Page 1

Data sheet

Manual presetting valves LENO™ MSV-BD

Description

Application

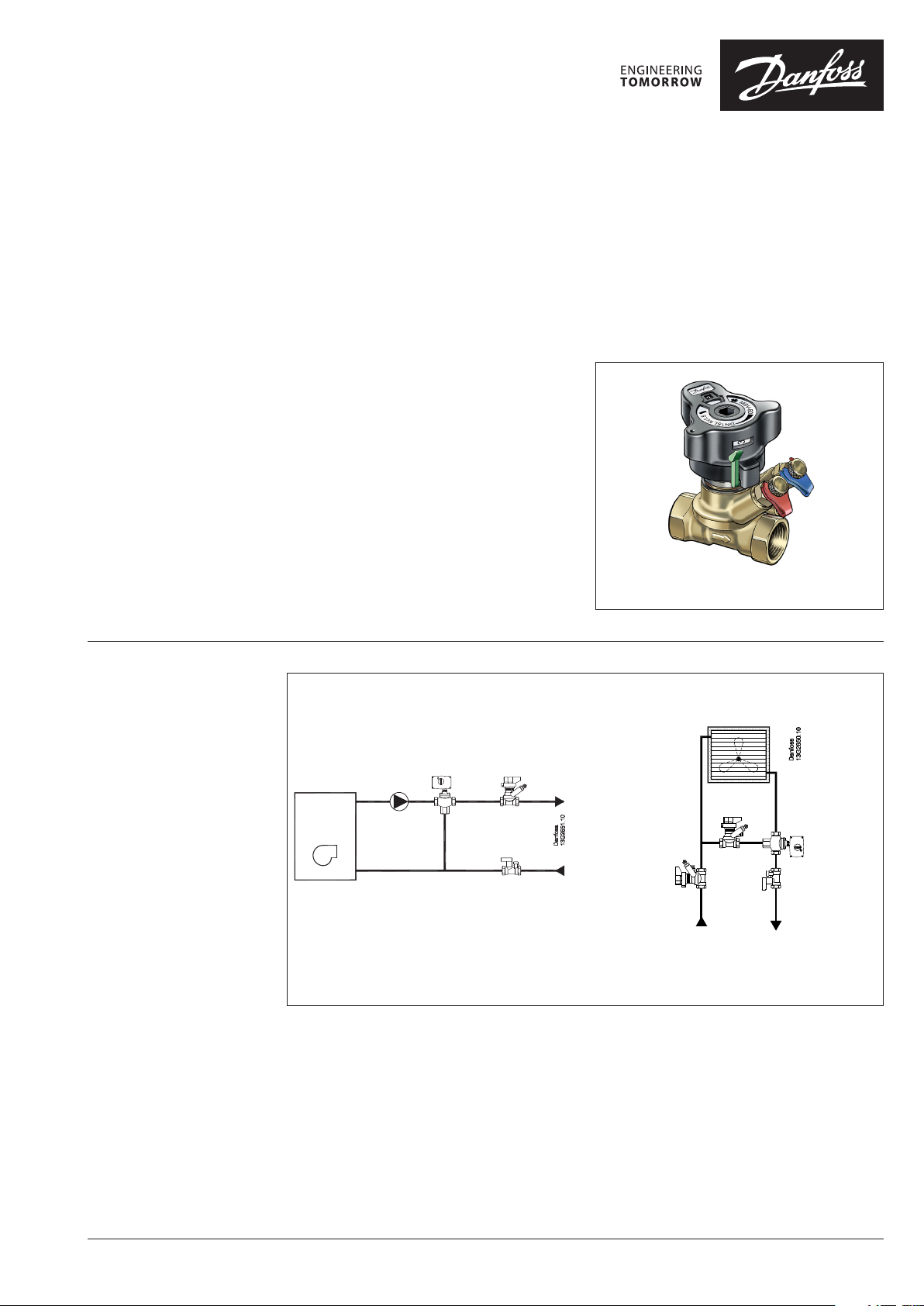

LENO™ MSV-BD is a range of manual valves for

balancing flow in heating and cooling systems.

LENO™ MSV-BD is a combined presetting and

shut off valve with a range of unique features:

• Removable hand wheel for easy mounting.

• 360° turnable measuring station for

convenient measuring and draining.

• Numeric presetting scale, visible from more

angles.

• Easy locking of presetting.

• Built-in test plugs for Ø 3 mm needles.

• Drain connection with separate draining of

inlet and outlet side of valve.

• Open-close with Allen key for extra force.

• Open-closed colour indicator.

It is recommended to use LENO™ MSV-BD in

constant flow systems. The valve may be mounted

in flow or return.

Boiler, flat station or heat pump

in 1-family houses

DN 15 and 20 valves are available with internal or

external thread. Other dimensions with internal

thread.

Danfoss PFM 1000/PFM 100 measuring instruments

contain valve data for LENO™ MSV-BD in memor y.

Air handling unit

• For balancing.

• Shut-off function for service/repair.

© Danfoss | 2020.08 AI144986479776en-001201 | 1

• For constant flow.

• For balancing.

• Shut-off function for service/repair.

Page 2

Data sheet LENO™ MSV-BD

Application

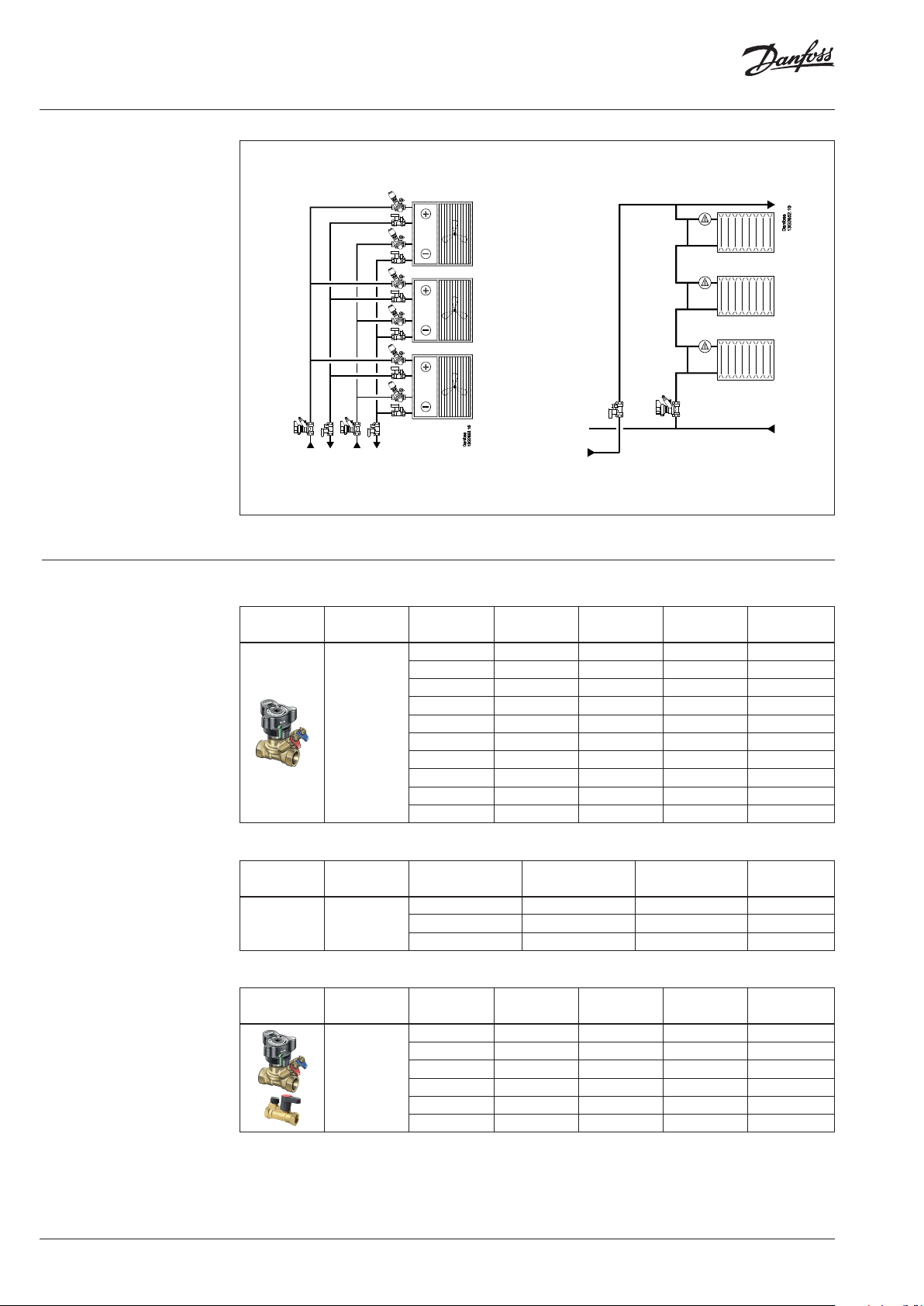

Fan coils 1-pipe system

• For flow verification.

• Shut-off function for service/repair.

DOMEST IC HOT WATER SYSTEMS: Dependin g on local legislation it can b e used in Domestic hot water a pplications.

• For balancing.

• Shut-off function for service/repair.

Ordering

LENO™ MSV-BD valve with internal thread

Typ e Material

DZR brass

Size k

(mm) (m3/h)

DN 15 LF 2.5 ½" 1 003Z4000

DN 15 3.0 ½" 1 003Z4001

DN 20 6.0 ¾" 1 003Z4002

DN 25 9.5 1" 1 003Z4003

1)

DN 32 18 1¼" 1 003Z4004

DN 40 26 1½" 1 003Z4005

DN 50 40 2" 1 003Z4006

DN 15 3.0 ½" 8 003 Z4261

DN 20 6.6 ¾" 8 003Z4262

DN 25 9.5 1" 8 003Z4263

VS

Connection Quantity Code No.

LENO™ MSV-BD valve with external thread

Typ e Material

DZR brass

Size k

(mm) (m3/h)

DN 15 LF 003Z4100

1)

DN 15 3.0 G ¾ A

DN 20 6.0 G 1 A 003 Z4102

VS

LENO™ MSV-BD/S set solution

Typ e Material

Size k

(mm) (m3/h) (l/h)

VS

DN 15 3.0 281 ½" 003 Z4051

DN 20 6.0 277 ¾" 003Z4052

DZR brass

1)

DN 25 9.5 316 1" 003Z4053

DN 32 18 305 1¼" 003Z4054

DN 40 26 208 1½" 003Z4 055

DN 50 40 308 2" 003Z4056

1)

Corrosion resistant brass

2)

Eurocone DIN V 3838

3)

Drain ow is measured at 1 bar static pressure and 0.1 bar dierential pressure.

Drain flow

Connection Code No.

2)

003 Z4101

3)

Connection Code No.

2 | AI144986479776en-001201 © Danfoss | 2020.08

Page 3

Data sheet LENO™ MSV-BD

Ordering (continued)

Accessories

Typ e Code No.

Standard test plugs, 2 pcs. 003Z4662

Measuring test plugs, 53 mm, red and blue 003Z3946

Operating handle 003Z4 652

Drain connection, ½" thread 003Z4096

Drain connection, ¾" thread 003Z4097

Flow measuring instrument PFM 1000 (10 bar) 003Z8260

Flow measuring instrument PFM 1000 (20 bar) 00 3Z8261

Identification tag & strips, 10 pcs. 003Z466 0

MSV-BD insulation, DN 15 003Z 4781

MSV-BD insulation, DN 20 003Z478 2

MSV-BD insulation, DN 25 003Z478 3

MSV-BD insulation, DN 32 003Z478 4

MSV-BD insulation, DN 40 003Z478 5

MSV-BD insulation, DN 50 003Z478 6

LENO™ MSV-BD valve with external thread

Pipe

(mm)

12 x 1.1 G ¾ 013G 4150

12 x 2 G ¾ 013G 4152 013G 4182

13 x 2 G ¾ 013G 4153

14 x 2 G ¾ 013G 4154 013G 4184

15 x 1.7 G ¾ 013G416 5

15 x 2.5 G ¾ 013G4155 013G4185

16 x 1.5 G ¾ 013G415 7

16 x 2 G ¾ 013G 4156 013G 4186

16 x 2.25 G ¾ 013G 4187

17 x 2 G ¾ 013G 4162

18 x 2 G ¾ 013 G4158 013 G4188

18 x 2.5 G ¾ 013G4159

20 x 2 G ¾ 013G 4160 013G 4190

20 x 2.5 G ¾ 013G 4161 013G419 1

Valve thread PEX fittings, Code no. Alupex fittings, Code no.

Compression fittings for valves with external thread

Steel/copper pipes Dimension Code no.

G ¾ x 15 013G 4125

G ¾ x 16 013G 4126

G ¾ x 18 013G 4128

G 1 x 18 013U 0134

G 1 x 22 013U 0135

AI144986479776en-001201 | 3© Danfoss | 2020.08

Page 4

Data sheet LENO™ MSV-BD

19

21

22

5 4 3 2 1

18

17

16

15

14

13

12

11

10

20

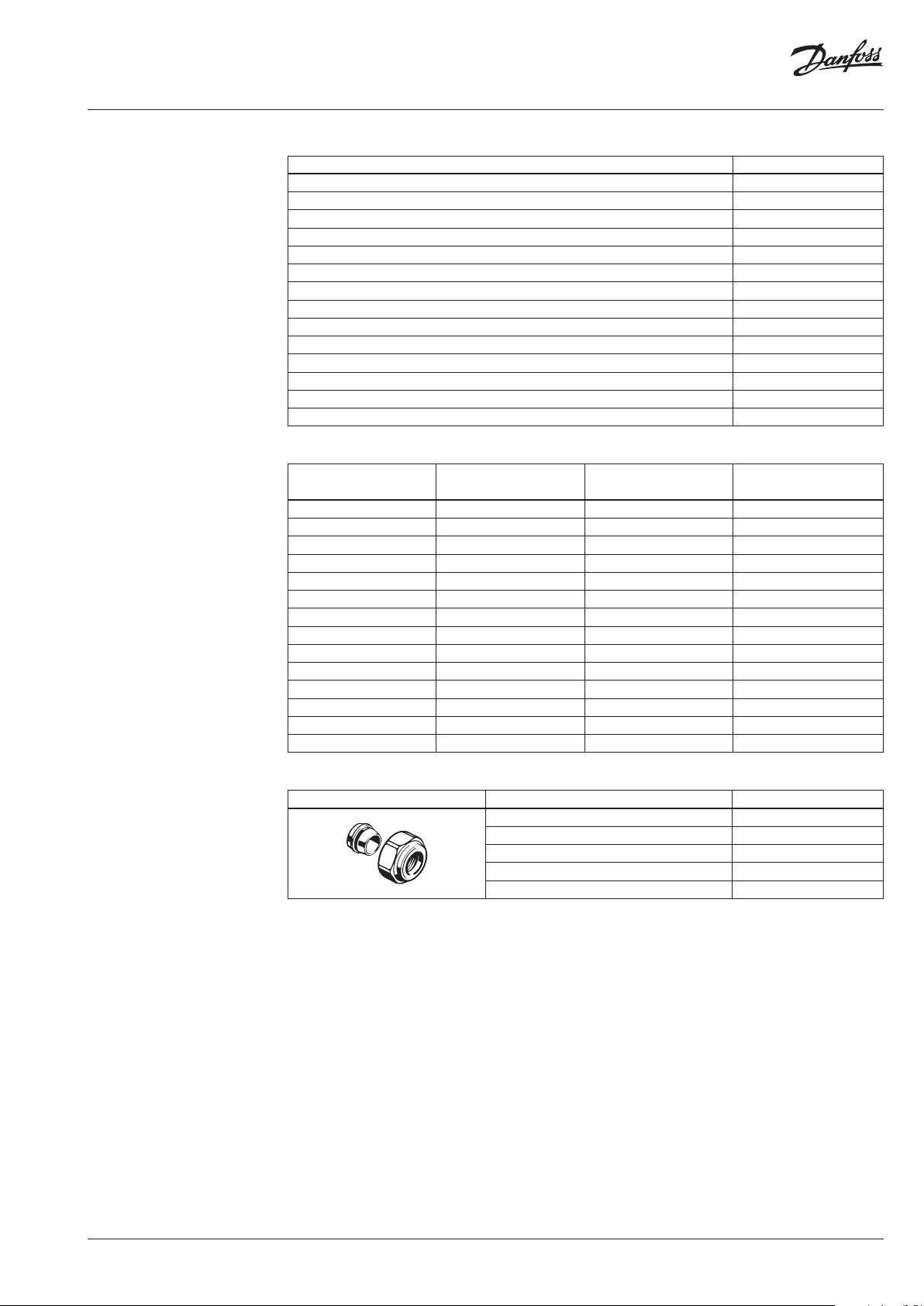

Design

9

8

7

6

Materials and parts in contact with water

Valve body DZR brass

O-rings EPDM

Ball Brass/chromium plated

Ball sealing Teflon

1. Valve body

2. Ball seat

3. Ball

4. Throttle bush

5. Support screw

6. O-ring

7. Shut-o bush

8. O-ring

9. O-ring

10. O-ring

11. Retaining ring (corrosion protected)

12. Spring

13. Valve top

14. Spindle

15. O-ring

16. Rotation lock

17. Spindle head

18. Retaining ring, corrosion protected

19. Strips, 2 pcs.

20. Test plugs protection screw

21. Hose connection

22. Stop plug

Technical data

Fitting

Max. static working pressure 20 bar

Static test pressure 30 bar

Max. differential pressure across valve 2.5 bar (250 kPa)

Max. flow temperature 120 °C

Min. temperature -20 °C

Cooling liquids Ethylene glycol / propylene glycol and HYCOOL (max. 30 %)

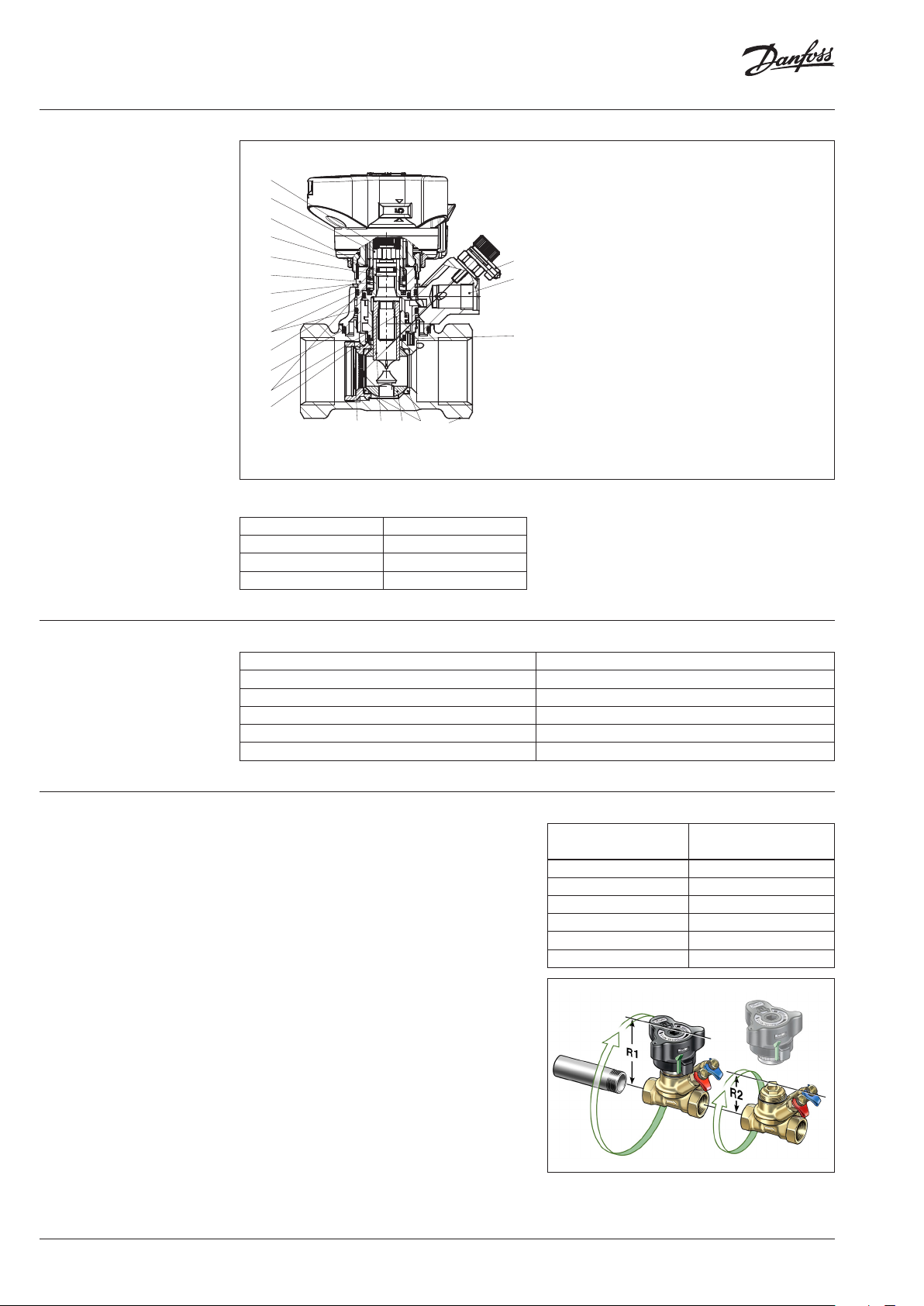

Before fitting the valve the installer must ensure

that the pipe system is clean and:

1. the valve can be turned 360 degrees (if

threaded pipe is used).

2. the valve is fitted according to the flow

direction arrow.

Removal of the handle

1. Set the handle at 0.0.

2. Release the setting lock (green).

DN

15 86/67

20 89/69

25 91/ 71

32 118 /8 4

40 118/8 4

50 124/ 90

R1/R 2

(mm)

3. Unscrew the union nut.

Calibration of the handle

Before refitting, ensure that the handle setting

is 0.0.

For DN 15 - 20 valves with external thread

Danfoss offers a complete range of compression

fittings for steel, cobber and PEX pipes.

4 | AI144986479776en-001201 © Danfoss | 2020.08

Page 5

Data sheet LENO™ MSV-BD

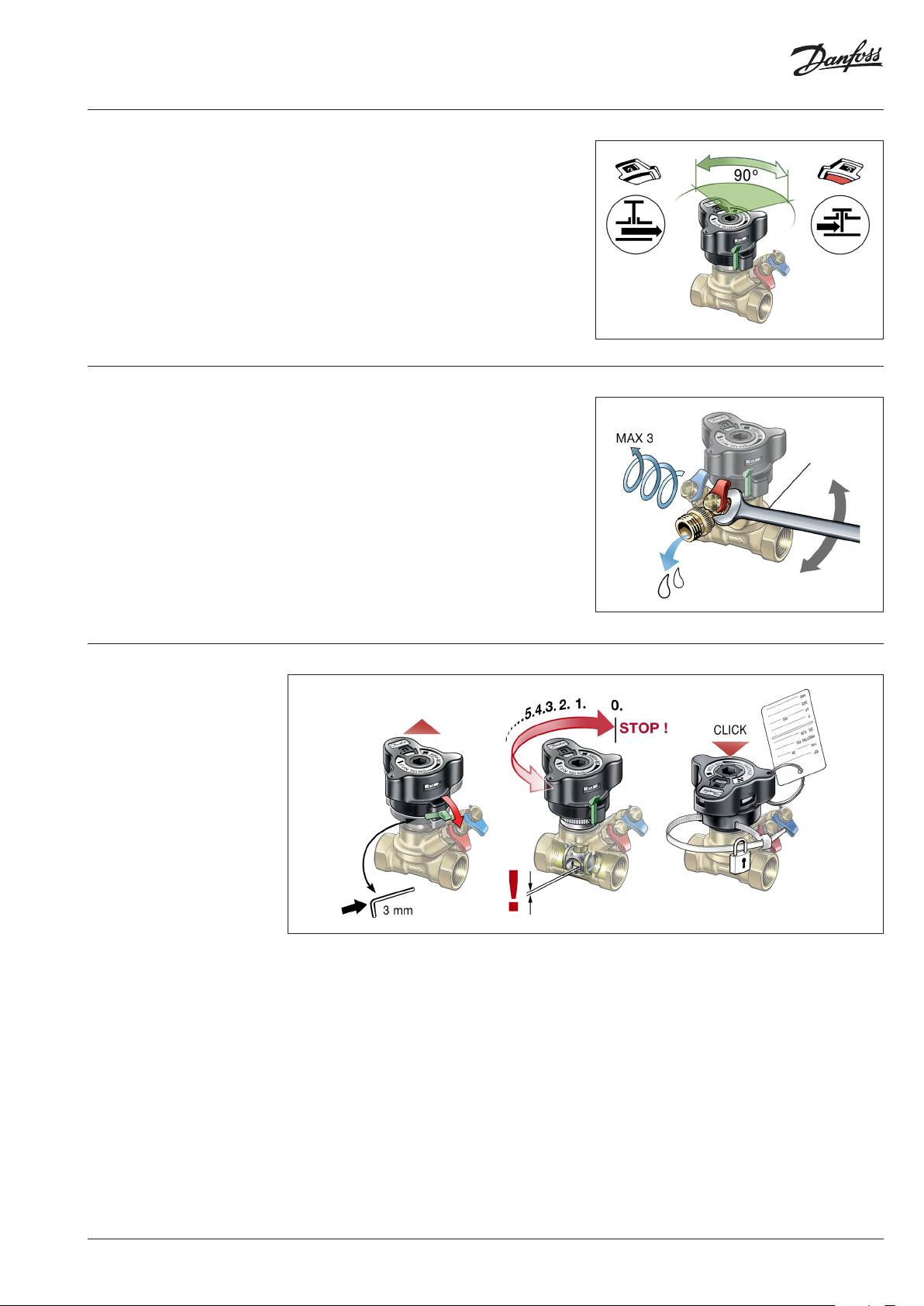

Shut-off

Draining

In order to shut-off the valve the handle must be

pressed down.

The shut-off function features a ball valve, which

only requires a 90 degree turn to shut the valve

completely.

An indicator window shows the actual setting:

• red = closed

• white = open

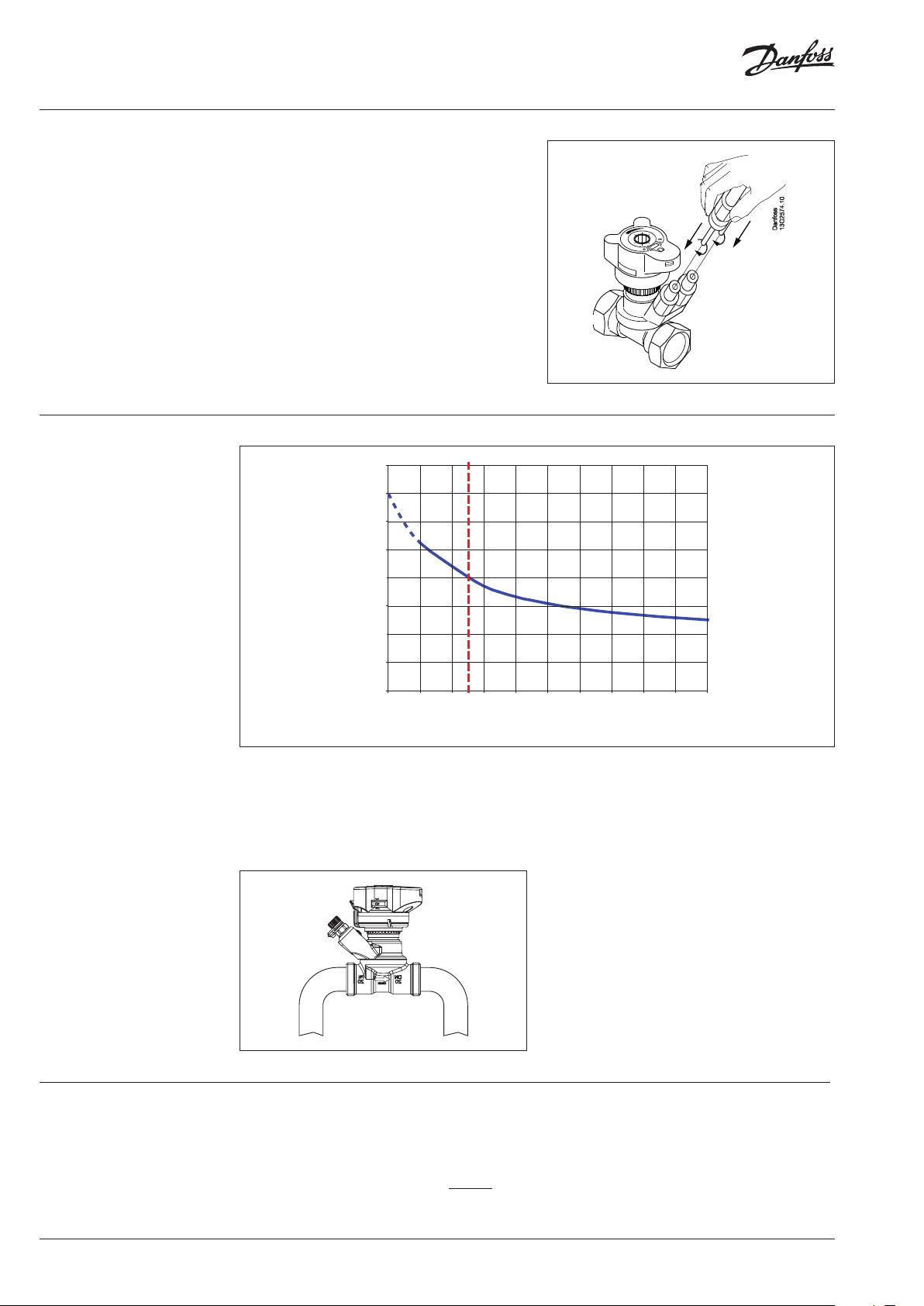

Note!

The drain connection is an accessory and

must be purchased separately.

The drain tap can rotate 360 degrees for

convenient operation.

Draining the system pipes can be done

selectively:

When the red test plug is opened, the valve inlet

pipe is drained.

Opening the blue test plug will drain the pipe

on the valve outlet side. Test plugs unscrewing

protection screw is located between valve test

plugs.

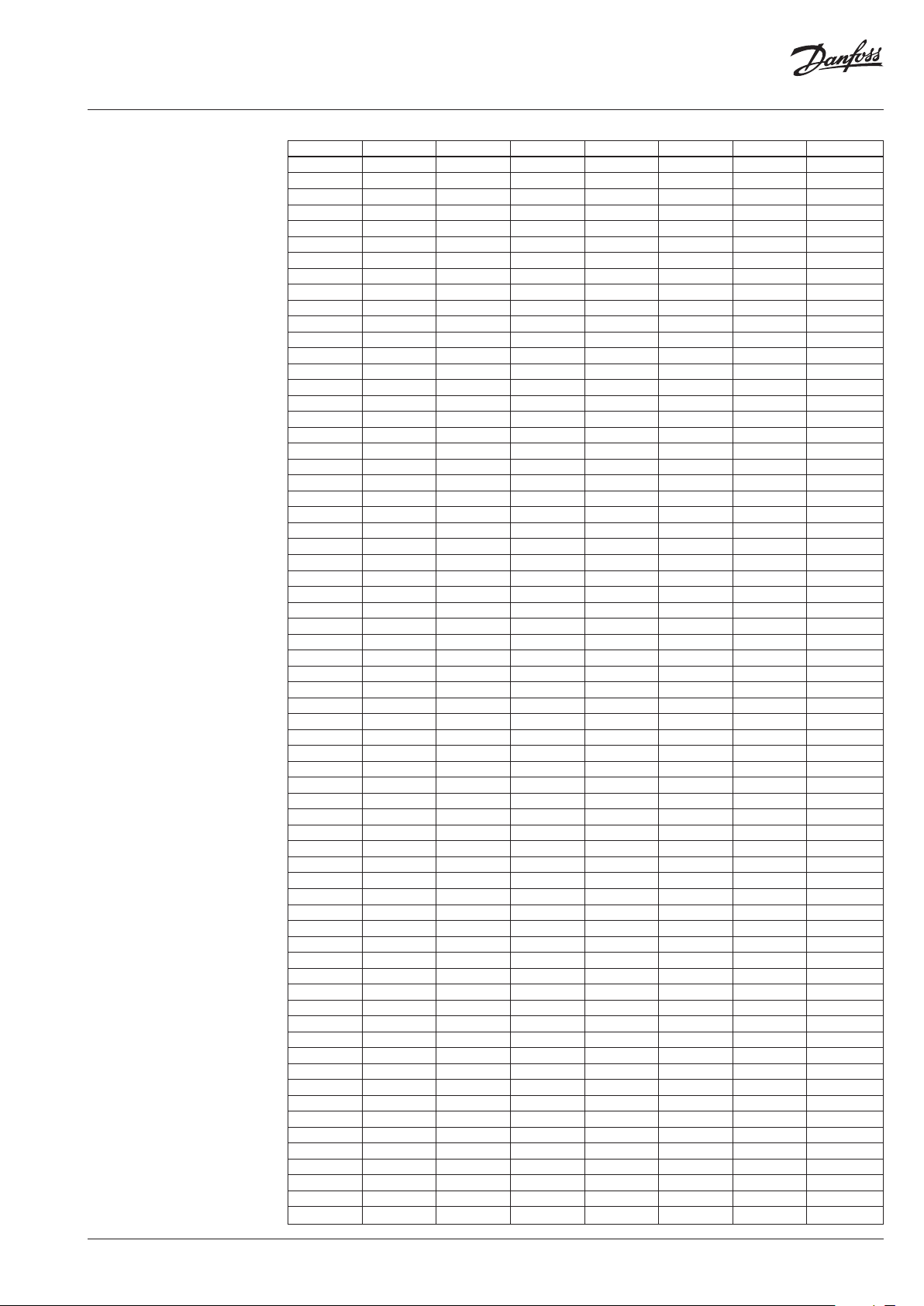

Setting and sealing

The valve has a presetting feature for setting/

adjusting flow ratings.

Setting the required flow is made in 5 steps:

1. In open position, release the lock using the

green lever or a 3 mm Allen key.

2. The handle pops up automatically.

3. The calculated value can now be set.

4. The setting is locked when the handled is

pressed to click.

5. The setting can be sealed by using a strip as

shown.

AI144986479776en-001201 | 5© Danfoss | 2020.08

Page 6

Data sheet LENO™ MSV-BD

16

14

12

10

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Measuring

Measuring accuracy

The flow through the LENO™ MSV-BD valve can

be measured using Danfoss PFM 1000 or other

brands of measuring instruments.

The LENO™ MSV-BD valve is supplied with two

test plugs for Ø3 mm needles.

A twin bracket enables the user to connect both

needles simultanously.

Procedure for flow measuring:

1. Select flow measuring.

2. Select valve brand.

3. Select valve type and dimension.

4. Enter presetting.

5. Connect valve and instrument.

6. Calibrate static pressure.

7. Measure the flow.

v

8

6

4

Error in % of measured k

2

0

% of max. setting

LENO™ MSV-BD is very accurate, due to the

separate functions for presetting and shut-off.

Valve can be mounted everywhere in the system

(closed to T-pieces, elbows, pumps, etc.), since

it is unaffected by turbulence in any setting or

instalation.

The red line indicates 25% of max. flow.

According to BS7350:1990 flow rates must be

within following values:

± 18% at 25% open position

± 10% at fully open position

Kv-signal

kv-signal values are used for non-Danfoss

measuring instruments. Danfoss PFM 1000 have

all data in memory, and the instruments are

using this formula:

∆P

val

= ∆P

sig

2

k

v-sig

k

)

v-val

∆p across the test plugs (kv-sig) and ∆p across the

valve (kv-val) is not the same due to turbulence

influence for pressure measuring.

6 | AI144986479776en-001201 © Danfoss | 2020.08

Page 7

Data sheet LENO™ MSV-BD

Kv-signal values

Setting DN 15LF DN 15 DN 20 DN 25 DN 32 DN 40 DN 50

0.0 0.07 0.10 0.12 0.34 0. 51 1.05 1.75

0.1 0.08 0.11 0.16 0.44 0.73 1. 20 2 .01

0.2 0.09 0.12 0.20 0.53 0.92 1. 36 2.25

0.3 0.11 0 .13 0.26 0 .61 1.10 1. 55 2. 47

0.4 0 .12 0 .14 0.32 0.67 1. 26 1.74 2.69

0.5 0.13 0.16 0.38 0.73 1.43 1.95 2.91

0.6 0 .15 0.19 0.45 0.79 1.6 0 2 .17 3.12

0.7 0 .16 0.21 0. 53 0.84 1.7 8 2.40 3. 35

0.8 0.17 0.24 0.60 0.90 1.97 2.64 3.58

0.9 0.19 0.26 0.67 0.95 2 .18 2.88 3.82

1.0 0.20 0.29 0.74 1. 01 2. 39 3.13 4.07

1.1 0.21 0. 32 0.82 1.08 2.62 3.39 4.33

1.2 0.23 0.34 0.89 1.14 2.87 3.64 4.60

1.3 0.25 0. 37 0.96 1. 22 3.12 3.90 4.89

1.4 0.27 0.40 1. 03 1. 29 3.38 4.16 5.18

1.5 0.30 0.44 1.09 1.37 3.64 4.43 5.49

1.6 0.32 0.47 1.16 1.46 3.92 4.69 5.80

1.7 0.35 0.51 1. 23 1. 55 4.19 4.96 6.13

1.8 0.37 0.54 1. 30 1.65 4.48 5.24 6.46

1.9 0.40 0.58 1. 38 1.75 4 .76 5.51 6.80

2.0 0.43 0.61 1.45 1.8 5 5.05 5.80 7.14

2.1 0.46 0.65 1. 53 1.9 6 5.35 6.08 7.49

2.2 0.49 0.69 1.61 2.07 5.65 6.38 7.8 4

2.3 0.52 0.73 1.6 9 2 .18 5.96 6.68 8.19

2.4 0.56 0.77 1.78 2.29 6.27 6.99 8 .55

2.5 0.59 0.80 1.87 2. 41 6.60 7.30 8 .91

2.6 0.62 0.85 1.97 2.53 6.94 7.63 9. 27

2.7 0.66 0.89 2.07 2.65 7.29 7.9 8 9.64

2.8 0.69 0.93 2 .17 2.77 7.67 8.33 10. 00

2.9 0.73 0.97 2.29 2.89 8.06 8.70 10.37

3.0 0. 76 1.01 2.40 3.01 8.48 9.08 10 .74

3.1 0.80 1.04 2.52 3 .13 8.92 9.48 11.11

3.2 0.83 1.0 8 2.65 3.25 9. 38 9.90 11 .49

3.3 0.87 1.12 2.78 3. 37 9.87 10. 33 11.8 8

3.4 0.90 1.16 2.91 3.49 10. 38 10.79 12. 27

3.5 0.94 1. 20 3.05 3.62 10.91 11. 26 12.67

3.6 0.97 1. 25 3.19 3.74 11. 46 11 .74 13.09

3.7 1.01 1.3 0 3.33 3.87 12.02 12. 25 13. 51

3.8 1.06 1.35 3.47 4.00 12. 58 12. 77 13.95

3.9 1.10 1.41 3 .61 4.13 13 .12 13. 30 14. 41

4.0 1.14 1. 47 3.75 4.26 13 .64 13 .85 14. 88

4.1 1.18 1. 53 3.89 4.39 14 .12 14. 41 15 .38

4.2 1.23 1.59 4.02 4.53 14. 52 14 .98 15. 89

4.3 1. 27 1.6 6 4 .15 4.68 14. 84 15.55 16.4 4

4.4 1. 31 1.73 4.28 4.82 16.13 17.00

4.5 1.35 1.81 4.40 4.98 16.69 17. 59

4.6 1.39 1.91 4.52 5.13 17. 25 18 .21

4.7 1.43 2.00 4.62 5.29 17. 80 18 .86

4.8 1.47 2.08 4.72 5.46 18. 32 19. 54

4.9 1. 51 2.16 4.82 5.64 18 .80 20.24

5-0 1.54 2.23 4.90 5.81 19.25 20.97

5.1 1.60 2.30 4.97 6.00 19. 65 21.73

5.2 1. 66 2.36 5.04 6.19 19.98 22. 51

5.3 1. 72

2.41 6.38 20.24 23.30

5.4 1.79 2.46 6.57 20.41 24.12

5.5 1.87 2.50 6.77 20.48 24.94

5.6 1.93 2.54 6.96 25.76

5.7 1.99 2.57 7.15 26.58

5.8 2.04 7.34 27.38

5.9 2.09 7.52 28 .16

6.0 2 .14 7.69 28.90

6.1 2 .18 7.8 5 29.59

6.2 2.22 7.9 8 30. 21

6.3 2.26 30.74

6.4 31.17

6.5 31.47

6.6 31.61

AI144986479776en-001201 | 7© Danfoss | 2020.08

Page 8

Data sheet LENO™ MSV-BD

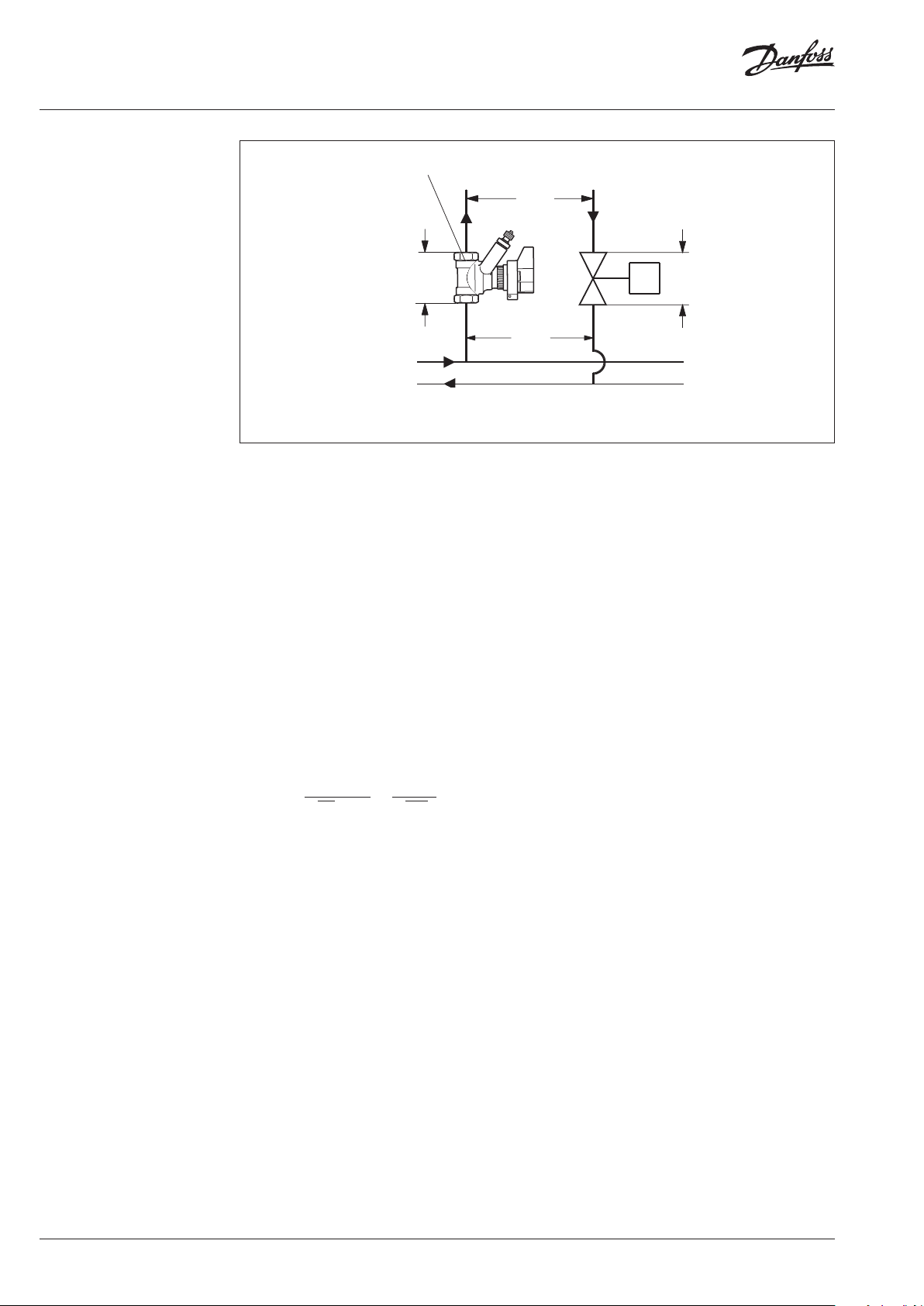

Leno™ MSV-BD

Valve size and presetting

∆p

r

i

∆p

∆pi Pre ssure drop across LENO™ MSV-BD valve

∆pm Pressure drop across valve

Example

Given:

Max. pipe flow Q ...............................................2.0 m3/h

∆pr ..............................................................................15 kPa

∆pa .............................................................................45 kPa

∆pm ............................................................................10 kPa

∆pi ...............................................................∆pa - ∆pv - ∆p

∆pi = 45 kPa - 15 kPa - 10KPa = 20 kPa

Correct valve size and presetting is found in the

sizing and flow diagrammes, p 9.

Q = 2.0 m3/h and ∆pi = 20 kPa

∆p

a

∆pr Necessary p ressure for the riser

∆pa Available p ressure for the riser

m

M

m

∆p

Setting can be also calculated from the formula:

kv =

Qm3/h

√∆pi bar √0.20

2.0

=

= 4.5 m3/h

8 | AI144986479776en-001201 © Danfoss | 2020.08

Page 9

Data sheet LENO™ MSV-BD

Sizing

Correction factors

Medium: Ethylene glycol / propylene glycol percentage (max. 30 %).

Tem p.

°C

-40.0 1) 1) 1) 1) 0.89 0.88

-17. 8 1) 1) 0.93 0.91 0.90 0.89 0.86

4.4 0.95 0.95 0.93 0.92 0.91 0.90 0.87

26.6 0.96 0.95 0.94 0.93 0.92 0.91 0.88

48.9 0.97 0.96 0.95 0.94 0.93 0.92 0.90

71.1 0.98 0.98 0.96 0.95 0.94 0.94 0.95

93.3 1.0 0 0.99 0.97 0.96 0.95 0.95 0.92

115 .6

1)

Below freezing point

2)

Above boiling point

25 30 40 50 60 65 100

2) 2) 2) 2) 2) 2)

Flow, m3/h

Example

Flow needed ............................30 m3/h

Flow after correction ........30 x 0.95 = 28 m3/h

AI144986479776en-001201 | 9© Danfoss | 2020.08

1)

0.94

Page 10

Data sheet LENO™ MSV-BD

2.5

k

v

-value

Setting

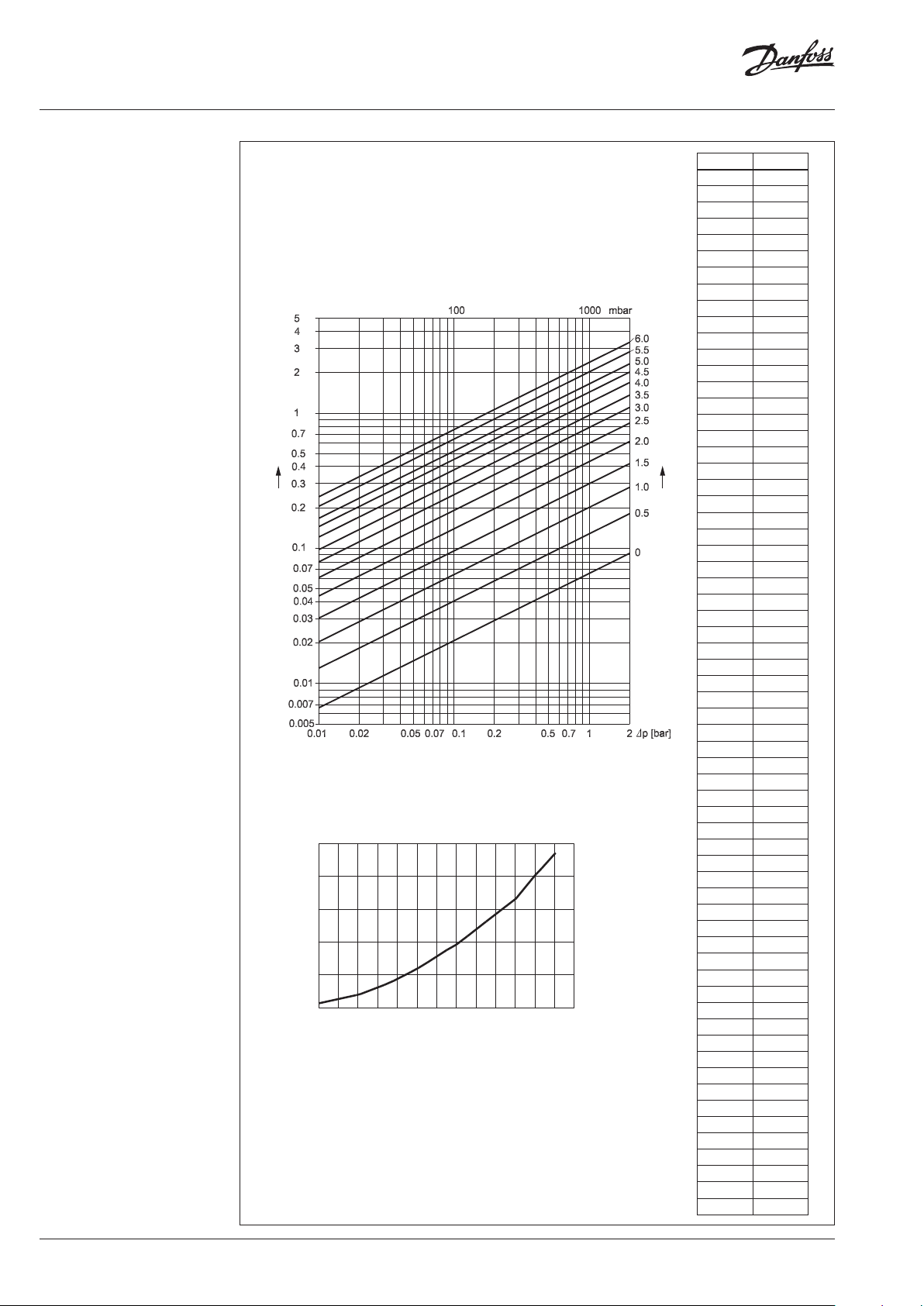

Flow diagrammes,

DN 15 LF

LENO™ MSV-BD DN 15 LF

/h]

3

Flow [m

Flow characteristics

2.0

1.5

1.0

0.5

0

0 1.0 2.0 3.0 4.0 5.0 6.0

Setting kV-value

Setting

0.0 0.07

0.1 0.08

0.2 0.09

0.3 0.11

0.4 0.12

0.5 0.13

0.6 0.15

0.7 0.16

0.8 0.17

0.9 0.19

1.0 0.20

1.1 0.22

1.2 0.23

1.3 0.25

1.4 0.28

1.5 0.30

1.6 0.32

1.7 0.35

1.8 0.38

1.9 0.41

2.0 0.44

2.1 0.47

2.2 0.50

2.3 0.53

2.4 0.56

2.5 0.60

2.6 0.63

2.7 0.67

2.8 0.71

2.9 0.74

3.0 0.78

3.1 0.82

3.2 0.86

3.3 0.89

3.4 0.93

3.5 0.97

3.6 1.01

3.7 1.05

3.8 1.10

3.9 1.15

4.0 1.19

4.1 1.24

4.2 1.29

4.3 1.33

4.4 1.38

4.5 1.43

4.6 1.48

4.7 1.52

4.8 1.56

4.9 1.61

5.0 1.65

5.1 1.72

5.2 1.78

5.3 1.86

5.4 1.94

5.5 2.03

5.6 2.10

5.7 2.17

5.8 2.23

5.9 2.30

6.0 2.36

6.1 2.42

6.2 2.47

6.3 2.53

10 | AI144986479776en-001201 © Danfoss | 2020.08

Page 11

6.0

3.5

Setting

k

v

-value

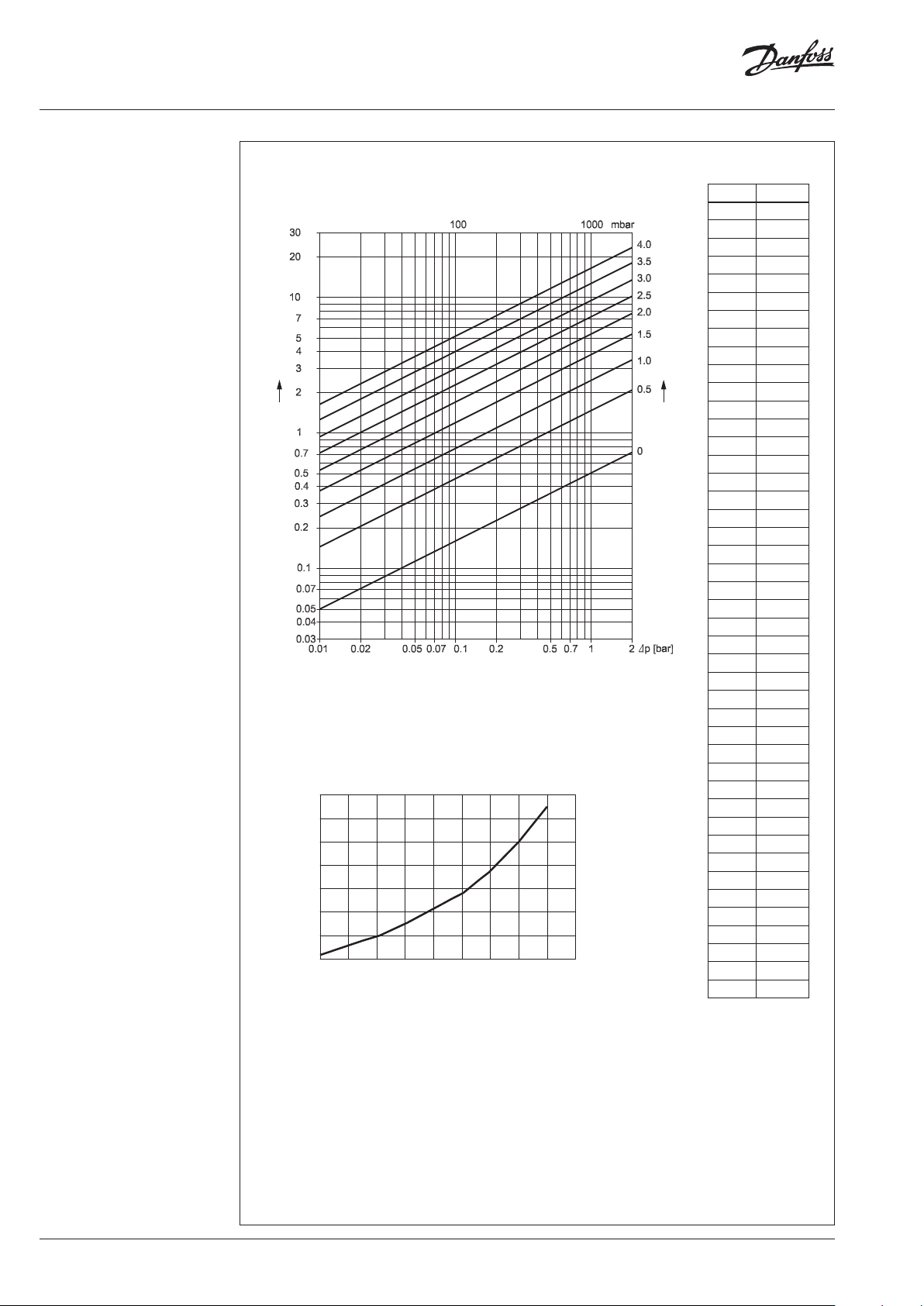

Data sheet LENO™ MSV-BD

Flow diagrammes,

DN 15

LENO™ MSV-BD DN 15

/h]

3

Flow [m

Flow characteristics

3.0

2.5

2.0

1.5

1.0

0.5

0

0 1.0 2.0 3.0 4.0 5.0

Setting kV-value

Setting

0.0 0.10

0.1 0.11

0.2 0.12

0.3 0.13

0.4 0.14

0.5 0.16

0.6 0.19

0.7 0.21

0.8 0.24

0.9 0.27

1.0 0.29

1.1 0.32

1.2 0.35

1.3 0.38

1.4 0.41

1.5 0.44

1.6 0.48

1.7 0.51

1.8 0.55

1.9 0.59

2.0 0.63

2.1 0.67

2.2 0.71

2.3 0.75

2.4 0.80

2.5 0.84

2.6 0.88

2.7 0.93

2.8 0.97

2.9 1.02

3.0 1.06

3.1 1.10

3.2 1.14

3.3 1.19

3.4 1.23

3.5 1.28

3.6 1.34

3.7 1.40

3.8 1.46

3.9 1.52

4.0 1.59

4.1 1.66

4.2 1.74

4.3 1.82

4.4 1.91

4.5 2.00

4.6 2.12

4.7 2.23

4.8 2.33

4.9 2.43

5.0 2.53

5.1 2.61

5.2 2.70

5.3 2.77

5.4 2.84

5.5 2.90

5.6 2.95

5.7 3.00

AI144986479776en-001201 | 11© Danfoss | 2020.08

Page 12

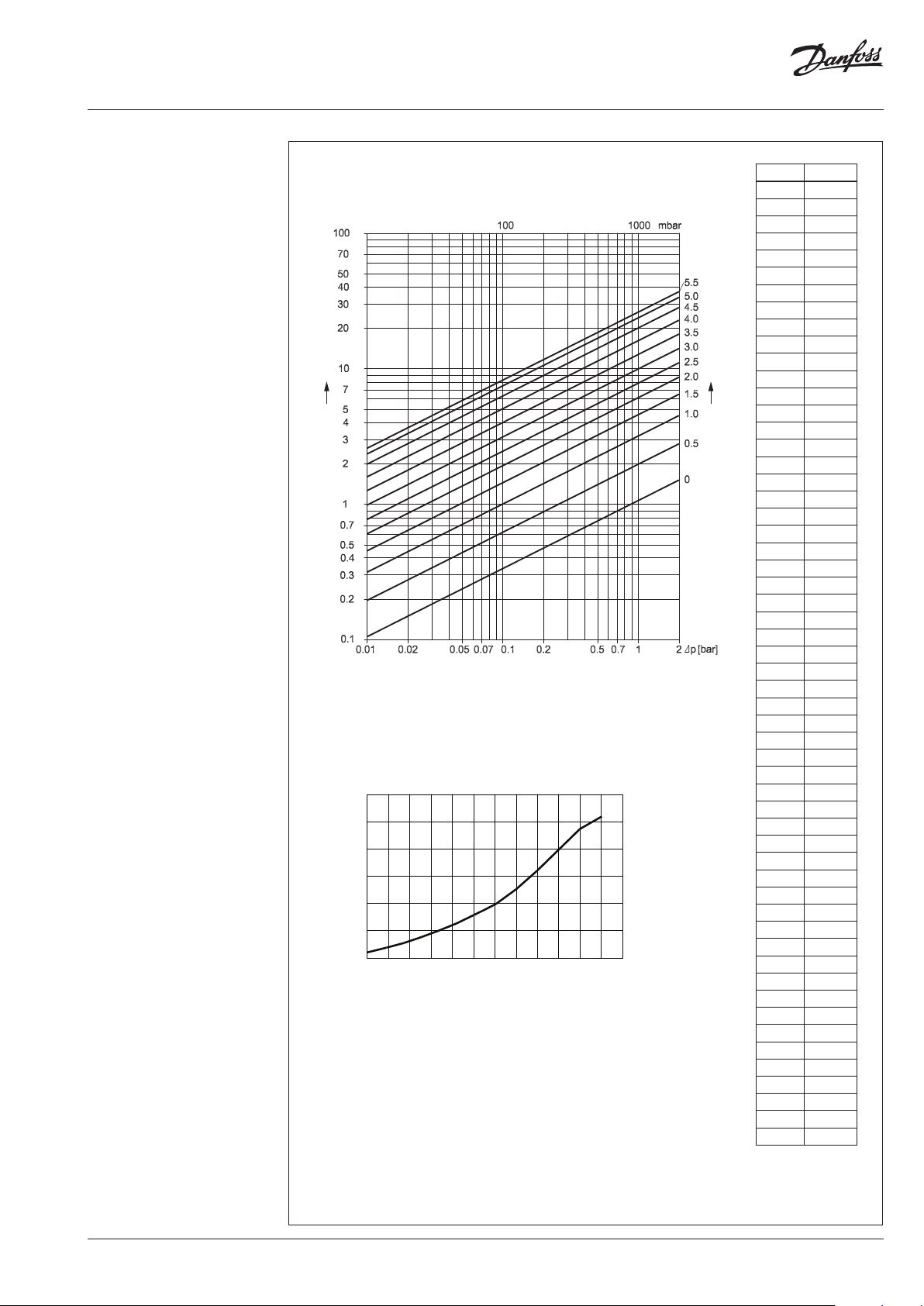

Data sheet LENO™ MSV-BD

Setting

k

-value

6.0

7.0

Flow diagrammes,

DN 20

LENO™ MSV-BD DN 20

/h]

3

Flow [m

Flow characteristics

6.0

5.0

4.0

3.0

v

2.0

1.0

0

0 1.0 2.0 3.0 4.0 5.0

Setting

Setting kV-value

0.0 0.13

0.1 0.15

0.2 0.19

0.3 0.24

0.4 0.30

0.5 0.37

0.6 0.45

0.7 0.53

0.8 0.61

0.9 0.68

1.0 0.76

1.1 0.84

1.2 0.92

1.3 0.99

1.4 1.06

1.5 1.13

1.6 1.21

1.7 1.28

1.8 1.35

1.9 1.43

2.0 1.50

2.1 1.59

2.2 1.67

2.3 1.76

2.4 1.86

2.5 1.96

2.6 2.07

2.7 2.19

2.8 2.31

2.9 2.44

3.0 2.58

3.1 2.72

3.2 2.87

3.3 3.03

3.4 3.19

3.5 3.36

3.6 3.53

3.7 3.70

3.8 3.87

3.9 4.05

4.0 4.23

4.1 4.40

4.2 4.58

4.3 4.75

4.4 4.91

4.5 5.07

4.6 5.22

4.7 5.37

4.8 5.51

4.9 5.64

5.0 5.77

5.1 5.88

5.2 6.00

12 | AI144986479776en-001201 © Danfoss | 2020.08

Page 13

Setting

10

Setting

k

v

-value

Data sheet LENO™ MSV-BD

Flow diagrammes,

DN 25

LENO™ MSV-BD DN 25

/h]

3

Flow [m

Flow characteristics

8

6

4

2

0

0 1.0 2.0 3.0 4.0 5.0 6.0

Setting kV-value

0.0 0.33

0.1 0.44

0.2 0.53

0.3 0.61

0.4 0.68

0.5 0.74

0.6 0.79

0.7 0.85

0.8 0.91

0.9 0.96

1.0 1.03

1.1 1.09

1.2 1.16

1.3 1.24

1.4 1.32

1.5 1.41

1.6 1.50

1.7 1.60

1.8 1.70

1.9 1.80

2.0 1.91

2.1 2.03

2.2 2.15

2.3 2.26

2.4 2.39

2.5 2.51

2.6 2.64

2.7 2.76

2.8 2.89

2.9 3.02

3.0 3.15

3.1 3.28

3.2 3.41

3.3 3.54

3.4 3.68

3.5 3.81

3.6 3.95

3.7 4.09

3.8 4.24

3.9 4.39

4.0 4.55

4.1 4.71

4.2 4.88

4.3 5.05

4.4 5.23

4.5 5.42

4.6 5.62

4.7 5.83

4.8 6.05

4.9 6.27

5.0 6.51

5.1 6.75

5.2 7.00

5.3 7.26

5.4 7.53

5.5 7.80

5.6 8.06

5.7 8.33

5.8 8.59

5.9 8.84

6.0 9.08

6.1 9.30

6.2 9.50

AI144986479776en-001201 | 13© Danfoss | 2020.08

Page 14

Data sheet LENO™ MSV-BD

Setting

k

-value

Flow diagrammes,

DN 32

LENO™ MSV-BD DN 32

/h]

3

Flow [m

Flow characteristics

16

12

v

4

0

0 1.0 2.0 3.0 4.0

Setting

Setting kV-value

0.0 0.50

0.1 0.75

0.2 0.95

0.3 1.13

0.4 1.29

0.5 1.45

0.6 1.62

0.7 1.80

0.8 1.99

0.9 2.20

1.0 2.42

1.1 2.66

1.2 2.92

1.3 3.19

1.4 3.47

1.5 3.75

1.6 4.05

1.7 4.36

1.8 4.67

1.9 4.98

2.0 5.30

2.1 5.63

2.2 5.97

2.3 6.32

2.4 6.68

2.5 7.06

2.6 7.46

2.7 7.89

2.8 8.34

2.9 8.83

3.0 9.35

3.1 9.92

3.2 10.52

3.3 11.16

3.4 11.85

3.5 12.51

3.6 13.23

3.7 13.98

3.8 14.74

3.9 15.49

4.0 16.23

4.1 16.91

4.2 17.51

4.3 18.00

14 | AI144986479776en-001201 © Danfoss | 2020.08

Page 15

Setting

6.0

30

Setting

k

v

-value

Data sheet LENO™ MSV-BD

Flow diagrammes,

DN 40

LENO™ MSV-BD DN 40

/h]

3

Flow [m

Flow characteristics

25

20

15

10

5

0

0 1.0 2.0 3.0 4.0 5.0

Setting kV-value

0.0 1.06

0.1 1.21

0.2 1.38

0.3 1.56

0.4 1.76

0.5 1.97

0.6 2.20

0.7 2.43

0.8 2.68

0.9 2.93

1.0 3.19

1.1 3.46

1.2 3.73

1.3 4.01

1.4 4.29

1.5 4.58

1.6 4.87

1.7 5.17

1.8 5.47

1.9 5.78

2.0 6.09

2.1 6.41

2.2 6.74

2.3 7.09

2.4 7.44

2.5 7.80

2.6 8.18

2.7 8.58

2.8 9.00

2.9 9.44

3.0 9.90

3.1 10.38

3.2 10.89

3.3 11.43

3.4 12.00

3.5 12.60

3.6 13.22

3.7 13.88

3.8 14.56

3.9 15.28

4.0 16.02

4.1 16.79

4.2 17.57

4.3 18.38

4.4 19.19

4.5 20.02

4.6 20.82

4.7 21.61

4.8 22.38

4.9 23.12

5.0 23.81

5.1 24.44

5.2 25.00

5.3 25.46

5.4 25.80

5.5 26.00

AI144986479776en-001201 | 15© Danfoss | 2020.08

Page 16

Data sheet LENO™ MSV-BD

Setting

7.0

Setting

k

v

-value

Flow diagrammes,

DN 50

LENO™ MSV-BD DN 50

/h]

3

Flow [m

Flow characteristics

40

30

20

10

0

0 1.0 2.0 3.0 4.0 5.0 6.0

Setting kV-value

0.0 1.74

0.1 2.03

0.2 2.28

0.3 2.51

0.4 2.73

0.5 2.95

0.6 3.16

0.7 3.38

0.8 3.61

0.9 3.85

1.0 4.10

1.1 4.37

1.2 4.65

1.3 4.95

1.4 5.26

1.5 5.59

1.6 5.93

1.7 6.28

1.8 6.64

1.9 7.01

2.0 7.39

2.1 7.78

2.2 8.17

2.3 8.56

2.4 8.96

2.5 9.36

2.6 9.76

2.7 10.17

2.8 10.58

2.9 10.99

3.0 11.41

3.1 11.84

3.2 12.27

3.3 12.71

3.4 13.16

3.5 13.62

3.6 14.10

3.7 14.60

3.8 15.12

3.9 15.66

4.0 16.23

4.1 16.84

4.2 17.47

4.3 18.14

4.4 18.84

4.5 19.59

4.6 20.38

4.7 21.21

4.8 22.08

4.9 23.00

5.0 23.96

5.1 24.96

5.2 26.00

5.3 27.07

5.4 28.17

5.5 29.30

5.6 30.44

5.7 31.64

5.8 32.83

5.9 34.01

6.0 35.14

6.1 36.23

6.2 37.24

6.3 38.14

6.4 38.93

6.5 39.56

6.6 40.00

16 | AI144986479776en-001201 © Danfoss | 2020.08

Page 17

Data sheet LENO™ MSV-BD

H

Dimensions

S

aa

a a

L

MSV-BD Size

003Z4000 DN 15 LF G ½ 65 92 27

003Z4001 D N 15 G ½ 65 92 27

003Z4002 DN 20 G ¾ 75 95 32

003Z4003 DN 25 G 1 85 98 41

003Z4004 DN 32 G 1¼ 98 121 50

003Z4005 DN 40 G 1½ 100 125 55

003Z4006 DN 50 G 2 130 129 67

003Z4100 DN 15 LF G ¾ A 70 92 -

003Z4101 DN 15 G ¾ 70 92 -

003Z4102 DN 20 G 1 A 75 95 -

a L H S

Thread ISO 228-1 (mm) (mm) (mm)

AI144986479776en-001201 | 17© Danfoss | 2020.08

Page 18

Data sheet LENO™ MSV-BD

Tender specifications

LENO™ MSV –BD can be used in heating and cooling systems.

Features LENO™ MSV-BD

Balancing / Commissioning •

Presetting •

Fixed orifice

Self sealing test plugs •

Digital visible scale from more sides •

Shut-off function (ball valve) •

Draining / filling •

Draining / f illing on both sides of the valve •

Removable handle •

Closing indicator •

Allen key for ball valve •

Parallel test plugs •

360° rotating measuring station (drain tap and test plugs) •

Presetting values are visible on top of the valve and from all sides.

Presetting is locked by pressing down the handle. When locked, the shut-off function can be used

without changing the presetting.

The handle is released with the green key or with a 3 mm Allen key.

To prevent unintended changes of the presetting, the handle can be sealed by using a strip.

The system can be drained and filled on both sides of the ball valve.

External thread versions comes in sizes DN 15 and DN 20 and are prepared for Danfoss standard

fittings. DN 15 is designed with Euro cone, according to DIN V 3838.

LENO™ MSV-BD has a leakage rate A according to ISO 5208, the ball valve is 100% tight.

The LENO™ MSV-BD measuring accuracy is 8% at 25% of max. setting.

Accuracy is according to BS 7350 : 1990.

Measuring instruments must be equipped with Ø3 mm measuring needles. Danfoss measuring

instruments PFM 1000 contain all relevant valve data.

Valve sizes....................DN 15 (LF) – DN 50

Pressure class..............................PN20

Static test pressure .......................30 bar

Working temperature............. -20°C to 120°C

Working area.......... 10-100% of the kvs-value

The valve body is made of DZR brass.

The ball is made of chromium plated brass.

O-rings are made from EPDM rubber.

18 | AI144986479776en-001201 © Danfoss | 2020.08

Page 19

Data sheet LENO™ MSV-BD

AI144986479776en-001201 | 19© Danfoss | 2020.08

Page 20

Data sheet LENO™ MSV-BD

© Danfoss | DHS-SMDBT/SI | 2020.0820 | AI144986479776en-001201

Loading...

Loading...