Page 1

Data sheet

Pressure switch

Type KP-E

KP-E pressure switches for use in refrigeration

and air conditioning systems are equipped with

SPDT gold plated contacts and stainless steel

bellows.

The high pressure switches are equipped with

failsafe double bellows, whereas the low pressure

switches are equipped with reduced bellow

travel to enhance bellows life time.

KP-E pressure switches are used to protect

against excessively low suction pressure or

excessively high discharge pressure.

The units are designed to operate in explosive

zones acc. to 2014/34/EU, Atex directive,

explosive zone 2, surface equipment, category 3.

KP-E pressure switches for HCFC, HFC and HC

refrigerants are equipped with ¼ in solder

connection to ensure a hermetic installation.

Features • Ultra-short bounce time thanks to snap-action

function (reduces wear to a minimum

and increases reliability)

• Manual trip function

(electrical contact function can be

tested without the use of tools)

• Vibration and shock resistant

Approvals

CE-marked in accordance with EN 60947-4/-5

(for sale in Europe)

CE marked in accordance with PED 2014/68/EU,

category IV, safety equipment

• Compact design

• Bellows without any welding points

• Stainless steel bellows

• High reliability both electrically and

mechanically

Ex II 3G Ex ic IIB T6 Gc in accordance with

2014/34/EU Atex directive

© Danfoss | DCS (rm) | 2019.11

DKRCC.PD.CD0.1B.02 | 1

Page 2

Data sheet | Pressure switch, type KP-E

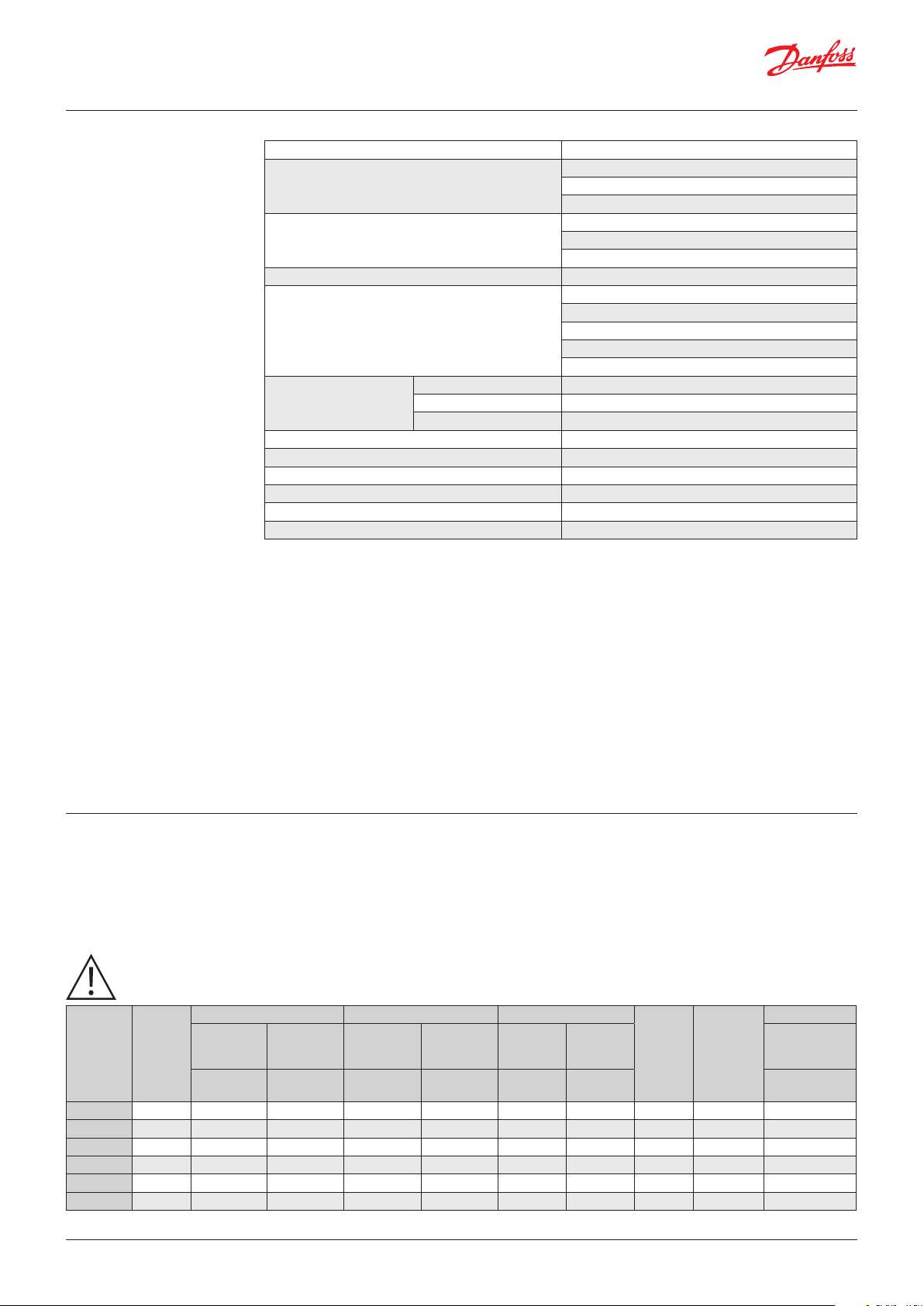

Technical data

Ambient temperature -20 – 60 °C

KP 1E: PS / MWP = 17.0 bar *

Max. working pressure

Max. test pressure

Cable connection Pg 13.5 screwed cable entry for 6 – 14 mm cable

Contact rating

solid / stranded 0.75 – 2.5 mm

Wire dimensions

Tightning torque max. 2 Nm

Rated impulse voltage 4 kV

Pollution degree 3

Short circuit protection, fuse 10 A

Insulation 400 V

Enclosure IP30 / IP44

*

Low pressure protection

flexible, without ferrules 0.7 – 2.5 mm

flexible, with ferrules 0.7 – 2.5 mm

KP 6EW, KP 6EB: PS / MWP = 46.5 bar

KP 7EW, KP 7EB: PS / MWP = 32 bar

KP 1E: Pe = 20 bar

KP 6EW, KP 6EB: Pe = 46.5 bar

KP 7EW, KP 7EB: Pe = 35 bar

Pi max: 1 W

Ui max: 30 V

Ii max: 0.1 A

Ci max: 0.5 nF

Li max: 0.2 H

2

2

2

Enclosure

IP30 to EN 60529 / IEC 529

Enclosure IP30 is obtained when the units

without top cover are mounted on a flat surface

or bracket. The bracket must be fixed to the unit

so that all unused holes are covered.

IP44 to EN 60529 / IEC 529

Enclosure IP44 is obtained when the units with

top cover are mounted on a flat surface or

bracket. The bracket must be fixed to the unit so

that all unused holes are covered. KP pressure

switches with auto reset are supplied with top

cover. For KP pressure switches with manual

reset, the top cover must be separately ordered

(code no. 060-109766)

Ordering

FOR R290, R32, R444B, R600, R600a, R1234ze, R1270

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers, where refrigerants are

listed as part of technical data.

This product is validated in accordance to EN 60079-0:2012 + A11:2013.

Ignition risk is evaluated in accordance to EN 60079-11:2012.

See safety requirements on the next page.

Low pressure (LP) High pressure (HP) Reset

Typ e Pressure

KP 1E Low - 0.2 – 7.5 0.7 – 4.0 – – Auto – SPDT PSL 060-530066

KP 1E Low - 0.9 – 7.0 0.7 – – Man. (Min.) – SPDT PZL 060-530266

KP 6EW High – – 8 – 42 4 – 10 – Auto SPDT PSH 060-522466

KP 6EB High – – 8 – 42 4 –

KP 7EW High – – 8 – 32 4 – 10 – Auto SPDT PSH 060-530466

KP 7EB High – – 8 – 32 4 –

*

PSL, PZL, PSH, PZH according to EN 12263:1998

Regulating

range

[bar] [bar] [bar] [bar]

Differential pRegulating

range

Differential

p

Low

pressure

LP

High

pressure

HP

Man. (Max.)

Man. (Max.)

Contact

system

SPDT PZH 060-522566

SPDT PZH 060-530666

Function *

Code no.

Connection

1

/4 in. ODF

solder

© Danfoss | DCS (rm) | 2019.11

DKRCC.PD.CD0.1B.02 | 2

Page 3

Danfoss

60-8070.11

Data sheet | Pressure switch, type KP-E

Safety requirements The KP-E can be applied on systems

with R290, R32, R444B, R600, R600a,

R1234ze, R1270 as the working fluid.

For countries where safety standards are not an

indispensable part of the safety system Danfoss

recommend the installer to get a third party

approval of the system containing flammable

refrigerant.

Note, please follow specific selection criteria

stated in the datasheet for these particular

refrigerants.

KP-E pressure switches comply with the

requirements for explosive atmosphere

2014/34/EU,

acc. to ATEX, zone 2.

Only apparatus designed, constructed and

released by Danfoss must be used for application

concerned. Danfoss can accept no responsibility

in case of alterations made on the switches or

the use of them against the Danfoss instructions.

Original Danfoss spare parts approved for use in

explosive atmosphere can only be used.

The application covers systems that must be

located within the EU or EFTA and comply with

the existing EU legislation, such as Pressure

Equipment Directive (PED) 2014/68/EU, the

directive concerning potential explosive

atmosphere (ATEX) 2014/34/EU, and other

related EU standards. The system where KPE is

mounted must always comply with local

directives, legislation or any other regulation

applying in the area of installation. The Danfoss

products comply with the requirements of ATEX

directive, but Danfoss takes no responsibility for

the classification of explosive zone.

Electrical connection

Intrinsic safety protection

method

The KP-E pressure switch placed in explosive

zone must always be wired through reliable Ex

zener barrier, placed outside ex-zone, to ensure

insufficient energy supply to cause the ignition

of surrounding atmosphere by an electrical spark

or the heating of components of circuitry.

The equipment to be used for electrical load

limiting must always be approved for use

in the zone concerned.

EX - zone Non EX - zone

KP-E

Cables and cable entries approved for the

application must be used and can not be in

contact with sharp edges. Cables must be

connected with adequate stress relief that way

that pulling forces can not be carried throug

the cable to the terminal.

Note:

A particular system can be classified in different

zones, for different parts of the system.

Electrical data for intrinsically safe

specification (for all KP-E types):

Pi max: 1 W

Ui max: 30 V

Ii max: 0.1 A

EX certified

Zenner barrier

Must be used with certified Ex ic barrier (product matching) satisfying the input parameters

Ci max: 0.5 nF

Li max: 0.2 µH

Signal

© Danfoss | DCS (rm) | 2019.11

DKRCC.PD.CD0.1B.02 | 3

Page 4

Data sheet | Pressure switch, type KP-E

Installation

and maintenance

Design / Function

Only authorised persons, who are certified in

installing and maintaining the systems may do

the installation, maintenance and change of the

switch.

In the event of strong pulsation in the system,

bellows must be protected against fatigue failure

by use of damping coil.

KP 1E KP 6EW, KP 7EW

The cycle frequency of the KP-E switch must be

kept as low as possible. The vibration level must

be kept as low as possible.

Any overload of the KP-E switch must be

prevented. Overloaded or damaged apparatus

must be exchanged.

1. Pressure setting spindle

2. Differential setting spindle

3. Main arm

4. Cable entry

5. Locking plate

6. Bellows travel reducer

(only KP 1E)

The switch in the KP-E has a snap-action function

when the cut-in or cut-out value is reached.

The design of the KP-E affords the following

advantages:

y ultra-short bounce time

y vibration resistance up to 4 g

in the range 0 – 1000 Hz

y long mechanical and electrical life

The KP 1E, KP 6EW, KP 6EB, KP 7EW and KP 7EB

switches have been tested and approved by TÜV

(Germany) in accordance with Directive

2014/68/EU.

KP 6E and KP 7E have a double bellows: an outer

bellows and a regulating bellows. When system

pressure exceeds the set value, the KP-E will

automatically stop the plant. The double bellows

system prevents loss of charge in the event of

bellows rupture.

A rupture in the outer bellows will cause the

control cut-out pressure to fall to about 3 bar

under the set value, thus providing a fail-safe

function.

Versions with designation W cut in again

automatically when the pressure has fallen

to the set value minus the differential.

Verions with designation B can be cut in

manually with the external reset button when

the pressure has fallen 4 bar under the set value.

© Danfoss | DCS (rm) | 2019.11

DKRCC.PD.CD0.1B.02 | 4

Page 5

Setting

Pressure switches with automatic reset – LP:

Set the LP start pressure on the “CUT-IN”

scale (range scale).

One rotation of the low pressure

spindle ~ 0.7 bar.

Set the LP differential on the “DIFF” scale.

One rotation of the differential spindle ~ 0.15 bar.

The LP stop pressure is the LP start pressure

minus the differential.

Pressure switches with automatic reset – HP:

Set the HP pressure on the “CUT-OUT” scale.

One rotation of the HP spindle ~ 2.3 bar.

Set the HP differential on the “DIF” scale.

One rotation of the differential spindle ~ 0.3 bar.

The HP start pressure is the HP stop pressure

minus the differential.

Pressure switches with manual reset:

Set the stop pressure on “CUT-OUT”

scale (range scale).

Low pressure switches can be manually reset

when the pressure is equal to the stop pressure

plus the differential.

Note:

The LP stop pressure must be above absolute

vacuum (Pe = -1 bar)!

If with low stop pressure the refrigeration

compressor will not stop, check to ensure that

the differential value has not been set too high!

Start and stop pressures for both the LP and HP

sides of the system should always be checked

with an accurate pressure gauge.

High pressure switches can be manually reset

when the pressure is equal to the stop pressure

minus the differential.

and weight [kg]

Solder connection, types KP 1E, KP 6EW, KP 6EB, KP 7EW, KP 7EBDimensions [mm]

84

61

114

Net weight: approx. 0.3 kg

44

© Danfoss | DCS (rm) | 2019.11

DKRCC.PD.CD0.1B.02 | 5

Loading...

Loading...