Page 1

PLUS+1™ GUIDE

Software

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block User Manual

142.0 mm

[5.59]

97.0 mm

[3.82]

144.5 mm

5.69

158.2 mm

6.23

PIN #1

INDICATED

2x 25.2 mm

[1.0]

2x ∅7.0

[.28]

MOUNTING

DIRECTION

#2

LED INDICATO R

LIGHTS

TM

COMPLIANT

CONNECTOR MATES

WITH DEUTCH

CONNECTOR #D TM-06-125A

51.6 mm

47.1 mm

[1.85]

[2.03]

1

12

6

7

1

6

12

7

CONNECTOR MATES

WITH DEUTCH

CONNECTOR #DTM-06-125A

Page 2

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

T

User Manual

About this Manual

Organization

and Headings

o help you quickly find information in this manual, the material is divided into sections,

topics, subtopics, and details, with descriptive headings set in red type. Section titles

appear at the top of every page in large red type.

In the PDF version of this document, clicking an item underlined in blue italic type

you to the referenced page in the document.

Special Text Formatting Controls and indicators are set in bold black type.

Table of Contents

A Table of Contents (TOC) appears on the next page. In the PDF version of this document,

the TOC entries are hyperlinked.

Revision History

Revision Date Comment

Rev BA September 2011

jumps

©2011 Sauer-Danfoss. All rights reserved.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer-Danfoss reserves the right to alter its products without prior notice. This also applies to products already

ordered provided that such alterations can be made without affecting agreed specifications.

All trademarks in this material are properties of their respective owners.

PLUS+1, GUIDE, and Sauer-Danfoss are trademarks of the Sauer-Danfoss Group. The PLUS+1 GUIDE, PLUS+1

2

Compliant, and Sauer-Danfoss logotypes are trademarks of the Sauer-Danfoss Group.

11007138 · Rev BA · September 2011

Page 3

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

Contents

JS2000_Y Function Block .............................................................................................................................. 4

Overview..................................................................................................................................................... 4

Inputs ........................................................................................................................................................... 4

Outputs ....................................................................................................................................................... 5

Connections and Signals Overview ................................................................................................... 5

Status and Fault Logic ............................................................................................................................ 6

Configuration Settings .......................................................................................................................... 7

About Calibration Windows and Default Calibration Values .................................................. 10

About Calibration Values and Deadbands .................................................................................... 12

MC Controller—Input Configuration .............................................................................................. 14

MC Controller—How to Configure a MFIn............................................................................ 14

MC Controller—How to Configure an AnIn ......................................................................... 15

MC Controller—How to Configure a DigAn ......................................................................... 16

SC Controller—Input Configuration ............................................................................................... 17

SC Controller—How to Configure a MFIn ............................................................................. 17

SC Controller—How to Configure a DigAn .......................................................................... 18

About the Para Input ............................................................................................................................ 19

About the Name Space Feature ....................................................................................................... 21

How to Enter a Name Space Value .......................................................................................... 21

·

11007138

Rev BA

·

September 2011

3

Page 4

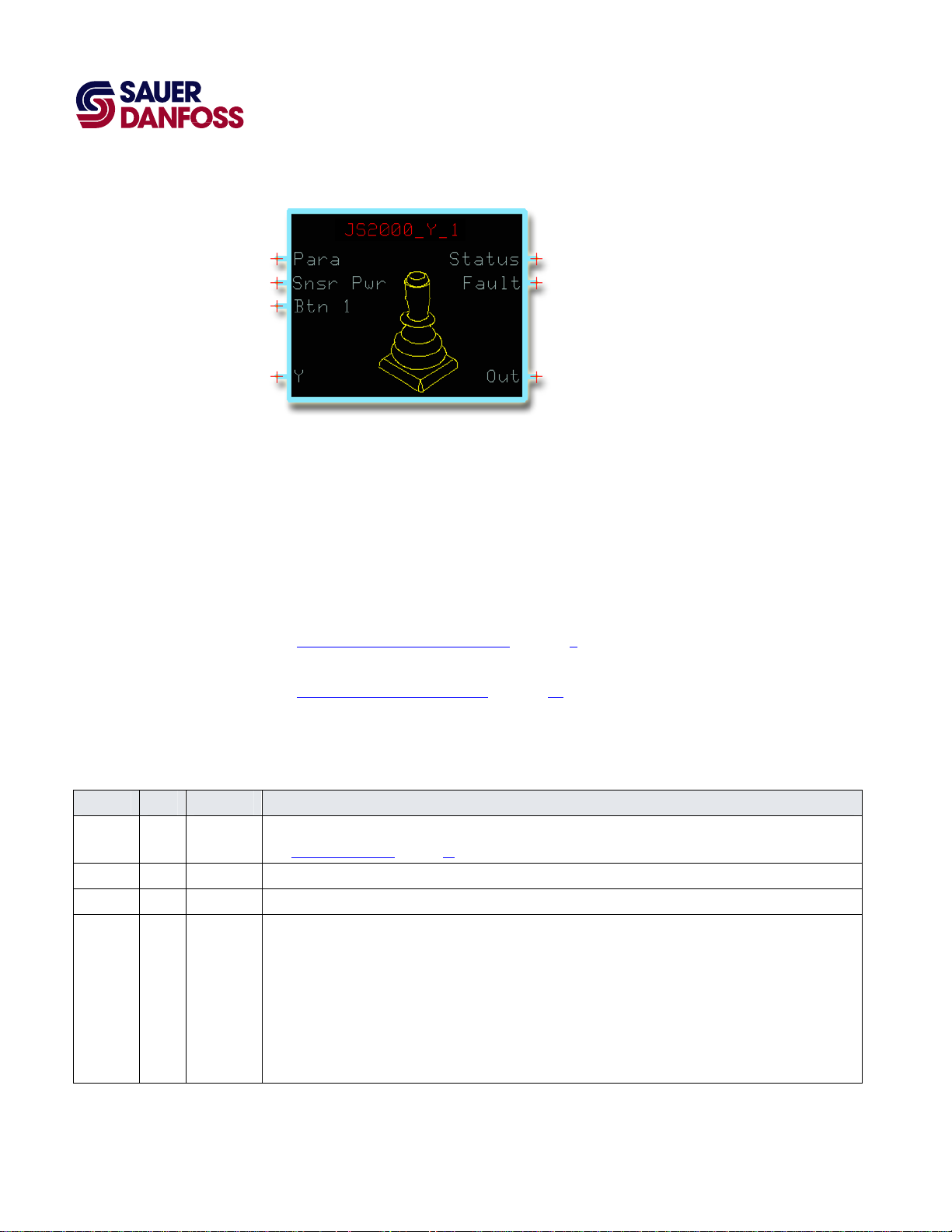

Overview

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

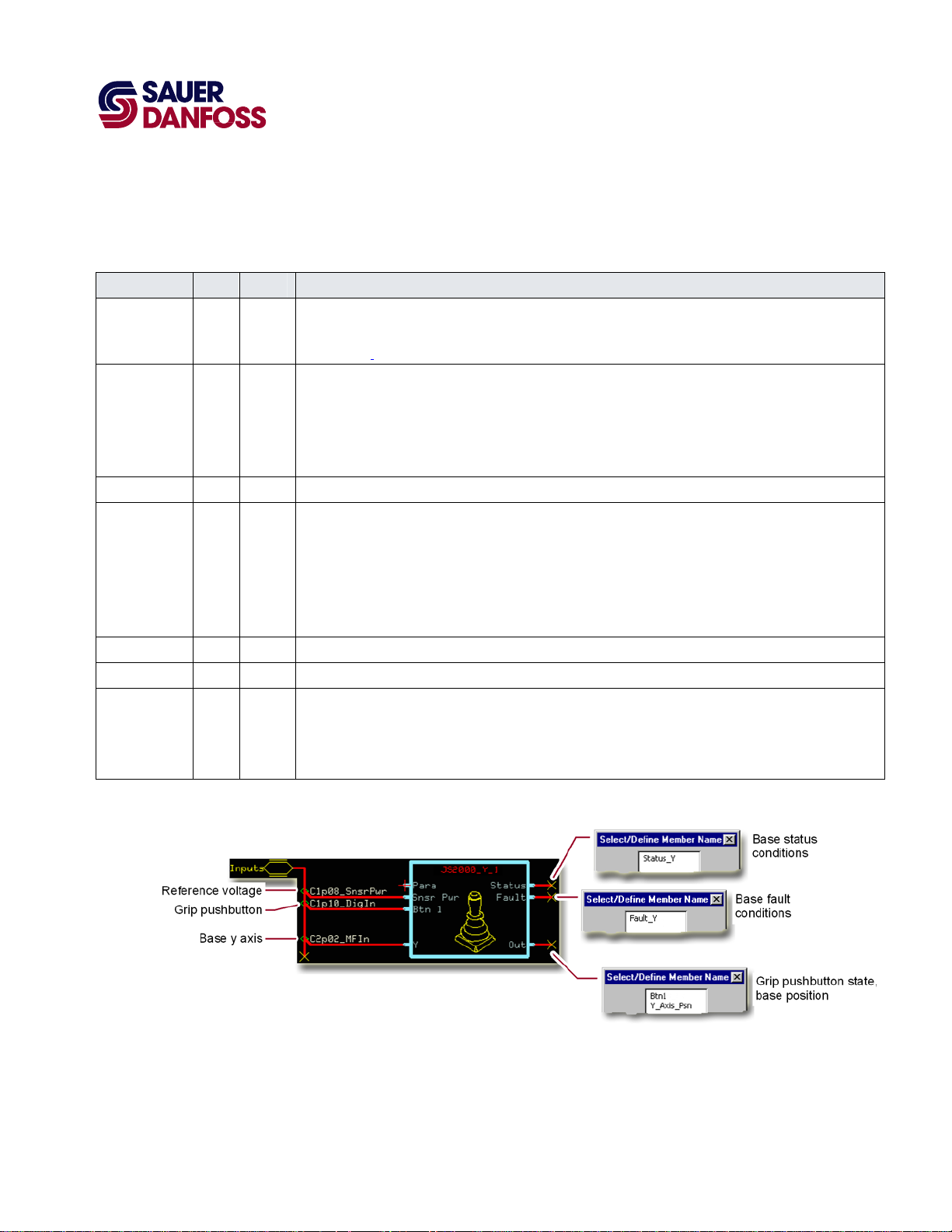

The JS2000_Y function block configures the output of a Sauer-Danfoss JS2000 Y-Axis

joystick.

This joystick has a:

• Base with a single three-point y-axis.

• Grip with a single pushbutton.

See:

• Connections and Signals Overview on page 5 for an overview of this function block’s

connections and signals.

• About the Name Space Feature on page 21 if you are using more than one of these

function blocks in your application.

Inputs

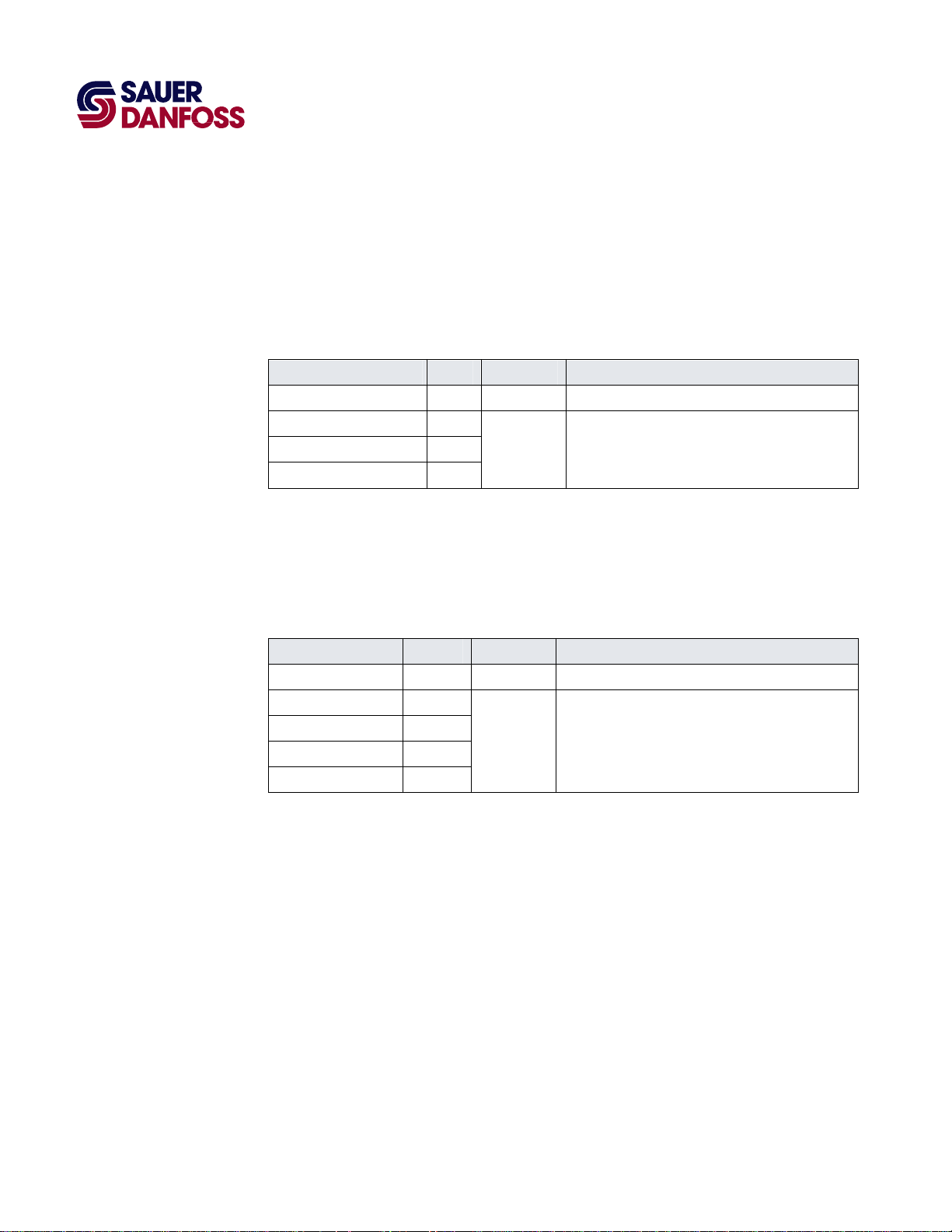

JS2000_Y Function Block Inputs

Input Type Range Description

Para —— —— Allows common parameters to be applied to multiple joystick function blocks.

See About the Para Input on page 19 for more information.

Snsr Pwr —— 0–5260 mV Inputs the sensor power voltage (reference voltage) that the controller applies to the joystick’s sensor power pin.

Btn 1 BOOL —— Inputs the signal from the grip-mounted pushbutton.

Y —— 0–5260 mV The voltage input to the Y pin indicates the position of the joystick base on its y-axis.

The default:

– CalLow calibration value for Y is 10% of the SnsrPwr voltage. A Y input at 10% of the SnsrPwr voltage

outputs a Y_Axis_Psn signal of -100%.

– CalMid calibration value for Y is 50% of the SnsrPwr voltage. A Y input at 50% of the SnsrPwr voltage

outputs a Y_Axis_Psn signal of 0%.

– CalHi calibration value for Y is 90% of the SnsrPwr voltage. A Y input at 90% of the SnsrPwr voltage outputs

a Y_Axis_Psn signal of 100%.

·

4

11007138

Rev BA

·

September 2011

Page 5

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

Outputs

JS2000_Y Function Block Outputs

Output Type Range Description

Status Outputs a bus that contains a Status signal.

The Status and Fault signals use the standard bitwise scheme described in the Basic Function Blocks Library

User’s Manual.

Status_Y U16 —— Indicates the calibration and setup condition of the Y input.

– 0x0000 = Block is OK.

– 0x8001 = Block is not calibrated.

– 0x8002 = Block is partially calibrated.

– 0x8008 = Invalid setup/calibration.

Fault Outputs a bus that contains a Fault signal.

Fault_Y U16 —— Indicates the operating condition of the Y input.

– 0x0000 = Block is OK.

– 0x8001 = Input value is too low.

– 0x8002 = Input value is too high.

– 0x8004 = Short circuit.

– 0x8008 = Open circuit.

Out Outputs a bus that contains a Btn and a Psn signal.

Btn1 BOOL —— Indicates the state of the grip pushbutton.

Y_Axis_Psn S16 ±10000 Indicates the position of the joystick base’s y-axis.

– -10000 = -100.00%.

– 0 = 0%.

– +10000 = +100.00%.

Connections and Signals Overview

11007138

·

Rev BA

·

September 2011

5

Page 6

Status and Fault Logic

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

The following table shows how:

• The Status output indicates the calibration conditions of the inputs.

• During calibration, the related Psn signal on the Out pin is zero.

Status Logic

Condition Status Psn Signal Comment

Block is OK. 0x0000 ±10000. Normal output of all Psn signals.

Block is not calibrated. 0x8001

Block is partially calibrated. 0x8002

Invalid setup/calibration. 0x8008

The following table shows how:

0*/±10000**.

*Calibration of an input sets its related Psn signal to

0.

**A valid input has a related Psn signal of ±10000.

• The Fault output indicates fault conditions.

• Any fault condition sets its related Psn signal on the Out pin to zero.

Fault Logic

Condition Fault Psn Signal Comment

Block is OK. 0x0000 ±10000. Normal output of both Psn signals.

Input value is too low. 0x8001

Input value is too high. 0x8002

0*/±10000**.

Short circuit. 0x8004

Open circuit. 0x8008

*An invalid input sets its related Psn signal to 0.

**A valid input has a related Psn signal of ±10000.

·

6

11007138

Rev BA

·

September 2011

Page 7

Configuration Settings

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

Enter the JS2000_Y page to change the JS2000_Y function block’s configuration settings.

When working with configuration settings for PLUS+1 compliant joysticks, note that:

• Configuration inputs with a _Base suffix configure the joystick base.

• Configuration inputs with a _Grip suffix configure the joystick grip.

JS2000_Y Function Block Configuration Settings

Input Type Range Description

CalMode —— 0–3 Selects the CalMode (Calibration Mode) that sets the CalHi, CalMid, and CalLow values.

– 0—download values with the PLUS+1 GUIDE Service Tool.

– 1—capture values using autocalibration or directly download values with the PLUS+1 GUIDE Service Tool.

In autocalibration, you operate the joystick and the block captures values that fall within defined windows.

– 2—the controller uses only the Default calibration values in the Memory page.

– 3—erases all calibration values.

RturnToNeut BOOL —— RturnToNeut (Return to Neutral) sets when the function block enables its Out signals after a controller startup,

calibration, or a Fault or Status condition.

– T—the block enables its Out signals only after all its inputs return to neutral.

– F—the block immediately enables its Out signals.

LatchPFlt BOOL —— The function block sets a Status condition when it receives an invalid setup or calibration parameter.

The block disables the signal on the Out pin that is related to the abnormal parameter.

The LatchPFlt (Latch Parameter Fault) sets when the block enables the signal after the condition clears.

– T—the block enables the Out signal only after you repower the controller.

– F—the block immediately enables the Out signal.

·

11007138

Rev BA

·

September 2011

7

Page 8

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

JS2000_Y Function Block Configuration Settings

Input Type Range Description

LatchInFlt BOOL —— The function block sets a Fault condition when it receives an invalid input.

The block disables the Out signal that is related to the abnormal input.

The LatchInFlt (Latch Input Fault) sets when the block enables the signal after the condition clears.

– T—the block enables the Out signal only after you repower the controller.

– F—the block immediately enables the Out signal.

CalWindow —— 0–3000 The CalWindow (Calibration Window) sets the width of three calibration windows.

These windows center on the default CalHi, CalMid, and CalLow calibration values.

For more information, see About Calibration Windows and Default Calibration Values on page 10.

The default calibration values are set in the Memory page. They are the Default inputs to the three Non-Volatile

Memory Dynamic with Default components in this page.

During autocalibration, input voltages must be within these windows for the function block to capture them as

valid calibration values.

The CalWindow value is set as percentage of SnsrPwr.

1000 = 10.00%.

CalDetectTm —— 0–65535 The CalDetectTm (Calibration Detect Time) sets the time during autocalibration that input voltages must remain

in each calibration window for the function block to capture them as valid CalHi, CalMid, and CalLow calibration

values.

1000 = 1000 ms.

Dband_Hi —— 0–4999 The Dband_Hi (Deadband High) sets the width of an upper deadband.

An input voltage within this band produces a +100% output.

This deadband extends below the CalHi calibration value.

The function block sets the width of the Dband_Hi as a percentage of the difference between the CalHi and

CalMid calibration values.

For more information, see About Calibration Values and Deadbands on page 12.

1000 =10.00%.

Dband_Mid —— 0–4999 The Dband_Mid (Deadband Middle) sets the width of a middle deadband.

An input voltage within this band produces a 0% output.

This deadband has an upper and lower half. The upper half extends above the CalMid calibration value. The

lower half extends below the CalMid calibration value.

The function block sets the width of the upper half of Dband Mid as a percentage of the difference between the

CalHi and CalMid calibration values.

The function block sets the width of the lower half of Dband Mid as a percentage of the difference between the

CalMid and CalLow calibration values.

For more information, see About Calibration Values and Deadbands on page 12.

1000 =10.00%.

·

8

11007138

Rev BA

·

September 2011

Page 9

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

JS2000_Y Function Block Configuration Settings

Input Type Range Description

Dband_Low —— 0–4999 The Dband_Low (Deadband Low) sets the width of a lower deadband.

This deadband extends above the CalLow calibration value.

An input voltage within this band produces a –100% output.

The function block sets the width of the Dband_Low as a percentage of the difference between the CalMid and

CalLow calibration values.

For more information, see About Calibration Values and Deadbands on page 12.

1000 = 10.00%.

FltDetectTm —— 0–65535 The FltDetectTm (Fault Detect Time) sets the time before an abnormal condition causes the function block to set

a Status or Fault condition.

1000 = 1000 ms.

·

11007138

Rev BA

·

September 2011

9

Page 10

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

About Calibration Windows and Default Calibration Values

The following graph shows the relationship between the default calibration values and the

windows in which the function block captures calibration values during autocalibration.

10

• The JS2000_Y function block’s SnsrPwr is 5000 mV.

• The JS2000_Y function block’s default:

− CalLow calibration value is 1000, or 10% (500 mV) of SnsrPwr.

− CalMid calibration value is 5000, or 50% (2500 mV) of SnsrPwr.

− CalHi calibration value is 9000, or 90% (4500 mV) of SnsrPwr.

• The JS2000_Y function block’s CalWindow (Calibration window) is 1000, or 500 mV

wide (10% of SnsrPwr).

(The Default values for CalLow, CalMid, and CalHi are set in the Memory page. The

CalWindow value is set in the JS2000_Y page.)

• The 500 mV wide calibration windows center on the Default values for CalLow,

CalMid, and CalHi.

·

11007138

Rev BA

·

September 2011

Page 11

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

• During autocalibration, an input voltage must be between:

− 250–750 mV to be captured as a CalLow calibration value.

− 2250–2750 mV to be captured as CalMid calibration value.

− 4250–4750 mV to be captured as a CalHi calibration value.

·

11007138

Rev BA

·

September 2011

11

Page 12

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

About Calibration Values and Deadbands

The following graph shows the:

• Formulas used by the function block to calculate high, middle, and low deadband

width.

• Relationship between the calibration values captured during autocalibration and the

width of the deadbands.

12

• During autocalibration, the JS2000_Y function block captured the:

− CalLo calibration value at 700 mV.

− CalMid calibration value at 2300 mV.

− CalHi calibration value at 4700 mV.

·

11007138

Rev BA

·

September 2011

Page 13

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

• An input voltage that falls within the:

− Dband_Low deadband produces a -100% output from the function block.

− Dband_Mid deadbands produces a 0% output from the function block.

− Dband_Hi deadband produces a +100% output from the function block.

·

11007138

Rev BA

·

September 2011

13

Page 14

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

MC Controller—Input Configuration

If you have an SC controller, see SC Controller—Input Configuration on page 17.

You can route the voltage needed by a joystick input though:

• A MFIn (Multifunction Input) on your controller.

• An AnIn (Analog Input) on your controller.

• A DigAn (Digital/Analog input) on your controller.

You must configure the input that you use to accept a voltage input.

MC Controller—How to Configure a MFIn

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn page that routes voltage to the input.

3. Delete the route as shown in the preceding figure.

14

11007138

·

Rev BA

·

September 2011

Page 15

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

MC Controller—How to Configure an AnIn

1. In the GUIDE template, enter the Inputs page.

2. Enter the AnIn page that routes voltage to the input.

3. Delete the route as shown in the preceding figure.

·

11007138

Rev BA

·

September 2011

15

Page 16

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

MC Controller—How to Configure a DigAn

1. In the GUIDE template, enter the Inputs page.

2. Enter the DigAn page that routes voltage to the input.

3. Delete the route as shown in the preceding figure.

16

11007138

·

Rev BA

·

September 2011

Page 17

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

SC Controller—Input Configuration

If you have an MC controller, see MC Controller—Input Configuration on page 14.

You can route the voltage needed by a joystick input though:

• A MFIn (Multifunction Input) on your controller.

• A DigAn (Digital/Analog) input on your controller.

You must configure the input that you use to accept a voltage input.

SC Controller—How to Configure a MFIn

1. In the GUIDE template, enter the Inputs page.

2. Enter the MFIn page that routes voltage to the input.

3. Delete the routes as shown in the preceding figure.

·

11007138

Rev BA

·

September 2011

17

Page 18

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

SC Controller—How to Configure a DigAn

1. In the GUIDE template, enter the Inputs page.

2. Enter the DigAn page that routes voltage to the input.

18

3. Delete the routes as shown in the preceding figure.

·

11007138

Rev BA

·

September 2011

Page 19

About the Para Input

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

Use the Para input to apply a common set of parameters to multiple function blocks.

The preceding figure shows a Parameters page that outputs common, shared parameters

to identical function blocks.

The preceding figure shows the contents of the Parameters page that applies the

common, shared parameters to the function blocks.

You create this Parameters page yourself. How you implement parameter sharing

determines the inputs, outputs, contents, and name of this page.

·

11007138

Rev BA

·

September 2011

19

Page 20

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

The preceding figure shows the changes made to a JS2000_Y page to enable this page to

accept common parameters through its Para input.

20

11007138

·

Rev BA

·

September 2011

Page 21

PLUS+1 Compliant JS2000 Y-Axis Joystick Function Block

User Manual

JS2000_Y Function Block

About the Name Space Feature

If you use this function block more than once in an application, you must change each

function block’s Name Space value to avoid compiler errors.

These function blocks allocate memory using memory names (“aliases”). Identical function

blocks have identical memory names. Identical memory names will cause a compiler error.

The Name Space value adds a unique prefix to each memory name to avoid memory

allocation errors.

How to Enter a Name Space Value

1. In the PLUS+1 GUIDE menu bar, click the Query/Change button.

2. Click the function block’s page name to display the Edit Page window.

3. In the Edit Page window, enter a meaningful Name Space value.

4. Press /.

5. Repeat these steps to enter unique Name Space values for other identical function

blocks.

·

11007138

Rev BA

·

September 2011

21

Page 22

p

Products we offer:

• Bent Axis Motors

• Closed Circuit Axial Piston Pumps

and Motors

• Displays

• Electrohydraulic Power Steering

• Electrohydraulics

• Hydraulic Power Steering

• Integrated Systems

• Joysticks and Control Handles

• Microcontrollers and Software

• Open Circuit Axial Piston Pumps

• Orbital Motors

• PLUS+1™ GUIDE

• Proportional Valves

• Sensors

• Steering

Sauer-Danfoss is a global manufacturer and supplier of highquality hydraulic and electronic components. We specialize in

providing state-of-the-art technology and solutions that excel in

the harsh operating conditions of the mobile off-highway market.

Building on our extensive applications expertise, we work closely

with our customers to ensure exceptional performance for a broad

range of off-highway vehicles.

We help OEMs around the world speed up system development,

reduce costs and bring vehicles to market faster.

Sauer-Danfoss—Your Strongest Partner in Mobile Hydraulics.

Go to www.sauer-danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Sauer-Danfoss.

We offer expert worldwide support for our customers, ensuring the

best possible solutions for outstanding performance. And with an

extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Transit Mixer Drives

•

Members of the Sauer-Danfoss Group:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmueller-inverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Sauer-Danfoss-Daikin

www.sauer-danfoss-daikin.com

Please contact the Sauer-Danfoss re

Local address:

Sauer-Danfoss Inc.

3500 Annapolis Lane North

Minneapolis, MN 55447, USA

Phone: +1 763 509-2000

Fax: +1 763 559-5769

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000

Fax: +1 515 239-6618

Sauer-Danfoss GmbH & Co. OHG

Postfach 2460, D-24531 Neumünster

Krokamp 35, D-24539 Neumünster,

Germany

Phone: +49 4321 871-0

Fax: +49 4321 871 122

resentative nearest you.

Sauer-Danfoss ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444

Fax: +45 7488 4400

Sauer-Danfoss-Daikin LTD

Shin-Osaka TERASAKI 3rd Bldg. 6F

1-5-28 Nishimiyahara, Yodogawa-ku

Osaka 532-0004, Japan

Phone: +81 6 6395 6066

Fax: +81 6 6395 8585

11007138 ● Rev BA ● September 2011

www.sauer-danfoss.com

Loading...

Loading...