Installation guide

Pressure switch

Type KP 21

© Danfoss A/S (AC-MCI / jmn), 2013-11 IC.PI.P10.G3.02 / 520B5881 1

060R9410

060R9410

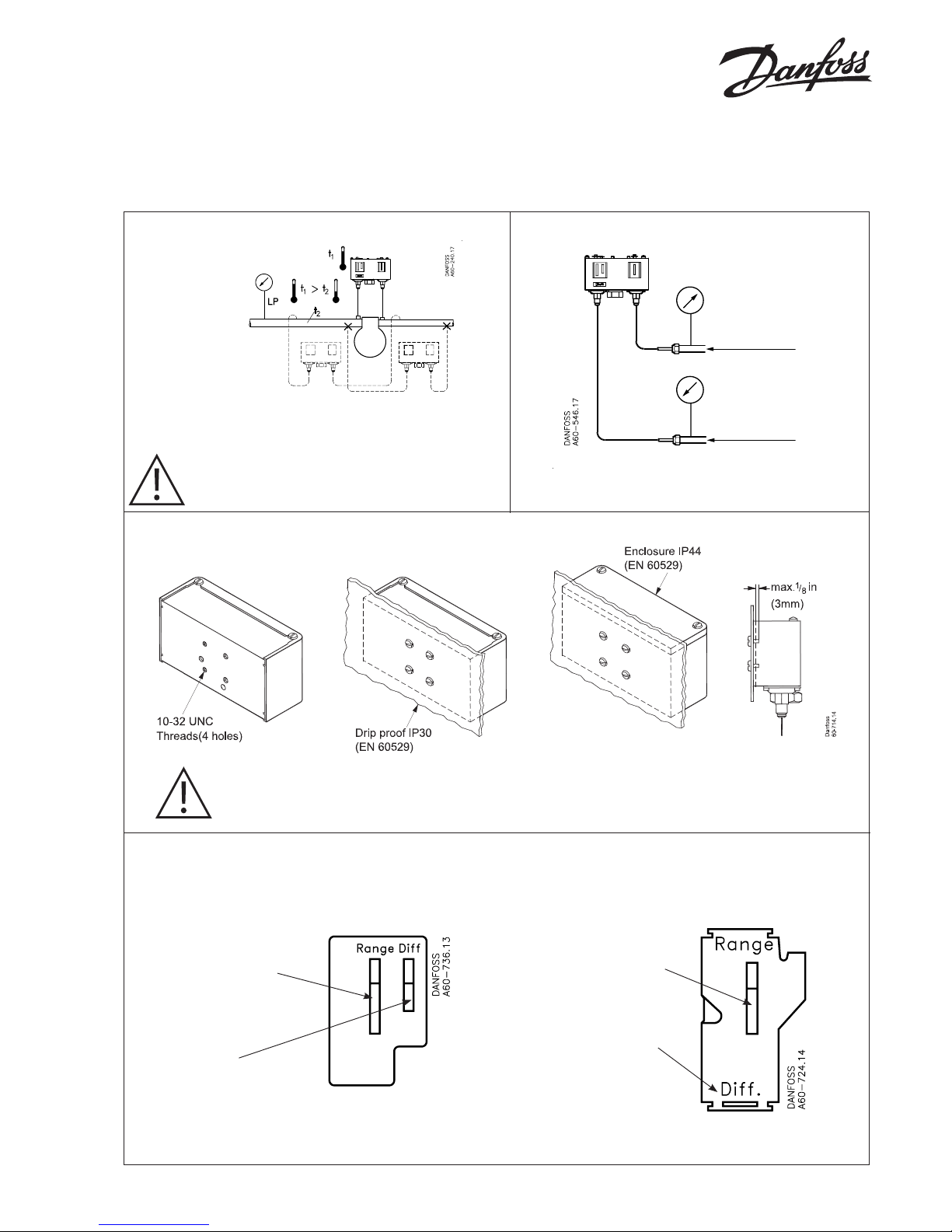

Ambient temperatures

Caution: Do not mount a switch in a position where

dirt, sediment or oil will aect the operation of the switch.

Enclosure

CAUTION: The mounting panel must be plane to avoid damage of switch.

Low pressure (LP) side setting

CUT-IN minus DIFFERENTIAL equals CUT-OUT

Test pressure (p

test

)

High pressure (HP) side setting

CUT-OUT minus DIFFERENTIAL equals CUT-IN

P

test

max.

20 bar P

e

P

test

max.

20 bar P

e

LP

HP

1. Adjust range spindle to

desired CUT-IN value

2. Adjust dierential

spindle to desired

DIFFERENTIAL

(DIFF.) value

LP

scale

1. Adjust range spindle to

desired CUT-OUT value.

2. DIFFERENTIAL (DIFF.)

is xed.

Value printed on scale plate.

tl min. −40°C (−40°F)

−25ºC (−13ºF)

tl max 65ºC (150ºF)

HP

scale

2 IC.PI.P10.G3.02 / 520B5881 © Danfoss A/S (AC-MCI / jmn), 2013-11

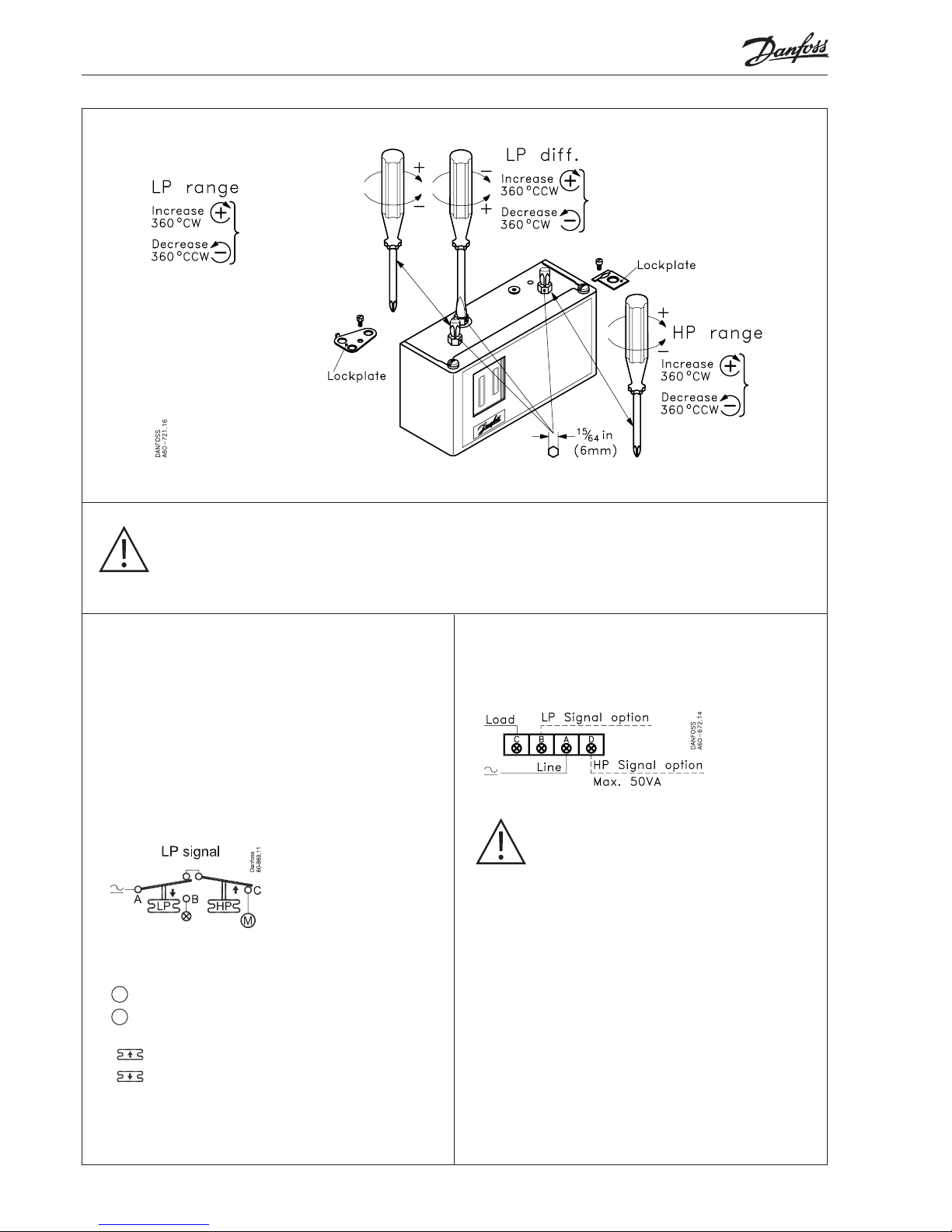

CAUTION:

Disconnect power supply before wiring connections are made or service to avoid possible electrical shock or damage

to equipment.

Do never touch live parts with your ngers or with any tool.

Controls with low pressure (LP) and

high pressure (HP) signal

Terminal block

Contact load

Alternating current:

AC 1: 16 A, 400 V

AC 3: 16 A, 400 V

AC15: 10 A, 400 V

Max. starting current (L.R.): 112 A, 400 V

Direct current:

DC13: 12 W, 220 V control current

Function

Note!

= Load

= Signal option

= Bellows movement on pressure rise

= Bellows movement on pressure drop

CAUTION: Use terminal screws furnished

in the contact block.

Use tightening torque (20 lb.) in 2.3 Nm.

Use copper wire only.

Low pressure (LP) side:

A-C close on LP rise

A-C open on LP drop

High pressure (HP) side.

A-C open on HP rise

A-C close on HP drop

LP signal option:

A-B close on LP drop

HP signal option

A-D close on HP rise

M

X

Loading...

Loading...