Page 1

Data Sheet

Pressure control valve

Type KDC 65-200

Ecient control of excessive discharge pressure

The KDC valve is a pressure control valve . The

valve controls the discharge pressure of the

compressor to ensure fast build-up of pressure

and lubrication pressure. The valve also acts as

a check valve in the discharge line of the

compressor.

The KDC valve is force-controlled so that when

pressure in the oil separator becomes 2 bar (29

psi) higher than the suction pressure, the

spring is compressed and the valve opens. In

lowpressure units (boosters), the spring

requires a dierential pressure of 0.5 bar (7 psi)

for the valve to open.

Features

• Applicable to HCFC, HFC, R717(Ammonia)

and R744 (CO2).

• Each valve type is clearly marked with type,

size and performance range

• Angle valves with weld connections

• Fast build-up of oil pressure in oil separator

during start-up.

• High closing force on the cone during

standstill, even without dierential pressure

across the valve

• Very low pressure drop because of spring

force

• Low part-load without risk of valve chattering

• Stainless steel bolts

• Housing and bonnet material is in low

temperature steel according to requirements

of the Pressure Equipment Directive and

other international classication authorities

• Pressure range: 40 bar (580 psig)

• Temperature range: -50 °C / +150 °C (-58 °F /

+302 °F)

• Classication: DNV, CRN, BV, EAC etc. To get

an updated list of certication on the

products please contact your local Danfoss

Sales Company.

AI225686433549en-001001

Page 2

Pressure control valve, type KDC 65-200

Functions

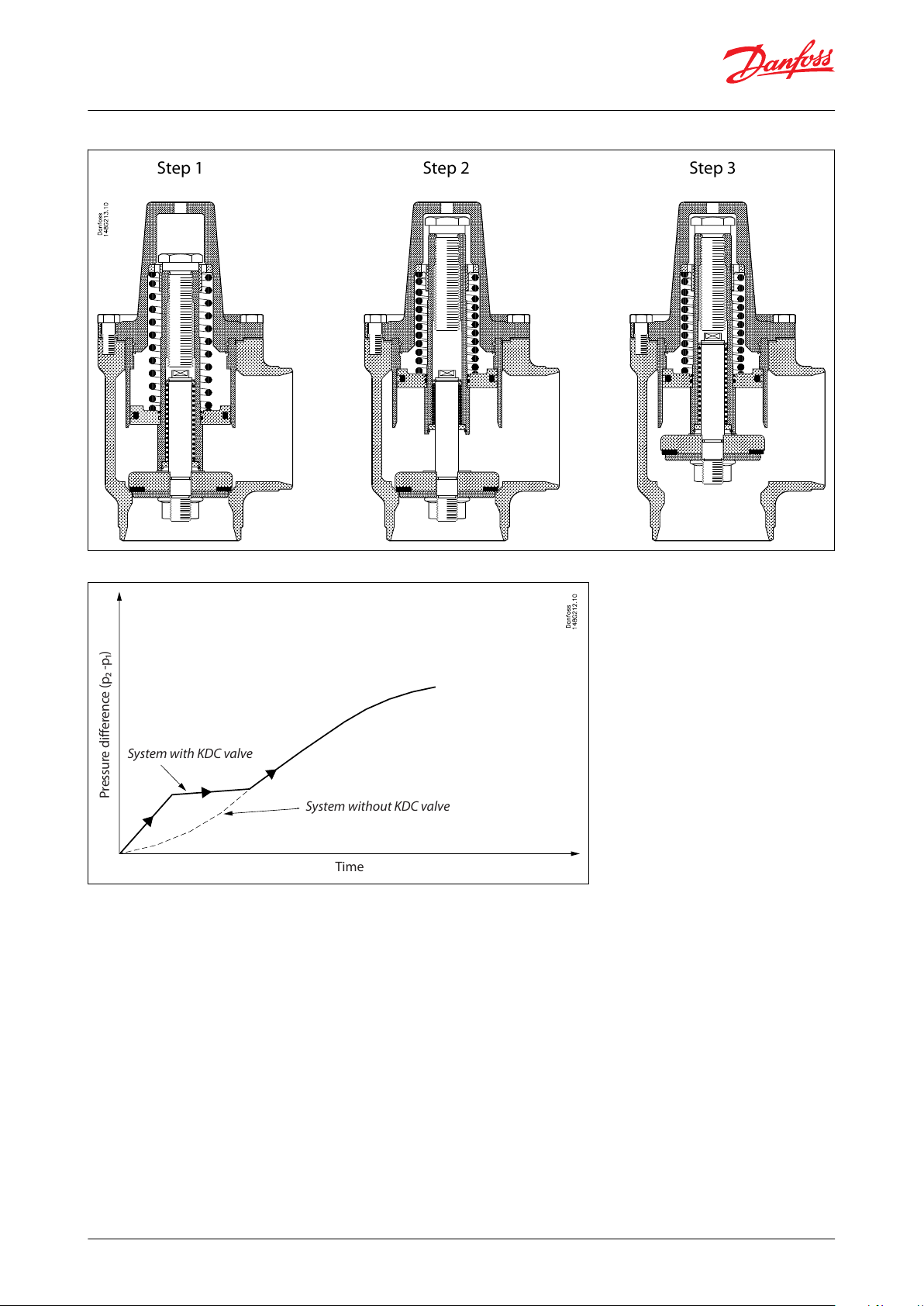

The KDC valve opens in a 3 step sequence. The sequence of steps depends on the start-up situation (see Figure 1:

KDC valve).

Step 1

The valve is always closed by a minimum dierential pressure of 1.5 to 2.0 bar (0.3 to 0.5 bar in a booster system).

Step 1 will occur when the compressor is stopped and the discharge pressure has equalized to the top of the valve

through the suction side of the compressor.

pc – p1 < 2 bar (0.5 bar for booster) and pc > p

2

Step 2

Step 2 will occur as soon as the condensing pressure becomes higher than the pressure in the oil separator, and

when the dierential pressure between suction side and condensing pressure is bigger than the spring force.

pc – p1 > 2 bar (0.5 bar for booster) and pc > p

2

When the compressor starts the valve will either be in step 1 or step 2 position, depending on the pressure

dierence between the oil separator and the condensing pressure.

Start up situation 1

Condensing pressure is lower than oil separator pressure.

Start up will occur from step 1 position and go to step 3 as soon as a dierential pressure between suction side and

oil separator that can overcome the spring force is present.

Start up situation 2

Condensing pressure is higher than oil separator pressure but the dierential pressure is lower than the spring force.

Start up will occur from step 1 and go to step 2 when dierential pressure between suction side and condensing

pressure is bigger than the spring force. When oil separator pressure comes close to the condensing pressure the

valve will start opening and the small spring will open the valve completely. The valve will then be in step 3 position.

Start up situation 3

Condensing pressure is higher than oil separator pressure + spring force pressure. Start up will occur from step 2

position.

When oil separator pressure comes close to the condensing pressure the valve will start opening and the small

spring will open the valve completely. The valve will then be in step 3 position.

When the compressor stops, the valve will be in step 3 position and as soon as the condensing pressure has

equalized to the suction side the spring force will close the valve. The valve will be in step 1 position until enough

dierential pressure between condensing pressure and oil separator/suction side pressure occurs for the valve to

enter into step 2 position.

NOTE:

The KDC valve cannot be used on compressor units where the non-return valve is placed between compressor and

oil separator instead of on the suction side of the compressor. The reason for this is that the KDC valve needs to have

the pilot pipe connected to a point on the compressor unit, where the pressure is low during running and high

during standstill.

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 2

Page 3

Step 1 Step 2 Step 3

System with KDC valve

System without KDC valve

Time

Pressure difference (p₂ -p₁)

Pressure control valve, type KDC 65-200

Figure 1: KDC valve

Figure 2: Time and Pressure dierence graph

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 3

Page 4

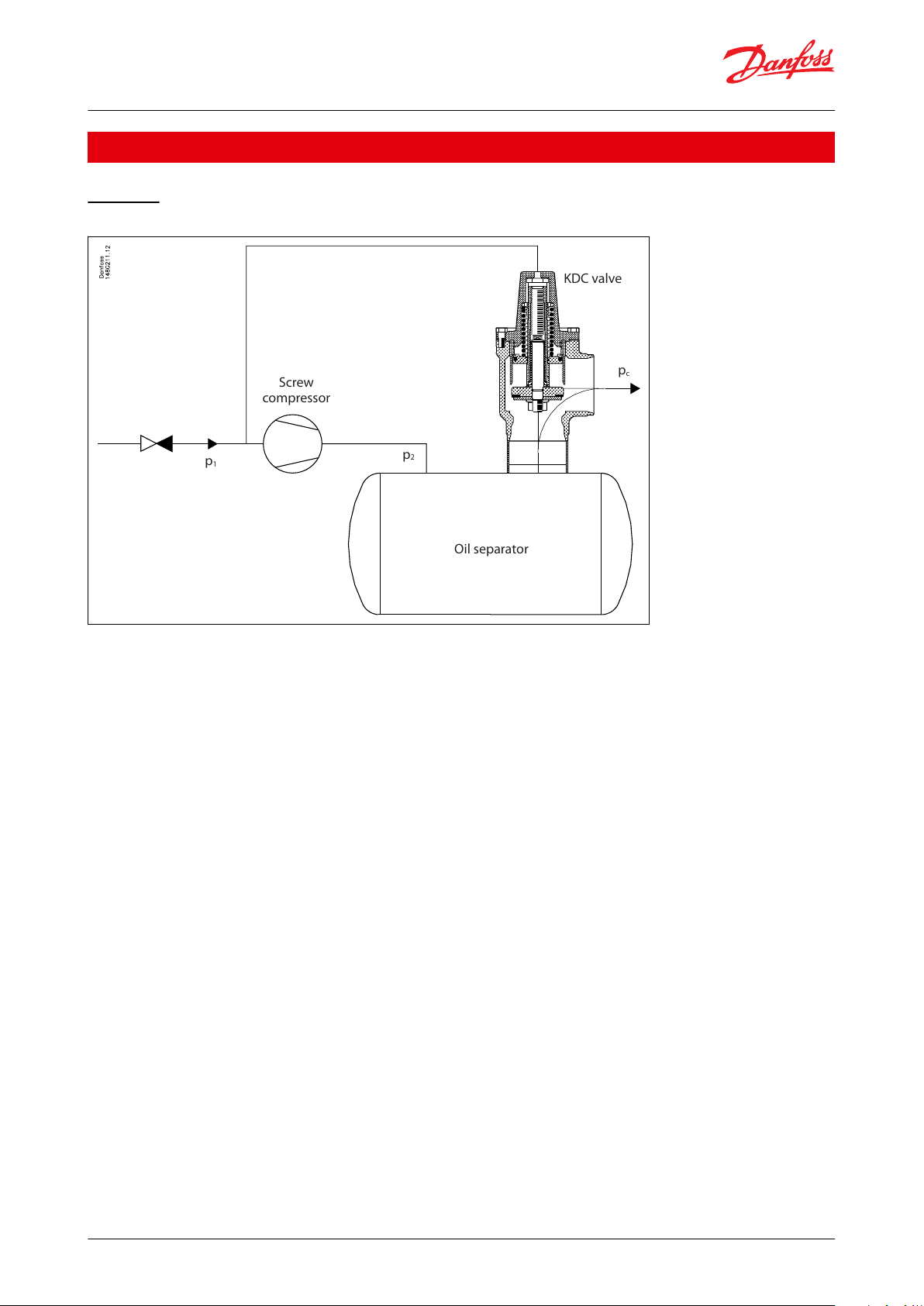

KDC valve

p

c

Screw

compressor

Oil separator

p

1

p

2

Pressure control valve, type KDC 65-200

Applications

Example

Figure 3: Compressor discharge line after oil separator

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 4

Page 5

Pressure control valve, type KDC 65-200

Media

Refrigerants

Applicable to HCFC, HFC, R717(Ammonia) and R744 (CO2).

For further information please see installation instruction for KDC.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 5

Page 6

Description

Values

Temperature range

-50 °C / +150 °C (-58 °F / +302 °F)

Pressure range

The valves are designed for max. working pressure

40 bar (580 psig)

Pressure control valve, type KDC 65-200

Product specication

Pressure and temperature

Table 1: Pressure and temperature

Design

Housing

Made of special, cold resistant steel approved for low temperature operations.

Valve cone

The valve cone has two teon tightening rings with built-in metallic stops to prevent damage to the teon rings in

case of an extreme pressure dierence.

Spindle

The spindle is made of gas-tempered steel. Consequently the valve spindle has an extremely hard and smooth

surface. The valve rod has an internal weak spring (Figure 4: KDC, pos. 13), which is active when the servo piston is in

upright position.

Actuator

The KDC actuator has one chamber. It is separated from the main ow by a piston (Figure 4: KDC, pos. 6). The

chamber has a spring (Figure 4: KDC, pos. 14) which provides dierential opening of the valve. The chamber of the

actuator is connected to the suction line of the compressor.

Installation

The valve must be mounted vertically with the cone in downward position. On top of the bonnet the actuator has

one threaded (NPT 1/4 in.) connection (Figure 4: KDC, pos. A) for the pilot line. Fittings for connection of steel pipe

DN 10 (do/di = 10/6 mm) by means of cutting rings. The valve is designed to resist very high internal pressure, but as

to the pipe system in general, hydraulic pressure caused by thermal expansions in entrapped refrigerants should be

avoided.

For further information please refer to KDC installation instruction.

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 6

Page 7

T

ØD

Danfoss

A148B15.10

SizemmSize

in.ODmmTmmODin.Tin.

kv-angle

m3/h

Cv-angle

USgal/min

652½76.1

2.930.117890

80

10034

88.9

114.3

3.2

3.6

3.50

4.50

0.13

0.14

118

203

137

235

125

150

200

5

6

8

139.7

168.3

219.1

4.0

4.5

6.3

5.50

6.63

8.63

0.16

0.18

0.25

333

509

757

386

590

878

Pressure control valve, type KDC 65-200

Figure 4: KDC Figure 5: Example of ID-plate for KDC

Connections

Available with the following connections:

• Butt-weld DIN (2448)

• Butt-weld ANSI (B 36.10 Schedule 40), DN 65 - 200 (2½ - 8 in.)

Figure 6: DIN

Table 2: Butt-weld DIN (2448)

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 7

Page 8

T

ØD

SizemmSize

in.ODmmTmmODin.Tin.

kv-angle

m3/h

Cv-angle

USgal/min

652½73.0

5.2

2.87

0.207890

80

10034

88.9

114.3

5.5

6.0

3.50

4.50

0.22

0.24

118

203

137

235

125

150

200

5

6

8

141.3

168.3

219.1

6.6

7.1

8.2

5.56

6.63

8.63

0.26

0.28

0.32

333

509

757

386

590

878

KDC 65

KDC 80

KDC 100

KDC 125

KDC 150

KDC 200

R717

434

656

1128

1851

2829

4207

R404A

132

200

344

564

863

1283

R22

157

238

410

672

1028

1528

KDC 65

KDC 80

KDC 100

KDC 125

KDC 150

KDC 200

R717

229

347

597

978

1496

2225

R404A

101

153

263

432

661

983

R22

102

154

265

435

665

990

Pressure control valve, type KDC 65-200

Figure 7: ANSI

Table 3: Butt-weld DIN (2448)

Nominal capacities

High pressure compressor

Capacity table at tc / to = +35 °C / -15 °C,

QN [kW],

Δp = 0.05 bar

Table 4: Capacity table

Booster compressor

Capacity table at tc / to = -18 °C / -40 °C,

QN [kW],

Δp = 0.05 bar

Table 5: Capacity table

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 8

Page 9

No.

Part

Material

EN

ISO

ASTM

1

Valve House

Steel

G20Mn5QT

EN10213-3

LCC

A352

2

Bonnet

Steel

P285QH

EN10222-4

LF2

A350

3

Piston

Steel

S235JRG2

EN10025

Fe260B

630

Grade C

A283

4

Piston rod

Steel

S235JRG2

EN10025

Fe260B

630

Grade C

A283

5

Piston

Steel

11SMn30

EN10087

Type 2

R683/9

Grade 1213

A29

6

Cone

Steel

11SMn30

EN10087

Type 2

R683/9

Grade 1213

A29

7

Screw for spring

Steel

11SMn30

EN10087

Type 2

R683/9

Grade 1213

A29

8

Bushing for spring

Cast iron

9

Cone plate

Steel

11SMn30

EN10087

Type 2

R683/9

Grade 1213

A29

10

Cone rod

Steel

11SMn30

EN10087

Type 2

R683/9

Grade 1213

A29

11

Rear bushing

Cast iron

12

Front bushing

Cast iron

13

Spring for cone

Steel14Spring

Steel16Teon ring

PTFE

17

Gasket

Fiber gasket

non-asbestos

18

Washer

Nylon19Glide ring

PTFE

Pressure control valve, type KDC 65-200

Material specication

Figure 8: KDC 65 - 200 (2½ - 8 in.)

Table 6: Material and Parts list

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 9

Page 10

No.

Part

Material

EN

ISO

ASTM

20

O-ring

Cloroprene (Neoprene)

(Standard KDC)

FKM

(Hydrocarbon KDC)

21

O-ring

Cloroprene (Neoprene)

(Standard KDC)

FKM

(Hydrocarbon KDC)

22

O-ring

Cloroprene (Neoprene)

(Standard KDC)

FKM

(Hydrocarbon KDC)

23

Retaining ring bore

Steel24Spring ring

Steel25Spring ring

Steel26Nut

Steel

27

Bolts

Steel

A2-70

EN1515-1

A2-70

3506

Grade B8

A320

28

ID plate

Aluminium

29

Driv screw

Steel30Washer

Steel31Nut

Steel32Screw

Steel

Pressure control valve, type KDC 65-200

Dimensions and weights

Figure 9: KDC 65 - 200 (2½ - 8 in.)

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 10

Page 11

Valve size

ABCØDWeight

KDC 65mm2506290427.3 kg

KDC 2½

in.

9.84

2.44

3.54

1.65

16.1 lb

KDC 80mm298901295111.1 kg

KDC 3

in.

11.73

3.54

5.08

2.01

24.5 lb

KDC 100mm346

106

1566417.3 kg

KDC 4

in.

13.62

4.17

6.14

2.52

38.1 lb

KDC 125mm407

128

1926436.9 kg

KDC 5

in.

16.02

5.04

7.56

2.52

81.3 lb

KDC 150mm471

145

2197549.9 kg

KDC 6

in.

18.54

5.71

8.62

2.95

110.0 lb

KDC 200mm539

180

2767599.6 kg

KDC 8

in.

21.22

7.09

10.87

2.95

219.6 lb

Pressure control valve, type KDC 65-200

Table 7: KDC types

NOTE:

Specied weights are approximate values only.

Bolt in top of the valve is for transportation purposes only. For further information please see installation instruction.

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 11

Page 12

Size

Type

bar

Code no.

mm

in.

652½KDC 65

0.5

2

3

148G3585

148G3586

148G3713

803KDC 80

0.5

2

3

148G3589

148G3590

148G3714

1004KDC 100

0.5

2

3

148G3593

148G3594

148G3715

1255KDC 125

0.5

2

3

148G3597

148G3598

148G3716

1506KDC 150

0.52148G3601

148G3602

2008KDC 200

0.52148G3605

148G3606

Size

Type

bar

Code no.

mm

in.

652½KDC 65

0.5

2

3

148G3587

148G3588

148G3811

803KDC 80

0.5

2

3

148G3591

148G3592

148G3812

1004KDC 100

0.5

2

3

148G3595

148G3596

148G3813

1255KDC 125

0.52148G3599

148G3600

1506KDC 150

0.52148G3603

148G3604

2008KDC 200

0.52148G3607

148G3608

Size

Type

bar

Code no.

mm

in.

652½KDC 65

0.52148G3825

148G3831

803KDC 80

0.52148G3826

148G3832

1004KDC 100

0.52148G3827

148G3833

1255KDC 125

0.52148G3828

148G3834

1506KDC 150

0.52148G3829

148G3835

2008KDC 200

0.52148G3830

148G3836

Pressure control valve, type KDC 65-200

Ordering

IMPORTANT:

Where products need to be certied according to specic certication societies or where higher pressures are

required, the relevant information should be included at the time of ordering.

Table 8: Standard KDC with welding branches - DIN

Table 9: Standard KDC with welding branches - ANSI

NOTE:

The HYDROCARBON versions of the KDC valves are not compatiable with Ammonia as refrigerant. They can only be

used in systems with HYDROCARBON as refrigerant.

Table 10: Standard KDC with welding branches - ANSI

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 12

Page 13

Type

Code no.

GASKET BONNET/HOUSING KDC/GVD 65

148G3048

GASKET BONNET/HOUSING KDC/GVD 80

148G3049

GASKET BONNET/HOUSING KDC/GVD 100

148G3050

GASKET BONNET/HOUSING KDC/GVD 125

148G3051

GASKET BONNET/HOUSING KDC/GVD 150

148G3052

GASKET BONNET/HOUSING KDC/GVD 200

148G3053

Type

Code no.

SEAL KIT SET KDC/GVD 65

148G3054

SEAL KIT SET KDC/GVD 80

148G3055

SEAL KIT SET KDC/GVD 100

148G3056

SEAL KIT SET KDC/GVD 125

148G3057

SEAL KIT SET KDC/GVD 150

148G3058

SEAL KIT SET KDC/GVD 200

148G3059

Type

Code no.

SEAL KIT SET KDC/GVD 65 Hydrocarbon

148G3837

SEAL KIT SET KDC/GVD 80 Hydrocarbon

148G3838

SEAL KIT SET KDC/GVD 100 Hydrocarbon

148G3839

SEAL KIT SET KDC/GVD 125 Hydrocarbon

148G3840

SEAL KIT SET KDC/GVD 150 Hydrocarbon

148G3841

SEAL KIT SET KDC/GVD 200 Hydrocarbon

148G3842

Pressure control valve, type KDC 65-200

Spare parts and accessories

Table 11: Spare parts

Table 12: Seal kit

Table 13: Seal kit

NOTE:

The HYDROCARBON versions of the seal kits are not compatible with Ammonia as refrigerant. They can only be used

in systems with HYDROCARBON as refrigerant.

The seal kit

Figure 10: The seal kit

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 13

Page 14

No.

Part

Material

16

Teon ring

PTFE17Gasket

Fiber gasket non-asbestos

18

Washer

Nylon19Glide ring

PTFE

20-22

O-ring

- Standard valve

- Hydrocarbon valve

Cloroprene (Neoprene) Viton

Pressure control valve, type KDC 65-200

Table 14: The seal kit

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 14

Page 15

KDC valves are approved according to the European standard specied in the Pressure Equipment Directive and are CE

marked.

KDC valves

Nominal bore

DN65-80 mm (1¼ - 3 in.)

DN100 - 200 mm (4-8 in.)

Classied for

Fluid group I

Category

II

III

File name

Document type

Document topic

Approval authority

RU Д-DK.БЛ08.В.00191_18

EAC Declaration

Machinery & Equipment

EAC

0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

-

TÜV

03709-F0 BV

Marine - Safety Certicate

-BVTSX71002520151142

Manufacturing Permission

-

GMPI

RU Д-DK.РА01.B.72054_20

EAC Declaration

PED

EAC

RU C-DK.БЛ08.B.01093_20

Pressure - Safety Certicate

PED

EAC

GL TAP0000001 Rev. 1

Marine - Safety Certicate

-

DNV GL

033F0685.AK

EU Declaration

EMCD/PED

Danfoss

033F0691.AE

Manufacturers Declaration

RoHS

Danfoss

0045 202 1204 Z 00355 19 D 001(00)

Pressure - Safety Certicate

-

TÜV

19.10048.266

Marine - Safety Certicate

-

RMRS

Pressure control valve, type KDC 65-200

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 15: Pressure Equipment Directive (PED)

For further details / restrictions - see Installation Instruction.

Table 16: KDC valves

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 15

Page 16

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its

products without notice. This also applies to products already on order provided that such alterations can be made without subsequential

changes being necessary in specications already agreed. All trademarks in this material are property of the respective companies. Danfoss and

the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.02 AI225686433549en-001001 | 16

Loading...

Loading...