Technical Information

Joysticks

JS6000 Joystick Base

powersolutions.danfoss.com

Technical Information

JS6000 Joystick Base

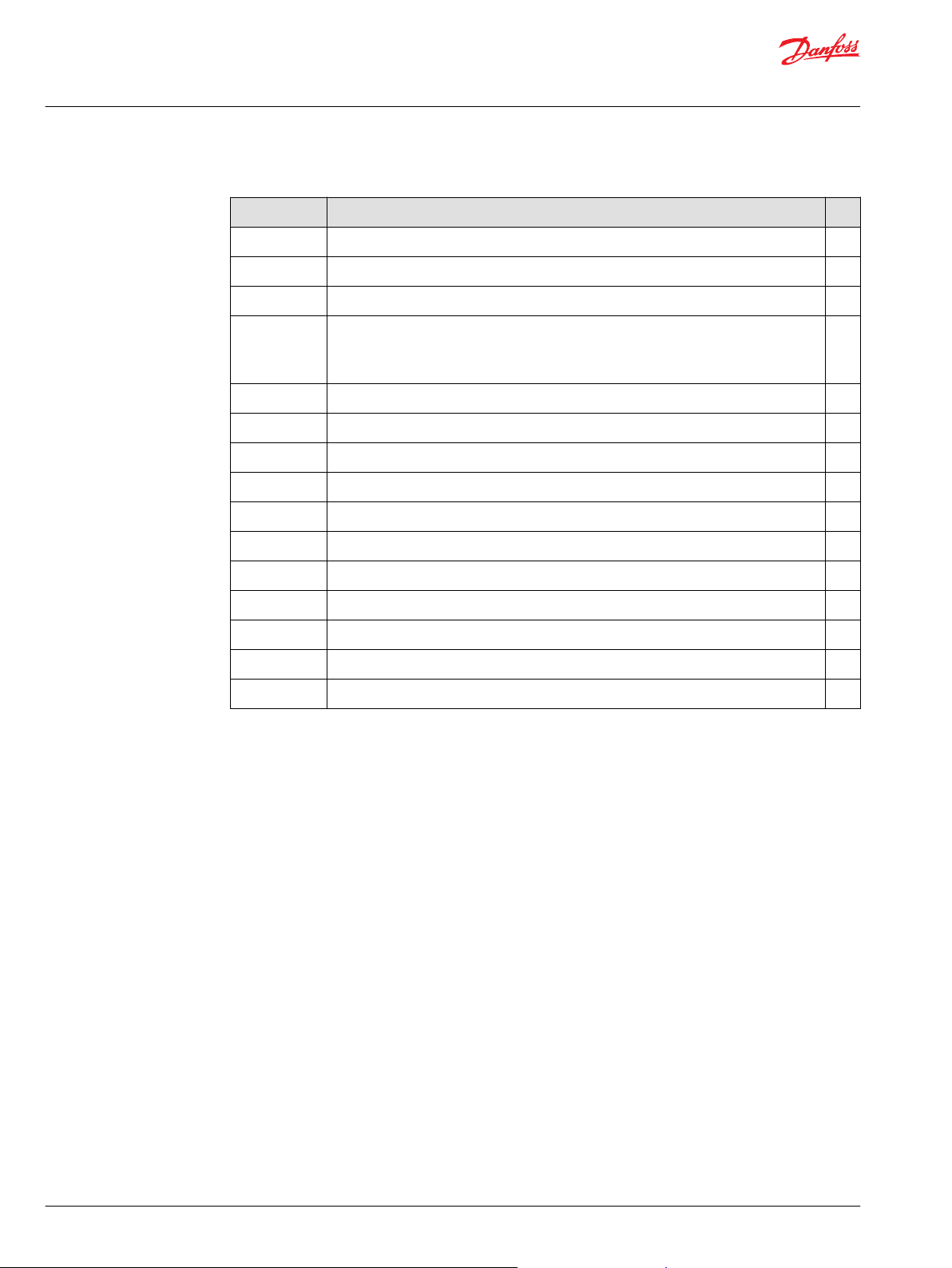

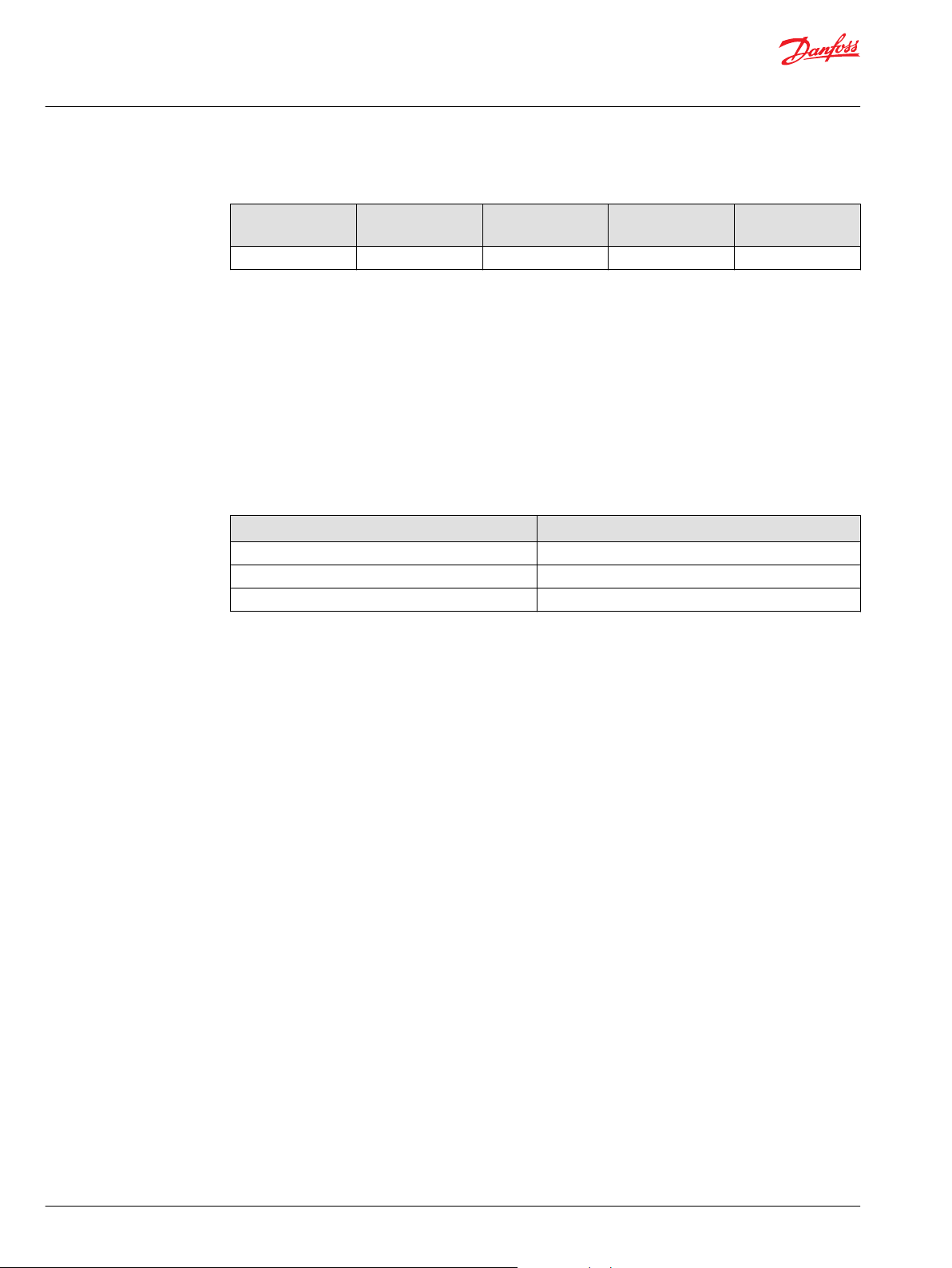

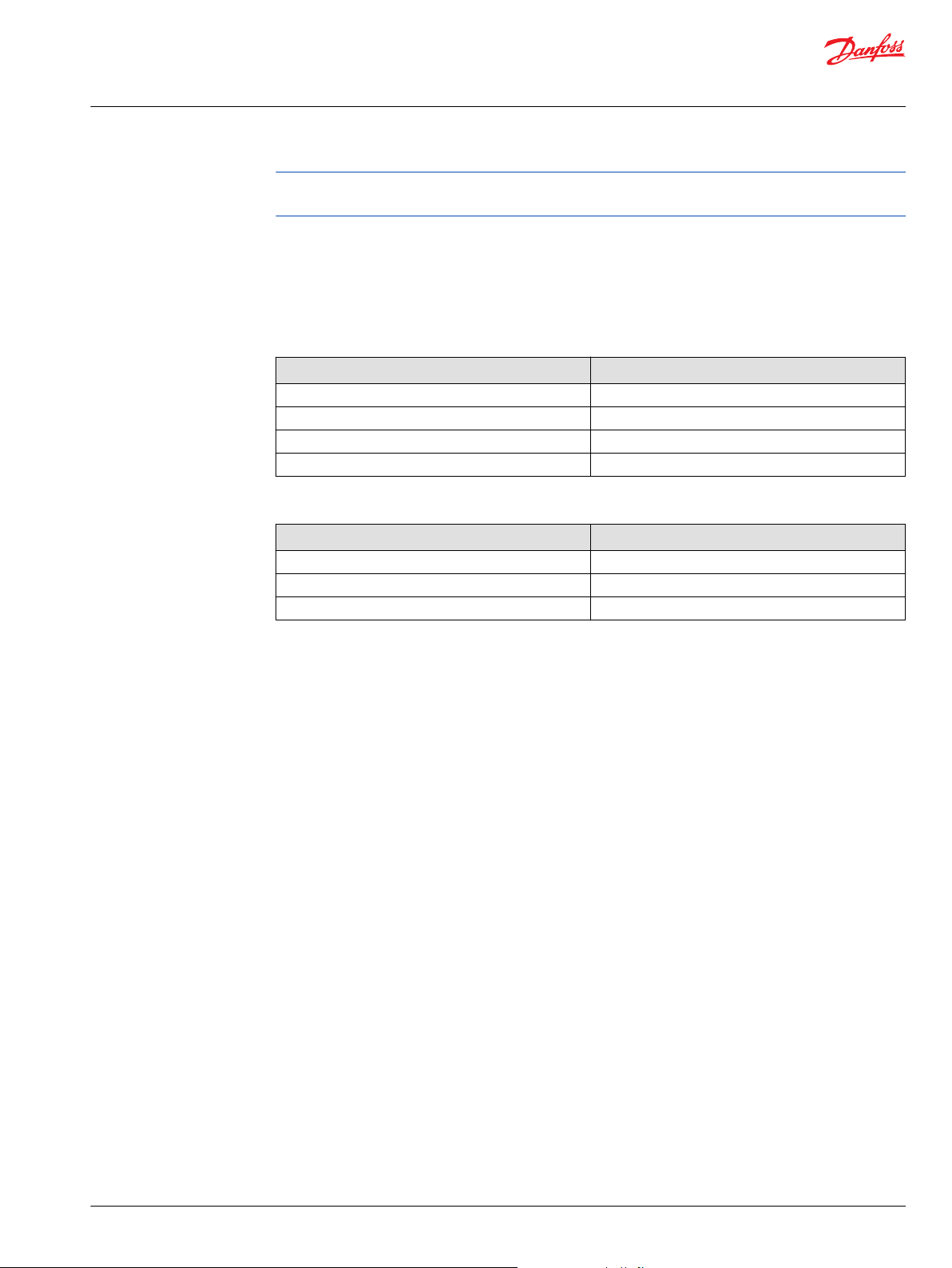

Revision history Table of revisions

Date Changed Rev

April 2017 Updated to Engineering Tomorrow design 1104

April 2017 Minor correction to note format and mis-spelling 1103

November 2015 Converted to Danfoss layout 1102

June 2010 Single or Dual Axis Options images; Dimensions and Installation, revised dimensions to

include 18 pin connector, added recommended mounting panel cut-out illustration, and

updated installation instructions.

February 2010 Axis base image, A Grip Front Plate Diagram illustration, Environmental Characteristics JA

September 2009 Content update IA

January 2008 A grip front plate diagram updated HA

November 2007 Grip options model code details; mechanical options: friction hold torque GA

June 2007 Corrected temperature and length conversion FA

June 2007 Text changes and addition of CAN+ EA

April 2007 Text changes D

February 2006 Text changes C

November 2005 Feature updates B

May 2005 Hall sensor pinouts A

December 2004 Initial release

KA

2 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

Contents

General Information

Product configuration

Model code details

JS6000 CAN messages

CAN message protocol

Description..........................................................................................................................................................................................5

Features and options...................................................................................................................................................................... 5

Product configuration model code............................................................................................................................................6

Base model code...............................................................................................................................................................................7

Grip model code............................................................................................................................................................................... 9

Code B: Single or dual axis options......................................................................................................................................... 10

Code C: Shaft sensor and output options............................................................................................................................. 12

Potentiometer sensor............................................................................................................................................................. 12

Center tap.............................................................................................................................................................................. 12

Directional potentiometer switches.............................................................................................................................13

Dual potentiometer outputs per axis................................................................................................................................13

Hall effect sensor.......................................................................................................................................................................14

Controller Area Network (CAN) output.............................................................................................................................14

CAN (configuration model code CAN).........................................................................................................................14

CAN+ (configuration model code CPL).......................................................................................................................14

Pulse Width Modulated (PWM) output.............................................................................................................................14

PWM (configuration model code PWM)..................................................................................................................... 14

Code D: Centering return spring options..............................................................................................................................15

Code E: Hardware configuration.............................................................................................................................................. 15

Code F: Mechanical options.......................................................................................................................................................16

Code G: Microswitch option.......................................................................................................................................................18

Code H: Electrical interface options........................................................................................................................................ 19

Analog...........................................................................................................................................................................................19

CAN 2.0B, J1939 protocol.......................................................................................................................................................19

CANopen 2.0B, J1939 protocol............................................................................................................................................19

PWM ............................................................................................................................................................................................. 19

H1 electrical interface options.............................................................................................................................................19

H2, 3 joystick location/CAN source address....................................................................................................................19

H4 CAN proportional output................................................................................................................................................20

Code I, J, K, L: Grip options..........................................................................................................................................................20

CAN option.......................................................................................................................................................................................21

CAN+ option....................................................................................................................................................................................21

CAN+ external inputs................................................................................................................................................................... 21

Analog inputs (AIN)..................................................................................................................................................................21

Digital inputs (DIN)...................................................................................................................................................................21

SAE J1939 CAN message specification...................................................................................................................................23

SAE J1939 basic joystick message...................................................................................................................................... 23

Data field......................................................................................................................................................................................23

Basic joystick message data field descriptions.............................................................................................................. 23

Joystick X-axis neutral position status.........................................................................................................................24

Joystick X-axis handle left negative position status............................................................................................... 24

Joystick X-axis handle right positive position status..............................................................................................25

Joystick X-axis position status........................................................................................................................................ 25

Joystick Y-axis neutral position status.........................................................................................................................25

Joystick Y-axis handle back negative position status............................................................................................ 25

Joystick Y-axis handle forward positive position status........................................................................................26

Joystick Y-axis position status.........................................................................................................................................26

SAE J1939 extended joystick message............................................................................................................................. 26

SAE J1939 error (DM1) messages........................................................................................................................................27

SAE CANopen protocol information.......................................................................................................................................28

A grip button and rocker CAN naming conventions........................................................................................................ 29

Top and operator present switch naming conventions.............................................................................................30

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 3

Technical Information

JS6000 Joystick Base

Contents

Product installation

Specifications

Proportional rocker naming conventions........................................................................................................................30

MG grip button CAN naming conventions...........................................................................................................................31

Dimensions and installation...................................................................................................................................................... 32

Dimensions................................................................................................................................................................................. 32

Recommended mounting panel cut-out.........................................................................................................................32

Installation...................................................................................................................................................................................33

Machine wiring guidelines......................................................................................................................................................... 33

Joystick safety critical functions............................................................................................................................................... 34

JS6000 connector pin assignments general information................................................................................................34

Pin assignments..............................................................................................................................................................................35

CAN output connector pin assignments..........................................................................................................................35

CAN output mating connector DEUTSCH DTM06-6S..................................................................................................35

CAN+ and PWM output connector pin assignments.................................................................................................. 36

CAN+ and PWM output mating connector DEUTSCH DT16-18SB......................................................................... 37

Potentiometer sensor with analog output connector pin assignments..............................................................38

Analog output mating connector ..................................................................................................................................... 39

Hall effect sensor with analog output pin assignments ............................................................................................40

Mechanical characteristics..........................................................................................................................................................41

Electrical characteristics...............................................................................................................................................................41

Microswitch characteristics........................................................................................................................................................ 43

Sensor power supply ratings..................................................................................................................................................... 43

Environmental characteristics...................................................................................................................................................43

4 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

General Information

Description

The JS6000 features metal construction with a large diameter stainless steel operating shaft, an

innovative ball and socket gimbal design manufactured from pressure die cast zinc alloys, a custom high

strength material for the center return cone, and optional contactless Hall effect sensing technology.

The CAN+ version of the JS6000 base allows the value and state of up to eleven digital or seven digital

and four analog inputs from external-to-the-joystick sources to be broadcast along with joystick

Controller Area network (CAN) messages.

The Pulse Width Modulation (PWM) version of the JS6000 base can be used to directly drive a valve, such

as the H1 hydrostatic transmission, without an intermediate microcontroller. This version allows joystick

operating parameters (e.g. ramp rates, button function assignments, output characteristics) to be

configured using the PLUS+1® Service Tool interface. Refer to JS6000 PWM User Manual, 11060942 for

instructions and information required to configure JS6000 PWM joystick options.

The flexible design of the JS6000 offers many options, making it the right choice for applications that

require more than a simple dual axis joystick with spring return to center.

JS6000 joystick base

Features and options

Hall effect or potentiometer sensing (model dependent)

•

One or two sensors per axis for redundancy

•

Single or dual axis

•

Mechanical direction switches

•

2 centering spring forces

•

3 available friction-hold options

•

Output options:

•

Analog

‒

CAN 2.0B, J1939 protocol

‒

CANopen protocol

‒

High current PWM

‒

Multiple grip options:

•

HKN — plain knob

‒

MG — with operator trigger and hand rest

‒

A— configurable ergonomic

‒

Custom designed grips

‒

External-to-joystick analog and digital information included in JS6000 CAN+messages

•

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 5

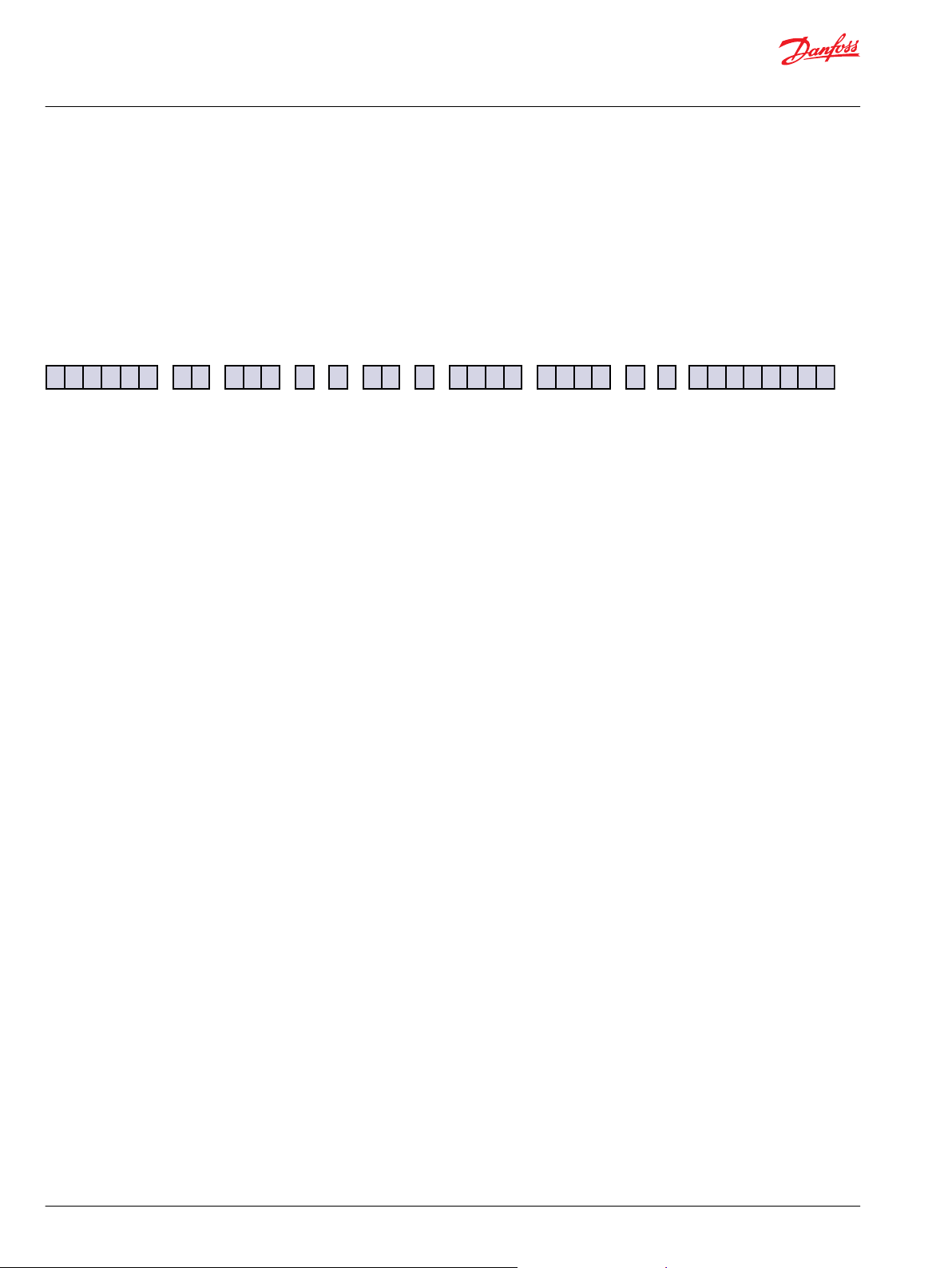

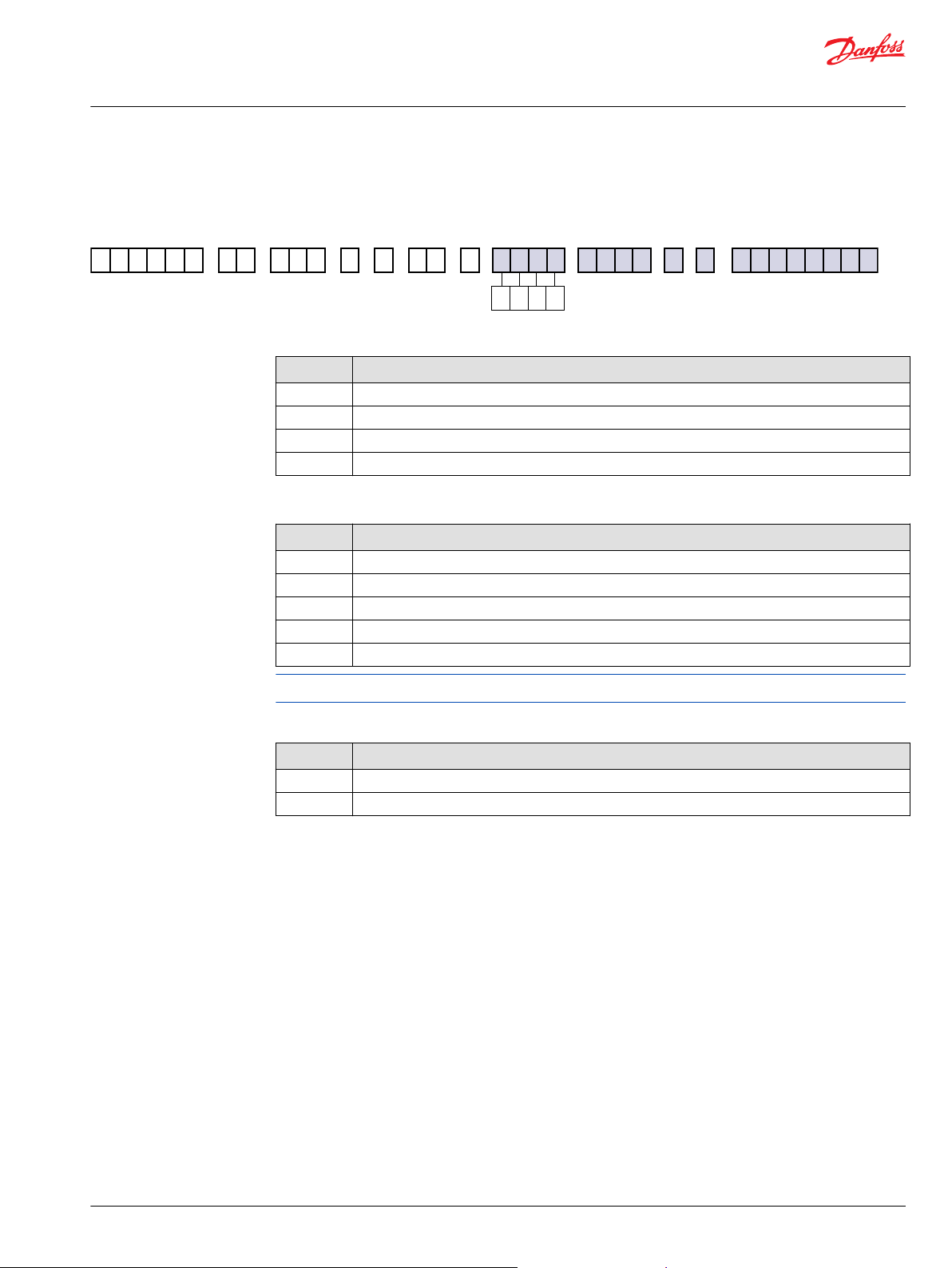

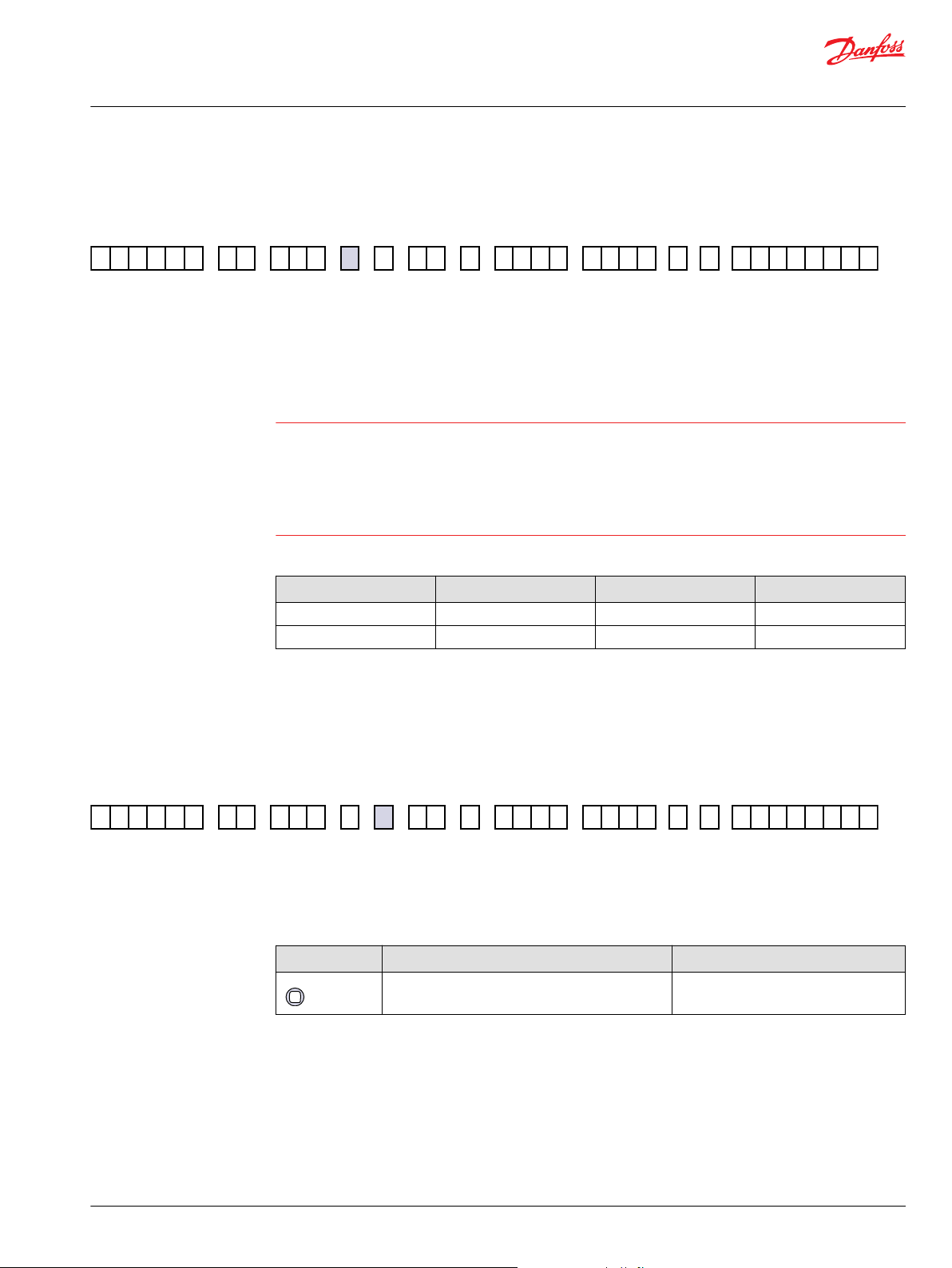

J S 6 0 0 0 X Y H M M H S N L N J 3 3 1 A 0 H 0 R V N N N N N N N N

Technical Information

JS6000 Joystick Base

Product configuration

Product configuration model code

Use the JS6000 product configuration model code to specify particular features when ordering a JS6000

joystick. The model code begins with the product family name: JS6000. Fill in the remaining fields to

configure the product with the desired features.

The model code includes both joystick base and joystick grip information. JS6000 Joystick Base Technical

Information Manual, 520L0760 provides information required to configure the base portion of the

joystick. JS1000, JS6000 Joystick Grips Technical Information Manual, 520L0872 provides information

required to configure JS6000 joystick grips.

Product configuration model code example

6 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

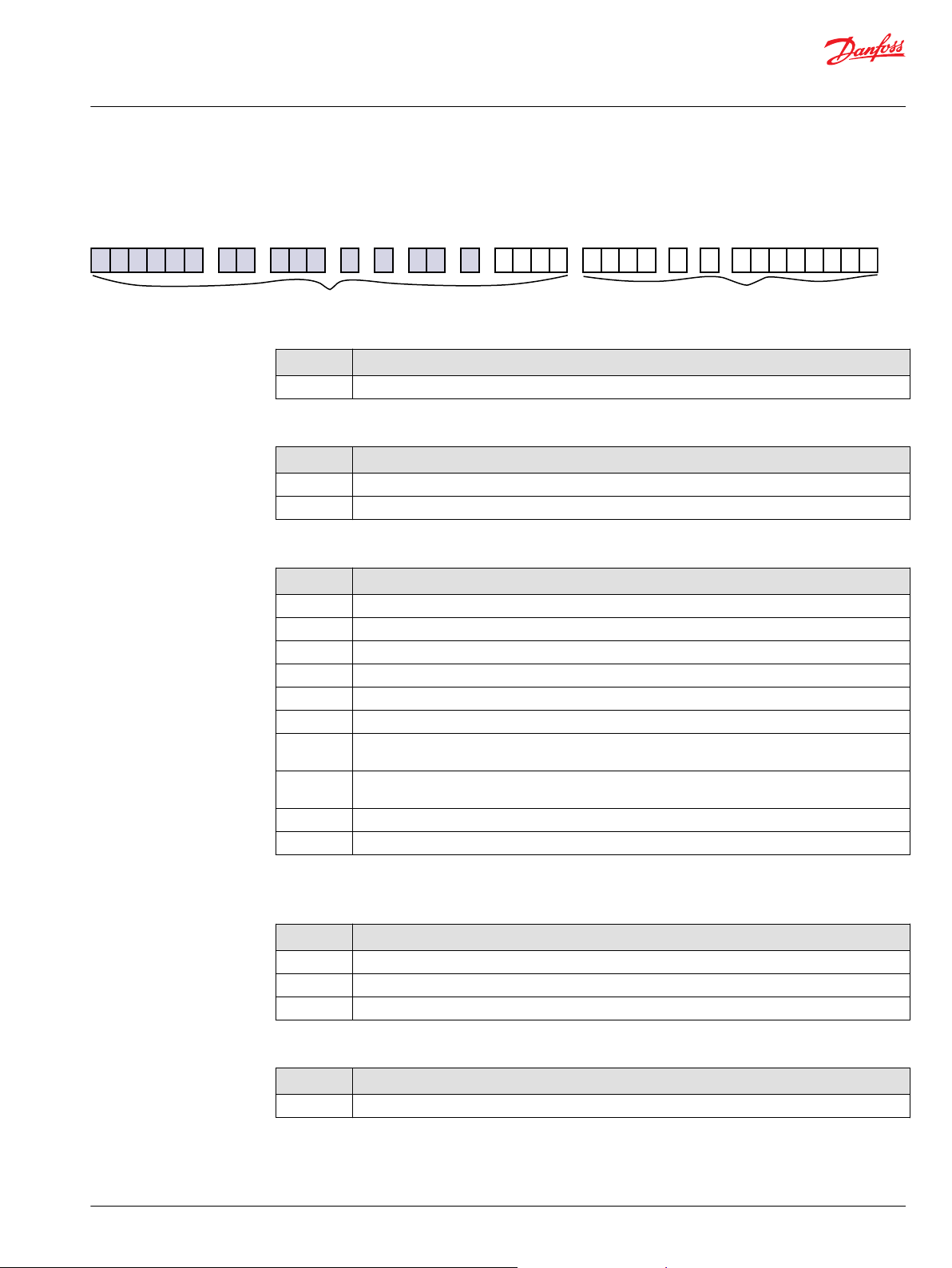

Base Grip

A B C D E F G H I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S N L N J 3 3 1 A 0 H 0 R V N N N N N N N N

Technical Information

JS6000 Joystick Base

Product configuration

Base model code

JS6000 product configuration model code example

A—Product series

Code Description

JS6000 Series JS6000 Joystick

B—Operational axis options

Code Description

XY Bi-directional: X and Y axis

NY Uni-directional: Y axis only (required for friction-holding)

C—Shaft position sensing and output options

Code Description

PRR Potentiometer: single output per axis; Vo = 10 to 90% of Vs; ±1.5° neutral threshold

PQQ Potentiometer: single output per axis; Vo = 25 to 75% of Vs; ±1.5° neutral threshold

PSS Potentiometer: single output per axis; Vo = 10 to 90% of Vs; ±5° neutral threshold

PTT Potentiometer: single output per axis; Vo = 25 to 75% of Vs; ±5° neutral threshold

PUU Potentiometer: dual output per axis; Vo = 10 to 90% of Vs; ±1.5° neutral threshold

HMM Hall effect: dual sensors per axis; Vs = 5 VDC; Vo = 0.5 to 4.5 V

CAN

*

CANopen*Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CANopen 2.0B J1939 communication, 6 pin connector

CPL Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CAN 2.0B communication, 18 pin connector

PWM Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; high current PWM and digital outputs

*

See H1 electrical interface options on page 19.

Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CAN 2.0B J1939 communication, 6 pin connector

DC

D—Centering spring options

Code Description

H Heavy force

M Medium force

F Friction-hold (position maintained, center detent)

E—Gate pattern options

Code Description

S Square, full output at 45 degree

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 7

Technical Information

JS6000 Joystick Base

Product configuration

F—Mechanical options

Code Description

NL No mechanical option; spring return to center only

FB Friction-held in Y axis; no X axis; center detent; 1.25 Nm [0.92 lb•ft] friction-hold force; 2.5 Nm [1.66 lb•ft]

breakout force

FC Friction-held in Y axis; no X axis; center detent; 1.25 Nm [0.92 lb•ft] friction-hold force; 3.25 Nm [2.40

lb•ft] breakout force

HC Friction-held in Y axis; no X axis; center detent; 2.25 Nm [1.66 lb•ft] friction-hold force; 4.0 Nm [2.95 lb•ft]

breakout force

G—Direction (microswitch) options

Code Description

N No switches

Y Microswitches installed

8 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

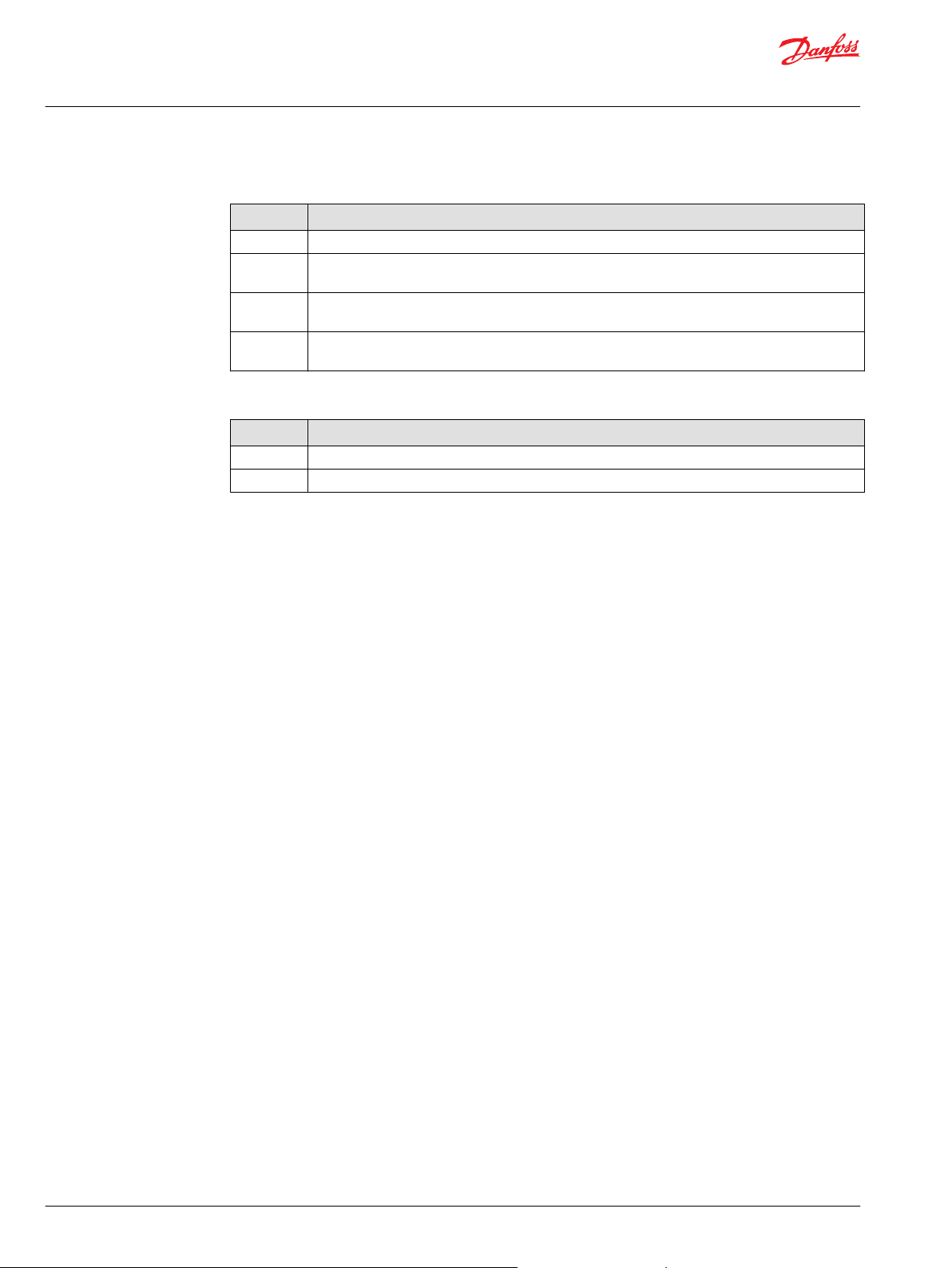

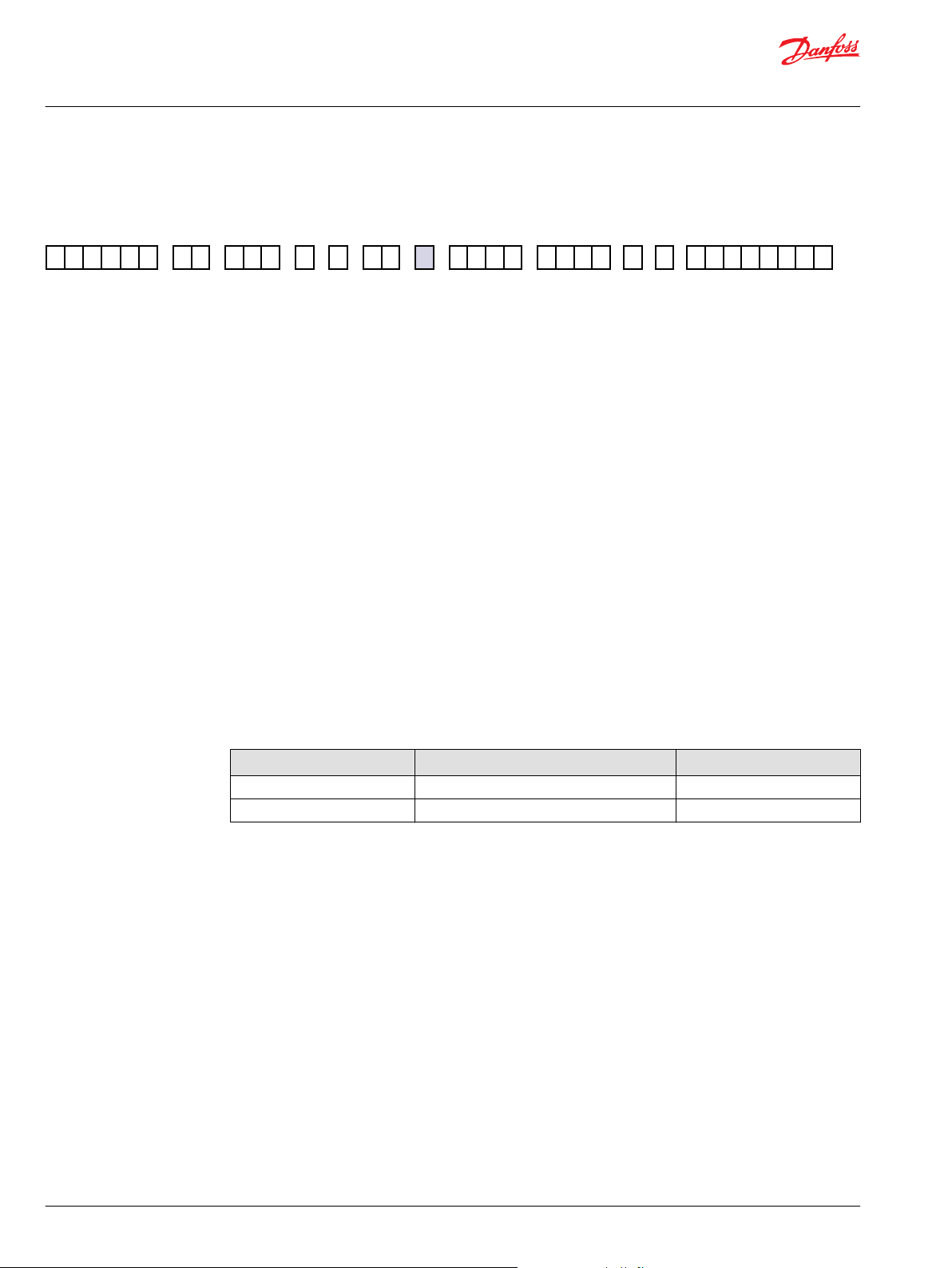

A B C D E F G H I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S N L N J 3 3 1 A 0 H 0 R V N N N N N N N N

1 2 3 4

Technical Information

JS6000 Joystick Base

Product configuration

Grip model code

JS6000 product configuration model code example

H1—Electrical interface options

Code Description

S Analog (DC voltage output)

J CAN, SAE J1939 protocol

W PWM output

P CANopen protocol (default: 125 Kbit band rate)

H2, 3—CAN source address*

Code Description

NN None—use with analog outputs when H1 = S

33 Source address = 0x 33 (use this source address with PWM outputs.)

34 Source address = 0x 34

35 Source address = 0x 35

36 Source address = 0x 36

*Consult the factory if additional source addresses are required.

H4—Joystick output type

Code Description

N None—use with analog and PWM outputs

1 CAN full scale output = 1000 counts

I, J, K, L, M, N, O, P, Q, R, S—Grip options

JS1000, JS6000 Joystick Grips Technical Information, 520L0872 provides information required to configure

the JS6000 joystick grip.

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 9

B

J S 6 0 0 0

+Y Axis

-Y Axis

+Y Axis

Orientation Mark

(lift boot)

-X Axis

-Y Axis

2456B

+X Axis

Technical Information

JS6000 Joystick Base

Model code details

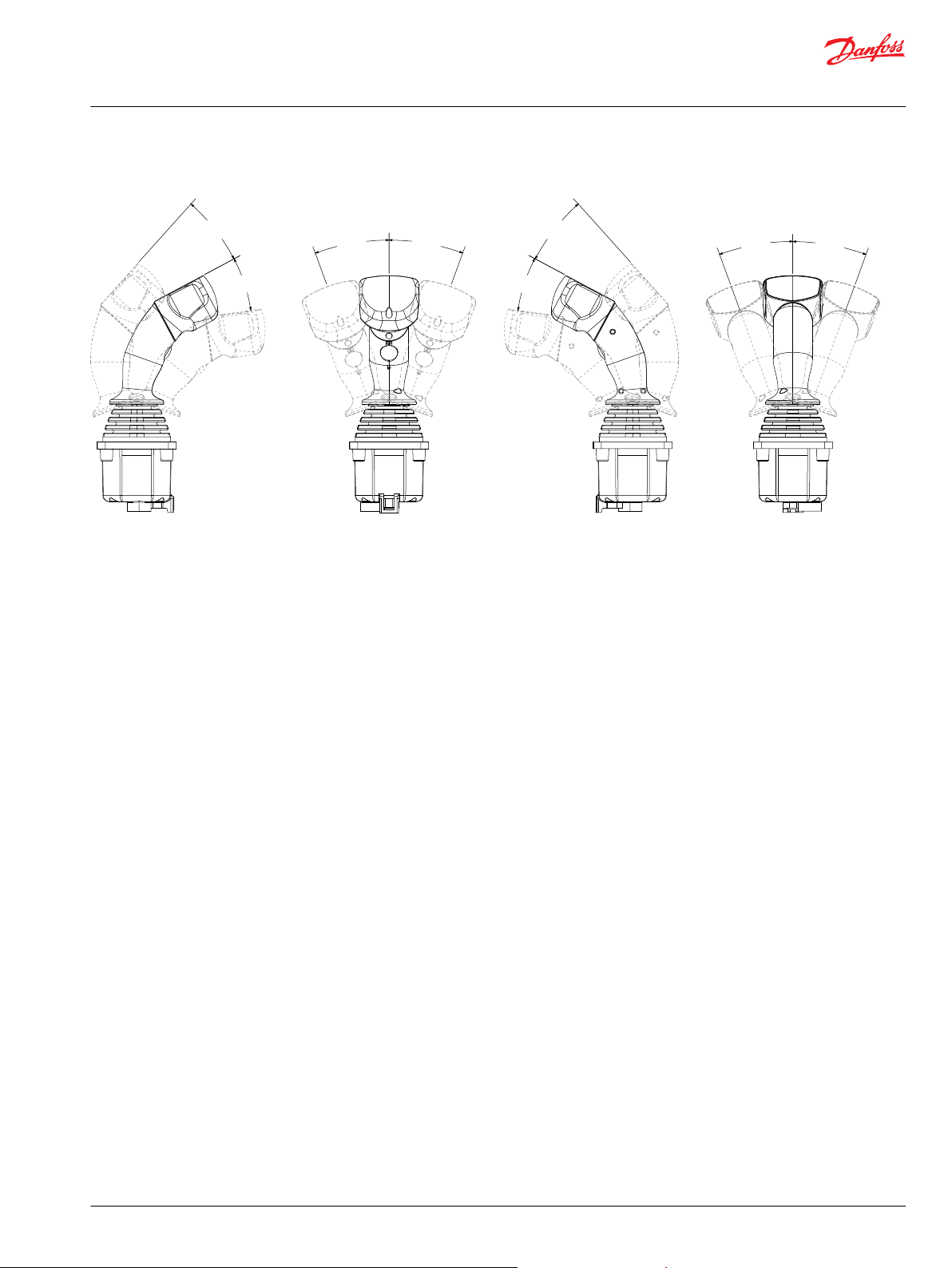

Code B: Single or dual axis options

JS6000 product configuration model code B

Code B designates the number of operational axes.

Single Axis Base—NY with friction hold option in the configuration code

Dual Axis Base—XY in the configuration code

10 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

20° ± 0°

20° ± 0°

20° ± 0° 20° ± 0°

20° ± 0°

20° ± 0°20° ± 0°

20° ± 0°

P200 001

Technical Information

JS6000 Joystick Base

Model code details

X and Y Operation (or movement).

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 11

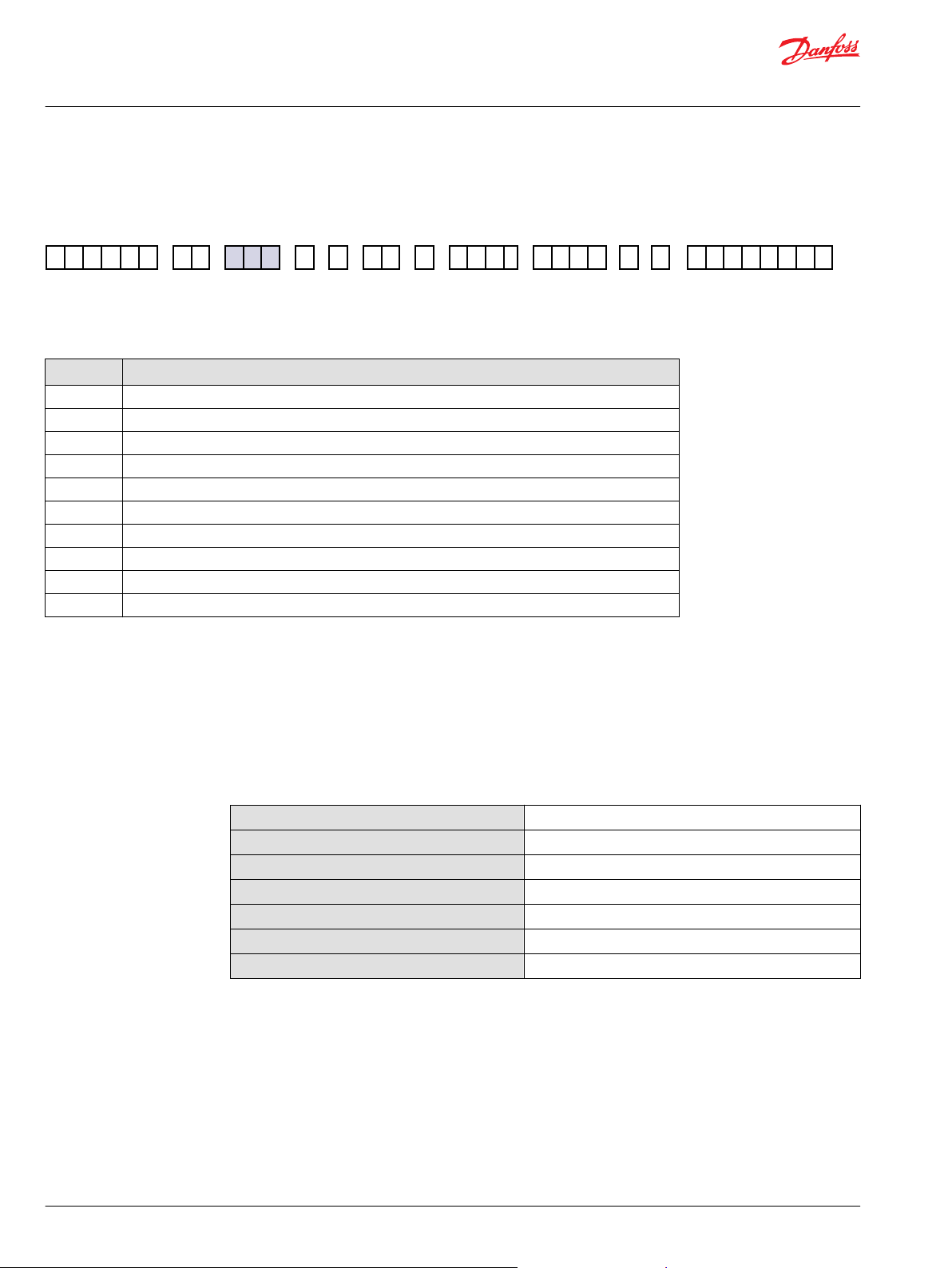

C

J S 6 0 0 0 X Y P R R

Technical Information

JS6000 Joystick Base

Model code details

Code C: Shaft sensor and output options

JS6000 product configuration model code C

Code C designates the shaft sensing technology; potentiometer or Hall effect; and the electrical output

characteristics of the joystick base.

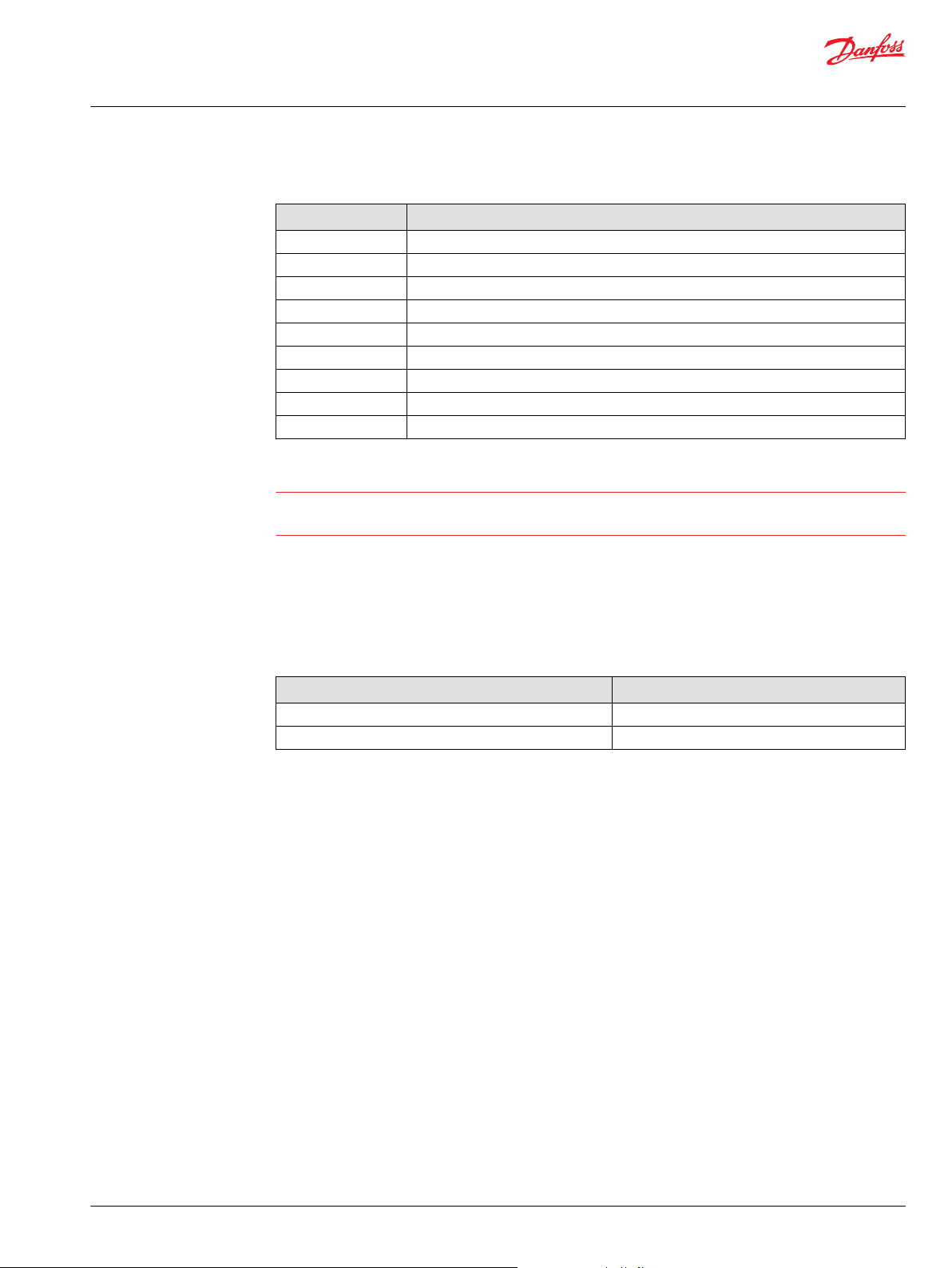

C—Shaft position sensing and output options

Code Description

PRR

PQQ

PSS

PTT

PUU

HMM

*

CAN

CANopen

CPL

PWM

*

See H1 electrical interface options on page 19.

Potentiometer: single output per axis; Vo = 10 to 90% of Vs; ±1.5° neutral threshold

Potentiometer: single output per axis; Vo = 25 to 75% of Vs; ±1.5° neutral threshold

Potentiometer: single output per axis; Vo = 10 to 90% of Vs; ±5° neutral threshold

Potentiometer: single output per axis; Vo = 25 to 75% of Vs; ±5° neutral threshold

Potentiometer: dual output per axis; Vo = 10 to 90% of Vs; ±1.5° neutral threshold

Hall effect: dual sensors per axis; Vs = 5 VDC; Vo = 0.5 to 4.5 V

Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CAN 2.0B J1939 communication, 6 pin connector

*

Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CANopen 2.0B J1939 communication, 6 pin connector

Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; CAN 2.0B communication, 18 pin connector

Hall effect: dual sensors per axis; Vs = 9 to 36 VDC; high current PWM and digital outputs

DC

Potentiometer sensor

The potentiometer sensor electrical connections are made via a 16 pin AMP 040 series MULTILOCK

connector mounted on the base of the unit.

Potentiometer outputs are ratiometric. The output value is dependent on the supply voltage. When the

joystick handle returns to center, the output will be between 48% and 52% of supply voltage (Vs).

Potentiometer sensor specifications

Minimum load impedance

Maximum wiper current

Supply voltage

Center tap/switch alignment

Potentiometer electrical angle

Center tap angle

Insulation resistance at 50 Vdc

1 MΩ recommended

5 mA

> 36 Vdc

Within 0.5º

± 18º

± 2.5º

> 50 MΩ

Center tap

A center tap is standard on all potentiometer tracks, where 50% of the supply voltage can be supplied to

force the sensor voltage to this known reference. When the center tap is not connected there will be a

center dead band (where the voltage output does not change on initial deflection) and the output

voltage will be between 48 and 52% of the supply voltage.

12 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

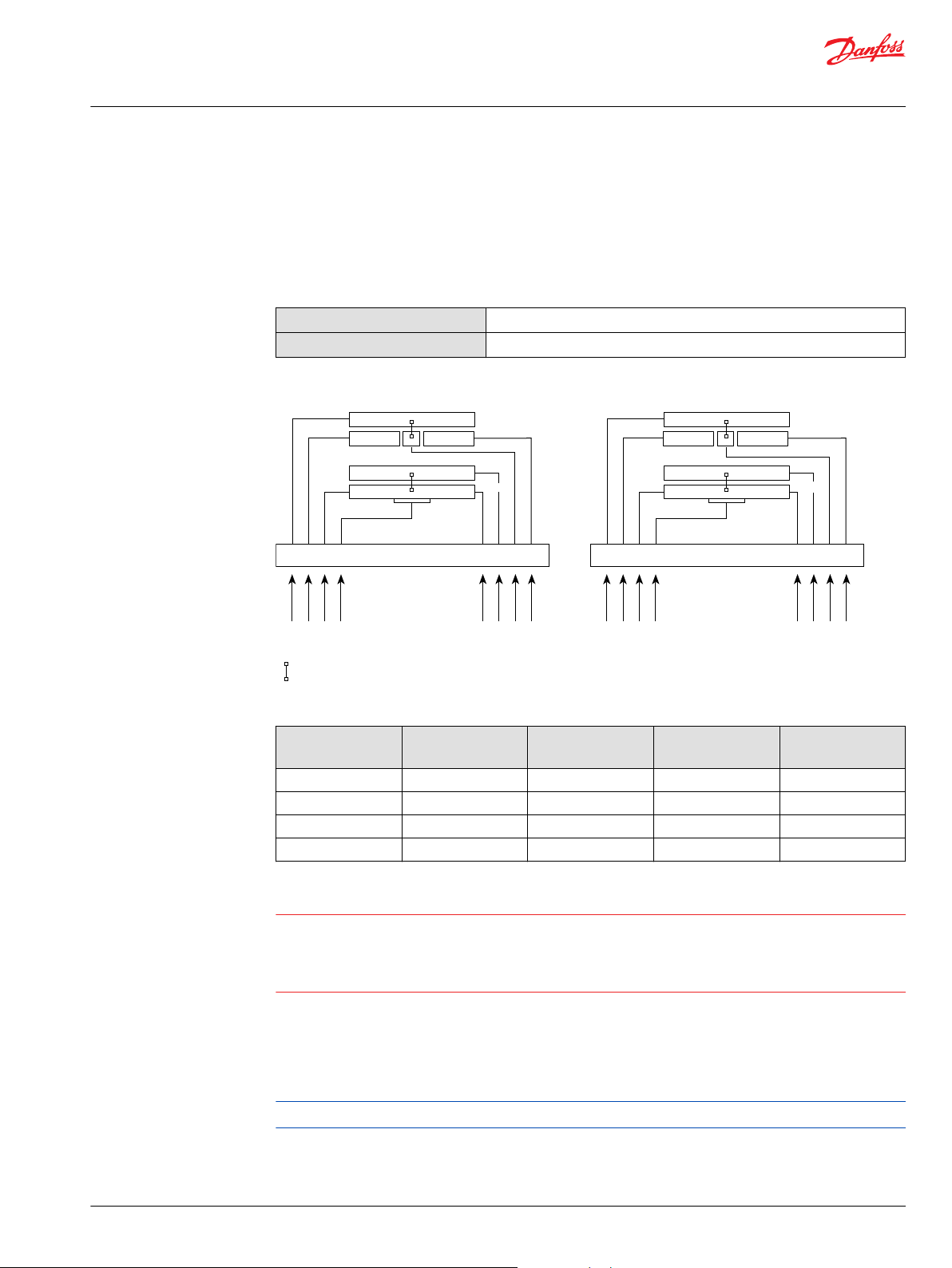

16 Pin Connector

13 14 9 12 11 10 16 1

Back

Handle Direction Switch

Center Tap

Forward

16 Pin Connector

7 8 3 6 5 4 2 15

Left

Center Tap

– Wiper Symbol

Pot

Right

Handle Direction Switch

Y-axis Pin Numbering

Pot

X-axis Pin Numbering

W

Technical Information

JS6000 Joystick Base

Model code details

Directional potentiometer switches

Potentiometer tracks have directional and normally closed (center on) position switches that operate at

the angles shown in the table below. Switch outputs are independent of the proportional potentiometer

elements on each axis and can be terminated by the customer to provide directional or center on/off

data to the control system.

Directional potentiometer switches specifications

Maximum load current

Maximum supply voltage

200 mA resistive

> 36 Vdc

Directional potentiometer switch circuit diagram

Potentiometer track outputs

Minimum output

Voltage (% Vs)

10 ± 2 90 ± 2 ±1.5º 1.6 to 2.4 R

25 ± 2 75 ± 2 ±1.5º 2.2 to 3.6 Q

10 ± 2 90 ± 2 ±5º 1.6 to 2.4 S

25 ± 2 75 ± 2 ±5º 2.2 to 3.6 T

Maximum output

Voltage (% Vs)

Switch track angle Resistance kΩ Order code

Warning

Potential uncommanded machine movement. When a JS6000 joystick with the 25% to 75%

potentiometer output option (designated Q or T) is used to directly drive a PVG valve, if the power or

ground side of the joystick is lost, there is a risk of the valve going full on in one direction or the other. To

avoid the possibility of unintended machine motion, the PVG valve must have Active Fault Monitoring.

Dual potentiometer outputs per axis

Dual potentiometer outputs are available that feature independent power inputs and sensor outputs.

The secondary potentiometer output connections are via an 8 pin AMP® connector. Secondary

potentiometer outputs do not provide secondary directional and center switches.

Hall sensing and dual potentiometer outputs are not available together.

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 13

Technical Information

JS6000 Joystick Base

Model code details

Dual potentiometer track selection

Minimum output

Voltage (% Vs)

10 ± 2 90 ± 2 ±1.5º 1.6 to 2.4 U

Hall effect sensor

The Hall effect sensor option includes dual sensors per axis. The sensors can be supplied from two

separate regulated 5 V supplies for a higher degree of redundancy, or can be supplied from a single

regulated 5 V supply.

Hall effect sensing electrical connections are made via a 12 pin AMP® 040 series MULTILOCK connector on

the base of the unit.

JS6000 Hall effect sensors are affected by temperature. Output values change temporarily by 2.6% and

permanently by 0.6% when subjected to a -40°C (-40°F) to 80°C (176°F) operating temperature range

cycle.

Hall effect sensor specifications

Supply voltage (Vs) 5 Vdc regulated

Minimum output voltage 10% ± 4% Vs

Center voltage 50% ± 2% Vs

Maximum output voltage 90% ± 4% Vs

Maximum output

Voltage (% Vs)

Switch track angle Resistance kΩ Order code

Controller Area Network (CAN) output

Three versions of JS6000 CAN joysticks are available:

•

A grip

•

MG grip

•

HKN grip

CAN (configuration model code CAN)

CAN 2.0bB J1939 protocol and CANopen 2.0B J1939 protocol (reference Code H: Electrical interface options

on page 19 product configuration model code, under H1 electrical interface options on page 19).

CAN+ (configuration model code CPL)

CAN+ output broadcasts joystick shaft position, grip switch states, grip proportional rocker position and

the state and value of up to 11 digital (DIN) or 7 digital (DIN) and 4 analog (AIN) inputs from sources

external to the joystick. The CAN+ option joystick base has an 18 pin DEUTSCH connector.

Pulse Width Modulated (PWM) output

One version of the JS6000 PWM joystick is available.

PWM (configuration model code PWM)

The PWM version of JS6000 joystick has two bi-directional PWM channels and six digital outputs. The

PWM option joystick base has an 18 pin DEUTSCH connector.

14 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

D

J S 6 0 0 0 X Y H M M H

W

E

J S 6 0 0 0 X Y H M M H S

Square

Technical Information

JS6000 Joystick Base

Model code details

Code D: Centering return spring options

JS6000 product configuration model code D

Code D designates centering spring force options.

The center spring returns the joystick to its center position when released by the operator and provides

the physical resistance to movement when the joystick is operated. Two levels of spring force are

available: heavy and medium. Spring force is selected by choosing a letter from the order character

column of the following table.

Warning

Potential uncommanded machine movement. The spring choice affects the joystick’s ability to resist

system vibrations. Each of the following springs give a different product harmonic range. This, in

combination with critical mass differences as a result of grip choice, results in each system (joystick and

machine) having different vibration characteristics. With this in mind, please consider the vibration range

of the system and determine whether any resonance exists in the joystick. Resonance causes dither and

could cause the joystick to leave neutral.

Centering spring selection

Spring option Breakout force on axis Force at full deflection Order code

Heavy duty spring 12 to 19 N [2.7 to 4.3 lbf] 31 to 47 N [6.7 to 10.6 lbf] H

Medium duty spring 6 to 8.5 N [1.3 to 1.9 lbf] 15 to 23 N [3.4 to 5.2 lbf] M

The above forces are measured 55 mm (2.17 in) from the joystick mounting surface and are perpendicular

to the shaft.

Code E: Hardware configuration

JS6000 product configuration model code E

Code E designates hardware configuration.

JS6000 joysticks have a square gate pattern as the standard configuration. This is designated as S in the

configuration code and includes a standard label.

Gate selection

Gate option Characteristics Order code

± 20º mechanical travel (on axis) S

The square gate offers full X and Y outputs when the joystick is moved to the corner positions.

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 15

F

J S 6 0 0 0 X Y H M M H S N L

Torque (N

.

m)

Angle (°)

3.0

2.5

4.5

-4.5

4.0

-4.0

-5.0

5.0

3.5

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

10 2 3 4 5 6 7 8 99 8 7 6 5 4 3 2 1 10 11 12 13 14 15 16 17 18 19 20 2121 20 19 18 17 16 15 14 13 12 11 10

2458

Technical Information

JS6000 Joystick Base

Model code details

Code F: Mechanical options

JS6000 product configuration model code F

Code F designates joystick mechanical options.

JS6000 joysticks are available with a friction-hold option. With this option, the joystick handle position

will remain in a position set by the operator and will not automatically return to center. This option is only

available in a single (Y) axis configuration. Four levels of friction/breakout from center force are available.

Friction-hold selection

Friction-hold torque Center detent breakout torque Order code

No mechanical options NL

1.25 Nm (0.92 lb•ft) 2.50 Nm (1.84 lb•ft) FB

1.25 Nm (0.92 lb•ft) 3.25 Nm (2.40 lb•ft) FC

2.25 Nm (1.66 lb•ft) 4.00 Nm (2.95 lb•ft) HC

JS6000 FB option

16 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Angle (°)

3.0

2.5

4.5

-4.5

4.0

-4.0

-5.0

5.0

3.5

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

10 2 3 4 5 6 7 8 99 8 7 6 5 4 3 2 1 10 11 12 13 14 15 16 17 18 19 20 2121 20 19 18 17 16 15 14 13 12 11 10

2459

Torque (N

.

m)

Angle (°)

3.0

2.5

4.5

-4.5

4.0

-4.0

-5.0

5.0

3.5

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

10 2 3 4 5 6 7 8 99 8 7 6 5 4 3 2 1 10 11 12 13 14 15 16 17 18 19 20 2121 20 19 18 17 16 15 14 13 12 11 10

2460

Torque (N

.

m)

Technical Information

JS6000 Joystick Base

Model code details

JS6000 FC option

JS6000 HC option

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 17

G

J S 6 0 0 0 X Y H M M H S N L N

Technical Information

JS6000 Joystick Base

Model code details

Code G: Microswitch option

JS6000 product configuration model code G

Code G designates joystick microswitch options.

Optional microswitch outputs can replace the low current directional potentiometer switches on the

potentiometer tracks. Microswitch outputs are on the 16 pin connector (potentiometer option). There are

two switches per axis and the microswitches are configured as normally open, with the handle centered.

The microswitch joystick shaft direction indication feature is not available with the dual potentiometer

sensing option.

Optional microswitches are also available with the Hall effect sensing option. Microswitch outputs, in this

case, are on the 8 pin connector.

Optional microswitches are only available on analog output joysticks with the spring-return-to-center

mechanical operation.

Optional microswitches are not available on BMM, CAN, CPL, or PWM output joysticks.

The Honeywell® microswitch electrical details follow. These details are taken directly from the switch

manufacturer’s specification. Further information is available from http://www.honeywell.com.

Microswitch operates at a mechanical deflection of 2 to 5 degrees in any direction

•

Contact ratings are 3 A at 125 Vac, 2 A at 30 Vdc

•

Life rating is 100,000 cycles minimum at 1 A 12 Vdc

•

Temperature range is -25°C to 85°C [-13°F to 185°F] (when fitted, the joystick temperature is limited to

•

this range)

With the microswitch option, choose the letter from the order character column of the following table.

The choice is either Y for microswitch N for none.

Microswitch option

Microswitch option Mechanical function description Order code

Without microswitch No switches N

Microswitch Microswitches installed Y

18 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

H

J S 6 0 0 0 X Y H M M H S N L N J 3 3 1

1 2 3 4

Technical Information

JS6000 Joystick Base

Model code details

Code H: Electrical interface options

JS6000 product configuration model code H

Code H designates joystick output options.

JS6000 joystick base signal outputs are available in analog voltage, PWM, or Controller Area Network

(CAN) versions.

Analog

The analog output option gives a direct voltage output from the joystick’s shaft sensors, position

switches and grip functions. No signal conditioning is performed. The PWM output option provides a

conditioned output from the joystick’s shaft sensors, position switches, and grip functions. Output

characteristics are configured using the PLUS+1® Service Tool.

CAN 2.0B, J1939 protocol

The CAN J1939 output option provides conditioned joystick output information in 2.0B, J1039 message

protocol.

CANopen 2.0B, J1939 protocol

The CANopen output option provides conditioned joystick output information in 2.0B, CANopen

message protocol.

PWM

The PWM output option provides high voltage outputs for directly driving valves. The CAN port is active

on the PWM version, but it is not designed to be used on a CAN bus in a system with other devices. The

CAN bus is only to be used for configuration and data logging while connected to a PC running the PLUS

+1® Service Tool.

H1 electrical interface options

H1 electrical interface options

Code Description

S Analog voltage

J CAN 2.0B, J1939 protocol

P CAN 2.0B, CANopen protocol

W PWM

H2, 3 joystick location/CAN source address

H2, 3 joystick location/CAN source address*

Code Description

NN None—use when H1 = S

33 Source address = 0x 33

34 Source address = 0x 34

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 19

I J K L M N O P Q R S

J S 6 0 0 0 X Y H M M H S N L N W 3 3 1 A 0 H 0 R V N N N N N N N N

1 2 3 4

Technical Information

JS6000 Joystick Base

Model code details

H2, 3 joystick location/CAN source address* (continued)

Code Description

35 Source address = 0x 35

36 Source address = 0x 36

* Source addresses are factory set. Additional addresses are available upon request.

H4 CAN proportional output

H4 CAN proportional output

Code Description

N None (if Analog or PWM)

1 CAN full scale output = 1000 counts

Code I, J, K, L: Grip options

JS6000 product configuration model code I

The Danfoss manual JS1000, JS6000 Joystick Grips Technical Information, 520L0872 provides instructions

and information required to specify JS6000 joystick grip options.

20 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

JS6000 CAN messages

CAN option

CAN+ option

Joysticks CAN J1939 protocol option, designated as model code CAN, broadcasts two J1939 messages to

communicate device information: Basic Joystick Message 1 (BJM1) and Extended Joystick Message 1

(EJM1). The two CAN options available are:

CAN 2.0B, J1939 protocol option

•

CAN 2.0B, CANopen protocol option

•

Joysticks with the CAN+ option, designated as model code CPL, allow eleven external inputs that are not

associated with the joystick shaft position or grip functions to be read by the joystick’s microcontroller

and broadcast by the joystick’s CAN transceiver.

CAN+ joysticks broadcast four CAN messages. Basic Joystick Message 1 and Extended Joystick Message 1

have the same data content as the CAN option, above. External digital input (DIN) and analog input (AIN)

input information is contained in Basic Joystick Message 3 and Extended Joystick Message 3. The data

field format for Basic Joystick Message 3 and Extended Joystick Message 3 is the same as that for Basic

Joystick Message 1 and Extended Joystick Message 1.

CAN+ external inputs

Analog inputs (AIN)

•

All external analog inputs must be powered by the joystick's 5 Vdc regulated power supply

(connector pin 8).

•

No calibration, error checking or software filtering is performed on analog data received from

external inputs.

•

External analog data is scaled in raw form from 0 to 1000 counts.

•

Data associated with CAN+ pins 9, 10,11 and 12 is broadcast in both Basic Joystick Message 3 and

Extended Joystick Message 3. For analog inputs use the appropriate data bytes in Basic Joystick

Message 3 or Extended Joystick Message 3.

Digital inputs (DIN)

External inputs are pull-down and must be powered by a voltage source <32 Vdc. Low state is

•

interpreted as <0.97 Vdc. High state is interpreted as >4.00 Vdc.

Data associated with CAN+ pins 9, 10, 11, 12 is broadcast in both BJM3 and EJM3. For digital inputs

•

use the appropriate data bytes in BJM3.

See Danfoss publication JS6000 PWM Service Tool User Manual, 11060942 for technical details on the

JS6000 PWM Joystick Base and complete details regarding the use of the PLUS+1® Service Tool interface

for troubleshooting and configuring the device.

Obtain free PLUS+1® Service Tool software license and download the P1D file at:

http://www.powersolutions.danfoss.com/products/PLUS-1-GUIDE/GUIDE-service-tool-software-and-license

External input pin assignment/J1939 basic joystick message 3 designation

CAN+ connector

pin number

7 5 Vdc sensor power (0 = 0 Vdc, 1000 = 5.25 Vdc) X-Axis Position

9 External input pin 9 AIN. Use if pin 9 data is required in analog

9 External input pin 9 DIN status. Use if pin 9 data is required in

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 21

CAN+ function Corresponding J1939 BJM3

data field designation

Y-Axis Position

form (0 = 0 Vdc, 1000 = 5.00 Vdc)

Button 1

digital form

W

Technical Information

JS6000 Joystick Base

JS6000 CAN messages

External input pin assignment/J1939 basic joystick message 3 designation (continued)

CAN+ connector

pin number

10 External input pin 10 DIN status. Use if pin 10 data is required

11 External input pin 11 DIN status. Use if pin 11 data is required

12 External input pin 12 DIN status. Use if pin 12 data is required

13 External input pin 13 status Button 5

14 External input pin 14 status Button 6

15 External input pin 15 status Button 7

16 External input pin 16 status Button 8

17 External input pin 17 status Button 9

18 External input pin 18 status Button 10

6 External input pin 6 status (see following Warning statement) Button 11

CAN+ function Corresponding J1939 BJM3

data field designation

Button 2

in digital form

Button 3

in digital form

Button 4

in digital form

Warning

Potential uncommanded machine movement. JS6000 CAN+ Joysticks fitted with an operator present

switch have an internal connection between the operator present switch and pin 6. The operator present

switch status is broadcast in BJM1 and BJM3. Unintended machine motion may result if an external DIN is

applied to pin 6 with a joystick that has a grip with operator present switch.

External input pin assignment/J1939 extended joystick message 3 designation

CAN+ connector

pin number

10 External input pin 10 AIN. Use if pin 10 data is required in

11 External input pin 11 AIN. Use if pin 11 data is required in

12 External input pin 12 AIN. Use if pin 12 data is required in

CAN+ function Corresponding J1939 EJM3

data field designation

Grip X-Axis

analog form (0 = 0 Vdc, 1000 = 5.00 Vdc)

Grip Y-Axis

analog form (0 = 0 Vdc, 1000 = 5.00 Vdc)

Grip Theta-Axis

analog form (0 = 0 Vdc, 1000 = 5.00 Vdc)

22 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

CAN message protocol

SAE J1939 CAN message specification

SAE J1939 basic joystick message

The JS6000 joystick uses the SAE J1939 basic joystick message to transfer information about the

measured status of the X and Y axes of a joystick, the state of switches on the joystick grip, and the state

of external-to-the-joystick digital inputs.

Basic joystick message structure

Basic

message

number

1 3 64982 FDD6 253 FD 214 D6

3 3 FDDA FD DA

*

Depends on position specified in master model code. See H2, 3 joystick location/CAN source address on page 19.

•

Message transmission rate: 20 ms

•

CAN bus baud rate: 250kbps

The resulting SAE J1939 basic joystick message PGN on the CAN bus is:

0xCFDD6 _*_ or 0xCFDDA _*_

* = joystick source address (hex)

Priority

Basic PGN

Dec hex Dec hex Dec hex Dec hex

PDU format PDU specific Source

address

* *

* *

Data field

8 bytes

8 bytes

Data field

The data field contains the joystick’s output information. SAE J1939 data fields contain 8 bytes of data.

Information in the data field

Byte#

Bit#

0 1 2 and so on

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

Basic joystick message data field descriptions

Basic joystick message parameters and data field locations

Start position (byte/bit) Length

(bits)

0/1 2 Joystick X-axis neutral position status

0/3 2 Joystick X-axis lever left negative position status

0/5 2 Joystick X-axis lever right positive position status

0/7 through 1/1-8 10 Joystick X-axis position (Byte 0 Bit 7 is LSB. Byte 1 Bit 8 is MSB)

2/1 2 Joystick Y-axis neutral position status

2/3 2 Joystick Y-axis lever back negative position

2/5 2 Joystick Y-axis lever forward positive position

2/7 through 3/1-8 10 Joystick Y-axis position (Byte 2 Bit 7 is LSB. Byte 3 Bit 8 is MSB)

4/5 2 Joystick Y-axis detent position status

4/7 2 Joystick X-axis detent position status

5/1 2 Grip button 4 pressed status

5/3 2 Grip button 3 pressed status

5/5 2 Grip button 2 pressed status

5/7 2 Grip button 1 pressed status

Parameter name

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 23

Technical Information

JS6000 Joystick Base

CAN message protocol

Basic joystick message parameters and data field locations (continued)

Start position (byte/bit) Length

(bits)

6/1 2 Grip button 8 pressed status

6/3 2 Grip button 7 pressed status

6/5 2 Grip button 6 pressed status

6/7 2 Grip button 5 pressed status

7/1 2 Grip button 12 pressed status

7/3 2 Grip button 11 pressed status

7/5 2 Grip button 10 presses status

7/7 2 Grip button 9 pressed status

Parameter name

Button naming convention: Refer to A grip button and rocker CAN naming conventions on page 29, for

button and proportional input definitions.

Data field examples

Byte

Bit

*

Least Significant Bit

0

8 7 6 5 4 3 2 1

The 2 LSB* of X-axis

position

X-axis lever right positive

status

X-axis lever left negative

position status

X-axis neutral position

status

Byte

Bit

†

Most Significant Bit

Byte

Bit

1

8 7 6 5 4 3 2 1

MSB† X-axis position

2

8 7 6 5 4 3 2 1

The 2 LSB* of Y-axis

position status

X-axis lever forward

positive status

Y-axis lever back negative

position status

Y-axis neutral position

status

Joystick X-axis neutral position status

Reports when the current joystick position is in the neutral position for the X-axis of travel.

Information in the data field

Bit status Remarks

00 Not in neutral position

01 In neutral position

10 Error indicator

11 Not available

Joystick X-axis handle left negative position status

Reports when the current joystick position is on the negative travel side (back, left, counterclockwise,

down) relative to the neutral position for the X-axis.

24 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

W

Technical Information

JS6000 Joystick Base

CAN message protocol

Information in the data field

Bit status Remarks

00 Not on negative side of neutral

01 On negative side of neutral

10 Error indicator

11 Not available

Joystick X-axis handle right positive position status

Reports when the current joystick position is on the positive travel side (forward, right, clockwise, up)

relative to the neutral position for the X-axis.

Information in the data field

Bit status Remarks

00 Not on positive side of neutral

01 On positive side of neutral

10 Error indicator

11 Not available

Joystick X-axis position status

The position of the joystick in the relative motion of travel from the neutral position. The position value of

0 is always neutral. The output range of the joystick handle at the end of travel is factory set according to

the option specified in the electrical interface options section of the master model code.

The master model code specifies that the full-scale output at the end of each linear zone will be 1000

counts.

Warning

Potential uncommanded machine movement. Per the SAE J1939-71 standard, if the JS6000 joystick

internal diagnostics detect a shaft position measurement error, the joystick output will be set to a value

of 1022 counts regardless of shaft position. Application software should be written to recognize this error

condition to avoid the possibility of unintended machine motion.

Per the SAE J1939-71 standard, if a specific joystick axis is not available, the basic joystick message for the

unavailable axis will indicate an output value of 1023 counts. Application software should be written to

recognize this condition to avoid the possibility of unintended machine motion.

Joystick Y-axis neutral position status

Reports when the current joystick position is in the neutral position for the Y-axis of travel.

Information in the data field

Bit status Remarks

00 Not in neutral position

01 In neutral position

10 Error indicator

11 Not available

Joystick Y-axis handle back negative position status

Reports when the current joystick position is on the negative travel side (back, left, counterclockwise,

down) relative to the neutral position for the Y-axis.

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 25

W

Technical Information

JS6000 Joystick Base

CAN message protocol

Information in the data field

Bit status Remarks

00 Not on negative side of neutral

01 On negative side of neutral

10 Error indicator

11 Not available

Joystick Y-axis handle forward positive position status

Reports when the current joystick position is on the positive travel side (forward, right, clockwise, up)

relative to the neutral position for the Y-axis.

Information in the data field

Bit status Remarks

00 Not on positive side of neutral

01 On positive side of neutral

10 Error indicator

11 Not available

Joystick Y-axis position status

The position of the joystick in the relative motion of travel from the neutral position. The position value of

0 is always neutral. The output range of the joystick handle at the end of travel is factory set according to

the option specified in the electrical interface options section of the master model code.

The master model code specifies that the full-scale output at the end of each linear zone will be 1000

counts.

Warning

Potential uncommanded machine movement. Per the SAE J1939-71 standard, if the JS6000 joystick

internal diagnostics detect a shaft position measurement error, the joystick output will be set to a value

of 1022 counts regardless of shaft position. Application software should be written to recognize this error

condition to avoid the possibility of unintended machine motion.

Per the SAE J1939-71 standard, if a specific joystick axis is not available, the basic joystick message for the

unavailable axis will indicate an output value of 1023 counts. Application software should be written to

recognize this condition to avoid the possibility of unintended machine motion.

Joystick button 1-8 pressed status

Bit status Remarks

00 Button not pressed

01 Button pressed

10 Error indicator

11 Not available (no button installed)

SAE J1939 extended joystick message

The JS6000 joystick uses the SAE J1939 extended joystick message to transfer information about the

measured status of up to 3 additional proportional input functions on the joystick grip, and external-tothe-joystick analog inputs. The joystick base X and Y-axis information is available in the basic joystick

message. The extended joystick message structure is as follows:

26 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

0xCFDD7 __ __ or 0xCFDDB __ __

* *

Technical Information

JS6000 Joystick Base

CAN message protocol

Extended joystick message structure

Extended

message

number

1 3 64983 FDD7 253 FD 215 D7

3 FDDB FD DB

*

Depends on position specified in master model code. See H2, 3 joystick location/CAN source address on page 19.

Message transmission rate: 20 ms

•

CAN bus baud rate: 250kbps

•

Priority Base PGN PDU format PDU specific Source address Data field

Dec hex Dec hex Dec hex Dec hex

* *

*

8 bytes

8 bytes

The resulting SAE J1939 basic joystick message PGN on the CAN bus is:

* = joystick source address (hex)

Extended joystick message parameters and data field locations

Start position (byte/bit) Length

(bits)

0/1 2 Grip X-axis neutral position status

0/3 2 Grip X-axis lever left negative position status

0/5 2 Grip X-axis lever right positive position status

0/7 through 1/1-8 10 Grip X-axis position

2/1 2 Grip Y-axis neutral position status

2/3 2 Grip Y-axis lever back negative position

2/5 2 Grip Y-axis lever forward positive position

2/7 through 3/1-8 10 Grip Y-axis position

6/5 2 Grip Y-axis detent position status-not available

6/7 2 Grip X-axis detent position status-not available

Parameter name

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 27

Data field descriptions and output ranges for extended joystick messages are similar to those for base X

and Y-axis basic joystick messages.

Grip proportional input naming convention

Proportional input location Extended joystick message designation

Horizontal orientation, top Y-axis

Horizontal orientation, bottom X-axis

Vertical orientation, left side X-axis

Vertical orientation, right side Y-axis

Refer to A grip button and rocker CAN naming conventions on page 29 for proportional input naming

conventions.

SAE J1939 error (DM1) messages

SAE J1939 DM1 error messages are supported by JS6000 software.

See the following tables for SPN and FMI information.

Technical Information

JS6000 Joystick Base

CAN message protocol

Failure: Voltage too high

Message Axis SPN FMI

BJM1 X 2660 3

BJM1 Y 2661 3

BJM1 Grip X 2662 3

BJM1 Grip Y 2663 3

BJM1 Grip Theta 2664 3

Failure: Voltage too low

Message Axis SPN FMI

BJM1 X 2660 4

BJM1 Y 2661 4

BJM1 Grip X 2662 4

BJM1 Grip Y 2663 4

BJM1 Grip Theta 2664 4

Failure: Input not calibrated

Message Axis SPN FMI

BJM1 X 2660 13

BJM1 Y 2661 13

BJM1 Grip X 2662 13

BJM1 Grip Y 2663 13

BJM1 Grip Theta 2664 13

Failure: Redundant input failure

Message Axis SPN FMI

BJM1 X 2660 14

BJM1 Y 2661 14

BJM1 Grip X 2662 14

BJM1 Grip Y 2663 14

BJM1 Grip Theta 2664 14

Sensor power fault (CAN+ only)

Message Power fault SPN FMI

Sensor power too high 3509 3

Sensor power too low 3509 4

SAE CANopen protocol information

JS6000 joysticks do not support SAE J1939 dynamic addressing, since the joystick source addresses are

hard-coded (static). However, JS6000 joysticks are compliant with SAE J1939 address claiming protocol

(in the unlikely event another node on the SAE J1939 bus claims an identical source address to the

JS6000, the JS6000 may cease communication on the bus, depending on the message priority of the

other node).

28 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

kwa1392485072935

A2H0

A2HD

A300

A30T

A30D

A30B

A400

A40T

A40D

A40B

2

3

X

2

3

1

4

2

3

1

A0B0

A0H0

A0HD

A100

A10T

A10D

A10B

A3L0

A3LT

A3LD

A3LB

X Y

X

X

1

2

6

1

A1R0

A1RT

A1RD

A1RB

A1L0

A1LT

A1LD

A1LB

A1H0

A1HD

A500

A50T

A50D

A50B

2

1

3 Y

X

X

2

3

1

4

5

A200

A20T

A20D

A20B

A2R0

A2RT

A2RD

A2RB

A2L0

A2LT

A2LD

A2LB

A600

A60T

A60D

A60B

1

2

3

2

3

Y

X

2

3

4

1

4

6

5

A000

A00T

A00D

A00B

A0R0

A0RT

A0RD

A0RB

A0L0

A0LT

A0LD

A0LB

A3R0

A3RT

A3RD

A3RB

Y

X

Y

3

5

4

Technical Information

JS6000 Joystick Base

CAN message protocol

When you want to use CANopen Joystick, go to http://powersolutions.danfoss.com/products/electronic-

components/joysticks/, and click on CANopen EDS to open CANopen Object Dictionary

A grip button and rocker CAN naming conventions

A grip front plate diagram

For CAN and CAN+ output models, include grip configurations: A0BD, A0BB, A0BT.

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 29

Technical Information

JS6000 Joystick Base

CAN message protocol

Top and operator present switch naming conventions

Top and operator present switch state information is broadcast on J1939 Basic Joystick Message 1 (BJM1)

Switch state information

Top switch

Operator present switch

BJM1 button 7

BJM1 button 8

Proportional rocker naming conventions

Grip rocker proportional output information is broadcast on J1939 Extended Joystick Message 1 (EJM1)

using the X and Y axis data bits. See A grip button and rocker CAN naming conventions on page 29 for

proportional rocker output X and Y naming conventions.

Each rocker switch also has two switch states—one for each end of travel. Rocker switch state

information is broadcast on BJM1 concurrently with proportional output information. See A grip button

and rocker CAN naming conventions on page 29 for rocker switch naming conventions.

30 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Switch 1 Position

CAN Grip Button 1

Switch 2 Position

CAN Grip Button 2

Switch 1 Position

CAN Grip Button 1

Operator Present Switch

CAN Grip Button 8

Operator Present Switch

CAN Grip Button 8

Operator Present Switch

CAN Grip Button 8

2461

Technical Information

JS6000 Joystick Base

CAN message protocol

MG grip button CAN naming conventions

MG grip button CAN naming conventions

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 31

Joystick

Mounting

Surface

Friction-held Boot

Spring

Return

Boot

Mating Connector (18 pin)

with Lead Wires Attached

105.6 [4.16]

80.00 [3.15]

"Forward"

Orientation Mark

61 [2.401]

(mounting screw centers)

(4 places)

75.6 [02.98] (maximum)

101.6 [04.0] (maximum)

165 [6.496] (maximum)

Ø3.218/3.2

[0.12669/0.126]

(typical)

Ø11.93/12.00

[0.46968/0.4724]

Ø9.518/9.531

[0.37472/0.37523]

32.0

[ 1.26]

15.0

[0.59]

9.7

[0.382]

61.00 [2.40]

30.50 [1.20]

61.00 [2.40]

30.50 [1.20]

Ø72.50 ± 0.50

Ø2.85 ± 0.020

Ø6.30 ± 0.12

Ø0.249 ± 0.00079

Technical Information

JS6000 Joystick Base

Product installation

Dimensions and installation

Dimensions

millimeter [inches]

The JS6000 is designed to be installed from the panel below, through a 68 mm [2.677 in] diameter hole.

Recommended mounting panel cut-out

32 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

W

C

Technical Information

JS6000 Joystick Base

Product installation

Machine wiring guidelines

Installation

1. Drive mounting screws to a maximum torque of 5 N.m [44.25 lbf.in] when clamped against a 3.0 to

6.0 mm [0.118 to 0.236 in] thick panel.

The joystick flange mounting hole depth is 12.6 mm [0.496 in].

2. For through-hole mounting, drive the screws at a torque of 3.5 N.m [30.98 lbf.in] directly through the

blind cast holes to remove the cast covers.

3. Use fit and seal for fitting and sealing of the joystick into the mounting panel using the screws

supplied.

•

Note the panel material type, thickness, strength and rigidity. Install in a panel with a minimum

thickness of 3.0 to 6.0 mm [0.118 to 0.236 in]. This allows the mounting screws to correctly clamp the

sealing boot.

•

Apply the specified screw torque to ensure sufficient and even clamping force on the sealing boot.

•

The mounting flange of the joystick should be connected to the vehicle chassis ground.

•

Protect wires from mechanical abuse, run wires in flexible metal or plastic conduits.

•

Use 85˚ C (185˚ F) wire with abrasion resistant insulation and 105˚ C (221˚ F) wire should be

considered near hot surfaces.

•

Use a wire size that is appropriate for the module connector.

•

Separate high current wires such as solenoids, lights, alternators or fuel pumps from sensor and other

noise-sensitive input wires.

•

Run wires along the inside of, or close to, metal machine surfaces where possible, this simulates a

shield which will minimize the effects of EMI/RFI radiation.

•

Do not run wires near sharp metal corners, consider running wires through a grommet when

rounding a corner.

•

Do not run wires near hot machine members.

•

Provide strain relief for all wires.

•

Avoid running wires near moving or vibrating components.

•

Avoid long, unsupported wire spans.

•

Ground electronic modules to a dedicated conductor of sufficient size that is connected to the

battery (-).

•

Power the sensors and valve drive circuits by their dedicated wired power sources and ground

returns.

•

Twist sensor lines about one turn every 10 cm (4 in).

•

Use wire harness anchors that will allow wires to float with respect to the machine rather than rigid

anchors.

Warning

Unintended movement of the machine or mechanism may cause injury to the technician or bystanders.

The module will be powered up if battery voltage is applied to the module's output pin. To protect

against unintended movement, secure the machine.

Caution

Warranty will be voided if module is damaged.

Avoid significant current driven back through an output pin.

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 33

Technical Information

JS6000 Joystick Base

Product installation

Joystick safety critical functions

For a system to operate safely it must be able to differentiate between commanded and uncommanded

inputs. Take steps to detect and manage joystick and system failures that may cause an erroneous

output.

For safety critical functions Danfoss recommends you use an independent momentary action system

enable switch. You can incorporate this switch into the joystick as an operator presence switch or can be

a separate foot or hand operated momentary switch. Disable all joystick functions that the joystick

controls when this switch is released.

Ensure the control system looks for the appropriate system enable switch input before the joystick is

displaced from its neutral position. Enable functions only after receiving this input.

Applications using CAN joysticks should continuously monitor for the presence of the CAN messages on

periodic basis. Messages are to be checked frequently enough for the system or operator to react if the

CAN messages lose priority or are no longer received.

JS6000 connector pin assignments general information

JS6000 Joystick base pin assignments are a function of the following options:

Type of shaft position sensor (potentiometer or Hall)

•

Electrical output (analog or CAN)

•

Grip type

•

Base pin and connector assignments are different for the potentiometer and Hall sensor options.

In all cases, grip pin assignments are dependent on the type of grip and the number of grip options that

are selected.

Refer to CAN output connector pin assignments on page 35.

Refer to CAN+ and PWM output connector pin assignments on page 36.

Refer to Potentiometer sensor with analog output connector pin assignments on page 38.

Refer to Hall effect sensor with analog output pin assignments on page 40.

34 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Pin 1

Pin 6

2239

Technical Information

JS6000 Joystick Base

Product installation

Pin assignments

CAN output connector pin assignments

Pin location

Pinout and wiring information

Pin CAN output

1 Ground

2 Power

3 CAN high

4 CAN low

5 CAN shield

6 No connection

CAN output mating connector DEUTSCH DTM06-6S

Danfoss provides mating connector kits (bag assemblies) for JS6000 joysticks. The bag assembly contains

loose parts you must assemble. The connector with wire harness features a fully assembled connector

with an unterminated wire harness.

Mating connector assemblies

Type Danfoss material number

Connector bag assembly 10101551

Connector with 400 mm [15.75 in] wire harness 10101557

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 35

Pin 1

Pin 13

Pin 18

Pin 6

2457

Technical Information

JS6000 Joystick Base

Product installation

CAN+ and PWM output connector pin assignments

Pin location

CAN+ output connector pinout and wiring information

Pin CAN output

1 Ground 2 Power +

3 CAN high

4 CAN low

5 CAN shield

6 Operator present/DIN11

7 Sensor ground 8 5 Vdc sensor power +

9 AIN1/DIN7

10 AIN2/DIN8

11 AIN3/DIN9

12 AIN4/DIN10

13 DIN1

14 DIN2

15 DIN3

16 DIN4

17 DIN5

18 DIN6

PWM output connector pinout and wiring information

Pin CAN output

1 Ground 2 Power +

3 CAN high

4 CAN low

5 PWM Valve Out 1 +

6 PWM Valve Out 1 7 PWM Valve Out 2 +

8 PWM Valve Out 2 9 AIN / CAN Shield

36 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

C

Technical Information

JS6000 Joystick Base

Product installation

PWM output connector pinout and wiring information (continued)

Pin CAN output

10 DIN

11 DOUT1

12 DOUT2

13 DOUT3

14 DOUT4

15 Operator Presence +

16 Operator Presence 17 DOUT5

18 DOUT6

Caution

Joystick electronics damage may occur possibly causing the joystick to non-function. Do not connect

battery power to operator presence + or operator presence -.

CAN+ and PWM output mating connector DEUTSCH DT16-18SB

Danfoss provides mating connector kits (bag assemblies) for JS6000 joysticks. The bag assembly contains

loose parts you must assemble. The connector with wire harness features a fully assembled connector

with an unterminated wire harness.

Mating connector assemblies

Type Danfoss material number

Connector bag assembly 11012648

Connector with 400 mm [15.75 in] wire harness 11012646

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 37

2240

Redundant Sensor Output

8 Pin Connector

Grip Output

12 Pin Connector

Shaft Position Output

16 Pin Connector

Pin 1

Pin 9

Pin 7

Pin 1

Pin 1

Pin 5

Technical Information

JS6000 Joystick Base

Product installation

Potentiometer sensor with analog output connector pin assignments

Pin location

16 pin sensor connections*

Pin Pin allocation description

1 N/O signal Y-axis direction switch forward

2 N/C signal X-axis direction switch center

3 X-axis ground

4 X-axis position signal

5 X-axis + supply voltage

6 X-axis center tap + supply voltage

7 X-axis direction switches + supply voltage

8 N/O signal X-axis direction switch left

9 Y-axis ground

10 Y-axis position signal

11 Y-axis + supply voltage

12 Y-axis center tap + supply voltage

13 Y-axis direction switches + supply voltage

14 N/O signal Y-axis direction switch back

15 N/O signal X-axis direction switch right

16 N/C signal Y-axis direction switch center

* Refer to Potentiometer sensor on page 12 for additional details referencing potentiometer measurement

and switch track connections.

8 pin redundant sensor connections

Pin Pin allocation description for redundant potentiometer sensor

1 Second Y axis + supply voltage

2 Second Y-axis center tap + supply voltage

3 Second Y-axis position signal

4 Second Y-axis ground

5 Second X-axis + supply voltage

6 Second X-axis position signal

7 Second X-axis center tap + supply voltage

8 Second X-axis ground

38 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

Product installation

For 12 pin grip output connections see Danfoss manual JS1000, JS6000 Joystick Grips Technical

Information, 520L0872 for grip connector pin out assignments.

Analog output mating connector

Danfoss provides mating connector kits (bag assemblies) for JS6000 joysticks. The bag assembly contains

loose parts you must assemble. The connector with 400 mm leads features a fully assembled connector

with an unterminated wire harness.

Bag assemblies

Type Danfoss material number

16 pin + contacts 10101552

12 pin + contacts 10101020

8 pin + contacts 10101022

12 + 8 pin + contacts 10101023

Wire harness

Type Danfoss material number

16 pin with 400 mm [15.75 in] leads 10101556

12 pin with 400 mm [15.75 in] leads 10101555

8 pin with 400 mm [15.75 in] leads 10101554

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 39

2241

Directional and Microswitch Output

8 Pin Connector

Grip Output

16 Pin Connector

Shaft Position Output

12 Pin Connector

Pin 1

Pin 9

Pin 7

Pin 1

Pin 1

Pin 5

Technical Information

JS6000 Joystick Base

Product installation

Hall effect sensor with analog output pin assignments

Pin assignments

12 pin shaft position connections

Pin Pin allocation description

1 Hall 3 and 4 5 Vdc + supply

2 Hall 3 and 4 ground

3 Hall 1 and 2 5 Vdc + supply

4 Hall 1 and 2 ground

5 Hall 3 forward/backward output

6 Hall 2 left/right output

7 Hall 4 left/right output

8 Hall 1 forward/backward output

9 Not connected

10 Not connected

11 Not connected

12 Not connected

8 pin microswitch and directional switch connections

Pin Pin allocation description

1 Joystick forward common

2 Forward switch output

3 Backward switch output

4 Switch backward common

5 Switch left common

6 Left switch output

7 Right switch output

8 Switch right common

For 12 pin grip output connections see Danfoss manual JS1000, JS6000 Joystick Grips Technical

Information, 520L0872.

40 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

Specifications

Mechanical characteristics

Mechanical

Shaft mechanical angle limits

Shaft maximum overload

Shaft maximum operating load

Shaft maximum downward loading

Shaft maximum torques

Base mechanical life (X and Y axis

only)

Base only mass

Breakout load on axis

Medium duty spring

Heavy duty spring

± 20˚

5 cycles only at 490 N [110.15 lbf] measured 130 mm [5.12 in] above

mounting surface

390 N [87.67 lbf] measured 130 mm [5.12 in] above mounting surface

2450 N [550.76 lbf]

15 N.m [11.06 lbf.ft]

> 7.5 million operating cycles

0.75 kg [1.65 lbf]

6 to 8.5 N [1.349 to 1.911 lbf]

12 to 19 N [2.698 to 4.271 lbf]

Electrical characteristics

Load at full deflection

Medium duty spring

Heavy duty spring

15 to 23 N [3.37 to 5.17 lbf]

31 to 47 N [6.97 to 10.57 lbf]

Potentiometer sensor with analog output

Supply voltage (Vs)

Maximum survival voltage

Maximum wiper current

Maximum load current

Center tap/switch alignment

Potentiometer electrical angle

Center tap angle

Insulation resistance at 50 Vdc

Minimum load impedance

9 to 36 Vdc

36 Vdc

5 mA

200 mA resistive

Within 0.5˚

± 18˚

± 2.5˚

> 50 MΩ

1 MΩ recommended

Potentiometer output options

Minimum voltage

(% Vs)

10 ± 2 90 ± 2 ± 1.5 1.6 to 2.4 R

25 ± 2 75 ± 2 ± 1.5 2.2 to 3.6 Q

10 ± 2 90 ± 2 ± 5 1.6 to 2.4 S

25 ± 2 75 ± 2 ± 5 2.2 to 3.6 T

Maximum voltage

(% Vs)

Switch track angle

(°)

Resistance

(kΩ)

Model code order

character

©

Danfoss | April 2017 520L0760 | BC00000111en-US1104 | 41

Technical Information

JS6000 Joystick Base

Specifications

Dual potentiometer output

Minimum voltage

(% Vs)

10 ± 2 90 ± 2 ± 1.5 1.6 to 2.4 U

Maximum voltage

(% Vs)

Switch track angle

(°)

Resistance

(kΩ)

Hall effect sensor with analog output

Supply voltage (Vs)

Maximum survival supply voltage

Maximum current draw (base only)

Minimum output voltage

Center voltage

Maximum output voltage

5 ± -0.5 Vdc

18 Vdc

90 mA

10% ± 4% Vs

50% ± 2% Vs

90% ± 4% Vs

Hall effect sensor with can output option

Supply voltage (Vs)

Maximum current draw (base only)

9 to 36 Vdc

90 mA

Model code order

character

Supports CAN 2.0B with SAE J1939 message protocol

Hall effect sensor with pwm output option

Supply voltage (Vs)

Maximum survival supply voltage

Maximum current draw (base only)

Valve outputs

Digital outputs

Maximum output current

9 to 36 Vdc

40 Vdc

13 amps

2.5 amps maximum

3.0 amps maximum

13.0 amps

External-to-joystick digital inputs

Property Minimum Maximum Comments

Allowed voltage at pin 0 Vdc 36 Vdc

Rising voltage threshold 2.48 Vdc 3.5 Vdc Digital input will be read as

Falling voltage threshold 1 Vdc 2.25 Vdc Digital input will be read as

CAN output latency 6 ms 24 ms Based on update rate of

Response to voltage below

minimum

Response to voltage above

maximum

high if voltage is greater

than 3.5 Vdc

low if voltage is less than 1

Vdc

application software

Non-damaging, non-

latching: reading saturates

to low limit

Non-damaging; nonlatching: reading saturates

to high limit

42 | © Danfoss | April 2017 520L0760 | BC00000111en-US1104

Technical Information

JS6000 Joystick Base

Specifications

External-to-joystick analog inputs

Property Minimum Maximum Comments

Allowed voltage at pin 0 Vdc 36 Vdc