Page 1

Data Sheet

Joystick

JS1000 Joystick Base

Rugged compact design

The unique design of the JS1000 joystick base

incorporates contactless Hall effect sensors into a

simple, compact and rugged mechanical construction

for the most demanding applications. It is ideally

suited for low clearance and armrest mounting, and

yet withstands the most punishing environments.

Environmental sealing

The JS1000 joystick base is designed and tested for

use in harsh out of cab environments. It meets IP 67

environmental protection below the panel mount if

the vent plug is installed. The vent plug is a base

option. If it is not ordered, the base is not protected

from below-panel particulate and moisture ingress.

Environmental protection above the panel mount is

IP 67 with the exception of the Pro grip option. The

Pro grip is for in machine cab use only.

Features

•

Non-contacting hall effect sensing

Available redundant sensing per axis

‒

for CAN output configurations

•

Single or dual axis

•

X – Y axis guided

•

Spring return to center

•

Choice of two centering spring forces

•

Operating life > 10 million cycles per

axis

•

Two output options:

0.5 to 4.5 V

‒

CAN 2.0 B, J1939 protocol

‒

CAN 2.0 B, CANopen protocol

‒

•

IP 67 environmental sealing above

panel (grip dependent)

©

Danfoss | May 2017 520L0724 | AI00000034en-US1101 | 1

DC

•

IP 67 environmental sealing below

panel with vent plug installed (base

dependent)

•

Integrated 6 pin DEUTSCH DTM

connector

•

Multiple grip options:

Ball grip

‒

Grip with analog rocker switch

‒

Grip with analog banana switch

‒

PRO style ergonomic grip, which

‒

offers a wide variety of configurable

push-button switches and

proportional roller switch functions.

(Pro grip is not recommended in an

open cab environment)

Custom designed grips to meet

‒

specific user requirements

Comprehensive technical literature online

at powersolutions.danfoss.com

Page 2

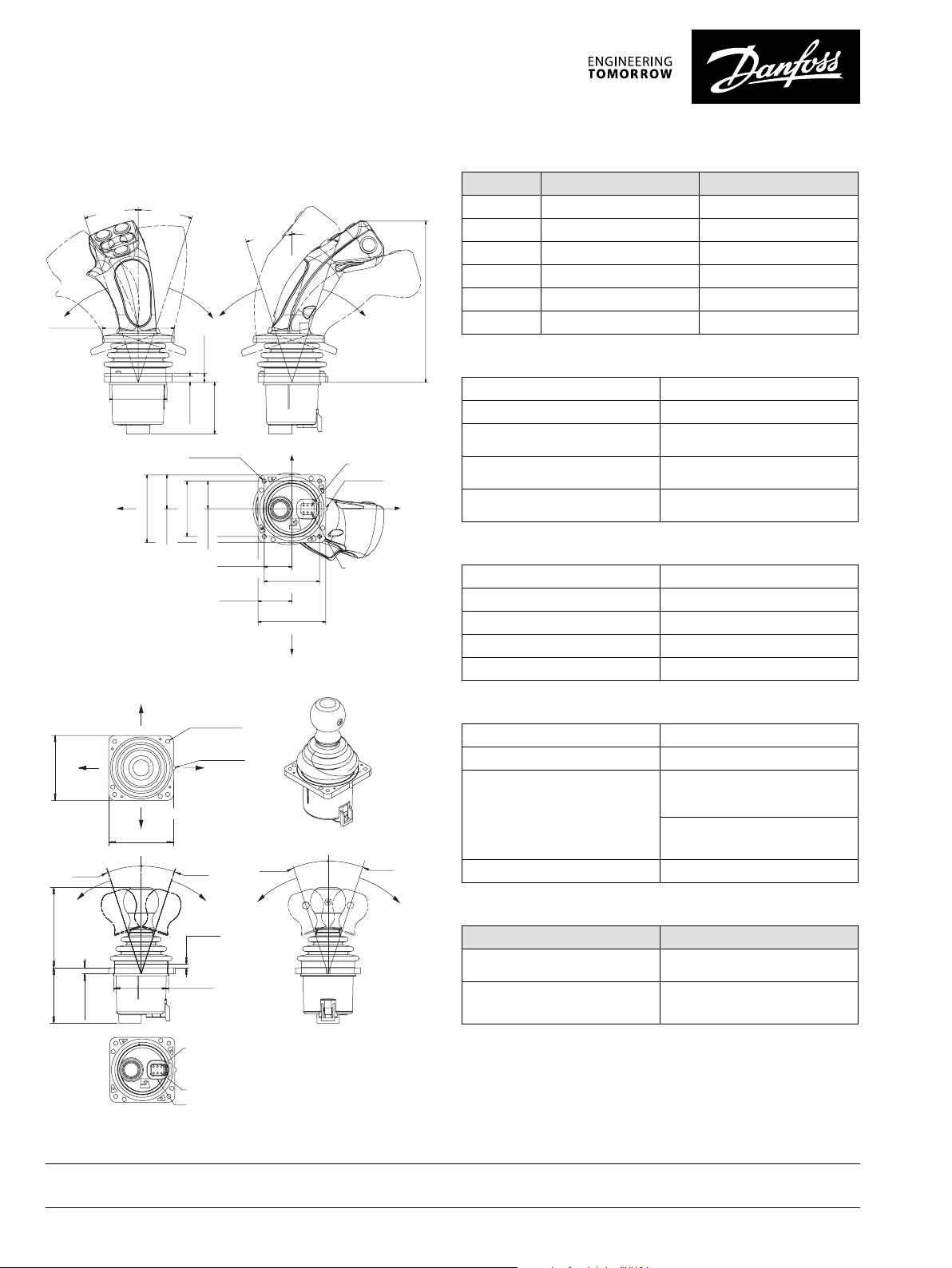

Dimensions in millimeters [inches] and connectors

4 x Ø4.57

±0.05

[0.180

±0.002]

Ø59.4

±0.5

[2.34

±0.02]

74.2 ±0.5 DIA

[2.92 ±0.02]

9.4

±0.5

[0.37 ±0.02]

53.46

±0.

5

[2.1 ±0.02]

6.35

±0.5

[0.25 ±0.02]

Pin 6

Pin 1

166.0

±1

[6.55

±0.0

4

]

18o REF

18

o

REF

18o REF

18o REF

28.58 ±0.12

[1.125 ±0.005]

28.58 ±0.1

2

[1.125 ±0.005]

34.92

±0.5

[1.38 ±0.02]

34.92 ±0.5

[1.38 ±0.02]

69.85

±0.5

[2.75 ±0.02]

69.85 ±0.

5

[2.75 ±0.02]

57.15

±0.12

[2.25 ±0.005]

R2.0

±0.5

[0.08 ±0.02]

57.15

±0.12

[2.25 ±0.005]

P005 244E

Decreasing

X

Decreasing

X

Increasing

X

Increasing

X

Increasing

Y

Increasing

Y

Decreasing

Y

Decreasing

Y

Motion

Multiaxis (X and Y)

Single Axis (Y only)

18o REF

3.8 [0.15]

Max panel

Feed-Thru MTG

18o REF

69.85

±0.

5

[2.75

±0.0

2

]

69.85 ±0.5

[2.75 ±0.02]

Decreasing

X

Decreasing

X

Increasing

X

Increasing

X

Increasing

Y

Increasing

Y

Decreasing

Y

Decreasing

Y

18o REF

18o REF

P005 243E

4 x Ø4.57

±0.05

[0.180

±0.002]

Ø59.4

±0.05

[2.34

±0.002]

59.6

±0.5

[2.35 ±0.02]

6.35

±0.5

[0.25 ±0.02]

86.61

±0.

5

[3.41 ±0.02]

R2.03

±0.5

[0.08 ±0.02]

Pin 6

Pin 1

Mating connector DEUTSCH DTM06-6S

PRO Grip

Ball Grip

Pin assignments

Pin CAN Analog

Pin 1 Ground Ground

Pin 2 Power Power

Pin 3 CAN high X output signal

Pin 4 CAN low Y output signal

Pin 5 CAN shield Rocker switch

Pin 6 No connection No connection

Electrical characteristics

Sensor type Hall effect

Resolution Infinite

Supply voltage (Vs)

Output

Current consumption

Analog output: 5 ± 0.5 Vdc

CAN: 9 to 32 Vdc

Analog: 0.5 to 4.5 Vdc nominal

CAN: 2.0 B, J1939 protocol

25 mA

PRO grip = 150 mA

Mechanical characteristics

Lever mechanical angle ±18° on axis

Operating life > 10 million cycles

Vibration 7.67 Gs RMS

Shock 50 Gs

Weight (base without grip) 0.38 kg [0.838 lb]

Environmental parameters

Operating temperature -40° C to +80° C [-40° F to +175° F]

Storage temperature -55° C to +85° C [-67° F to +180° F]

Protection

EMI/RFI rating 100 V/m

Mating connector assemblies

Type Danfoss part number

6 pin DEUTSCH connector

bag assembly

6 pin connector with 400 mm

[15.75 in] leads

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

2 | © Danfoss | May 2017 520L0724 | AI00000034en-US1101

Above panel ball grip: IP 67

(PRO grip IP 43 and IP 40 with

proportional roller function)

Below panel: IP 67 with vent plug

installed

10101551

10101557

Loading...

Loading...