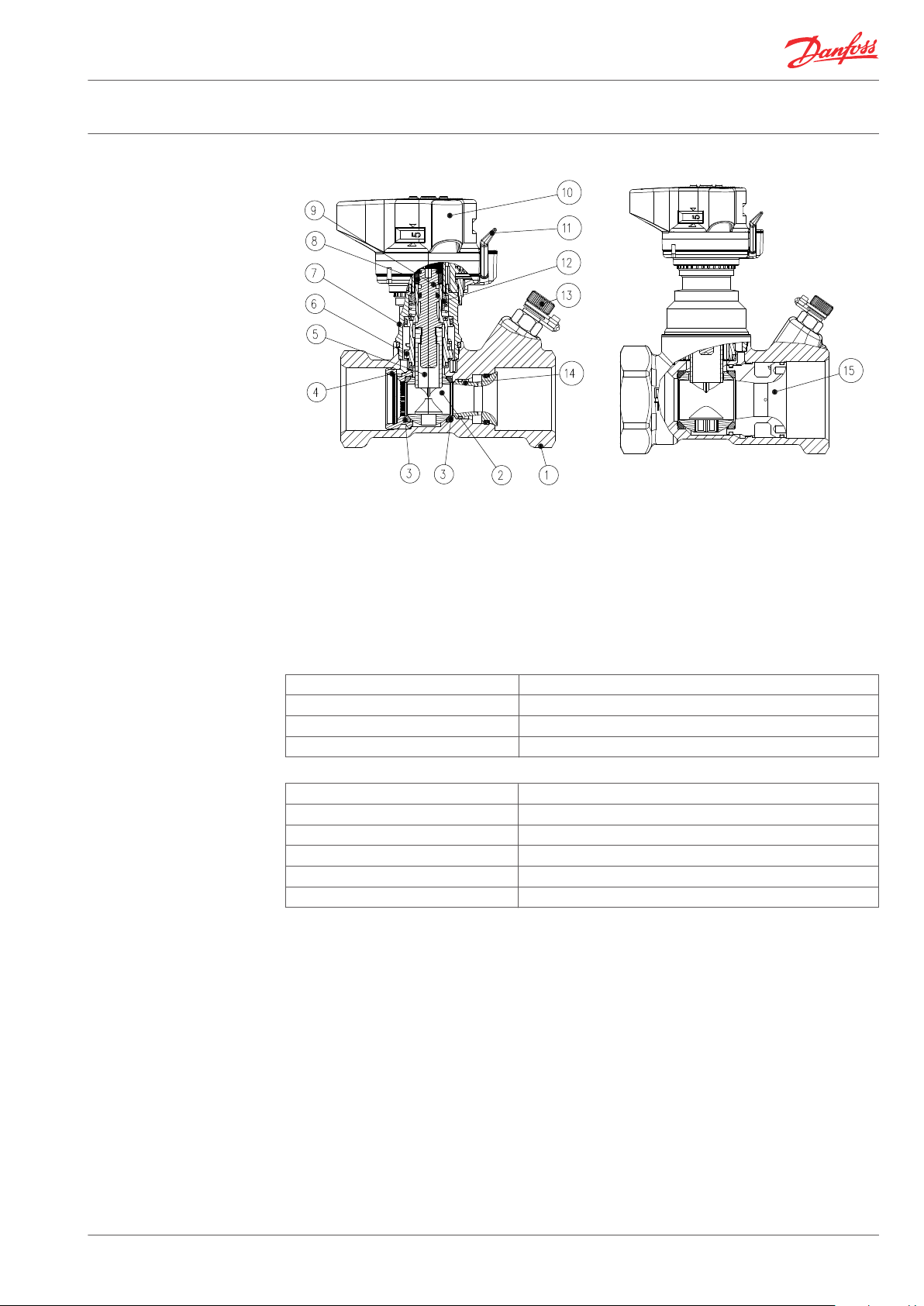

Design

1. Valve house 6. Closing bush 11. Release lever

2. Ball 7. Valve top 12. Rotation lock

3. Ball seat 8. Spindle head 13. Measuring nipple

4. Suppert screw 9. Spindle 14. Venturi

5. Throttle 10. Handle 15. Suppert screw with venturi

Technical Data

Materials and parts in contact with water

Valve body DZR brass

O-rings EPDM

Ball Brass/chromium plated

Ball sealing Teflon

Max. static working pressure 20 bar

Static test pressure 30 bar

Max. differential pressure across valve 2.5 bar (250 kPa)

Max. flow temperature 120 °C

Min. temperature -20°C

Cooling liquids Ethylene glycol / propylene glycol and HYCOOL (max. 30 %)

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 3

Page 4

Data Sheet Manual Presetting Valves LENO™ MSV-O

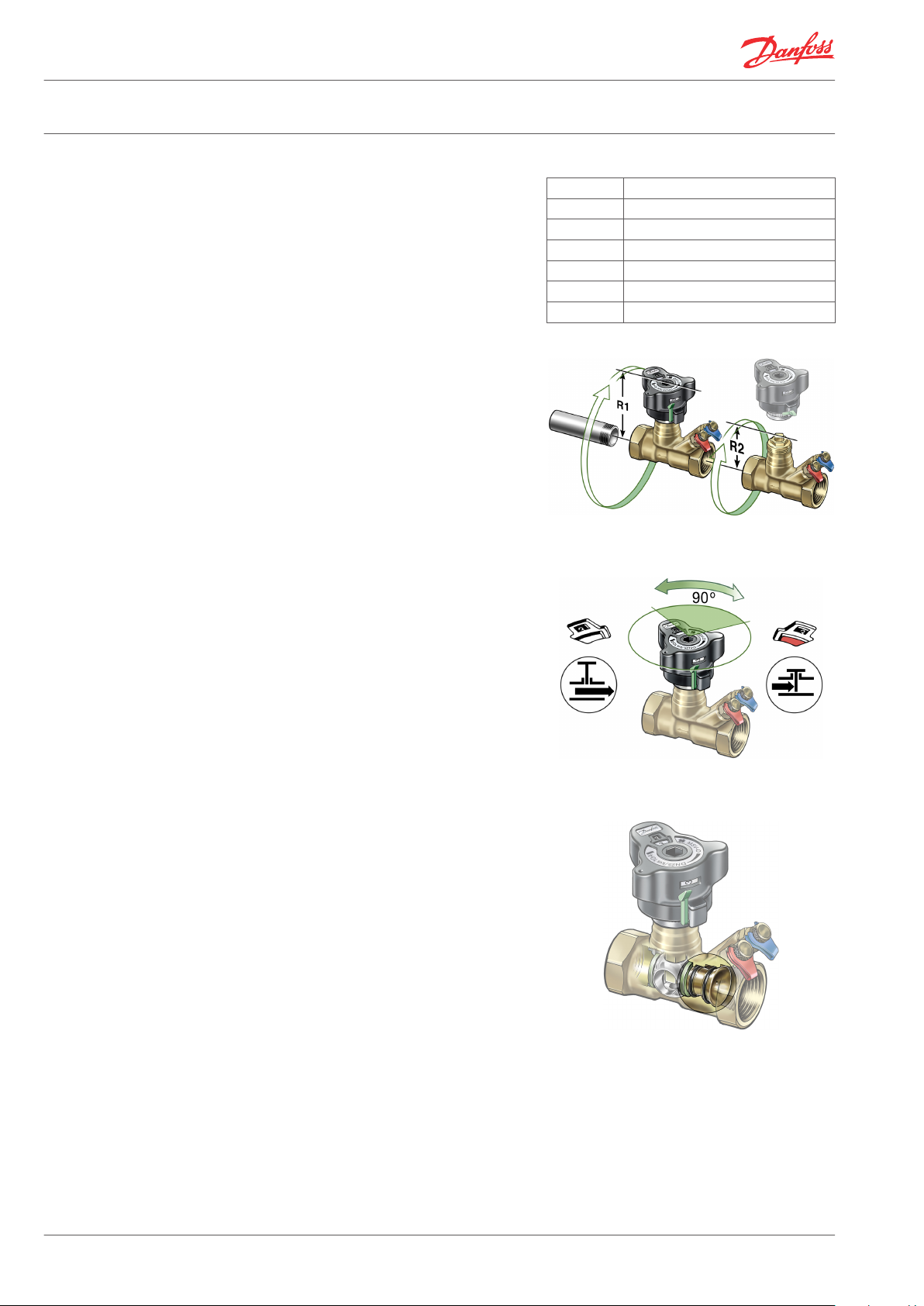

Fitting

Shut-Off

Before fitting the valve the installer must ensure

that the pipe system is clean and:

1. the valve can be turned 360 degrees (if

threaded pipe is used).

2. the valve is fitted according to the flow direction arrow.

Removal of the handle

1. Set the handle at 0/0.

2. Release the setting lock (green).

3. Unscrew the union nut.

Calibration of the handle

Before refitting, ensure that the handle setting is

0/0.

In order to shut-off the valve the handle must be

pressed down.

The shut-off function features a ball valve, which

only requires a 90 degree turn to shut the valve

completely.

DN

15 96/58

20 99/60

25 101/63

32 124/87

40 127/90

50 131/94

R1/R2 (mm)

Fixed Orifice

An indicator window shows the actual setting:

red = closed

▪

white = open

▪

LENO™ MSV-O has a fixed venturi orifice in the

valve body with constant kvs-value. This feature

makes it possible to read flow on the measuring

device, without typing in presetting.

This feature saves time for commissioning for

each valve installed.

4 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 5

Data Sheet Manual Presetting Valves LENO™ MSV-O

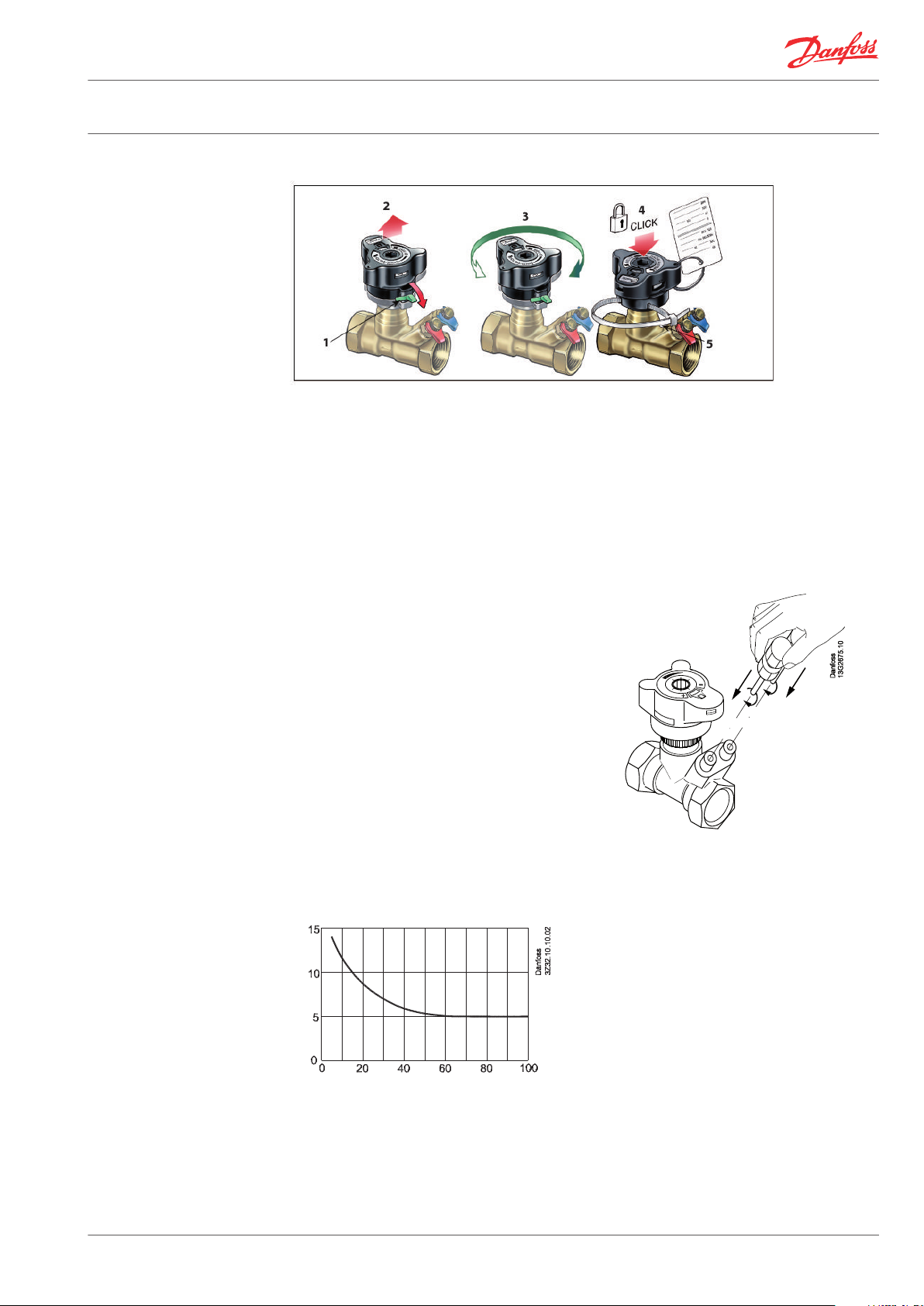

Setting and Locking

Measuring

The valve has a built-in presetting feature for accurate flow ratings.

Setting the required flow is made in 5 steps:

1. Release the lock using the green lever or a 3

mm Allen key.

2. The handle pops up automatically.

The flow through the LENO™ MSV-O valve can be

measured using Danfoss PFM 5000/100 or other

brands of measuring instruments.

The LENO™ MSV-O valve is supplied with two

measuring nipples for 3 mm needles. A twin

bracket enables the user to connect both needles

simultanously.

Procedure for flow measuring:

1. Select flow measuring

2. Select valve brand

3. Select valve type and dimension

4. Connect valve and instrument

5. Calibrate static pressure

6. Measure the flow

3. The calculated value can now be set.

4. The setting is locked when the handled is

pressed to click.

5. Seal - the setting can be protected by using

a strip as shown.

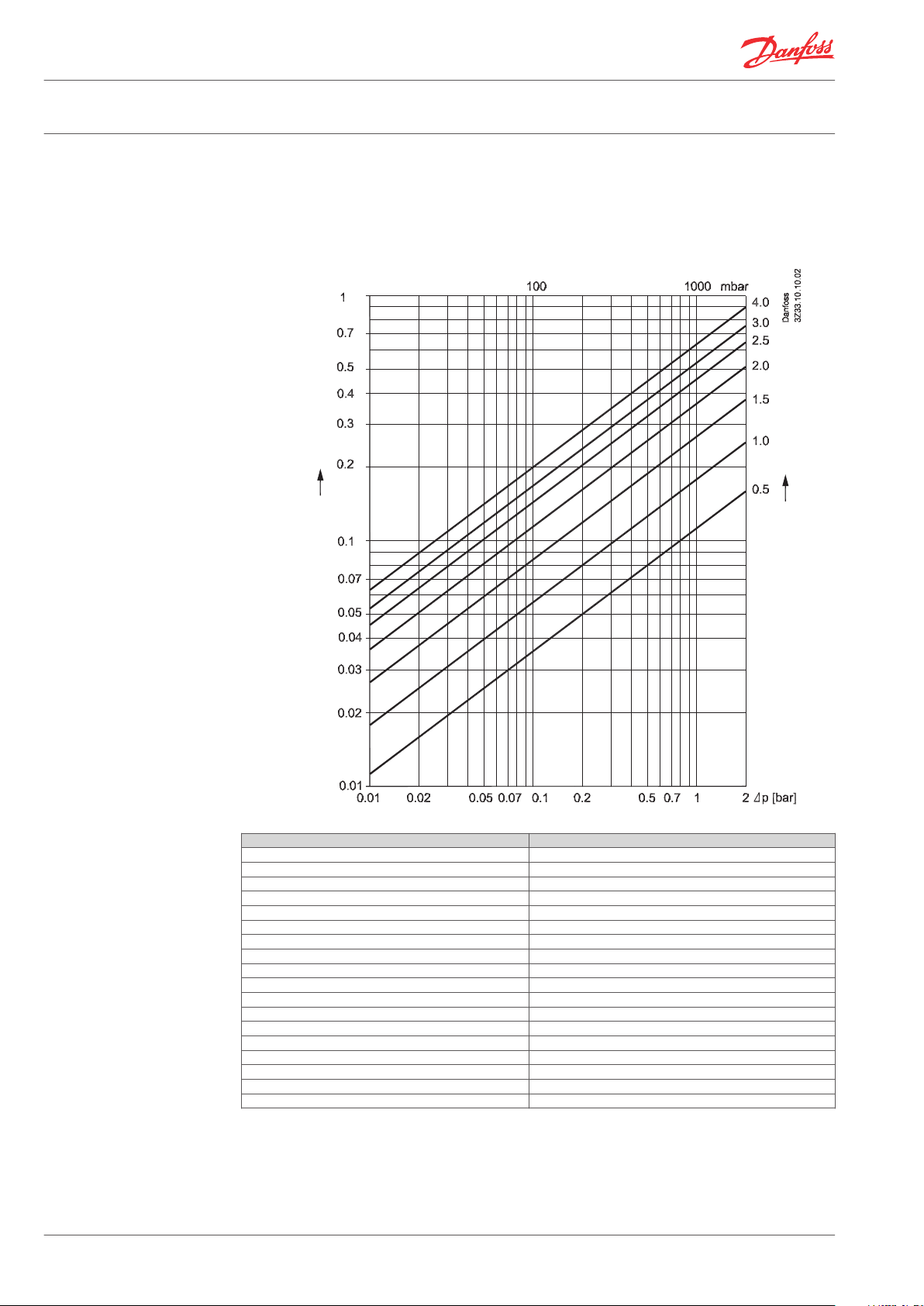

Measuring Accuracy

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 5

Maximum error in

measured flow [%]

Flow % of K

The red line indicates 25% of max. flow.

According to BS7350:1990 flow rates must be within

following values:

vs

± 18 % at 25 % open position

± 10 % at fully open position

LENO™ MSV-O is very accurate, due to the separate functions for presetting and shut-off.

Page 6

Danfoss

3Z47.10

Data Sheet Manual Presetting Valves LENO™ MSV-O

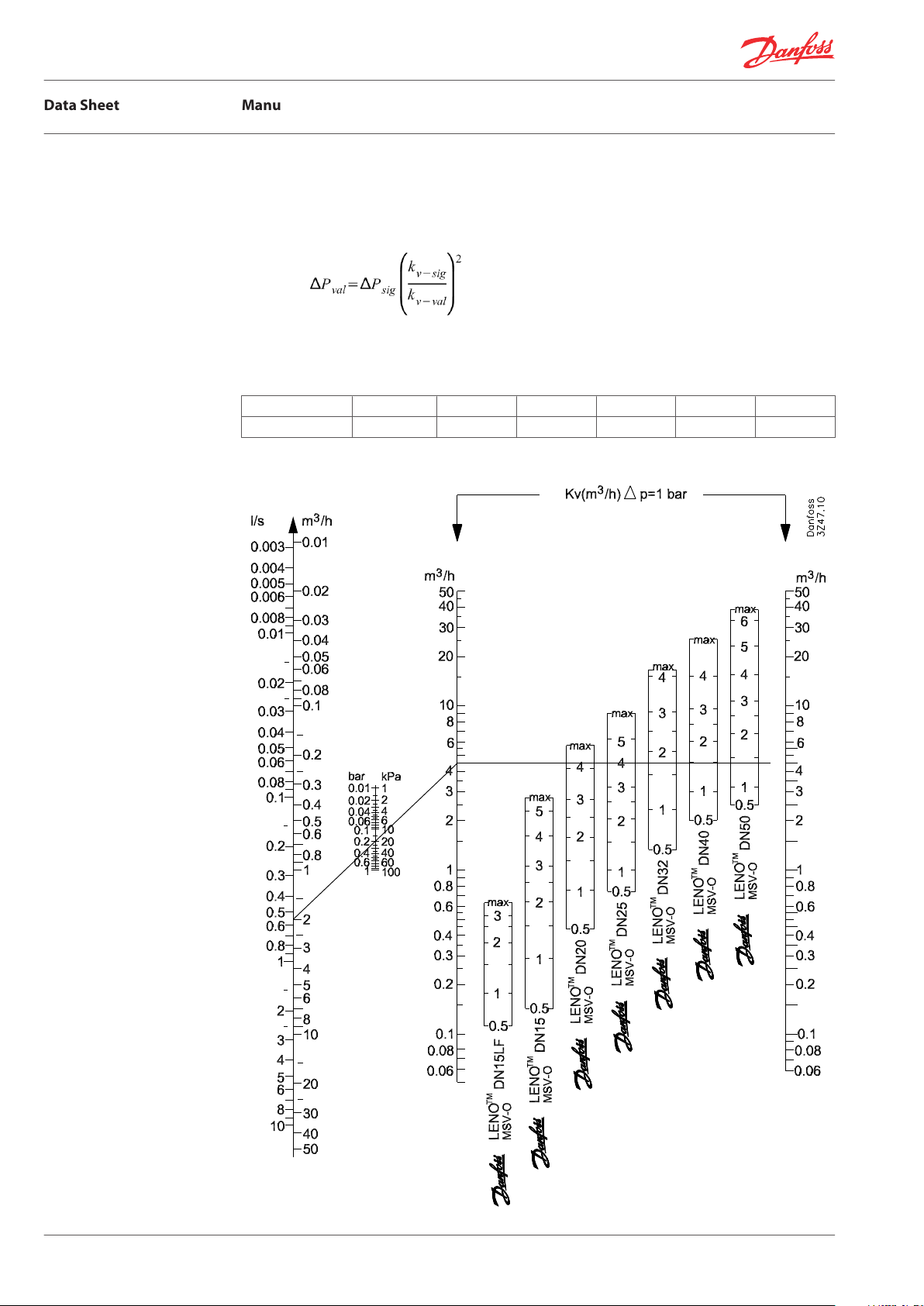

Kv-Signal

Kv-Signal Values

Sizing

Kv-signal values are used for non-Danfoss measuring instruments. Danfoss PFM 3000*/4000 have

all data in memory, and the instruments are using

∆p across the measuring nipples (k

across the valve (k

) is not the same due to tur-

v-val

bulence influence for pressure measuring.

this formula:

* with software 9.4 or higher

DN 15LF DN 15 DN20 DN25 DN32 DN40 DN50

0.356 1.434 3.453 5.80 10.33 14.72 22.94

v-sig

) and ∆p

6 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 7

Data Sheet Manual Presetting Valves LENO™ MSV-O

Correction Factors

Valve Size and Presetting

Temp.

°C

-40.0

-17.8

ethylene glycol / propylene glycol percentage (max. 30 %)

25 30 40 50 60 65 100

1) 1) 1) 1)

1) 1)

Correction factors,

0.89 0.88

0.93 0.91 0.90 0.89 0.86

4.4 0.95 0.95 0.93 0.92 0.91 0.90 0.87

26.6 0.96 0.95 0.94 0.93 0.92 0.91 0.88

48.9 0.97 0.96 0.95 0.94 0.93 0.92 0.90

71.1 0.98 0.98 0.96 0.95 0.94 0.94 0.95

93.3 1.00 0.99 0.97 0.96 0.95 0.95 0.92

115.6

1)

Below freezing point

2)

Above boiling point

2) 2) 2) 2) 2) 2)

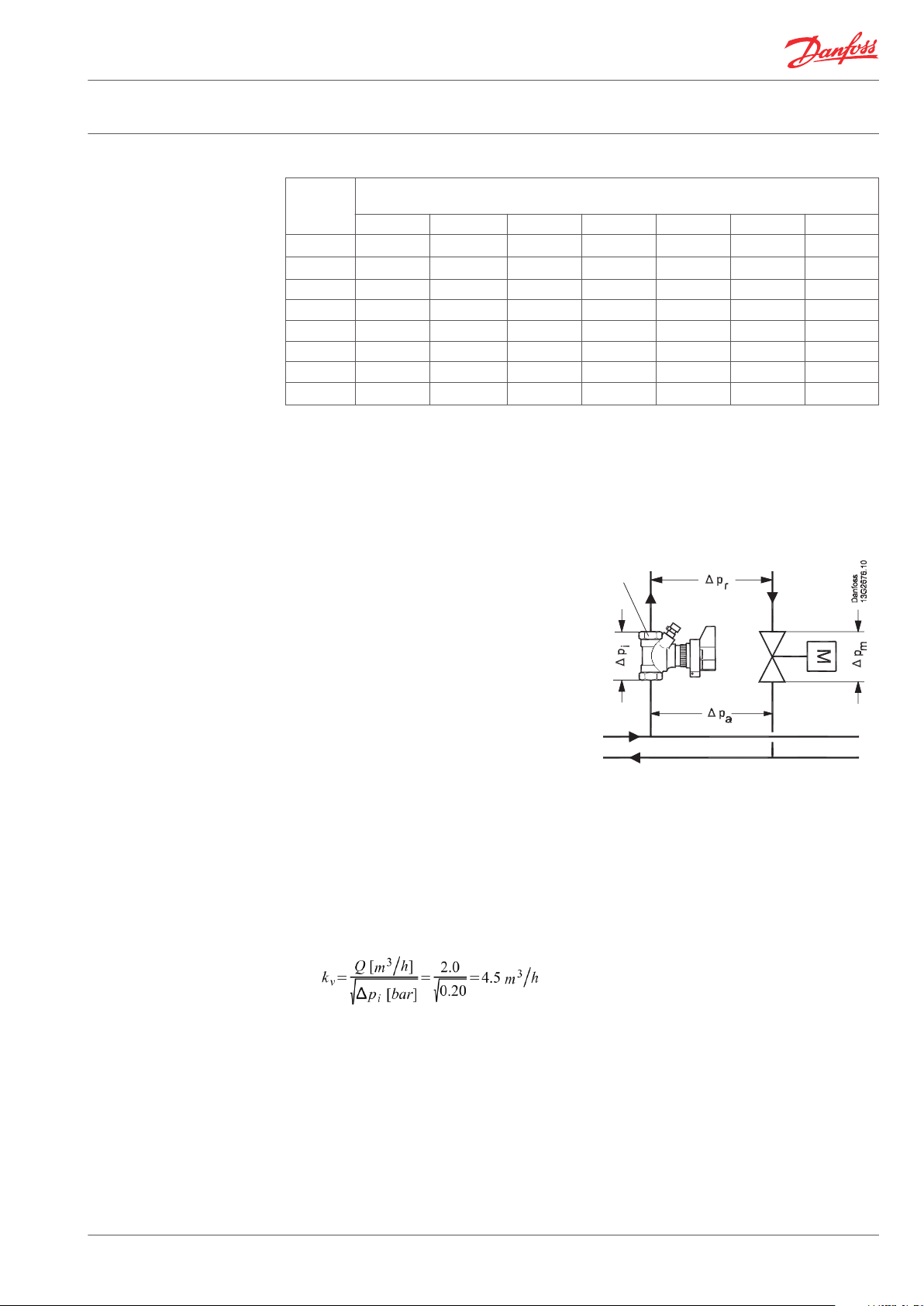

Example: Flow needed = 30 m³/h

Flow after correction:

30 x 0.95 = 28 m³/h

Example:

MSV-O

Given

Max. pipe flow Q = 2.0 m³/h

∆pr= 15 kPa

∆pa= 45 kPa

∆pm= 10 kPa

∆pi= ∆pa – ∆pv – ∆pm

∆pi= 45 kPa – 15 kPa – 10KPa = 20 kPa

1)

0.94

Correct valve size and presetting is found in flow

diagramme, page 7.

Q= 2.0 m³/h and ∆pi = 20 kPa

On page 11 intersect guides and presetting is

found to be 4.2 (DN 20 valve)

Setting can be also calculated from the formula:

which corresponds to presetting 4.2 as shown on

pages 7 and 11.

∆piPressure drop across LENO™ MSV-O valve

∆pmPressure drop across valve

∆prNecessary pressure for the riser

∆paAvailable pressure for the riser

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 7

Page 8

Data Sheet Manual Presetting Valves LENO™ MSV-O

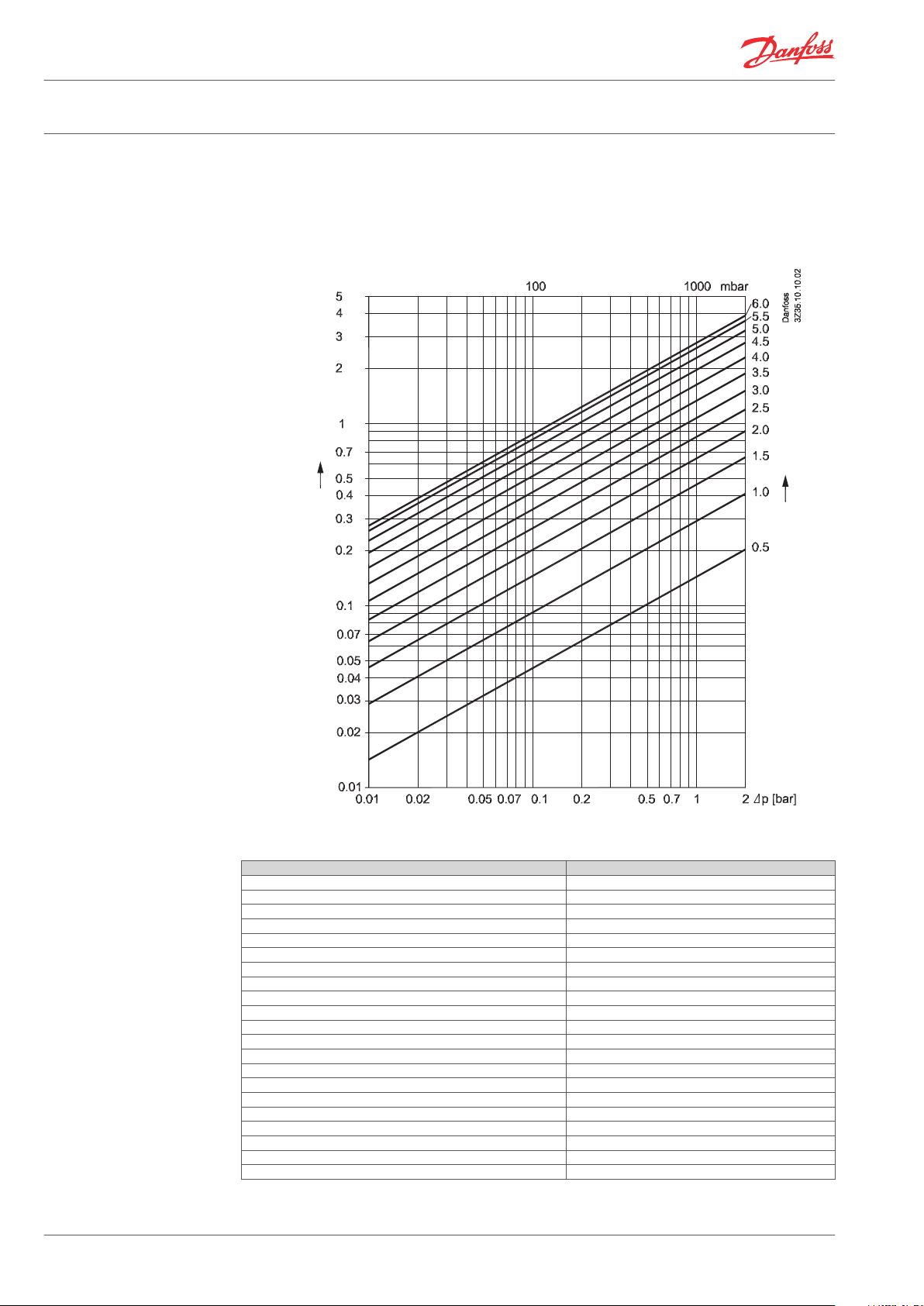

Flow Diagrammes, DN 15

LF

LENO™ MSV-O DN 15 LF

Flow [m³/h] Setting

Setting DN15LF

0.5 0.11

0.6 0.12

0.7 0.13

0.8 0.15

0.9 0.16

0.10 0.18

1.1 0.19

1.2 0.21

1.3 0.23

1.4 0.25

1.5 0.27

1.6 0.28

1.7 0.30

1.8 0.32

1.9 0.34

2.0 0.36

2.1 0.38

2.2 0.40

8 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 9

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN15LF

2.3 0.42

2.4 0.44

2.5 0.45

2.6 0.47

2.7 0.49

2.8 0.50

2.9 0.52

3.0 0.53

3.1 0.54

3.2 0.55

3.3 0.57

3.4 0.58

3.5 0.59

3.6 0.59

3.7 0.60

3.8 0.61

3.9 0.62

4.0 0.62

4.1 0.63

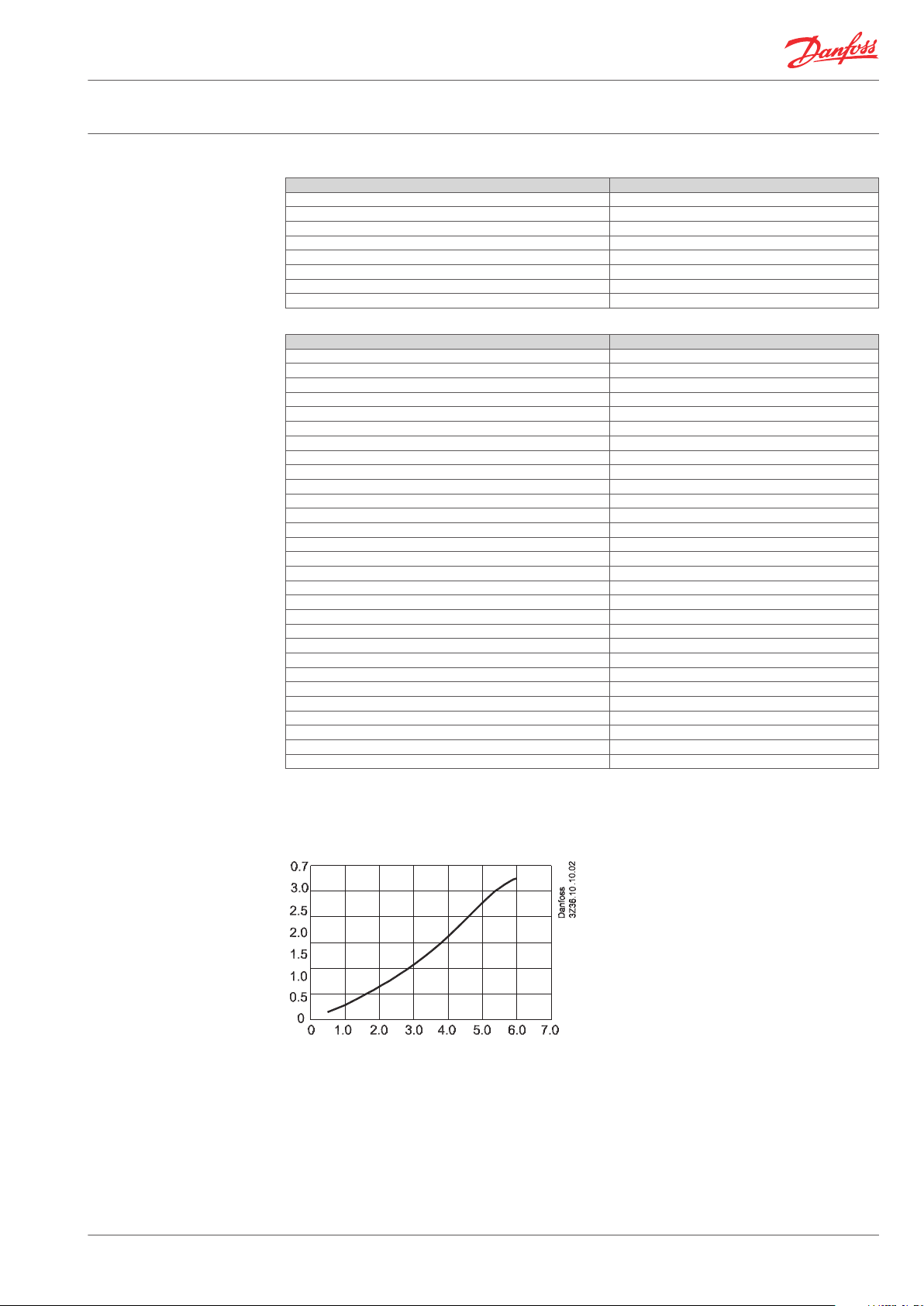

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 9

Page 10

Data Sheet Manual Presetting Valves LENO™ MSV-O

Flow Diagrammes, DN 15

LENO™ MSV-O DN 15

Flow [m³/h] Setting

Setting DN15

0.5 0.14

0.6 0.17

0.7 0.20

0.8 0.23

0.9 0.26

0.10 0.29

1.1 0.32

1.2 0.35

1.3 0.39

1.4 0.42

1.5 0.46

1.6 0.49

1.7 0.53

1.8 0.56

1.9 0.60

2.0 0.64

2.1 0.68

2.2 0.72

2.3 0.75

2.4 0.80

2.5 0.84

10 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 11

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN15

2.6 0.88

2.7 0.92

2.8 0.97

2.9 1.01

3.0 1.06

3.1 1.11

3.2 1.16

3.3 1.21

Setting DN15

3.4 1.27

3.5 1.32

3.6 1.38

3.7 1.44

3.8 1.50

3.9 1.56

4.0 1.62

4.1 1.68

4.2 1.75

4.3 1.81

4.4 1.88

4.5 1.94

4.6 2.01

4.7 2.08

4.8 2.15

4.9 2.21

5.0 2.28

5.1 2.34

5.2 2.40

5.3 2.46

5.4 2.51

5.5 2.57

5.6 2.61

5.7 2.65

5.8 2.69

5.9 2.72

6.0 2.74

6.1 2.75

6.2 2.80

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 11

Page 12

4.2

Data Sheet Manual Presetting Valves LENO™ MSV-O

Flow Diagrammes, DN 20

LENO™ MSV-O DN 20

Flow [m³/h] Setting

Setting DN20

0.5 0.44

0.6 0.49

0.7 0.55

0.8 0.61

0.9 0.68

0.10 0.75

1.1 0.82

1.2 0.90

1.3 0.98

1.4 1.06

1.5 1.14

1.6 1.22

1.7 1.31

1.8 1.40

1.9 1.49

2.0 1.58

2.1 1.68

2.2 1.77

2.3 1.88

2.4 1.98

2.5 2.09

2.6 2.20

12 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 13

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN20

2.7 2.31

2.8 2.43

Setting DN20

2.9 2.56

3.0 2.68

3.1 2.81

3.2 2.95

3.3 3.09

3.4 3.23

3.5 3.38

3.6 3.53

3.7 3.68

3.8 3.83

3.9 3.99

4.0 4.15

4.1 4.31

4.2 4.47

4.3 4.62

4.4 4.78

4.5 4.93

4.6 5.07

4.7 5.21

4.8 5.34

4.9 5.46

5.0 5.57

5.1 5.61

5.2 5.66

5.3 5.70

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 13

Page 14

Data Sheet Manual Presetting Valves LENO™ MSV-O

Flow Diagrammes, DN 25

LENO™ MSV-O DN 25

Flow [m³/h] Setting

Setting DN25

0.5 0.74

0.6 0.76

0.7 0.80

0.8 0.86

0.9 0.92

0.10 1.00

1.1 1.08

1.2 1.18

1.3 1.27

1.4 1.38

1.5 1.48

1.6 1.59

1.7 1.70

1.8 1.81

1.9 1.93

2.0 2.04

2.1 2.16

2.2 2.27

2.3 2.39

2.4 2.50

2.5 2.61

14 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 15

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN25

2.6 2.73

2.7 2.84

2.8 2.96

2.9 3.07

3.0 3.19

3.1 3.31

3.2 3.43

3.3 3.55

3.4 3.67

Setting DN25

3.5 3.80

3.6 3.93

3.7 4.06

3.8 4.20

3.9 4.34

4.0 4.49

4.1 4.64

4.2 4.80

4.3 4.96

4.4 5.13

4.5 5.30

4.6 5.49

4.7 5.67

4.8 5.87

4.9 6.07

5.0 6.27

5.1 6.49

5.2 6.70

5.3 6.93

5.4 7.16

5.5 7.39

5.6 7.62

5.7 7.86

5.8 8.10

5.9 8.34

6.0 8.57

6.1 8.81

6.2 9.04

6.3 9.26

6.4 9.48

6.5 9.70

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 15

Page 16

Data Sheet Manual Presetting Valves LENO™ MSV-O

Flow Diagrammes, DN 32

LENO™ MSV-O DN 32

Flow [m³/h] Setting

Setting DN32

0.5 1.33

0.6 1.44

0.7 1.61

0.8 1.82

0.9 2.07

0.10 2.34

1.1 2.62

1.2 2.91

1.3 3.21

1.4 3.51

1.5 3.81

1.6 4.11

1.7 4.40

1.8 4.70

1.9 5.00

2.0 5.30

2.1 5.61

2.2 5.93

2.3 6.26

16 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 17

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN32

2.4 6.61

2.5 6.98

2.6 7.37

2.7 7.79

2.8 8.23

2.9 8.71

3.0 9.21

3.1 9.75

3.2 10.31

3.3 10.90

3.4 11.51

3.5 12.14

3.6 12.78

3.7 13.42

3.8 14.05

3.9 14.67

4.0 15.25

4.1 15.78

4.2 16.24

4.3 16.60

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 17

Page 18

Data Sheet Manual Presetting Valves LENO™ MSV-O

Flow Diagrammes, DN 40

LENO™ MSV-O DN 40

Flow [m³/h] Setting

Setting DN40

0.5 2.02

0.6 2.13

0.7 2.29

0.8 2.50

0.9 2.74

0.10 3.00

1.1 3.29

1.2 3.59

1.3 3.90

1.4 4.22

1.5 5.54

1.6 5.85

1.7 5.17

1.8 5.49

1.9 5.80

2.0 6.12

2.1 6.43

2.2 6.75

2.3 7.06

2.4 7.39

2.5 7.72

18 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 19

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN40

2.6 8.06

2.7 8.41

2.8 8.78

2.9 9.17

Setting DN40

3.0 9.57

3.1 10.00

3.2 10.46

3.3 10.94

3.4 11.46

3.5 12.00

3.6 12.57

3.7 13.18

3.8 13.82

3.9 14.49

4.0 15.19

4.1 15.92

4.2 16.67

4.3 17.45

4.4 18.24

4.5 19.04

4.6 19.84

4.7 20.64

4.8 21.43

4.9 22.19

5.0 22.92

5.1 23.60

5.2 24.22

5.3 24.76

5.4 25.20

5.5 25.40

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 19

Page 20

Data Sheet Manual Presetting Valves LENO™ MSV-O

Flow Diagrammes, DN 50

LENO™ MSV-O DN 50

Flow [m³/h] Setting

Setting DN50

0.5 2.49

0.6 2.52

0.7 2.61

0.8 2.76

0.9 2.96

0.10 3.20

1.1 3.48

1.2 3.79

1.3 4.12

1.4 4.47

1.5 4.83

1.6 5.21

1.7 5.59

1.8 5.97

1.9 6.36

2.0 6.75

2.1 7.14

2.2 7.53

2.3 7.92

2.4 8.31

2.5 8.70

20 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 21

Data Sheet Manual Presetting Valves LENO™ MSV-O

Setting DN50

2.6 9.09

2.7 9.49

2.8 9.88

2.9 10.28

3.0 10.69

3.1 11.11

3.2 11.54

3.3 11.97

3.4 12.43

Setting DN50

3.5 12.90

3.6 13.39

3.7 13.90

3.8 14.43

3.9 14.99

4.0 15.57

4.1 16.18

4.2 16.83

4.3 17.50

4.4 18.2

4.5 18.94

4.6 19.71

4.7 20.52

4.8 21.35

4.9 22.22

5.0 23.12

5.1 24.05

5.2 25.01

5.3 25.99

5.4 27.00

5.5 28.02

5.6 29.05

5.7 30.09

5.8 31.14

5.9 32.18

6.0 33.21

6.1 34.22

6.2 35.20

6.3 36.15

6.4 37.04

6.5 37.90

Flow characteristics

Kv-value

Setting

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 21

Page 22

Data Sheet Manual Presetting Valves LENO™ MSV-O

Dimensions

Size

(DN)

15 G ½ 82 92 27

20 G¾ 89 95 32

25 G 1 104 98 41

32 G 1¼ 122 121 50

40 G 1½ 122 125 55

50 G2 151 129 67

ISO

228-1

a (mm)

L

(mm)H(mm)S(mm)

22 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Page 23

Data Sheet Manual Presetting Valves LENO™ MSV-O

Danfoss Heating Solutions VDB4H302 © Danfoss 09/2013 23

Page 24

Data Sheet Manual Presetting Valves LENO™ MSV-O

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone: +45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss Heating Solutions and the Danfoss Heating Solutions logotype are trademarks of Danfoss A/S. All rights reserved.

24 VDB4H302 © Danfoss 09/2013 Danfoss Heating Solutions

Loading...

Loading...