Page 1

Data Sheet

Pressure switch

Type KP

The KP pressure switches can be used as safety

switches against too low a suction pressure

and / or too high a discharge pressure in

refrigeration and air conditioning systems. They

can also be used to start / stop compressors

and fans for air-cooled condensers.

They are available in both single and dual

versions and include a single pole double

throw (SPDT) switch.

Features:

• Ultra-short bounce time thanks to snapaction function (reduces wear to a minimum

and increases reliability)

• Available with gold-plated contacts

• SPDT switch design Oers open or close

switching action on pressure rise or fall

• Fail safe double bellows Prevent refrigerant

loss and system contamination - standard on

KP 7 and KP 17 pressure switches

• Convenient manual trip feature To test

electrical contact function - no tools needed

• Pressure wire connectors For easy electrical

wiring

• No spade or lug terminals required

• Integral 1⁄2 NPSM swivel cable connector

Allows direct attachment of 1⁄2 in male pipe

thread connector

• Lockplate Prevents tampering with range and

dierential settings

• Universal mounting hole patterns

AI216886432258en-001101

Page 2

421 4 2 1

Danfoss

A60-1032.10

A

B

C

D

E

F

G

H

I

I

ABCDEFGHI

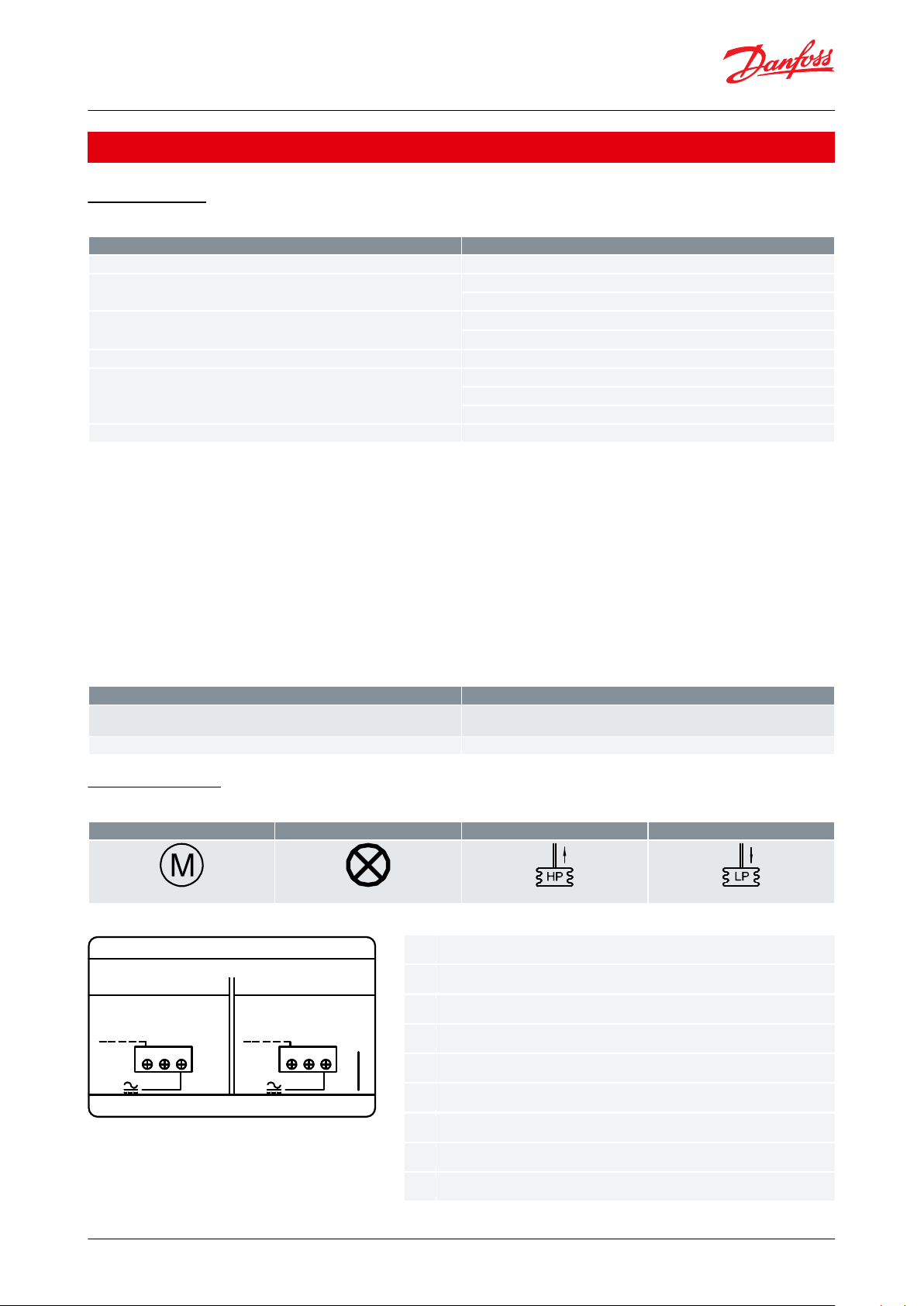

SPDT - signal pole double throw

Pressure / Temperature

Rise

Drop

Load Cut-in (term.1-4)

Load Cut-out (term.1-2)

Load Cut-out (term.1-4)

Load Cut-in (term.1-2)

Line

Features

Values

Ambient temperature

-40 – 149 °F (175 °F for maximum 2 hours)

Maximum working pressure

LP: MWP = 245 psig

HP: MWP = 465 psig

Maximum test pressure

LP: pe = 285 psig

HP: pe = 510 psig

Switch

Single pole changeover switch (SPDT)

Contact load

120 V AC: 16 FLA, 96 LRA

240 V AC: 8 FLA, 48 LRA

240 V DC: 12 W pilot duty

Terminal D, dual switches

240 V, 50 VA

Control type

Material

KP 1, KP 2, KP 5, KP 7, KP 15, KP 17, KP 25

Tin bronze, no. CW452K, EN 1652 Nickel plated free cutting steel, no. 1.0737 /

1.0718 to EN 10277

KP with cap. tube

Copper SF-Cu, no. 2.0090 to DIN 1787

Load

Signal option

Bellows movement on pressure rise

Bellows movement on pressure drop

Pressure switch, Type KP

Product specication

Technical data

Table 1: Technical data

Cable entry

Integral 1⁄2 in female NPSM swivel cable connector allows direct attachment of 1⁄2 in male pipe thread connector.

Enclosure

~NEMA 1

This grade of enclosure is obtained when the units without top cover are mounted on a at surface or bracket.

The bracket must be xed to the unit so that all unused holes are covered.

~ NEMA 2

This grade of enclosure is obtained when the units with top cover are mounted on a at surface or bracket.

The bracket must be xed to the unit so that all unused holes are covered

Table 2: Materials in contact with the medium

Electrical wiring

Table 3: Electrical wiring

Figure 1: Low or high pressure

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 2

Page 3

1.2.3.4.5.

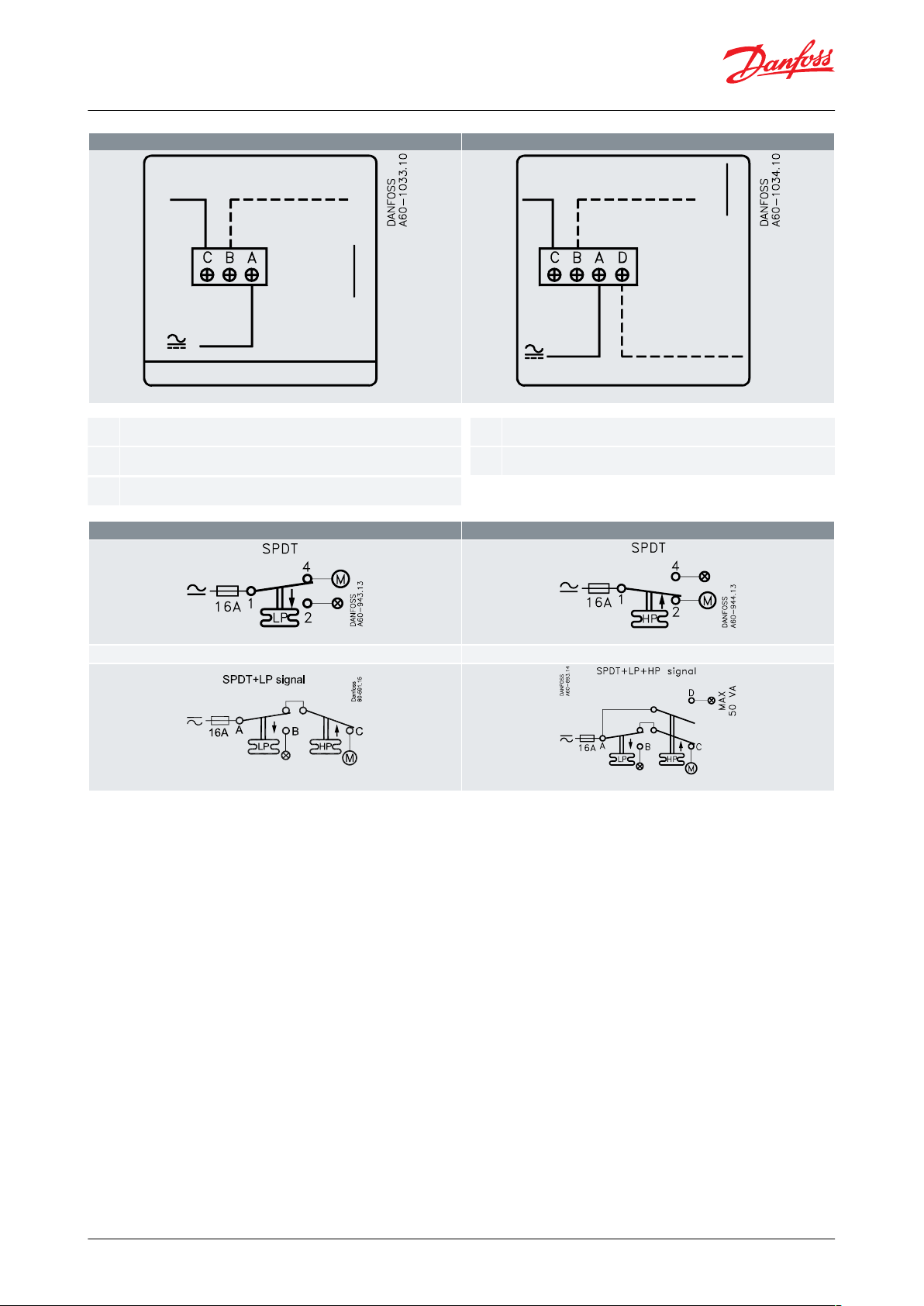

Dual (low and high) pressure, LP signal

Dual (low and high) pressure, LP and HP signal

1

2

3

4

A2113

1

2

3 5

A2115

Load

LP - signal option

Line

Wiring instruction

HP - signal option

Low pressure, LP: KP 1 and KP 2

High pressure, HP: KP 5, KP 7W and KP 7B

Dual (low and high) pressure: KP 15, KP 17W, KP 17B and KP 25

Dual (low and high) pressure: KP 15, KP 17W, KP 17B and KP 25

Pressure switch, Type KP

Metric conversions

1 psi = 0.07 bar

5⁄9 (t1 °F - 32) = t2 °C

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 3

Page 4

1.2.3.5.7.8.9.

10.

11.

12.

13.

14.

15.

16.

18.

19.

30.

Pressure switch, type KP

KP 1, KP 2, KP 5

FW

FW

KP 15, KP 25 are

KP 1, KP 2, KP 5, KP 15, KP 25, KP 7W, KP 7B, KP 17W, capillary tube

FW

Low pressure setting spindle, (LP)

Dierential setting spindle

Main arm

High pressure setting spindle, (HP)

Main spring

Dierential spring

Bellows

LP connection

HP connection

Switch

Terminals

Earth terminal

Cable entry

Tumbler

Locking plate

Arm

Reset button

Pressure switch, Type KP

Design

Table 4: Design

The switch in the KP has a snap-action function where the bellows move only when the cut-in or cut-out value is

reached.

The bellows are connected to the low or high pressure side of the system through connection (10) or (11).

The design of the KP gives the following advantages:

• high contact load

• ultra-short bounce time

• high resistance to pulsation

• vibration resistance up to 4 g in the range 0 – 1000 Hz

• long mechanical and electrical life

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 4

Page 5

1.2.3.5.15.

18.

KP 7W (KP 7B), are

KP 7W (KP 7B), capillary tube

KP 17W (KP 17B), are

Pressure setting spindle, (LP)

Dierential setting spindle

Main arm

Pressure setting spindle, (HP)

Cable entry

Locking plate

Pressure switch, Type KP

The KP with designations W or B have been tested and approved by TÜV (Germany) in accordance with EN 12263.

Versions with designation W will cut in automatically when the pressure has fallen to the setpoint minus the

dierential.

Versions with designation B can be cut in manually using the external reset button when:

KP 1 – the pressure has increased to 10 psi above the setpoint.

KP 7 – the pressure has fallen 58 psi below the setpoint.

KP 7 and KP 17 are equipped with fail-safe double bellows; a regulation bellows and an outer bellows. The double

bellows system protects against loss of system charge in the event of a bellows rupture.

A rupture in the outer bellows will cause the control to trip approximately 43 psi lower than the actual control

setting. This features provides a warning without a loss of charge.

All KP pressure switches, including those which are PED-approved, operate independently of changes in the

ambient temperature around the control housing. Therefore the set cut-out pressure and dierential are kept

constant provided the permissible ambient temperatures are not exceeded.

Terminology

Reset

1.Manual reset: Units with manual reset can only be reset during operation by activation of the reset button.

2.Automatic reset: After operational stop, these units reset automatically.

Maximum working pressure

The Maximum working pressure is determined by the pressure that can be safely allowed in the refrigerating system

or any of the units within it. The maximum working pressure is designated MWP.

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 5

Page 6

KP 1, KP 2 and KP 5

Danfoss

60-760.13

KP 15 and KP 25

Danfoss

60-908.11

KP 7W and KP 7B

Danfoss

60-1014.12

KP 17W and KP 17B

Danfoss

60-1015.14

Pressure switch, Type KP

Test pressure

The test pressure is the pressure used in strength tests and / or leakage tests on refrigerating systems or individual

parts in systems. The test pressure is designated Pe.

“Snap function”

A certain contact force is maintained until irrevocable “snap” is initiated. The time during which the contact force

approaches zero is thus limited to a very few milliseconds. Therefore contact bounce cannot occur as a result of, for

example, slight vibrations, before the cut-out point. Contact systems with “Snap function” will change over even

when micro-welds are created between the contacts during cut-in. A very high force is created during cut-out to

separate the contacts. This force immediately shears o all the welds. Thus the cut-out point of the unit remains very

accurate and completely independent of the magnitude of the current load.

Setting

Pressure switches with automatic reset – LP: Set the LP start pressure on the “CUT-IN” scale (range scale). One

rotation of the low pressure spindle ~10 psi. Set the LP dierential on the “DIFF” scale. One rotation of the

dierential spindle ~ 3 psi. The LP cut-out pressure is the LP cut-in pressure minus the dierential.

NOTE:

The LP cut-out pressure must be above absolute vacuum pe = 30 in Hg. If compressor will not stop at low cut-out

pressure, check whether the dierential value is set at too high a value!

Metric conversions 1 psi = 0.07 bar

Pressure switches with automatic reset – HP: Set the HP cut-out pressure on the “CUT-OUT” scale. One rotation of

the HP spindle ~ 33 psi. Set the HP dierential on the “DIFF” scale.

One rotation of the dierential spindle ~ 4 psi. The HP cut-in pressure is the HP cut-out pressure minus the

dierential. Pressure switches with manual reset. Set the cut-out pressure on “CUT-OUT” scale (range scale). Low

pressure controls can be manually reset when the pressure is equal to the cut-out pressure plus the dierential.

High pressure switches can be manually reset when the pressure is equal to the cut-out pressure minus the

dierential.

Cut-in and cut-out pressures for both the LP and HP sides of the system should always be checked with an accurate

pressure gauge.

Dimensions [in] and weight [lb]

Table 5: Flare connection

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 6

Page 7

KP 1, KP 2, KP 5, KP 7W and KP 7B

Danfoss

60-950.13

KP 15, KP 17W, KP 17B and KP 25

Danfoss

60-991.14

Single switches

Danfoss

60-1023.14

Dual switches

Danfoss

60-1024.14

Wall bracket

Angle bracket

Danfoss

60-1011.13

Pressure switch, Type KP

Table 6: Capillary tube connection

Net weight:

KP 1, KP 2, KP 5 and KP 7:

approx. 0.7 lbs.

KP 15, KP 17 and KP 25:

approx. 1.1lbs.

Metric conversions:

1 in = 25.5 mm

1 lb = 0.454 kg

Table 7: KP switches, rear side

Table 8: Bracket dimensions

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 7

Page 8

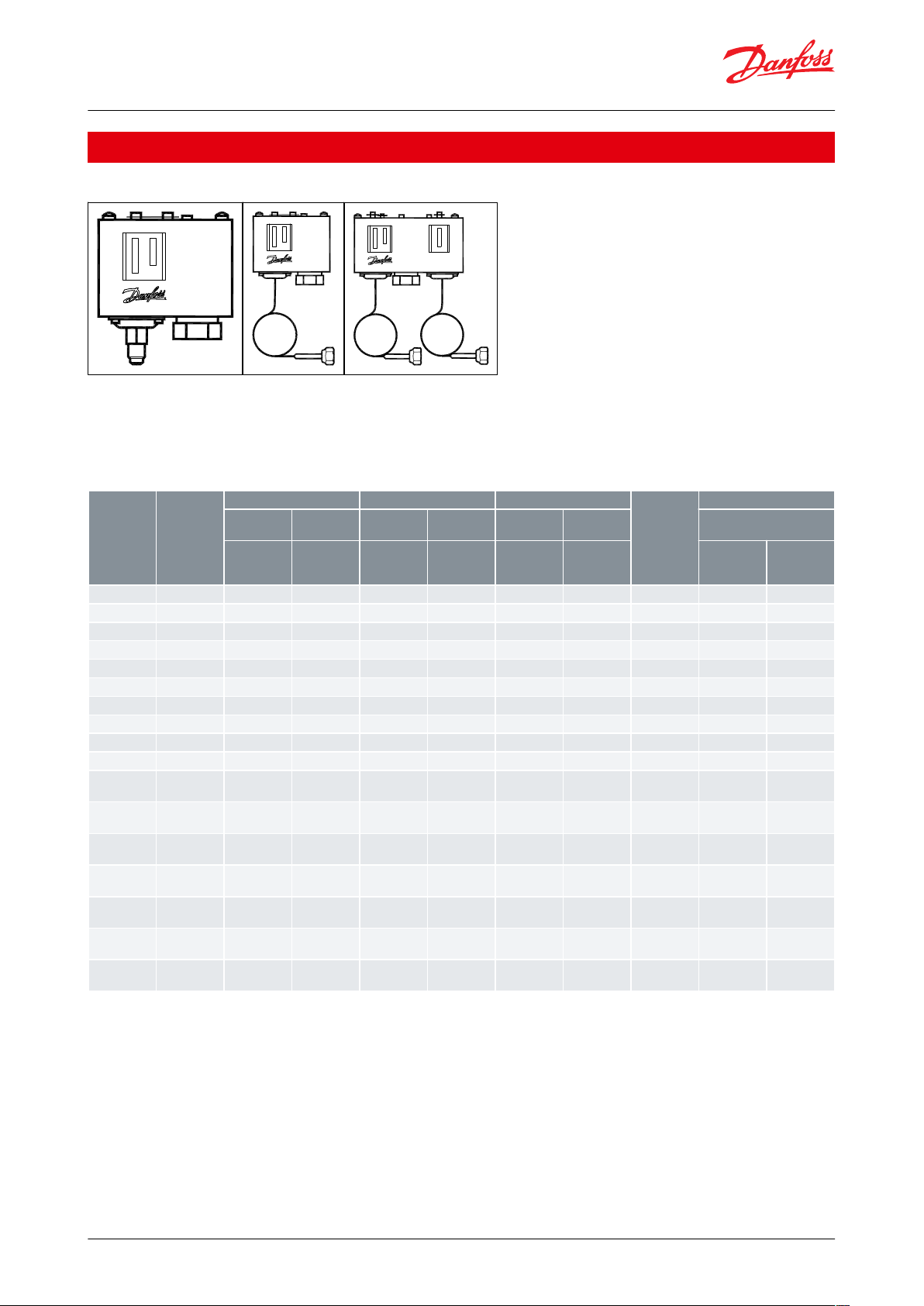

Type

Pressure

Low pressure (LP)

High pressure (HP)

Reset

Contact

functio

Code no.

Regulating

range

Dierential

∆p

Regulating

range

Dierential

∆p

Low pres‐

sure

High pres‐

sure

connection

[inHg] [psig]

[psi]

[psig]

[psi]

[LP]

[HP]

1⁄4 in are

Cap. tube w.

1⁄4 in are

nut 36 in

KP 1

Low

6 in – 108

10 – 58––

Auto–SPDT

060-200191

–

KP 1

Low

6 in – 108

10 – 58––

Auto–SPDT

–

060-205191

KP 1

Low

27 in – 10010––Man. (Min.)

–

SPDT

–

060-205291

(1)

KP 2

Low

6 in – 50

6 – 32––

Auto–SPDT

–

060-206391

KP 5

High––

115 – 465

25 – 85–Auto

SPDT

060-201491

–

KP 5

High––

115 – 465

25 – 85–Auto

SPDT

–

060-206491

KP 7W

(2)

High––

115 – 465

58 – 140–Auto

SPDT

060-200391

–

KP 7W

(2)

High––

115 – 465

58 – 140–Auto

SPDT

–

060-205391

KP7B

(2)

High––

115 – 46558–

Man. (Max.)

SPDT

060-200491

–

KP7B

(2)

High––

115 – 46558–

Man. (Max.)

SPDT

–

060-205491

KP 15

Dual

6 in – 108

10 – 58

115 – 465

58

Auto

Auto

SPDT/w. L P

signal

060-200891

–

KP 15

Dual

6 in – 108

10 – 58

115 – 465

58

Auto

Auto

SPDT/w. L P

signal

–

060-205891

KP 15

Dual

6 in – 108

10 – 58

115 – 465

58

Auto

Man. (Max.)

SPDT/w. L P

signal

–

060-205991

KP 15

Dual

6 in – 108

10 – 58

115 – 465

58

Man. (Min.)

Man. (Max.)

SPDT/w. L P

signal

–

060-206091

KP 15

Dual

6 in – 108

10 – 58

115 – 465

58

Auto

Auto

SPDT/w. LP +

HP signal

–

060-203191

KP 15

Dual

6 in – 108

10 – 58

115 – 465

58

Auto

Man. (Max.)

SPDT/w. LP +

HP signal

060-202691

–

KP 17W

(2)

Dual

6 in – 108

10 – 58

115 – 465

58

Auto

Auto

SPDT/w. LP +

HP signal

–

060-202991

Pressure switch, Type KP

Ordering

Figure 2: Ordering

For R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R448A, R449A, R450A, R452A, R507A, R513A

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

Table 9: Ordering

(1)

(1)

With dial knob

With dial knob

(2)

(2)

With fail safe double bellows

With fail safe double bellows

Metric conversions

1 psi = 0.07 bar

5⁄9 (t1 °F - 32) = t2 °C

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 8

Page 9

Document type

Approval authority

UL certicate

UL

EAC document

EAC

EU declaration

Danfoss

CCC declaration

Danfposs

Quality - Assurance Certicate

TUV

Marine safety certicate

DNV G L ,LR and BV

Manufacturer declaration for China ROHS

Danfoss

Pressure switch, Type KP

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 10: Certicates, declarations, and approvals

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 9

Page 10

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI216886432258en-001101 | 10

Loading...

Loading...