Page 1

User Manual

PLUS+1 ® Compliant

JS1 CANopen CANplus Joystick Function

Blocks

www.danfoss.com

Page 2

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

Revision history Table of revisions

Date Changed Rev

February 2020 First Edition 0101

2 | © Danfoss | February 2020 AQ309185946321en-000101

Page 3

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

Contents

JS1 CANopen CANplus Function Block

Overview..............................................................................................................................................................................................4

Inputs....................................................................................................................................................................................................5

Parameters.....................................................................................................................................................................................5

Outputs................................................................................................................................................................................................ 6

Status and Fault Logic..................................................................................................................................................................11

Boolean Output Signals..........................................................................................................................................................11

Proportional Output Signals.................................................................................................................................................11

Configuration of the PLUS+1 GUIDE Template...................................................................................................................12

JS1 CANplus Service Screens

JS1 CANplus 18 Pin Service Screens........................................................................................................................................13

JS1 CANplus 24 Pin Service Screens........................................................................................................................................15

©

Danfoss | February 2020 AQ309185946321en-000101 | 3

Page 4

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

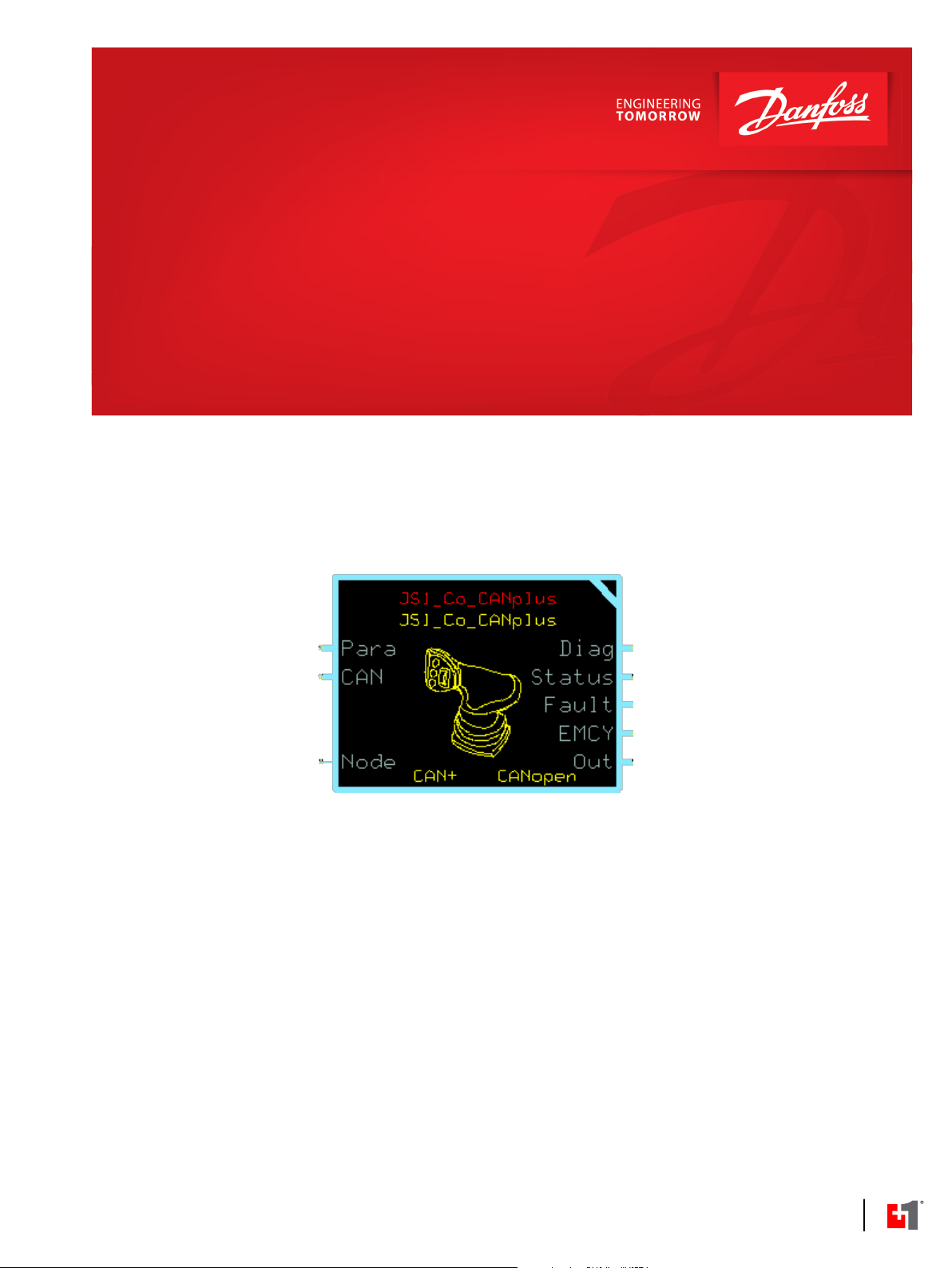

JS1 CANopen CANplus Function Block

Overview

The JS1 function block configures the output of a Danfoss JS1 CANopen CANplus joystick.

•

The JS1_Co_CANplus_18Pin function block configures the output of a Danfoss JS1 18 Pin CANplus

joystick.

•

JS1_Co_CANplus_24Pin function block configures the output of a Danfoss JS1 24 Pin CANplus

joystick.

In addition to grip and handle inputs, the JS1 CANplus joystick also has 11 external inputs. Four of these

inputs can be configured as analog inputs.

The JS1 CANplus joystick broadcasts these CANopen messages that report joystick inputs:

•

CANopen HEARTBEAT Message - Reports the operational state of the joystick.

•

CANopen EMCY message - In the event of a fault, this message reports the details of the fault.

•

CANopen PDO1 Message - The state of buttons 1 to 12. The state of digital inputs external to the

joystick.

•

CANopen PDO2 Message - The position of the x and y axis position of the joystick

•

CANopen PDO3 Message - The position of the proportional (analog) inputs on the joystick grip.

•

CANopen PDO4 Message - The value of other analog inputs that are external to the joystick.

The JS1 function block receives these messages and parses them into meaningful signals that can be

used in an application.

4 | © Danfoss | February 2020 AQ309185946321en-000101

Page 5

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

Inputs

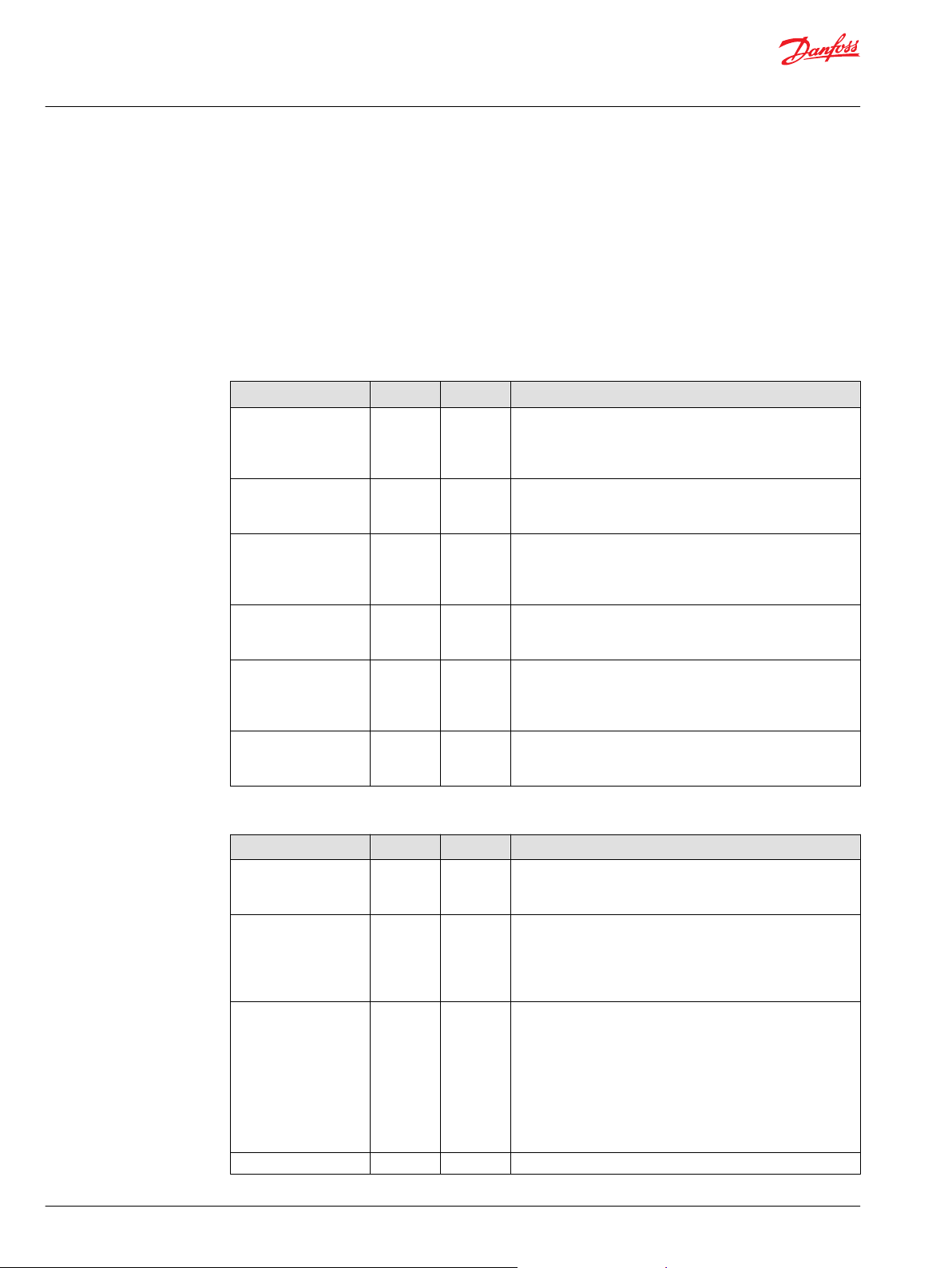

JS1_CANplus function block inputs

Input Type Range Description

Node —— —— Specifies the CANopen address of the joystick.

All Node addresses on the same CANopen bus must be

different. Do not use the same address twice.

The Type code on the joystick label identifies the source

address. Typical addresses are C33 (right), C34 (left),

C35 (center), and C36 (auxiliary).

Enter the source address in hexadecimal format as shown in the

following examples:

C33 (right) = 0x33

C34 (left) = 0x34

C35 (center) = 0x35

C36 (auxiliary) = 0x36

CAN —— —— In the GUIDE template, identify the CAN bus that inputs CAN

messages from the joystick. Route this bus to the CAN input on

this function block.

CAN messages sent from the joystick to the function block

contain information about the availability and state of joystick

inputs, joystick input faults, and joystick commands.

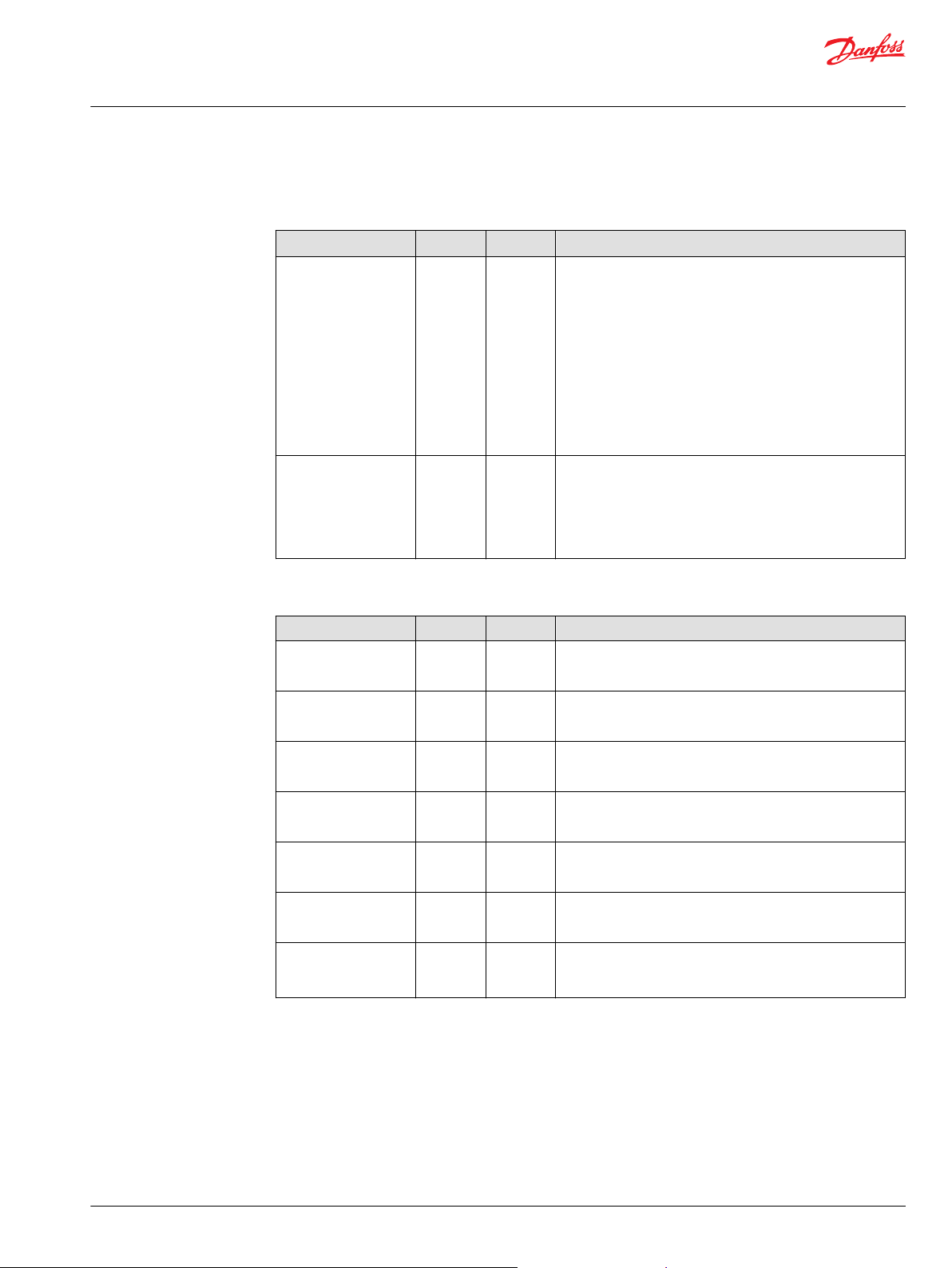

Parameters

Signal Type Range Description

Heartbeat_Timeout

PDO1_Timeout

PDO2_Timeout

PDO3_Timeout

PDO4_Timeout

NMT_Strt BOOL T/F Enables the function block to transmit a request to the joystick

Ext BOOL T/F

U16 0 to 1000 How many milliseconds to wait for a response before timing

out. A value less than twenty for this parameter disables

timeout checking.

U16 0 to 1000 How many milliseconds to wait for a response before timing

out. A value less than twenty for this parameter disables

timeout checking.

U16 0 to 1000 How many milliseconds to wait for a response before timing

out. A value less than twenty for this parameter disables

timeout checking.

U16 0 to 1000 How many milliseconds to wait for a response before timing

out. A value less than twenty for this parameter disables

timeout checking.

U16 0 to 1000 How many milliseconds to wait for a response before timing

out. A value less than twenty for this parameter disables

timeout checking.

to enter the operational state when the joystick is in Boot up or

Pre-operational state.

Determines whether the messages use 11 or 29 bit identifiers.

T = 29 bit identifier

F = 11 bit identifier

©

Danfoss | February 2020 AQ309185946321en-000101 | 5

Page 6

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

Outputs

The JS1 CANplus function block has Status, EMCY, Fault, and Out outputs.

Status outputs a bus with signals that report on the status of the joystick. See the following table for

•

a description of these signals.

EMCY outputs a bus with signals that indicate error and failure information from the joystick.

•

Fault outputs a bus with signals that report joystick faults. See the table for a description of these

•

signals.

Out outputs a bus with command signals. See the table for a description of these signals.

•

JS1 CANplus function block Status output

Signal Type Range Description

Btn1_NA–Btn12_NA BOOL —— Indicates if an input is available from a grip-mounted push

button switch.

T = Not available

F = Available

T_NA BOOL —— Indicates if an input from a rotational (theta) axis is available.

T = Not available

F = Available

XGrp_NA BOOL —— Indicates if an input from a grip-mounted, x-axis, proportional

switch is available.

T = Not available

F = Available

X_NA BOOL —— Indicates if an input from the joystick’s x axis is available.

T = Not available

F = Available

YGrp_NA BOOL —— Indicates if an input from a grip-mounted, y-axis, proportional

switch is available.

T = Not available

F = Available

Y_NA BOOL —— Indicates if an input from the joystick’s y axis is available.

T = Not available

F = Available

JS1 CANplus function block EMCY output

Signal Type Range Description

EMCY —— ——

Error_Code U16 0 to 0xFFFF

Error_Register U8 0 to 10000

OccurrenceCounter U8 0 to 127 Indicates number of recorded instances of the error.

Outputs a bus that contains the following status signals. These

signals indicate errors and failure information reported by the

joystick.

Indicates the specific error condition reported for the joystick.

• 0x3110 = Voltage high

• 0x3120 = Voltage low

• 0xFF10 = Not calibrated

• 0xFF20 = Redundancy failure

Indicates what type of error is reported by the joystick.

• Bit 0 : Generic

• Bit 1 : Current

• Bit 2 : Voltage

• Bit 3 : Temperature

• Bit 4 : Communication

• Bit 5 : Device

• Bit 6 : Reserved

• Bit 7 : Manufacturer Specific

6 | © Danfoss | February 2020 AQ309185946321en-000101

Page 7

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

JS1 CANplus function block EMCY output (continued)

Signal Type Range Description

SensorIdentifier U8 0 to 255

Rx_EMCY BOOL ——

Fault outputs a bus with signals that report joystick faults. The following table describes these signals.

JS1 CANplus function block Fault output

Signal Type Range Description

Btn1_Flt–Btn12_Flt BOOL —— Indicates if the input from a grip-mounted push-button switch

T_Flt BOOL —— Indicates if the input from the joystick’s rotational (theta) axis

TimeOut_Heartbeat BOOL —— Indicates if the function block receives a CAN Rx_HEARTBEAT

TimeOut_PDO1 BOOL —— Indicates if the function block receives a CAN Rx_PDO1 (Process

TimeOut_PDO2 BOOL —— Indicates if the function block receives a CAN Rx_PDO2 (Process

Indicates the source of the error reported by the joystick.

• 0x80 = X

• 0x81 = Y

• 0x82 = Grip X

• 0x83 = Grip Y

• 0x84 = Grip Theta

Indicates when the function block receives a CANopen EMCY

message. This message reports joystick detected failures and

fault conditions.

T = Message received.

F = Message not received.

has a fault.

T = Fault

F = No fault

has a fault.

T = Fault

F = No fault

(Receive HEARTBEAT Message) within a defined timeout limit.

This message reports the NMT state of the joystick.

T = Message not received within Heartbeat_Timeout limit

F = Message received within Heartbeat_Timeout limit

Data Object 1) within a defined timeout limit.

This message reports the status of buttons and digital inputs.

When this signal is T, the function block sets all Out signals

associated with the Rx_PDO1 message to either 0 or F. It sets all

Fault signals associated with the Rx_PDO1 message to T.

When this signal becomes F again, the function block enables

all Out signals associated with the Rx_PDO1 message. It resets

all Fault signals associated with the Rx_PDO1 message to F.

T = Message not received within a PDO1_Timeout limit

F = Message received within a PDO1_Timeout limit

Data Object 2) within a defined timeout limit.

When this signal is T, the function block sets all Out signals

associated with the Rx_PDO2 message to either 0 or F. It sets all

Fault signals associated with the Rx_PDO2 message to T.

When this signal becomes F again, the function block enables

all Out signals associated with the Rx_PDO2 message. It resets

all Fault signals associated with the Rx_PDO2 message to F.

T = Message not received within PDO2_Timeout limit

F = Message received within PDO2_Timeout limit

©

Danfoss | February 2020 AQ309185946321en-000101 | 7

Page 8

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

JS1 CANplus function block Fault output (continued)

Signal Type Range Description

TimeOut_PDO3 BOOL —— Indicates if the function block receives a CAN Rx_PDO3 (Process

Data Object 3) within a defined timeout limit.

When this signal is T, the function block sets all Out signals

associated with the Rx_PDO3 message to either 0 or F. It sets all

Fault signals associated with the Rx_PDO3 message to T.

When this signal becomes F again, the function block enables

all Out signals associated with the Rx_PDO3 message. It resets

all Fault signals associated with the Rx_PDO3 message to F.

T = Message not received within PDO3_Timeout limit

F = Message received within PDO3_Timeout limit

TimeOut_PDO4 BOOL —— Indicates if the function block receives a CAN Rx_PDO4 (Process

Data Object 4) within a defined timeout limit.

This message reports the sensor power of the joystick.

When this signal is T, the function block sets all Out signals

associated with the Rx_PDO4 message to either 0 or F. It sets all

Fault signals associated with the Rx_PDO4 message to T.

When this signal becomes F again, the function block enables

all Out signals associated with the Rx_PDO4 message. It resets

all Fault signals associated with the Rx_PDO4 message to F.

T = Message not received within PDO4_Timeout limit

F = Message received within PDO4_Timeout limit

NoMsgReceived_Heart

beat

NoMsgReceived_PDO1 BOOL —— No PDO1 received from the device.

NoMsgReceived_PDO2 BOOL —— No PDO2 received from the device.

NoMsgReceived_PDO3 BOOL —— No PDO3 received from the device.

NoMsgReceived_PDO4 BOOL —— No PDO4 received from the device.

XGrp_Flt BOOL —— Indicates if the input from a grip-mounted, x-axis proportional

X_Flt BOOL —— Indicates if the input from the joystick’s x axis has a fault.

YGrp_Flt BOOL —— Indicates if the input from a grip-mounted, y-axis proportional

Y_Flt BOOL —— Indicates if the input from the joystick’s y axis has a fault.

BOOL —— No Heartbeat received from the device.

T = No message received since power on.

F = At least one message has been received.

T = No message received since power on.

F = At least one message has been received.

T = No message received since power on.

F = At least one message has been received.

T = No message received since power on.

F = At least one message has been received.

T = No message received since power on.

F = At least one message has been received.

switch has a fault.

T = Fault

F = No fault

T = Fault

F = No fault

switch has a fault.

T = Fault

F = No fault

T = Fault

F = No fault

Out on the JS1_CAN plus function block outputs a bus with command signals.

These command signals originate from the:

8 | © Danfoss | February 2020 AQ309185946321en-000101

Page 9

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

Joystick and its grip mounted buttons and switches.

•

Inputs on the joystick’s connector(s).

•

The following table describes the joystick signals.

(See the table for a description of the signals that originate from the 18 and 24 pin variants.)

JS1 CANplus function block Out output—joystick signals

Signal Type Range Description

Btn1–Btn12 BOOL —— Indicates the states of grip-mounted push-button switches.

T = Closed

F = Open

Rx_PDO1 BOOL —— Indicates when the function block receives a CAN Rx_PDO1

(Process Data Object 1).

T = Message received

F = Message not received

Rx_PDO2 BOOL —— Indicates when the function block receives a CAN Rx_PDO2

(Process Data Object 2).

T = Message received

F = Message not received

Rx_PDO3 BOOL

T_Axis_Psn S16 ±10000 Indicates the position of the joystick’s rotational (theta) axis.

XGrp_Psn S16 ±10000 Indicates the position of a grip-mounted, x-axis proportional

X_Axis_Psn S16 ±10000 Indicates the position of the joystick’s x axis.

YGrp_Psn S16 ±10000 Indicates the position of a grip-mounted, y-axis proportional

Y_Axis_Psn S16 ±10000 Indicates the position of the joystick’s y axis.

Curr_NMT_State U8 0 to 0xFF

Rx_Heartbeat BOOL

Status U16 0, 0x8008 This signal indicates if a parameter fault is declared. It’s a bitwise

—— Indicates when the function block receives a CAN Rx_PDO3

(Process Data Object 3).

T = Message received

F = Message not received

-10000 = -100%

+10000 = +100%

switch.

-10000 = -100%

+10000 = +100%

-10000 = -100%

+10000 = +100%

switch.

-10000 = -100%

+10000 = +100%

-10000 = -100%

+10000 = +100%

The current NMT state of the joystick.

0x00 = Boot Up

0x04 = Stopped

0x05 = Operational

0x7F = Preoperational

—— Indicates when the function block receives a CAN Rx_Heartbeat.

This message reports the joystick's NMT state.

T = Message received

F = Message not received

code, so multiple items can be reported at a time. The following

status codes are provided:

0x0000: No fault

0x8008: At least one parameter is out of range

The following table describes the signals that originate from inputs on the18 pin joystick.

©

Danfoss | February 2020 AQ309185946321en-000101 | 9

Page 10

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

JS1 CANplus function block Out output—18 pin joystick signals

Signal Type Range Description

C1p06_DigIn —— —— The C1p06_DigIn bus contains a DigIn signal.

DigIn BOOL Indicates the state of the input on joystick connector pin

C1p06.

T = Active

F = Inactive

C1p09_DigAn—

C1P12_DigAn

Voltage U16 0–5000 Indicates the voltage applied to joystick connector pins C1p09,

C1p13_DigIn—

C1p18_DigIn

Rx_PDO4 BOOL

—— —— The C1p09, C1p10, C1p11, and C1p12 buses each contain a

DigIn and a Voltage signal.

DigIn BOOL —— Indicates the state of the inputs on joystick connector pins

C1p09, C1p10, C1p11, and C1p12.

T = Active

F = Inactive

C1p10, C1p11, and C1p12.

—— —— The C1p13, C1p14, C1p15, C1p16, C1p17, and C1p18 buses

each contain a DigIn signal.

DigIn BOOL —— Indicates the state of the inputs on joystick connector pins

C1p13, C1p14, C1p15, C1p16, C1p17, and C1p18.

T = Active

F = Inactive

—— Is true for the first cycle that new data is received.

Indicates that the following signals updated -

C1P09_DigAn.Voltage, C1p10_DigAn.Voltage,

C1p11_DigAn.Voltage, C1p12_DigAn.Voltage.

T = A PDO4 message was received this cycle.

F = A PDO4 message was not received this cycle.

The following table describes the signals that originate from inputs on the 24 pin joystick.

JS1 CANplus function block Out output—24 pin joystick signals

Signal Type Range Description

C2p01_DigIn —— —— The C2p01_DigIn bus contains a DigIn signal.

DigIn BOOL Indicates the state of the input on joystick connector pin

C2p01.

T = Active

F = Inactive

C1p07_DigAn, ,C1p08_

DigAn, C1p11_DigAn,

C1p12_DigAn

Voltage U16 0–5000 Indicates the voltage applied to joystick connector pins C1p07,

C2p07_DigIn—

C2p12_DigIn

—— —— The C1p07, C1p08, C1p11, and C1p12 buses each contain a

DigIn and a Voltage signal.

DigIn BOOL —— Indicates the state of the inputs on joystick connector pins

C1p07, C1p08, C1p11, and C1p12.

T = Active

F = Inactive

C1p08, C1p11, and C1p12.

—— —— The C2p07, C2p08, C2p09, C2p10, C2p11, and C2p12 buses

each contain a DigIn signal.

10 | © Danfoss | February 2020 AQ309185946321en-000101

Page 11

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

JS1 CANplus function block Out output—24 pin joystick signals (continued)

Signal Type Range Description

DigIn BOOL —— Indicates the state of the inputs on joystick connector pins

C2p07, C2p08, C2p09, C2p10, C2p11, and C2p12.

T = Active

F = Inactive

Rx_PDO4 BOOL

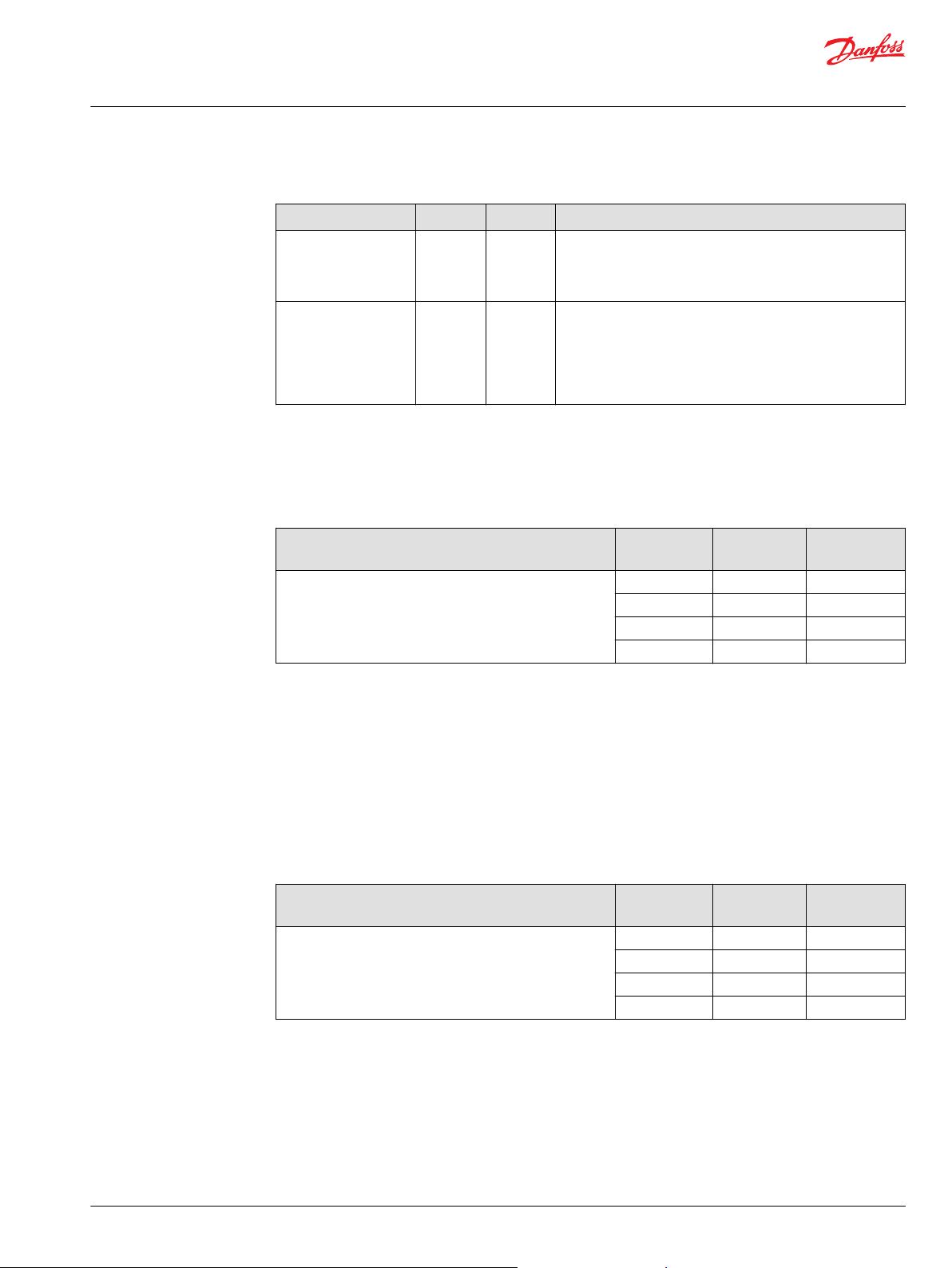

Status and Fault Logic

Boolean Output Signals

The changing states of the Status and Fault signals affect the value of Boolean output signals.

—— Is true for the first cycle that new data is received.

Indicates that the following signals updated -

C1p08_DigAn.Voltage, C1p11_DigAn.Voltage,

C1p12_DigAn.Voltage.

T = A PDO4 message was received this cycle.

F = A PDO4 message was not received this cycle.

Output Signal

Btn1–Btn12, T_Axis_Det, XGrp_Det, X_Axis_Det,

YGrp_Det, Y_Axis_Det

Status Signal

State

F F T or F

T T F

T F F

F T F

Fault Signal

State

Output Signal

Value

For example:

As long as the Status signal and the Fault signal for the Btn1 input are both F, the Btn1 output signal

•

can be either T or F.

As soon as either the Status signal or the Fault signal for the Btn1 input becomes T, the Btn1 output

•

signal goes to and stays F.

When the Status signal and the Fault signal for the Btn1 input are again both F, the Btn1 output

•

signal returns to its normal T or F operation.

Proportional Output Signals The states of the Status and Fault signals can change and affect the value of proportional output signals.

Status Signal

Output Signal

T_Axis_Psn, XGrp_Psn, X_Axis_Psn, YGrp_Psn, Y_Axis_Psn F F ±10000

State

T T 0

T F 0

F T 0

Fault Signal

State

Output Signal

Value

For example:

As long as the Status signal and the Fault signal for the T_Axis_Psn input are both F, the

•

T_Axis_Psn output signal ranges ±10000.

As soon as either the Status signal or the Fault signal for the T_Axis_Psn input becomes T, the

•

T_Axis_Psn output signal goes to and stays at 0.

When the Status signal and the Fault signal for the T_Axis_Psn input are again both F, the

•

T_Axis_Psn output signal returns to its normal ±10000 operation.

©

Danfoss | February 2020 AQ309185946321en-000101 | 11

Page 12

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANopen CANplus Function Block

Configuration of the PLUS+1 GUIDE Template

You do not have to change the configuration of either inputs or outputs in the PLUS+1 GUIDE template

to use the function block.

12 | © Danfoss | February 2020 AQ309185946321en-000101

Page 13

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANplus Service Screens

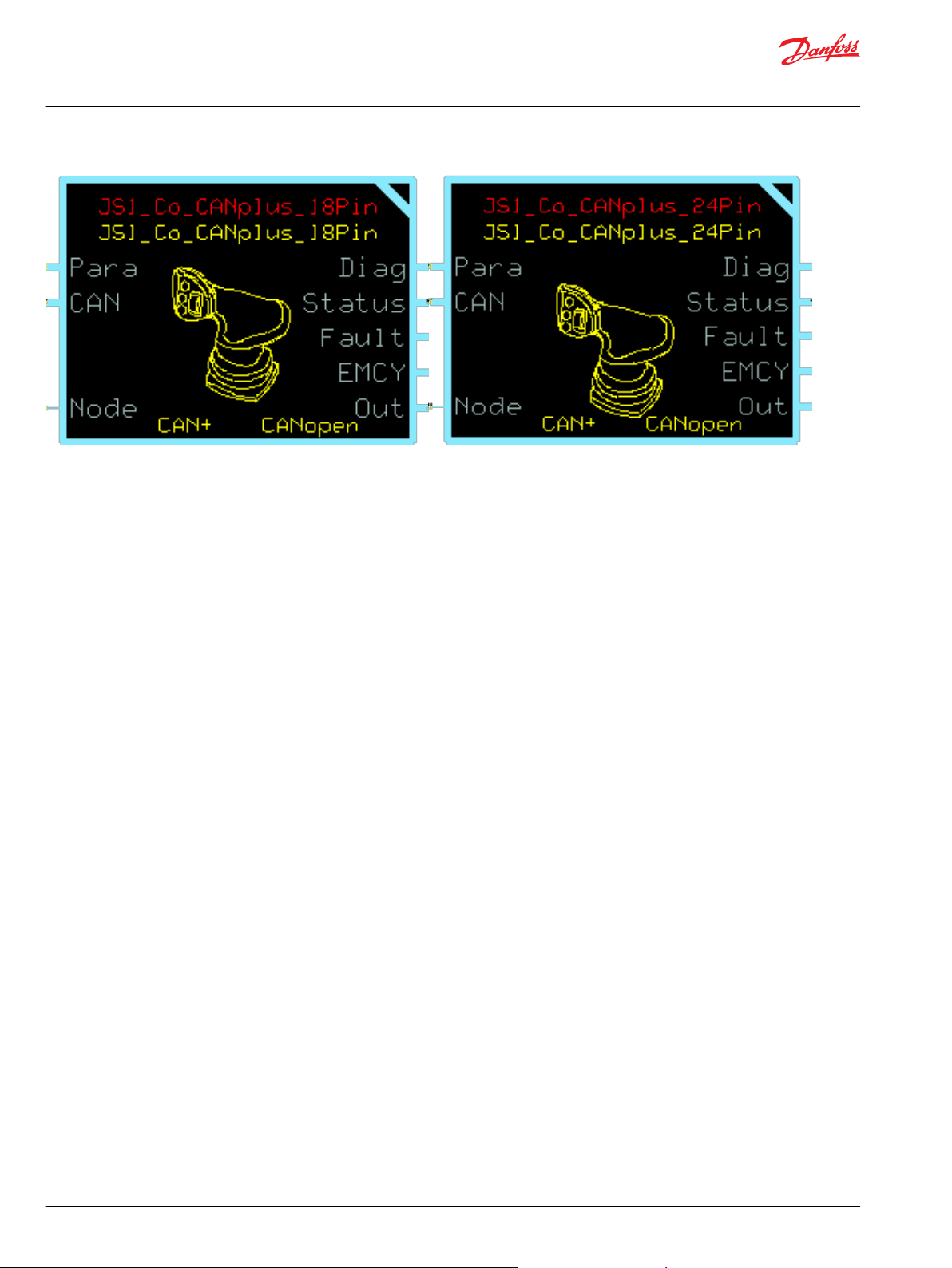

JS1 CANplus 18 Pin Service Screens

JS1_CANplus_18Pin Reusable Panel Screen

JS1_CANplus_18Pin Reusable Panel External Inputs screen description

Name Unit Description

C1p09_DigAn mV

C1p10_DigAn mV

C1p11_DigAn mV

C1p12_DigAN mV

Digitals –

C1p06, C1p13-C1p18

Heartbeat - Timed Out --

Heartbeat NoMsgRcvd

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

--

Indicates the state of the associated digital input on the joystick connector.

On = Active

Off = Inactive

Indicates if the function block receives a CAN Rx_HEARTBEAT (Receive HEARTBEAT

Message) within a defined timeout limit.

This message reports the NMT state of the joystick.

T = Message not received within Heartbeat_Timeout limit

F = Message received within Heartbeat_Timeout limit

--

No Heartbeat message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

©

Danfoss | February 2020 AQ309185946321en-000101 | 13

Page 14

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANplus Service Screens

JS1_CANplus_18Pin Reusable Panel External Inputs screen description (continued)

Name Unit Description

PDO1 - Timed Out --

PDO1 - NoMsgRcvd --

PDO4 - Timed Out --

PDO4 - NoMsgRcvd --

Indicates if the function block receives a CAN Rx_PDO1 (Process Data Object 1)

within a defined timeout limit.

This message reports the status of buttons and digital inputs.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO1 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO1 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO1 message. It resets all Fault signals associated with the

Rx_PDO1 message to F.

T = Message not received within a PDO1_Timeout limit

F = Message received within a PDO1_Timeout limit

No PDO1 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

Indicates if the function block receives a CAN Rx_PDO4 (Process Data Object 4)

within a 2500 ms timeout limit.

This message reports the sensor power of the joystick.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO4 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO4 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO4 message. It resets all Fault signals associated with the

Rx_PDO4 message to F.

T = Message not received within PDO4_Timeout limit

F = Message received within PDO4_Timeout limit

No PDO4 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

JS1_CANplus_18Pin Reusable Panel Joystick Signals screen description

Item Unit Description

Buttons - Btn (1 to 12) --

Node Address --

Positions – X Axis %

Positions – Y Axis %

Positions – T Axis %

Indicates the states of grip-mounted push-button switches.

On = Closed

Off = Open

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Specifies the factory-set node address of the joystick.

The Type code on the joystick label identifies the node address.

Indicates the position of the joystick’s X-axis.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Indicates the position of the joystick’s Y-axis.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Indicates the position of the joystick’s T-axis.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

14 | © Danfoss | February 2020 AQ309185946321en-000101

Page 15

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANplus Service Screens

JS1_CANplus_18Pin Reusable Panel Joystick Signals screen description (continued)

Item Unit Description

Positions – X Grp Axis %

Positions – Y Grp Axis %

PDO1 - Timed Out --

PDO1 - NoMsgRcvd --

PDO2 - Timed Out --

PDO2 - NoMsgRcvd --

PDO3 - Timed Out --

PDO3 - NoMsgRcvd --

Status --

Indicates the position of the joystick’s X-axis proportional switch.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Indicates the position of the joystick’s Y-axis proportional switch.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

How many milliseconds to wait for a response before timing out. A value less than

twenty for this parameter disables timeout checking.

No PDO1 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

How many milliseconds to wait for a response before timing out. A value less than

twenty for this parameter disables timeout checking.

No PDO2 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

How many milliseconds to wait for a response before timing out. A value less than

twenty for this parameter disables timeout checking.

No PDO3 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

This signal indicates if a parameter fault is declared. It’s a bitwise code, so multiple

items can be reported at a time. The following status codes are provided:

0x0000: No fault

0x8008: At least one parameter is out of range

JS1 CANplus 24 Pin Service Screens

This screen shows two panels for the JS1_CANplus_24Pin Function Block. These panels can be reused in

other diagnostic applications.

JS1_CANplus_24Pin Reusable Panel Screen

©

Danfoss | February 2020 AQ309185946321en-000101 | 15

Page 16

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANplus Service Screens

JS1_CANplus_24Pin Reusable Panel External Inputs screen description

Item Unit Description

C1p07_DigAn mV

C1p08_DigAn mV

C1p11_DigAn mV

C1p12_DigAN mV

Digitals –

C2p01, C2p07-C2p12

Heartbeat - Timed Out --

Heartbeat NoMsgRcvd

PDO1 - Timed Out --

PDO1 - NoMsgRcvd --

PDO4 - Timed Out --

PDO4 - NoMsgRcvd --

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

Indicates the voltage applied to the associated joystick connector pin. This signal

also has a digital input that is indicated here.

On = Active

Off = Inactive

--

Indicates the state of the associated digital input on the joystick connector.

On = Active

Off = Inactive

Indicates if the function block receives a CAN Rx_HEARTBEAT (Receive HEARTBEAT

Message) within a defined timeout limit.

This message reports the NMT state of the joystick.

T = Message not received within Heartbeat_Timeout limit

F = Message received within Heartbeat_Timeout limit

--

No Heartbeat message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

Indicates if the function block receives a CAN Rx_PDO1 (Process Data Object 1)

within a defined timeout limit.

This message reports the status of buttons and digital inputs.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO1 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO1 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO1 message. It resets all Fault signals associated with the

Rx_PDO1 message to F.

T = Message not received within a PDO1_Timeout limit

F = Message received within a PDO1_Timeout limit

No PDO1 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

Indicates if the function block receives a CAN Rx_PDO4 (Process Data Object 4)

within a 2500 ms timeout limit.

This message reports the sensor power of the joystick.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO4 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO4 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO4 message. It resets all Fault signals associated with the

Rx_PDO4 message to F.

T = Message not received within PDO4_Timeout limit

F = Message received within PDO4_Timeout limit

No PDO4 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

16 | © Danfoss | February 2020 AQ309185946321en-000101

Page 17

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANplus Service Screens

JS1 CANplus_24Pin Reusable Panel Joystick Signals screen description

Item Unit Description

Buttons - Btn (1 to 12) --

Node Address --

PDO1 - Timed Out --

PDO1 - NoMsgRcvd --

PDO2 - Timed Out --

PDO2 - NoMsgRcvd --

PDO3 - Timed Out --

PDO3 - NoMsgRcvd --

Positions – X Axis %

Indicates the states of grip-mounted push-button switches.

On = Closed

Off = Open

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Specifies the factory-set node address of the joystick.

The Type code on the joystick label identifies the node address.

Indicates if the function block receives a CAN Rx_PDO1 (Process Data Object 1)

within a defined timeout limit.

This message reports the status of buttons and digital inputs.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO1 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO1 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO1 message. It resets all Fault signals associated with the

Rx_PDO1 message to F.

T = Message not received within a PDO1_Timeout limit

F = Message received within a PDO1_Timeout limit

No PDO1 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

dicates if the function block receives a CAN Rx_PDO2 (Process Data Object 2) within

a defined timeout limit.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO2 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO2 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO2 message. It resets all Fault signals associated with the

Rx_PDO2 message to F.

T = Message not received within PDO2_Timeout limit

F = Message received within PDO2_Timeout limit

No PDO2 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

Indicates if the function block receives a CAN Rx_PDO3 (Process Data Object 3)

within a defined timeout limit.

When this signal is T, the function block sets all Out signals associated with the

Rx_PDO3 message to either 0 or F. It sets all Fault signals associated with the

Rx_PDO3 message to T.

When this signal becomes F again, the function block enables all Out signals

associated with the Rx_PDO3 message. It resets all Fault signals associated with the

Rx_PDO3 message to F.

T = Message not received within PDO3_Timeout limit

F = Message received within PDO3_Timeout limit

No PDO3 message received from the device.

Flt = No message received since power on.

OK = At least one message has been received.

Indicates the position of the joystick’s X-axis.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

©

Danfoss | February 2020 AQ309185946321en-000101 | 17

Page 18

User Manual

PLUS+1® Compliant JS1 CANopen CANplus Joystick Function Block

JS1 CANplus Service Screens

JS1 CANplus_24Pin Reusable Panel Joystick Signals screen description (continued)

Item Unit Description

Positions – Y Axis %

Positions – T Axis %

Positions – X Grp Axis %

Positions – Y Grp Axis %

Status --

Indicates the position of the joystick’s Y-axis.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Indicates the position of the joystick’s T-axis.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Indicates the position of the joystick’s X-axis proportional switch.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

Indicates the position of the joystick’s Y-axis proportional switch.

If the NA is active, then the signal is not available. The associated signal is set to

false.

If the Flt is active, then a fault condition currently exists for the signal. The

associated signal is set to false.

This signal indicates if a parameter fault is declared. It’s a bitwise code, so multiple

items can be reported at a time. The following status codes are provided:

0x0000: No fault

0x8008: At least one parameter is out of range

18 | © Danfoss | February 2020 AQ309185946321en-000101

Page 19

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 2080 6201

Products we offer:

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

DCV directional control

•

valves

Electric converters

•

Electric machines

•

Electric motors

•

Gear motors

•

Gear pumps

•

Hydrostatic motors

•

Hydrostatic pumps

•

Orbital motors

•

PLUS+1® controllers

•

PLUS+1® displays

•

PLUS+1® joysticks and

•

pedals

PLUS+1® operator

•

interfaces

PLUS+1® sensors

•

PLUS+1® software

•

PLUS+1® software services,

•

support and training

Position controls and

•

sensors

PVG proportional valves

•

Steering components and

•

systems

Telematics

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electric components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market as well as the

marine sector. Building on our extensive applications expertise, we work closely with you to

ensure exceptional performance for a broad range of applications. We help you and other

customers around the world speed up system development, reduce costs and bring vehicles

and vessels to market faster.

Danfoss Power Solutions – your strongest partner in mobile hydraulics and mobile

electrification.

Go to www.danfoss.com for further product information.

We offer you expert worldwide support for ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also

provide you with comprehensive global service for all of our components.

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequent changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

©

Danfoss | February 2020 AQ309185946321en-000101

Loading...

Loading...