Page 1

MAKING MODERN LIVING POSSIBLE

Operating Instructions

VLT® ISD Encoder Box

Page 2

Page 3

Contents

Contents

VLT® ISD Encoder Box Operating Instructions

1 General Information

1.1 Important Safety Warnings

1.2 Copyright

1.3 Disclaimer

1.4 Approvals

1.5 Service and Support

2 Introduction

2.1 System Overview

2.2 Terminology

2.3 Purpose of the Operating Instructions

2.4 Additional Resources

3 Safety Instructions

3.1 Symbols used in this Manual

3.2 General

3.3 Safety Instructions and Precautions for the ISD 410 Servo System

3.4 Qualified Personnel

4

4

4

4

4

4

5

5

6

6

6

7

7

7

7

9

3.5 Due Diligence

3.6 Intended Use

3.7 Foreseeable Misuse

4 Description

4.1 Supported Encoders

4.2 ISD Encoder Box Display

4.3 Connection Cable/Cabling

4.3.1 ISD Servo System with 1 Connection Box 12

4.3.2 ISD Servo System with 2 Connection Boxes 13

4.3.3 Connections 14

4.3.3.1 24 V Power Supply (X201) 14

4.3.3.2 CAN Connector (X501 & X502) 15

4.3.3.3 RS 422 I; AB, BiSS and SSI Encoder Connector (X601) 15

4.3.3.4 RS 422 II; Additional Encoder Connector (X602) 16

4.3.3.5 SD Card Slot 16

5 Installation/Fitting

9

9

10

11

11

11

12

17

5.1 Transport and Delivery

5.1.1 Scope of Delivery 17

5.1.2 Transport 17

5.1.3 Inspection on Receipt 17

MG75F102 - VLT® is a registered Danfoss trademark 1

17

Page 4

Contents

VLT® ISD Encoder Box Operating Instructions

5.2 Safety Measures during Installation

5.3 Installation Environment

5.4 Preparation for Installation

5.5 Mechanical Installation

5.5.1 Earthing (Grounding) the Encoder Box 18

5.5.2 Mounting 18

5.5.3 Demounting 18

5.6 Electrical Installation

5.6.1 Electrical Environmental Conditions 18

5.6.2 24 V Power Supply Requirements 18

5.6.3 Connecting the CAN Cable 18

5.6.4 Connecting the Encoder Cable 18

5.6.5 Inserting the SD Card 19

5.6.6 Connecting the 24 V Power Supply 19

6 Commissioning

6.1 Standard Configuration

6.2 Parameter Setting

17

17

17

18

18

20

20

20

6.2.1 Encoder Box Parameter List 20

6.2.2 Changing the Parameters 20

6.2.3 CAN Settings 20

6.2.4 CAN-ID Setting 21

6.3 Switching the Encoder Box on

7 Operation

7.1 Operating Display

7.1.1 Operating LEDs 22

7.1.2 Display Mode 23

7.1.3 7-Segment Display 23

7.1.4 <SET> Push Button 24

7.1.5 <CAN-ID> BCD Switch 24

7.1.6 Service Interface 24

7.2 Display via Toolbox and CoDeSys

8 Faults

8.1 Emergency

21

22

22

24

25

25

8.2 Error History

8.3 Debugging

8.4 Under-Voltage / Power-Failure Behaviour

8.4.1 Under-Voltage during Power-Up 26

8.4.2 Sudden Voltage Drop 26

2 MG75F102 - VLT® is a registered Danfoss trademark

25

25

25

Page 5

Contents

VLT® ISD Encoder Box Operating Instructions

8.4.3 Power Failure 26

8.5 Troubleshooting

9 Maintenance and Repair

9.1 Maintenance tasks

9.2 Inspection during Operation

9.3 Repair

10 Decommissioning and Disposal

10.1 Decommissioning

10.2 Dismounting

10.3 Recycling and Disposal

10.3.1 Recycling 29

10.3.2 Disposal 29

11 Specifications

11.1 Nameplate

11.2 Storage

11.3 Characteristic Data

27

28

28

28

28

29

29

29

29

30

30

30

30

11.4 Dimensions

11.4.1 Front View 31

11.4.2 Side View 32

12 Appendix

12.1 Glossary

12.2 Encoder Box Parameters

12.3 Emergency Codes

12.4 Error Codes

Index

31

33

33

36

39

39

40

MG75F102 - VLT® is a registered Danfoss trademark 3

Page 6

R

C US

General Information

VLT® ISD Encoder Box Operating Instructions

11

1 General Information

1.1 Important Safety Warnings

WARNING

HIGH VOLTAGE

The ISD 410 servo system contains components which

operate at a high voltage when connected to the electrical

supply network. A hazardous voltage is present on the

servomotors, the power supply module and the

connection box whenever they are connected to the mains

network. There are no indicators on the servomotor that

indicate the presence of mains voltage. This indication is

provided on the connection box. Installation, commissioning and maintenance may only be performed by

qualified staff. Incorrect installation, commissioning or

maintenance can lead to death or serious injury.

WARNING

UNINTENDED START

The ISD 410 servo system contains servomotors which are

connected to the electrical supply network and can start

running at any time. This may be caused by an external

switch, a CAN bus command, a reference signal, or clearing

a fault condition. Servomotors and all connected devices

must be in good operating condition. A deficient operating

condition may lead to death, serious injury, damage to

equipment or other material damage when the unit is

connected to the electrical supply network. Take suitable

measures to prevent unintended starts.

1.2

Copyright

Disclosure, duplication and sale of this document, as well

as communication of its content, are prohibited unless

explicitly permitted. Infringement of this prohibition incurs

liability for damages. All rights reserved with regard to

patents, utility patents and registered designs.

ISD is a registered trademark.

1.3 Disclaimer

No liability is assumed for any damage or breakdown

resulting from:

Failure to observe the information in the

•

instruction manuals

Unauthorised modifications to the ISD servo

•

system or its components

Operator error

•

Improper work on or with the ISD servo system

•

or its components.

1.4

Approvals

1.4.1 ISD 410 Servomotor, ISD Encoder Box

and ISD Connection Box

WARNING

DISCHARGE TIME

The servomotors, the connection box and the power

supply module contain DC link capacitors, that remain

charged for some time after the mains supply is switched

off at the power supply module.

To avoid electrical shock, fully disconnect the power

supply module from the mains before carrying out any

maintenance on the ISD servo system or its components.

Wait for at least the time listed below before carrying out

maintenance work:

Number Minimum waiting time (discharge time)

1-60 servomotors 10 minutes

Note: High voltage may still be present even if the LED on the

ISD connection box is not lit!

Table 1.1 Discharge Time

4 MG75F102 - VLT® is a registered Danfoss trademark

Table 1.2 Approvals for the ISD 410 Servomotor, ISD Encoder Box

and ISD Connection Box

ISD Power Supply Module

1.4.2

Table 1.3 Approvals for the ISD Power Supply Module

1.5

Service and Support

Contact your local service representative for service and

support:

http://www.danfoss.com/Contact/Worldwide/

Page 7

130BC480.12

1

2 3

4

5

6

7

9

101112

ISD Connection Box

Failure

Warning

Output (300V) OK

Stand-By

Output (90V) OK

Enable

Error

300V OK

90V OK

300V

Signal Outputs

10A

Signal Inputs

ISD Power Supply Module

AC/DC Power Supply 300VDC 8/10A

Run/Err

U

ZK

24V

Safe

Warn Err

CAN-ID

5V

CAN

RS232

Service

Set

2 8

6

4

Safety I Safety II

Fuse L I CAN 1.In CAN 2.In CAN 3.In CAN 4.In CAN 5.In

X11 X12 X13 X14 X15

Fuse L II CAN 1.Out CAN 2.Out CAN 3.Out CAN 4.Out CAN 5.Out

X21 X22 X23 X24 X25

0

8

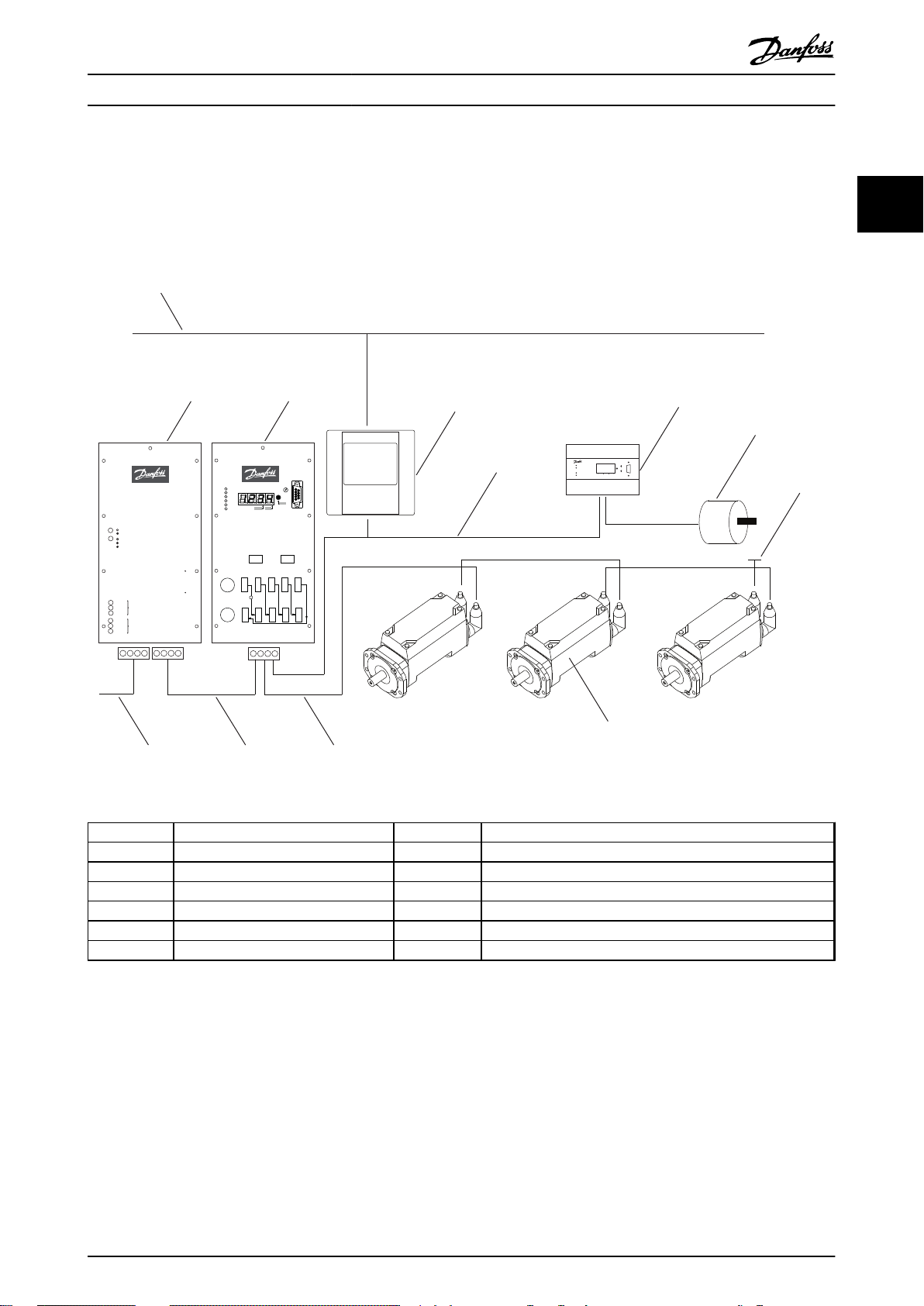

Introduction

2 Introduction

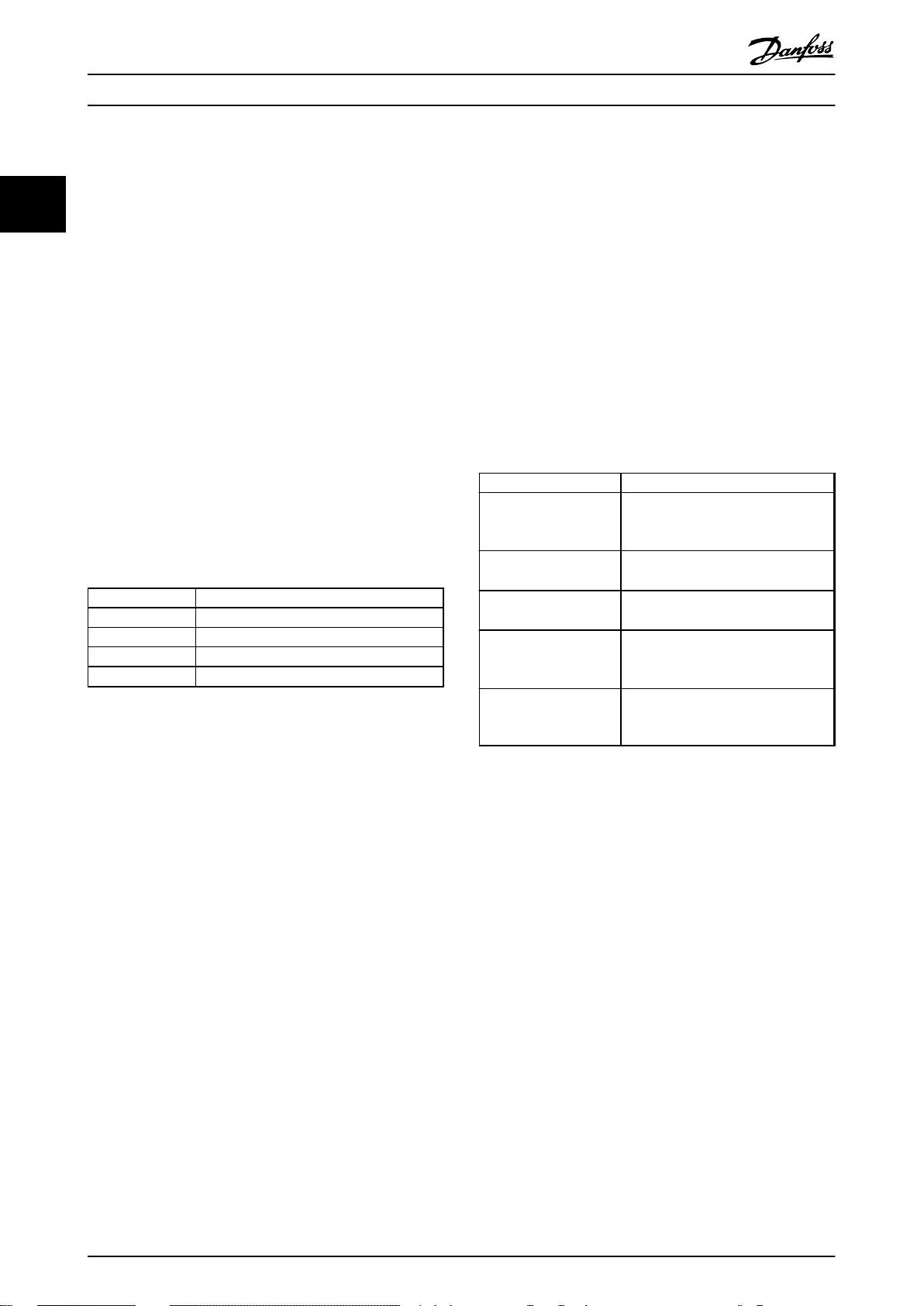

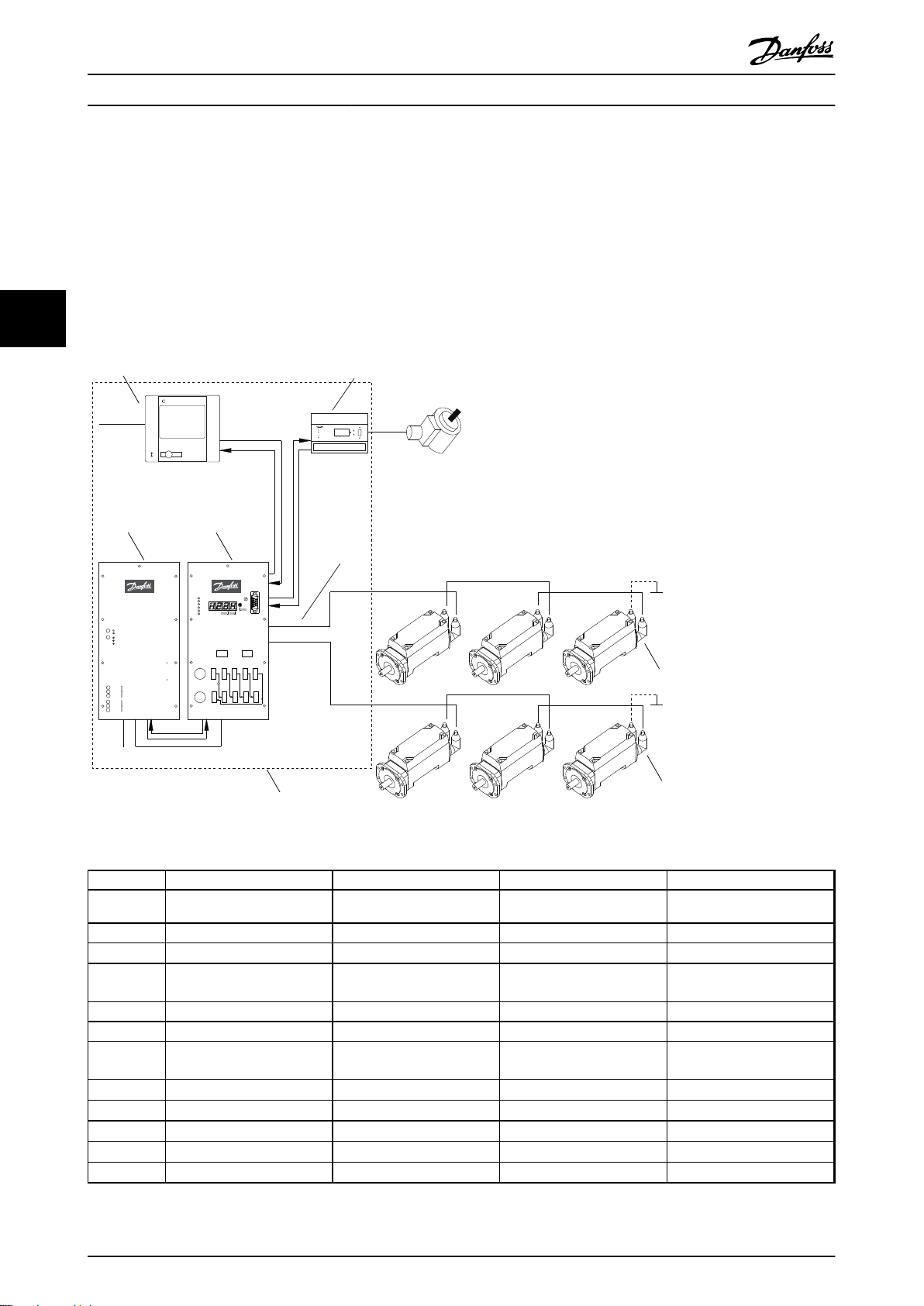

2.1 System Overview

VLT® ISD Encoder Box Operating Instructions

2 2

Illustration 2.1 ISD Servo System with 3 Servomotors

Number

Description Number Description

1 Ethernet 7 Master encoder

2 Power supply module 8 Terminating resistor

3 Connection box 9 ISD servomotor

4 Master 10 Hybrid cable (DC & CAN)

5 CAN line 11 DC line

6 Encoder box 12 AC line

Table 2.1 Legend to Illustration 2.1

The servomotors are self-contained distributed drives,

which means that the drive electronics is housed together

with the motor in the same casing. The motion control

software also runs independently in the servomotor; which

reduces the load on the higher-level control system.

A master system controls the servomotors. In this system

servomotors operated in a DC group are controlled by a

master system.

MG75F102 - VLT® is a registered Danfoss trademark 5

Page 8

Introduction

VLT® ISD Encoder Box Operating Instructions

Several motors can be operated in a group using a hybrid

cable. This cable carries the DC supply voltage and the

CAN bus signals. The ISD 410 servo system is designed to

22

accommodate up to 60 ISD 410 servomotors and consists

of:

1 Power supply module

•

1 Connection box

•

1 Encoder Box

•

Servomotors

•

1 Master

•

Hybrid cables

•

NOTE

The ISD 410 servomotors cannot be used in other servo

systems from other manufacturers!

Motors from other manufacturers cannot be used in the

Danfoss ISD 410 servo system!

2.2 Terminology

ISD Integrated Servo Drives

ISD servo system Complete system including all components.

ISD master Control system hardware

ISD master system Control system hardware and software

ISD servo drive ISD servomotor with hybrid cable

Table 2.2 Terminology

2.3

Purpose of the Operating Instructions

The purpose of these operating instructions is to describe

the Danfoss ISD encoder box exclusively in the context of

a Danfoss ISD 410 servo system.

These operating instructions contain information about:

Installation

•

Commissioning

•

Operation

•

Troubleshooting

•

Maintenance and repair

•

These operating instructions are intended for use by

qualified personnel. Read these operating instructions in

full in order to use the servo system safely and professionally, and pay particular attention to the safety

instructions and general warnings. These operating

instructions are an integral part of the ISD encoder box.

Keep these operating instructions available with the servo

system at all times.

Compliance with the information in the operating

instructions is a prerequisite for:

Trouble-free operation

•

Recognition of product liability claims

•

Therefore, read these operating instructions before

working with the encoder box!

The operating instructions also contain important service

information. The operating instructions should therefore be

kept close to the encoder box.

2.4 Additional Resources

Available documents for the ISD 410 servo system:

Document Contents

VLT® ISD 410

Servomotor Operating

Instructions

VLT® ISD Encoder Box

Operating Instructions

VLT® ISD Connection Box

Operating Instructions

VLT® ISD Power Supply

Module Operating

Instructions

VLT® ISD 410 Design

Guide

Table 2.3 Available Documents for the ISD 410 Servo System

Technical literature for Danfoss drives is also available

online at http://www.danfoss.com/BusinessAreas/DrivesSolutions/Documentations/Technical+Documentation.htm.

Firmware updates may be available. When firmware

updates are available, they can be downloaded from the

www.danfoss.com website. For further information see the

VLT® ISD 410 Design Guide.

Information about the commissioning

and operation of the servomotors

Information about the commissioning

and operation of the encoder box

Information about the commissioning

and operation of the connection box

Information about the commissioning

and operation of the power supply

module

Information about the construction

and commissioning of the ISD 410

servo system

6 MG75F102 - VLT® is a registered Danfoss trademark

Page 9

Safety Instructions

VLT® ISD Encoder Box Operating Instructions

3 Safety Instructions

3.1 Symbols used in this Manual

The following symbols are used in this document.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

WARNING

HAZARDOUS SITUATION

If the servomotor or the bus lines is/are incorrectly

connected, there is a risk of death, serious injury or

damage to the unit.

Always comply with the instructions within these operating

instructions, as well as national and local safety

regulations. Also read the operating instructions for the

other components of the servo system.

3

3

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

CAUTION

Indicates a situation that may result in equipment or

property-damage-only accidents.

NOTE

Indicates highlighted information that should be regarded

with attention to avoid mistakes or operate equipment at

less than optimal performance.

3.2 General

The following safety instructions and precautions relate to

the ISD 410 servo system. The number of servomotors in

the servo system is not significant.

Read the safety instructions carefully before starting to

work in any way with the servo system.

Pay particular attention to the safety instructions in the

relevant sections of this instruction manual.

Also observe the safety instructions and precautions in the

instruction manuals for the other system components.

WARNING

HIGH VOLTAGE

The ISD 410 servo system contains components which

operate at a high voltage when connected to the electrical

supply network.

A hazardous voltage is present on the servomotors, the

power supply module and the connection box whenever

they are connected to the mains network.

There are no indicators on the servomotor that indicate

the presence of mains voltage. This indication is provided

at the connection box. Installation, commissioning and

maintenance may only be performed by qualified staff.

Incorrect installation, commissioning or maintenance can

lead to death or serious injury.

3.3 Safety Instructions and Precautions for

the ISD 410 Servo System

Read the safety instructions carefully before starting to

work in any way with the servo system. Compliance with

the safety instructions and precautions is necessary at all

times.

Orderly and proper transport, storage, fitting and

•

installation, as well as careful operation and

maintenance, are essential for the trouble-free

and safe operation of this servo system and its

components.

Only suitably trained and qualified staff may work

•

on the servo system and its components or in its

vicinity. See chapter 3.4 Qualified Personnel.

Use only accessories and spare parts approved by

•

the manufacturer.

Comply with the specified ambient conditions.

•

The information in these operating instructions

•

about the use of available components is

provided solely by way of examples of

applications and suggestions.

The plant engineer or system engineer is

•

personally responsible for checking the suitability

of the supplied components and the information

provided in this document for the specific

application concerned:

- for compliance with the safety

regulations and standards relevant to

the specific application concerned.

- for implementing the necessary

measures, changes and extensions.

Commissioning the servo system and its

•

components is not allowed until it has been

ascertained that the machine, system or plant in

which they are installed conforms to the statutory

provisions, safety regulations and standards that

apply in the country of use to that application.

MG75F102 - VLT® is a registered Danfoss trademark 7

Page 10

Safety Instructions

VLT® ISD Encoder Box Operating Instructions

3

Operation is allowed only in compliance with the

•

national EMC regulations for the application

concerned.

See the VLT® ISD 410 Design Guide for information

•

regarding EMC-compliant installation of the servo

system.

Compliance with the limit values specified by

•

national regulations is the responsibility of the

producer of the plant, system or machine.

Compliance with the specifications, connection

•

conditions and installation conditions in this

instruction manual is mandatory.

The safety regulations and safety provisions of

•

the country in which the equipment is used must

be observed.

Care must be taken to ensure that orderly

•

protective earthing of the equipment, which

protects the user against the supply voltage and

protects the power supply module against

overload, is performed in accordance with local

and national regulations.

Overload protection for the servomotor can be

•

programmed using the master system. For more

information, see Programming in the VLT

Design Guide.

Do not remove or replace the SD card on the

•

encoder box during operation, otherwise the

contents of the SD card could be destroyed.

Switch the encoder box off and wait 10 seconds

before removing the SD card.

®

ISD 410

WARNING

EARTHING HAZARD

For reasons of operator safety, the components of the

servo system must be earthed correctly in accordance with

national or local electrical regulations and the information

in these operating instructions. The earth leakage current

is greater than 3.5 mA. Improper earthing of the

servomotor may result in death or serious injury.

Operational Safety

Safety-related applications are allowed only if

•

they are explicitly and unambiguously mentioned

in the VLT® ISD 410 Design Guide. Otherwise they

are not allowed.

All applications that can cause hazards to people

•

or damage to property are safety-related

applications.

The stop functions implemented in the software

•

of the master system do not interrupt the mains

voltage supply to the power supply module and

are therefore not allowed to be used as safety

switches for the servo system.

The motor can be brought to a stop by a

•

software command or a zero speed setpoint, but

DC voltage remains present on the servomotor

and/or mains voltage in the power supply

module. If personal safety considerations (e.g. risk

of personal injury caused by contact with moving

machine parts after an unintended start) make it

necessary to ensure that an unintended start

cannot occur, these stop functions are not

sufficient. In this case the servo system must be

detached from the mains network or a suitable

stop function must be implemented.

When the servomotor is stopped, it may start up

•

again on its own if the circuitry of the servomotor

is defective or after the elimination of a

temporary overload, a problem with the supply

voltage or a problem with the servomotor. If

personal safety considerations (e.g. risk of

personal injury caused by contact with moving

machine parts after an unintentional start) make

it necessary to ensure that an unintended start

cannot occur, the normal stop functions of the

servomotor are not sufficient. In this case the

servo system must be disconnected from the

mains network or a suitable stop function must

be implemented.

The servomotor may start running unintentionally

•

during parameter configuration or programming.

If this can pose a risk to personal safety (e.g. risk

of personal injury due to contact with moving

machine parts), unintended motor starting must

be prevented, for example by using the Safe Stop

function or by safe disconnection of the

servomotors.

Do not disconnect the cables from the

•

servomotor while the servo system is connected

to mains voltage. Ensure that the mains supply is

disconnected and the required waiting time has

elapsed before disconnecting or connecting the

hybrid cable or disconnecting cables from the

connection box and/or the power supply module.

8 MG75F102 - VLT® is a registered Danfoss trademark

Page 11

Safety Instructions

VLT® ISD Encoder Box Operating Instructions

In addition to the L1, L2 and L3 supply voltage

•

inputs on the power supply module, the servo

system has other supply voltage inputs, including

external DC 24 V. Before commencing repair

work, check that all supply voltage inputs have

been switched off and that the necessary

discharge time for the intermediate circuit

capacitors has elapsed.

The supply of power to the servo system must be

•

switched off for repair work. Before disconnecting

or connecting the hybrid cable or disconnecting

cables from the connection box and/or the power

supply module, ensure that the mains supply is

disconnected and the necessary discharge time

has elapsed.

WARNING

DISCHARGE TIME

The servomotors, the connection box and the power

supply module contain DC link capacitors, that remain

charged for some time after the mains supply is switched

off at the power supply module.

To avoid electrical shock, fully disconnect the power

supply module from the mains before carrying out any

maintenance on the ISD servo system or its components.

Wait for at least the time listed below before carrying out

maintenance work:

Number Minimum waiting time (discharge time)

1-60 servomotors 10 minutes

Note: High voltage may still be present even if the LED on the

ISD connection box is not lit!

Table 3.1 Discharge Time

CAUTION

Never connect or disconnect the hybrid cable to or from

the servomotor when voltage is present. Doing so will

damage the electronic circuitry. Observe the discharge

time for the DC link capacitors.

3.4 Qualified Personnel

Installation, commissioning and maintenance of the

ISD 410 servo system may only be carried out by qualified

personnel.

For the purposes of this document and the safety

instructions in this document, qualified staff are trained

staff who are authorised to fit, install, commission, earth

and label equipment, systems and circuits in accordance

with the standards for safety technology and who are

familiar with the safety concepts of automation

engineering.

Additionally, the personnel must be familiar with all the

instructions and safety measures described in these

operating instructions.

They must have suitable safety equipment and be trained

in first aid.

3.5 Due Diligence

The operator and/or fabricator must ensure that:

the servo system and its components are used

•

only as intended

the components are operated only in a perfect

•

operational condition

the operating instructions are always available

•

near the servo system in complete and readable

form

the servo system and its components are fitted,

•

installed, commissioned and maintained only by

adequately qualified and authorised personnel

these personnel are regularly instructed on all

•

relevant matters of occupational safety and

environmental protection, as well as the contents

of the operating instructions and in particular the

instructions it contains

the product markings and identification markings

•

applied to the components, as well as safety and

warning instructions, are not removed and are

always kept in a legible condition

the national and international regulations

•

regarding the control of machinery and

equipment, that are applicable at the place of use

of the servo system, are complied with

the users always have all current information

•

relevant to their interests about the servo system

and its use and operation

3.6

Intended Use

The components of the ISD servo system are intended to

be installed in machines used in commercial and industrial

environments.

To ensure that the product is used as intended, the

following conditions must be fulfilled before use:

Everyone who uses Danfoss products in any

•

manner must read and understand the

corresponding safety regulations and the

description of the intended use

Hardware must be left in its original state, which

•

means that no structural changes may be made

to the hardware

3

3

MG75F102 - VLT® is a registered Danfoss trademark 9

Page 12

3

Safety Instructions

Software products may not be reverse-engineered

•

and their source code may not be altered

Damaged or faulty products may not be installed

•

or put into service

It must be ensured that the products are installed

•

in conformance with the regulations mentioned

in the documentation

Any specified maintenance and service intervals

•

must be observed

All protective measures must be complied with

•

Only the components described in these

•

operating instructions may be fitted or installed.

Third-party devices and equipment may be used

only in consultation with Danfoss

The documentation must be read completely and

•

correctly followed

The servo system may not be used in the following

application areas:

VLT® ISD Encoder Box Operating Instructions

Areas with potentially explosive atmospheres

•

Mobile or portable systems

•

Floating or airborne systems

•

Inhabited facilities

•

Sites where radioactive materials are present

•

Areas with extreme temperature variations or in

•

which the maximum rated temperatures may be

exceeded

Under water

•

3.7

Foreseeable Misuse

Any use not expressly approved by Danfoss constitutes

misuse. This also applies to failure to comply with the

specified operating conditions and applications.

Danfoss assumes no liability of any sort for damage attributable to improper use.

10 MG75F102 - VLT® is a registered Danfoss trademark

Page 13

130BD085.10

Run/Err

Power

CAN I

Warn

Err

0

CAN-ID

CAN II

RS232

Service

Set

2 8

6

4

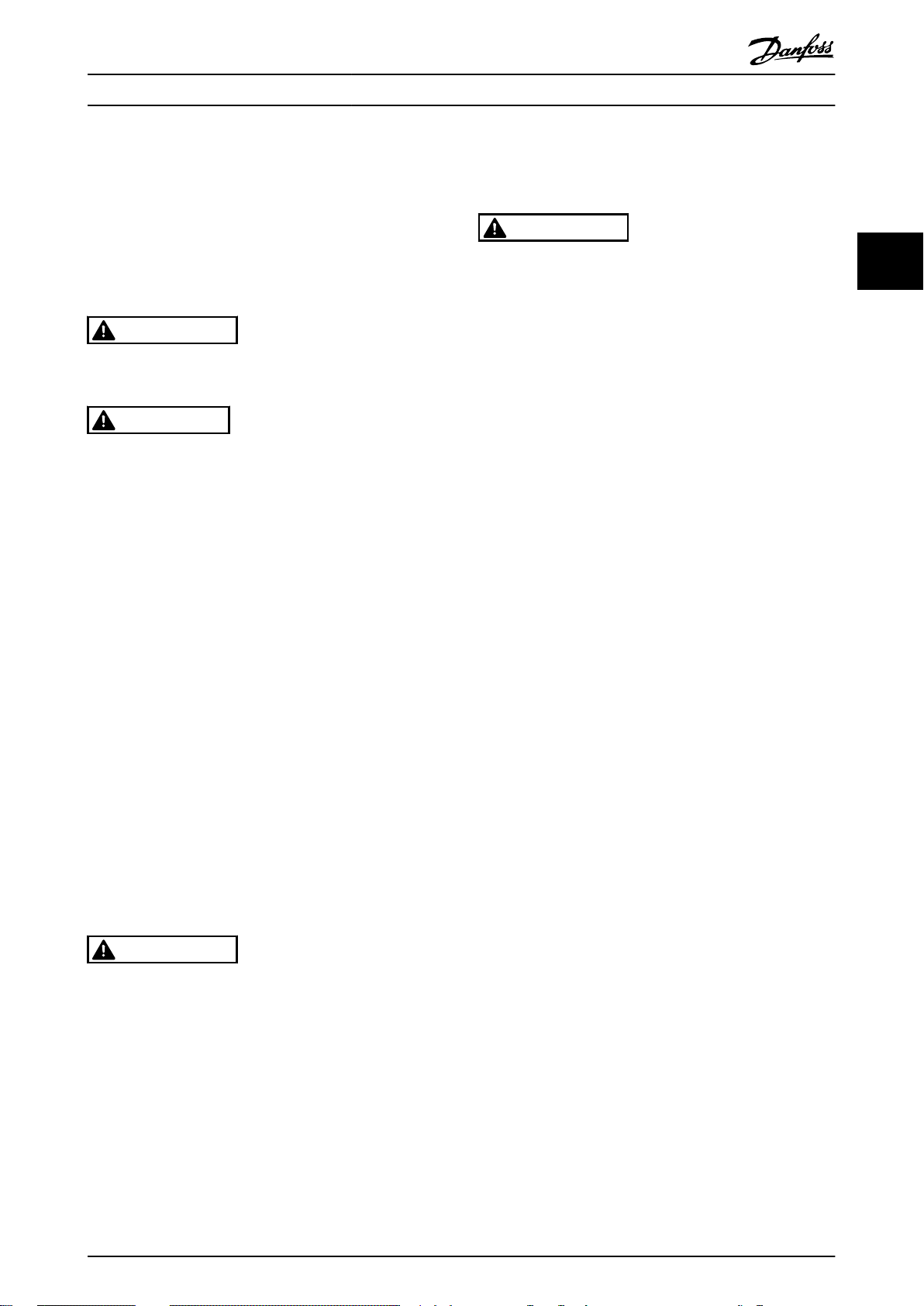

ISD Encoder Box

Description

VLT® ISD Encoder Box Operating Instructions

4 Description

The encoder box is intended to be used in an environment

where several servo drives require an exact position in

order to follow a specific curve profile, or to determine the

speed at which the machine is running. The position can

be read either from an externally connected encoder or

from a software encoder simulation running on the

encoder box.

The encoder box reads the position values from

•

an absolute or incremental encoder, applies a

precise timestamp and sends them periodically to

the CAN.

DS301 and DS406 of the CAN-CiA-Standard are

•

implemented in the encoder box.

The object dictionary is detailed in the VLT

•

ISD 410 Design Guide.

The encoder box fulfils the requirements of class

•

2 encoders according to the DS406 CAN standard.

When simulating the encoder the speed and

•

ramp can be set.

If an error or unexpected event occurs the

•

encoder box transmits an emergency message

(error code).

Every error is logged in the encoder box memory

•

and remains in the error history. However a

maximum of 6 errors and 6 warnings are saved

and older events are overwritten (first-in-first-out

principle).

®

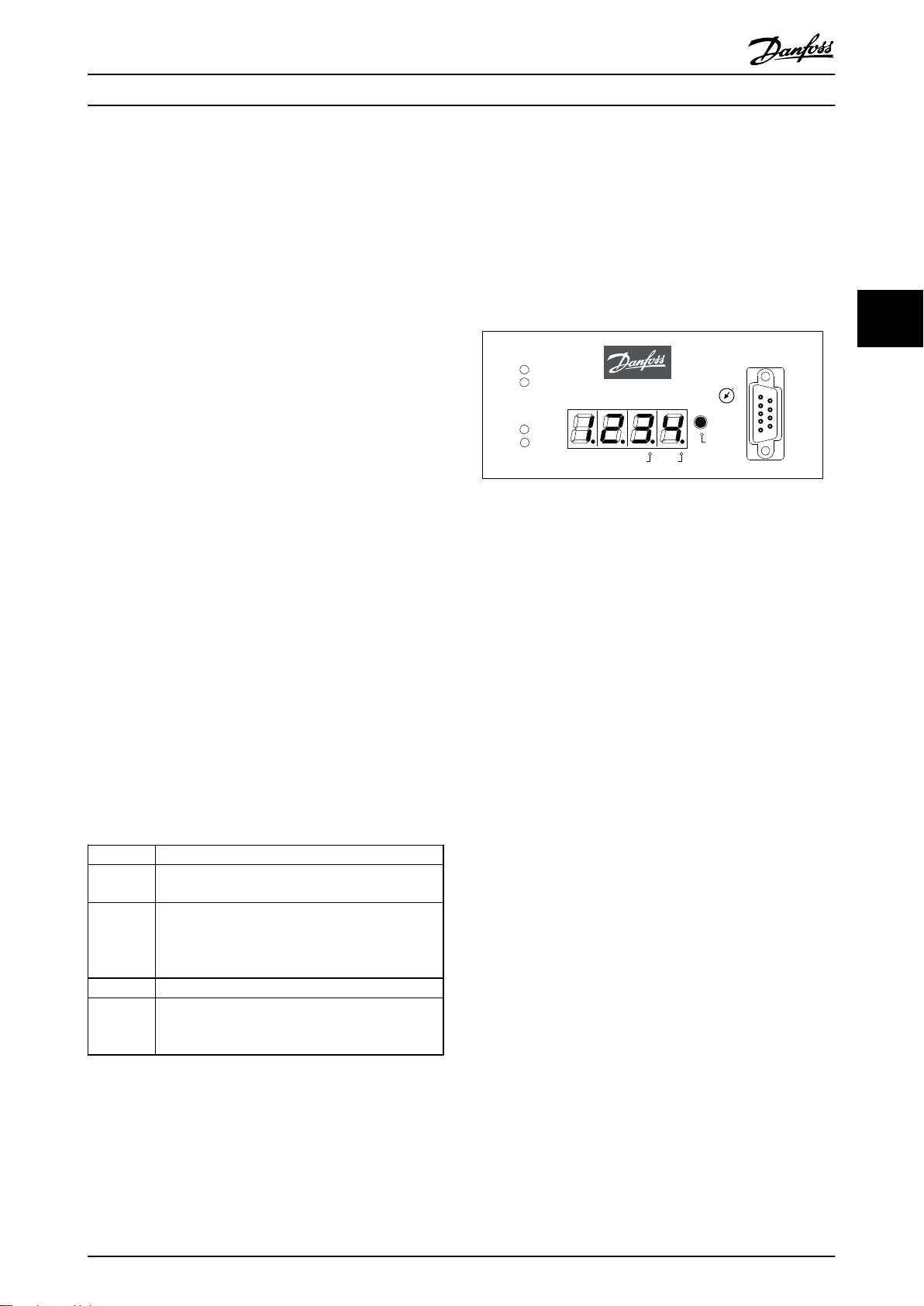

4.2

ISD Encoder Box Display

The display shows the operating status of the encoder box.

Illustration 4.1 Encoder Box Display

See chapter 7.1 Operating Display for detailed information

on the display.

4 4

4.1

Supported Encoders

Encoder Description

SSI All single-turn SSI encoders are compatible up to

28 bit.

SSI-CRC All single-turn SSI-CRC encoders are compatible up

to 28 bit.

The CRC Polynomial is fixed and the CRC-Check can

be enabled or disabled.

QEP All QEP encoders are compatible up to 24 bit.

BiSS All single-turn BiSS encoders are compatible up to

32 bit.

The CRC polynomial can be parameterised.

Table 4.1 Supported Encoders

MG75F102 - VLT® is a registered Danfoss trademark 11

Page 14

130BD089.11

1 2

5

3

4

4

6

ISD Connection Box

Failure

Warning

Output (300V) OK

Stand-By

Output (90V) OK

Enable

Error

300V OK

90V OK

300V

Signal Outputs

10A

Signal Inputs

ISD Power Supply Module

AC/DC Power Supply 300VDC 8/10A

Run/Err

U

ZK

24V

Safe

Warn Err

CAN-ID

5V

CAN

RS232

Service

Set

2 8

6

4

Safety I Safety II

Fuse L I CAN 1.In CAN 2.In CAN 3.In CAN 4.I n CAN 5.In

X11 X12 X13 X14 X15

Fuse L II CAN 1.Out CAN 2.Out CAN 3.Out CAN 4.Out CAN 5.Out

X21 X22 X23 X24 X25

B

ERGHOF

AC DC 300 V

ISD 410

ISD 410

DC+CAN

DC+CAN

0

CAN

CAN

Ethernet

7

Description

VLT® ISD Encoder Box Operating Instructions

4.3 Connection Cable/Cabling

The encoder box is connected to the ISD servo system via the CAN bus.

The encoder is connected via an RS 422 interface.

The maximum cable length between the encoder box and the encoder is limited to 50 m, other than BiSS encoders with

CRC at 8 MHz, which are limited to 10 m.

4.3.1 ISD Servo System with 1 Connection Box

44

The ISD servo system is set up with 1 connection box when the servomotors are used in ISD curve mode.

Illustration 4.2 ISD Servo System with 1 ISD Connection Box

No.

1 ISD Power Supply Module – – –

Name Line Type Cross-section Flexible Cable

2 ISD Connection Box – – –

3 Feed cable Hybrid cable (DC & CAN)

4 Terminating resistor Connector with terminating

5 ISD Encoder Box – – –

resistor

1 mm2 / 2.5 mm

– –

2

6 Master – – –

– Ethernet Ethernet cable 4 x 2 x 0,27 mm², shielded

– CAN line CAN cable (screened)

– Encoder line Encoder cable

– Loop cable Hybrid cable (DC & CAN)

– DC cable Single wire

– AC feed Single wire

Table 4.2 Legend to Illustration 4.2

twisted pairs (CAT 5)

4 x 0.25 mm

4 x 0.25 mm

1 mm2 / 2.5 mm

1.5 mm

1.5 mm

2

2

2

2

2

12 MG75F102 - VLT® is a registered Danfoss trademark

X (only with 2.5 mm2)

X

–

–

X (only with 2.5 mm2)

–

–

Page 15

1 2

4

4

4

4

1 2

3

5

3

7

6

130BD088.11

ISD Connection Box

Failure

Warning

Output (300V) OK

Stand-By

Output (90V) OK

Enable

Error

300V OK

90V OK

300V

Signal Outputs

10A

Signal Inputs

ISD Power Supply Module

AC/DC Power Supply 300VDC 8/10A

Run/Err

U

ZK

24V

Safe

Warn Err

CAN-ID

5V

CAN

RS232

Service

Set

2 8

6

4

Safety I Safety II

Fuse L I CAN 1.In CAN 2.In CAN 3.In CAN 4.I n CAN 5.In

X11 X12 X13 X14 X15

Fuse L II CAN 1.Out CAN 2.Out CAN 3.Out CAN 4.Out CAN 5.Out

X21 X22 X23 X24 X25

ISD Connection Box

Failure

Warning

Output (300V) OK

Stand-By

Output (90V) OK

Enable

Error

300V OK

90V OK

300V

Signal Outputs

10A

Signal Inputs

ISD Power Supply Module

AC/DC Power Supply 300VDC 8/10A

Run/Err

U

ZK

24V

Safe

Warn Err

CAN-ID

5V

CAN

RS232

Service

Set

2 8

6

4

Safety I Safety II

Fuse L I CAN 1.In CAN 2.In CAN 3.In CAN 4.I n CAN 5.In

X11 X12 X13 X14 X15

Fuse L II CAN 1.Out CAN 2.Out CAN 3.Out CAN 4.Out CAN 5.Out

X21 X22 X23 X24 X25

B

ERGHOF

AC DC 300 V

AC DC 300 V

ISD 410

ISD 410

ISD 410

ISD 410

0

0

CAN

CAN

CAN II CAN I

DC+CAN

DC+CAN

DC+CAN

DC+CAN

Description

VLT® ISD Encoder Box Operating Instructions

4.3.2 ISD Servo System with 2 Connection Boxes

The ISD servo system is set up with 2 connection boxes if the maximum number of servomotors for one connection box is

reached or the application requires more power.

The encoder box has 2 different CAN lines (CAN I and CAN II). Both of them use the same CAN-ID.

If there is a machine with ISD 410 servomotors that are split up in 2 separate CAN lines and all of them have to listen to the

same encoder value, the encoder box CAN I should be put on the first line and the encoder box CAN II on the second line.

Hereby, the drives can operate synchronously with the same guide value. CAN line II can be enabled or disabled via the SD

card parameter (General.SecondCANLineEnable).

4 4

Illustration 4.3 ISD Servo System with 2 ISD Connection Boxes

MG75F102 - VLT® is a registered Danfoss trademark 13

Page 16

130BD090.10

Run/Err

Power

CAN I

Warn

Err

0

CAN-ID

CAN II

RS232

Service

Set

2 8

6

4

ISD Encoder Box

SD Card

Power

GNDFE+24V

X201

CAN I

in out

GNDLoHi

Vcc

GND

Lo

Hi

Vcc

CAN II

in out

GND

Lo

Hi

Vcc

GND

Lo

Hi

Vcc

in1+

in1

in2+

in2

in3+

in3

GND

out1+

out1

GND

out2+

out2

RS 422

X501 X502 X601 X602

-

-

-

-

-

130BD094.10

Description

VLT® ISD Encoder Box Operating Instructions

No. Name Line Type Cross-section Flexible Cable

1 ISD Power Supply Module – – –

2 ISD Connection Box – – –

3 Feed cable Hybrid cable (DC & CAN)

4 Terminating resistor Connector with terminating

1/2.5 mm

– –

2

X (only with 2.5 mm2)

resistor

5 ISD Encoder Box – – –

6 Master – – –

7 Control Cabinet – – –

44

– Ethernet Ethernet cable 4 x 2 x 0.27 mm², shielded

X

twisted pairs (CAT 5)

– CAN line CAN cable (screened)

– Encoder line Encoder cable

– Loop cable Hybrid cable (DC & CAN)

– DC cable Single wire

– AC feed Single wire

4 x 0.25 mm

4 x 0.25 mm

1/2.5 mm

1.5 mm

1.5 mm

2

2

2

2

2

–

–

X (only with 2.5 mm2)

–

–

Table 4.3 Legend to Illustration 4.3

Connections

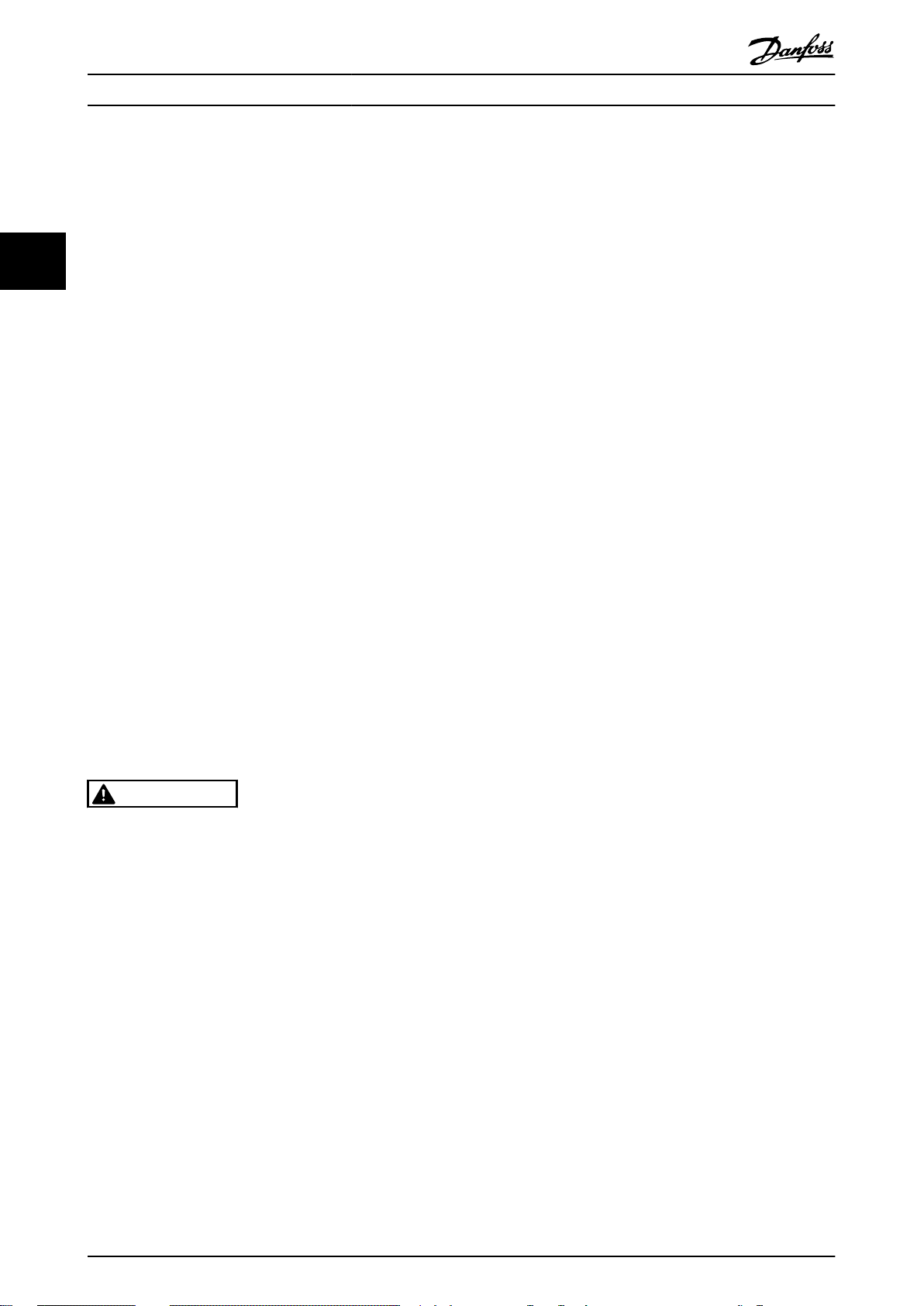

4.3.3

Illustration 4.4 Connections on the ISD Encoder Box

Inscription Function Designation

Power 24 V Power supply X201

CAN I (in / out) Connection CAN line I X501

CAN II (in / out) Connection CAN line II X502

RS 422-I Connection encoder I X601

RS 422-II Connection encoder II (currently

X602

not in use)

SD SD card slot –

Table 4.4 Connections on the ISD Encoder Box

4.3.3.1

24 V Power Supply (X201)

Illustration 4.5 24 V Housing and Plug

Pin Signal Description Cross-Section

1 GND_24 V Power Supply Input (DC Ground)

2 FE Functional- Earth connection

3 +24 V Power Supply Input (DC 24 V)

1 mm

1 mm

1 mm

2

2

2

Table 4.5 Connector Pin Assignment

14 MG75F102 - VLT® is a registered Danfoss trademark

Page 17

130BD092.10

130BD093.10

Description

VLT® ISD Encoder Box Operating Instructions

4.3.3.2 CAN Connector (X501 & X502)

Illustration 4.6 CAN Housing and Plug

Pin Signal Description Cross-Section

1 CAN I in GND CAN Power Supply Input

(Ground)

2 CAN I in Lo CAN Low Signal Input

3 CAN I in Hi CAN High Signal Input

4 CAN I in V

5 CAN I out GND CAN Power Supply Output

6 CAN I out Lo CAN Low Signal Output

7 CAN I out Hi CAN High Signal Output

8 CAN I out VCCCAN Power Supply Output

CAN Power Supply Input

CC

( +5 V)

(Ground)

(+5 V)

0.5 mm

0.5 mm

0.5 mm

0.5 mm

0.5 mm

0.5 mm

0.5 mm

0.5 mm

2

2

2

2

2

2

2

2

4.3.3.3

RS 422 I; AB, BiSS and SSI Encoder

Connector (X601)

Illustration 4.7 RS 422 I Housing and Plug

Pin Signal Function

BiSS SSI QEP

1 in1+ – – A

2 in1– – – /A

3 in2+ – – B

4 in2– – – /B

5 in3+ D+ D+ 0

6 in3– D– D– /0

7 GND GND GND GND

8 n.c. – – –

9 out1+ CLK+ CLK+ –

10 out1– CLK– CLK– –

4 4

Table 4.6 Connector Pin Assignment

The input and output pin assignment of the CAN plug

connectors is the same for CAN lines I and II.

Table 4.7 Connector Pin Assignment

MG75F102 - VLT® is a registered Danfoss trademark 15

Page 18

130BD091.10

Description

VLT® ISD Encoder Box Operating Instructions

4.3.3.4 RS 422 II; Additional Encoder

4.3.3.5

SD Card Slot

Connector (X602)

Slot for standard SD card with maximum 2 GB memory.

The memory card must be formatted using file-system

FAT16.

SDHC-SD is not supported.

CAUTION

Do not remove or replace the SD card during operation,

44

otherwise the contents of the SD card could be destroyed.

Switch the encoder box off and wait 10 seconds before

removing the SD card

Illustration 4.8 RS 422 II Housing and Plug

Pin

1 GND_24 V –

2 out2+ –

3 out2– –

Table 4.8 Connector Pin Assignment

Signal Function

16 MG75F102 - VLT® is a registered Danfoss trademark

Page 19

Installation/Fitting

5 Installation/Fitting

5.1 Transport and Delivery

5.1.1 Scope of Delivery

VLT® ISD Encoder Box Operating Instructions

All safety regulations and protective measures are

•

complied with, and the environmental conditions

are observed.

The documentation is read and understood.

•

The scope of delivery of the ISD Encoder Box comprises:

The encoder box

•

1 SD card, pre-formatted with software installed

•

1 set of plug connectors (see chapter

•

4.3.3 Connections)

These operating instructions

•

Transport

5.1.2

The maximum weight of a packaged encoder box is

approximately 2.5 kg.

Avoid vibration during transportation.

•

Avoid heavy impacts and blows.

•

Inspection on Receipt

5.1.3

After receiving the delivery, immediately check whether

the scope of delivery matches the shipping documents.

Danfoss will not honour claims for faults registered at a

later time.

Register a complaint immediately:

5.3 Installation Environment

Environmental Conditions

The installation must provide the following environmental

conditions to allow the encoder box to be operated safely

and efficiently.

The allowable operating ambient temperature

•

range is not exceeded.

The relative humidity is ≤ 85%, non-condensing.

•

The vibration level is ≤ 1 g / 20 m/s2 without

•

resonance excitation.

Unrestricted ventilation is available.

•

The maximum operating temperature is 40 °C. A

•

control cabinet climate control should be used if

necessary.

Contact Danfoss if it is not possible to comply with these

environmental conditions.

5.4

Preparation for Installation

Mount the DIN rail on the back wall of the control cabinet.

5 5

with the carrier in case of visible transport

•

damage;

with the responsible Danfoss representative in

•

case of visible defects or incomplete delivery.

5.2

Safety Measures during Installation

Always observe the safety instructions in chapter 3 Safety

Instructions during installation.

Pay particular attention to ensuring that the following

points are observed carefully:

Installation may only be performed by qualified

•

staff.

Installation must be performed with due care and

•

attention.

MG75F102 - VLT® is a registered Danfoss trademark 17

Page 20

Installation/Fitting

VLT® ISD Encoder Box Operating Instructions

5.6.2

24 V Power Supply Requirements

5.5 Mechanical Installation

5.5.1 Earthing (Grounding) the Encoder Box

A dedicated PE line is required for the encoder box. Use

the faston connector on the rear of the encoder box to

earth (ground) the unit.

5.5.2 Mounting

55

CAUTION

Do not squash the PE line.

1. Hook the encoder box onto the DIN-rail.

2. Press the lower part of the encoder box onto the

DIN-rail until it clicks into place.

Demounting

5.5.3

The encoder box must be supplied with DC 24 V power

supply with the following properties:

Input range: DC 18–30 V

•

Overload protection (for 30 V) 33.3 V

•

Reverse voltage protection

•

A PTC ("Polyswitch") resistor can be used for over-

•

voltage protection and reverse voltage

protection; tripping current: 2.2 A

Power input: 110 mA current demand

•

NOTE

Use a 24 V power supply which is CE marked according to

the standards EN 61000-6-2 and EN 61000-6-4 or similar for

industrial use. The power supply can only be used for the

ISD system.

5.6.3 Connecting the CAN Cable

1. Push the encoder box upwards to release it from

the DIN-rail.

2. Pull the encoder box towards you.

The CAN cable connects the encoder box to the ISD servo

system.

5.6

Electrical Installation

For the electrical connection, the relevant local and

national regulations must be observed in addition to the

information in these operating instructions.

Electrical Environmental Conditions

5.6.1

Compliance with the following electrical environmental

conditions is necessary to enable safe and effective

operation of the encoder box:

Mounting in a control cabinet

•

Suitable DC 24 V power supply unit (see chapter

•

5.6.2 24 V Power Supply Requirements)

PE line

•

Observe national statutory provisions

•

1. Assemble the CAN cable according to the

connector pin assignment in chapter

4.3.3 Connections.

2. Lay the CAN cable according to the local

conditions.

3. Connect the CAN cable to the encoder box and

the connection box.

Use CAN line I if only 1 CAN line is being used.

Pay attention to the correct CAN cable number

when 2 CAN cables (for 2 connection boxes) are

being used.

Observe the connection diagrams in chapter

4.3 Connection Cable/Cabling.

Connecting the Encoder Cable

5.6.4

The encoder cable connects the encoder to the encoder

box.

1. Assemble the encoder cable according to the

connector pin assignment in chapter

4.3.3 Connections.

2. Lay the encoder cable according to the local

conditions.

3. Connect the encoder cable to the encoder box.

18 MG75F102 - VLT® is a registered Danfoss trademark

Page 21

Installation/Fitting

VLT® ISD Encoder Box Operating Instructions

5.6.5 Inserting the SD Card

NOTE

The SD card delivered with the encoder box is preformatted and contains the necessary parameter file. If the

SD card has to be replaced, the new SD card must be

formatted and the parameter file copied to it before use.

See chapter4.3.3.5 SD Card Slot for further information

about formatting the SD card.

1. Insert the SD card into the slot above the display.

5.6.6 Connecting the 24 V Power Supply

1. Assemble the power supply cable according to

the connector pin assignment in chapter

4.3.3 Connections.

2. Connect the power supply as described in the

manual for the power supply.

5 5

MG75F102 - VLT® is a registered Danfoss trademark 19

Page 22

Commissioning

6 Commissioning

VLT® ISD Encoder Box Operating Instructions

6.2.2

Changing the Parameters

6

6.1 Standard Configuration

In the standard configuration the encoder box can read

the positions from the following encoder types:

SSI

•

SSI-CRC

•

BiSS

•

QEP

•

Encoder Box internal encoder simulation

•

In the default setting the position value is transmitted

every 5 ms.

The encoder box is controlled via CAN commands.

When the encoder box is ready for operation the various

encoder sources can be selected and the input can be

started and stopped at any time.

The encoder type currently being used can be read from

the object dictionary.

6.2 Parameter Setting

6.2.1 Encoder Box Parameter List

In order to modify the encoder-specific parameters, the

parameters in the encoder box parameter list must be

changed.

Proceed as follows:

CAUTION

Do not remove or replace the SD card during operation,

otherwise the contents of the SD card could be destroyed.

Switch the encoder box off and wait 10 seconds before

removing the SD card.

1. Switch the encoder box off and wait 10 seconds.

2. Remove the SD card.

3. Change the parameters on the SD card on a PC

using the text editor.

4. Replace the SD card in the encoder box.

5. Switch the encoder box on.

CAN Settings

6.2.3

The encoder box parameters are saved on the SD card

under the filename "MPARAM.dat".

The encoder box parameter list is loaded when the

encoder box is switched on. At the same time the software

checks that all fields exist. Missing or incorrectly written

parameters are set to 0, except the CAN-ID, which is set to

127.

The encoder box can still be started and operated

normally even when a value is missing. It is recommended

that the encoder box parameter list contains all fields,

even if these are not used or the value is set to 0.

If the encoder box parameter list is missing, the encoder

box cannot be started and error code “Err2” is shown on

the 7-segment display.

The complete encoder box parameter list can be found in

chapter 12.2 Encoder Box Parameters.

The encoder box has 2 different CAN lines (CAN I and

CAN II). Both of them use the same CAN-ID. See chapter

4.3.2 ISD Servo System with 2 Connection Boxesfor further

information.

CAN line II can be enabled or disabled via the SD card

parameter (General.SecondCANLineEnable).

Available CAN bit rates are 50, 125, 250, 500 and

1000 kBaud. The encoder box is preset to 500 kBaud. This

parameter can be configured via the SD card parameter

(General.BitRate) or by writing the bit rate to the

corresponding object in the object dictionary.

To activate this parameter, carry out a restart or an NMT

reset.

20 MG75F102 - VLT® is a registered Danfoss trademark

Page 23

Commissioning

VLT® ISD Encoder Box Operating Instructions

6.2.4 CAN-ID Setting

The General.BaseCanId and General.DefaultCanId are preset

to 100. All the settings can also be read from the object

dictionary.

There are several ways to set/change the CAN-ID. The

easiest way is setting via the BCD switch.

6.3

Switching the Encoder Box on

Ensure that the SD card is inserted and that the encoder

box parameter file (MPARAM.dat) exists before switching

on the encoder box. If not, the encoder box cannot be

started and error code “Err2” is shown on the 7-segment

display.

BCD switch is set to 0

The CAN-ID specified as General.DefaultCanId on

•

the SD card will be used.

The ISD ID distribution protocol can be used to

•

give another ID to the box. Note that the ID will

be stored on the SD card as the new

General.DefaultCanId

BCD switch is set to between 1 and 9

The CAN-ID is calculated by General.BaseCanId +

•

the value of the BCD switch.

The message for the ID setting over CAN bus is shown in

the table below. Note that the first 4 bytes have to be 0,

otherwise the encoder box ignores the ID setting message.

This is also the case if the BCD switch is not set to 0. After

this message is sent, the new CAN-ID will start flashing on

the encoder box display. Press the <SET> button on the

encoder box to accept the new ID. The encoder box will

only leave this ID setting mode following the acceptance

of the new ID or after an NMT reset.

Note that the other ISD servo system components will also

be in ID setting mode after this message is sent, so an

“NMT reset communication” message has to be sent to

release all devices from this mode.

This error can only be reset by inserting an SD card (with a

valid parameter file) and carrying out a re-start (removing

and replacing the mains supply plug).

Furthermore, the CAN bus and the encoder must be

connected to the encoder box correctly.

For the servo system to function correctly, all components

must be wired correctly. Read the operating instructions of

the other ISD components carefully.

Switching on (booting up)

The encoder box parameter file (MPARAM.dat) contains the

parameter list and is automatically read after the encoder

box is switched on.

The pre-configuration of the defined objects for the

chosen encoder takes place. During this initialisation

phase, the LED "Run / Err." flashes green.

CAUTION

Do not remove or replace the SD card during operation,

otherwise the contents of the SD card could be destroyed.

Switch the encoder box off and wait 10 seconds before

removing the SD card.

6

6

Note that whilst in ID setting mode, it is not possible to

communicate with the device.

COB-ID

0x7F2 0 0 new CAN-ID

Table 6.1 ISD ID Setting Message

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

MG75F102 - VLT® is a registered Danfoss trademark 21

Page 24

130BD086.10

Run/Err

Power

CAN I

Warn

Err

0

CAN-ID

CAN II

RS232

Service

Set

2 8

6

4

ISD Encoder Box

1

2 3

4

56

Operation

7 Operation

VLT® ISD Encoder Box Operating Instructions

Operating LEDs

7.1.1

7.1 Operating Display

The operating LEDs show the operating status.

The display shows the operating status of the encoder box.

LED Description

Run/Err.

(green/red)

“Power”

(green)

77

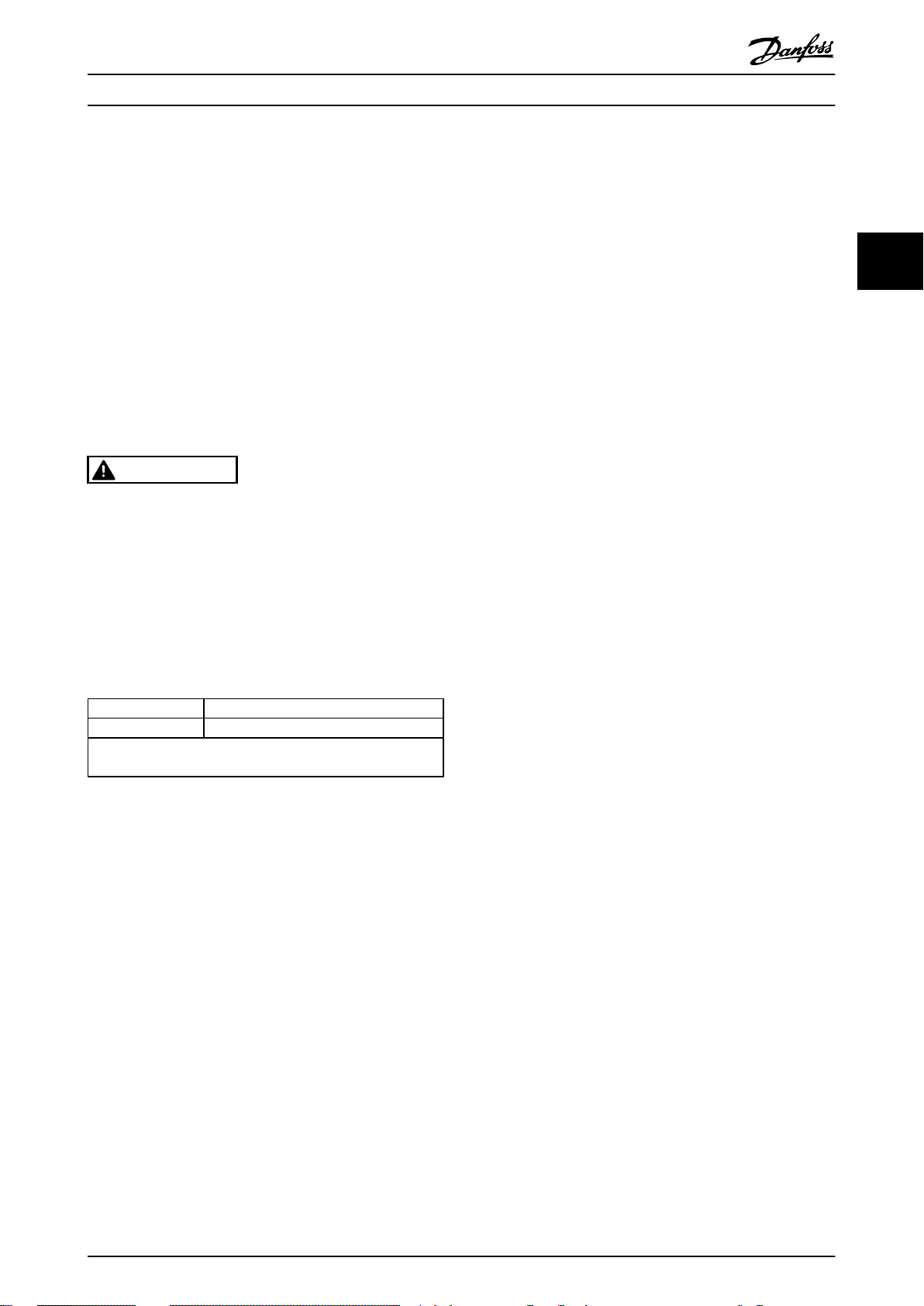

Illustration 7.1 Encoder Box Display

1 Operating LEDs 4 Service interface

2 7-segment display 5 <SET> push button

3 BCD switch 6 Segment dots

CAN I

(green/red)

CAN II

(green/red)

Table 7.2 Description of the Operating LEDs

Constant light (green): Normal operation

•

Flashing LED (green): Encoder box is being

•

initialised.

Constant light (red): Active encoder box

•

error

Constant light (green): 24 V power supply is

•

connected

Flashing LED (green): CAN communication

•

on line I

Constant light (red): CAN error on line I

•

Flashing LED (green): CAN communication

•

on line II

Constant light (red): CAN error on line II

•

Table 7.1 Legend to Illustration 7.1

22 MG75F102 - VLT® is a registered Danfoss trademark

Page 25

130BD087.10

CAN ID WARN ERROR

SET

>3sec

SET SETSET

Idle

n

(max n=6)

n

(max n=6)

WarningList[n] ErrorList[n]

Warn Error

Operation

VLT® ISD Encoder Box Operating Instructions

7.1.2 Display Mode

The CAN-ID, warnings and error codes can be displayed on

the 7-segment display.

A dot at the bottom right of the display segment shows

the respective type of indicator. The sequence of the

display occurs as demonstrated in the graphic below.

Continually pressing the <SET> push button enables

scrolling through the display.

7.1.3

7-Segment Display

During operation the 7-segment display shows the current

encoder box CAN-ID. The LED "Run/Err" is constantly lit

green.

The last 6 warnings and error messages can be called up

on the 7-segment display. Press the <SET> push button

repeatedly to scroll through the individual lists. These are

displayed as a continual loop (see Illustration 7.2):

CAN-ID

•

Warnings

•

Errors

•

CAN-ID

•

Warnings

•

Errors

•

...

•

Press the <SET> push button for 3 seconds to jump to the

start (CAN-ID).

7 7

Illustration 7.2 Display Sequence with <SET> Push Button

Display /

Segment Dot

CAN-ID

(no segment

dot)

WARN

(segment dot

“Warn”)

ERROR

(segment dot

“Err”)

Table 7.3 Description of the Segment Dots

Description

Encoder box CAN-ID

Display: decimal.

•

Factory setting: 100.

•

See chapter 6.2.3 CAN Settings for information

on how to change the CAN-ID.

Warning about a potential error, e.g. incorrect

CAN-ID.

Display: 4-digit hexadecimal code

•

See chapter 12.3 Emergency Codes for a

description of the emergency codes.

An error occurred, e.g. encoder CRC error.

Display: 4-digit hexadecimal code

•

See chapter 12.3 Emergency Codes for a

description of the emergency codes.

When a new event occurs, it is displayed as follows:

The error code is shown on the 7-segment

•

display immediately. The type of event is shown

via the "Warn" or "Err" segment dot.

The LED "Run/Err" is constantly lit red.

•

The error message (CAN emergency message)

•

appears on the CAN bus.

The cause of the error and the date and time

•

stamp are saved in the log file.

An entry is made in the error memory. This can

•

be read via SDO (Service Data Object).

Depending on the error, the encoder box switches to a

different NMT-state. For example, the encoder box

switches to "pre-operational" if an encoder error occurs.

The full list of error codes and NMT reactions are detailed

in chapter 12.3 Emergency Codes.

NOTE

It is not possible to reset errors or warnings on the

encoder box itself. An active error can only be deleted by

carrying out an NMT-Reset or by restarting the encoder

box. See chapter 12.3 Emergency Codes for further

information.

MG75F102 - VLT® is a registered Danfoss trademark 23

Page 26

Operation

VLT® ISD Encoder Box Operating Instructions

7.1.4 <SET> Push Button

The <SET> push button can be used to scroll through the

list of messages and during the ID setting procedure.

The CAN-ID is shown when the push button is pressed for

3 seconds.

7.1.5 <CAN-ID> BCD Switch

The <CAN-ID> BCD switch is used to assign the ID

manually. See chapter 6.2.4 CAN-ID Setting.

7.1.6 Service Interface

CAUTION

The service interface is only for use by Danfoss Service.

77

7.2 Display via Toolbox and CoDeSys

In addition to the display on the ISD encoder box, it is

possible to query the status of the encoder box via ISD

Toolbox.

In order to do this, it is necessary to connect to the CAN

bus network via a PC/laptop. A CAN dongle is required,

which realises the physical connection between the CAN

bus network and the encoder box.

The ISD Toolbox enables the individual ISD components to

be displayed directly and thereby information about the

ISD components to be attained.

The parameters of the ISD components can also be read

via CoDeSys on the master controller.

The ISD Toolbox software, firmware updates, EDS files and

CoDeSys libraries can be downloaded from the Danfoss

website (www.danfoss.com).

24 MG75F102 - VLT® is a registered Danfoss trademark

Page 27

Faults

VLT® ISD Encoder Box Operating Instructions

8 Faults

Encoder box faults are displayed on the 7-segment display

on the encoder box (see chapter 7.1 Operating Display).

8.3

Debugging

The behaviour of the encoder box is detailed in the

following chapters. Information on troubleshooting can be

found in chapter 8.5 Troubleshooting.

NOTE

If a fault cannot be eliminated by one of the measures

listed, notify Danfoss Service (see chapter 1.5 Service and

Support).

Have the following information available to enable Danfoss

to help you quickly and effectively:

Type number

•

Error message number

•

Firmware version

•

8.1 Emergency

If an error occurs the encoder box sends an emergency

message. Possible emergencies are listed in chapter

12.3 Emergency Codes.

8.2

Error History

The encoder box keeps an error history with the

emergency codes from chapter 12.3 Emergency Codes along

with a date and timestamp.

The encoder box keeps a maximum of 12 emergencies

divided into 6 errors and 6 warnings. After the history is

filled, the oldest will be replaced. All 12 emergencies can

be read by using SDO.

For debugging purposes the encoder box logs the

following information on the SD card with time and date

information from the real-time clock:

1. Power on

Software version information

•

System information CPU frequency

•

CAN settings: baud rate and CAN-ID

•

2. Events

New control code received

•

Unknown control parameter received

•

3. Encoder interface behaviour: which encoder is

activated

4. Emergencies including power fail emergency

5. Load/save commands

The process of write-parameter is

•

logged: open file, write file.

8.4

Under-Voltage / Power-Failure

Behaviour

The encoder box is able to detect and handle 3 different

voltage level scenarios:

Under-voltage during power-up

•

Sudden drop in the supply voltage

•

Power-failure

•

The encoder box reaction to the different scenarios

ensures predetermined behaviour while ensuring the

integrity of the file and log content.

8 8

NOTE

The encoder box is designed to have enough power to

ensure that the parameter and log file are not damaged

during a power failure or voltage drop.

MG75F102 - VLT® is a registered Danfoss trademark 25

Page 28

130BD095.10

Err1

1

Power

on

16 V

>18 V

max. 5 s

2

130BD096.10

1

2

>18 V

3

1

2

>18 V

130BD097.10

Faults

VLT® ISD Encoder Box Operating Instructions

8.4.1 Under-Voltage during Power-Up

In this case the voltage level is high enough for the

encoder box to boot and load the firmware correctly, but

the voltage level is not high enough to ensure that a

power failure can be handled correctly.

8.4.3

Power Failure

In this case the voltage drop to <18 V means a power

failure, in which case the encoder box will log the event,

close the log file on the SD card, and send a voltage

emergency message.

The under-voltage during power-up is detected with a

timeout of 5 seconds and the encoder box displays “Err1”.

To reset this error, apply the correct supply voltage of 24 V

and carry out a power cycle.

Illustration 8.3 Power Failure

1 Log event, send emergency message, close log

2 Power failure

Illustration 8.1 Under-Voltage during Power-Up

Table 8.3 Legend to Illustration 8.3

88

1 Power up and normal operation

2 Under-voltage during power-up, “Err1” shown on display

Table 8.1 Legend to Illustration 8.1

Sudden Voltage Drop

8.4.2

If the supply voltage suddenly drops, the encoder box will

log the event, close the log file on the SD card, and send a

voltage emergency message. If the drop is not enough to

shut down the encoder box, it remains in a state where

the voltage level is verified continuously in order to detect

a possible voltage rise. If a voltage rise is detected, an

internal reset is issued.

Illustration 8.2 Voltage Drop

1 Log event, send emergency message, close log

2 Wait for voltage rise

3 Internal reset

Table 8.2 Legend to Illustration 8.2

26 MG75F102 - VLT® is a registered Danfoss trademark

Page 29

Faults

VLT® ISD Encoder Box Operating Instructions

8.5 Troubleshooting

When problems occur in the servo system, they must first be located and properly identified.

The following table lists potential faults on the encoder box, their possible causes, and actions for correcting the faults.

If it is not possible to correct the fault, contact Danfoss Service.

Fault Possible Cause Possible Solution

LED "Power" is off although

24 V power supply is

connected.

LED "Run / Err" flashes green for

>1 min.

LED "Run / Err" is lit red

constantly.

LED "CAN I" or "CAN II" is off. No CAN messages on the bus.

LED "CAN I" or "CAN II" is red

(constantly).

Fault code 5100 (hex) Power supply failure.

Fault code 8100 / 8101 (hex) CAN controller error counter reached

Fault code 8120 / 8121 (hex) CAN passive error CAN line I / II.

Fault code 8140 / 8141 (hex) Bus off CAN line I / II.

Fault code FF02 (hex) Write to log failed.

Fault code FF05 (hex) BiSS encoder is not connected while

Fault code FF06 (hex) Encoder is counting in reverse.

Fault code FF09 (hex) QEP failed to detect zero pulse.

Fault code FF0A (hex) Encoder CRC failure.

Fault code FF0B (hex)

Fault code FF0F (hex) Incorrect CAN-ID.

Fault code Err1 Under-voltage during power-up. Check 24 V power supply

Fault code Err2 SD card not available.

Cable connected incorrectly.

•

24 V power supply voltage not

•

present.

Error during initialisation. Carry out a power cycle.

Active encoder box error. See error codes below.

Current CAN bus problems on line I

or II.

limit CAN line I / II.

start-BiSS command is executed.

Encoder MaxAngleDifference

threshold exceeded.

Check cabling

•

Check 24 V power supply

•

Check cabling

•

Check terminating resistors

•

Check cabling

•

Check terminating resistors

•

Check parameter General.BitRate

•

Check cabling

•

Check 24 V power supply

•

Check CAN cabling and voltage

•

Check terminating resistors

•

Check for EMC interference

•

Check parameter General.BitRate

•

Ensure the SD card is inserted correctly

•

Check if the file-system on the SD card is corrupt

•

Check cabling to BiSS encoder

Check cabling to encoder

•

Check direction parameter for the specific encoder type used

•

Check parameter General.WrongDirectionCheck

•

Check cabling to encoder

•

Check parameter QEP.PulsesPerRevolution

•

Check cabling to encoder

•

Check for EMC interference

•

Check CRCPoly parameter for the specific encoder type used

•

Check parameter General.MaxAngleDifference in relation to

maximum encoder speed

Check parameters General.DefaultCanId and General.BaseCanId

•

Check the BCD switch setting

•

Ensure the SD card is inserted correctly

•

Ensure the SD card contains the parameter file

•

8 8

Table 8.4 Troubleshooting Overview

MG75F102 - VLT® is a registered Danfoss trademark 27

Page 30

Maintenance and Repair

VLT® ISD Encoder Box Operating Instructions

9 Maintenance and Repair

9.1 Maintenance tasks

The encoder boxes are largely maintenance free.

The maintenance tasks listed in the following table may be

performed by the customer. No other tasks are required.

Component Maintenance

Task

Encoder box Clean Regularly or as

24 V supply

cable

CAN cable

Encoder

cable

Table 9.1 Overview of Maintenance Tasks

Check for

damage and

wear

Maintenance

Interval

necessary

Every 6 months Replace cable if

Instruction

Clean the

surface with a

dry cloth

damaged or

worn

99

9.2 Inspection during Operation

Carry out regular inspections during operation. Check the

encoder box at regular intervals for anything unusual.

Pay particular attention to:

Loose fastenings

•

Condition of electrical wiring and cables

•

In the event of irregularities or problems, see chapter

8.5 Troubleshooting.

9.3

Repair

NOTE

No repairs to the encoder box are allowed.

Always return defective encoder boxes to Danfoss.

28 MG75F102 - VLT® is a registered Danfoss trademark

Page 31

Decommissioning and Disposa...

VLT® ISD Encoder Box Operating Instructions

10 Decommissioning and Disposal

10.1 Decommissioning

The procedure for decommissioning the encoder box is

the reverse of the installation procedure described in

chapter 5 Installation/Fitting.

Proceed as follows:

Disconnect the power supply and wait for the

•

discharge time to elapse.

10.2 Dismounting

The procedure for dismounting the servomotor is the

reverse of the fitting procedure described in chapter

5 Installation/Fitting .

Proceed as follows:

1. Disconnect the power supply and wait for the

discharge time to elapse.

2. Disconnect the electrical cables.

3. Dismount the encoder box.

10.3

Recycling and Disposal

10.3.1 Recycling

Take metals and plastics to recycling stations.

The entire encoder box is classified as electronic waste,

and the packaging is classified as packaging waste.

10.3.2

Devices containing electronic components cannot be

disposed of as normal domestic waste.

Dispose of the encoder box as hazardous waste, electrical

waste, recyclable waste, etc. in accordance with applicable

local regulations.

Disposal

10

10

MG75F102 - VLT® is a registered Danfoss trademark 29

Page 32

130BD098.10

ISD Encoder Box

Made in Germany

Uin: 24VDC

Encoder Box:

Iin/max: 0,5ADC

CAN Bus: 5VDC

PART NO: 175G7750

SERIAL NO : 000000M000

175G775000000M000

1

2

3

6

7

Ambient: 5...40 C/41...104 F

o o

Enclosure: IP 20

4

5

oo

Specifications

11 Specifications

VLT® ISD Encoder Box Operating Instructions

11.1 Nameplate

Check the nameplate and compare it with the order data.

Use the part number for reference.

The part number uniquely identifies the encoder box.

Illustration 11.1 Nameplate

The following data is shown on the nameplate of the ISD

encoder box:

11.3

Characteristic Data

Definition Value and Unit

Environmental Conditions

Operating temperature 5–40 °C

Storage temperature 0–55 °C

Humidity 5–85%, non-condensing (according to

IEC 60721-3-3)

Protection rating 2

Vibration rating 3M4

Protection type IP20

Housing

Dimensions (W x H x D) 142 x 105.2 x 70.78 mm

Weight 0.46 kg

Mounting In a control cabinet

Table 11.2 Characteristic Data

11

1

2 Current details 6 Part number

3 Bus details 7 Serial number

4 Ambient temperature range

Table 11.1 Legend to Illustration 11.1

Ensure that the nameplate is clearly legible.

11.2

Store the encoder box in a dry, dust-free location with low

vibration (V

The storage location must be free from corrosive gases.

Avoid sudden temperature changes.

Supply voltage 5 Protection rating

Storage

≤0.2 mm/s).

eff

30 MG75F102 - VLT® is a registered Danfoss trademark

Page 33

130BD099.10

142 mm

105.2 mm

Power

GND

FE

+24V

X201

CAN I

CAN II

IN

OUT

GNDLOHI

VCC

GNDLOHI

VCC

in1+

in1

-

in2+

in2-in3+

in3

GND

out1+

out1

GND

out2+

out2

RS 422

X501

X502

X601 X602

IN

OUT

GNDLOHI

VCC

GNDLOHI

VCC

NC

-

-

-

Specifications

11.4 Dimensions

11.4.1 Front View

All dimensions are in mm.

VLT® ISD Encoder Box Operating Instructions

Illustration 11.2 Front View

11

11

MG75F102 - VLT® is a registered Danfoss trademark 31

Page 34

130BD100.10

70.78 mm

Specifications

11.4.2 Side View

All dimensions are in mm.

VLT® ISD Encoder Box Operating Instructions

11

Illustration 11.3 Side View

32 MG75F102 - VLT® is a registered Danfoss trademark

Page 35

Appendix

VLT® ISD Encoder Box Operating Instructions

12 Appendix

12.1 Glossary

A flange

The A side is the shaft side of the motor.

Ambient temperature

The temperature in the immediate vicinity of the servo

system or component.

Clamping set

A mechanical device, which, for example, can be used to

secure gears to a motor shaft.

CoDeSys

Controller Development System; a development

environment for programming controller applications,

based on IEC 61131-3 and developed by 3S-Smart Software

Solutions GmbH.

Axial force

The force in newton-metres acting on the rotor axis in the

axial direction.

BCD

Binary-coded decimal

Bearings

The ball bearings of the servo drive.

B flange

The rear side of the servomotor with the plug-and-socket

connectors.

BiSS

Bi-directional Synchronous Serial

Brake

Power-off brake of the ISD servomotor, on the A side of

the motor.

CAN

Controller Area Network

Connection box

The connection box provides the link between the power

supply module and the servo drives.

Connector (M23)

Servomotor connector.

Cooling

ISD servo drives are cooled by convection, which means

without fans.

CRC

Cyclic Redundancy Check

CSA

Canadian test and certification mark.

DC link

Each servomotor has its own DC link, consisting of

capacitors.

DC link voltage

A DC voltage shared by several ISD servomotors connected

in parallel.

12 12

CANopen DS301

A standard that specifies the application layer and

communication profile.

CANopen DS402

An object-based CAN standard that specifies the device

profile for drives and motion control.

CANopen DS406

An object-based CAN standard that specifies the device

profile for encoders.

CE

European test and certification mark.

MG75F102 - VLT® is a registered Danfoss trademark 33

DC voltage

A direct constant voltage.

DSP

Digital signal processor; processor IC on an ISD control

board.

Encoder box

The encoder box allows external encoder signals to be

sent to the servo drives over the CAN bus with high

precision.

Feed cable

Hybrid connection cable between connection box and

servomotor, with a connector.

Page 36

Appendix

VLT® ISD Encoder Box Operating Instructions

Feedback system

Feedback systems for servomotors in general.

Fieldbus

Communication bus between controller and servo axis; in

general between controller and field nodes.

Firmware

Software in the unit; runs on the control board.

Flash

Memory IC on the ISD control board; a form of EPROM.

Function block

Device functionalities are accessible via CoDeSys.

Gear ratio

The speed ratio of the input pinion and the output shaft of

the gear unit.

Gear unit

External gear unit used to change the output shaft speed

and the torque on the motor shaft.

Hole circle

The hole patterns of the ISD and IEC flanges.

IEC flange

Industry-standard flange

Installation elevation

Installation elevation above normal sea level, typically

1212

associated with a derating factor.

ISD

Integrated servo drive, integrated servomotor solution.

ISD flange

The standard flange for ISD servo drives; larger than the

IEC flange.

ISD servomotor

Designates the ISD servomotor with hybrid cable.

Motor shaft

Rotating shaft on the A side of the servomotor, typically

without a key groove.

Multi-turn encoder

Describes a digital absolute encoder, in which the absolute

position remains known after several revolutions.

NMT

Network Management

PELV

Low-voltage directive regarding voltage levels and

distances between lines.

PDO

Process Data Object (see CANopen DS301).

Planetary gear

A specific type of gearing, typically used with servomotors.

Power-off principle

The brake is normally engaged. It is released by applying a

voltage (safety function).

Power supply module

The power supply module provides a regulated DC 300 V