Page 1

Installation guide

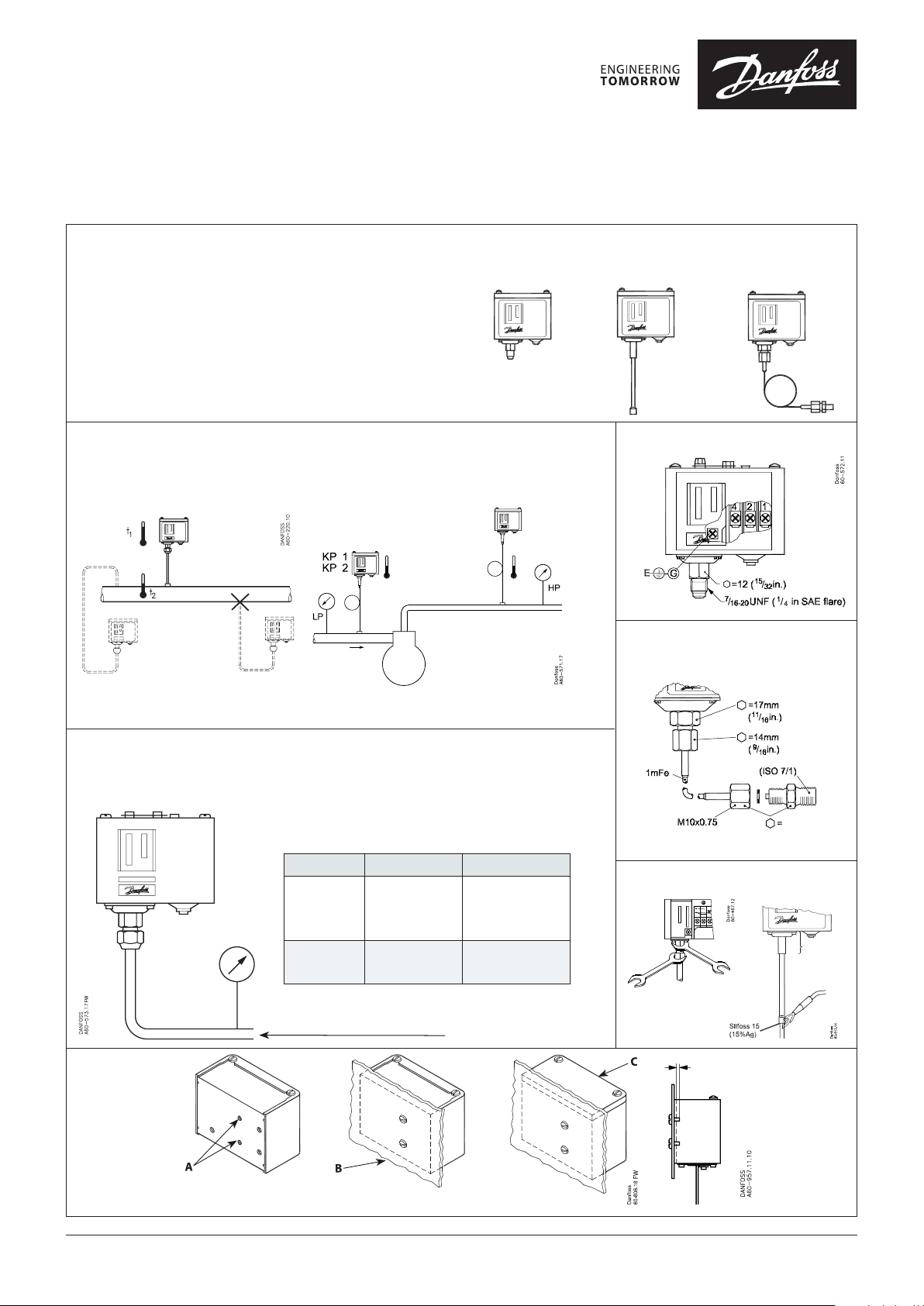

Pressure switch, KP 1, KP 1W, KP 1A, KP 2, KP 5, KP 5A, KP6W, KP 6B,

KP 6S, KP 6AW, KP 6AB, KP 6AS, KP 7W, KP 7B, KP 7S

Refrigerants:

R22, R134a, R404A, R407A, R407C, R407F, R410A*) R422B, R422D,

060R9750

R448A, R449A, R452A, R507A, R513A, R717**)

For complete list of approved refrigerants, go to

http://products.danfoss.com/all-products/

*) only for KP 6W, KP 6B, KP 6S, KP 6AW, KP 6AB, KP 6AS

**) only for KP 1A, KP 5A, KP 6AW, KP 6AB, KP6 AS

Ambient temperatures / Mounting requirements

-40 – 65 °C

-25 – 65 °C (PED approved units)

KP 5, KP 6, KP 7

KP 1, KP 2,

KP 5, KP 6, KP 7

KP 1, KP 2,

KP 5, KP 6, KP 7 KP 1A, KP 5A

Connections

Connections

for KP 1A, KP 5A, KP 6AS

060R9750

Relative humidity RH: 30 – 98%

Vibrations resistance: 4 g (10 – 1000 Hz)

Test pressure (P

PS/MWP

test

)

P

test

KP 1, KP 2: 20 bar pe (285 psig)

KP 2: 12 bar pe (174 psig)

KP 5, KP 7: 35 bar pe (510 psig)

KP 6: 46,5 bar pe (675 psig)

Typ e Regulation range PS/MWP

KP 1

KP 1, reset

KP 1 W

KP 2

KP 2

KP 5

KP 6

KP 7

PS/MWP

(Maximum Working Pressure)

Enclosure

max.:

-0.2 – 7.5 bar

-0.9 – 7.0 bar

0.5 – 3.0 bar

-0.2 – 5. 0 bar

-0.2 – 3.5 bar

8 – 32 bar

8 – 42 bar

8 – 32 bar

245 psig / 17 bar

245 psig / 17 bar

245 psig / 17 bar

245 psig / 17 bar

145 psig / 10 bar

510 psig / 35 bar

675 psig / 46,5 ba r

510 psig / 35 bar

Mounting

max. 3 mm (1/8 in.)

R ¼

14 mm

(9/16 in.)

Max. 100 ºC

(212 ºF)

A: 8 – 32 UNC (M4)

B: Enclosure IP30

© Danfoss | Climate Solutions | 2021.05

(EN 60529)

C: Enclosure IP44

(EN 60529)

AN211886 440281en-000701 | 1

Page 2

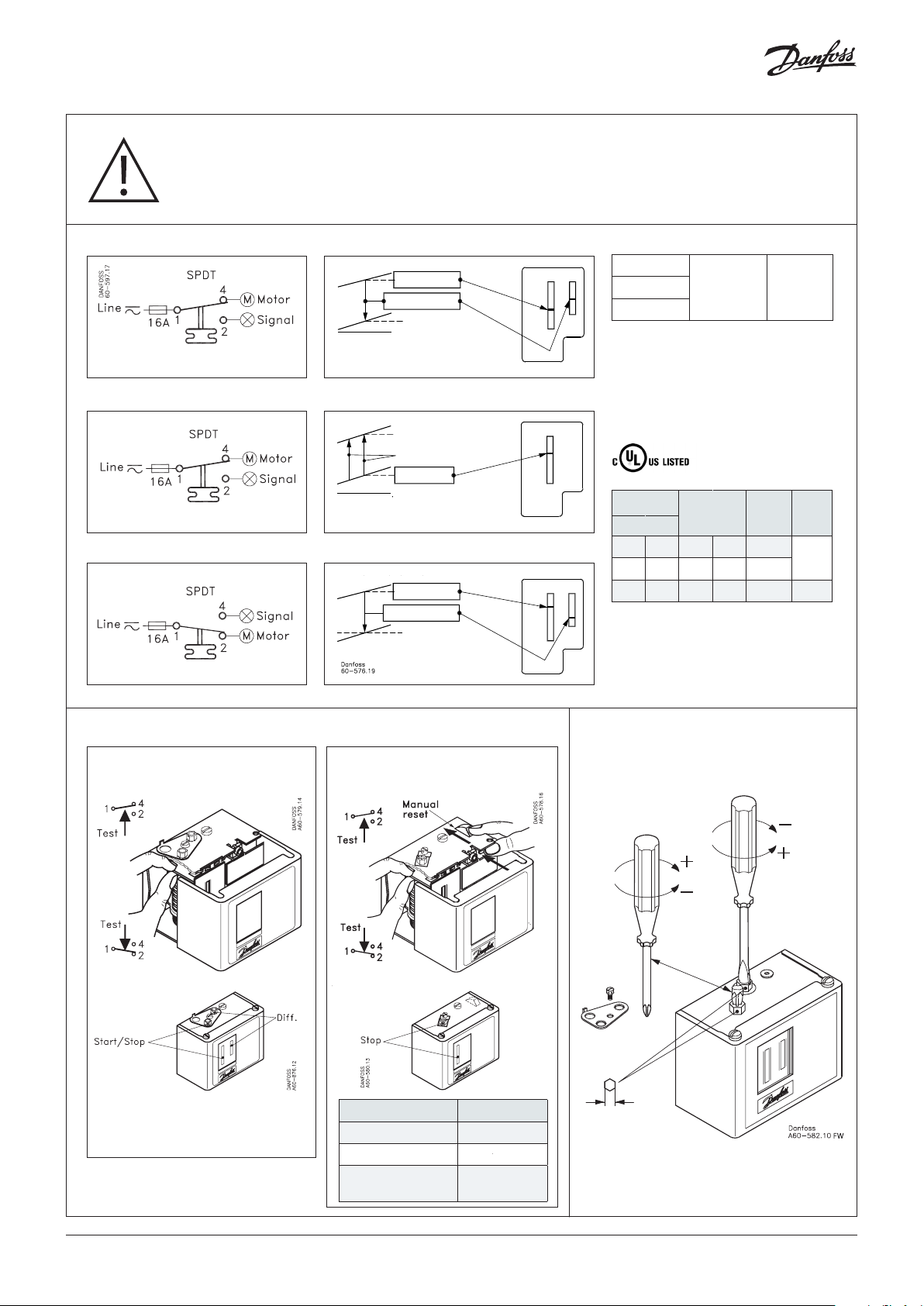

CAUTION:

Disconnect power supply before wiring connections are made or service to avoid possible electrical shock

or damage to equipment. Do never touch live parts with your ngers or with any tool.

Contact 1-4 opens on pressure drop

Contact 1-4 opens on pressure drop

Contact 1-2 opens on pressure rise

KP 1, KP 2

Cut In

Dierential

Cut Out

-1 bare (30 in. Hg)

KP 1W, KP 1 manual reset

Cut In

Dierential xed

Cut Out

-1 bare (30 in. Hg)

KP 1W: 0.5 bare

KP 5, KP 5A, KP 6, KP 6A, KP 7

Cut Out

Dierential

Cut In

AC 1: 16 A

AC 3: 16 A

AC 15: 10 A

400 V a.c.

DC 13

12 W

220 V

Short circuit protection:

Fuse 16 Amp.

When used acc. to UL regulations

Listed refrigeration

controller 61B5

Voltage FL LR

AC DC A A

240 — 8 48 8 A

120 — 16 96 16 A

— 240 — — — 12 W

Resist.

load

Use copper wire only

Tightening torque 20 lb. in.

Pilot

duty

3A

Manual trip function

Automatic reset

Note:

use FINGERS ONLY!

(Do NOT use screwdriver)

Manual reset

Typ e Dierential

KP 1, KP 1A 0.7 bar (10 psi)

KP 5, KP 5A 3 bar (43 psi)

KP 6B, KP 6S, K P 6AB,

KP 6AS, KP 7B, KP 7S

4 bar (58 psi)

Adjustment

Dierential

Range

6 mm

(15/64 in.)

© Danfoss | Climate Solutions | 2021.05

AN211886 440281en-000701 | 2

Page 3

CAUTION:

Only for selected A2L refrigerants: R455A, R454C, R1234yf, R1234yz, R1234ze

For complete list of approved A2L refrigerants, go to http://products.danfoss.com/all-products/

Electrical rating

AC-3: 16 A / 250 V AC

AC-15: 10 A / 250 V AC

Voltage Current range

Power factor

(cos phi)

Frequency

250V AC ≤ 4.0 A PF ≥ 0,400 50Hz/60Hz

250V AC > 4.0 to 6.0 A PF ≥ 0,594 50Hz/60Hz

250V AC > 6.0 to 16,0 A PF ≥ 0,780 50Hz/60Hz

IMPORTANT NOTICE

Safety requirements

1. KP pressure switches shall only be employed in the units/systems which comply with the requirements for charge limits and

requirements for avoiding ignition sources of IEC 60335-2-24, IEC 60335-2-40, IEC 60335-2-89, ISO 5149, EN378-1 or equivalent.

2. Applying the overload on the KPs must be prevented. If by any chance it was damaged, the system / unit shall be stopped and

KP shall be replaced as necessary.

3. Electrostatic discharge protection and Electrical leakage protection shall be surely implemented by grounding or other

measures.

4. Only trained personnel are authorized to handle ammable refrigerants systems and may do the installation, maintenance and

exchange of the switch by using appropriate tools.

5. It is recommended to regularly check the function of KP switch.

6. The KP pressure switches shall be used as built-in devices that cannot be accessible from outside and protected against

mechanical impact.

7. The KPs shall be installed in water free environment. In addition, protection of the KP switches against corrosion shall be taken

into consideration when using them in corrosive environment.

8. Cables shall not be in contact with sharp edges. The cables shall be connected with adequate stress relieve in order to prevent

that pulling forces can be carried thorough the cable to the terminal.

9. In the event of pressure pulsation in the system, where switch is connected, these must be eectively dumped to prevent

failure of the bellows. The cycle frequency of KP switch shall be kept as low as possible.

10. The KP switches shall not be installed in places where high level of vibration is present.

Disclaimer

The user is responsible for ensuring that third parties also comply with this Notice, e.g. in case that the KP switches are supplied to

third parties, and e.g. that all installation guides are available with the KP switches during installation. It is required that all

conditions of this guide are being met and secured when using KP pressure switches.

Danfoss shall not be responsible for any kind of direct and indirect or consequential damage or loss, including, but not limited to,

loss of property, production, loss of prot, human injury arising out of the explosion or re caused by the ammable nature of

refrigerant.

© Danfoss | Climate Solutions | 2021.05

AN211886 440281en-000701 | 3

Loading...

Loading...