Operation instruction

JIP Hot Tap Equipment

Description

The equipment makes it possible to connect new

branches to the net while in operation within the

dimensions from DN 20 up to DN 100.

This hot tap equipment should only be used in

district heating systems. If another application is

requested, please contact the producer.

Preparations

Notice: Generally good visibility and secured

position is required on the place to drill and

tap. To avoid injuries please make use of

protective gloves, protective spectacles and

protective clothing.

*

Before every drilling the main tool has to be

inspected. Please make sure that the drill/

hole-saw is in such a condition that the

process can be carried through; otherwise the

drill/hole saw has to be sharpened or renewed.

* Defective sealing and gaskets are to be

renewed.

* All Screws, which hold the centre drill and

the hole saw, have to be tightened very hard

before every tapping process.

Important message

Please observe the German directive FW 432

from October 1998 (former: AGFW-directive

4.2.8 from June 1995). This directive contains:

“Betriebliche Mindestanforderungen an die

Erstellung eines Rohr-abzweiges an in Betrieb

befindlichen Fernwärme-leitungen” (min.

working instructions when connection branches

to district heating pipes in operation according

to the hot tap method).

DEN-SMT/SI

VI.KD.E1.02 © Danfoss 04/2014

1

Operation instruction JIP Hot Tap Equipment

Design

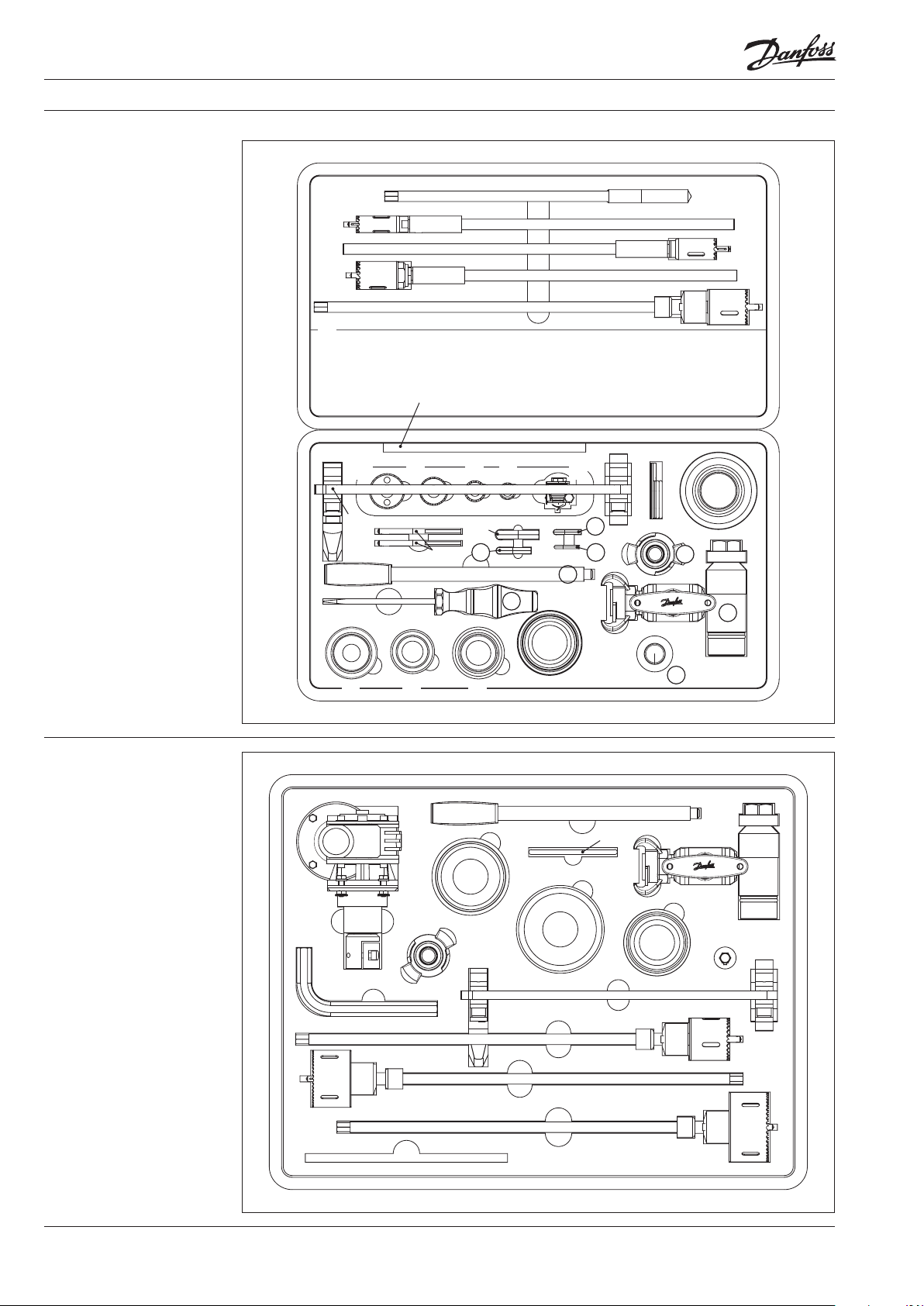

1. 065N8006 - Drill Ø15

2. 065N7997 - Hole saw Ø19

3. 065N8008 - Hole saw Ø24

4. 065N7998 - Hole saw Ø32

5. 065N8010 - Hole saw Ø40

6. 20100098 - Center drill inst.

20100100 - Hot tapping inst.

20100101 - Table of contents

7. 065N8013 - Hole saw ø40

8. 065N8089 - Hole saw ø32

9. 065N8012 - Hole saw ø24

10. 065N8086 - Hole saw ø19

11. 065N8099 - Allen key set

12. 065N8101 - Service set

13. 065N8080 - Adapter ø26,9

14. 065N8087 - Adap. ø33,7-ø42,4

15. 065N8005 - Adap. ø48,3-ø60,3

16. 065N8084 - Adap. ø26,9-ø33,7

17. 065N8151 - Adap. ø48,3-ø60,3

18. 065N8103 - Feed tool

19. 065N8016 - Center drill 1/4"

20. 065N8241 - Allen key 10 mm

21. 065N8247 - Allen key 7 mm

22. 80100022 - Allen key 5 mm

23. 065N8248 - Allen key 4 mm

24. 065N7996 - Screw coupling

25. 065N8109 -

26. 065N8090 - Schrewdriver

27. 065N8130 - Hot tapping tool

28. 8010010 0 - Handle

Handle for feed tool

①

③

⑤

⑦ ⑧ ⑨ ⑩ ⑪

⑱

⑥

⑲

⑳

21

26

25

22

23

②

④

⑫

⑮

24

27

Design

1. 065N8102 - Reduction

wren ch 1:7

2. 065N8109 - Handle for feed

tool

3. 065N8130 - Hot tapping tool

4. 065N8112 - Service set

5. 065N8091 - Adapter ø76,1

6. 065N8094 - Adapter ø88,9

7. 065N8095 - Adapter ø114,3

8. 065N7995 - Stem for drilling

machine

9. 065N7996 - Screw coupling

10. 065N8242 - Allen key 14 mm

11. 065N8103 - Feed tool

12.

065N8172 - Hole saw ø48 comp.

13.

065N8192 - Hole saw ø65 comp.

14.

065N8193 - Hole saw ø79 comp.

15. 20100099 - Center drill inst.

20100100 - Hot tapping inst.

20100102 - Table of contents

⑬ ⑭

⑯

①

⑨

⑩

⑬

②

⑥

⑪

⑰

⑦

④

⑤

28

③

⑧

⑫

⑭

⑮

2

VI.KD.E1.02 © Danfoss 04/2014

DEN-SMT/SI

Operation instruction JIP Hot Tap Equipment

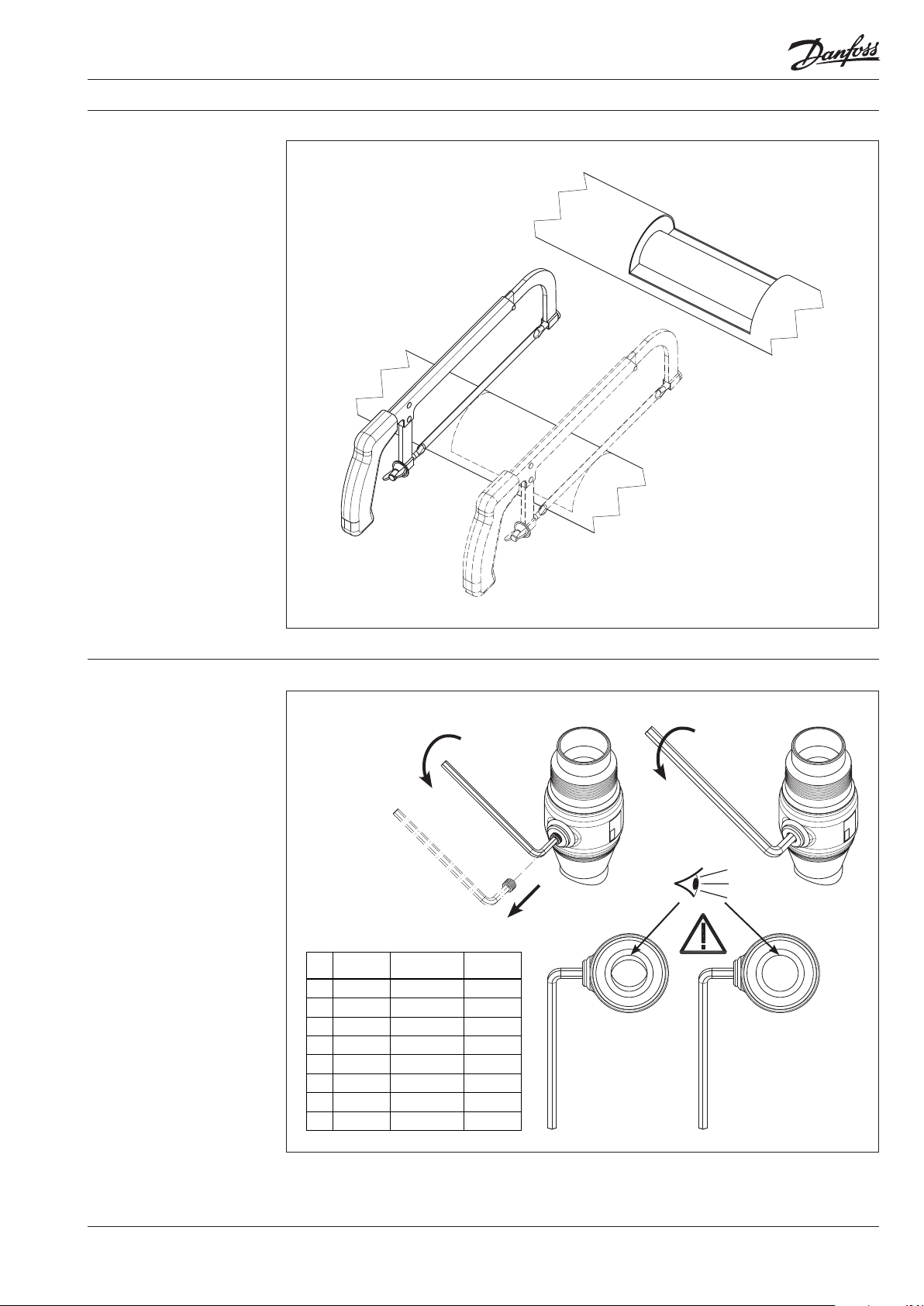

Removing the insulation

Note:

Remove the insulation and clean the

surface of the main pipe carefully.

Adjust the hot tap valve

Note:

Before adjusting the hot tap valve

remove the conical lock screw ①

from hot tap valve, operate the

valve and set it back to fully open

position ③ using correct tools.

①

①

Conical

DN

lock screw

20 Allen Key 5 Flat screw driver 065N0106

25 Allen Key 7 All en Key 10 06 5N 0111

32 Allen Key 7 Allen Key 10 06 5N 0116

40 A llen Key 7 Alle n Key 10 065N 0121

50 Allen Key 7 Al len Key 10 065N0126

65 Allen Key 10 Allen Key 14 06 5N0131

80 Allen Key 10 Allen Key 14 0 65N0 136

100 Allen Key 10 Alle n Key 14 065N 0141

③

Valve

Operation

Valve

Code No.

③

②

DEN-SMT/SI

VI.KD.E1.02 © Danfoss 04/2014

3

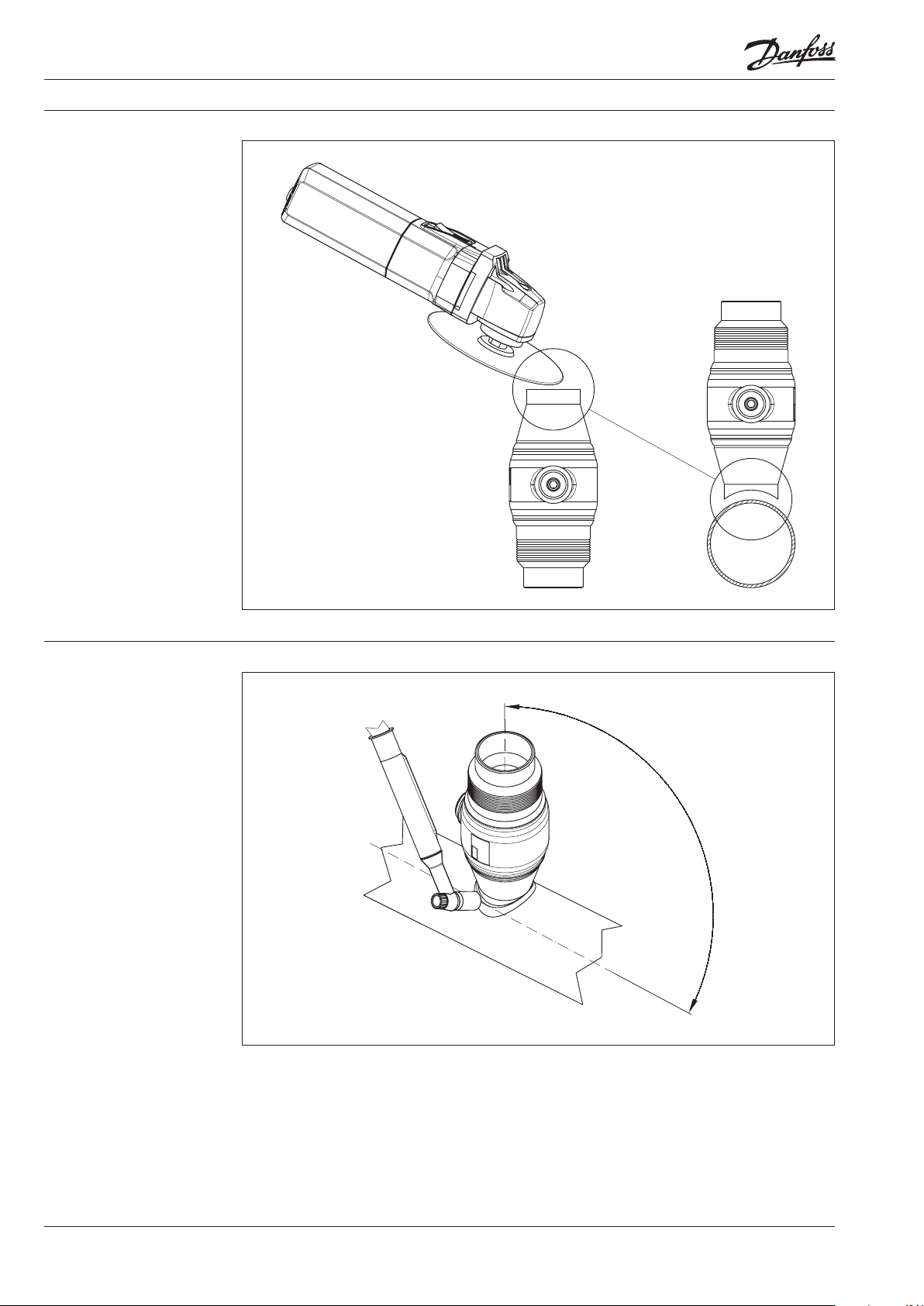

Operation instruction JIP Hot Tap Equipment

Adjust the hot tap valve

continuous

Note:

It is important that the valve is

handled in a way to prevent grind

particles or other foreign particles

to get into the valve. The hot tap

valve MUST be in completely open

position.

Adjust the weld end of the hot

tap valve by means of a grinding

machine to the rounding of the

main pipe.

Welding of the hot tap valve

Note:

The hot tap valve can be welded on

to the pipe in whatever direction

you wish, but with an angle of

90° on center line of the main

pipe. During welding the hot tap

valve MUST be in completely open

position.

The valve has to be welded on by

electric arc welding. Since you are

going to drill through the valve, it is

very impor tant to make sure that no

welding material enters the valve.

90°

4

VI.KD.E1.02 © Danfoss 04/2014

DEN-SMT/SI

Operation instruction JIP Hot Tap Equipment

Tools mounting

Note:

Respective adapter and drill/holesaw should be selected according to

the valve size.

Mounting

Jip Hot tap Drill / Hole s aw Hole Ø Adapter

20 Drill Ø 15 mm Ø 26,9

25

Hole saw Ø 24 mm Ø 33,7 - Ø 42,4

32

40 Hole saw Ø 40 mm Ø 48,3 - Ø 6 0,3

Jip Hot tap Drill / Hole s aw Hole Ø Adapter

50 Hole saw Ø 40 mm Ø 48,3 - Ø 6 0,3

65 Hole saw Ø 48 mm Ø 76 ,1

80 Hole saw Ø 65 mm Ø 88 ,9

100 Hole saw Ø 79 mm Ø 114, 3

⑦

⑥

⑤

Note:

Adapter is mounted using special

handle following by hole-saw and

hot-tapping tool as shown on the

drawing above.

④

③

②

①

DEN-SMT/SI

VI.KD.E1.02 © Danfoss 04/2014

5

Operation instruction JIP Hot Tap Equipment

Installing feeding tool

⑤

②

≈0°

①

≈35°

③

Note:

To achieve a central pressure on the

drill equipment, it is recommended

to use the enclosed feeding tool.

④

⑥

⑦

6

VI.KD.E1.02 © Danfoss 04/2014

DEN-SMT/SI

Operation instruction JIP Hot Tap Equipment

Reduction wrench

①

Note:

For hot tap valves larger than DN

50 a reduction wrench is to be used.

This is also reccomended for the

smaller valves.

Mounting

④

③

②

⑤

Note:

Always operate with low speed and

without applying high pressure on

the drilling spindle.

Recommended maximum speeds

of the drilling are shown in the table

on the right.

DEN-SMT/SI

Hot-tap

valve size

100 120 rev/min

VI.KD.E1.02 © Danfoss 04/2014

Maxim um

drilling speed

(rev/min)

20

400 rev/min

25

32

40

250 rev/min

50

65 200 rev/min

Using reduction

wranch

Recommended

Obligatory80 150 rev/min

⑦

⑥

⑧

⑨

⑩

7

Operation instruction JIP Hot Tap Equipment

Installing Water hose

①

②

③

④

Note:

The outlet hose is to be connected

firmly with the coupling of the flush

valve. The free end of the hose has

to be placed far away from the place

of drilling and it has to be fastened

to avoid uncontrolled leak of hot

water.

⑦

⑥

⑤

⑧

8

VI.KD.E1.02 © Danfoss 04/2014

DEN-SMT/SI

Operation instruction JIP Hot Tap Equipment

The drilling process

Note:

Before starting the process of

drilling by means of the holesaw, it is to be checked that the

center drill of the hole-saw does

not prevent the ball from closing.

The drill equipment is pulled back

to stop-face and then the ball is

closed carefully. If the center drill is

projected too far into the passage

of the valve, then the tool has to be

dismounted and the center drill has

to be re-adjusted.

Note:

When started - point of no return

Don’t pull back again, you can

damage the barb, and loose the cut

out disc

Look out for reflex pulling back

when the center drill is through the

main pipe wall

Apply moderate pressure on the

feed tool

smaller drilling and sawing chips

less risk of loosing the disc

If hole saw gets stuck do not pull

back, reverse the drilling machine

Adapt flushing ball valve to the

situation

Avoid immerging the hole saw too

deeply into the water flow in the

main pipe.

When drilling large DN under high

pressure

Look out for forces on the drilling

shaft, pushing drilling machine,

feed tool and gear against yourself.

90°

③

②

①

DEN-SMT/SI

VI.KD.E1.02 © Danfoss 04/2014

9

Operation instruction JIP Hot Tap Equipment

The drilling process

continuous

32mm

Before and during drilling the packing box nut

on the main tool is to be tightened manually

to achieve optimal tightness, but at the same

time the drill equipment must be smoothrunning.

①

At the process of drilling it is important that

a necessary differential pressure is achieved

through optimal opening of the flush valve,

at that moment, when the circular blank has

been cut out. The pressure is necessary to

keep the cut away circular blank up in the

hole-saw. Therefore do not enter the drill

equipment further into the main pipe than

necessary.

③

Note:

When the drill /hole-saw is through the

wall of the main p ipe then pull the drill/

hole-saw ca refully all the way back to the

stop- face.

10

VI.KD.E1.02 © Danfoss 04/2014

②

DEN-SMT/SI

Operation instruction JIP Hot Tap Equipment

The drilling process

continuous

Note:

Turn the ball of the hot tap val ve 90° to

closed positio n by using a screwdriver/

Allen key. Make sure th at water does not

run from the hos e. Since the ball in the

hot tap valve has no auto matic stop, you

may have to adjus t the position of the

ball until it is in cor rectly closed position.

Remove the cut out piece

90°

Note:

Now the hot tap too l is to be dismounted

in opposite ord er and the cut out piece

should be rem oved.

Remove the cut out piece

Note:

Afterwa rds the valve can be opened

and the conical scre w mounted and

tightened. To get a ful ly welded pipe

system you must p lace a weld round the

conical screw.

DEN-SMT/SI

VI.KD.E1.02 © Danfoss 04/2014

11

Operation instruction JIP Hot Tap Equipment

The functioning of the

lock-screw

②

①

To illustrate the correct function of the conical lock-screw description is divided two scenarios (a

and b). Both scenarios are based on external demands to design and to the valves being installed in

underground district heating systems.

The design of the valve optimized for pre-insulated systems and insulation can be done without

unnecessary adaption and the requirements in EN 488 regarding fully welded district heating systems

are fulfilled.

Welding the conical lock-screw:

a) After welding in the valve, but before extending the pipe system

If the valve should function as an end valve for a longer period - before the pipeline is extended an end plate is welded on the free end of the valve. In this case the conical lock-screw is sealed with

a suitable sealing material (Teflon band) according to correct guidelines for good workmanship

and hereafter fastened with a common Allen key.

b) After extending the pipe system, but before insulating and covering the digging

When the work extending the pipe system has been finished and the valve is opened, the conical

lock-screw is dismounted, so that the valve can be turned into open position. Hereafter the conical

lock-screw is mounted again and fastened. Finally a welding seam is placed around the conical

lock-screw.

Attention - alternative 1!

It is important to pay attention to the fact that the simple O-ring situated at the stem of the valve

is not securing tightness on a longer view. The final and absolute tightness is reached by placing

the final welding seam around the lock-screw. Hereby you fulfill the requirements to a fully welded

system.

Attention - alternative 2!

If you, for some reason, do not want to fulfill the requirements for a fully welded system, you can

omit the welding seam. In this case the conical lock-screw is sealed with a suitable sealing material

(f.e. Teflon band) according to correct guidelines for good workmanship and hereafter fastened with

a common Allen key. Danfoss A/S consider this solution acceptable and the risk for untightens is

minimal. Danfoss A/S does however not grant any guarantee for tightness.

Insulation

When installation had been finalized insulation should be established.

12

VI.KD.E1.02 Produce d by Danfoss A/S © 0 4/2014

Loading...

Loading...