Page 1

Installation Guide

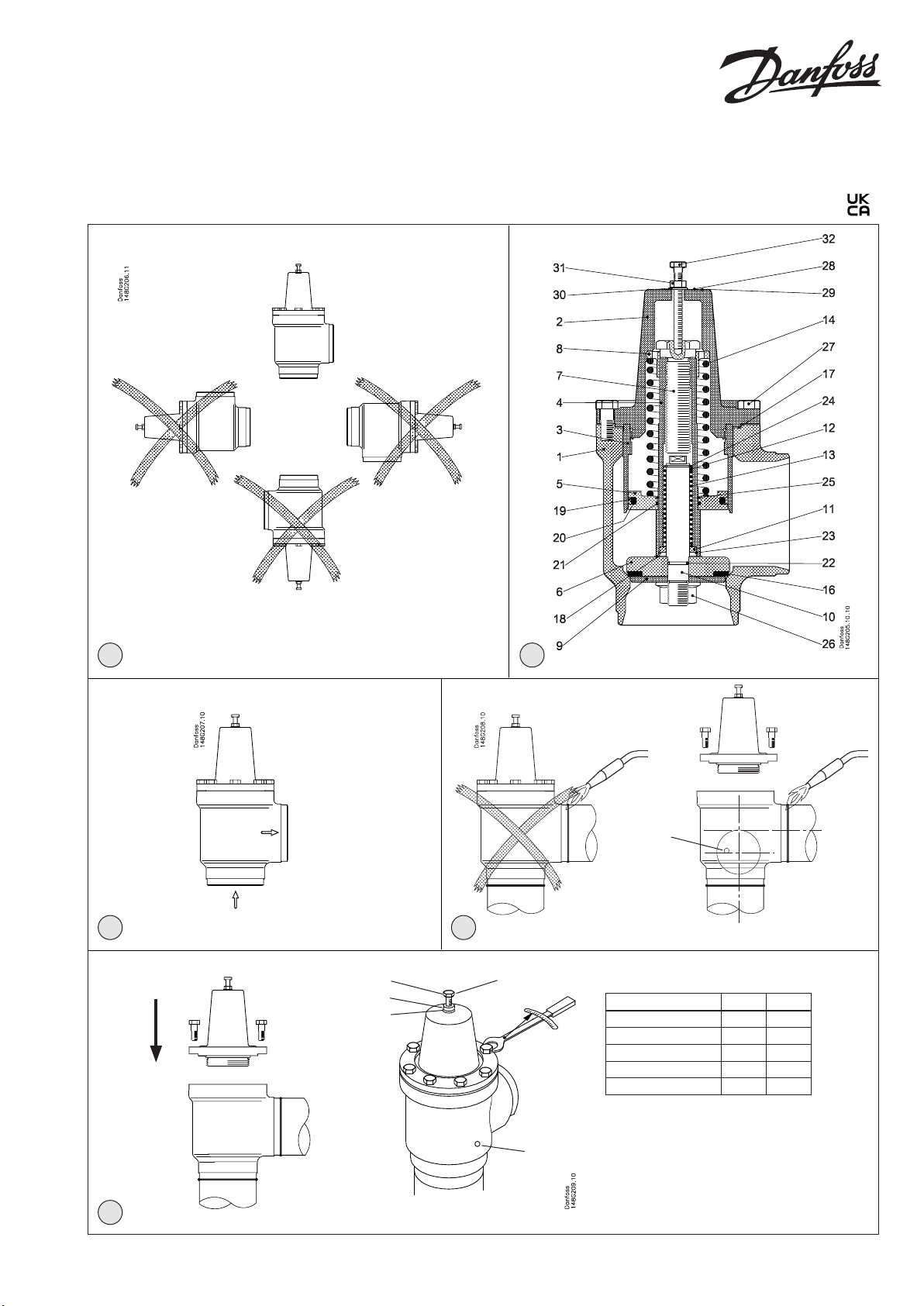

Multifunctional compressor valve

KDC 65 - 200 (2½ - 8 in.)

148R9532

1 2

148R9532

15

3 4

32

31

30

M8

Nm LB-feet

DN 65 75 53

DN 80 44 32

DN 100 75 53

DN 125-150 183 135

DN 200 370 272

15

5

© Danfoss A/S (AC-MCI/MWA), 2021-01 AN105686415739en-000401 | 1

Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

Page 2

ENGLISH

Installation

Refrigerants

Applicable to HCFC, HFC, R717 (Ammonia)

and R744 (CO2).

Flammable hydrocarbons are not

recommended. The valve is only

recommended for use in closed circuits.

For further information please contact

Danfoss.

Temperature range

KDC: –50/+150°C (–58/+302°F).

Pressure range

The valves are designed for a max. working

pressure of 40 bar g (580 psi g).

Installation (Fig. 1)

The valve must be installed with the

spindle vertically upwards (g. 1).

The valve is designed to withstand a high

internal pressure. However, the piping

system should be designed to avoid liquid

traps and reduce the risk of hydraulic

pressure caused by thermal expansion. It

must be ensured that the valve is protected

from pressure transients like “liquid

hammer” in the system.

Flow direction (Fig. 3)

Important: The ow direction must be from

the cone side towards the branch.

Welding (Fig. 4)

Remove the actuator before welding to

prevent damage to the gasket between

the valve body and bonnet, as well

as the teon gasket in the valve seat.

Only materials and welding methods,

compatible with the valve housing

material, must be welded to the valve

housing. The valve should be cleaned

internally to remove welding debris on

completion of welding and before the

valve is reassembled.

Avoid welding debris and dirt in the

threads of the housing and the bonnet.

Assembly (Fig. 5)

Remove welding debris and any dirt from

pipes and valve body before assembly.

Mount the hexagon screw (pos. 32), the

hexagon ange nut (pos. 31) and the

nylon ring (pos. 30) as shown on g. 5,

and tighten the nut (pos. 31) a few rounds

in order to redraw the valve cone from

the seat. Remove disassembly bolt after

mounting the bonnet and the bonnet

bolts have been tightened. The purpose of

the bolt is to secure insert from falling out

during disassembly and avoid damage of

the Teon seat when bonnet is mounted.

Note! Always pull the valve seat back in

open position before assembling the valve.

Use DN10 steel pipe for a pilot line. It could

be either connected directly to the valve

using NPT ¼” thread or using adapter for

cutting ring.

Tightening (Fig. 5)

Tighten the bonnet with a torque wrench,

to the values indicated in the table (g. 5).

Colours and identication

The KDC valves are painted with a red

oxide primer in the factory. Precise

identication of the valve is made via the

ID ring at the top of the bonnet, as well

as by the stamping on the valve body.

The external surface of the valve housing

must be prevented against corrosion

with a suitable protective coating after

installation and assembly. Protection of

the ID ring when repainting the valve is

recommended.

Maintenance

Dismantling the valve (Fig. 4 and g. 5)

Do not remove the bonnet while the valve

is still under pressure.

Evacuate the pipe system in which the

valve is installed. Remember to evacuate

refrigerant from both sides of the valve

(inlet and outlet). Use service port (pos. 15)

on the valve to evacuate refrigerant from

above the cone.

Assembly (Fig. 5)

Remove welding debris and any dirt from

pipes and valve body before assembly.

Mount the hexagon screw (pos. 32), the

hexagon ange nut (pos. 31) and the

nylon ring (pos. 30) as shown on g. 5,

and tighten the nut (pos. 31) a few rounds

in order to redraw the valve cone from

the seat. Remove disassembly bolt after

mounting the bonnet and the bonnet

bolts have been tightened. The purpose of

the bolt is to secure insert from falling out

during disassembly and avoid damage of

the Teon seat when bonnet is mounted.

Note! Always pull the valve seat back in

open position before assembling the valve.

The valve housing must be free from

stresses (external loads) after installation.

KDC valves must not be mounted in

systems where the outlet side of the valve

is open to atmosphere. The outlet side of

the valve must always be connected to the

system or properly capped o, for example

with a welded-on end plate.

2 | AN105686415739en-000401 © Danfoss A/S (AC-MCI/MWA), 2021-01

Mount the dismantling bolt (pos. 32),

the hexagon ange nut (pos. 31) and the

nylon ring (pos. 30) as shown on g. 5, and

tighten the nut (pos. 31) a few rounds in

order to redraw the valve cone from the

seat. Remove the bolts. Remove the valve

top (actuator).

- Check that the O-ring has not been

damaged.

- Check that the Teon seat is free of

scratches and impact marks.

Loading...

Loading...