Page 1

Data Sheet

Pressure switches and thermostats

Type KP

For steam, air, gaseous and liquid media

KP Pressure Switches

Danfoss KP switches are used for regulating,

monitoring and alarm systems in the industry.

They provide automatic limit protection or

manual reset limit protection for pressure

systems. Can be used with steam, air, gaseous

and liquid media.

The pressure switches are tted with singlepole changeover switch (SPDT). The position of

the switch depends on the setting of the

pressure switch and the pressure in the

connector.

KP Thermostats

KP thermostats are temperature-operated

electric circuit breakers. The thermostats are

tted with single-pole changeover switch

(SPDT)

The position of the switch depends on the

thermostat setting and sensor temperature. A

KP thermostat can be connected and switch to

single-phase alternating current motors of up

to 2 kW.

AI209986438809en-000602

Page 2

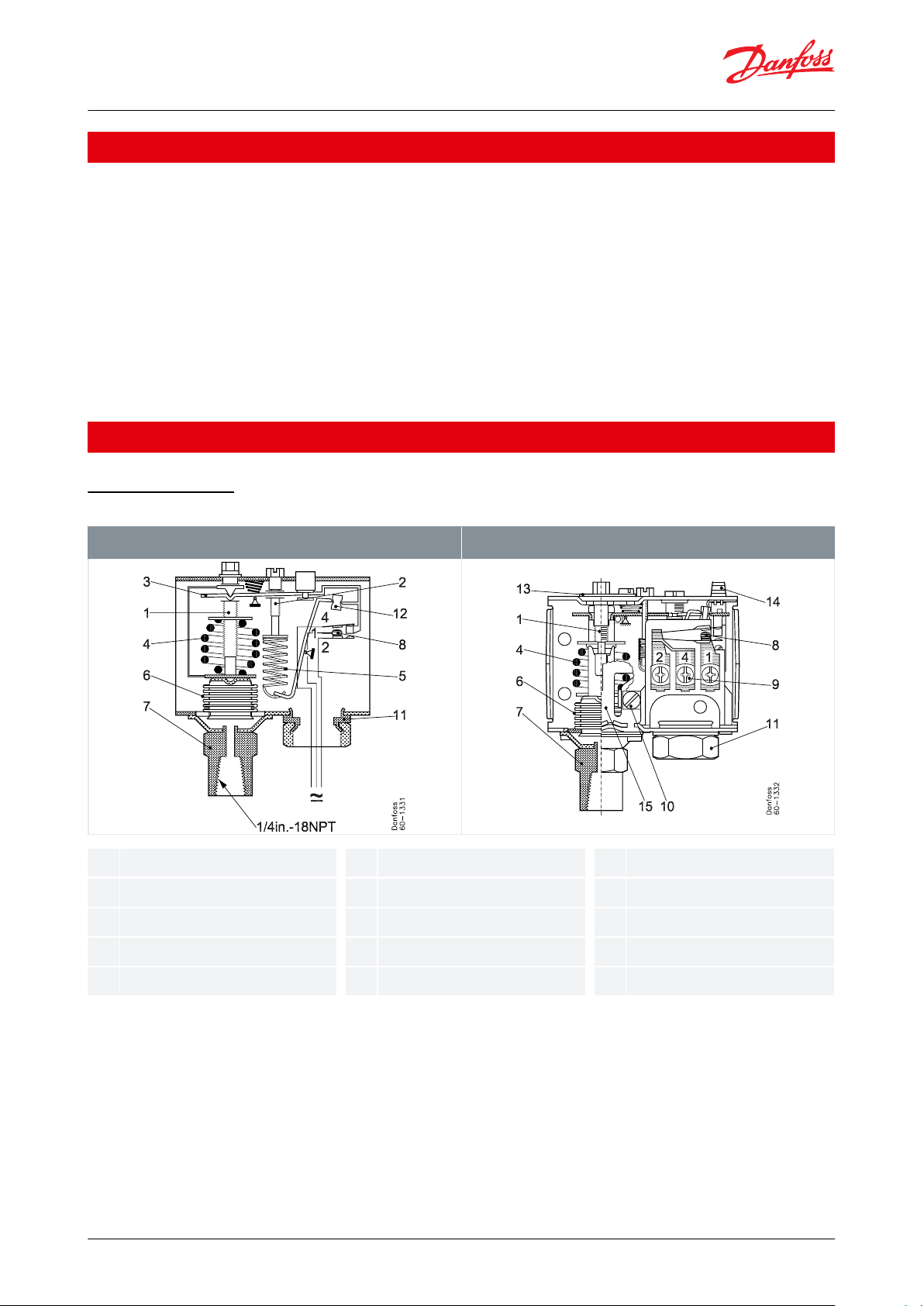

123456789101112131415

Key sketch of KP pressure switch

Simplied drawing of KP pressure switch without front cover and scale.

Version with manual reset.

Range setting spindle

Dierential setting spindle

Main arm

Main spring

Dierential spring

Bellows

Pressure connector

Contact system

Switch terminals

Ground terminal

Cable entry: ½ in female NPSM

Tumbler

Locking screw

Manual reset

Distance plate

Pressure switches and thermostats, Type KP

Features

• Wide regulating range

• Small dimensions

⁃ Space-saving, easy to install in panels

• Shock and impact resistant

• Ultra-short bounce time. Limits wear to an absolute minimum and increases reliability

• Snap action electrical contacts minimize chatter, bounce, and wear, and ensure long term electrical and

mechanical reliability

• Electrical connection from front of the unit. Makes rack mounting easier and also saves space

• Suitable for alternating current and direct current

• Screwed wiring, makes rewiring easy

• Manual trip allows electrical function test without tools

• Versions with automatic and manual reset available

Functions

Pressure switches

Table 1: Design and function

The contact system of KP switches has a snap-action function and the bellows moves only when cut-in or cut-out

set point is reached.

The design has the following advantages:

• higher contact load

• ultra short bounce time

• long mechanical and electrical lifetime

• high resistance to vibrations and pulsations

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 2

Page 3

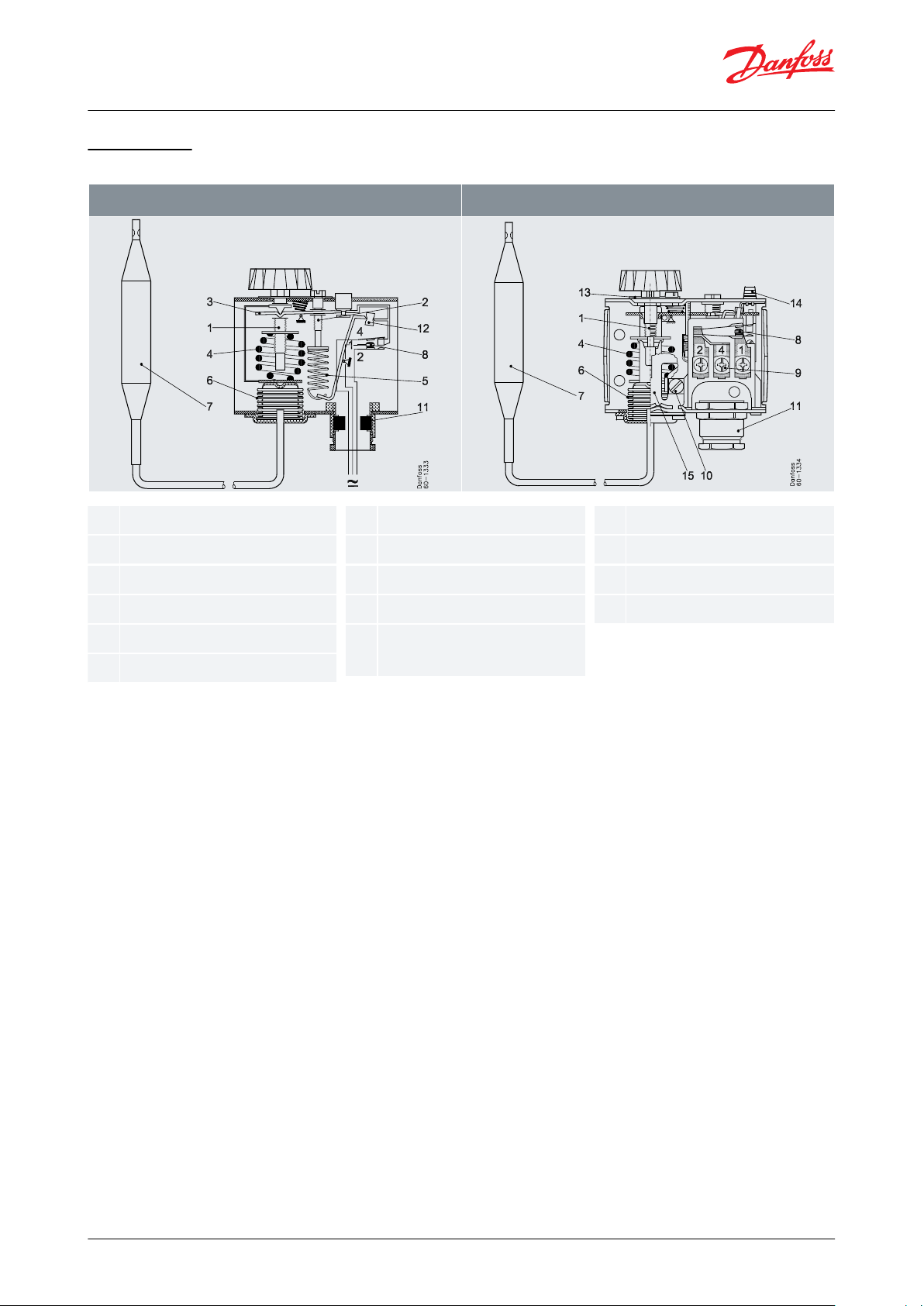

123456789

1011121314

15

Key sketch of KP 79, KP 81 thermostats

Simplied drawing of KP thermostat without front cover and scale.

Version with manual reset.

Range setting spindle

Dierential setting spindle

Main arm

Main spring

Dierential spring

Bellows

Temperature sensors

Contact system

Terminals

Ground terminal

Cable entry: ½ in female cable

gland

Tumbler

Locking screw

Manual reset

Distance plate

Pressure switches and thermostats, Type KP

Thermostats

Table 2: Design and function

The contact system of KP switches has a snap-action function and the bellows moves only when cut-in or cut-out

set point is reached.

The design has the following advantages:

• higher contact load

• ultra short bounce time

• long mechanical and electrical lifetime

• high resistance to vibrations and pulsations

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 3

Page 4

Features

Descriptions

Ambient temperature

-40 – 150 ˚F (175 ˚F for short period of time)

Media temperature

-40 – 212 ˚F

Sensor material

Tinned copper Cu/Sn5

Parts in contact with medium:

Bellows:

Stainless steel

Pressure connection:

Free-cutting steel, nickel plated

Wire dimension

12 AWG max.

Contact system

SPST (close on temp. rise), SPDT

Contact material AgCdO

Contact load

Alternating current

FLA

0.5 ~ 16 A/120 V AC

0.5 ~ 8 A/240 V AC

LRA

96 A/120 V AC

48 A/240 V AC

Direct current

240 V DC: 12 W pilot duty

Enclosure

NEMA ~1 (when mounted on a at surface with all unused holes covered)

Cable entry

Integral ½ in female NPSM swivel cable connector, allows direct attachenments of ½ in. male

pipe thread connector

Features

Descriptions

Ambient temperature

-40 – 150 ˚F (175 ˚F for short period of time)

Sensor material

Tinned copper Cu/Sn5

Wire dimension

12 AWG max.

Contact system

SPDT – single pole double throw

Contact load

Alternating current

FLA

0.5 ~ 16 A/120 V AC

0.5 ~ 8 A/240 V AC

LRA

96 A/120 V AC

48 A/240 V AC

Direct current

240 V DC: 12 W pilot duty

Enclosure

NEMA ~1 (when mounted on a

at surface with all unused holes covered)

Cable entry

Integral ½ in female NPSM swivel cable connector, allows direct attachenments of ½ in. male

pipe thread connector

Switch type - single pole double throw

Switch action

Application

Terminals 1 – 4 close high and open low

Terminals 1 – 2 can be used as low pressure alarm

Low pressure cut-out

Terminals 1 – 2 open high and close low

Terminals 1 – 4 can be used as high pressure alarm

High pressure cut-out

Pressure switches and thermostats, Type KP

Product specication

Technical data

Pressure switches

Table 3: Technical data

Thermostats

Table 4: Technical data

Contact system and application

Pressure switches

Table 5: Contact system and application

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 4

Page 5

Switch type - single pole double throw

Switch action

Application

Terminals 1 – 4 close high and open low

Terminals 1 – 2 can be used as low temperature alarm

Low pressure cut-out

Terminals 1 – 2 open high and close low

Terminals 1 – 4 can be used as high temperature alarm

High pressure cut-out

Pressure switches and thermostats, Type KP

Thermostats

Table 6: Contact system and application

Setting

Pressure switches

Cut-in and cut-out pressures of the system should always be checked with an accurate pressure gauge.

Pressure setting for switches with automatic reset.

Set the cut-out pressure on RANGE scale and dierential on DIFF scale.

NOTE:

Restart pressure is equal to cut-out pressure minus dierential value.

Pressure switches with manual reset

Set the cut-out pressure on the RANGE scale. Pressure limiters can be manually reset by pressing reset button when

the pressure is equal to the cut-out pressure minus xed value of the dierential.

Thermostats

Thermostats with automatic reset

Set the cut-out temperature on the RANGE scale and dierential on the DIFF scale. Restart temperature is equal to

the cut-out temperature minus dierential value.

NOTE:

The dierential scale is only a reference. The exact value of distances on the scale depends on where in its range the

switch cut-in is set. Use the dierential scale as a guide, and if precise function is required, establish the dierential

setting by comparing function with an accurate thermometer in the controlled zone.

Thermostats with manual reset

Set the cut-out temperature on the range scale.

The dierential is xed. Restart the system by pressing the reset button after the temperature of the sensor falls to a

value equal to the range scale setting minus the xed dierential.

Terminology

Pressure switches

Set point

A predetermined value to which a switch is adjusted and at which it performs its intended function.

Reset:

1.

Manual reset: Units with manual reset can only be restored to operational mode by activation of the external

reset button.

2.

Automatic reset: Units with automatic reset is restored to operational mode automatically.

Maximum working pressure

The maximum permissible pressure for safe functioning of a heating system or any of its part.

Snap function

A specic contact force is maintained until snap is initiated. The time over which contact force reaches zero is a few

milliseconds; therefore, contact bounce cannot occur as a result, for example, of slight vibrations before cut-out. The

snap-action contact system will continue to function even when micro-welds are created between the contacts

during cut-in. The force created to separate the contacts is strong, and instantly shears o all contact surface welds

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 5

Page 6

A

B

C

D

ABCDAdsorption charge

Bellows

Capillary tube

Sensor

Pressure switches and thermostats, Type KP

that have been created as the result of cut-in action. These design features ensure that the cut-out point of the KP

switch remains very accurate and completely independent of the magnitude of the current load.

FLA - Motor Full Load Amperes

FLA is the largest current that a motor or other device is designed to carry at rated voltage and other specic

conditions. Also often called current at rated conditions.

LRA - Locked Rotor Amperes

LRA is the current in amperes drawn by an electric motor with the shaft or rotor immobilized.

Thermostats

Dierential

The dierential is the dierence between the cut-in and cut-out temperatures.

The dierential is necessary for satisfactory automatic operation of the controlled system. Mechanical dierential

(intrinsic dierential). The mechanical dierential is the dierential set by the dierential spindle.

Reset:

1.

Manual reset: Units with manual reset can only be restarted after activation of the reset button. On max reset

units the set value is equal to cut-out value for rising temperature.

2.

Automatic reset: Units with automatic reset is restored to operational mode automatically.

Snap function

A specic contact force is maintained until snap is initiated. The time over which contact force reaches zero is a few

milliseconds; therefore, contact bounce cannot occur as a result, for example, of slight vibrations before cut-out. The

snap-action contact system will continue to function even when micro-welds are created between the contacts

during cut-in. The force created to separate the contacts is strong, and instantly shears o all contact surface welds

that have been created as the result of cut-in action. These design features ensure that the cut-out point of the KP

switch remains very accurate and completely independent of the magnitude of the current load.

FLA - Motor Full Load Amperes

FLA is the largest current that a motor or other device is designed to carry at rated voltage and other specic

conditions. Also often called current at rated conditions.

LRA - Locked Rotor Amperes

LRA is the current in amperes drawn by an electric motor with the shaft or rotor immobilized.

Thermostat charge

Figure 1: Thermostat charge

Sensors with adsorption charges contain a superheated gas together with a solid having a large adsorption surface.

The sensor can be placed in zones that are warmer or colder than the switch housing and capillary tube, but

variations of more than 70 °F may inuence scale accuracy.

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 6

Page 7

Figure 2: KP 35, KP 36 and KP 37

Figure 3: KP 34

Approximate weight: 0.83 lb

Approximate weight: 0.9 lb

Pressure switches and thermostats, Type KP

Dimensions [in]

Pressure switches

Table 7: Dimensions

Thermostats

Figure 4: KP 79, KP 81

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 7

Page 8

Type

Range [psig]

Dierential [psi]

Reset

Pressure connec‐

tion

Max. operating

pressure [psig]

Min. burst pres‐

sure [psig]

Code nos

KP 34

2 – 15

2 – 6

Automatic

¼” 18 NPT58435

060-214991

KP 34

2 – 15

3 xed

Manual

¼” 18 NPT58435

060-214891

KP 35

6 – 50

6 – 32

Automatic

¼” 18 NPT

145

1015

060-215191

KP 35

6 – 50

7 xed

Manual

¼” 18 NPT

145

900

060-215091

KP 36

15 – 150

10 – 58

Automatic

¼” 18 NPT

245

1015

060-214491

KP 36

15 – 150

10 xed

Manual

¼” 18 NPT

245

1015

060-214591

KP 37

58 – 300

26 – 45

Automatic

¼” 18 NPT

405

1450

060-214691

KP 37

58 – 300

43 xed

Manual

¼” 18 NPT

405

1450

060-214791

Type

Setting Range [˚F]

Dierential [˚F]

Reset function

Capillary tube

length [in]

Max. sensor temper‐

ature [˚F]

Code nos

KP 79

122 – 210

9 – 27

Automatic

80

300

060L223866

KP 79

122 – 210

10 xed

Manual80300

060L223966

KP 81

176 – 240

9 – 45

Automatic

80

480

060L224066

KP 81

176 – 240

16 xed

Manual80480

060L224166

Part

Symbol

Description

Code no.

Brackets with mounting screws and

washers for pressure switches and

thermostats

Angle bracket

4 screws 10–32 UNC + 4 washers

060-105366

Top cover for pressure switches and

thermostats

When the bracket is mounted on the back plate of the housing, the grade of enclosure of the KP switch is IP44. Top cover

covers the setting spindles.

060-109766

Document type

Approvals Authority

Electrical - Safety

Certicate

CCC

Manufacturer Declaration

EAC

EU Declaration

CE/ LVD

Food and Health - Performance

Certicate

PZH

Marine safety

certicate

RINA

Marine Approval

RMRS

Manufacturer Declaration

RoHS China

Electrical - Safety

Certicate

FM

Electrical - Safety

Certicate

UL

Pressure switches and thermostats, Type KP

Ordering

Pressure switches

Table 8: Ordering

Thermostats

Table 9: Ordering

Table 10: Accessories

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 11: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 8

Page 9

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI209986438809en-000602 | 9

Loading...

Loading...