Page 1

Data Sheet

Pressure switch

Type KP

KP pressure switchs are for use in refrigeration

and air conditioning systems to give protection

against excessively low suction pressure or

excessively high discharge pressure.

KP pressure switches are also used for starting

and stopping refrigeration compressors and

fans on air-cooled condensers.

A KP pressure switch can be connected directly

to a single-phase AC motor of up to approx. 2

kW or installed in the control circuit of DC

motors and large AC motors.

KP pressure switches are tted with a singlepole double-throw (SPDT) switch. The position

of the switch is determined by the pressure

switch setting and the pressure at the

connector. KP pressure switches are available in

IP30, IP44 and IP55 enclosures.

Features:

• Ultra-short bounce time thanks to snapaction function (reduces wear to a minimum

and increases reliability)

• Manual trip function (electrical contact

function can be tested without the use of

tools)

• Types KP 6, KP 7 and KP 17 with fail-safe

double bellows element

• Vibration and shock resistant

• Compact design

• Fully welded bellows element

• High reliability both electrically

and mechanically

AI213186439478en-001201

Page 2

Features

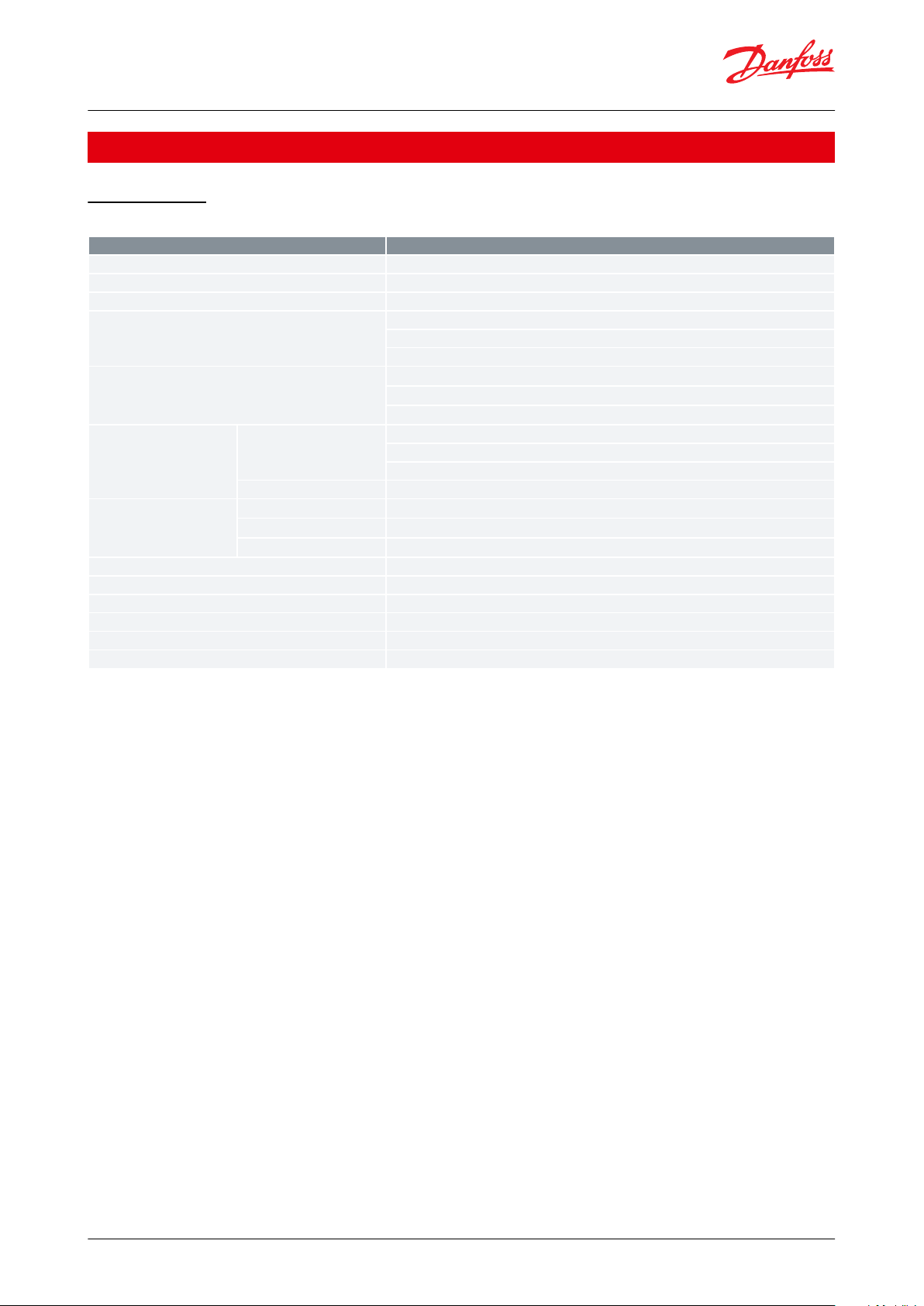

Values

Ambient temperature

-40 – 65 °C (80 °C for max. 2 hours)

Ambient temperature (PED approved units)

-25 – 65 °C (80 °C for max. 2 hours)

Media temperature

(1)

-50 – 100 °C

Max. working pressure

LP: PS / MWP = 17 bar

HP: PS / MWP = 35 bar

KP 6: PS / MWP = 46.5 bar

Max. test pressure

LP: Pe = 20 bar

HP: Pe = 35 bar

KP 6: Pe = 46.5 bar

Contact load

Alternating current

AC1 =16 A, 400 V

AC3 = 16 A, 400 V

AC15 = 10 A, 400 V

Direct current

DC13 = 12 W, 220 V control current

Wire dimensions

solid / stranded

0.75 – 2.5 mm

2

exible, without ferrules

0.7 – 2.5 mm

2

exible, with ferrules

0.5 – 1.5 mm

2

Tightening torque

max. 2 Nm

Rated impulse voltage

4 kV

Pollution degree

3

Short circuit protection, fuse

16 A

Insulation

400 V

Enclosure

IP30 / IP44 / IP55

Pressure switch, Type KP

Product specication

Technical data

Table 1: Technical data

(1)

(1)

The media temperature can be out of ambient temperature range under necessary condition that temperature inside KP must be kept in

The media temperature can be out of ambient temperature range under necessary condition that temperature inside KP must be kept in

ambient temperature range.

ambient temperature range.

Cable connection

The cable entry can be used for 6 – 14 mm dia. cables. A Pg 13.5 screwed cable entry can also be used for 6 – 14 mm

cable.With 8 – 16 mm cable a standard Pg 16 screwed cable entry can be used.

Enclosure

IP30 to EN 60529 / IEC 60529

Enclosure IP30 is obtained when the units without top cover are mounted on a at surface or bracket. The bracket

must be xed to the unit so that all unused holes are covered.

IP44 to EN 60529 / IEC 60529

Enclosure IP44 is obtained when the units with top cover are mounted on a at surface or bracket. The bracket must

be xed to the unit so that all unused holes are covered.

KP pressure switches with auto reset are supplied with top cover. For KP pressure switches with manual reset, the

top cover must be separately ordered (code no. 060-109766 for single pressure switches and code no.

060-109866 for dual pressure switches).

IP55 to EN 60529 / IEC 60529

IP55 is obtained when the KP pressure switches are mounted in an IP55 enclosure, (code no. 060-033066 for single

pressure switches and code no. 060-035066 for dual pressure switches). IP55 enclosure has to be ordered

separately.

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 2

Page 3

Low pressure (LP)

High pressure (HP)

Dual pressure (LP/HP)

Dual pressure (LP/HP)

Dual pressure (HP/HP)

Type

Material

KP 1, KP 2, KP 5, KP 6, KP 7, KP 15 and KP 17

Tinbronze, no. CW452K, EN 1652

Nickel plated free cutting steel, no. 1.0737 / 1.0718, EN 10277

KP 1A, KP 5A, KP 6A, KP 7A and KP 15A only

Stainless steel 18/8, no. 1.4306, EN 10088-2

Free cutting steel, no. 1.0737, EN 10277

Cold forming steel, no. 1.0338, EN 10139

Steel, no 1.0308, EN 10305

Free cutting steel, no. 1.0715, EN10277

Free cutting steel, no. 1.0718, EN 10277

Aluminium, no. AW-3005, EN 573

Pressure switch, Type KP

Contact systems

Table 2: Low and high pressure

Table 3: Dual pressure

Materials in contact with the medium

Table 4: Materials in contact with the medium

Terminology

Reset

1.

Manual (Min. / Max.) reset:

Units with manual reset can only be reset during operation by activation of the reset button.

2.

Automatic reset:

After operational stop, these units reset automatically.

3.

Convertible reset:

Units with optional reset can be activated by automatic and/or manual reset

Permissible working pressure

The permissible working pressure is determined by the pressure that can be safely allowed in the refrigerating

system or any of the units within it.

Test pressure

The test pressure is the pressure used in strength tests and/or leakage tests on refrigerating systems or individual

parts in systems. The test pressure is designated Pe.

“Snap function”

A certain contact force is maintained until irrevocable “snap” is initiated. The time during which the contact force

approaches zero is thus limited to a very few milliseconds. Therefore contact bounce cannot occur as a result of, for

example, slight vibrations, before the cut-out point. Contact systems with “Snap function” will change over even

when micro-welds are created between the contacts during cut-in. A very high force is created during cut-out to

separate the contacts. This force immediately shears o all the welds. Thus the cut-out point of the unit remains very

accurate and completely independent of the magnitude of the current load.

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 3

Page 4

Pressure switch, type KP

KP 1, KP 2, KP 5

KP 15

Capillary tube for KP 1A, KP 5A and KP 15A

MK

Pressure switch, Type KP

Setting

Pressure switches with automatic reset – LP: Set the LP start pressure on the "CUT-IN" scale (range scale). One

rotation of the low pressure spindle ∼ 0.7 bar.Set the LP dierential on the "DIFF" scale. One rotation of the

dierential spindle ∼ 0.15 bar.The LP stop pressure is the LP start pressure minus the dierential.

NOTE:

The LP stop pressure must be above absolute vacuum (Pe = -1 bar)!

If with low stop pressure the refrigeration compressor will not stop, check to ensure that the dierential value has

not been set too high!

Pressure switches with automatic reset – HP: Set the HP pressure on the “CUT-OUT” scale. One rotation of the HP

spindle ∼ 2.3 bar. Set the HP dierential on the “DIFF” scale. One rotation of the dierential spindle ∼ 0.3 bar. The

HP start pressure is the HP stop pressure minus the dierential.

Start and stop pressures for both the LP and HP sides of the system should always be checked with an accurate

pressure gauge.

Pressure switches with manual reset Set the stop pressure on “CUT-OUT” scale (range scale).

Low pressure switches can be manually reset when the pressure is equal to the stop pressure plus the dierential.

High pressure switches can be manually reset when the pressure is equal to the stop pressure minus the dierential.

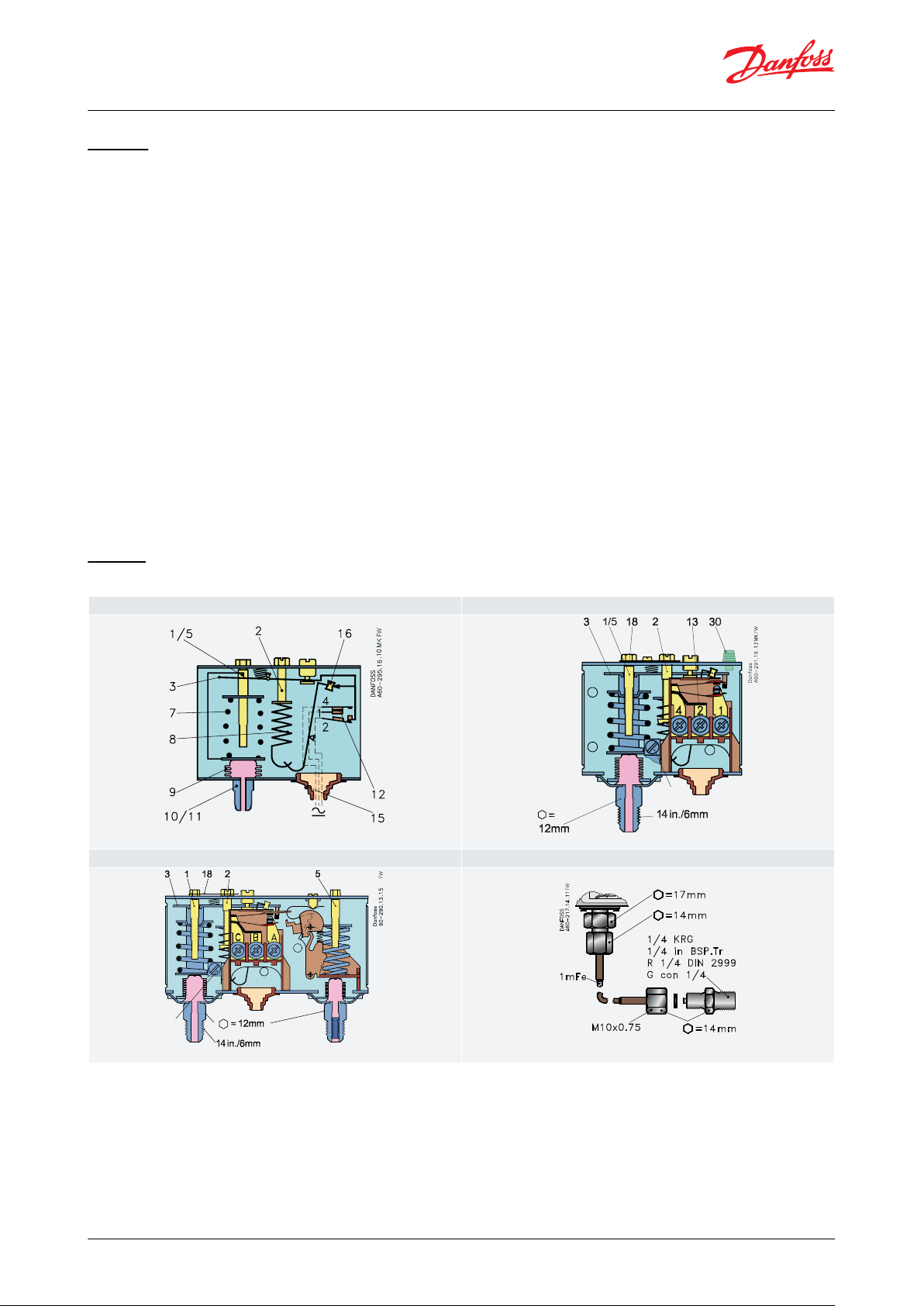

Design

Table 5: Design

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 4

Page 5

1.2.3.5.7.8.9.

10.

11.

12.

13.

14.

15.

16.

18.

30.

Low pressure setting spindle, (LP)

Dierential setting spindle

Main arm

High pressure setting spindle, (HP)

Main spring

Dierential spring

Bellows

LP connection

HP connection

Switch

Terminals

Earth terminal

Cable entry

Tumbler

Locking plate

Reset button

KP 7W,

are

KP 7W, solder

MK

1

MK.FW

KP 7BS

MK

25

30

1

Pressure switch, Type KP

The switch in the KP has a snap-action function where the bellows move only when the cut-in or cut-out value is

reached.

The bellows are connected to the low or high pressure side of the system through connection (10) or (11).

The design of the KP gives the following advantages:

• high contact load

• ultra-short bounce time

• high resistance to pulsation

• vibration resistance up to 4 g in the range 0 – 1000 Hz

• long mechanical and electrical life

Table 6: Design

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 5

Page 6

12315182530

Pressure setting spindle

Dierential setting spindle

Main arm

Cable entry

Locking plate

Int. reset arm

Ext. reset button

KP 1, KP 2, KP 5, KP 6, KP 7B, KP 7S and KP 7W

KP 15 and KP 17W

=12

84

44

6128 – 30

44

122

61

28 – 32

28 – 30

=12

Danfoss

60-306.16

KP 1A, KP 2A and KP 5A

KP 15A, KP 7AS and KP 7ABS

84

44

6125

=12

Danfoss

60-303.19

=12

122

61

25 – 29

44

Danfoss

60-305.12

Pressure switch, Type KP

Types KP1, KP1A, KP2, KP6, KP6A, KP7 and KP17 units with designation W, B or S have been tested and approved by

TÜV, Rheinland in accordance with EN 12263.

Types KP6, KP6A, KP7 and KP17 have a double bellows: an outer bellows and a regulating bellows. When system

pressure exceeds the set value, the KP will automatically stop the plant. The double bellows system prevents loss of

charge in the event of bellows rupture.

A rupture in the inner bellows will cause the control cut-out pressure to fall about 3 times less the set value, thus the

refrigeration plant compressor will stop.

A rupture in the outer bellows will cause the control cut-out pressure to fall to about 3 bar under the set value, thus

providing a fail-safe function.

Versions with designation W or AW cut in again automatically when the pressure has fallen to the set value minus

the dierential.

Versions with designation B or AB can be cut in manually with the external reset button when the pressure in KP1

has increased 0.7 bar above set value and in KP6 and KP7 has fallen 4 bar under the set value.

Versions with designation S or AS can be cut in manually with the internal reset arm when the pressure has fallen 4

bar under the set value.

All KP pressure switches, including those which are PED-approved, operate independently of changes in the

ambient temperature around the control housing. Therefore the set cut-out pressure and dierential are held

constant provided the permissible ambient temperatures are not exceeded.

Dimensions [in] and weight [lb]

Table 7: Pressure switchess with are connection

Table 8: M10 × 0.75 connection

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 6

Page 7

KP 1, KP 2, KP 5, KP 7B, KP 7S and KP 7W

KP 15, 1 KP 7W

44

84

61

112 – 114

122

61

112 – 114

112 – 116

44

=12

122

44

6128 – 30

28 – 32

7

IP55 enclosure

IP55 enclosure for dual types

Pressure switch, Type KP

Table 9: Solder connection

Figure 1: KP with top cover

Net weight:

KP 1, KP 2, KP 5 and KP 7: approx. 0.3 kg

KP 15, KP 17 and KP 7BS: approx. 0.5 kg

KP 1A and KP 5A: approx. 0.3 kg

KP 15A and KP 7ABS: approx. 0.5 kg

Table 10: IP55 enclosure

Figure 2: Weld nipple for KP-A

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 7

Page 8

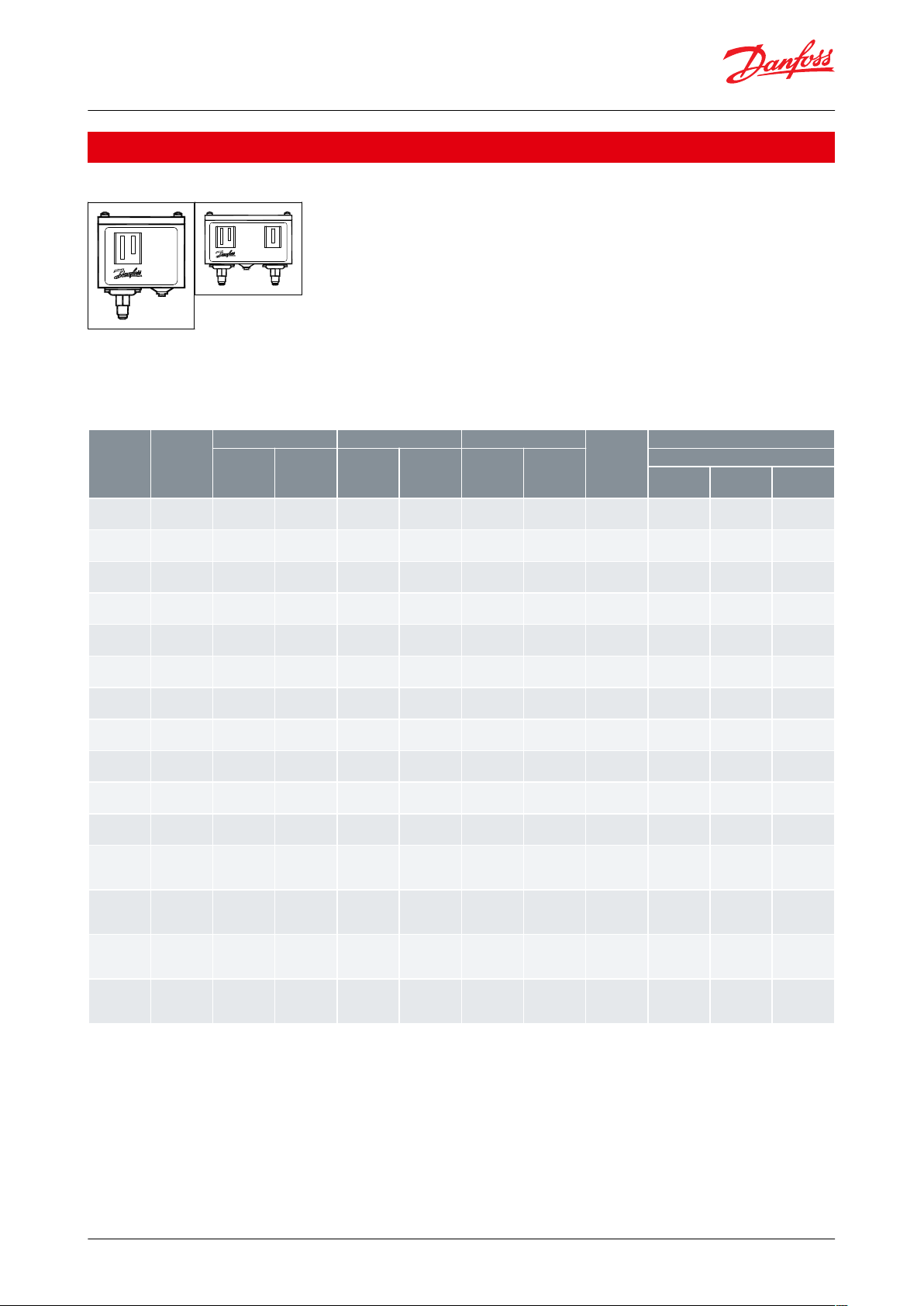

Pressure

Type

Low pressure (LP)

High pressure (HP)

Reset

Contact

system

Code no.

Regulating

range [bar]

Dierential

∆p [bar]

Regulating

range [bar]

Dierential

∆p [bar]

Low

pressure LP

High

pressure

HP

Connection

1/4 in. 6

mm are

1/4 in. ODF

solder

6 mm ODF

solder

Low

KP 1

-0.2 – 7.5

0.7 – 4.0––

Auto–SPDT

060-110166

(1)(4)

060-111266

(4)

060-111066

(4)

Low

KP 1

-0.2 – 7.5

0.7 – 4.0––

Auto–SPDT

060-114166

(2)(4)

––Low

KP 1

-0.9 – 7.0

0.7––

Man. (Min.)

–

SPDT

060-110366

(1)

060-111166

060-110966

Low

KP 2

-0.2 – 5.0

0.5 – 1.5––

Auto–SPDT

060-112066

(1)(4)

–

060-112366

(4)

High

KP 5––

8 – 32

1.8 – 6.0–Auto

SPDT

060-117166

(1)(4)

060-117966

(4)

060-117766

(4)

High

KP 5––

8 – 323–

Man. (Max.)

SPDT

060-117366

(1)

060-118066

–

Dual

KP 15

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Auto

SPDT + LP

signal

060-124166

(4)

060-125466

(4)

–

Dual

KP 15

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Man. (Max.)

SPDT + LP

signal

060-124366

(1)

––Dual

KP 15

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Man. (Max.)

SPDT + LP

signal

060-114866

(2)

––Dual

KP 15

-0.9 – 7.0

0.7

8 – 32

4

Man. (Min.)

Man. (Max.)

SPDT + LP

signal

060-124566

(1)

––Dual

KP 15

-0.9 – 7.0

0.7

8 – 324Conv.

(3)

Conv.

(3)

SPDT + LP

signal

060-126166––

Dual

KP 15

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Auto

SPDT + LP

and HP sig-

nal

060-126566

(1)(4)

060-129966

(4)

–

Dual

KP 15

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Man. (Max.)

SPDT + LP

and HP sig-

nal

060-126466

(1)

060-128466

(1)

–

Dual

KP 15

-0.2 – 7.5

0.7 – 4.0

8 – 324Conv.

(3)

Conv.

(3)

SPDT + LP

and HP sig-

nal

060-115466

(4)

060-001066

(4)

–

Dual

KP 15

-0.9 – 7.0

0.7

8 – 324Conv.

(3)

Conv.

(3)

SPDT + LP

and HP sig-

nal

060-122066––

Pressure switch, Type KP

Ordering

Figure 3: KP

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

Table 11: For R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R448A, R449A, R450A, R452A, R507A, R513A and

selected A2L refrigerants: R455A, R454C, R1234yf, R1234yz, R1234ze

(1)

(1)

Available in Asia market with code 060-xxxx91

Available in Asia market with code 060-xxxx91

(2)

(2)

Pressure switches with gold-plated contacts

Pressure switches with gold-plated contacts

(3)

(3)

Conv.: optional automatic or manual reset

Conv.: optional automatic or manual reset

(4)

(4)

Enclosure IP44

Enclosure IP44

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 8

Page 9

Pressure

Type

Low pressure (LP)

High pressure (HP)

Reset

Contact

system

Code no.

Regulating

range [bar]

Dierential

∆p [bar]

Regulating

range [bar]

Dierential

∆p [bar]

Low

pressure LP

High

pressure HP

Connection

M10 × 0.75

1 m cap.

tube with

M10 × 0.75

Low

KP 1A

-0.2 – 7.5

0.7 – 4.0––

Auto–SPDT

060-116266

(1)

060-116066

(2)

Low

KP 1A

-0.9 – 7.0

0.7––

Man. (Min.)

–

SPDT

–

060-116166

High

KP 5A––

8 – 32

1.8 – 6.0–Auto

SPDT

–

060-123066

High

KP 5A––

8 – 323–

Man. (Max.)

SPDT

060-115366

(1)

060-123166

Dual

KP 15A

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Auto

SPDT + LP

and HP signal

060-129566

060-129366

Dual

KP 15A

-0.2 – 7.5

0.7 – 4.0

8 – 324Auto

Man. (Max.)

SPDT + LP

and HP signal

060-129666

060-129466

Dual

KP 15A

-0.9 – 7.0

0.7

8 – 32

4

Conv.

(3)

Conv.

(3)

SPDT + LP

signal

–

060-128366

Pressure

Type

(1)

Low pressure (LP)

High pressure (HP)

Reset

Contact

system

Code no.

Regulating

range [bar]

Dierential

∆p [bar]

Regulating

range [bar]

Dierential

∆p [bar]

Low

pressure LP

High

pressure HP

Connection

1/4 in. 6 mm

are

6 mm ODF

solder

Low

KP 1

-0.2 – 7.5

0.7 – 4.0––

Auto–SPDT

060-110166

(2)(3)

060-111066

(3)

Low

KP 1

-0.9 – 7

0.7––

Man. (Min.)

–

SPDT

060-110366

(2)

060-110966

Low

KP 2

-0.2 – 5

0.5 – 1.5––

Auto–SPDT

060-112066

(2)(3)

060-112366

(3)

High

KP 6W––

8 – 42

4 – 10–Auto

SPDT

060-519066

(3)

–

High

KP 6B––

8 – 424–

Man. (Max.)

SPDT

060-519166

–

High

KP 7W––

8 – 32

4 – 10–Auto

SPDT

060-119066

(3)

060-120366

(3)

High

KP 7B––

8 – 324–

Man. (Max.)

SPDT

060-119166

–

High

KP 7S––

8 – 324–

Man. (Max.)

SPDT

060-119266

(3)

–

Dual

KP 7BS––

8 – 324–

Man. (Max.)

Man. (Max.)

SPST

060-120066

–

Dual

KP 17W

-0.2 – 7.5

0.7 – 4

8 – 324Auto

Auto

SPDT + LP

and HP signal

060-127566

(3)

060-127666

(3)

Dual

KP 17W

-0.2 – 7.5

0.7 – 4

8 – 324Auto

Auto

SPDT+ LP sig-

nal

060-126766

(3)

–

Dual

KP 17B

-0.2 – 7.5

0.7 – 4

8 – 324Auto

Man. (Max.)

SPDT

060-126866

060-127466

Dual

KP 17WB

-0.2 – 7.5

0.7 – 4

8 – 324Auto

Conv.

(5)

SPDT + LP

and HP signal

060-539766

(3)(4)

–

Pressure switch, Type KP

Table 12: For R717, R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R438A, R448A, R449A, R450A, R452A, R507A,

R513A and selected A2L refrigerants : R455A, R454C, R1234yf, R1234yz, R1234ze

(1)

(1)

Available in Asia market with code 060-xxxx91

Available in Asia market with code 060-xxxx91

(2)

(2)

Enclosure IP44

Enclosure IP44

(3)

(3)

Conv.: optional automatic or manual reset

Conv.: optional automatic or manual reset

Pressure switches PED 2014/68/EU approved; EN 12263

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

Table 13: For R22, R134a, R404A, R407A, R407C, R407F, R410A(for KP6W, KP6B), R422B, R422D, R438A, R448A, R449A, R450A,

R452A, R507A, R513A and selected A2L refrigerants: R455A, R454C, R1234yf, R1234yz, R1234ze

(1)

(1)

W = PSH (pressure switch), B = PZH (pressure switch with ext. reset), S = PZHH (pressure switch with int. reset)

W = PSH (pressure switch), B = PZH (pressure switch with ext. reset), S = PZHH (pressure switch with int. reset)

(2)

(2)

Available in Asia market with code 060-xxxx91

Available in Asia market with code 060-xxxx91

(3)

(3)

Enclosure IP44

Enclosure IP44

(4)

(4)

Factory setting: LP side: Range 1 bar Pe,

Factory setting: LP side: Range 1 bar Pe,

(5)

(5)

Conv.: optional automatic or manual reset

Conv.: optional automatic or manual reset

Di. 1 bar; HP side: Range 18 bar Pe, Di. 4 bar xed

Di. 1 bar; HP side: Range 18 bar Pe, Di. 4 bar xed

For complete list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers,

where refrigerants are listed as part of technical data.

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 9

Page 10

Pressure

Type

Low pressure (LP)

High pressure (HP)

Reset

Contact

system

Code no.

Regulating

range [bar]

Dierential

∆p [bar]

Regulating

range [bar]

Dierential

∆p [bar]

Low

pressure LP

High

pressure HP

Connection

M10 × 0.75

1 m cap.

tube with

M10 × 0.75

Low

KP 1A

-0.2 – 7.5

0.7 – 4.0––

Auto–SPDT

060-116266

(1)

060-116066

(2)

Low

KP 1A

0.9 – 7

Fixed 0.7––

Man. (Min.)

–

SPDT

–

060-116166

Dual

KP 7ABS––

8 – 32

Fixed 4

–

Man. (Max.)

Man. (Max.)

SPST

–

060-120566

Voltage

Current range

Power factor (cos phi)

Frequency

250V AC

≤ 4.0 A

PF ≥ 0,400

50Hz/60Hz

250V AC

> 4.0 to 6.0 A

PF ≥ 0,594

50Hz/60Hz

250V AC

> 6.0 to 16,0 A

PF ≥ 0,780

50Hz/60Hz

Pressure switch, Type KP

Table 14: For R717, R22, R134a, R404A, R407A, R407C, R407F, R422B, R422D, R438A, R448A, R449A, R450A, R452A, R507A,

R513A and selected A2L refrigerants: R455A, R454C, R1234yf, R1234yz, R1234ze

(1)

(1)

Available in Asia market with code 060-xxxx91

Available in Asia market with code 060-xxxx91

(2)

(2)

Enclosure IP44

Enclosure IP44

Use with A2L refrigerants (R455A, R454C, R1234yf, R1234yz, R1234ze)

CAUTION:

While using A2L refrigerants the following safety requirements should be followed

Safety requirements

1.

KP pressure switches shall only be employed in the units/systems which comply with the requirements for

charge limits and requirements for avoiding ignition sources of IEC 60335-2-24, IEC 60335-2-40, IEC 60335-2-89,

ISO 5149, EN378-1 or equivalent

2.

Applying the overload on the KPs must be prevented. If by any chance it was damaged, the system / unit shall be

stopped and KP shall be replaced as necessary

3.

Electrostatic discharge protection and Electrical leakage protection shall be surely implemented by grounding or

other measures

4.

Only trained personnel are authorized to handle ammable refrigerants systems and may do the installation,

maintenance and exchange of the switch by using appropriate tools

5.

It is recommended to regularly check the function of KP switch

6.

The KP pressure switches shall be used as built-in devices that cannot be accessible from outside and protected

against mechanical impact

7.

The KPs shall be installed in water free environment. In addition, protection of the KP switches against corrosion

shall be taken into consideration when using them in corrosive environment

8.

Cables shall not be in contact with sharp edges. The cables shall be connected with adequate stress relieve in

order to prevent that pulling forces can be carried thorough the cable to the terminal

9.

In the event of pressure pulsation in the system, where switch is connected, these must be eectively dumped to

prevent failure of the bellows. The cycle frequency of KP switch shall be kept as low as possible

10.

The KP switches shall not be installed in places where high level of vibration is present

Electrical rating for use with A2L refrigerants (R455A, R454C, R1234yf, R1234yz, R1234ze)

AC-3: 16 A / 250 V AC

AC-15: 10 A / 250 V AC

Table 15: Electrical rating

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 10

Page 11

Low pressure

Manual reset

(1)

Automatic reset

Automatic reset

Manual reset

High pressure

Manual reset

(1)

Manual reset

Automatic reset

Automatic reset

Pressure switch, Type KP

Pressure switch setting with convertible reset

Table 16: Pressure switch setting with convertible reset

(1)

(1)

Factory setting

Factory setting

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 11

Page 12

File name

Document type

Document topic

Approval authority

01 202 PL-Q-11 0004

Quality - Assurance Certicate

PED

TÜV

01 202 641-B-19 0006-02

Pressure - Safety Certicate

PED

TÜV

17.20386.258

Marine - Safety Certicate

Marine approval

RMRS

LR 17-20047(E1)

Marine - Safety Certicate

Marine approval

LR

FZ2015006584

Logo Printing Permission

-

CCC

ELE-086320XG-003

Marine - Safety Certicate

Marine approval

RINA

BV 03650-K0 BV

Marine - Safety Certicate

Marine approval

BV

RU Д-DK.ГА02.В.03367

EAC Declaration

EMC

EAC

DNV GL TAA00001VZ

Marine - Safety Certicate

Marine approval

DNV GL

RU C-DK.БЛ08.В.00063_18

Electrical - Safety Certicate

EMC/LVEc

EAC

UA.1O146.D.00075-19

UA Declaration

EMCD/LVD

LLC CDC EURO TYSK

UL E31024

Electrical - Safety Certicate

-

UL

Pressure switch, Type KP

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 17: Certicates, declarations, and approvals

CE-marked in accordance with:

• LVD 2014/35/EU (EN 60947-1, EN 60947-4-1, EN 60947-5-1)

• PED 2014/68/EU, category IV (EN 12263): KP 1, KP 2, KP 6, KP 7 and KP 17

• Underwriters Laboratories Inc., UL listed China Compulsory Certicate, CCC

Ship approvals

Det Norske Veritas and Germanischer Lloyd, DNV GL

Registro Italiano Navale, RINA

Bureau Veritas, BV

Lloyd’s Register, LR

Russian Maritime Register of Shipping, RMRS

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 12

Page 13

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.10 AI213186439478en-001201 | 13

Loading...

Loading...