Fact Sheet

VLT® Integrated Servo Drive ISD® 510

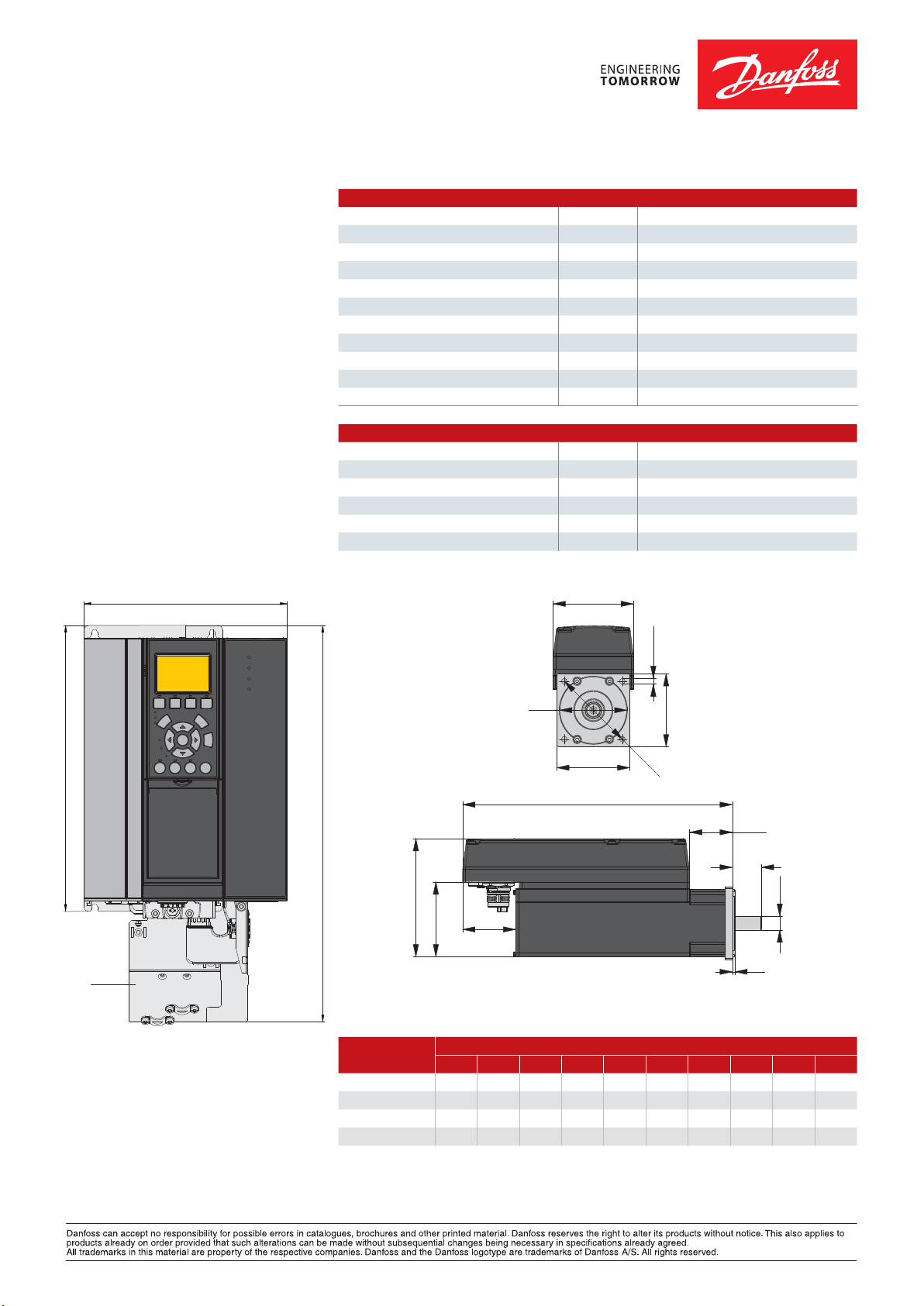

VLT® Servo Access Box SAB®

The SAB® generates a 600 V DC power

supply and guarantees high power

density. It has a removable Local Control Panel (LCP) and is based on the

proven quality of a Danfoss frequency

converter. The SAB® delivers an output

of 7.5 kW and 15 A.

1.5-13 Nm

torque

range gives you

more design

fl exibility in your

decentralized

system plans

VLT® Integrated Servo Drive ISD® 510

is a high-performance decentral

servo motion solution, developed

specifically for the Food & Beverage

and Packaging industries. The servo

system comprises a central power

supply SAB®, drive modules and

cabling infrastructure. The decentralization of the drive unit offers

benefits in mounting, installation,

and operation. Depending on the

application, the SAB® can power up

to 64 drives in a servo drive system.

The open system supports both

EtherCAT® and Ethernet POWERLINK®.

Servo Drive

The motion control is integrated into

the drive so that the motion sequences

can take place independently. This

releases the central PLC and offers a

highly flexible drive concept. The master can be programmed via IEC 61131-3

and hybrid cables are used to connect

the servo drives, making installation fast

and simple.

The perfect solution for:

Packaging machines

Food & Beverage machines

Pharmaceutical machines

Real-Time Ethernet

SAB®

Quick

Main

Alarm

Status

Menu

Menu

Log

Cancel

Back

Info

OK

Auto

Hand

Reset

On

On

AUX 1

AUX 2

SAFE 1

SAFE 2

ISD® 510

400–480 V AC

UDC + Real-Time Ethernet + STO + U

1

23 n

130BE384.10

AUX

. . .

. . .

Quick

Main

Alarm

Status

Menu

Menu

Log

Ca

n

c

el

Back

I

nfo

OK

Hand

Auto

Reset

On

On

LCP

Feature Benefit

Dynamic servo performance Fast, accurate, and energy-effi cient

Compact and decentral servo drive Reduced costs and high fl exibility

64 standard servo drive variants in sizes 1 and 2

Real-time systems EtherCAT® and

Ethernet POWERLINK®

Control via IEC 61131-3 Open system

System setup performance

Hybrid cables in daisy-chain concept

Removable Local Control Panel (LCP)

LEDs on servo drive and SAB® Fast and eff ective monitoring

Standard and advanced servo drive variants Cost-eff ective solution

Selection of most suitable drive for the

application’s torque and power requirements

Fast process communication

Simple and fast confi guration of

several drives

Easy and fast installation, reduced

number of cables

Direct connection to the servo drives for fast

commissioning, diagnosis, and service

www.danfoss.com/drives

83.5

[3.29]

85

[3.35]

76

[2.99]

76

[2.99]

70

[2.76]

5.8

[0.23]

(X4)

130BE438.1

Available Options

Mechanical holding brake

Feedback:

– Resolver

– Single-turn

– Multi-turn

Customized fl ange on request

Shaft seal

Flexible hybrid cable

Dimensions

190.5

Specifications

ISD® 510

Rated voltage U

Rated torque M

Maximum torque M

Rated current I

Maximum current I

Rated speed n

Rated power P

DC link

N

0max

N

0max_rms

N

N

Inertia (without mechanical brake) J 0.85 / 1.45 / 2.09 / 2.73 kgcm

Shaft diameter 14/19 mm

Protection rating IP54/IP67 (shaft IP65)

Safety rating STO (Safe Torque Off )

Servo Access Box

Input voltage U

Input current I

Output voltage U

Rated power P

Rated current I

IN

IN

OUT

N

N

Enclosure IP20

DC 565 V

1.5-3.8 Nm

6.1-13 Nm

1.4-1.8 A

5.7–6.4 A

2400–4600 rpm

0.72-0.94 kW

400–480 V AC ±10%, 3-phase

11.14 A @ 400 V / 9.3 A @ 480 V

565–680 V DC ±10%

7.5 kW

15 A

2

268

A

A = decoupling plates

Aux 1

Aux 2

STO 1

STO 2

280

[11.02]

371.5

Servo Drive

ISD® 510

123

[4.84]

78

[3.07]

55.4

[2.18]

Dimensions [mm]

ABCDEFGH I J

44.5

[1.75]

30

[1.18]

2.5

[0.09]

14

[0.55]

Size 1 (1.5 Nm) 85 70 76 280 39.5 30 14 2.5 70 115

Size 2 (2.1 Nm) 100 80 84 252.5 15 40 19 3.0 84 129

Size 2 (2.9 Nm) 100 80 84 281.5 44.5 40 19 3.0 84 129

Size 2 (3.8 Nm) 100 80 84 310.5 73.5 40 19 3.0 84 129

Danfoss Drives, Ulsnaes 1, DK-6300 Graasten, Denmark, Tel. +45 74 88 22 22, Fax +45 74 65 25 80, www.danfoss.com/drives, E-mail: info@danfoss.com

DKDD.PFP.801.A6.02 © Copyright Danfoss Drives | 2015.11

Loading...

Loading...