Page 1

Data sheet

Pressure switch and Thermostat

KP and KPI

The KP and KPI pressure switches and

thermostats are used for control, monitoring

and alarm systems in a wide variety of industry

applications.

KP pressure switches are mainly used for gaseous

fluid whereas KPI pressure switches are more

for liquid and gaseous fluid. The products

are available in IP30 enclosure as well as IP55

enclosure.

The KP pressure range include special designed

pressure switches and limiters for steam boilers

and other heating applications.

For water pump control and protection (dry run)

the dual pressure switch KP44 is suitable and

secure improved life time of the water pump.

Features • Wide setting range

• Shock and impact resistant

• Snap action electrical contacts minimize

chatter, bounce, and wear, and ensure long

term electrical and mechanical reliability

• Small dimensions - space saving and easy

to install in panels

• Electrical connection from front

of the unit makes rack mounting easier

and also saves space

• Suitable for alternating current

and direct current

• Single pressure switches and thermostats are

fitted with a single pole double throw contact

system (SPDT)

• Can be used for both liquids and gases (KPI)

Approvals CE-marked in accordance with LVD 2014/35/EU:

EN 60947-1, EN 60947-4-1, EN 60947-5-1

Underwriters Laboratories Inc., UL

• Manual trip function enables electrical

connections verification without any tools or

pressure changes in the application

• Versions with automatic and manual

reset available

• For demineralized water, there are special KP

models with wetted parts made of stainless

steel (AISI 316L)

China Compulsory Certificate, CCC

(excluding boiler versions)

GOST (excluding KPI)

© Danfoss | DCS (rm) | 2019.12

IC.PD.P10.F9.02 | 1

Page 2

Data sheet | Pressure switch and Thermostat, KP and KPI

Technical data

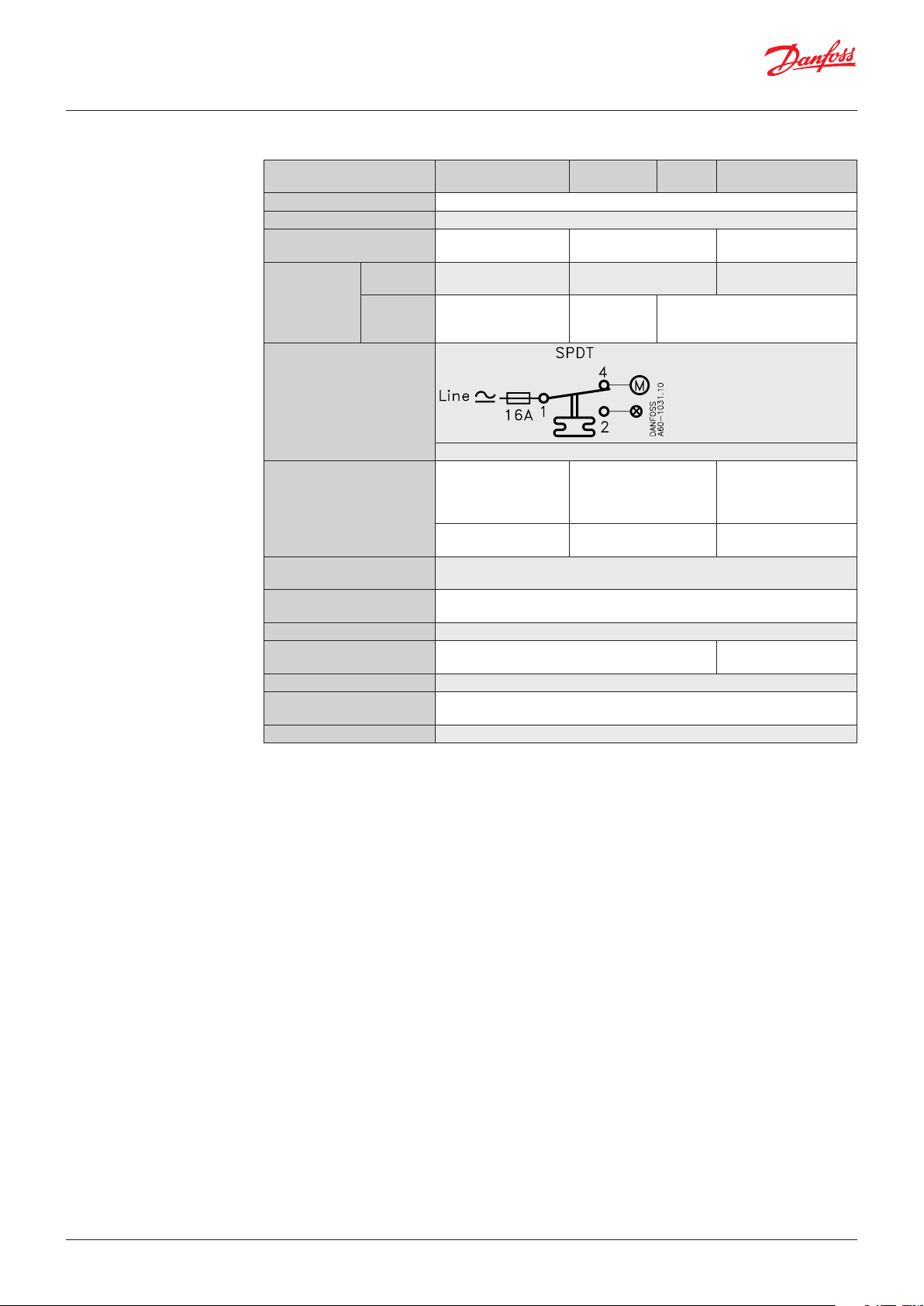

Single pressure switch

Description KP 35, KP 36 KPI 35, KPI 36 KPI 38

Ambient temperature [°C] -40 – 65 °C (for max. 2 hours up to 80 °C)

Media temperature [°C] -40 – 100 °C

Fluid Gaseous media

Bellows

Parts in contact

with fluid

Contact system

Contact load, Silver

Contact load,

Gold plated contact set

Enclosure, IP30 grade

Enclosure, IP44 grade Mounted as IP30 plus fitting of top cover, code no. 060-109766

Enclosure, IP55 grade

Cable entry Rubber cable gland entry for 6 – 14 mm diameter cables

Mounted on back

plate / wall bracket

Mounted on angle bracket Not recommended in areas where vibrations occur

Pressure

connector

Phosphor bronze

or Stainless steel

Free-cutting steel

(nickel plated)

or Stainless steel

Single-pole double throw (SPDT)

Alternating current:

AC-1: 16 A, 400 V

AC-3: 16 A, 400 V

AC-15: 10 A, 400 V

Direct current:

DC-13: 12 W, 220 V

See information page 15

Unit must be mounted on a flat surface / a flat fitting and all unused holes

covered

Unit mounted in a special IP55 enclosure, code no.

060-033066 or 060-062866

Vibration proof in the range 0 – 1000 Hz, 4 g [1 g = 9.81 m/s2

Gaseous media and

liquids

Phosphor bronze Stainless steel

Brass Free-cutting steel (nickel plated)

Alternating current:

AC-1: 10 A, 440 V

AC-3: 6 A, 440 V

AC-15: 4 A, 440 V

Direct current:

DC-13: 12 W, 220 V

KP 34, KP 35, KP 36,

KP 37 boiler version

Steam, air, gaseous

media & liquids

Alternating current:

AC-1 : 16 A, 400 V

AC-3 : 16 A, 400 V

AC-15 : 10 A, 400 V

Direct current:

DC-13: 12 W, 220 V

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 2

Page 3

Data sheet | Pressure switch and Thermostat, KP and KPI

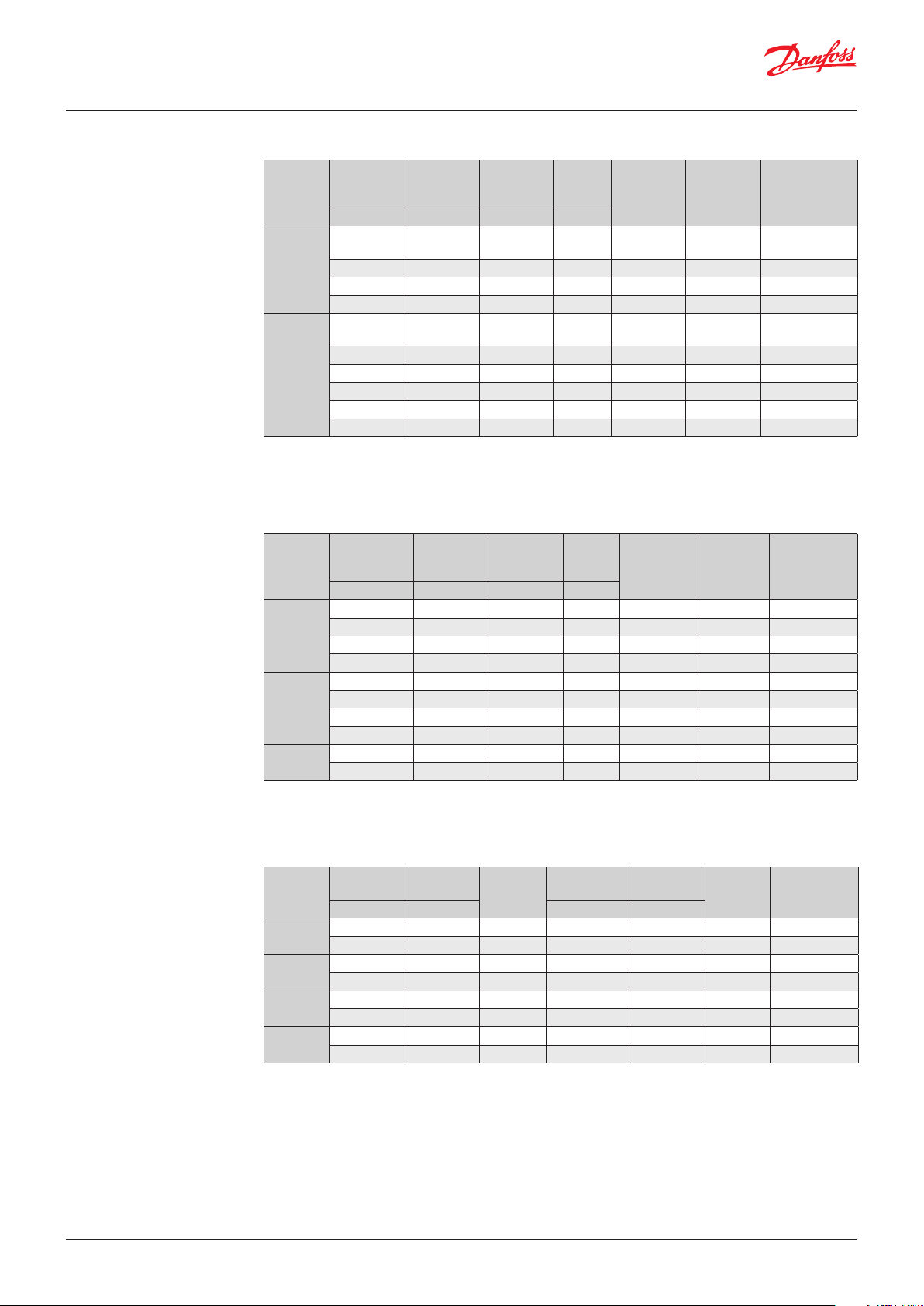

Ordering Pressure switch, types KP 35 and KP 36

Permissible

Typ e

Setting

range P

e

Differential

[bar] [bar] [bar] [bar]

-0.2 – 7.5 0.7 – 4.0 17 22 G 1⁄4 A silver

KP 35

-0.2 – 7.5 0.7 – 4.0 17 22 G 1⁄4 A gold-plated 060-50476 6

-0.2 – 7.5 0.7 – 4.0 17 22 G 1⁄4 A silver 060-538666 2)

-0.2 – 7.5 0.7 – 4.0 17 22 G 1⁄4 A silver 060-450366 3)

2.0– 14.0 0.7 – 4.0 17 22 G 1⁄4 A silver

2.0– 14.0 0.7 – 4.0 17 22 G 1⁄4 A gold 060-113 766

KP 36

2.0– 14.0 0.7 – 4.0 17 22 G 1⁄4 A silver 06 0-538766 2)

4.0 – 12.0 0.5 – 1.6 17 22 G 1⁄4 A silver 06 0-122166

4.0 – 12.0 0.5 – 1.6 17 22 G 1⁄4 A gold 06 0-114 4 66

4.0 – 12.0 0.5 – 1.6 17 22 G 1⁄4 A silver 06 0-450166 3)

1

) Available only in Asia market

2

) IP55 transparent enclosure

3

) Stainless steel version, IP55 non-transparent enclosure

Pressure switch, types KPI 35 – KPI 38

Setting

Typ e

range P

[bar] [bar] [bar] [bar]

-0.2 – 8.0 0.4 – 1.5 18 18 G 1⁄4 A silver 06 0-121766

KPI 35

-0.2 – 8.0 0.4 – 1.5 18 18 G 1⁄4 A gold-plated 060-3164 66

-0.2 – 8.0 0.5 – 2.0 18 18 G 1⁄4 A silver 06 0-1219 66

-0.2 – 8.0 0.4 – 1.5 18 18 G 1⁄4 A silver 060 -315766 1)

4 .0– 12.0 0.5 – 1.6 18 18 G 1⁄4 A silver 06 0-118966

KPI 36

4.0 – 12.0 0.5 – 1.6 18 18 G 1⁄4 A gold-plated 0 60 -113866

2.0 – 12.0 0.5 – 1.6 18 18 G 1⁄4 A silver 060-3169 66

2.0 – 12.0 0.5 – 1.6 18 18 G 1⁄4 A silver 06 0-3193 66 2)

KPI 38

1

) IP55 transparent enclosure

2

) IP55 non-transparent enclosure

8.0 – 28.0 1.8 – 6.0 30 30 G 1⁄4 A silver 060-508166

8.0 – 28.0 1.8 – 6.0 30 30 G 1⁄4 A silver 060-54186 6 2

e

Differential

operating

pressure P

Permissible

operating

pressure P

pressure

e

e

Max.

test

Max.

test

pressure

Pressure

connection

Pressure

connection

Contact

material

Contact

material

Code no.

060-113 366

060-113 391 1)

060-110866

060-110891 1)

Code no.

Pressure switch, types KP 34 – KP 37, boiler version

Typ e

KP 34

KP 35

KP 36

KP 37

Setting

range pe

Differential

Reset

[bar] [bar] [bar] [bar]

0.1 – 1.0 0.1 – 0.4 Automatic G 1⁄2 A 4.0 silver 0 60-216 466

0.1 – 1.0 0.2 Manual G 1⁄2 A 4.0 silver 060 -216366

0.4 – 3.4 0.4 – 2.2 Automatic G 1⁄2 A 10 silver 060-216666

0.4 – 3.4 0.5 Manual G 1⁄2 A 10 silver 060-216566

1.0 – 10.0 0.7 – 4.0 Automatic G 1⁄2 A 17 silver 060 -21596 6

1.0 – 10.0 0.7 Manual G 1⁄2 A 17 silver 060-216066

4.0 – 20.0 1.8 – 3.1 Automatic G 1⁄2 A 28 silver 060 -216166

4.0 – 20.0 3.0 Manual G 1⁄2 A 28 silver 060 -216266

Pressure

connection

Max. test

pressure

Contact

material

Code no.

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 3

Page 4

Data sheet | Pressure switch and Thermostat, KP and KPI

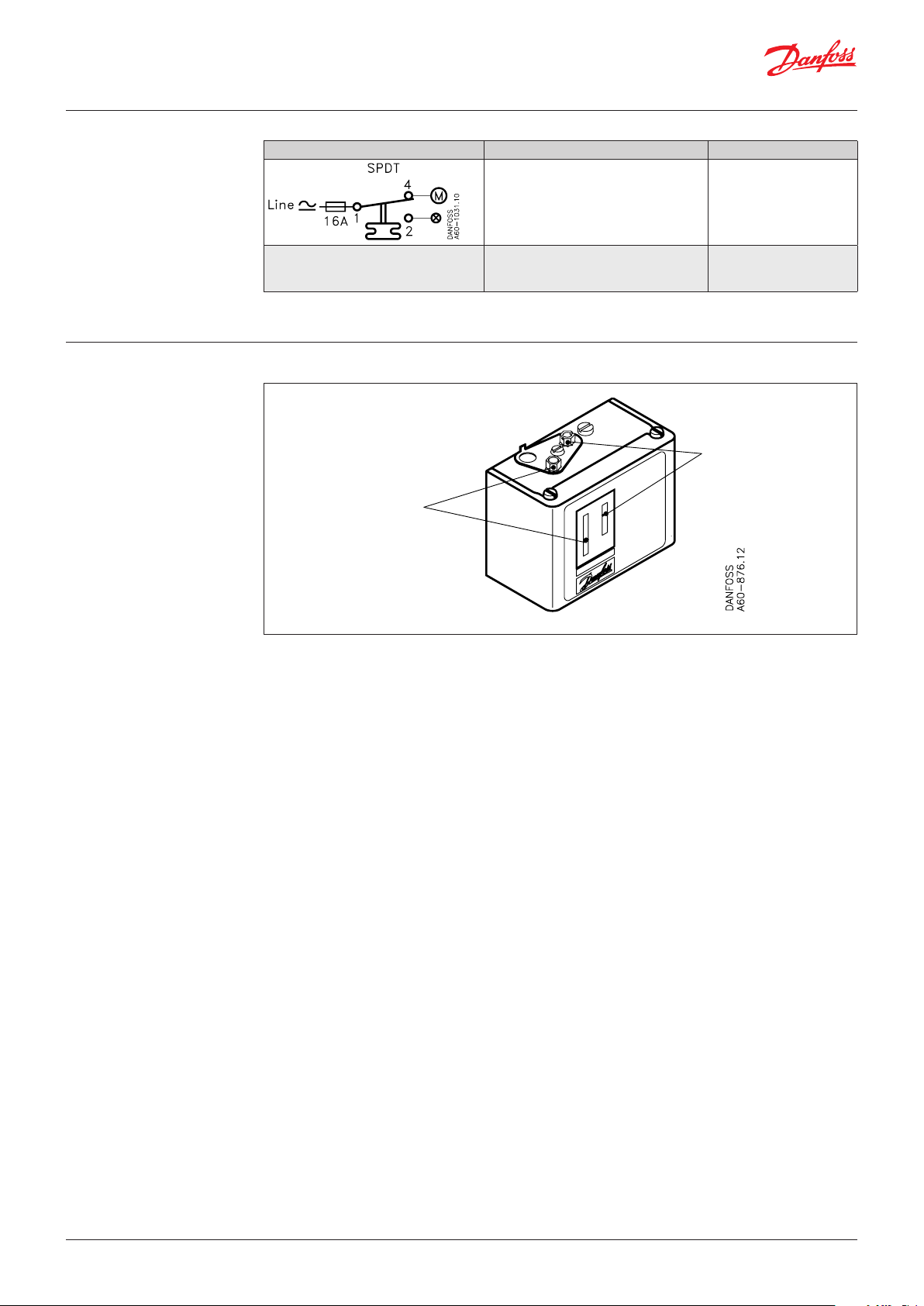

Contact system

and application

Setting

Switch type – single pole double throw Switch action Application

1. Terminal 1 – 4 close high and open low

SPDT

Terminal 1 – 2 can be used as low

pressure alarm

2. Terminal 1 – 2 open high and close low

Terminal 1 – 4 can be used as high

pressure alarm

1. Low pressure cut-out

2. High pressure cut-out

Diff.

Range

Note:

For low pressure switches

the restart pressure is equal

to cut-out pressure plus

differential value.

Cut-in and cut-out pressures of the system

should always be checked with an accurate

pressure gauge.

Pressure setting for switches with automatic

reset.

1. Set the cut-in pressure on the “CUT-IN”

scale (range scale).

2. Set the differential on the “DIFF” scale.

The cut-out pressure must be above absolute

vacuum (pe = -1 bar).

For high pressure switches the restart pressure

is equal to cut-out pressure minus differential.

Pressure switches with manual reset

Set the cut-out presure on the “CUT-OUT”

scale (range scale).

High pressure limiters can be manually reset

when the pressure is equal to the stop pressure

minus the differential.

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 4

Page 5

60-973.13.10

60-972.13.10

13 122

13

60-776.17.10

60-974.12.10

4 3 1 13 2 12

13 2 12

Data sheet | Pressure switch and Thermostat, KP and KPI

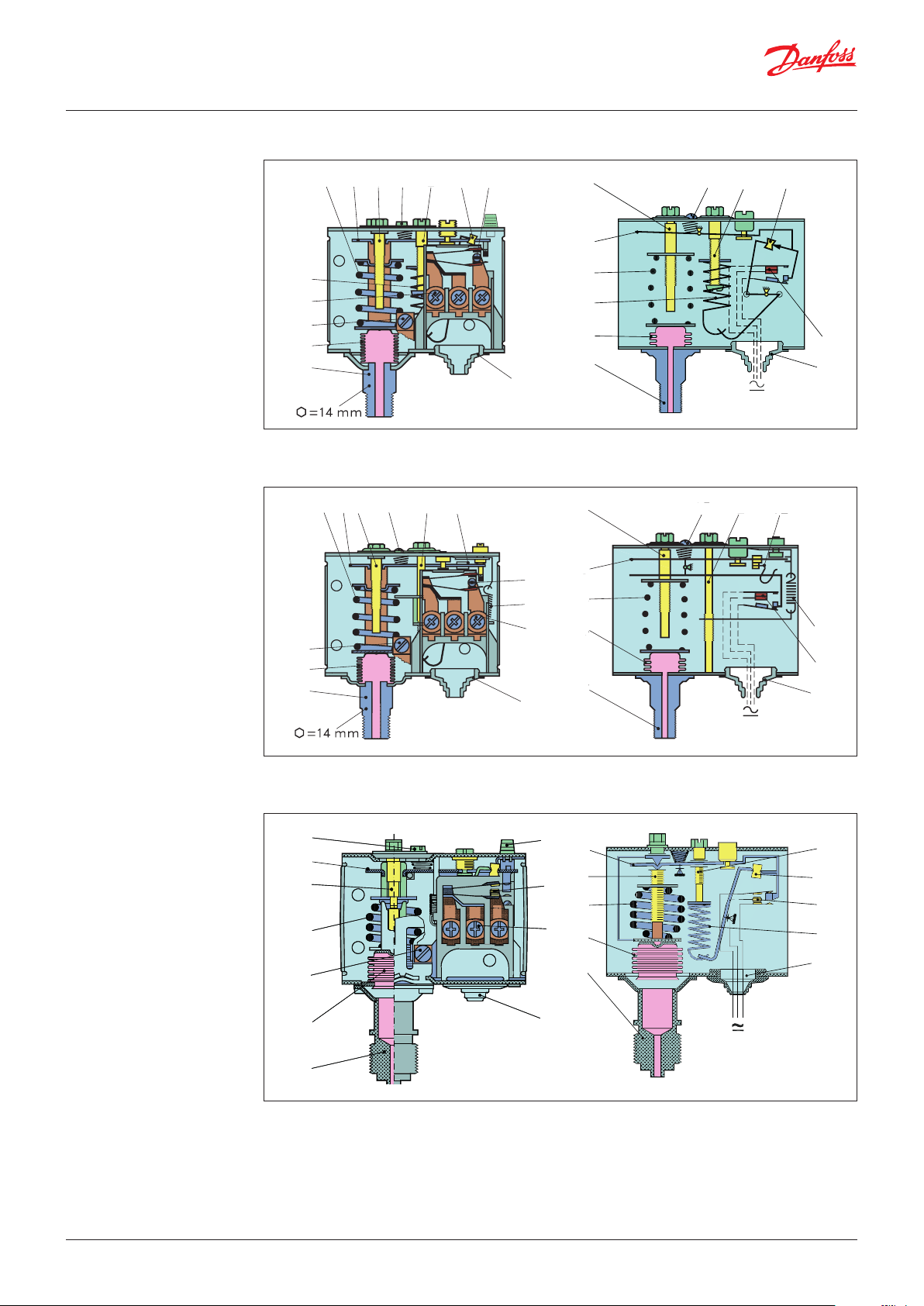

Design / Function

1. Setting spindle

2. Differential setting

spindle

3. Main arm

4. Main spring

5. Differential spring

6. Bellows

7. Pressure connector

8. Contact system

9. Connection terminals

10. Earth terminal

11. Cable entry

12. Omega spring (KPI)

12. Tumbler (KP)

13. Locking screw

14. Manual reset

Key sketch of KP pressure switch

4

3

1 13 2 12 8

5

4

9

10

6

7

Key sketch of KPI pressure switch

2 4 1

10

6

7

1

3

Danfoss

2

1

4

4

1

2

Danfoss

5

6

11

7

8

11

1

Danfoss

8

5

9

3

2

4

1

Danfoss

4

6

5

8

11

7

11

Key sketch of KP pressure switch, boiler version

3

3

1

2

4

10

6

7

The contact system in KP pressure switches has

a snap function. This means that the bellows

is active only when the cut-in or cut out value

is reached.

The bellows is connected to the pressure of the

controlled plant via the connector (7).

4 1

14

11

Danfoss

60-1356.11.10

3

1

8

4

9

6

4

1

2

7

Danfoss KPI pressure switches are designed

so that the bellows moves in the same

proportion as the pressure switches change.

To ensure a snap function on contact change

over, an omega spring is located between

bellows and contact system.

Danfoss

60-1355.11.10

2

12

8

5

11

© Danfoss | DCS (rm) | 2019.12

IC.PD.P10.F9.02 | 5

Page 6

84

44

6128 – 30

Danfoss

60-1358.11

60-1357.11

60-221.13

60-221.13

Danfoss

60-221.13

Data sheet | Pressure switch and Thermostat, KP and KPI

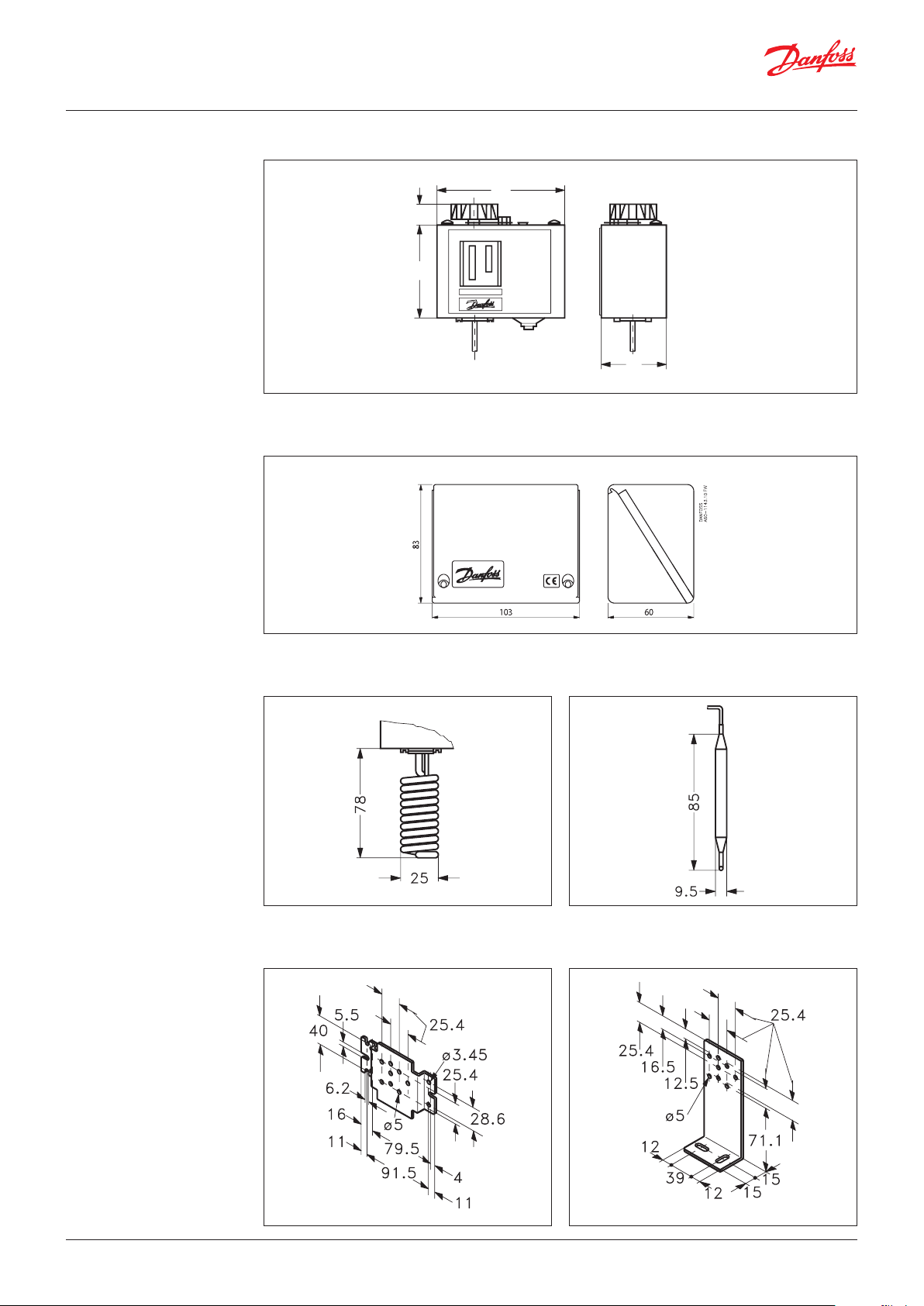

Dimensions [mm]

and weights [kg]

Pressure switch, types KP 35, KP 36, KPI 35, KPI 36 and KPI 38

Standard IP30 housing

=14

IP55 enclosure

Danfoss

60-9059.10

Net weight approx. 0.3 kg

Dimensions [mm]

and weights [kg]

(Boiler version)

Wall bracket Angle bracket

Danfoss

Pressure switch, types KP 35 and KP 36 Pressure switch, type KP 34

Danfoss

© Danfoss | DCS (rm) | 2019.12

Rubber Grommet

for 6 – 14 mm cable

G 1/2 A

Net weight approx. 0.34 kg

Rubber Grommet

for 6 – 14 mm cable

G 1/2 A

Net weight approx. 0.43 kg

IC.PD.P10.F9.02 | 6

Danfoss

Page 7

Data sheet | Pressure switch and Thermostat, KP and KPI

Accessories for KP pressure switches

Part Symbol Description Tot al Code no.

Brackets

with mounting

screws

and washers

Screwed

cable entry

Sealing screw For sealing the setting on KP 2 06 0-105766

Top cove r

Protective cap

Wall bracket for KP 1 060-105566

Angle bracket for KP 1 060-105666

PG 13.5 with special nut

For 6 –14 mm diameter cables

If a bracket is mounted on the backplate of the housing,

the KP thermostats will have an IP44 grade of enclosure.

The cover protects the setting spindles

Protective cap for KP pressure switches and thermostats.

To protect the unit against rain and humidity.

Grade of enclosure: IP44

Material: Polyethylene

Max. ambient temperature: 65 °C

Min. ambient temperature: -40 °C

1 060-105966

1 06 0-10 9766

1 060 -003166

IP55

nontransparent

enclosure

IP55

transparent

enclosure

If the unit risk being exposed to heavy water influence

a better grade of enclosure can be achieved when

mounting product in a special IP55 enclosure

If the unit risk being exposed to heavy water influence

a better grade of enclosure can be achieved when

mounting product in a special IP55 enclosure

1 060-033066

1 060-062866

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 7

Page 8

Data sheet | Pressure switch and Thermostat, KP and KPI

Technical data Dual pressure switch

Ambient temperature [°C] - 40 – 65 °C (for max. 2 hours up to 80 °C)

Media temperature [°C] Max. 100 °C

Fluid Liquids

Parts in contact with fluid

Contact system

Contact load, Silver

IP level IP22

Cable entry Rubber cable gland entry for 6 – 14 mm diameter cables

Mounted on backplate or wall bracket Vibration-proof in the range 0 – 1000 Hz, 4 g [1 g = 9.81 m/s2

Mounting on angle bracket Not recommended for areas where vibration occurs

Bellows Phosphor bronze, CuSn6

Pressure connector Free-cutting steel (nickel plated)

left

side

Alternating current:

AC-1: 16 A, 400 V

AC-3: 16 A, 400 V

AC-15: 10 A, 400 V

Direct current:

DC-13: 12 W, 220 V

right

side

manual

start

Ordering

Pressure switch, type KP 44

Pressure range Differential Permissible

[bar] [bar] [bar] [bar] [bar] [bar]

2.0 – 12.0 0.5 – 6.0 0.7 – 4.0 1.0

operating

pressure p

Left side: 17

Right side: 17

e

Right side: 19

Max. test

pressure

Left side: 25

Pressure

connection

2 × G 1⁄4 A silver 0 60- 001366

Contact

material

Code no.Control Safety Control Safety

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 8

Page 9

60-1175.12.10

1 6 14 2 13 9 4 14

12 10 8

Data sheet | Pressure switch and Thermostat, KP and KPI

Design / Function Key contact system of KP 44 pressure switch

3

1. Lefthand pressure

setting spindle

5

2. Differential setting

spindle

11

3. Main arm

4. Righthand pressure

setting spindle

5. Main spring

6. Differential spring

7. Bellows

8. Pressure connections

7

9. Contact system

10. Terminal

8

11. Earth terminal

12. Cable entr y

13. Tu mb ler

14. Locking plate

15. Impulse lever

Water supply from reservoir or well

The contact system in the KP 44 has a snapaction function and allows the bellows moves

only when the cut-in or cut-out value is reached.

If water is running short in the well or reservoir,

the pump will no longer be able to increase the

pressure to the cut-out value. Consequently the

pump will keep running - perhaps without water.

However, the KP 44 pressure switch will stop the

pump as soon as the righthand bellows pressure

drops below the safety cut-out setting.

The pump can be started again by lifting the

impulse lever. The pump will continue to operate

when the impulse lever is released, provided that

the righthand bellows pressure is higher than the

safety cut-out setting plus a fixed differential

of 1 bar. If this is not the case, the pump

will cut-out again indicating insufficient

water supply.

Danfoss

5

15

7

Pressurized water supply direct to pump

When water supply fails on the inlet side,

the pump will no longer be able to boost the

pressure to the cut-out value. Consequently the

pump will keep running - perhaps without water.

However, the KP 44 pressure switch will stop the

pump as soon as the pressure in the pump

suction line drops below the safety cut-out

setting. The pump will automatically start again

when the pump suction pressure has reached

the level of 1 bar above the safety cut-out

setting.

Automatic start-up will only take place if the

righthand bellows is connected to the pump

suction line. Air pockets should be avoided to

prevent the pump from starting up on air

pressure rise, without the presence of water.

In a hydrophore system where water is pumped

from a well or an open tank, both bellows are

connected to a pressure outlet on the air

side in the pump pressure line, if possible.

© Danfoss | DCS (rm) | 2019.12

In a booster system receiving pressurized

water the righthand bellows is connected

• to the low pressure side of the pump

forautomatic start-up

• to the high pressure side of the pump

for manual start-up

The lefthand bellows is always connected

to the high pressure side of the pump.

IC.PD.P10.F9.02 | 9

Page 10

60-1178.12

Data sheet | Pressure switch and Thermostat, KP and KPI

Setting

Dimensions[mm]

and weights [kg]

Safety cut-out setting

The righthand bellows will automatically cut-out

the pump at the safety cut-out setpoint.

Automatic start-up, if any, will take place when

the pressure has reached the level of 1 bar above

the setpoint. Manual cut-in is made by lifting the

impulse lever and releasing it again when the

The safety cut-out setpoint is normally

determined by the static pressure (the water

column). However, in order to avoid disturbing

signal interaction, care should be taken to ensure

that the safety cut-out setting is at least 1.5 bar

lower than the control pressure cut-in setting.

See table with pressure setting examples below.

pressure has increased by min. 1 bar.

Required tap water pressure ≥ 2.3 bar ≥ 4.0 bar ≥ 5.0 bar ≥ 8.0 bar

Control pressure cut-out setting 3.0 bar 5.0 bar 8.0 bar 12 bar

Differential 0.7 bar 1.0 bar 3.0 bar 4.0 bar

Control pressure cut-in setting 2.3 bar 4.0 bar 5.0 bar 8.0 bar

Max. safety cut-out setting 0.8 bar 2.5 bar 3.5 bar 6.0 1 bar

1)

6.0 bar is the normal max. setpoint

Control pressure settings

Control pressure cut-out setpoint

is set on the lefthand pressure setting scale.

The differential is set between 0.7 and 4 bar.

The control pressure cut-in setting will be the

cut-out control pressure less the differential.

Danfoss

Net weight approx. 0.5 kg

Accessories for KP 44

pressure switches

Part Symbol Description Tot al Code no.

Wall bracket 1 060-105566

Brackets with

mounting

screws and

washers

Screwed

cable entry

Sealing screw For sealing the setting on KP 2 06 0-10576 6

Angle bracket 1 060-105666

Screwed cable entry

Pg 13.5 with special nutfor 6 – 14 mm cables

1 060-105966

© Danfoss | DCS (rm) | 2019.12

IC.PD.P10.F9.02 | 10

Page 11

Data sheet | Pressure switch and Thermostat, KP and KPI

Technical data

Single thermostat

Ambient temperature [°C] - 40 – 65 °C (for max. 2 hours up to 80 °C)

Sensor material Tinned copper Cu/Sn5

Contact system

Single-pole double throw (SPDT)

Alternating current:

AC-1: 16 A, 400 V

Contact load, Silver

Contact load,

Gold plated contact set

Enclosure, IP30 grade

Enclosure, IP44 grade Mounted as IP30 plus fitting of top cover, code no. 060-109766

Enclosure, IP55 grade

Cable entry Entry for 6 – 14 mm diameter cable

Mounted on backplate or wall bracket Vibration-proof in the range 0 – 1000 Hz, 4 g [1 g = 9.81 m/s2

Mounted on angle bracket Not recommended for areas where vibration occurs

AC-3: 16 A, 400 V

AC-15: 10 A, 400 V

Direct current:

DC-13: 12 W, 220 V

See Information page 15

Unit must be mounted on a flat surface / a flat fitting

and all unused holes covered

Unit mounted in a special IP55 enclosure, code no. 060-033066

or 060-062866. Exception: KP 75

Ordering

Thermostat, types KP 75 – KP 81

Typ e

KP 75

KP 78 30 – 90 5 – 15 150 2 silver 060L118466

KP 79 50 – 100 5 – 15 150 2 silver 060L112666

KP 81 80 – 150 7 – 20 200 2 silver 060L112566

KP 81 80 – 150 7 – 20 200 3 silver 060L118366

KP 81 80 – 150 7 – 20 200 5 silver 060L117066

KP 81

(max. reset)

Setting range Differential

[°C] [°C] [°C] [m]

0 – 40 3 – 10 80 Room sensor silver 060L1212 66

0 – 40 3 – 10 80 Room sensor gold-plated 060L117166

80 – 150

8

(max. reset)

Max. sensor

temperature

200 2 silver 060L115566

Capillary

tube length

Contact

material

Code no.

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 11

Page 12

7

11

10

60-971.13.10

12118

1

4

5

6

8

7

12

11

Danfoss

60-970.12.10

8

7

12

11

12

7

Data sheet | Pressure switch and Thermostat, KP and KPI

Design / Function Key sketch of KP thermostat, types KP 78, KP 79, KP 81

1. Temperature setting

spindle

2. Differential setting

spindle

3. Main arm

4. Main spring

5. Differential spring

6. Bellows

7. Sensor

8. Contact system

9. Connection terminals

10. Earth terminal

11. Cable entry

12. Tumbler

10

7

12

2

3

4

4

5

5

9

8

9

6

6

1

2

3

4

5

6

Danfoss

KP 75 room sensor

The contact system in KP thermostats has a snap

function. This means that the bellows is active

only when the cut-in or cut-out value is reached.

12

8

11

7

Charges

6. Bellows

7. Sensor

13. Capillary tube

Setting

© Danfoss | DCS (rm) | 2019.12

7

oss

6

13

Danfoss

60-909.11.10

Thermostats with automatic reset

Set the upper limit temperature on the range

scale. Then set the differential on the DIFF scale.

The temperature set on the range scale is also

the temperature at which contact changeover

re-occurs on rising temperature.

The contacts changeover when the temperature

has fallen to a value lower than that set on the

DIFF scale.

If at lower settings the plant will not start/stop,

the reason might be that the differential has

been set too high.

Absorption charge

The charge consists partly of a superheated gas

and partly of a solid substance with a large

absorption surface.

The solid substance is concentrated in the sensor

(7), and consequently it is always the sensor that

comprises the temperature-regulating part of

the thermostatic element.

The sensor can be placed both warmer or colder

than the thermostat housing and capillary tube.

However, placing it in an ambient temperature

higher or lower than 20 °C can affect the

accuracy of the scale.

Thermostats with minimum reset

Set the temperature on the range scale.

The differential setting is fixed.

Min. reset units will restart after the temperature

at the thermostat sensor has risen by a value

greater than that of the fixed differential.

Thermostats with maximum reset

Set the stop temperature on the range scale.

The differential setting is fixed.

Max. reset units will restart after the temperature

at the thermostat sensor has fallen by a value

greater than that of the fixed differential.

IC.PD.P10.F9.02 | 12

Page 13

60-298.16

61 14

84

60-435.13

60-663.11

60-221.13

60-221.13

Danfoss

60-221.13

Data sheet | Pressure switch and Thermostat, KP and KPI

Dimensions [mm]

and weights [kg]

Thermostat, types KP 75, KP 78, KP 79, KP 81

Danfoss

Net weight approx. 0.4 kg

IP55 enclosure

KP 75 Sensor: Tinned copper Cu/Sn 5

Danfoss

Wall bracket

KP 78, 79, 81 Sensor: Tinned copper Cu/Sn 5

Danfoss

Angle bracket

© Danfoss | DCS (rm) | 2019.12

Danfoss

Danfoss

IC.PD.P10.F9.02 | 13

Page 14

Data sheet | Pressure switch and Thermostat, KP and KPI

Accessories for KP thermostats

Part Symbol Description Tot al Code no.

Brackets

with mounting

screws

and washers

Sensor holder

Screwed

cable entry

Sealing screw For sealing the setting on KP 2 06 0-10576 6

Top cove r

Wall bracket for KP 1 060-105566

Angle bracket for KP 1 060-105666

Sensor holder for wall mounting with four capillary

tube clips and 9-off 12 mm pins

PG 13.5 with special nut

For 6 – 14 mm diameter cables

A standard Pg 16 cable entry can be used for 8 –16

mm diameter cables

If a bracket is mounted on the backplate of the

housing, the KP thermostats will have an IP44 grade

of enclosure. The cover protects the setting spindles

1 017-420166

1 060-105966

1 06 0-109766

Protective cap

Sensor pocket

Heatconductive

aluminium

paste

Brass Stainless steel

Permissible pressure of sensor pipe medium

Tub e

Protective cap for KP pressure switches and thermostats.

To protect the unit against rain and humidit y.

Grade of enclosure: IP44

Material: Polyethylene

Max. ambient temperature: 65 °C

Min. ambient temperature: -40 °C

For all KP thermostats with cylindrical remote sensor.

Sensor pocket, gasket and union for screwing into G½

connectors welded onto tubes, containers, etc.

Int. diameter 9.6 mm, insert depth 112 mm (brass).

Ext. diameter 11 mm

Int. diameter 9.6 mm, insert depth 112 mm (st 18/8).

Ext. diameter 11 mm

Int. diameter 9.6 mm, insert depth 465 mm (brass).

Ext. diameter 11 mm

Media temperature for sensor: 250 °C

This temperature can be increased by applying a different gasket material

For KP and RT thermostats

with sensor mounted in a sensor pocket.

Temperature range: -20 – 150 °C (short-lived 220 °C)

Tube with 5 g aluminium paste

1 060-003166

1 017- 437066

1 017- 436 966

1 017-421666

1 0 41E0114

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 14

Page 15

Data sheet | Pressure switch and Thermostat, KP and KPI

General information

Gold contacts

Contact material Gold-plated silver

Contact

system

Single-pole double throw (SPDT)

Contact load

(when Au

surface is burnt

away)

Alternating current:

Ohmic load: AC-1: 10 A, 440 V

Inductive load: AC-3: 6 A, 440 V

AC-15: 4 A, 440 V

Direct current: DC-13: 12 W, 220 V

Curve A gives the maximum load.

Hatched area B: Acceptable load

for the gold plating of the contact (DC-13).

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 15

Page 16

Terminology

Range setting / Set point

The pressure range within which the unit

will give a signal (contact changeover).

Differential

The difference between contact changeover

on rising and falling pressure.

The differential is a condition for stable

automatic plant operation.

Manual reset

A unit with manual reset can only

be restored to operational mode by activation

of the external reset button.

Min. reset units will restart after the pressure

has risen by a value greater than that of the fixed

differential.

Max. reset units will restart after the pressure

has fallen by a value greater than that of the fixed

differential.

Permissible operating pressure

The highest permissible constant pressure

or pressure variation the unit can be exposed to.

Maximum working pressure

The maximum permissible pressure

for safe functioning of a heating system

or any of its parts.

Snap function

A specific contact force is maintained until snap

is initiated. The time over which contact force

reaches zero is a few milliseconds; therefore,

contact bounce cannot occur as a result, for

example, of slight vibrations before cut-out.

The snap-action contact system will continue

to function even when micro-welds are created

between the contacts during cut-in.

The force created to separate the contacts

is strong, and instantly shears off all contact

surface welds that have been created as the

result of cut-in action.

These design features ensure that the cut-out

point of the KP control remains very accurate

and completely independent of the magnitude

of the current load.

Automatic reset

Units with automatic reset

restart automatically after stop.

Maximum test pressure

The maximum pressure applied

in strength or leakage tests on heating

system or components thereof.

Current ratings:

AC – 1

The alternating current rating, in amperes,

of the non-inductive, slightly inductive

loads or resistive furnaces

AC – 3

The alternating current rating, in amperes,

of the squirrel-cage motors: starting,

plugging, inching

AC – 15

The alternating current rating, in amperes,

of electromagnetic loads (>72VA)

DC – 13

The direct current rating, in amperes,

of electromagnets

© Danfoss | DCS (rm) | 2019.12 IC.PD.P10.F9.02 | 16

Loading...

Loading...