Data sheet

Full bore JIP™ ball valves (PN 16/25/40)

Description

Danfoss JIP™ full bore ball valves are shut off

valves developed for District Heating and District

Cooling networks, with circulating medium.

It is a range of steel ball valves with fully welded

body.

The valve design makes them ideal for building

installation due to:

• Energy saving: with optimum flow design

valves have highest kv on the market and

consequently lowest pump energy costs.

• Long lifetime and optimal tightness due to

design and material selection in ball seal and

stem seal (carbon reinforced PTFE).

• The valves are maintenance free, besides the

shut off valves in the core distribution

network Danfoss offers a range of

supplementary valves, e.g. hot tap valves,

branching valves, house insertions and twin

valves.

Main data:

• DN 15-400

• kVS= 11-37, 50 0 m3/h

• PN 16 / 25 / 40

• Leakage rate A

(according to EN12266-1) - both directions

• Temperature: 0 … 180 °C

• Medium:

Circulation water / glycolic water up to 50 %

•

Min. storage and transport temperature: − 40 °C

Approvals and norms:

• 100 % final inspection. Leak and shell test as

well as dimension and functionality test is

performed on each and every valve according

to applicable standard

(EN 12266 part 1 P10-P11-P12 & part 2 F20).

• PED Directive 2014/68/EU Modul H1

• Danfoss A/S is certified according to ISO 9001

• Furthermore certified according to ISO 14001

and OHSAS 18001.

© Danfoss | 2021.09 AI182286465485en-011006 | 1

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

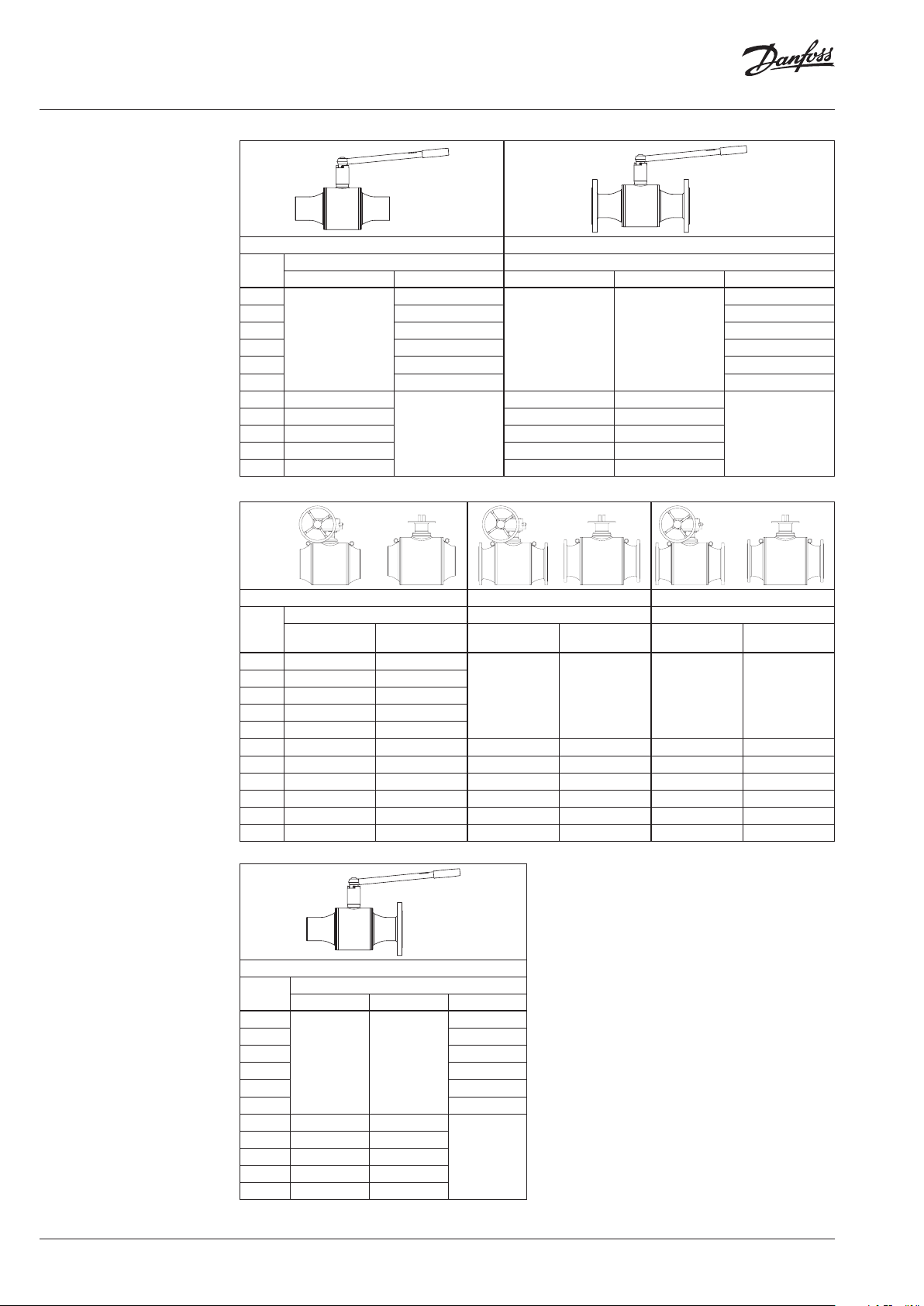

Ordering

JIP-WW welding

JIP-FF flange

JIP-WW welding JIP-FF flange

DN

(mm)

15

20 06 5N11 05 06 5N1305

25 0 65N 1110 06 5N1310

32 0 65 N1115 0 65N1315

40 06 5N112 0 065 N1320

50 065 N1125 06 5N1325

65 06 5N11 30

80 06 5N113 5 06 5N1235 06 5N1335

100 06 5N1740 0 65N1840 065 N1940

125 0 65N174 5 065N1845 0 65N1945

150 06 5N1751 065 N1851 065N1951

Code No. Code No.

PN25 PN40 PN16 PN25 PN40

065 N0100

-

-

065N0300

- -

06 5N1230 06 5N1330

-

JIP-FW flange / welding

JIP-WW welding JIP-FF flange JIP-FF flange

DN

(mm)

50 06 5N11 23 06 5N11 28

65 0 65N 1131 0 65N 1132

80 06 5N1136 0 65 N1137

100 06 5N11 41 06 5N1142

125 0 65N 1146 0 65N 1147

150 0 65N 1151 0 65N 1152 065N12 51 06 5N1252 065N13 51 06 5N1352

200 0 65N115 6 06 5N115 7 0 65N125 6 065 N1257 0 65N13 56 06 5N1357

250 0 65 N1161 065N1162 065N1261 065N1262 06 5N1361 065N1362

300 0 65N 1166 0 65N116 7 065N1266 065N1267 065 N1366 0 65N13 67

350 0 65 N1173 06 5N117 4 0 65N127 3 065N12 74 065 N1373 065 N1374

400 0 65N 1176 065 N1177 065N12 76 065N12 77 06 5N1376 065N1377

DN

(mm)

15

20 06 5N1705

25 06 5N1710

32 0 65N1715

40 065N1720

50 065N1725

65 065N15 30 065 N1630

80 065 N1535 0 65N1635

100 065N1955 065N1970

125 0 65N1961 065N1975

150 065N1965 065N1981

Code No. W W PN25 Code No. FF PN16 Code No. FF PN25

Valve with

worm gear

PN16 PN25 PN40

- -

Valve with

gear flange

JIP-FW flange / welding

Code No.

Valve with

worm gear

065N0700

-

Valve with

gear flange

- - - -

Valve with

worm gear

Valve with

gear flange

2 | AI182286465485en-011006 © Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

Ordering (continuous)

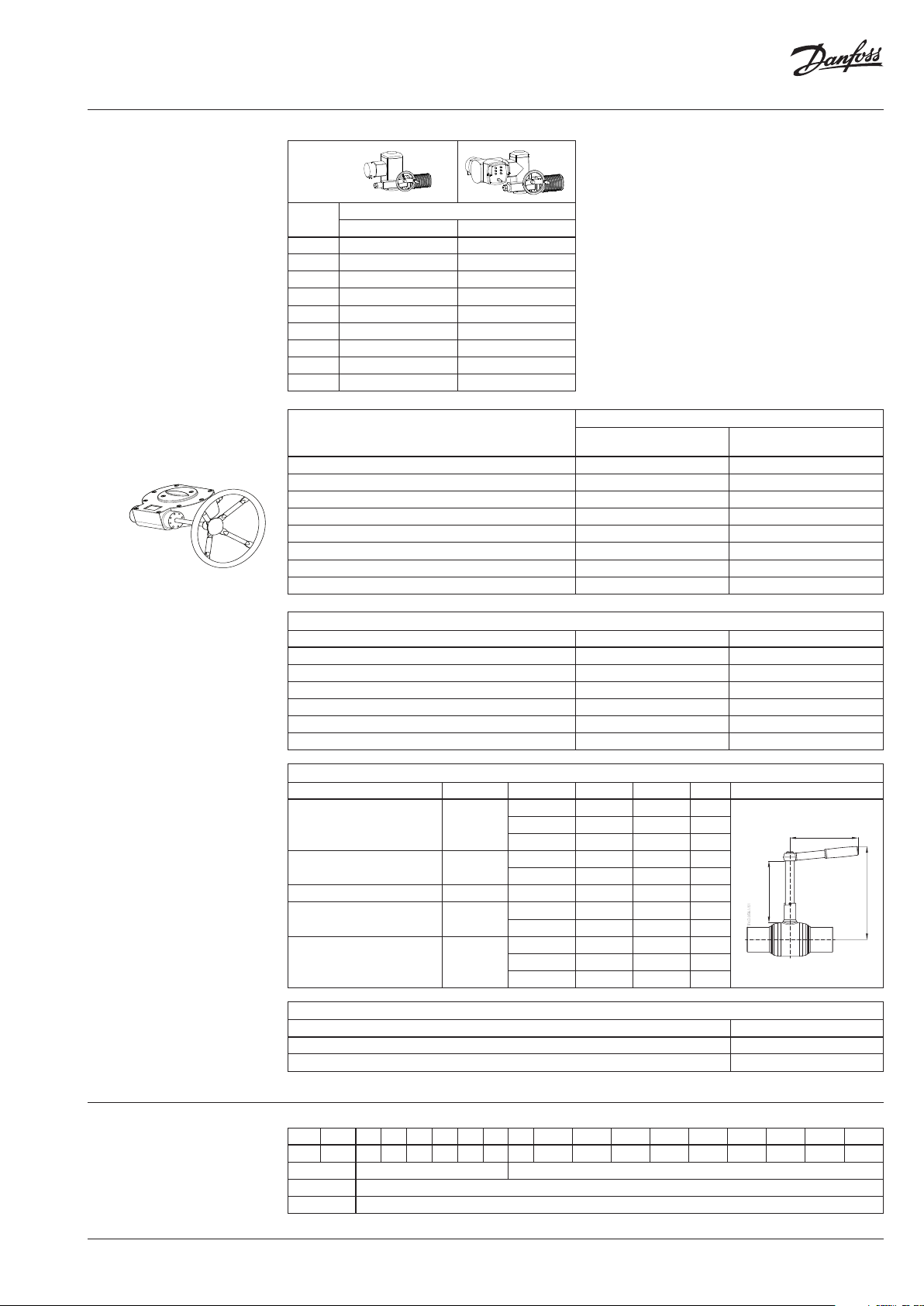

Actuators

Worm gear

Accessories

DN

(mm)

50 065N8397 065N8398

65 065 N8199 065N8399

80 065N8200 065N8400

100-150 065N8205 065N8405

200 065N8220 065N8420

250 065N8225 065N8425

300 065N8235 065N8435

350 065N8240 065N8440

400 065N8265 065N8266

Worm gear for DN50 065N0683 065N0694

Worm gear for DN65-80 065N0684 065N0695

Worm gear for DN 100/125/150 full bore 065N0685 065N0695

Worm gear for DN 200 full bore 065N0691 065N0696

Worm gear for DN 250 full bore 065N0687 065N0697

Worm gear for DN 300 full bore 065N0688 065N0698

Worm gear for DN 350 full bore 065N0689 065N0699

Worm gear for DN 400 full bore 065N0690 065N0699

Type of handle Fixation Code No.

L Steel DN 15-25 full bore with plastic grip spring pin 065N8256

L Steel DN 32-40 full bore with plastic grip spring pin 065N 8257

L Steel DN 50 full bore with plastic grip spring pin 065N8258

L Steel DN 65-80 full bore with plastic grip spring pin 065N8259

L Steel DN 100 full bore with plastic grip screw 065N8000

L Steel angled DN 125-150 full bore with plastic grip screw 065N8001

Auma NORM

Code No.

1)

Description

Auma MATIC

Replacement handles

1)

1)

More information on pag e 12. For additional inf ormation

related to the ele ctric actuator orderin g, please contact local

Danfoss representative.

Code No.

Worm gear

Position indicator with end

switch

Technical data

Handles with extended shaft for pipes with thick insulation

Type of handle Code No. Va lve DN H h S Picture

15 142 196 11 5

Handle DN 15-25 FB L115-H 065N8350

Handle DN 32-40 FB L157-H 065N8351

Handle DN 50 FB L205-H 065N8352 50 208 310 205

Handle DN 65-80 FB L405-H 065N 8353

Handle DN 100 -150FB/

DN200RB L645-HexT-H

Handles Code No.

Red knobs (bag with 100 pieces) 065N8303

Blue knobs (bag with 100 pieces) 065N8304

DN mm 15 20 25 32 40 50 65 80 100 12 5 150 20 0 250 300 35 0 400

kVSm3/h 11 50 90 160 235 395

PN 40 16/2 5

Temp range 0 … 180 °C

Medium Circulation water / glycolic water up to 50 %

065N8356

Marking knobs for handles DN 15-80 full bore (red/blue)

20 142 199 115

25 141 204 115

32 201 279 157

40 200 284 15 7

65 224 351 405

80 224 364 405

100 241 449 6 45

125 251 47 2 645

150 245 492 645

820

1,100 2,300 3,700 6,100 11,000 17,500

H

24,000

S

30,000

37,500

h

AI182286465485en-011006 | 3© Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

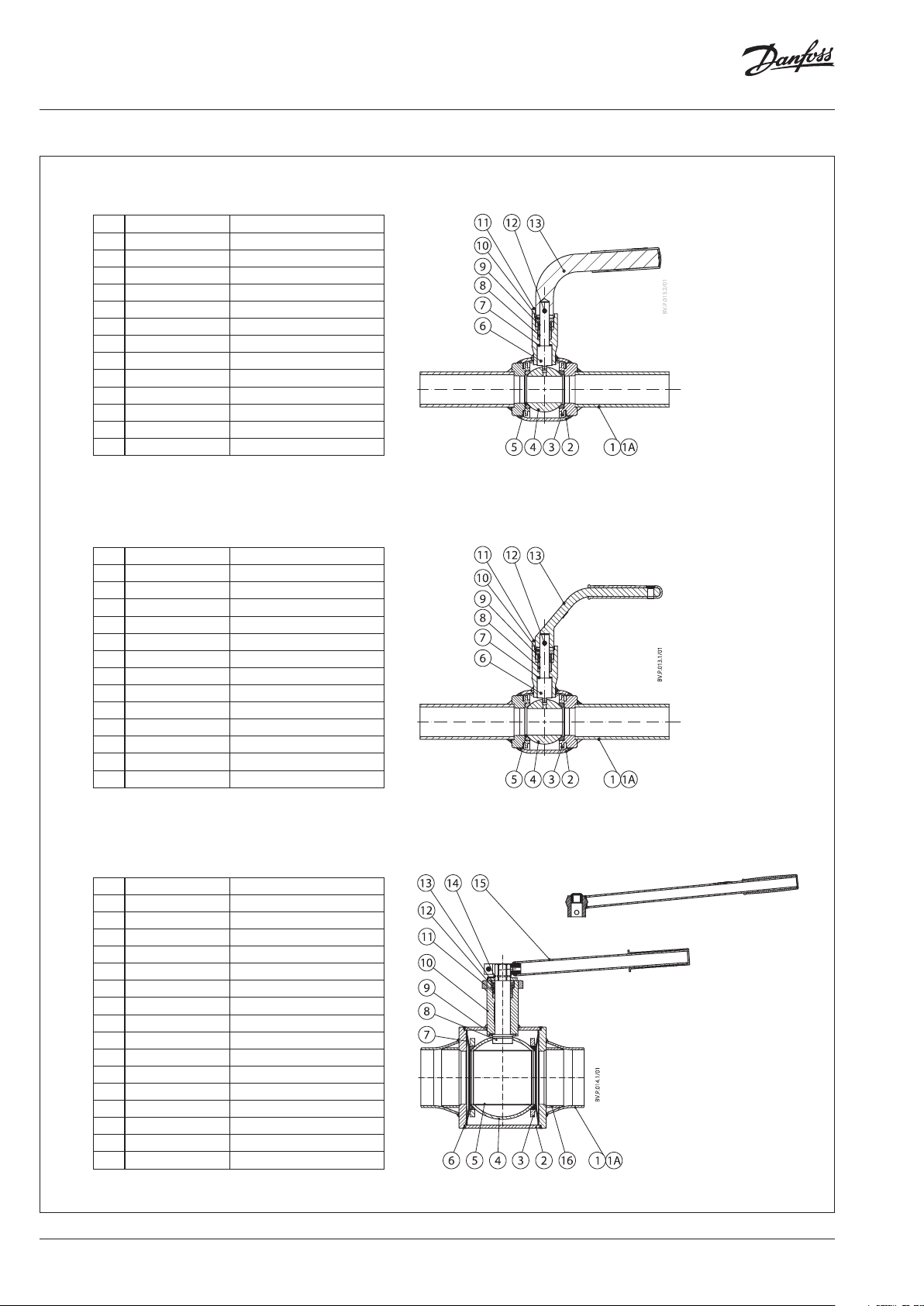

Design & material

1 Welding end *Weldable mild steel 20#

1A Flange *Weldable mild steel 20#

2 Shell *Weldable mild steel 20#

3 Ball seal retainer *Weldable mild steel 20#

4 Ball Stainless steel

5 Ball seal Carbon reinforced PTFE

6 Stem Stainless steel

7 Washer Carbon reinforced PTFE

8 Stem sealing Carbon reinforced PTFE

9 Compression ring Steel

10 Compression nut Steel

11 Packing box *Weldable mild steel 20#

12 Pin Spring steel

13 Handle Steel

DN 15-40 with handle

1 Welding end *Weldable mild steel 20#

1A Flange *Weldable mild steel 20#

2 Shell *Weldable mild steel 20#

3 Ball seal retainer *Weldable mild steel 20#

4 Ball Stainless steel

5 Ball seal Carbon reinforced PTFE

6 Stem Stainless steel

7 Washer Carbon reinforced PTFE

8 Stem sealing Carbon reinforced PTFE

9 Compression ring Steel

10 Compression nut Steel

11 Packing box *Weldable mild steel 20#

12 Pin Spring steel

13 Handle Steel

1 Welding end *Weldable mild steel 20#

1A Flange *Weldable mild steel 20#

2 Shell *Weldable mild steel 20#

3 Ball seal retainer *Weldable mild steel 20#

4 Ball Stainless steel

5 Pipe insert Stainless steel

6 Ball seal Carbon reinforced PTFE

7 Disc spring Domex 650 MC

8 Stem Stainless steel

9 Washer Carbon reinforced PTFE

10 Packing box *Weldable mild steel 20#

11 Stem sealing Carbon reinforced PTFE

12 Compression ring Steel

13 Compression nut Steel

14 Retaining ring Stainless steel

15 Handle Steel

16 Guiding pipe *Weldable mild steel 20#

DN 50-65 with handle

DN80 handle

DN 80-150 with handle

4 | AI182286465485en-011006 © Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

30 0

1,0000

0,1000

0,0100

0,0010

0,0001

0,0005

0,0050

0,0500

0,5000

0,1 0,5 550101

m/sec

100

Design & material (continuous)

1 Welding end *Weldable mild steel 20#

1A Flange *Weldable mild steel 20#

2 Guiding pipe *Weldable mild steel 20#

3 Shell *Weldable mild steel 20#

4 Ball seal retainer *Weldable mild steel 20#

5 Ball Stainless steel

6 Pipe insert Stainless steel

7 Ball seal Carbon reinforced PTFE

8 Disc spring Domex 650 MC

9 Stem Stainless steel

10 Washer Carbon reinforced PTFE

11 Packing box *Weldable mild steel 20#

12 Stem sealing Carbon reinforced PTFE

13 Compression ring Steel

14 Compression nut Steel

15 Retaining ring Stainless steel

16 Key Steel

* According to the GB/T8163. Or equivalent mild s teel in

accordance with CE- PED

DN 50-40 0 with gear flange

Pressure drop / velocity

diagram

∆P (bar)

15 0

50

32

40

15 20

25

DN

400

125

65

200/250

80

00

1

JiP FB

AI182286465485en-011006 | 5© Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

∆P (bar)

15 50 500 5000 5000010 100 1000 10000 100000

m

/h

1,0000

0,1000

0,0100

0,0010

0,0001

0,0005

0,0050

0,0500

0,5000

JiP FB

Pressure drop / flow diagram

Pressure / temperature

diagram

JIP-WW

DN 15 -50

DN15

DN20

DN40

DN32

DN25

DN80

DN50

DN65

DN100

DN125

DN150

DN200

DN250

DN300

DN400

3

DN 65-400

Legend:

Normal operating area

(water)

Steam area

6 | AI182286465485en-011006 © Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

Pressure / temperature

JIP-FF

PN 16, DN 65-400

PN 25, DN 65-400

Legend:

Normal operating area

(water)

Steam area

PN 40, DN 15-50

AI182286465485en-011006 | 7© Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

Hh

S

t

Dimensions

JIP WW welding

F

DN

ØA t ØB ØD L H F ØC S

(mm)

15 42 .4 2.6 21.3 15 230 125 58 24. 5 115 1

20 48.3 2.6 26.9 20 220 125 60 24. 5 115 1.2

25 60.3 2.6 33.7 25 240 130 61 24.5 115 1.4

32 76 .1 2.6 42.4 32 270 170 90 35 15 7 2.7

40 88.9 2.6 48.3 40 275 175 92 35 157 3.6

50 114 .3 2.9 60.3 50 320 19 0 108 45 205 6

65 133 2.9 76.1 65 280 210 113 49 257 8

80 159 3.2 88.9 80 360 225 120 49 257 12

100 193 .7 3.6 114 .3 100 315 245 136 60 360 20

125 219.1 4 139 .7 125 355 295 146 60 655 28

150 273 4.5 168.3 150 375 315 15 2 60 655 41

ØC

ØD

L

ØB

ØA

H

Weight

(kg)

ØC

F

t

ØD

E

L

DN

ØA t ØB ØD L Hh Hg E F ØC O G1 G2 G3

(mm)

50 114. 3 2.9 60.3 50 320 265 120 115 10 8 45 200 107 40 10 0 7

65 133 2.9 76.1 65 280 306 135 13 5 113 49 250 129 54 131 12

80 159 3.2 88.9 80 360 318 125 145 120 49 250 129 54 131 17

100 193.7 3.6 11 4. 3 10 0 315 356 145 165 136 60 250 129 58 132 22

125 219.1 4 139.7 125 355 378 15 4 205 146 60 250 129 58 132 30

150 273 4.5

200 355.6 6.3 219.1 200 485 613 416 340 209 87 450 169 78 192 10 4

250 457 6.3 273 250 595 6 61 493 400 225 100 450 242 107 255 210

300 521 8 323.9 300 740 714 554 480 258 139.7 450 285 143 323 288

350 660 8 335. 6 349 960 803 662 652 324

400 711 8.8

All weights vali d for valves with mounted worm gea r

168.3

150 375 4 01 294 240 145 60 250 129 58 13 2 42

406.4

400 1030 831 693 690 322

Hg

ØB

ØA

G1 G2

168.3

500 324 147 337 635

168.3

500 324 147 337 831

G3

O

Weight

(kg)

8 | AI182286465485en-011006 © Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

S

I

Hh

Dimensions (continuous)

JIP FF flanged

Dimensions (continuous)

JIP FF flanged

F

t

DN

ØA ØD H F ØC S L DF I kg L DF I

(mm)

15 42. 4 15 12 5 58 24.5 11 5 130 95 23 2.3

20 48.3 20 125 60 24.5 115 150 105 21 3

25 60.3 25 13 0 61 24.5 115 16 0 115 20 3.7

32 76 .1 32 170 90 35 15 7 180 140 40 6.2

40 88.9 40 175 92 35 157 200 150 41 7. 4

50 114 .3 50 19 0 108 45 205 230 165 56 11

PN 16 / 25 PN 16 PN 25

65 133 65 210 113 49 257 290 185 59 17.1 290 18 5 59 17. 5

80 15 9 80 225 120 49 257 370 200 64 18.8 310 200 64 20.2

100 193.7 100 245 136 60 360 325 220 83 28 325 235 76 31.4

125 219.1 125 295 146 60 655 365 250 91 38 490 270 81 43.4

150 273 150 315 15 2 60 655 385 285 94 53. 8 510 300 86 61

ØC

ØD

L

ØA

DF

H

Weight

-

(kg)

ØC

I

F

ØA

ØD

E

L

ØA ØD Hh Hg E F ØC O G1 G2 G3 L DF I

DN

(mm)

150 273 150

200

355.6

250 457 250

300 521 300 714 554

350 660 349

400 711

All weights vali d for valves with mounted worm gea r

401

200 613 416

661

803

400

831 693 690 322

PN 16/ 25 PN 16 PN 25

294 240 15 2 60 250 129 58 132 385

340

209

87 450 16 9 78 192 500

493

400

225

100 450 242

480

258

139. 7 450 285

662 652 324

168.3

168.3

Hg

500 324

500 324

DF

107

143

147

147

G2

G1

285

94 57 510

340

148 13 6 635

255

720

405

158 256 720 425 149 26 6

323

835

460

190 329 835

337

980 520 242 690 980 550

337

110 0

580

235 74 8

O

Weight

(kg)

G3

L DF I

110 0

Weight

(kg)

300

86 57

360

138 136

485

178 329

227

690

620 215 74 8

AI182286465485en-011006 | 9© Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

S

ØA

Dimensions (continuous)

JIP FW flanged/welding

ØC

ØB

DN

ØA ØB H F ØC S L DF I kg L DF I

(mm)

15 42.4 15 125 58 24.5 115 18 0 95 23 1.6

20 48.3 20 125 60 24.5 115 185 105 21 2 .1

25 60.3 25 130 61 24.5 115 200 115 20 2.6

32 76.1 32 170 90 35 157 230 140 40 4.5

40 88.9 40 175 92 35 15 7 235 150 41 5.6

50 114. 3 50 190 108 45 205 275 165 56 8.5

PN 16 / 25 PN 16 PN 25

65 133 65 210 113 49 257 285 185 59 10.7 285 185 59 10.7

80 159 80 225 120 49 257 365 200 64 15. 8 335 200 64 15.9

100 19 3.7 10 0 245 136 60 360 320 220 83 22.5 320 235 76 24

125 219.1 125 295 146 60 655 360 250 91 32 .5 360 270 81 35.2

150 273 15 0 315 152 60 655 380 285 94 47.1 380 300 86 50.9

ØD

L

I

F

DF

H

Weight

-

(kg)

10 | AI182286465485en-011006 © Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

Ød

ØD

ØK

Dimensions (continuous)

Valve top and gear flange

DN 50-250 DN 300-400

ØK

ØR

p

n

Open position

l

r

q

t

ØK

ØR

tt

n

l

r

ØD

q

ØR

Full bore

DN

(mm)

Gear

flange

50

65 20 44 16.5 4 6 41 6

80 20 44 16.5 4 6 45 6

100

F10/F12

125 30 50 26 4 8 50.4 7

150 30 50 26 4 8 46.4 7

200

250 60 60 53. 2 6 18 63.7 11

300

350 100 105 80 6 28 113 16

400 F30 100 105 80 6 28 113 16

Ød n q r p l t

PN 16

16 26 13.1 4 5 30 5

F07

30 49 26 4 8 50 7

50 55 44.5 5 14 60 9

F16

75 70 60 6 20 75 12

F25

ØD

Gear

flange

F07

F10 11. 5 150 102 85

F12 13 150 12 5 85

F16 21 210 165 13 0

F25

F30 21 350 298 230

No. of

bolt holes

4

8

Diameter of

bolt holes

ØD ØK ØR

9 88 70 55

17 300 254 20 0

mm

AI182286465485en-011006 | 11© Danfoss | 2021.09

Data sheet Full bore JIP™ ball valves (PN 16/25/40)

S

Dimensions (continuous)

Handles

H

AUMA NORM electrical

actuators for Danfoss

ball valves

DN

100 356 28

125 -150 654 54

Danfoss ball valves Auma Actuators

DN

(mm)

50-65 SQ 05.2 16

80 SQ 07. 2 32

100-150 SQ 10. 2 32

200-250 SA 7.6 (22) + GS 100.3 + VZ 4. 3 142

300 SA 10.2 (22) + GS 125.3 + VZ 4.3 142

350 SA 10.2 (32) + GS 160.3 + GZ 160.3 i=8:1 207

400 SA 10.2 (32) + GS 160.3 F30+ GZ 160.3 i=8:1 207

S H

Typ e

mm

Operating time for 90º turn

(s)

Features:

• 2 limit switches – opening / closing

• 2 torque switches - opening / closing

• Heater

• Blinker switch for operating phase

• Manual operation with hand wheel

• Thermo switch

Main Data:

• Nominal voltage:

- 3×400 VAC, 50 Hz

• Grade of enclosure: IP 68

• Wiring diagram: TPA 00R1AA-000

The actuators can be equipped with various

accessories.

Control and regulating unit AUMA Matic in the

basis design can be supplied.

For other mains voltages than 3×400 V/50 Hz or

additional questions please contact us.

When commissioning and under certain

problematic system conditions, it can be

necessary to choose slower actuators to avoid

water hammering and oscillations.

© Danfoss | DCS-S/SI | 2021.0912 | AI182286465485en-011006

Loading...

Loading...